Wafer bonding method and preparation method for foreign substrate

A technology of wafer bonding and heterogeneous substrates, applied in welding equipment, manufacturing tools, optomechanical equipment, etc., can solve problems such as thermal expansion coefficient mismatch, heterogeneous bonding structure fragmentation, bonding structure debonding, etc. Achieve the effects of improving reliability, reducing thermal strain, and expanding the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

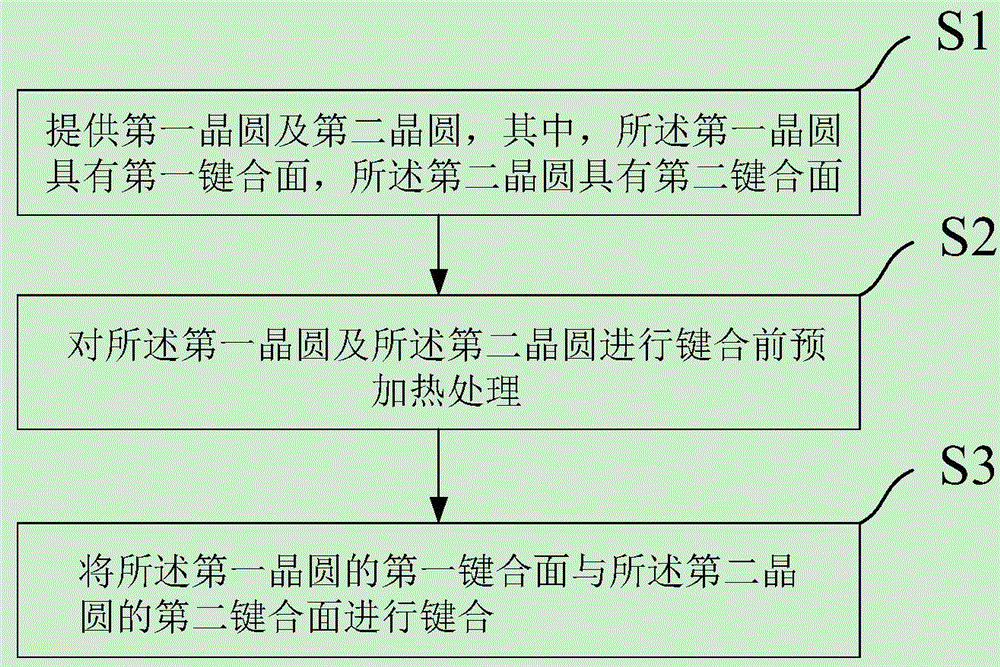

[0039] see figure 1 , the present invention provides a wafer bonding method, the method at least comprising:

[0040] S1: providing a first wafer and a second wafer, wherein the first wafer has a first bonding surface, and the second wafer has a second bonding surface;

[0041] S2: Pre-heating the first wafer and the second wafer before bonding;

[0042] S3: Bonding the first bonding surface of the first wafer to the second bonding surface of the second wafer;

[0043] The wafer bonding method of the present invention will be described in detail below with reference to specific drawings.

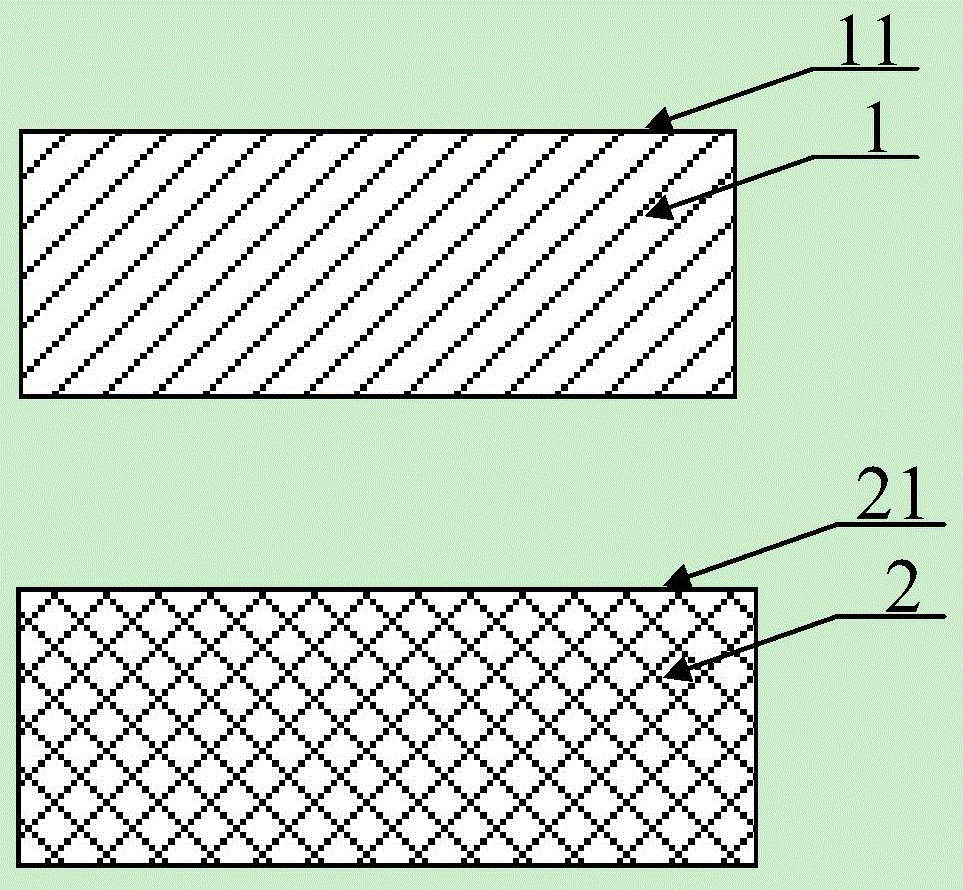

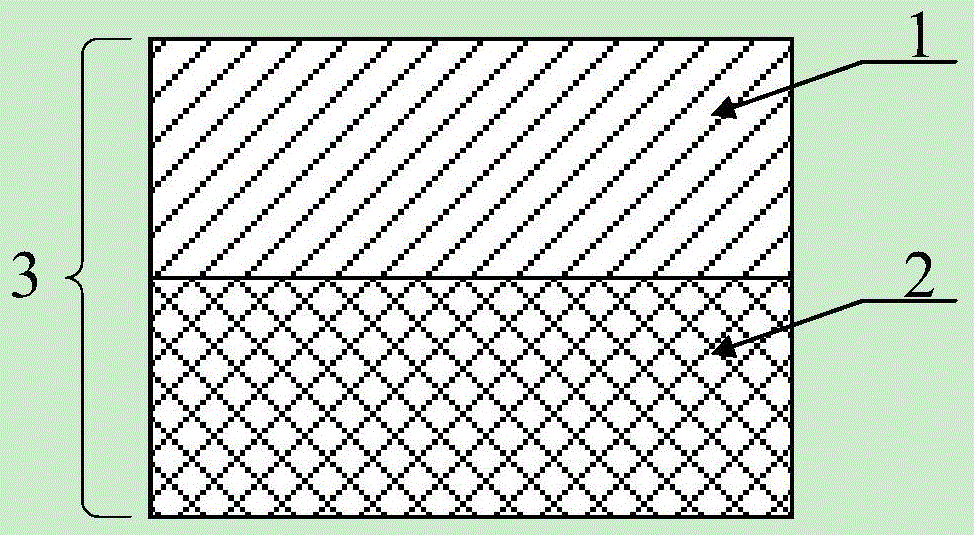

[0044] see figure 1 S1 and figure 2 , performing step S1, providing a first wafer 1 and a second wafer 2, wherein the first wafer 1 has a first bonding surface 11, and the second wafer 2 has a second bonding surface 21;

[0045] Specifically, the first wafer 1 has an upper surface and a lower surface, which can be used as the first bonding surface 11; the second wafer 2 has an upper su...

Embodiment 2

[0071] The present invention also provides a method for preparing a heterogeneous substrate, the preparation method at least includes: adopting the steps included in the wafer bonding method described in any one of the solutions in Embodiment 1, and also includes;

[0072] Before the heat treatment, ion implantation is performed on the first bonded surface 11 or the second bonded surface 21, so that at the preset depth of the first wafer 1 or the second wafer 2 Form a defective layer;

[0073] The first annealing treatment is performed on the structure having the defect layer obtained through the wafer bonding method, so as to peel part of the wafer along the defect layer.

[0074] Specifically, the first treatment is preferably carried out in a vacuum environment or under N 2 , O 2 , Ar, He, H 2 . Carry out under a protective atmosphere formed by at least one gas in the air, the temperature of the annealing treatment is 50°C-1300°C, and the time of the annealing treatment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com