Condensate pump used in nuclear power station

A technology for condensate pumps and nuclear power plants, which is applied to the components, pumps, and pump elements of the pumping device for elastic fluids, which can solve the problems that the strength and rigidity of the outer cylinder are not high enough, the overall weight and cost of the pump group are high, and the pump is affected. Group service life and other issues, to achieve the effect of increasing strength and stiffness, good support, and reducing overall weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to better understand the technical solution of the present invention, it will be described in detail below through specific embodiments in conjunction with the accompanying drawings:

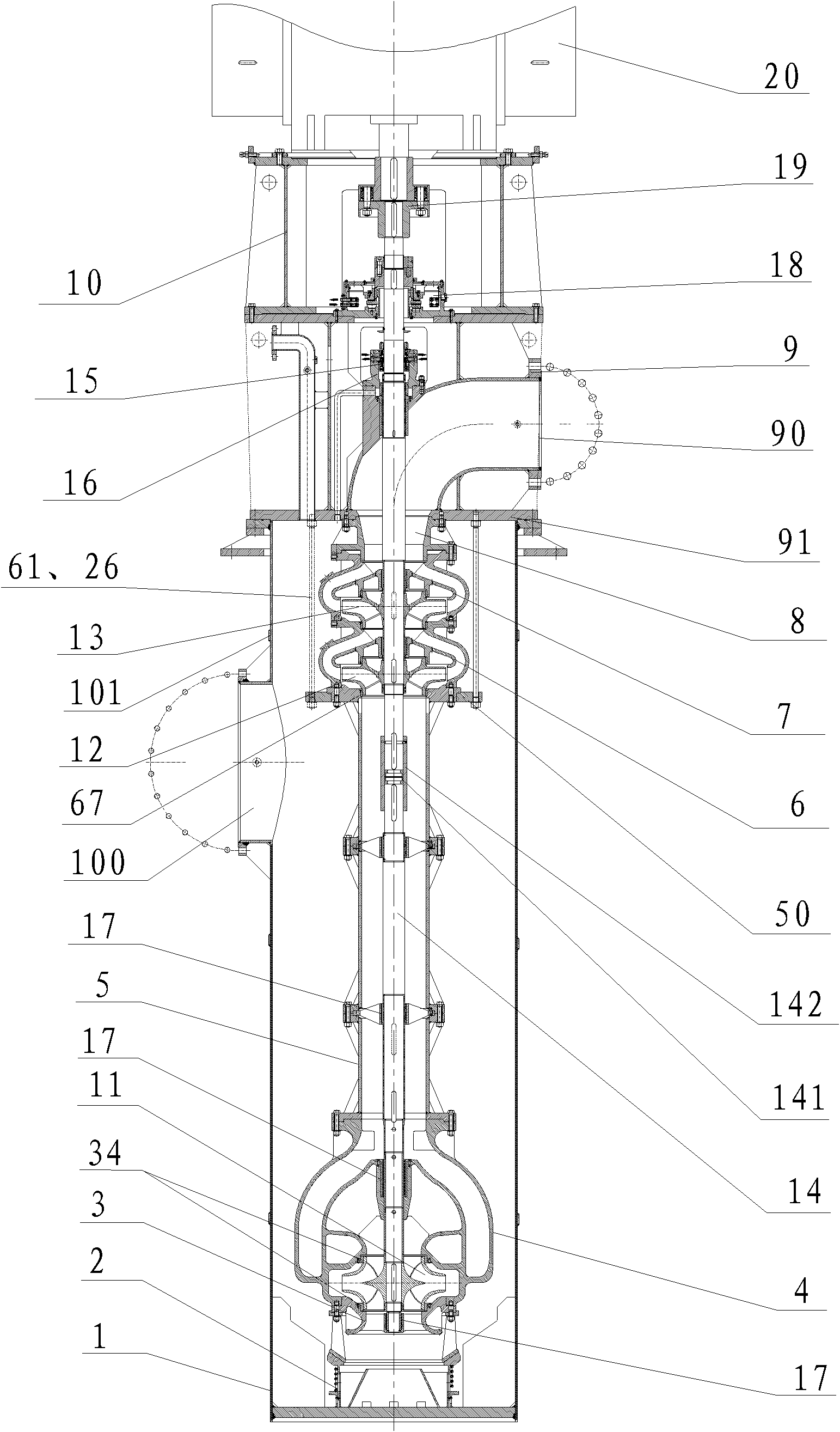

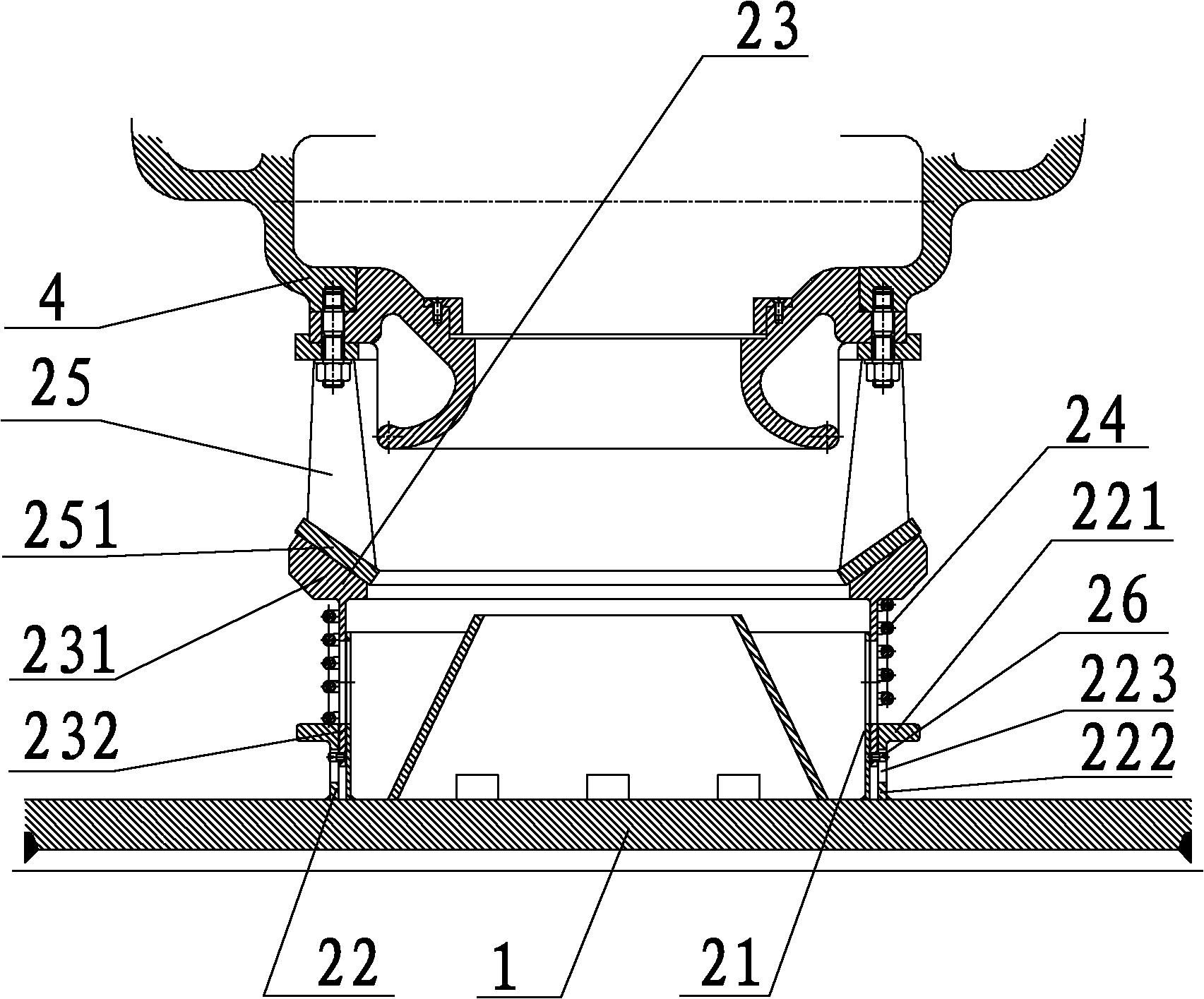

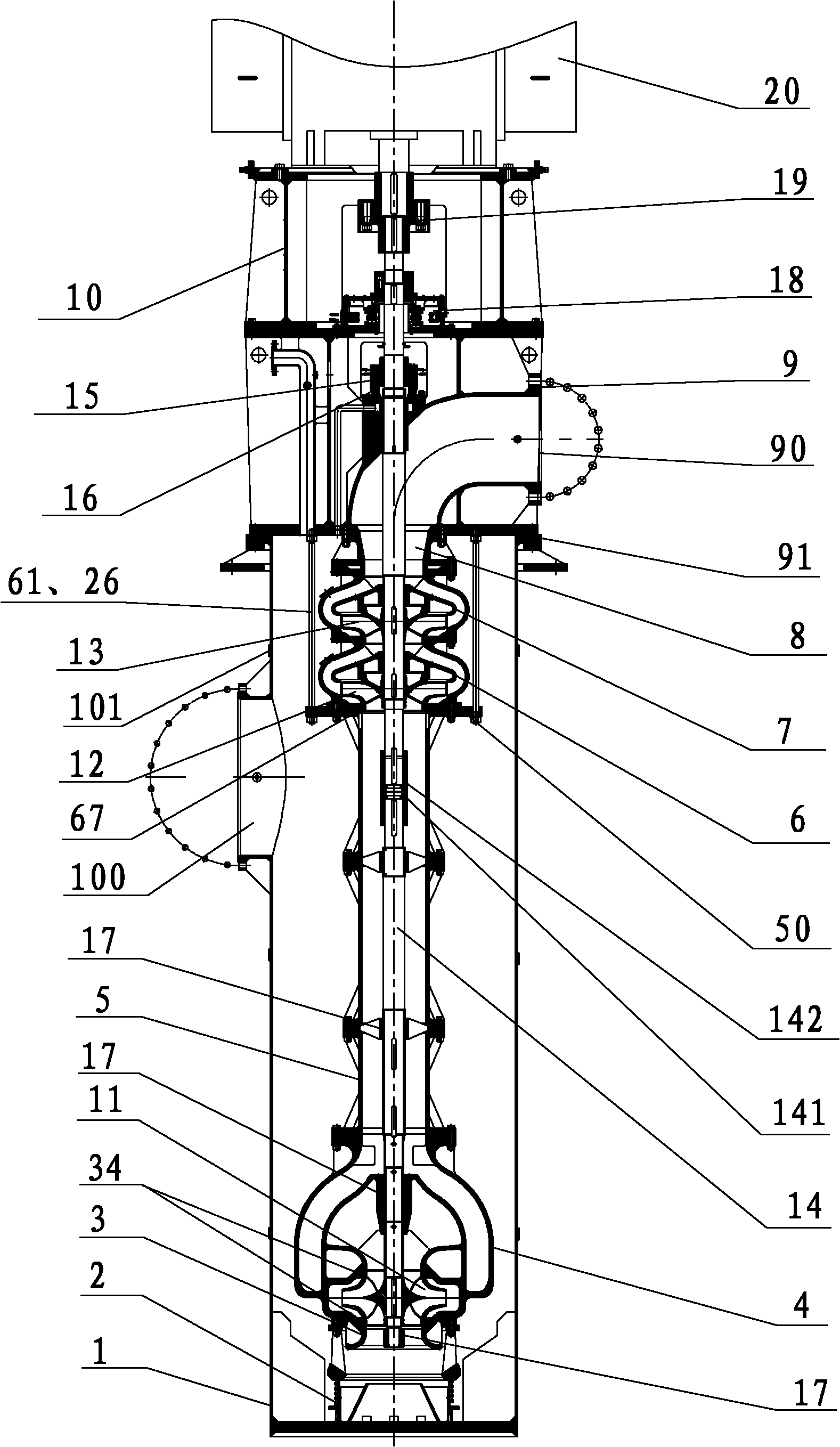

[0015] see figure 1 , The condensate pump for nuclear power plants of the present invention includes a vertical outer cylinder 1, an auxiliary support device 2, a pump body, a motor frame 10, a first stage impeller 11, a secondary impeller 12, a final stage impeller 13, a pump shaft 14, Mechanical seal 15, bearing assembly and motor 20, wherein:

[0016] The pump body includes a water inlet horn 3, a double-suction volute case 4, a straight pipe 5, a secondary guide vane 6, a final guide vane 7, a different-diameter housing 8 and a water outlet shell, which are coaxially connected to each other in sequence from bottom to top. body 9; the water outlet shell 9 is fixed on the upper end of the outer cylinder 1, the water inlet horn 3, the double-suction volute case 4, the straight ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com