Constant velocity universal joint outer joint member and manufacturing method for same

一种万向联轴、制造方法的技术,应用在联轴器、弹性联轴器、刚性轴联轴器等方向,能够解决难杯状部与轴部一体成形等问题,达到削减不良率、削减制造成本、高焊接品质的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0088] Embodiments of the present invention will be described below based on the drawings.

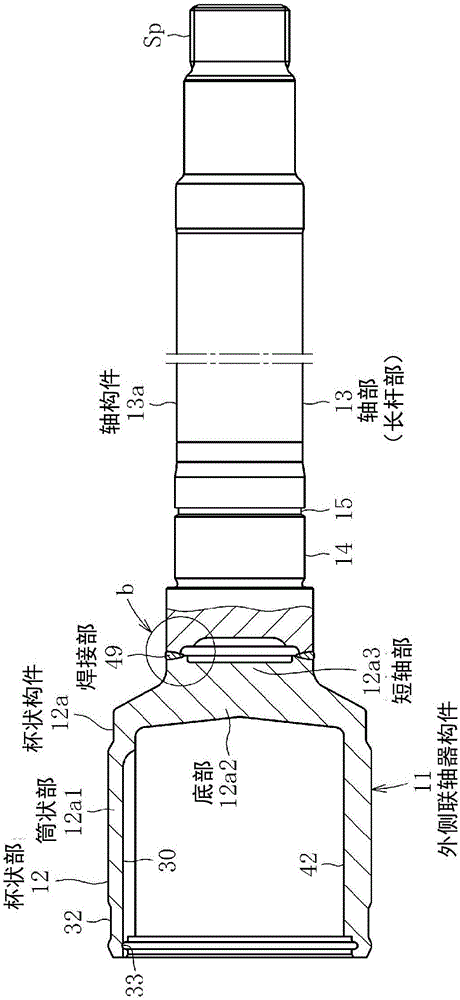

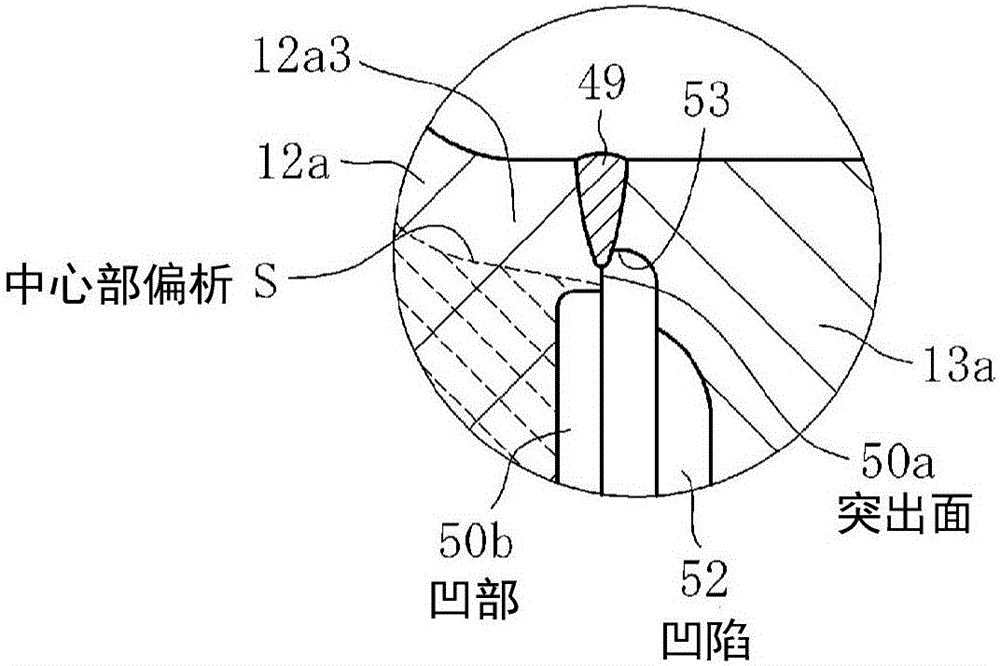

[0089] First, refer to figure 1 and Figure 2a~2c The first example of the outer coupling member is described, and then, refer to Figure 3-16 A first example of the manufacturing method of the outer joint member will be described.

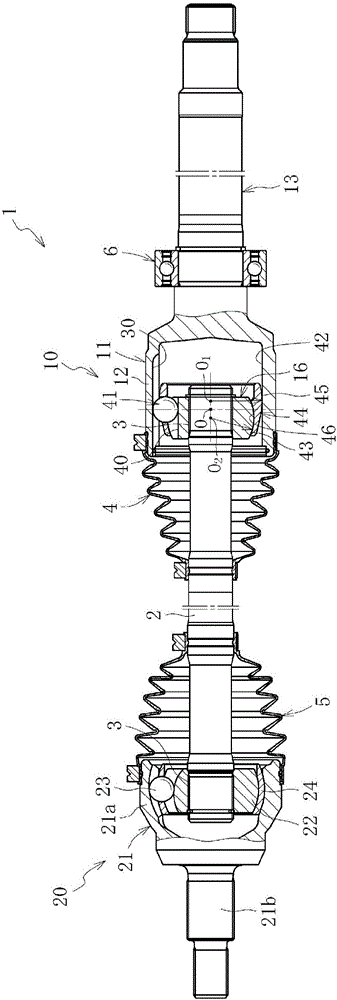

[0090] figure 1 Shows the overall structure of the drive shaft 1. The drive shaft 1 has a sliding constant velocity universal joint 10 , a fixed constant velocity universal joint 20 , and an intermediate shaft 2 connecting both the joints 10 , 20 as main components. The sliding type constant velocity universal joint 10 is arranged on the differential side (the right side in the figure: also called the inner disc side), and the fixed type constant velocity universal joint 20 is arranged on the driving wheel side (the left side in the figure: Also known as the outer disk side).

[0091] The sliding type constant velocity universal joint 10 is a so-ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com