Patents

Literature

67results about How to "Strong anti-eccentric load ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

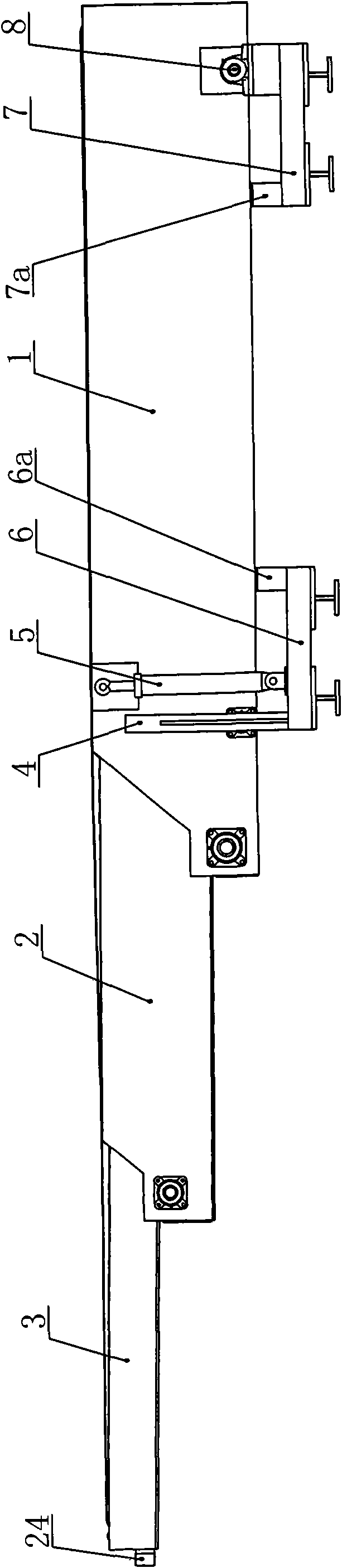

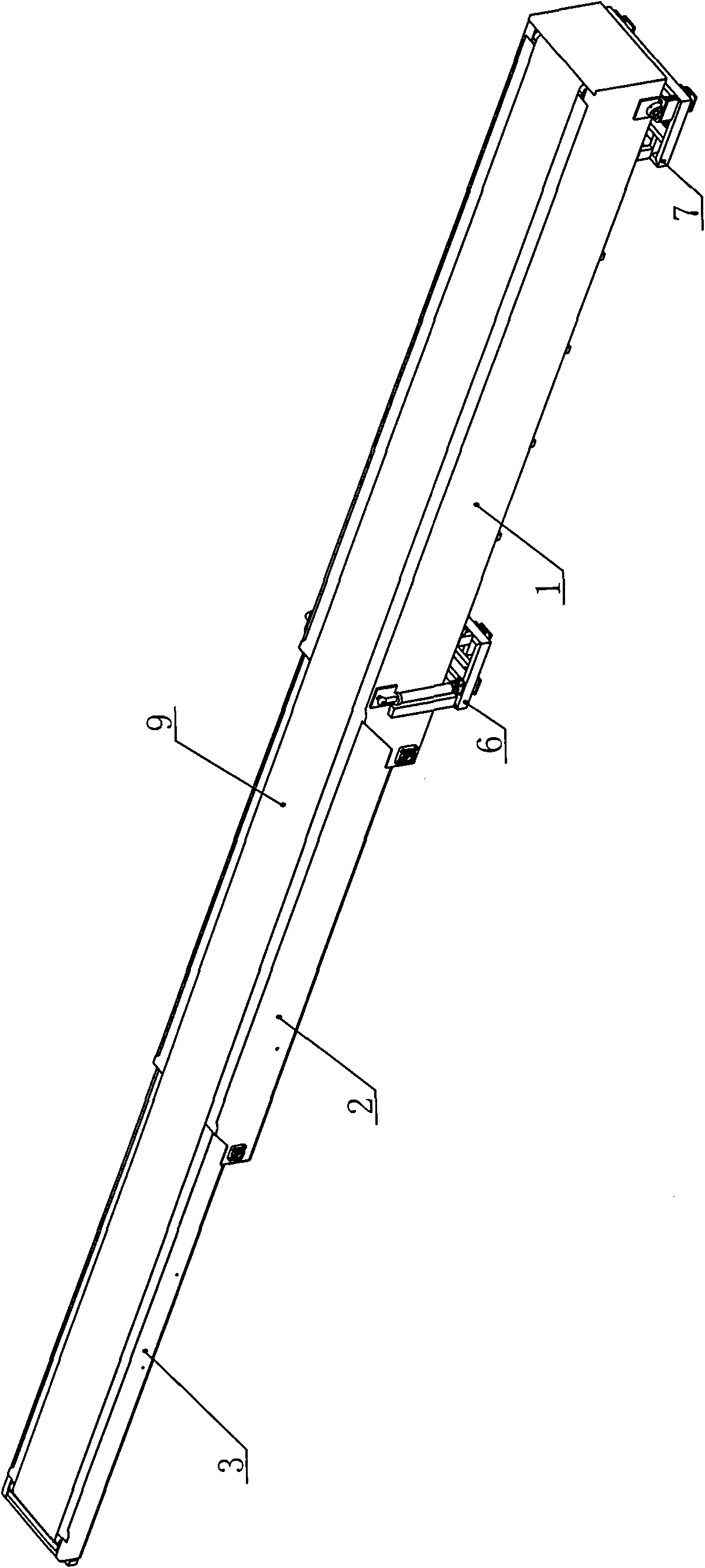

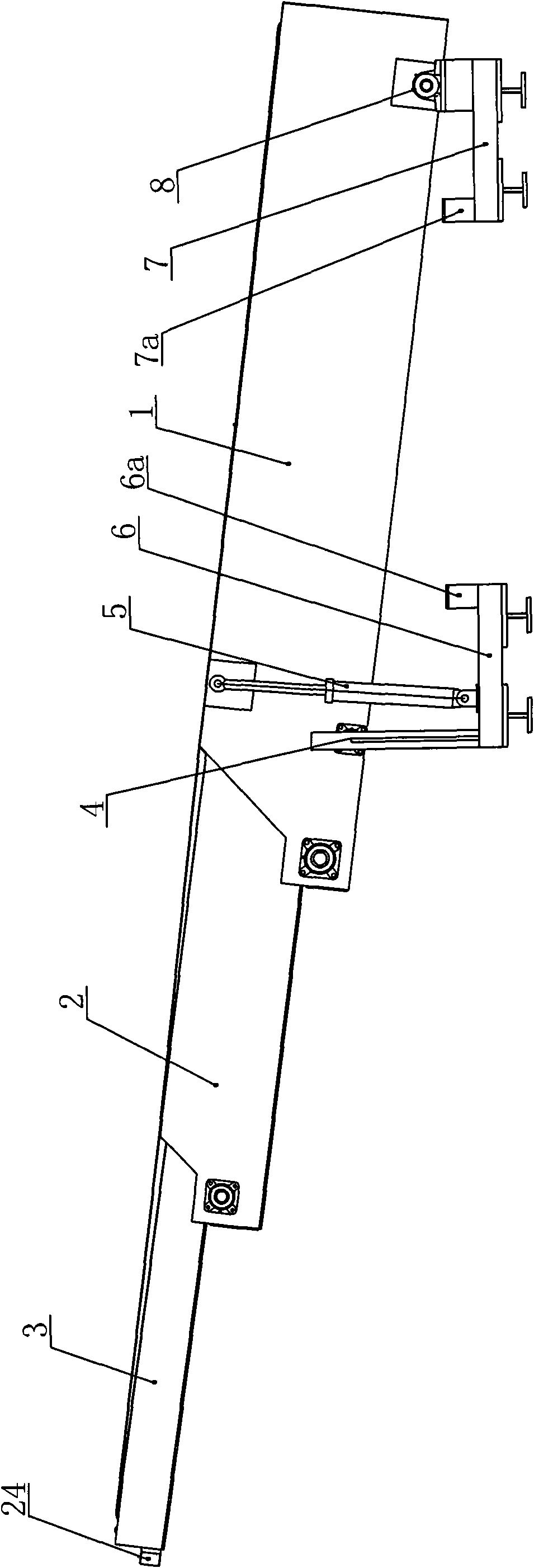

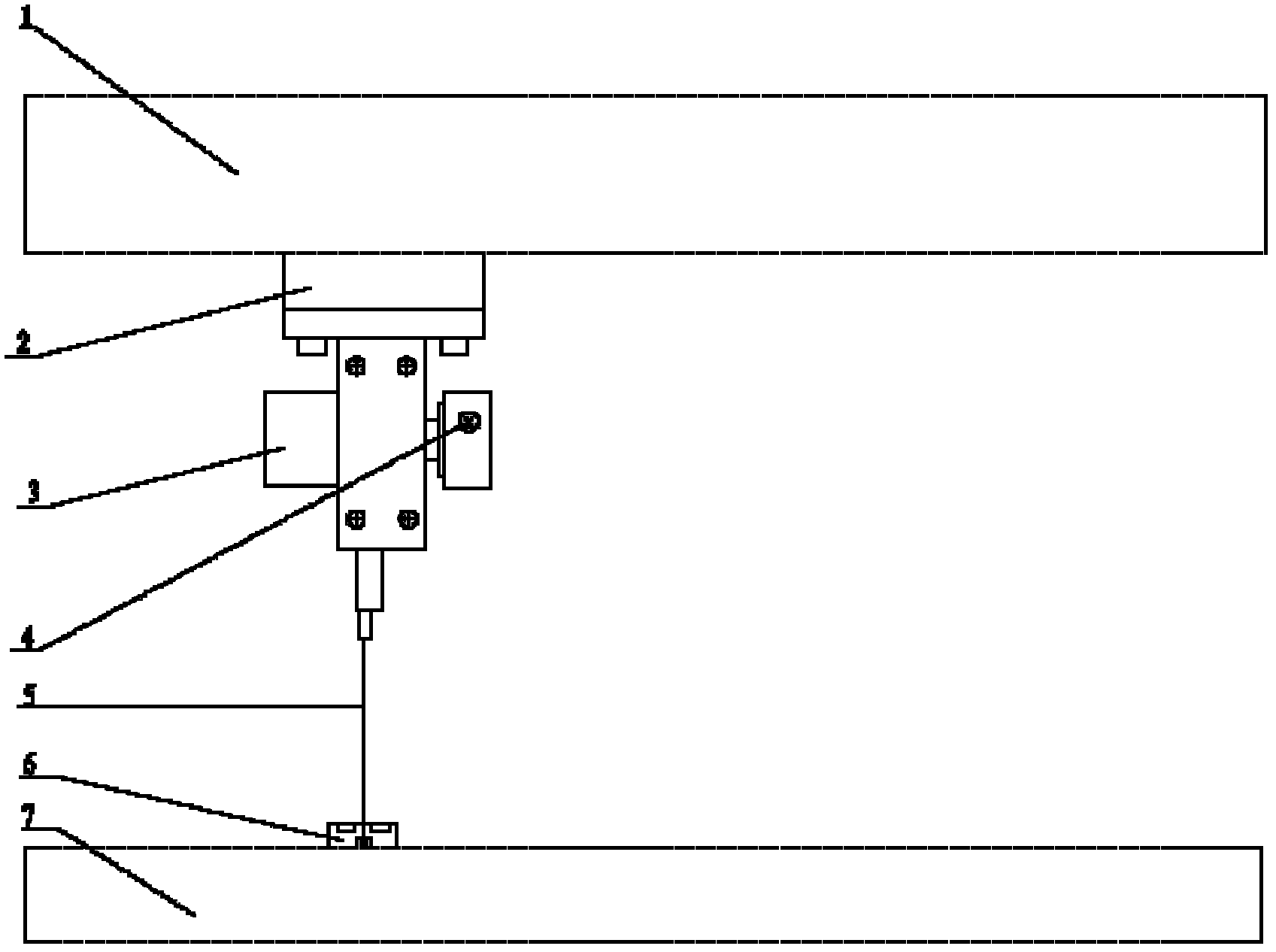

Telescopic bidirectional loading and unloading conveyor

ActiveCN101955068AIncrease contact areaAccurate connectionConveyorsControl devices for conveyorsEngineeringExpansion joint

The invention discloses a telescopic bidirectional loading and unloading conveyor, which belongs to the field of storage and logistics. The telescopic bidirectional loading and unloading conveyor comprises a base joint, a primary expansion joint, a secondary expansion joint, a belt conveying mechanism, a telescopic mechanism, and an elevator mechanism, wherein a front pedestal and a back pedestalare respectively arranged below the two ends of the base joint, and the back part of the base joint is hinged on the back pedestal; a lifting oil cylinder of the elevator mechanism is hinged on the front pedestal and a piston rod of the elevator mechanism is hinged on the front part of the base joint; the primary expansion joint is nested in the cavity of the base joint and can expand and contract along the base joint under the driving of the primary expansion joint; the secondary expansion joint is nested in the cavity of the primary expansion joint and can expand and contract along the primary expansion joint; the belt conveying mechanism comprises a conveying motor, a belt driven roller and a conveying belt; turnabout drums are respectively arranged at the front and back ends of the base joint, the primary expansion joint and the secondary expansion joint; and the conveying belt can be orderly wrapped on the belt driven roller and each turnabout drum to form a sealed conveying ring. The loading and unloading conveyor has the advantages of bidirectional conveying, convenient move, adjustable conveying height and distance, safety and reliability.

Owner:YANGZHOU SINO-EU IND ROBOT CO LTD

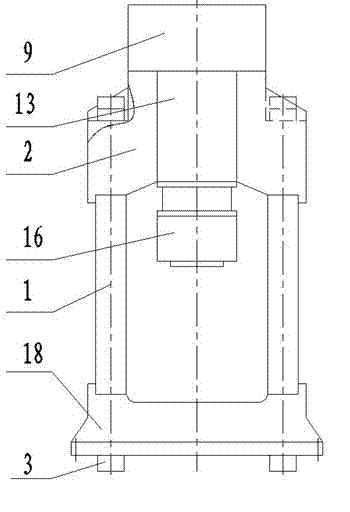

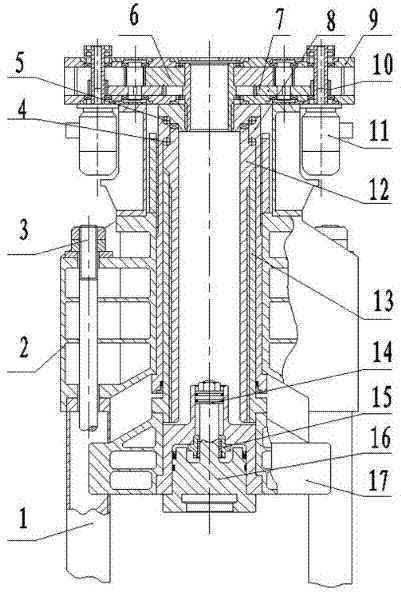

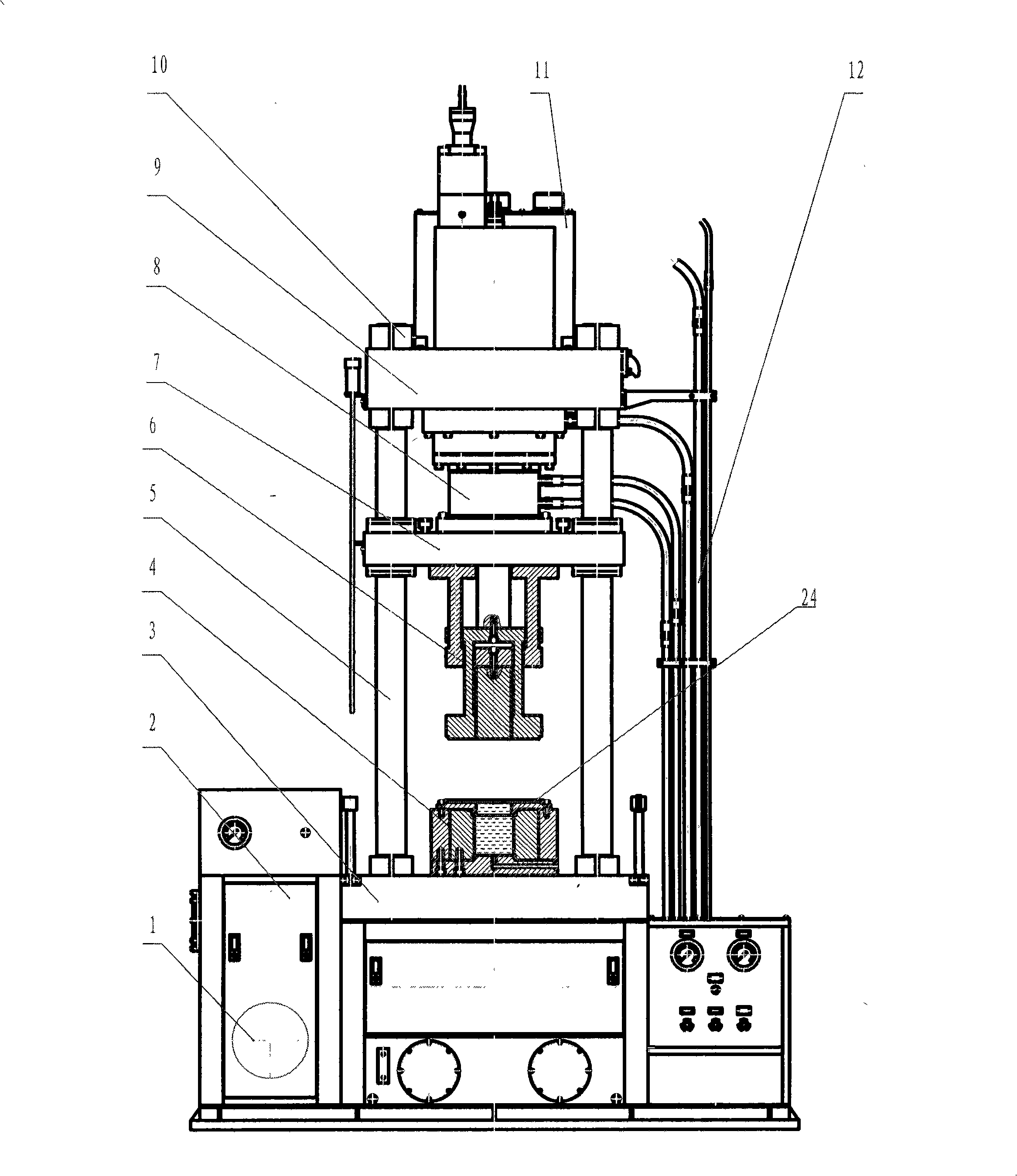

a forging press

InactiveCN102259154ASimple structureEasy to operateForging press detailsForging press drivesHydraulic cylinderEngineering

A forging apparatus comprises an upper beam (2), a lower beam (18) and at least one column (1). The lower end of the column (1) is fixed on the lower beam (18), the upper beam (2) is disposed at the upper end of the column (1), a movable beam driving apparatus is disposed on the upper beam (2), and the movable beam driving apparatus is connected through a spiral mechanism to a main hydraulic cylinder (16) and a return cylinder (14) capable of cushioning. The forging apparatus may connect the spiral mechanism in the driving apparatus, the main hydraulic cylinder (16) and the return cylinder (14) together without being provided with the movable beam. The forging apparatus is characterized in that the structure is simple, and the operation is convenient and fast; the structural strength is high, the vibration is small, the anti-unbalanced loading capability is strong, the manufacturing, assembly and repair are convenient, and the cost is low.

Owner:GUANGDONG HUAYE POWER TECH

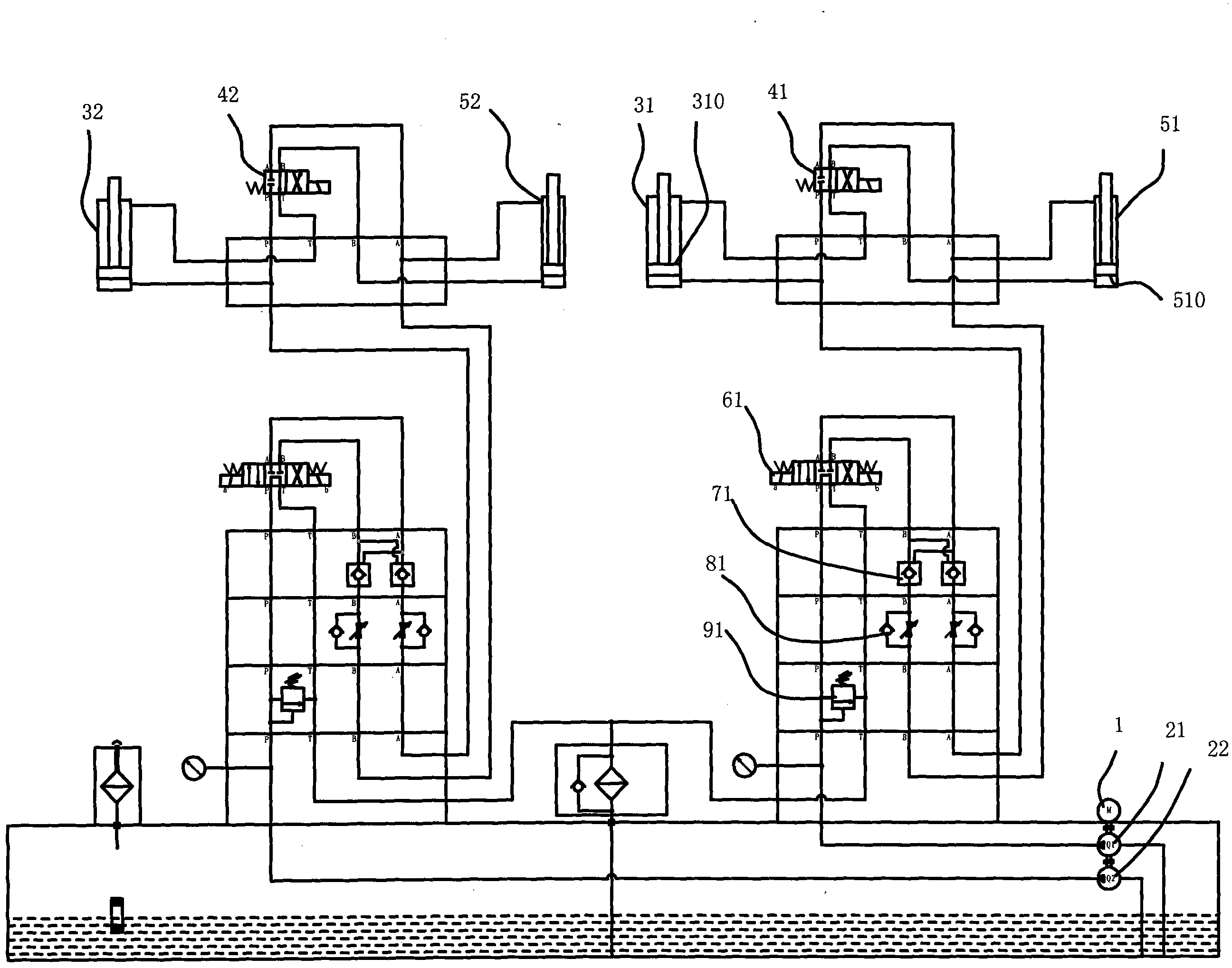

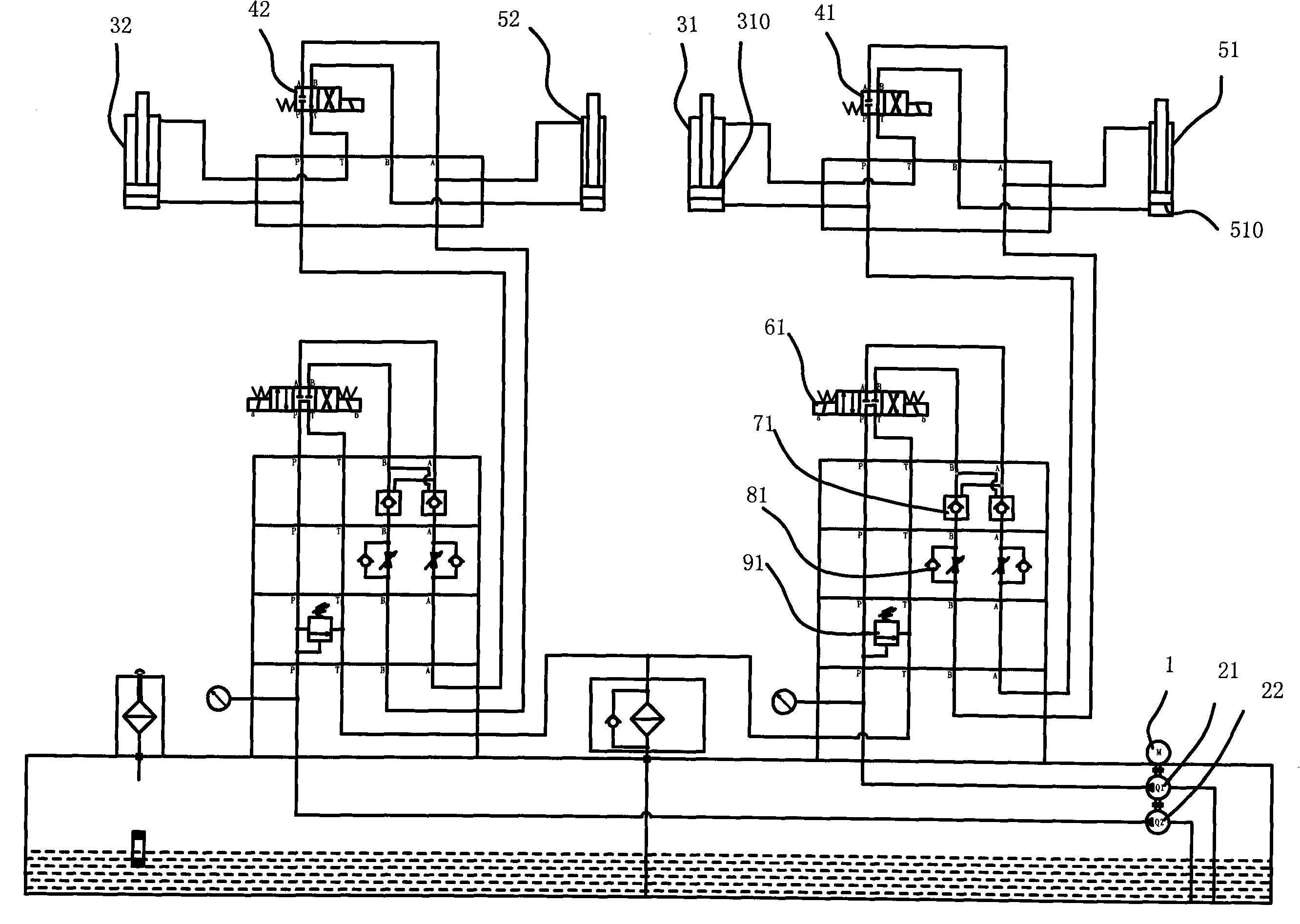

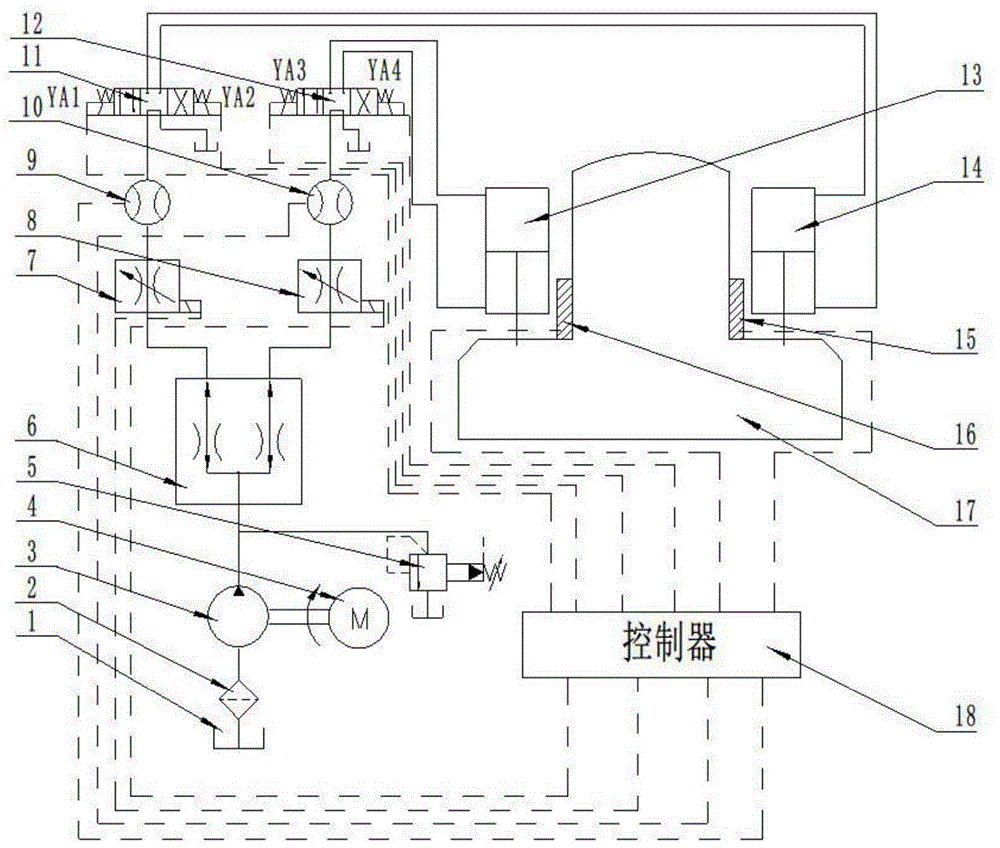

Four-cylinder synchronous hydraulic system

InactiveCN102022392ANo pressure lossReduce temperature riseServomotorsTop dead centerMaster cylinder

The invention discloses a four-cylinder synchronous hydraulic system relating to a synchronous hydraulic system synchronously lifting through a four-corner driving platform. The system can carry out online automatic compensation to ensure four-point synchronous lifting. The four-cylinder synchronous hydraulic system comprises a master cylinder A, a slave cylinder A, a master cylinder B, a slave cylinder B, an oil pump, two oilway reversing control valve banks and a hydraulic oil tank, wherein the master cylinder A, the slave cylinder A, the master cylinder B and the slave cylinder B respectively drive four corners of a horizontal table top, and the two oilway reversing control valve banks are arranged between the oil pump and the master cylinder and the slave cylinder; the rod cavities and the rodless cavities of the master cylinders and the rodless cavities and the rod cavities of the slave cylinders are in serial and parallel switching connection through a two-position four-way solenoid valve, and the working areas of the rod cavities of the master cylinders are equal to those of the rodless cavities of the slave cylinders. The four-cylinder synchronous hydraulic system comprises two same independent serial / parallel cylinder synchronous circuits; under the normal condition, master oil cylinders and slave oil cylinders in each circuit are synchronous through serial connection. When the master oil cylinders and the slave oil cylinders are asynchronous due to the leakage of the oil cylinders, the four oil cylinders can be lifted to top dead centers, and the master oil cylinders and the slave oil cylinders are switched into a parallel mode through the two-position four-way solenoid valve and then are switched to a serial mode after the four oil cylinders are synchronous.

Owner:江苏扬力数控机床有限公司

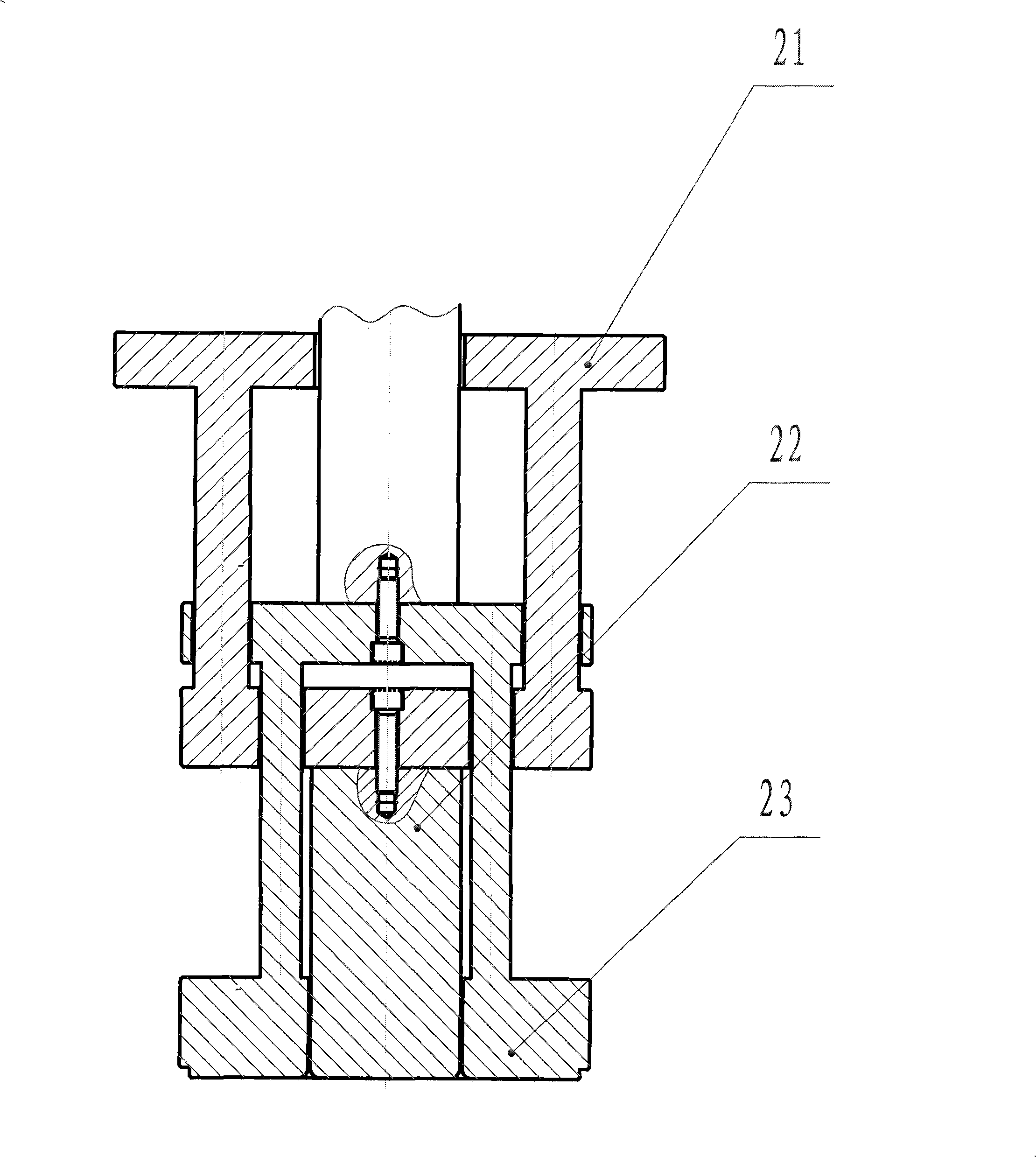

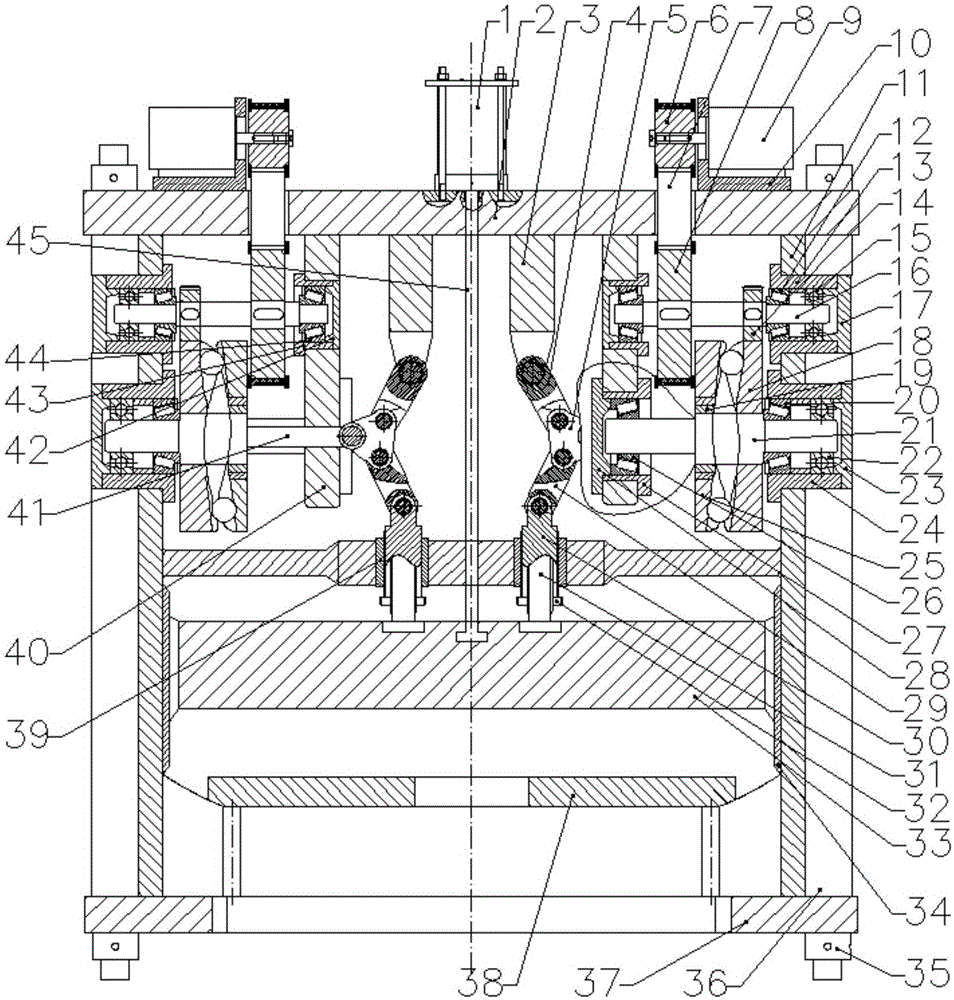

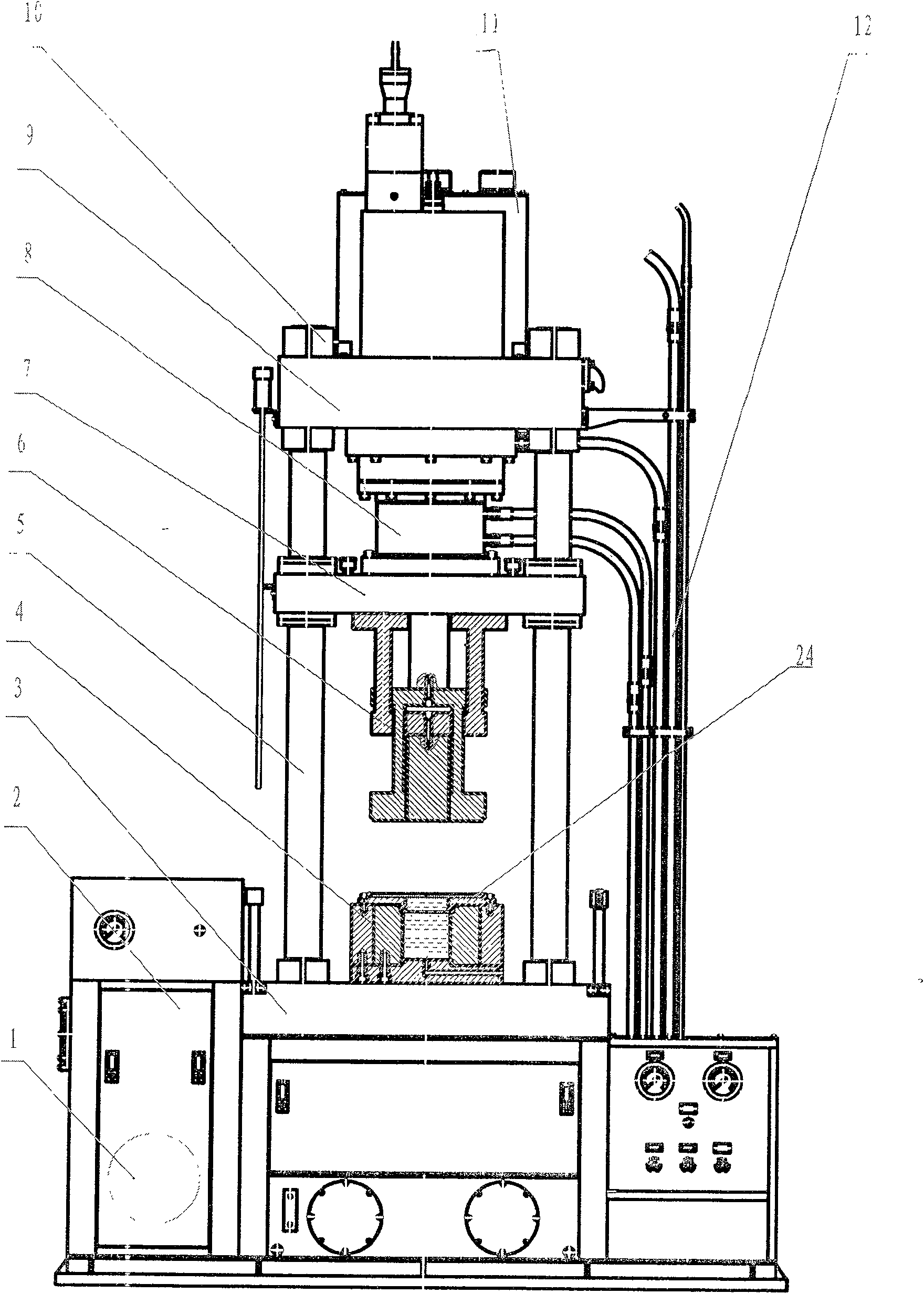

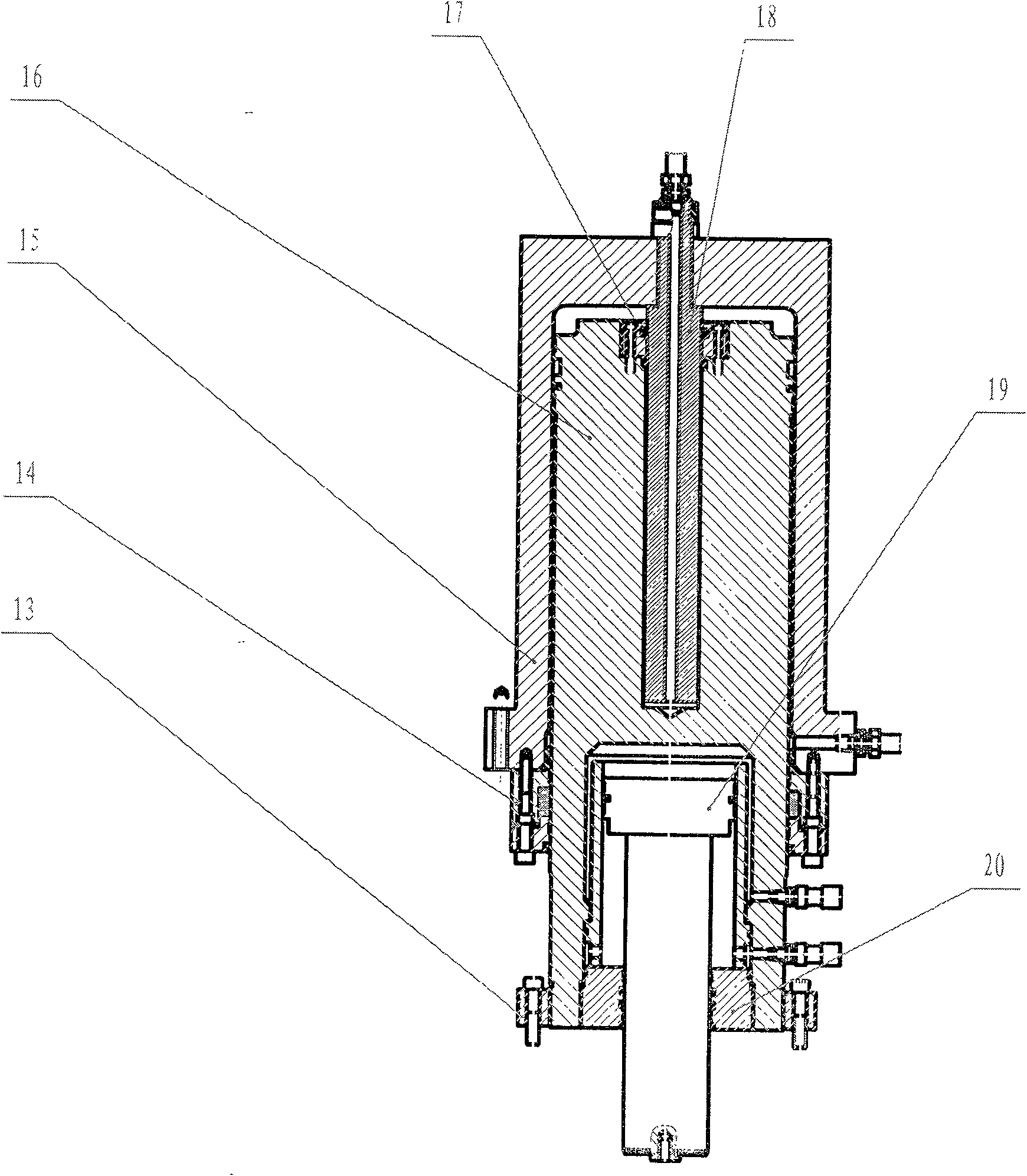

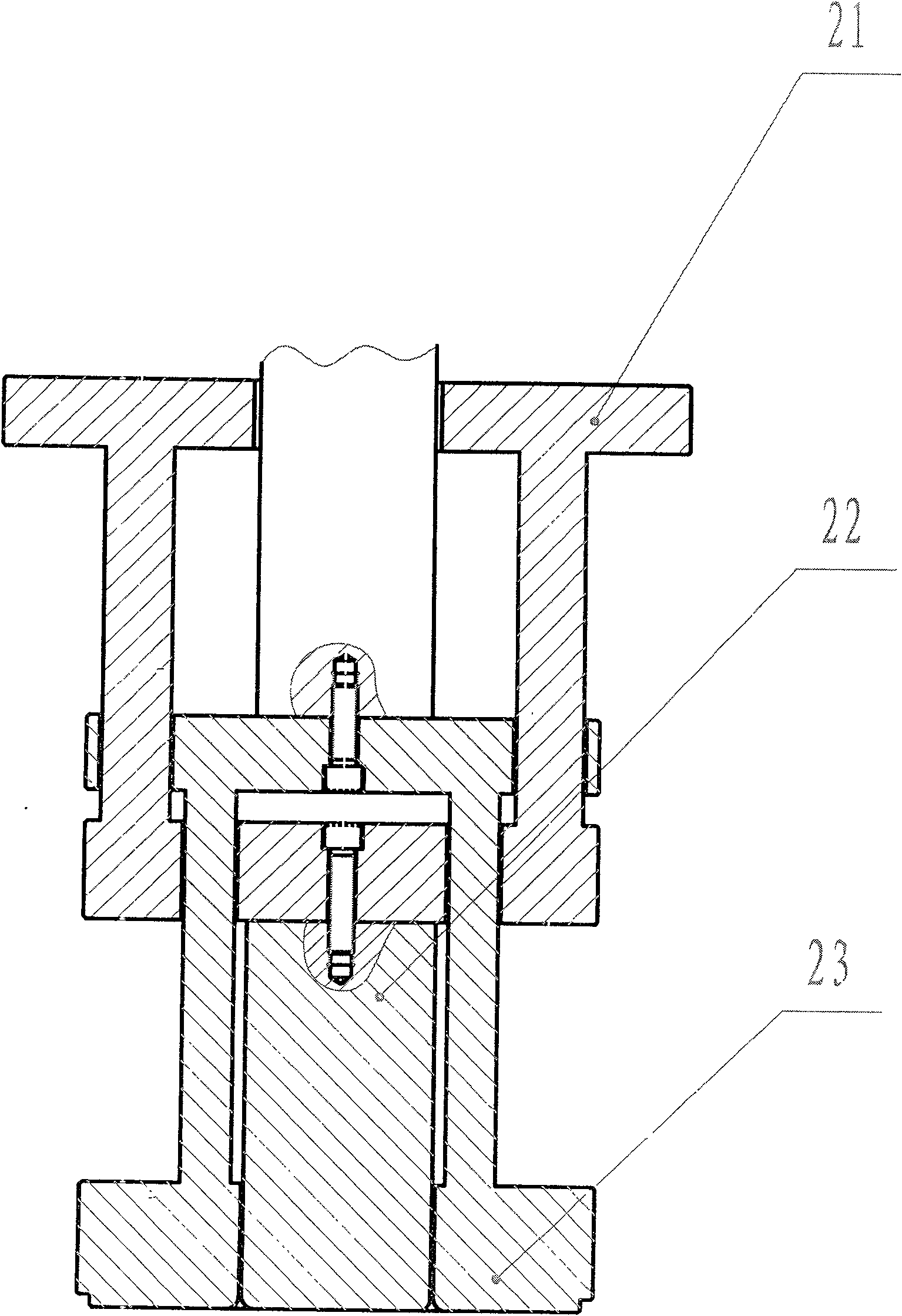

Plate liquid-filling shaping hydraulic machine

ActiveCN101298087AQuality improvementImprove mechanical propertiesMeasurement devicesPower control systemMaster cylinder

The invention discloses a sheet hydraulic-forming hydraulic press which is characterized by essentially comprising an underbeam, an upright post arranged on the underbeam, a top beam arranged on the upright post, a stretching beam connected on the upright post in a sliding manner, a compound master cylinder arranged on the top beam, a coaxial link deep-drawing and blank holding device arranged bellow the stretching beam, a liquid chamber arranged on the underbeam, a support oil tank which comprises a hydraulic power control system, a supercharger, etc. The underbeam, the upright post and the top beam are connected together by upright post nuts to form a rigid body; the compound master cylinder is essentially composed of a cylinder body fixed on the top beam, a master cylinder piston arranged in the cylinder body, a quick rod bush arranged on the master cylinder piston, a quick rod arranged in the rod bush, an embedded bank holding cylinder piston arranged in a master cylinder piston and flanges arranged at the mouth of the cylinder body; the master cylinder piston is connected with the stretching beam by the flanges; the embedded bank holding cylinder piston is connected with the coaxial link deep-drawing and blank-holding device which is essentially composed of a drawing slide, a blank holding slide which is coaxially connected to the drawing slide and is connected with the embedded bank holding cylinder piston and a male die which is fixed on the drawing slide. Compared with the prior art, the hydraulic press of the invention has the advantages of possessing dies with universality, reducing die cost and shortening production cycle.

Owner:FOSHAN CONSTANT HYDRAULIC MACHINERY

Sliding block balance electro-hydraulic servo synchronous control system of bending machine

ActiveCN104405733ASimple structureEasy assembly and adjustmentServomotor componentsServomotorsHydraulic cylinderSynchronous control

The invention discloses a sliding block balance electro-hydraulic servo synchronous control system of a bending machine. An oil tank is connected with a filter; the filter is connected with a quantitative hydraulic pump; the shaft end of the quantitative hydraulic pump is connected with a motor; the pump port of the quantitative hydraulic pump is connected with an inlet pipe of a diverter valve; and the system further comprises two electromagnetic speed regulating valves connected with two oil outlets of the diverter valve, first and second flow meters mounted on two branch oil pipes, two electromagnetic reversing valves mounted on two branches, hydraulic cylinders mounted at the two sides of the upper side of a sliding block, grating ruler displacement sensors arranged at the two sides of the sliding block, a programmable logic controller PLC with a PID adjusting function, a power supply and the like. The system is reasonable in design and simple in assembly and regulation, can realize synchronous vertical movement of the two ends of the sliding block, is excellent in balance, and has the characteristics of strong unbalance loading resistance and high control precision.

Owner:JIANGSU UNIV

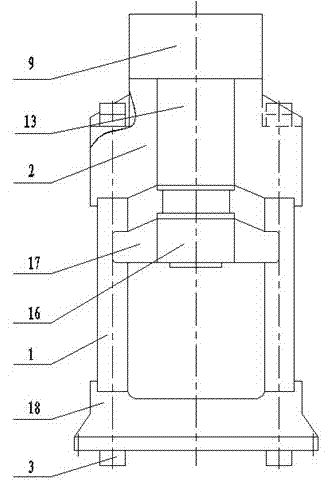

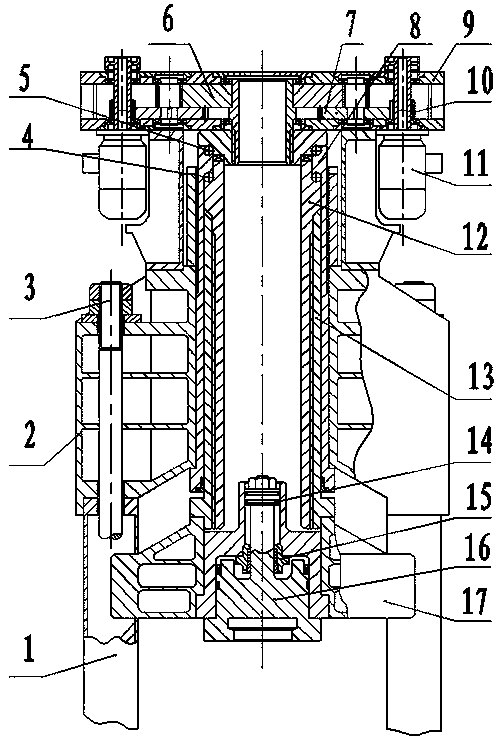

Axial force sensor

The invention discloses an axial force sensor, which comprises an elastic body, wherein the elastic body is of a flat plate shape; an axis penetration through hole is formed in the middle of the plate surface; a plurality of bolt penetration holes are formed at the periphery of the elastic body; the whole shape of the elastic body is similar to that of a gasket of a flange disk; an annular stress slot concentric with the shaft axis penetration through hole is formed on each of the front plate surface and the rear plate surface of the elastic body, and the diameters of the annular stress slots are equal substantially; the stress slots are close to the axis penetration through hole; resistance strain gauges are attached to the stress slots and form a WheatStone balance bridge which is connected with an external electric appliance. The axial force sensor is low in height, small in size and similar to the gasket in the shape, can be conveniently assembled between the force applying shaft of the appliance and the flange disk or a stressed part at the connection shaft end of the appliance, is damaged difficultly, and is firm and high in lateral and unbalance loading resistance; and when the sensor is stressed by an axial load, part of the elastic body in each stress slot is effectively deformed, so that an axial force value can be sensitively and accurately detected.

Owner:ZHONGHANG ELECTRONICS MEASURING INSTR

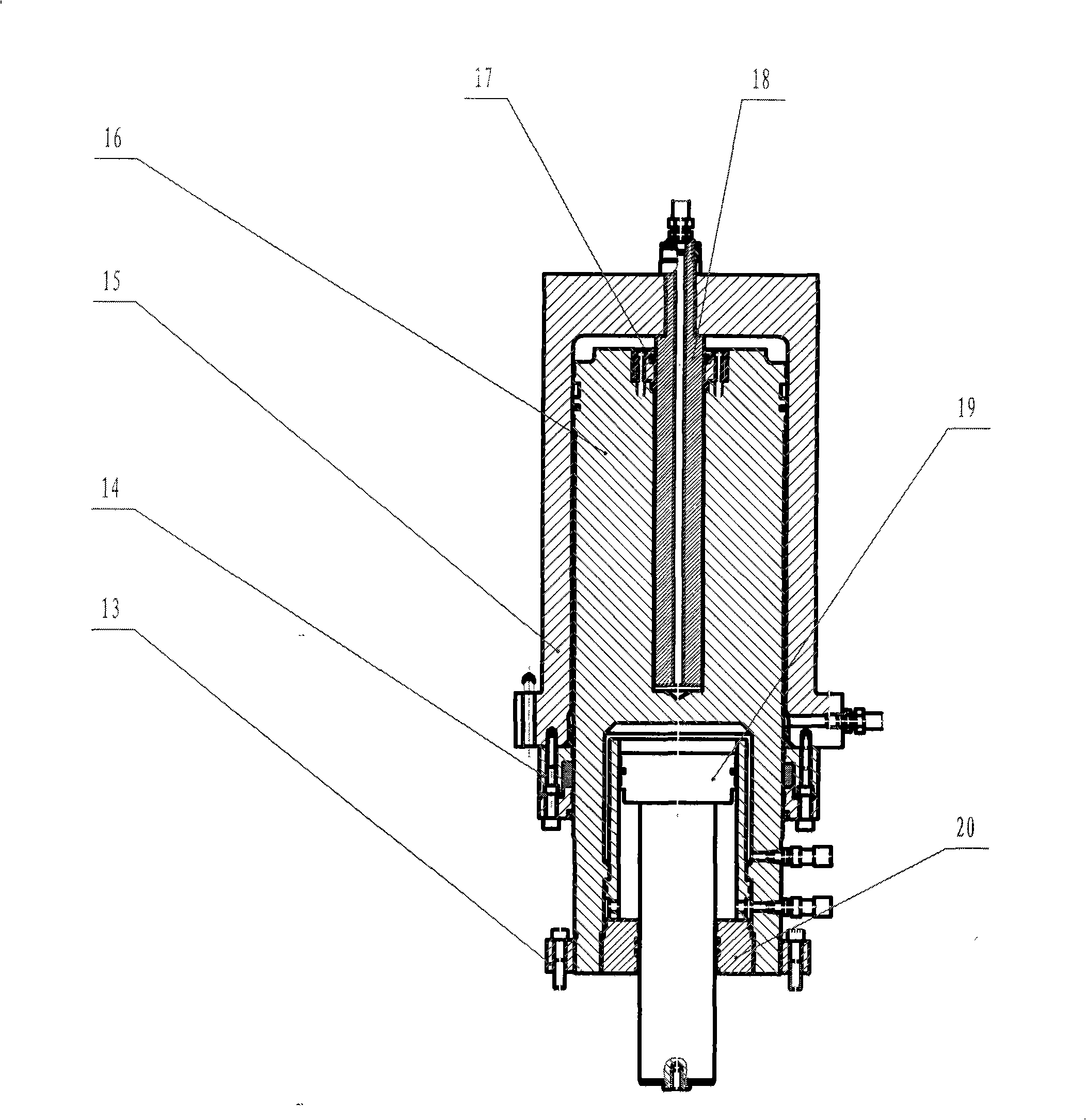

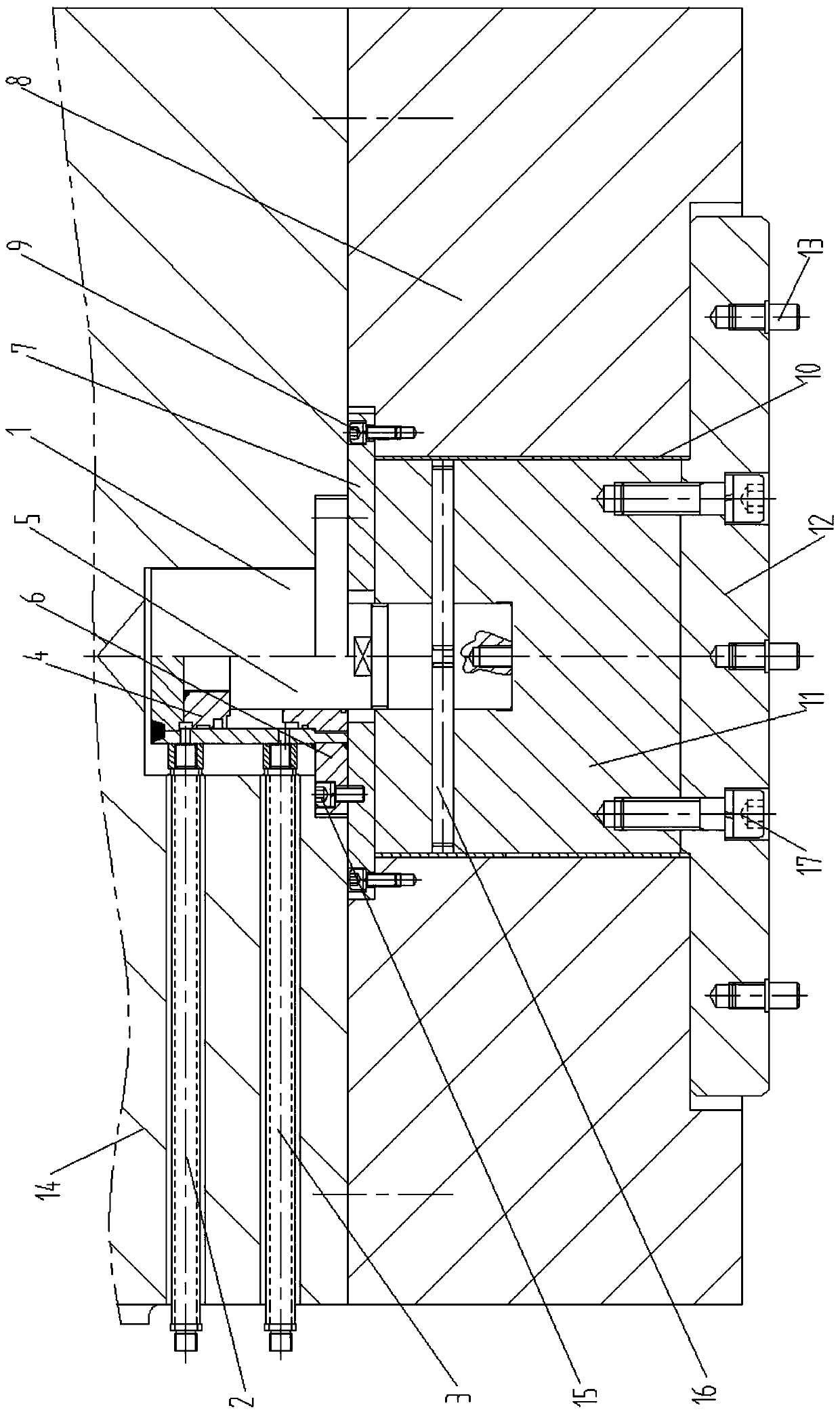

Hydraulic cylinder plunger installation structure for powder hydraulic press

The invention relates to a hydraulic cylinder plunger installation structure for a powder hydraulic press, comprising a cylinder body, a plunger and a guide sleeve. The hydraulic cylinder plunger installation structure is characterized in that a center blind hole is arranged at the outer connecting end of the plunger; a spherical column is arranged in the center blind hole; an unbalance loading gap is reserved between the spherical column and the center blind hole; a spherical pad is arranged between the spherical column and the center blind hole; a spherical pad is arranged between the other end of the spherical column and the outer connecting piece; two annular lug bosses are arranged on the spherical column; and two split flanges are symmetrically arranged between the two annular lug bosses, wherein one flange is connected with the plunger, and the other flange is clamped on the annular lug boss positioned outside and connected with the outer connecting piece. When the hydraulic press bears unbalance load, the spherical column realizes the unbalance load compensation along the spherical trace in a certain angle range and the wear of the plunger and other relevant components is reduced to the minimum when large unbalance force is applied, thereby prolonging the service life of the components and improving the work efficiency of the equipment.

Owner:TIANJIN TIANDUAN PRESS CO LTD

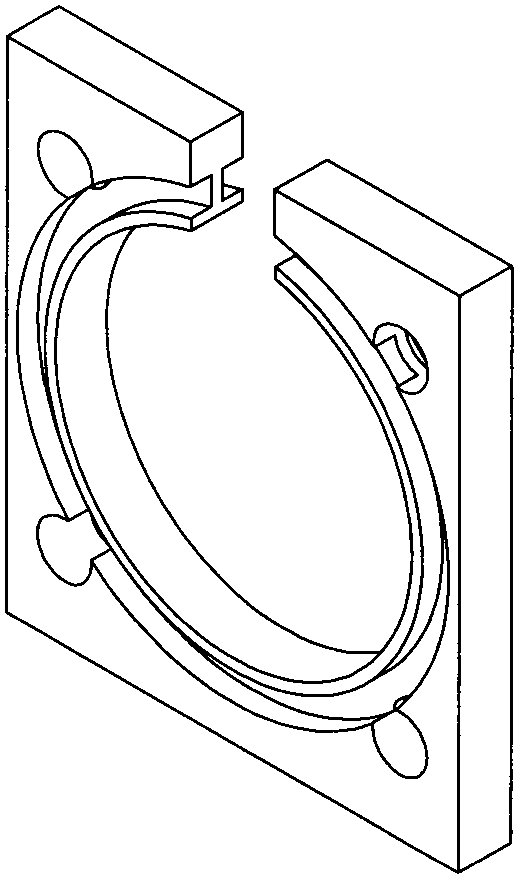

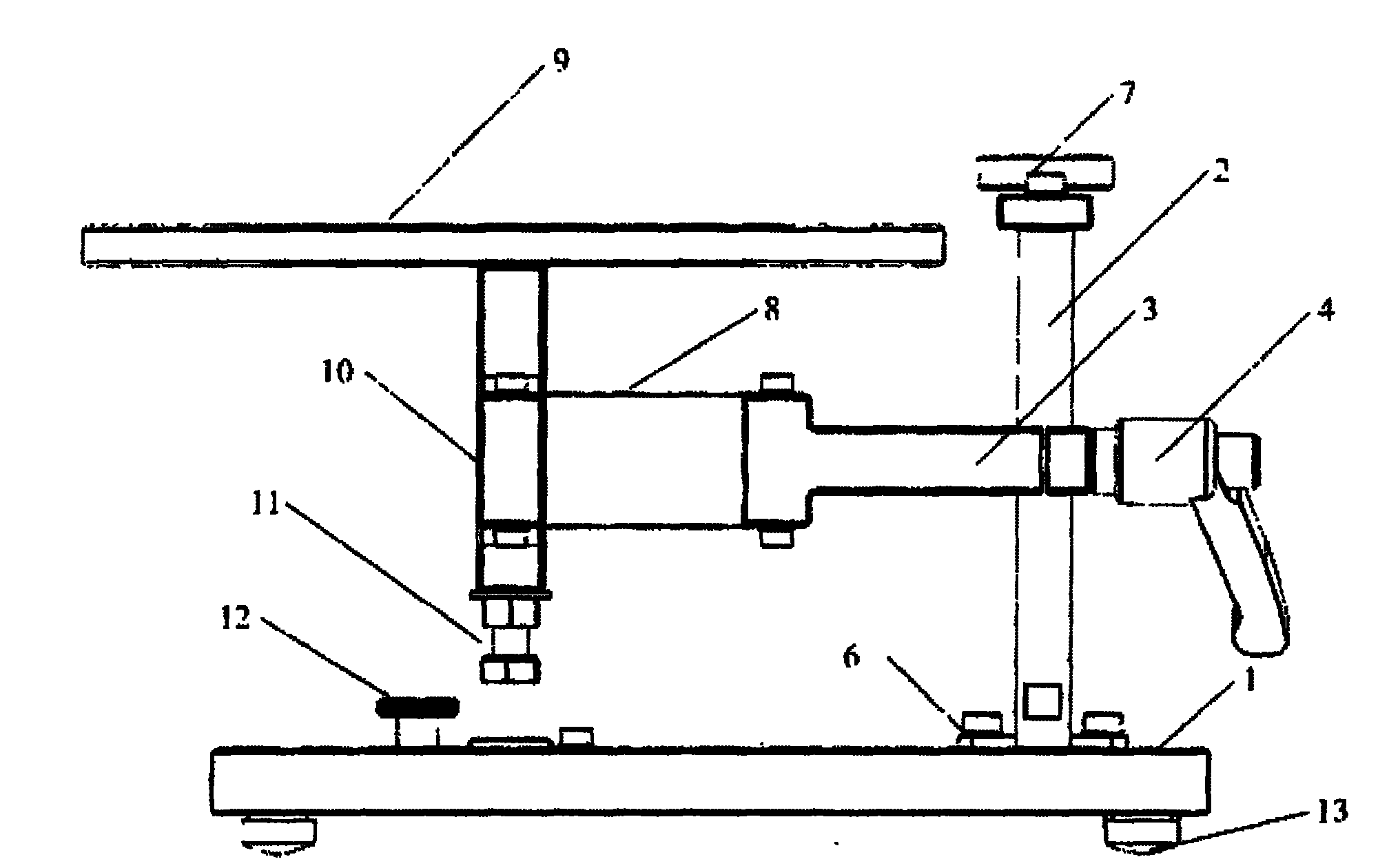

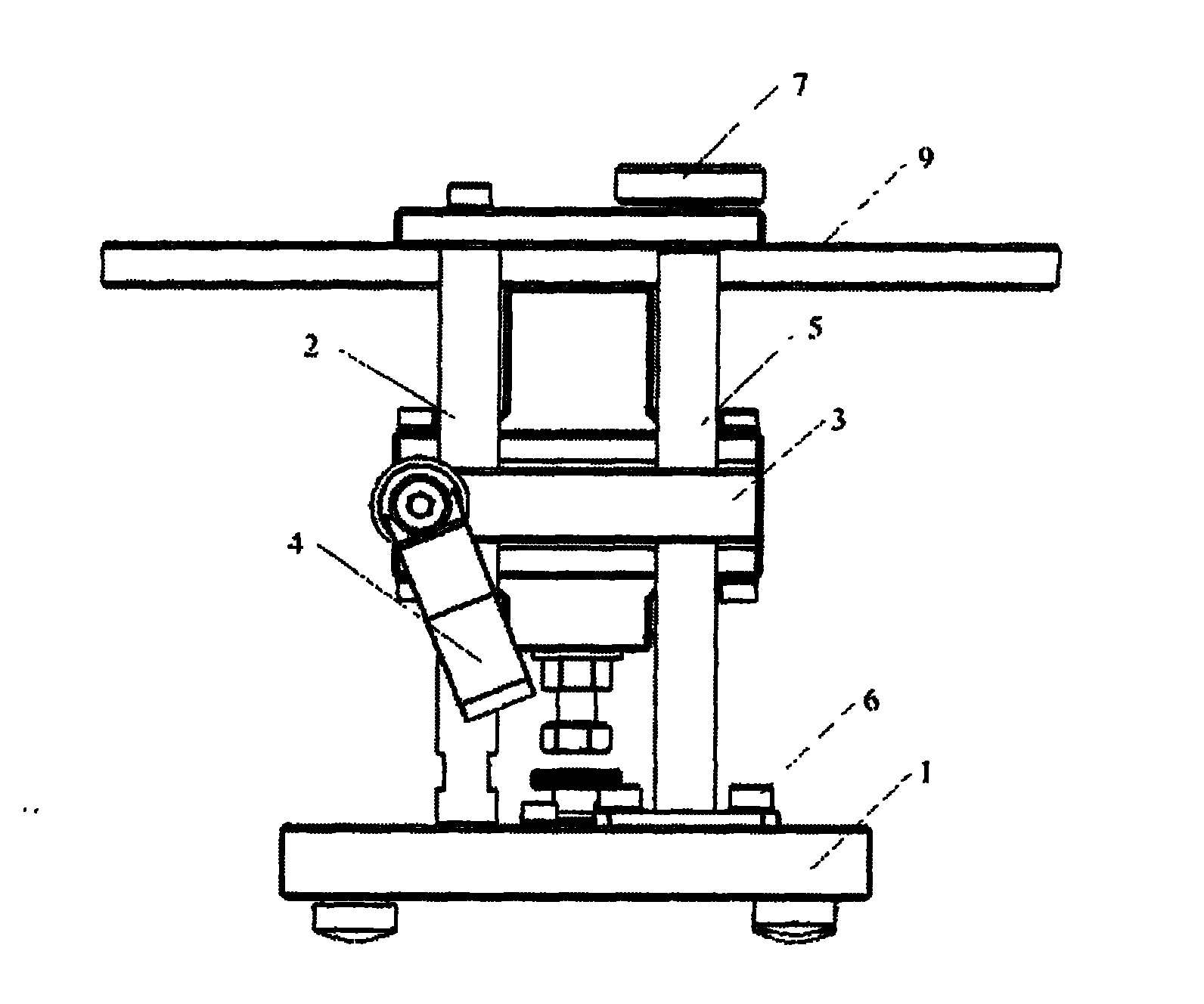

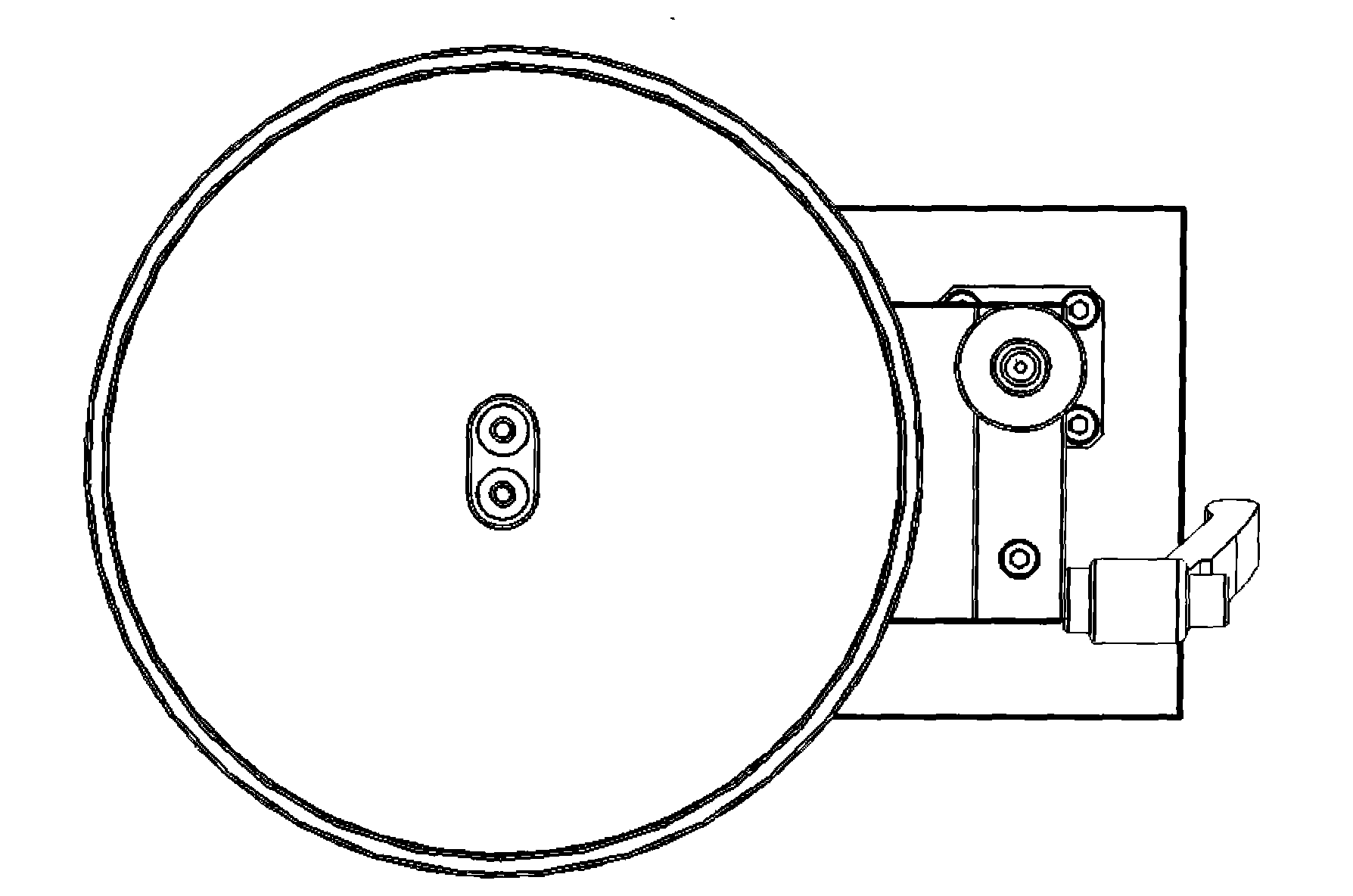

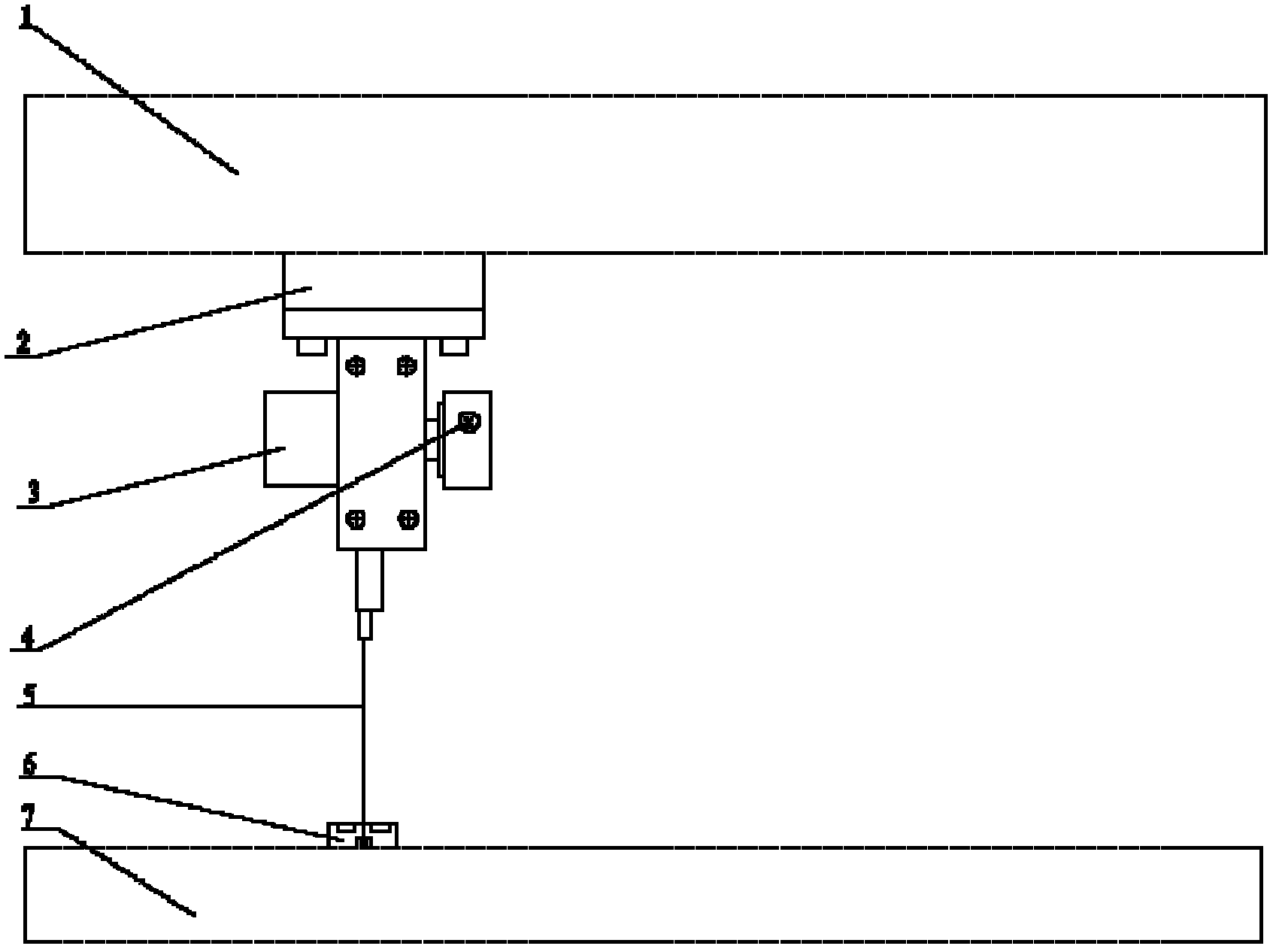

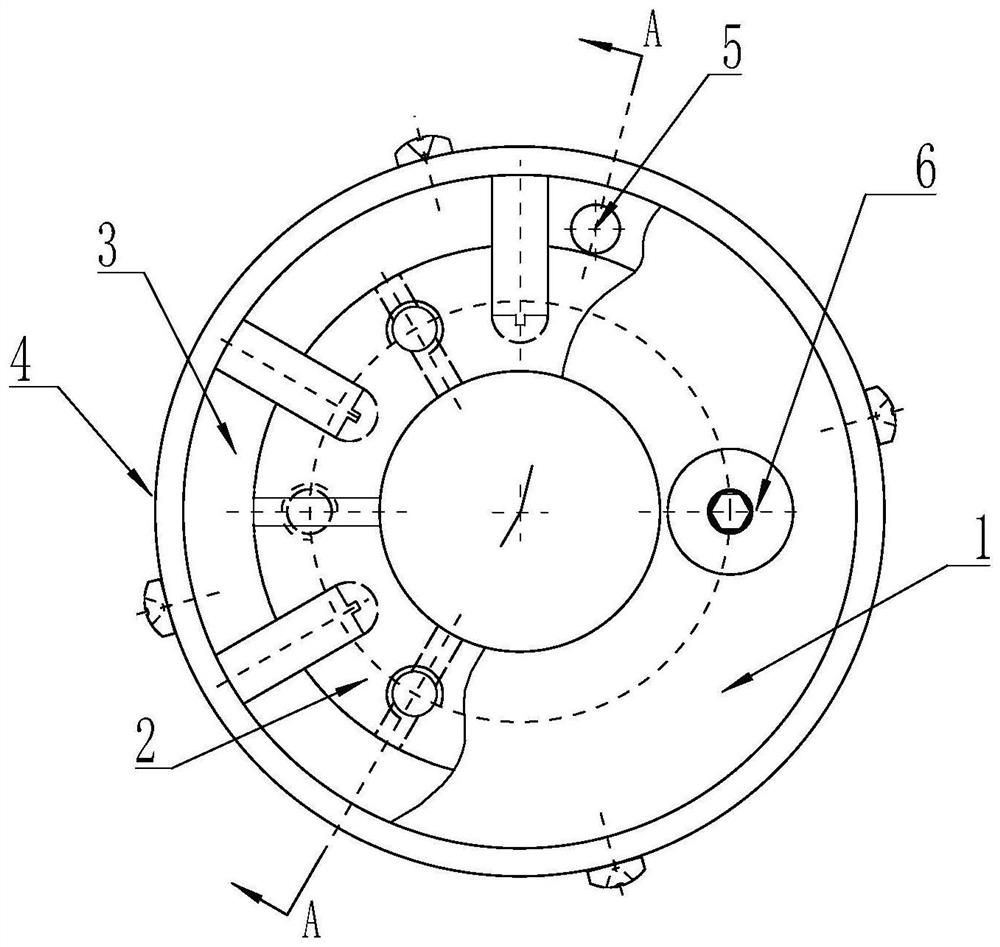

Calibration device of miniature pressure sensor

InactiveCN101793579AStrong anti-eccentric load abilityHigh precisionForce/torque/work measurement apparatus calibration/testingLoad resistanceEngineering

The invention discloses a calibration device of a miniature pressure sensor, which comprises a calibration device pedestal, a load bearing seat, a loading disc, a fixed guiding shaft, an adjusting seat and a sensor pressure head, wherein the fixed guiding shaft is arranged on the load bearing seat; the adjusting seat is arranged on the fixed guiding shaft and can move up and down along the fixed guiding shaft; the loading disc is arranged at the upper end of the load bearing seat; the lower end of the load bearing seat is provided with the sensor pressure heat; and the load bearing seat is connected with the adjusting seat through four deviation-rectifying spring steel sheets. By adopting the structure, the calibration device of the invention has self-balancing capacity and high eccentric load resistance performance. The invention provides the calibration device of the miniature pressure sensor, which has the characteristics of high accuracy, simple mounting, convenient operation and universality.

Owner:SOUTHEAST UNIV

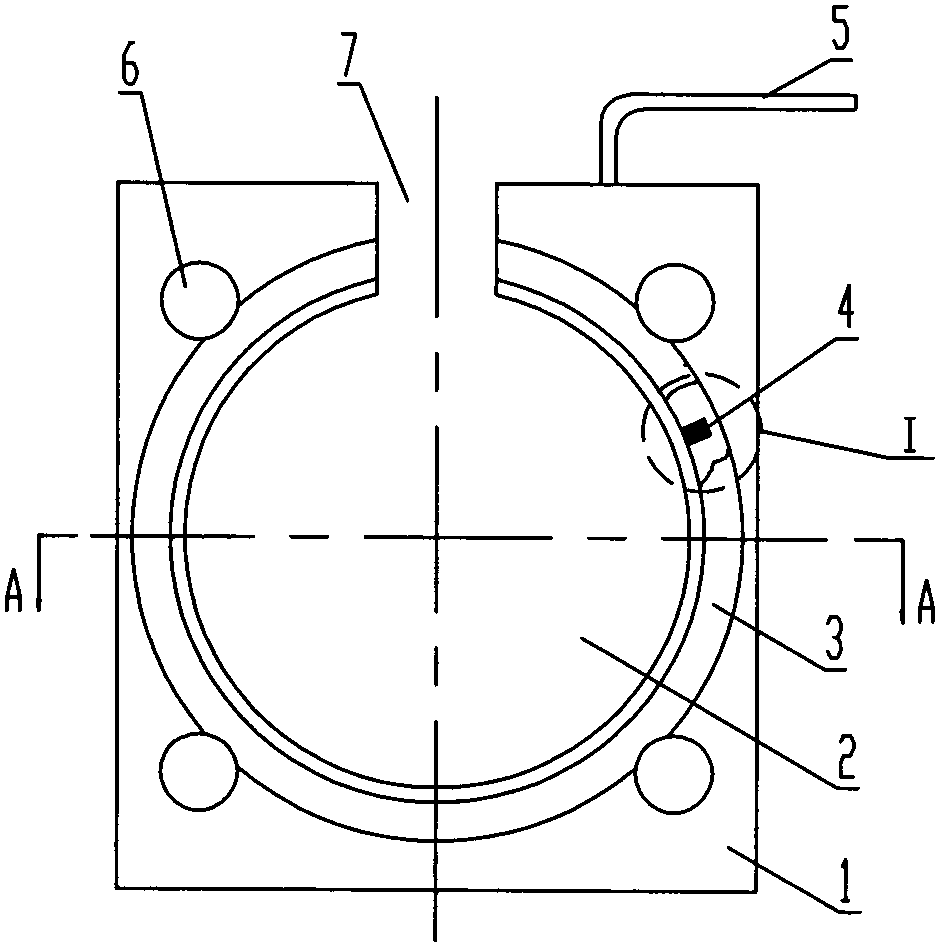

Three-point high speed precision press machine

InactiveCN103101207ASmall amount of deformationStrong anti-eccentric load abilityPress ramBall bearingDynamic balance

The invention relates to a three-point high speed precision press machine which comprises a motor (1). The motor (1) drives a crankshaft connecting rod system to run through a transmission mechanism. An output end of a crankshaft (6) of the crankshaft connecting rod system drives a dynamic balance block (13) to run through a balance connecting rod (12). A connecting rod (7) of the crankshaft connecting rod system drives guide pillars (9) and a sliding block (10) which is arranged at the lower end of the guide pillar to run through ball bearings (8). The sliding block (10) is provided with three guide pillars (9). The dynamic balance block (13) is arranged in the middle and is arranged on the middle guide pillar (9) through the connecting rod (7). Due to the fact that three plunger type guide pillars are arranged in the sliding block to guide a direction, unbalance loading resistant capability of a machine tool is strong, deformation of the sliding block is reduced by 40 percent under the same blanking condition, and meanwhile, a reverse dynamic device which is arranged on the crankshaft moves up and down, weights of the sliding block and a die are well balanced, whole rigidity of the machine tool is good, accuracy of a bottom dead center of the machine tool is good, and working stability is good.

Owner:YANGZHOU FORGING MACHINE TOOL

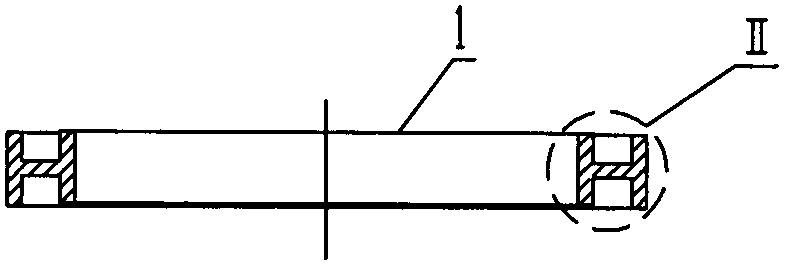

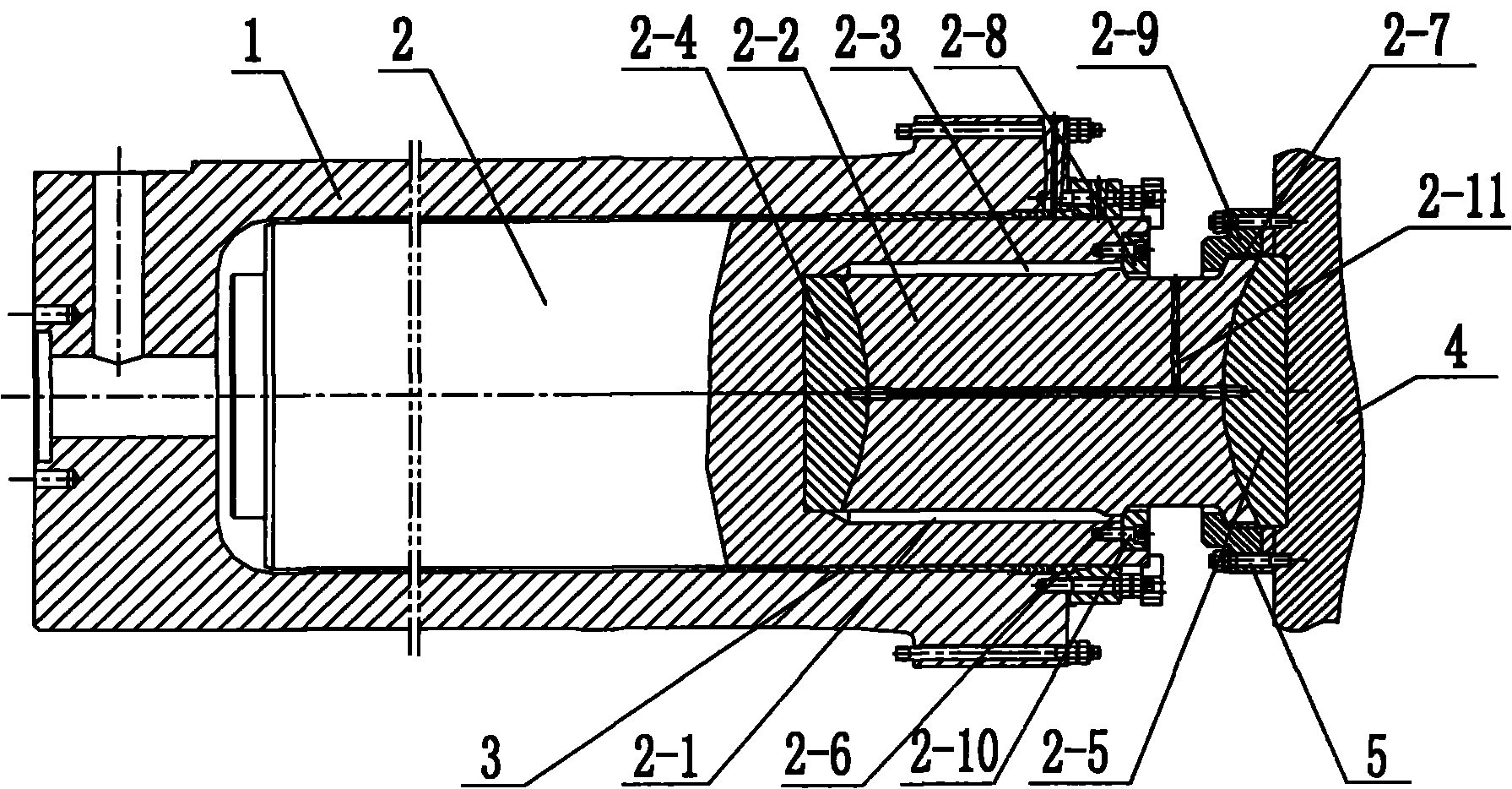

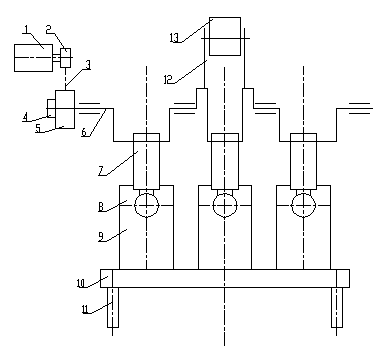

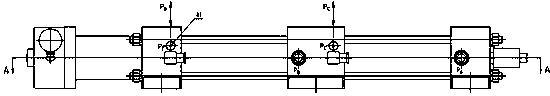

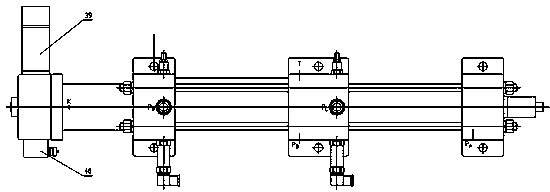

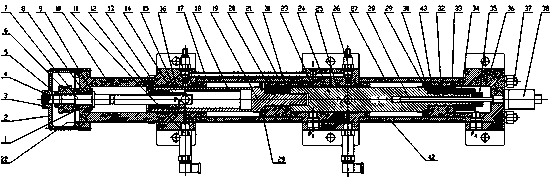

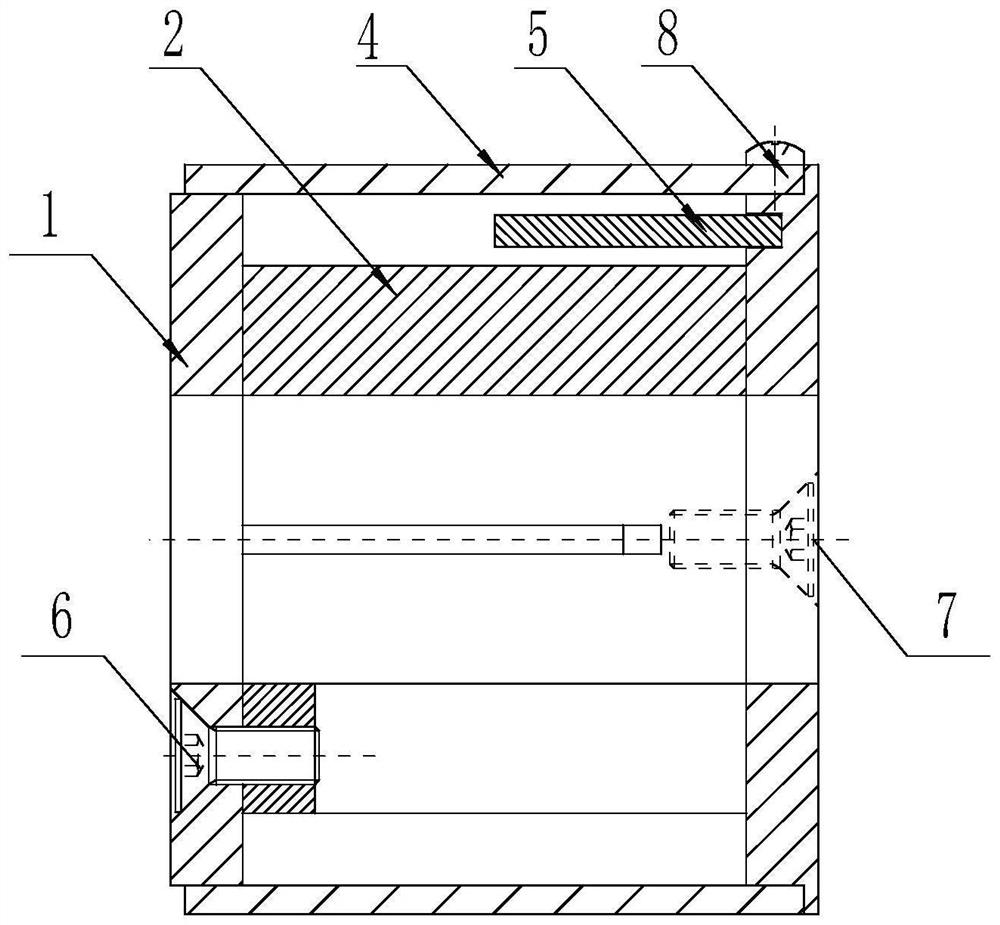

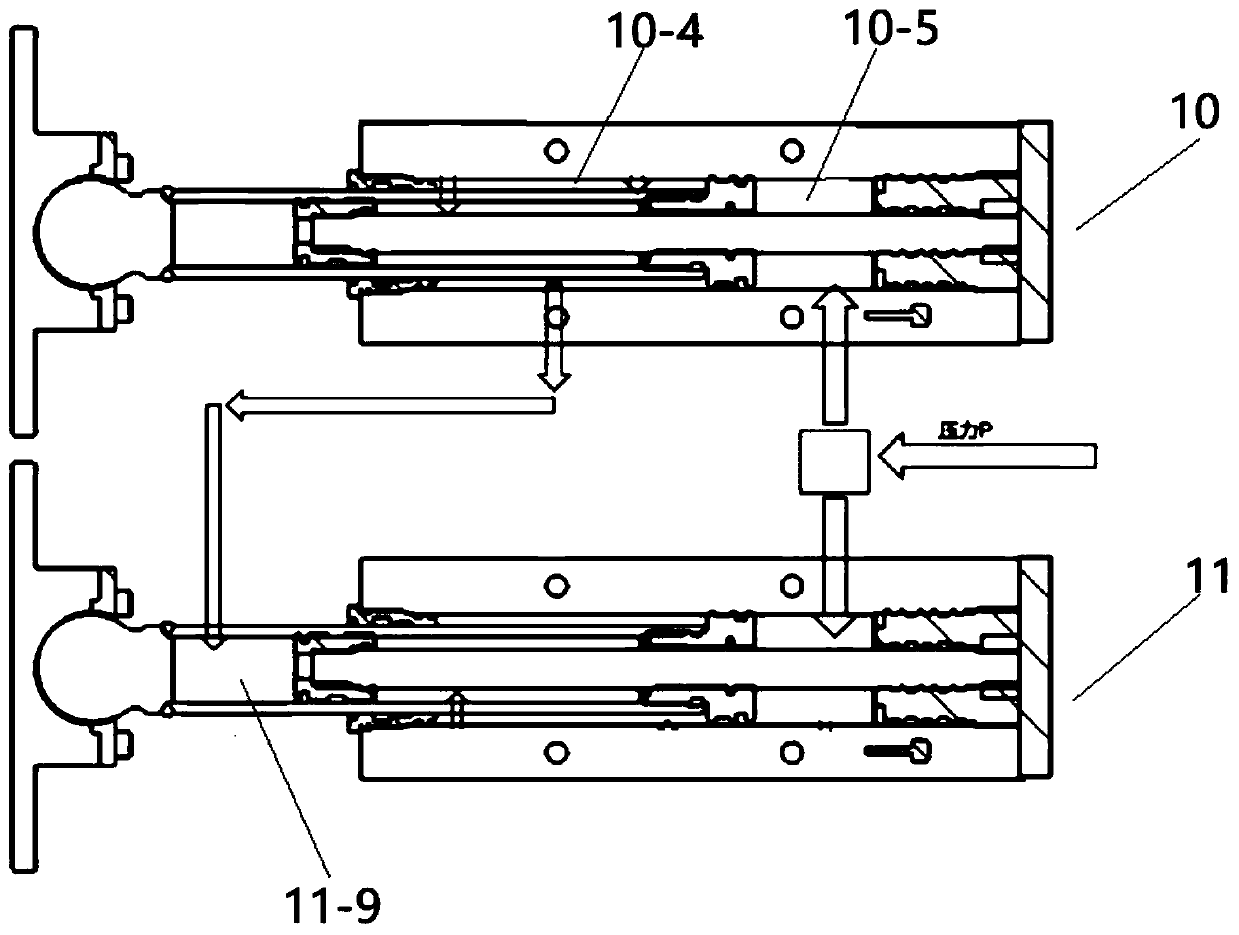

Integration series connection cylinder with adjustable stroke

ActiveCN103758816AGuaranteed gas contentClean deflateFluid-pressure actuatorsHydraulic cylinderPulp and paper industry

The invention discloses an integration series connection cylinder with an adjustable stroke. The integration series connection cylinder with the adjustable stroke comprises a front piston, a back piston, a front cylinder body, a back cylinder body, a piston rod I, a piston rod II, a cylinder front body, a cylinder middle body, a cylinder cover and a set of pull rods. The integration series connection cylinder with the adjustable stroke is characterized in that a front hydraulic cylinder is composed of the cylinder front body, the front cylinder body, the cylinder middle body, the front piston, the piston rod I and the like, a back hydraulic cylinder is composed of the cylinder middle body, the back cylinder body, the cylinder cover, the back piston, the piston rod II and the like, and the front hydraulic cylinder and the back hydraulic cylinder are connected through the cylinder middle body, the piston rod II and the set of pull rods in series to form the series connection cylinder. The integration series connection cylinder with the adjustable stroke is high in synchronization precision and anti-unbalance loading capability, the stroke is adjustable, and the stroke adjusting amount of a plate bending machine can be directly controlled; the integration series connection cylinder with the adjustable stroke is high in integration degree, the hydraulic system is simplified, the control capability is high, and the integration series connection cylinder with the adjustable stroke is safe and reliable.

Owner:MAANSHAN YUHUA MACHINERY MFG

Hydraulic inclined blade shears

InactiveCN106270715AStrong anti-eccentric load abilityGuaranteed uptimeShearing machinesShearing toolsEngineeringLoad deflection

The invention discloses hydraulic inclined blade shears which comprise a machine frame, an upper cross beam, machine frame middle columns, a shearing oil cylinder, a backlash adjusting device, an upper tool rest and a lower tool rest. According to the machine frame, four large pull rods and two small pull rods are connected into a closed frame body. The upper cross beam is formed by welding a plurality of steel plates and fixed to the upper portion of the machine frame. The machine frame middle columns are middle supports for connecting the upper cross beam with the lower tool rest and are distributed on the two sides of the machine frame. The shearing oil cylinder is installed at the bottom of the upper cross beam of the machine frame and drives the upper tool rest to move downwards, so that an upper shearing blade completes shearing operation. The backlash adjusting device is fixed to one side of the machine frame, and the minimum shearing blade gap position is controlled through a limiting switch. According to the hydraulic inclined blade shears, a prestress machine frame assembling structure is adopted, the weight is reduced by 70 t compared with the traditional design, and the equipment production cost is reduced. A series-connection oil cylinder synchronization mode is adopted by the shearing oil cylinder, the load-deflection resistance is high, operation is stable, and vibration is small. The backlash adjusting device is additionally arranged, and the shearing blade gap is kept unchanged.

Owner:刘雷

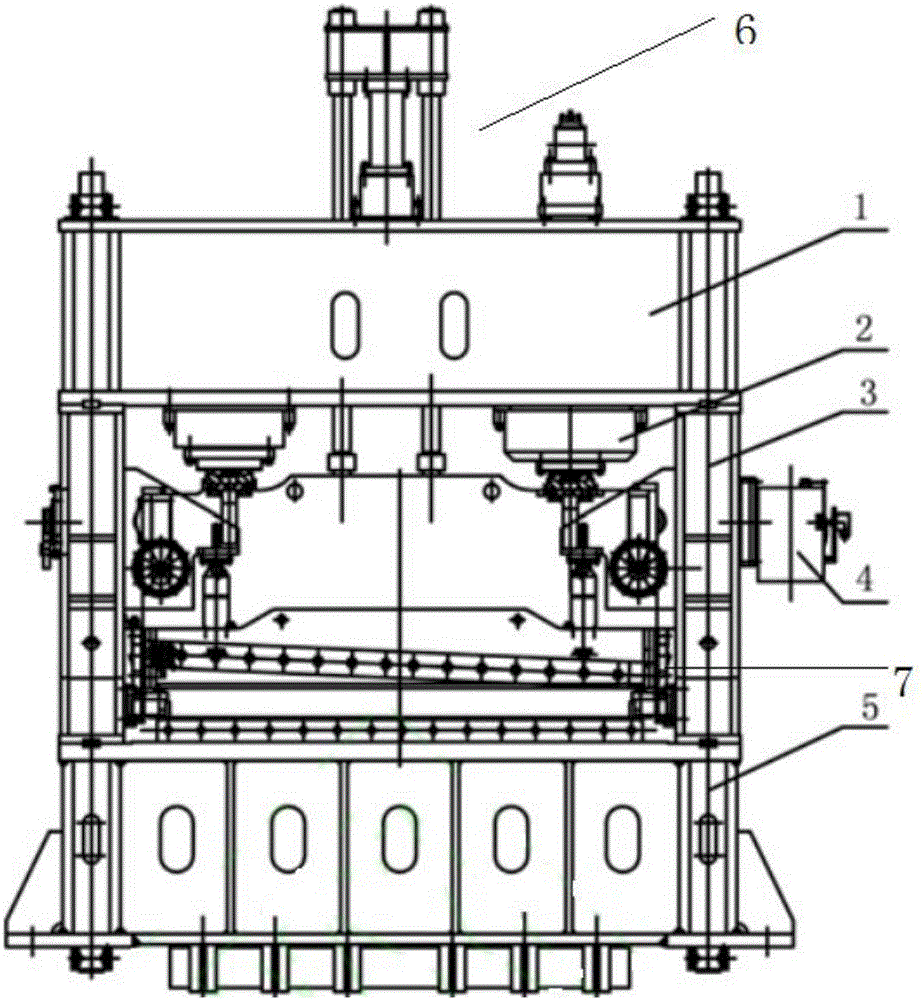

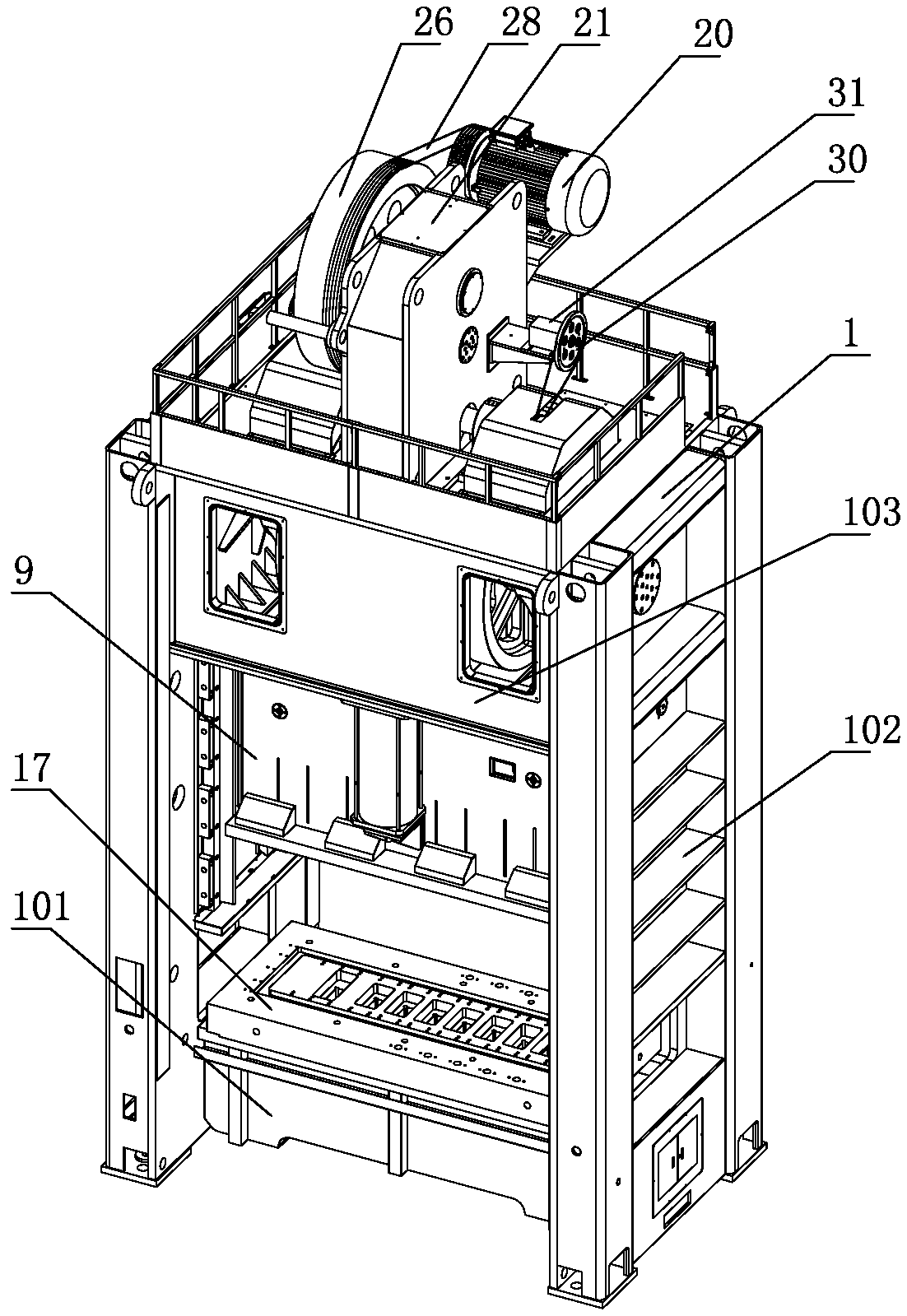

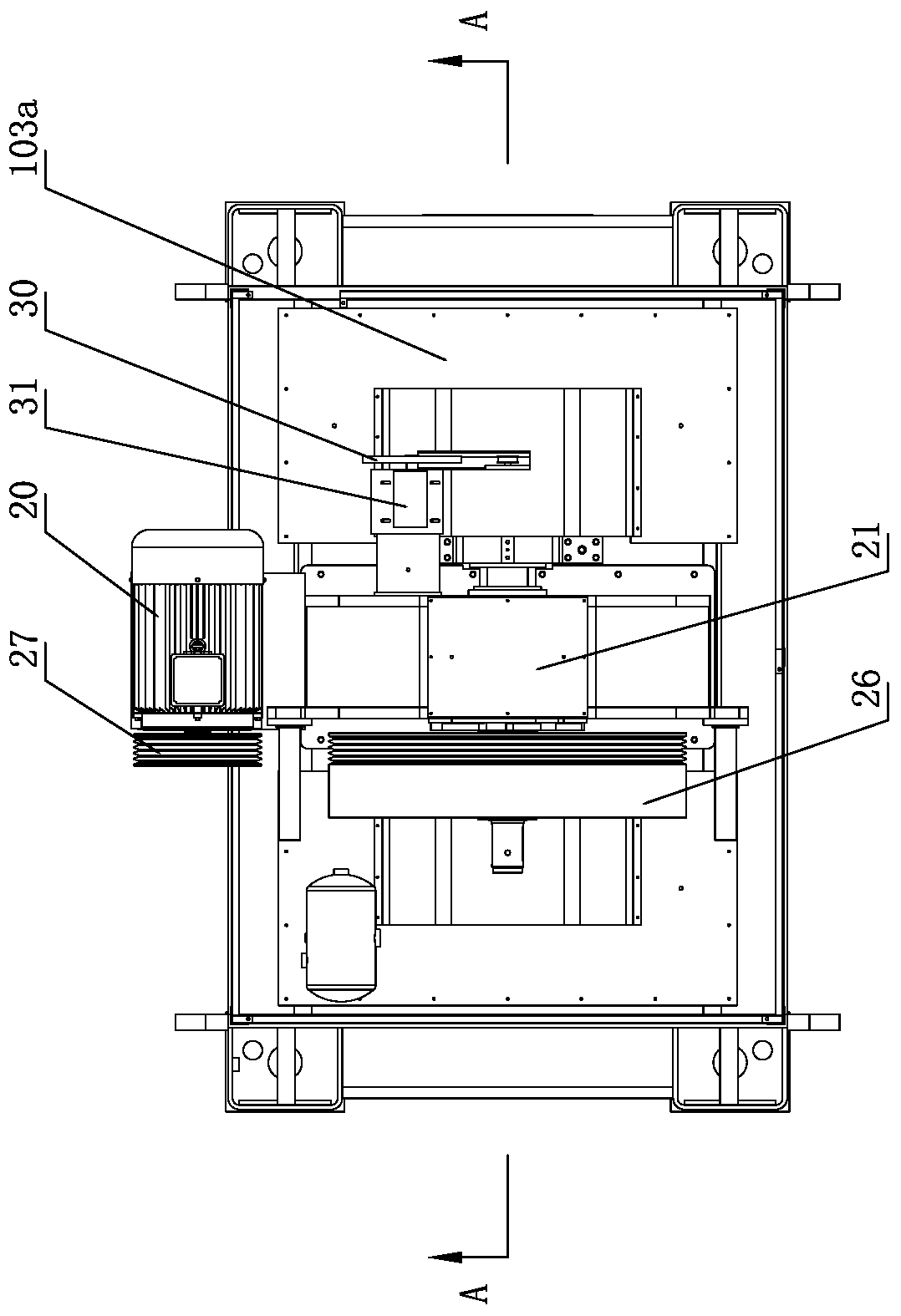

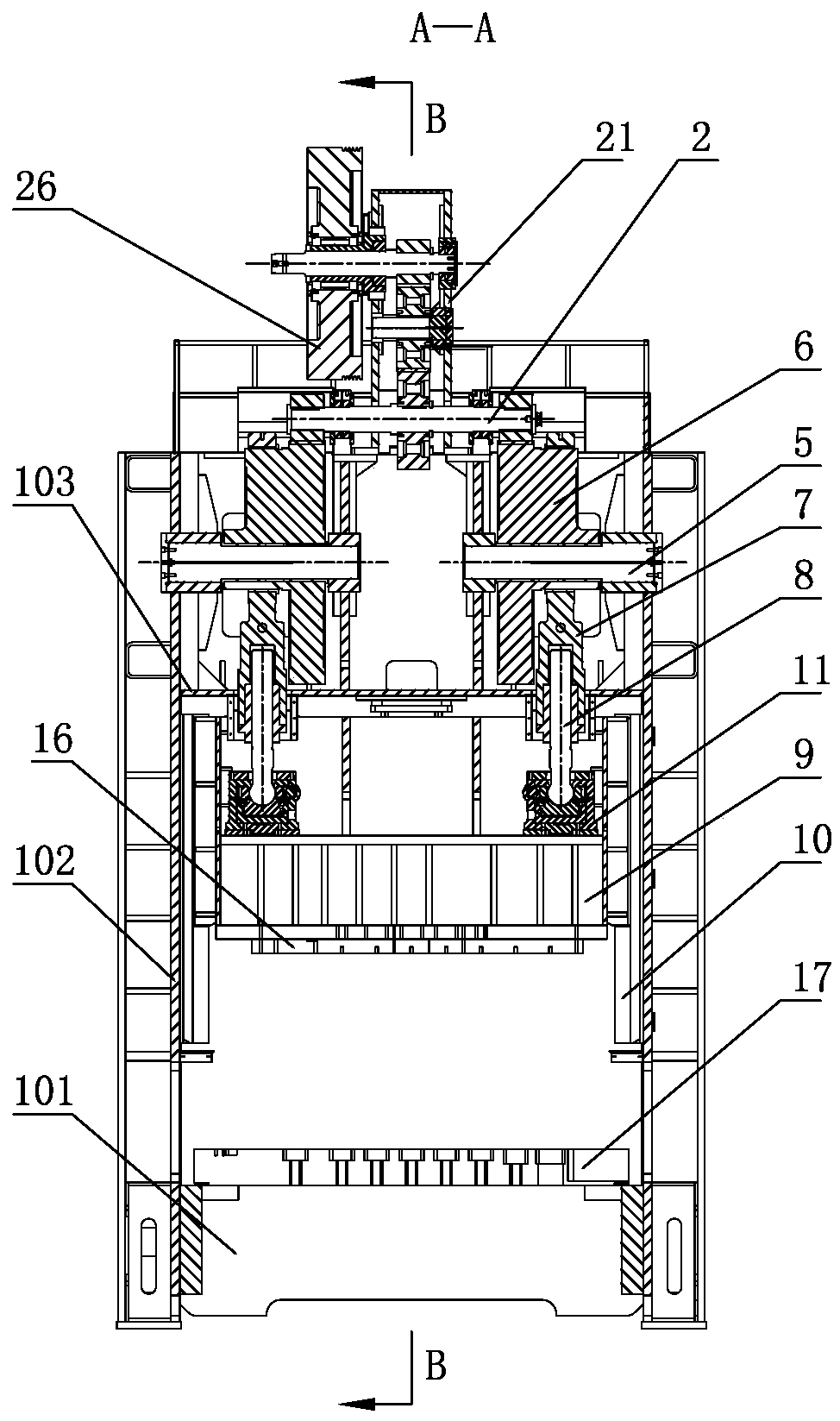

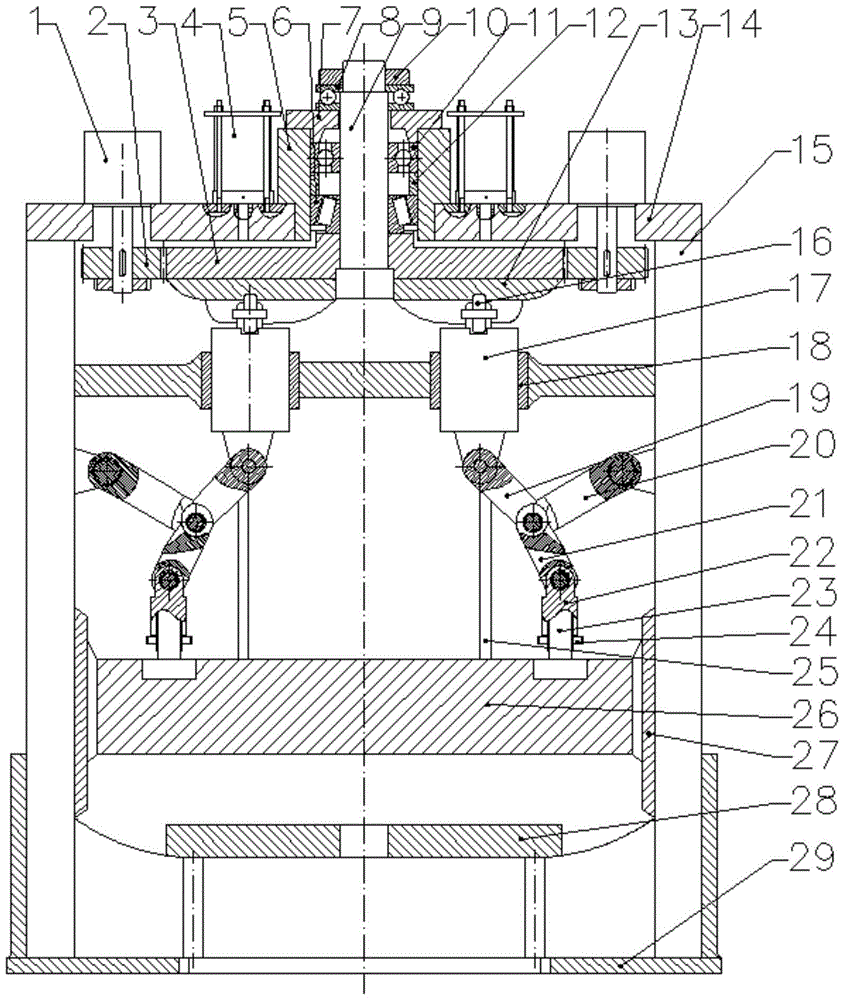

Servo press machine using symmetrically-arranged multi-end-face cams for driving even number of independent toggle rods

The invention discloses a servo press machine using symmetrically-arranged multi-end-face cams for driving an even number of independent toggle rods. The servo press comprises an upper machine body and a lower machine body. Two servo motors are symmetrically mounted on the upper machine body. Output shafts of the servo motors transmit rotation to transmission shafts through small belt wheels, synchronous belts and big belt wheels. Small gears on the transmission shafts are engaged with teeth machined on the outer sides of driving end face cams, and the driving end face cams are matched with driven end face cams. The driven end face cams are supported on supporting shafts through sliding bearings and are connected with push rods, and the push rods are connected with upper connecting rods and lower connecting rods through oscillating bars. The lower connecting rods are connected with the upper ends of guiding plunger type connecting rods, the lower ends of the guiding plunger type connecting rods are connected with adjusting screws, and the lower ends of the adjusting screws are connected with a sliding block. A lower die fixed on the lower machine body is matched with the sliding block so that forging and pressing work can be conducted. According to the servo press machine, forming of the sliding block and the running speed of the working stroke and the idle stroke can be controlled by setting the space motion trails of the push rods in the end face cams; the structure is compact, the bearing capacity is high and the working characteristics of the motors are improved remarkably.

Owner:XI AN JIAOTONG UNIV

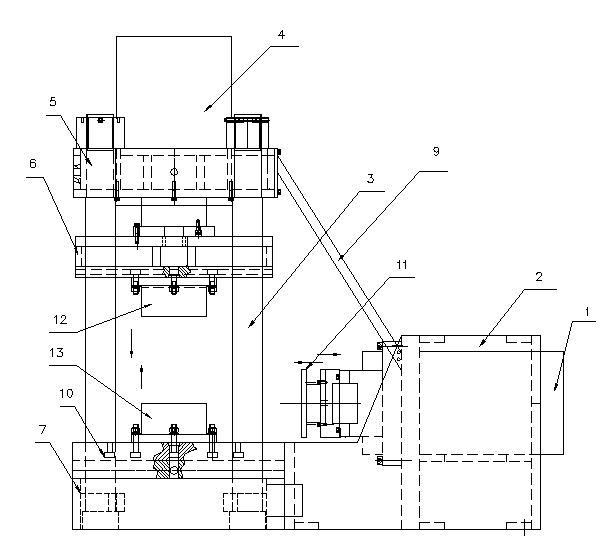

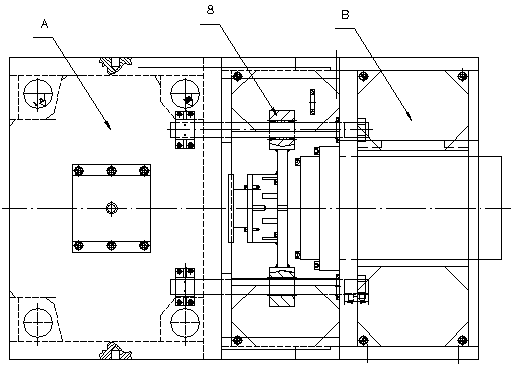

L-shaped multifunctional oil press and work method

The invention relates to an L-shaped multifunctional oil press and a work method, and relates to the field of presses. According to the technical scheme, an L shape is formed by a vertical oil press body (A) and a horizontal oil press body (B), and the vertical oil press body and the horizontal oil press body are controlled by a hydraulic control system. The L-shaped multifunctional oil press is characterized in that the vertical oil press body and the horizontal oil press body are connected through a reinforcing rib (9), one end of the reinforcing rib (9) is connected with an upper beam of the vertical oil press body, and the other end of the reinforcing rib (9) is connected with the upper portion of a rack of the horizontal oil press body; the right end of a workbench of the vertical oil press body is movably connected with the mold end of the horizontal oil press body to form a frame closed structure. In the working process, a right mold arranged on the left end face of the horizontal oil press body is adopted as a left mold when an upper mold and a lower mold of the vertical oil press body are combined, and products of different types, such as connecting rod types, mushroom types, step types and piston types, can be produced through the function of the upper mold, the lower mold, the right mold and the left mold.

Owner:CHANGSHA LEIFENG HEAVY FORGING

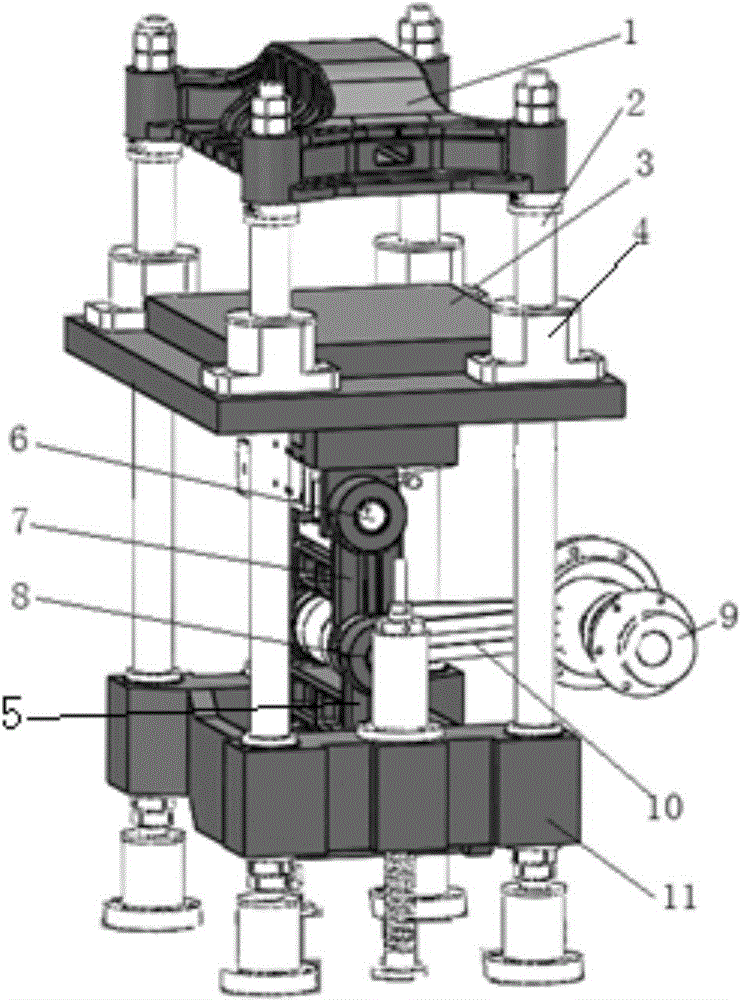

Under-drive punch press

InactiveCN104647786AReduce volumeReduce the overall heightPress ramPunch pressMechanical engineering

The invention discloses an under-drive punch press which comprises a rack, an upper working platform, a servo drive mechanism, a crankshaft connecting rod mechanism and a toggle rod mechanism, wherein the rack comprises a bottom plate and four upright posts; the upper working platform slides along the upright posts; the servo drive mechanism, the crankshaft connecting rod mechanism and the toggle rod mechanism are arranged at the lower part of the upper working platform; the toggle rod mechanism comprises an upper toggle rod, a lower toggle rod and a toggle shaft; one ends of the upper toggle rod and the lower toggle rod are connected by virtue of the toggle shaft; the servo drive mechanism drives the crankshaft connecting rod mechanism; the other end of the connecting rod of the crankshaft connecting rod mechanism is connected to the toggle shaft of the toggle rod mechanism in a sleeving manner; the other end, namely the upper end, of the upper toggle rod is hung onto a mounting shaft below the upper working platform; the other end, namely the lower end, of the lower toggle rod is fixed on the bottom plate by virtue of a second mounting shaft; and four corners of the upper working platform are arranged on the upright posts in a sleeving manner, and the upper working platform moves up and down along with the upright posts.

Owner:无锡凡荣工业自动化科技有限公司

High-speed clutch type spiral closed punch press

InactiveCN111716785AAccelerating mass is smallSensitive stroke controlPress ramPunch pressBall bearing

The invention relates to a high-speed clutch type spiral closed punch press. The high-speed clutch type spiral closed punch press comprises a press body, a sliding block, lifting supporting arms, lifting rods, pneumatic return cylinders, a copper nut, a screw rod, a radial cylindrical roller bearing seat, a radial cylindrical roller bearing, a brake disc, a brake cylinder, a one-way ball bearing,a belt wheel type large flywheel, a deep groove ball bearing, a friction clutch disc, friction blocks, a piston, a cylinder body, a spring piston guide screw rod, a piston return spring, a piston guide screw rod, a right upper fastening nut, a motor and a small belt pulley. According to the high-speed clutch type spiral closed punch press, the sliding block stroke is automatically adjusted, the motor power is reduced, power is saved, and energy saving is remarkable; the sliding block can stop at any position of the press stroke, the service life of a die is long, the unbalance loading resistance is high, and multi-station die forging can be achieved; the sliding block rapidly returns, the production efficiency is high, and the output energy is high; and the sliding block striking speed ishigh, the striking force is large, environmental friendliness is achieved, the overload safety protection effect is achieved, and operation is reliable. The high-speed clutch type spiral closed punchpress can be widely applied to the forge piece pressure forming process, in particular to the stamping process.

Owner:青岛浩源益友锻压机械有限公司

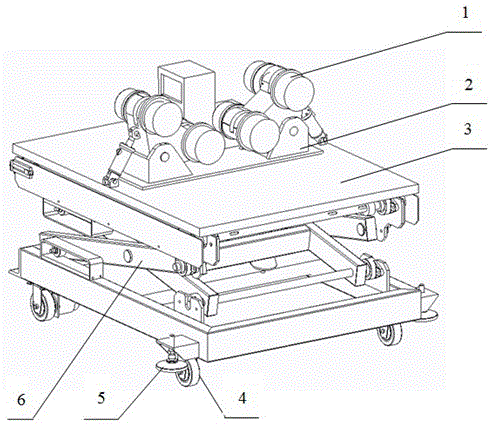

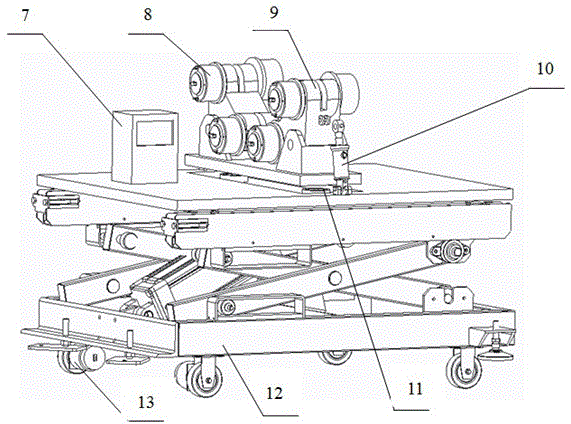

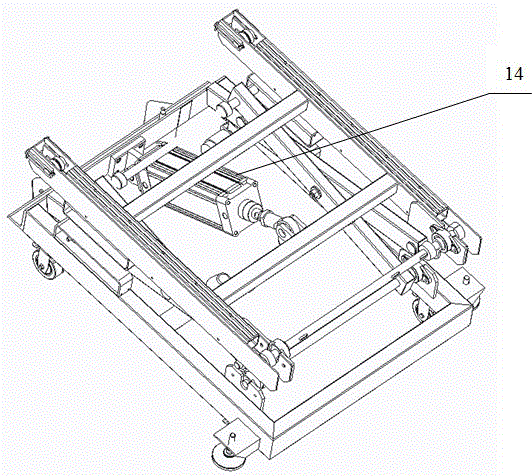

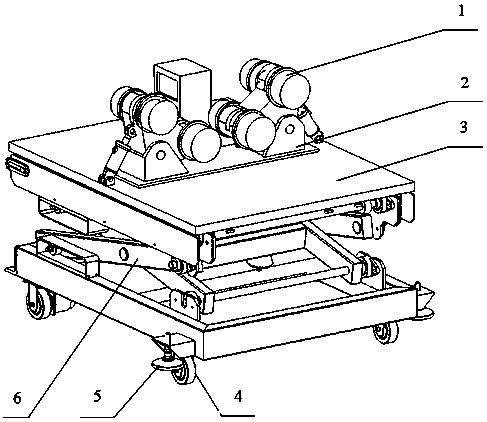

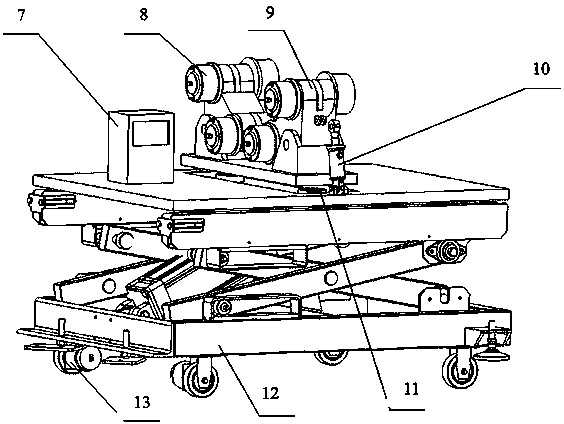

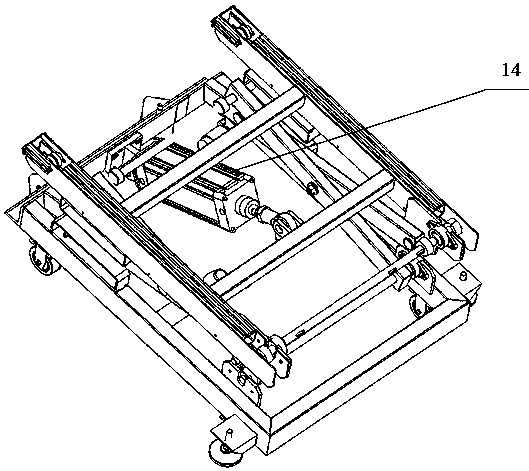

Novel marine counterweight pipe coating trolley

InactiveCN105643790AQuality improvementHigh precisionSurface layering apparatusHydraulic motorHydraulic cylinder

The invention relates to a novel marine counterweight pipe coating trolley, which is mainly composed of hydraulic motors, supporting hydraulic cylinders, supporting wheels, bases, supporting seats, a control cabinet, a lifting platform, a lifting hydraulic cylinder, scissors fork arms, a chassis, wheels, a walking hydraulic motor, retractable supporting legs and weighing sensors; the supporting wheels are two pairs of supporting wheels different in spacing; the supporting wheels at a large spacing therebetween are used for supporting a large-caliber pipe, while the supporting wheels at a small spacing therebetween are used for supporting a small-caliber pipe; the supporting seats can be adjusted by certain angles by means of expansion and contraction of piston rods of the supporting hydraulic cylinders, such that an application range to pipes is widened; a pipe casting height of the lifting platform is realized by means of a hydraulic support-scissors fork machine lifting structure, which has good stability; the weighing sensors are capable of weighing cast concrete in real time during pipe coating, and the control cabinet is capable of controlling a rectilinear motion speed, a pipe rotating speed and a lifting height of the coating trolley in real time according to feedback data from the weighing sensors. The coating trolley provided by the present invention is wide in pipe application range, capable of weighing the coated concrete in real time, stable in mechanical structure, and high in automation degree.

Owner:SOUTHWEST PETROLEUM UNIV

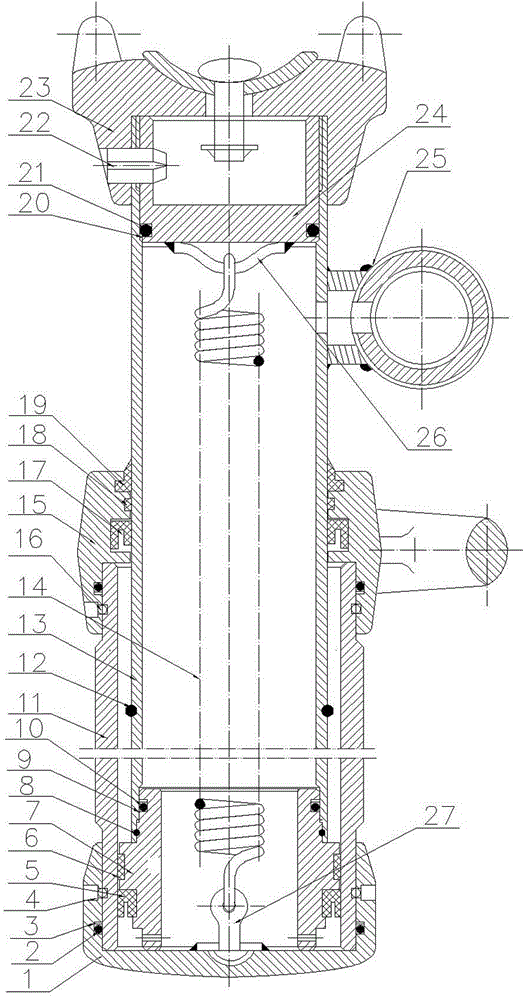

Non-joint single hydraulic prop for blasting mining

InactiveCN104533476AReduce labor intensityIncrease the itineraryProps/chocksBarrel ShapedEngineering

The invention discloses a non-joint single hydraulic prop for blasting mining, and aims at solving the problems such as short travel, high minimum height, easy breaking and a plurality of processing processes of the existing device. The non-joint single hydraulic prop for blasting mining is characterized in that a movable prop body is a complete hollow barrel shaped body; the bottom end is in soft connection with a hollow piston body; a sealing block is mounted in the top end of the movable prop body, and a top cover is mounted at the outer part of the top end; the piston body is mounted in the base; a D-shaped sealing ring I and a guide ring are mounted between the piston body and an oil cylinder; the lower part of the oil cylinder is completely sealed through the base; the base is connected with the oil cylinder through a connecting steel wire I; a three-purpose valve seat is firmly welded on the outer wall of the movable prop body on the lower surface of the top cover. The non-joint single hydraulic prop for blasting mining is large in travel and small in minimum height; the movable prop is of a complete movable prop structure, so that the possibility of a joint, a prop head, a weld joint and breaking can be avoided; the load-deflection resistance is high; the base is in a form of a coated base, so that the bottom part of the oil cylinder is greatly protected; the prop can be quickly returned, and thus the safety is improved; the processing process is simple, and few materials are used; the piston body is of a dirt storage form and can be used for storing coal dust and other impurities entering the movable prop.

Owner:HUAIBEI ANLAI ELECTROMECHANICAL EQUIP

Longitudinal beam hydraulic press displacement detection device

InactiveCN102310126AImprove detection accuracyCommunication is simple and convenientMetal working apparatusLoad resistanceBus interface

The invention relates to a longitudinal beam hydraulic press displacement detection device, which comprises a stretching-type displacement sensor and an on-site bus interface. One end of the stretching-type displacement sensor is fixedly connected on the lower surface of an upper beam of the hydraulic press; a stay rope outgoing end of the stretching-type displacement sensor is connected with an upper surface of a hydraulic press slide block; and the on-site bus interface forms a communication connection with a controller through the on-site bus. The device provided by the invention is suitable for position detection of the long center longitudinal beam hydraulic press slide block stroke, has advantages of high precision, strong partial load resistance and high defense grade, and is convenient to install.

Owner:TIANJIN TIANDUAN PRESS CO LTD

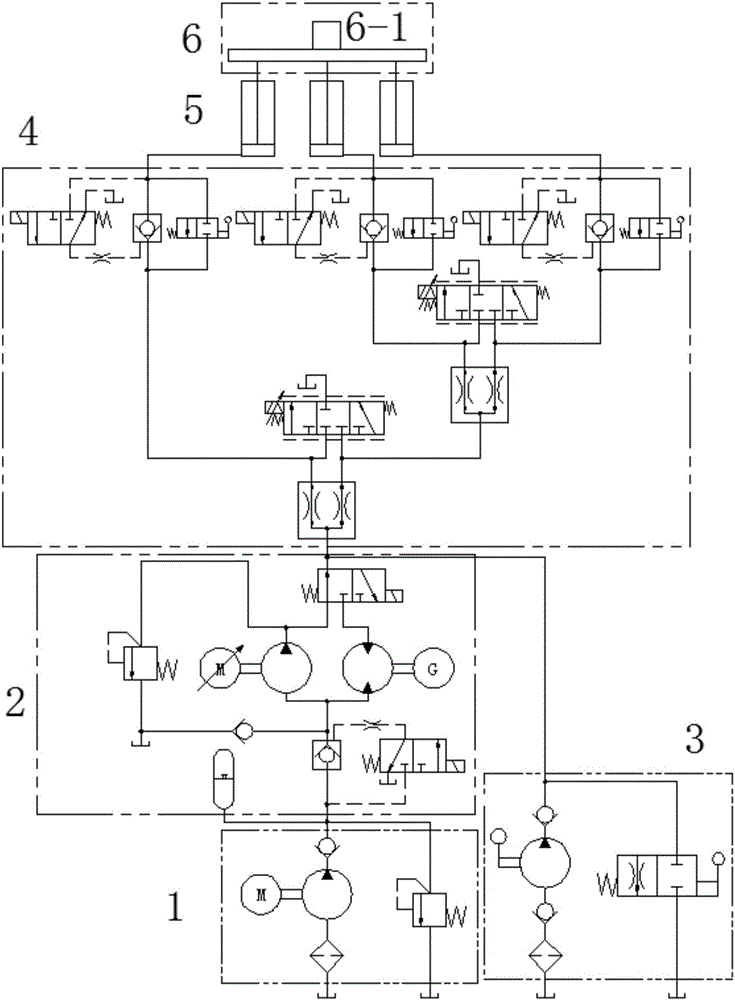

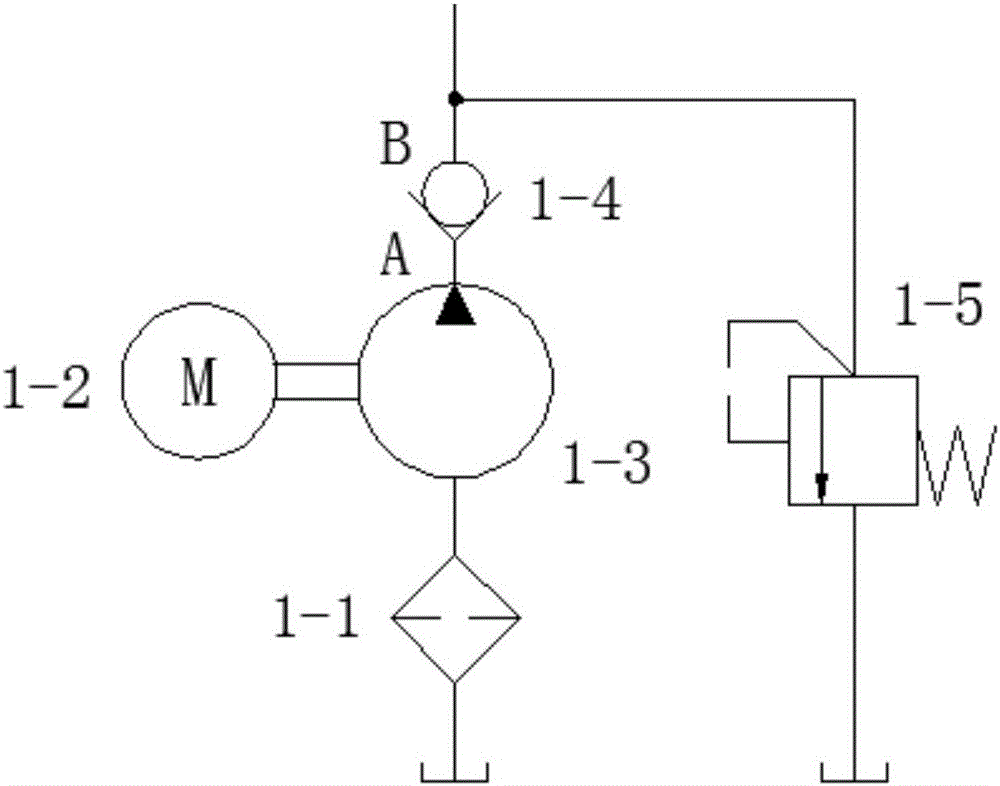

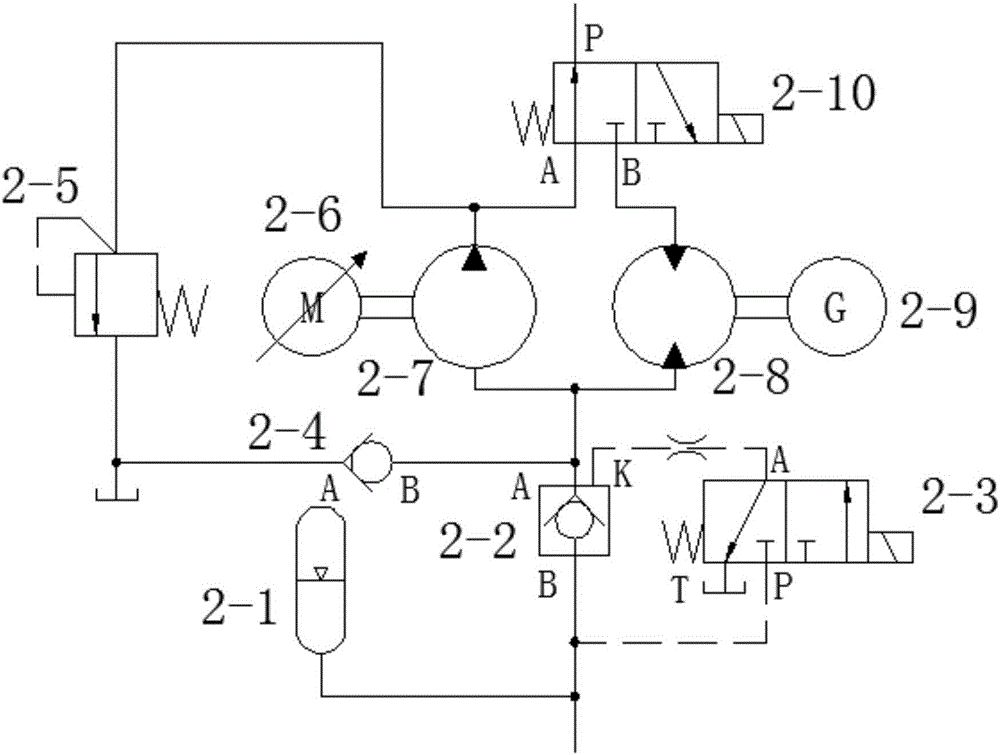

A multi-cylinder synchronous energy-saving and high-efficiency hydraulic lifting system and method

InactiveCN105179343BAchieve recyclingEnergy efficient operationServomotor componentsServomotorsHydraulic cylinderLoad resistance

A multi-cylinder synchronous energy-saving and high-efficiency hydraulic lifting system and method, suitable for lifting systems such as hydraulic elevators and construction lifting platforms. The system includes an oil supply circuit, a volumetric speed regulation and energy recovery circuit, a manual lifting circuit, a synchronous locking circuit, a hydraulic cylinder and an inclination sensor. The oil supply circuit is used to supplement the shortage of hydraulic oil in the closed-loop system caused by synchronous locking circuit adjustment and system leakage and reduce the temperature rise of the oil; the volumetric speed regulation and energy recovery circuit provide power, speed regulation and energy recovery for the system; The manual lifting circuit function is to manually lift the platform when the system fails; the synchronous locking circuit function is to adjust the synchronous lifting and lowering of multiple hydraulic cylinders and lock the cylinders when the platform is stationary; the inclination sensor detects the posture of the platform in real time and feeds it back to the control center to achieve a closed loop control. The system is highly efficient and energy-saving, achieving energy recovery and precise synchronization of multiple cylinders. The lifting platform has strong anti-eccentric load capability, stable operation and high reliability.

Owner:CHINA UNIV OF MINING & TECH

Plate liquid-filling shaping hydraulic machine

ActiveCN100594078CQuality improvementImprove mechanical propertiesMeasurement devicesPower control systemMaster cylinder

The invention discloses a sheet hydraulic-forming hydraulic press which is characterized by essentially comprising an underbeam, an upright post arranged on the underbeam, a top beam arranged on the upright post, a stretching beam connected on the upright post in a sliding manner, a compound master cylinder arranged on the top beam, a coaxial link deep-drawing and blank holding device arranged bellow the stretching beam, a liquid chamber arranged on the underbeam, a support oil tank which comprises a hydraulic power control system, a supercharger, etc. The underbeam, the upright post and the top beam are connected together by upright post nuts to form a rigid body; the compound master cylinder is essentially composed of a cylinder body fixed on the top beam, a master cylinder piston arranged in the cylinder body, a quick rod bush arranged on the master cylinder piston, a quick rod arranged in the rod bush, an embedded bank holding cylinder piston arranged in a master cylinder piston and flanges arranged at the mouth of the cylinder body; the master cylinder piston is connected with the stretching beam by the flanges; the embedded bank holding cylinder piston is connected with thecoaxial link deep-drawing and blank-holding device which is essentially composed of a drawing slide, a blank holding slide which is coaxially connected to the drawing slide and is connected with the embedded bank holding cylinder piston and a male die which is fixed on the drawing slide. Compared with the prior art, the hydraulic press of the invention has the advantages of possessing dies with universality, reducing die cost and shortening production cycle.

Owner:FOSHAN CONSTANT HYDRAULIC MACHINERY

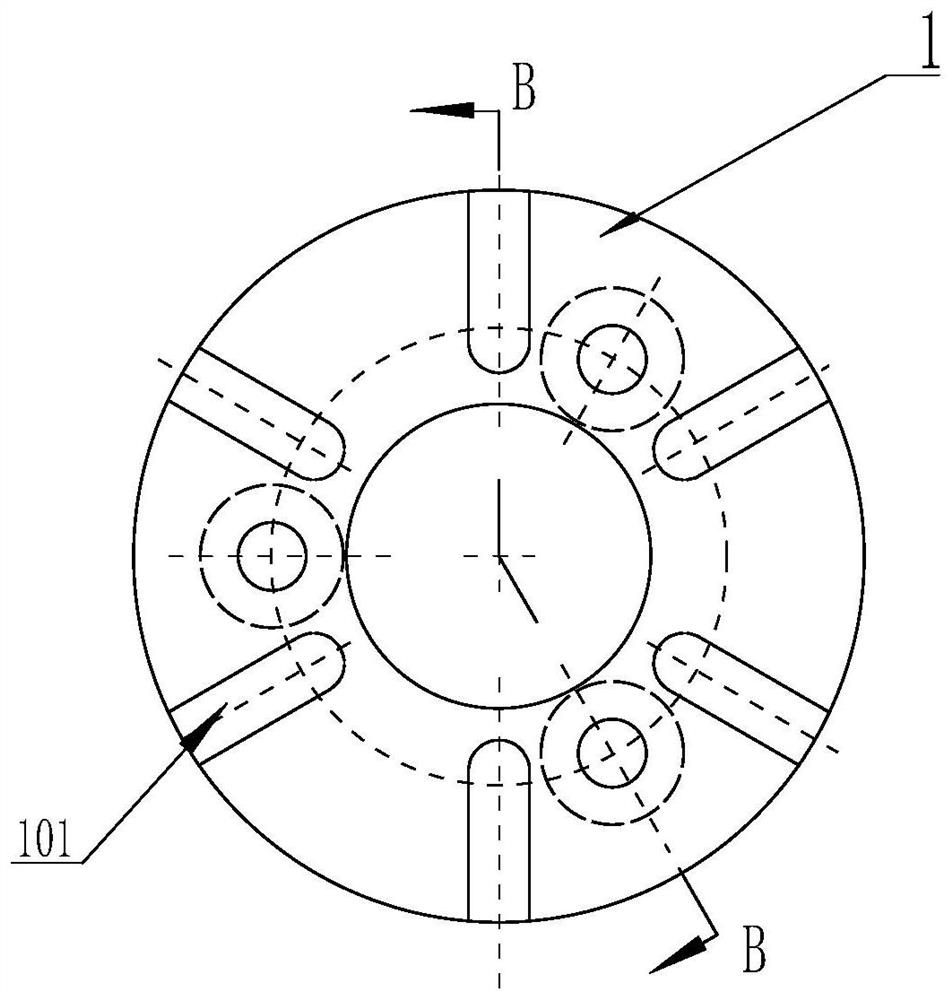

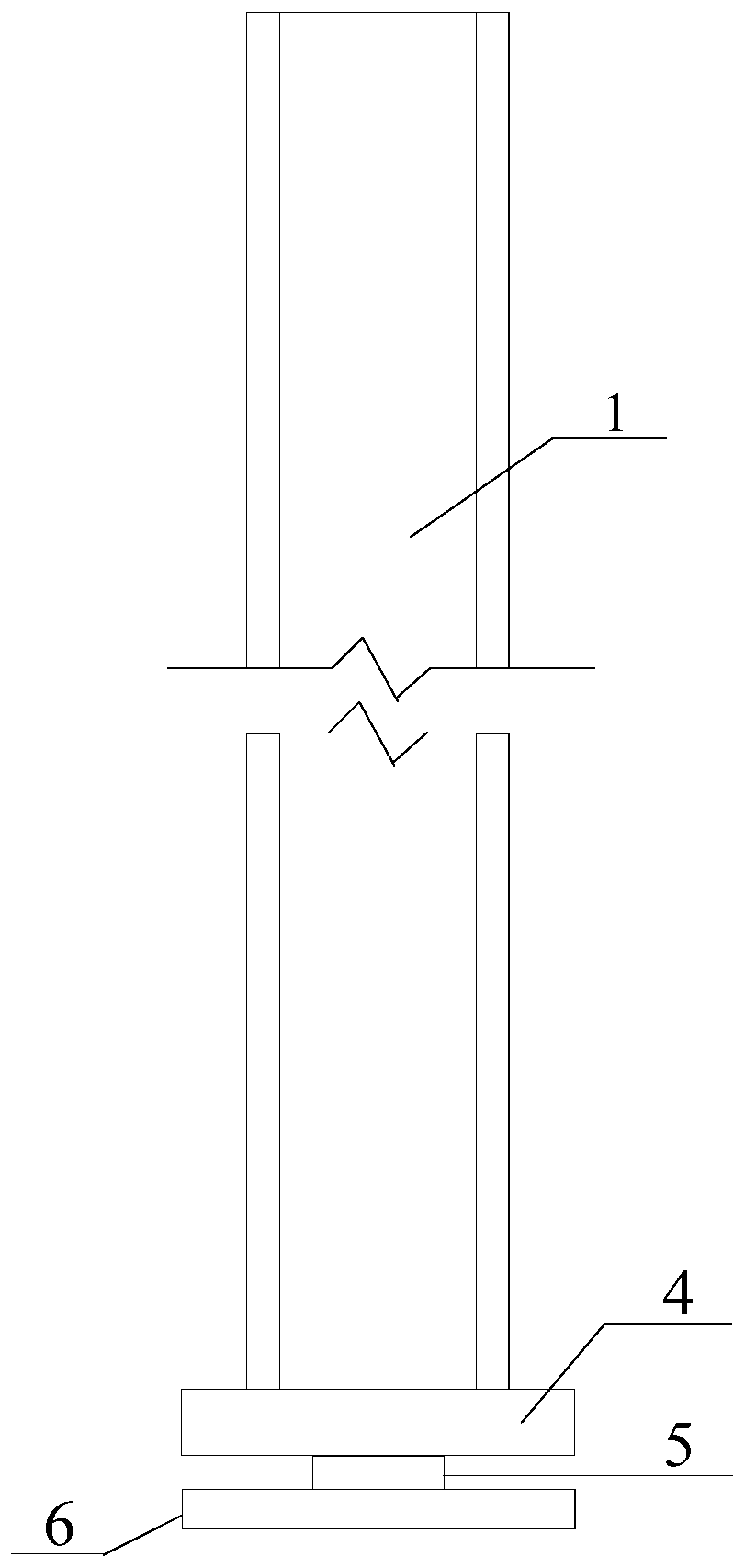

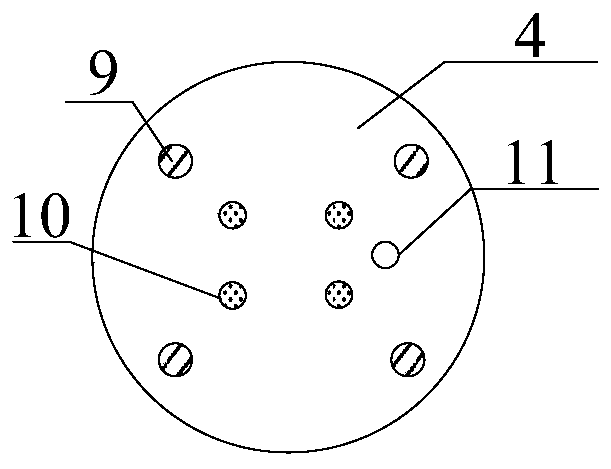

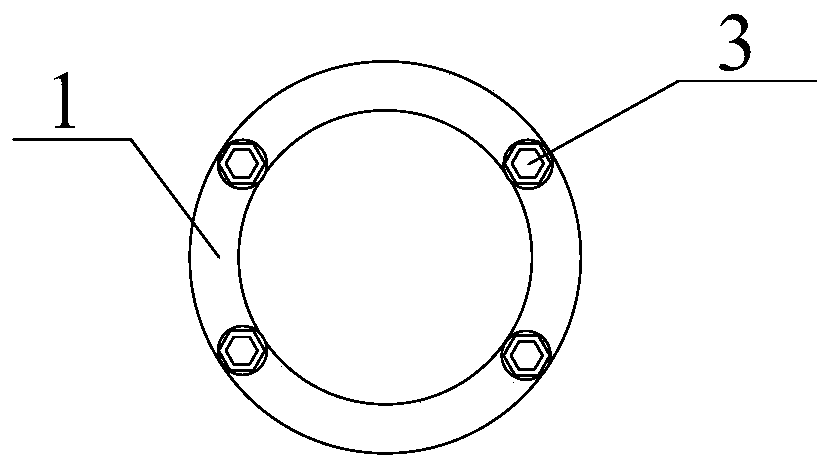

Upper jacking system with multi-station jacking function

PendingCN111185566AEnsure stabilityExtended service lifeForging/hammering/pressing machinesHydraulic cylinderStructural engineering

The invention provides an upper jacking system with a multi-station jacking function. The upper jacking system comprises a hydraulic cylinder body mounted in a center hole of a sliding block, an upperoil inflow pipeline, a lower oil inflow pipeline, a piston, a piston rod, a flange plate, a check disc mounted on the flange plate through a flange plate countersunk bolt, a base, check disc countersunk bolts, a guide sleeve mounted in a stepped hole in the center of the base, a concave guide column located in the guide sleeve, matched with the guide sleeve and mounted at the end of the piston rod through horizontally-arranged connecting pins, a jacking bottom disc mounted on the end face of the tail end of the concave guide column through jacking bottom disc countersunk bolts and multiple jacking rods mounted on the jacking bottom disc through threaded connection. The upper jacking system is large in jacking force, rapid in action response, high in production efficiency, simple in transmission chain, high in jacking precision, flexible in operation, suitable for automatic production, high in production efficiency, long in service life, high in anti-unbalance-loading capacity and suitable for multi-station forging occasions, and can be widely used for a screw press and especially applied to a large screw press.

Owner:青岛宏达锻压机械有限公司

Semi-combined pressure ring sensor and design method thereof

PendingCN114235238AExcellent anti-environmental vibration performanceImprove vibration performanceForce measurement by measuring optical property variationStructural engineeringElectrical and Electronics engineering

The invention discloses a semi-combined pressure ring sensor and a design method thereof, and relates to a sensor and a design method thereof. The sensor comprises an upper pressing plate, a pressure bearing ring, a lower pressing plate and an outer sleeve; the outer sleeve is installed on the lower pressing plate, the pressure-bearing ring is located in the outer sleeve, and the two ends of the pressure-bearing ring are connected with the upper pressing plate and the lower pressing plate respectively. The pressure-bearing ring is provided with n dividing seams, the pressure-bearing ring is uniformly distributed into n pressure-bearing areas, the cross section shapes and areas of the pressure-bearing areas are the same, and each pressure-bearing area is provided with a working groove and a measuring point groove I; the measuring point groove I is located in the middle line of the bottom of the working groove and internally provided with a measuring point. The method comprises the following steps: respectively calculating the minimum pressure-bearing area, the minimum outer diameter and the minimum height of the pressure-bearing ring; and an upper pressing plate, a lower pressing plate, an outer sleeve and a temperature compensation column are respectively designed to obtain the minimum outer diameter and the minimum height of the sensor. The device has the advantages of being high in precision, good in unbalance loading resistance, suitable for being installed in a narrow space, excellent in environmental vibration resistance, good in durability, high in batch production efficiency and easy to apply and popularize.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Volume closed-loop synchronous oil cylinder and control system

PendingCN110925266ASimple structureSmall footprintFluid-pressure actuatorsControl systemSynchronous control

The invention relates to a volume closed-loop synchronous oil cylinder and control system, which comprises an outer cylinder barrel, wherein a piston is slidably arranged in the outer cylinder barrel,one side of the piston is connected with a piston rod, the piston rod is slidably arranged in the outer cylinder barrel, an inner cavity of the outer cylinder barrel is divided into an outer cylinderrod cavity and an outer cylinder rodless cavity by means of the piston, and an outer cylinder rod cavity oil port and an outer cylinder rodless cavity oil port are further formed in the outer cylinder barrel; a second piston is slidably arranged in the piston rod and the piston, and is connected with one end of the second piston rod; the other end of the second piston rod is connected with a right end cover; an inner cavity of the piston rod is divided into an inner cylinder rod cavity and an inner cylinder rodless cavity by means of the second piston; and an inner cylinder rodless cavity oilport is formed in the piston rod. The volume closed-loop synchronous oil cylinder and control system is simple and compact in structure; the synchronous oil cylinders are connected in series by meansof an oil outlet volume cavity and an oil inlet volume cavity which are completely equal and are generated when telescopic stroke occurs on synchronous oil cylinders, so as to achieve volume closed-loop synchronous control; and the volume closed-loop synchronous oil cylinder and control system has very high synchronization precision, and the measurement and calculation synchronization precision reaches up to five thousandths.

Owner:HAWE HYDRAULIK (WUXI) CO LTD

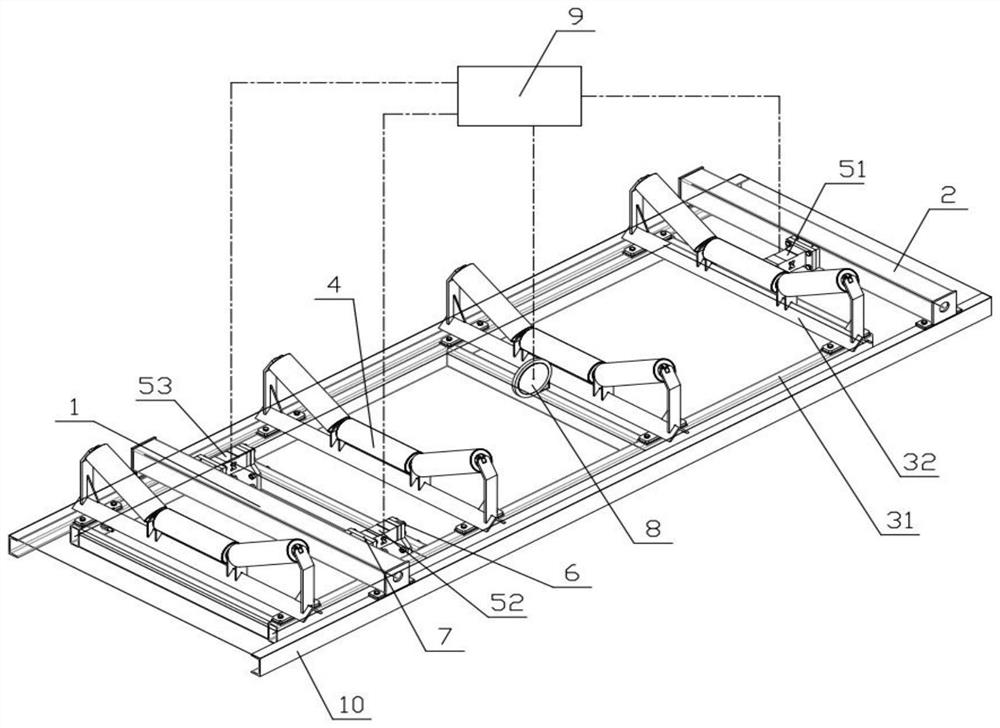

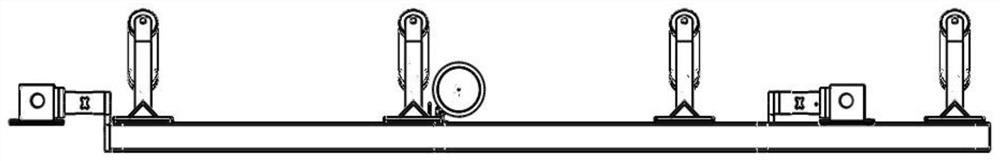

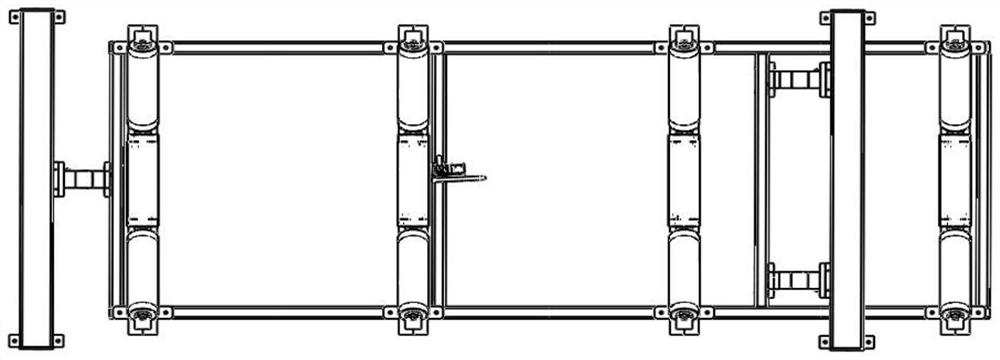

Three-fulcrum single-scale redundant electronic belt scale and working method

PendingCN112161682AUniform and stable forceStrong anti-eccentric load abilityWeighing apparatus testing/calibrationWeighing apparatus for continuous material flowLoad cellMeasurement precision

The invention provides a three-fulcrum single-scale redundant electronic belt scale and a working method. The three-fulcrum single-scale redundant electronic belt scale comprises a belt frame, whereina bearing frame is movably arranged on the belt frame, two ends of the belt frame are respectively provided with a first fixed cross beam and a second fixed cross beam, two ends of the first fixed cross beam are provided with a weighing sensor C and a weighing sensor B, a weighing sensor A is arranged in the center of the second fixed cross beam, and the weighing sensor A, the weighing sensor B and the weighing sensor C are connected with the movable bearing frame through connecting plates; and the movable bearing frame is further provided with a speed sensor, and final data can be obtained through calculation of the controller. The three-fulcrum single-scale redundant electronic belt scale has the advantages that the measurement precision is high, stress is uniform and stable, the unbalance loading resistance is high, and the measuring range is longer.

Owner:王祝辉

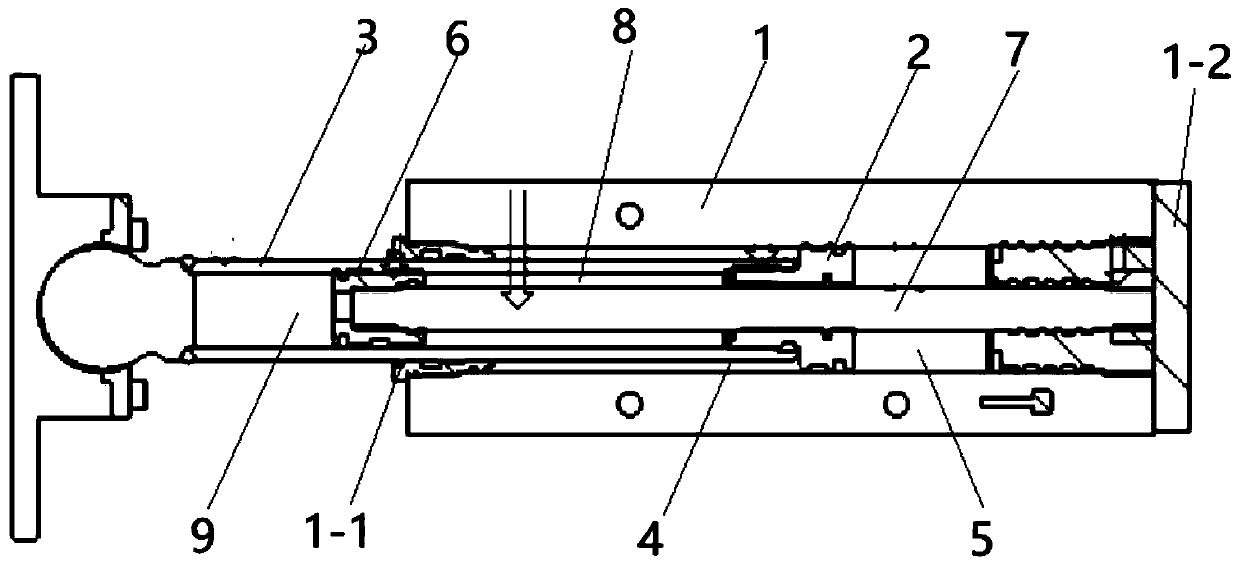

A large-stroke multi-station stretching press

ActiveCN106881391BSmall force point intervalLarge force point intervalPress ramDrive shaftMachine tool

The invention discloses a large-stroke multi-station drawing press in the field of punching machines. The large-stroke multi-station drawing press comprises a press body, a transmission shaft is arranged on the upper portion of the press body, a first gear is arranged in the middle of the transmission shaft, second gears are arranged at the two ends of the transmission shaft, two power shafts are arranged on the press body, and eccentric gears are arranged on the power shafts and engaged with the corresponding second gears. The eccentric gears are provided with connecting rods, and the lower portions of the connecting rods are connected with bulb threaded rods through threads. A sliding block body is arranged below the press body, an external support is arranged on the upper portion of the sliding block body, an oil cylinder is arranged in the external support, bulb supports are arranged in the oil cylinder, and bulbs abut against spherical face grooves. Bulb cover plates are arranged between the external support and the bulb threaded rods, an external cover plate is arranged on the outer side of the external support, an upper die plate is arranged on the lower portion of the sliding block body, a lower die plate is arranged on the lower portion of the press body, a multi-station upper die is arranged on the upper die plate, and a multi-station lower die is arranged on the lower die plate. The large-stroke multi-station drawing press adopts the eccentric gears, the stroke of the press can be increased, the eccentric gears on the two sides are stable in transmission, the span of points of force application is large, and the unbalance loading resisting capacity is high.

Owner:YANGLI GRP CORP LTD

A horizontal cam servo press driven by multiple motors

ActiveCN105127347BCompact structureIncreased strength and rigidityForging press drivesMotor driveGear drive

A multi-motor-driven, horizontally placed end face cam servo press, including an upper body, two servo motors are symmetrically installed on the upper body, the output shaft of the servo motor is equipped with a small gear, and the two small gears are connected to the large gear. Cooperate, the large gear is connected to the shaft, the shaft is connected to the upper body, the large gear is connected to the end face cam, the end face cam cooperates with the upper end of the guide plunger type push rod, and the lower end of the guide plunger type push rod is connected to the active link. The connecting rods are respectively connected with the upper connecting rod and the lower connecting rod. The lower connecting rod is connected with the push rod, the adjusting screw and the slider. The small gear is driven by the servo motor to rotate, and the small gear drives the end face cam to move through the large gear, and then drives the guide plunger type push rod to do reciprocating linear motion, and drives the slider to move through the active connecting rod, upper connecting rod, lower connecting rod and push rod After the forging is completed, the invention has high rigidity and strength, and the working characteristics of the motor are significantly improved.

Owner:XI AN JIAOTONG UNIV

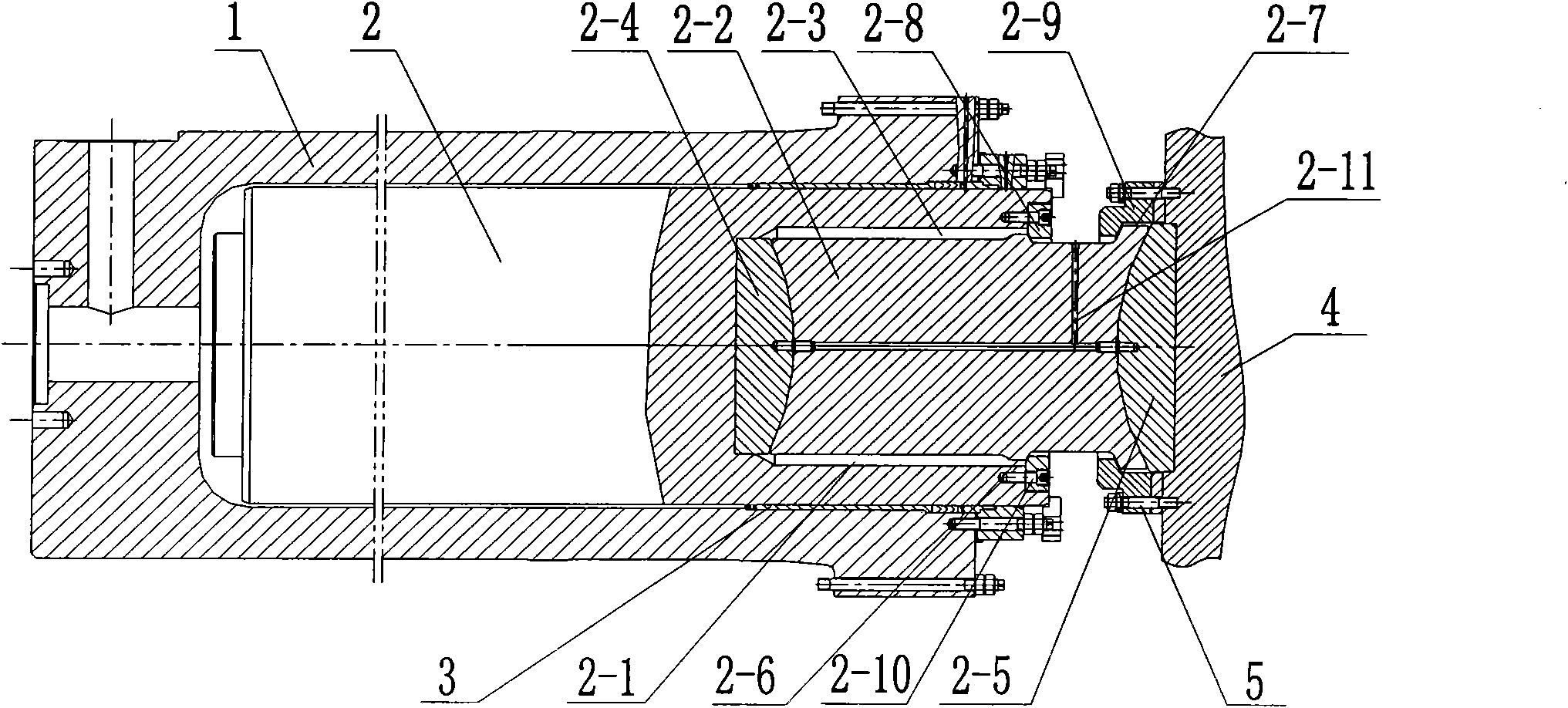

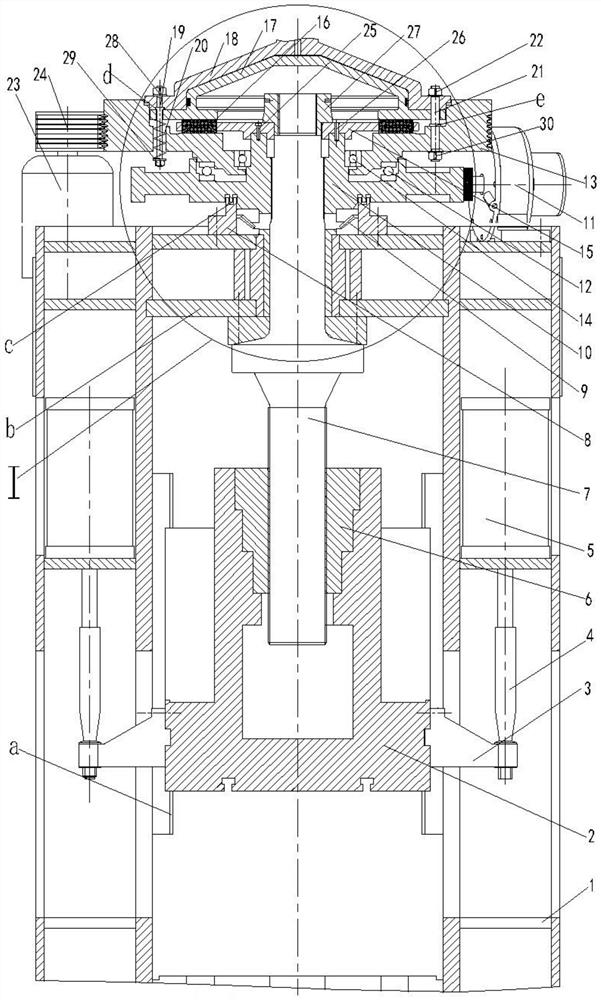

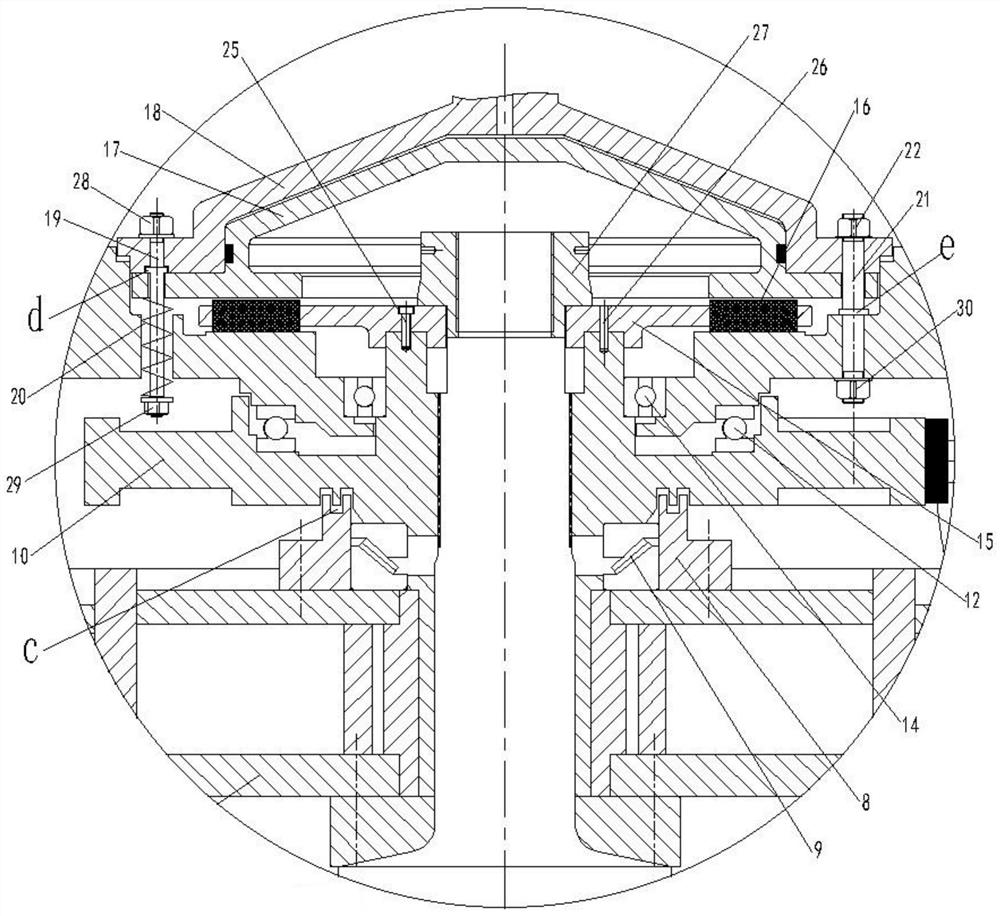

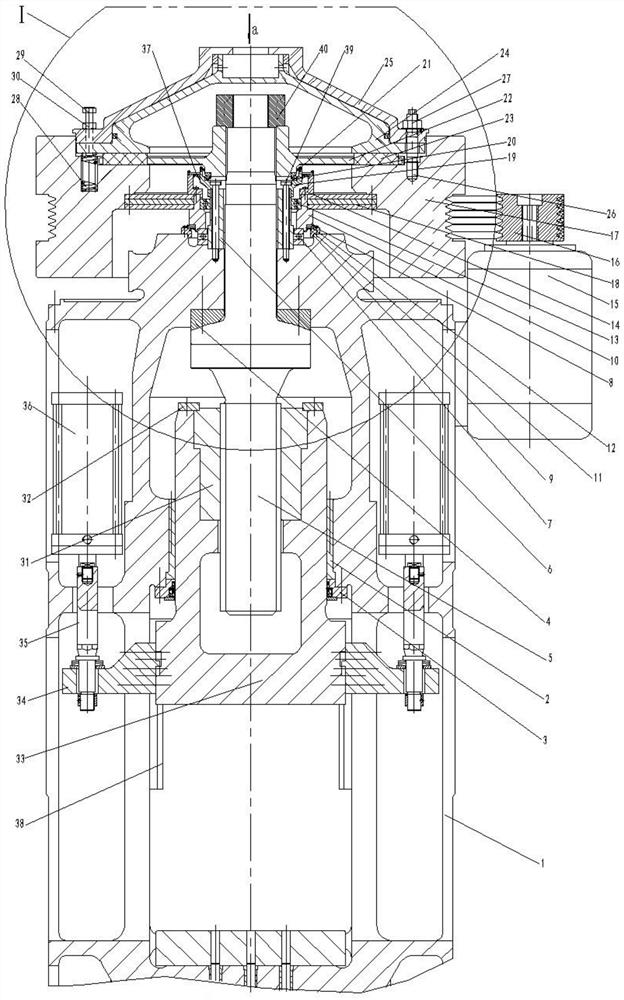

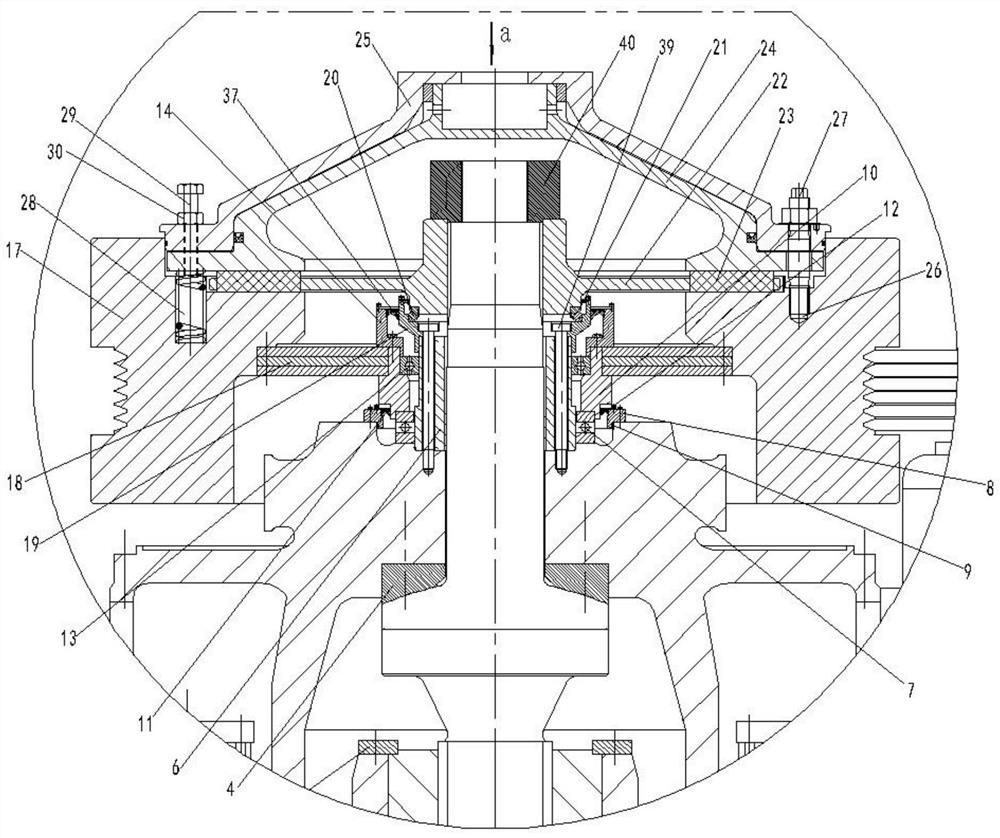

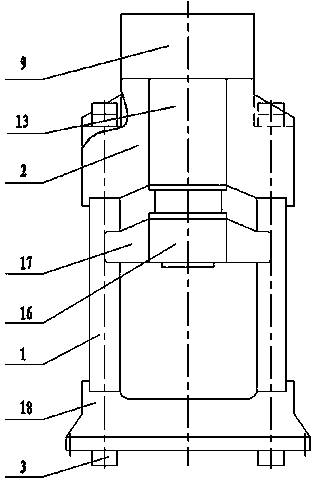

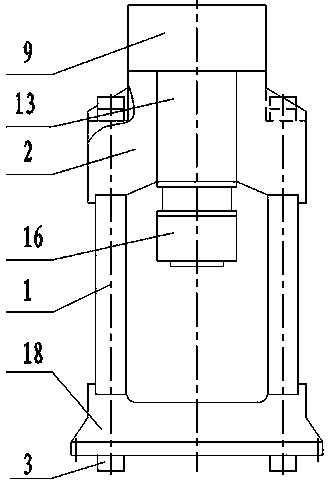

Energy-saving and environment-friendly high-energy screw press

The invention discloses an energy-saving and environment-friendly high-energy screw press. The energy-saving and environment-friendly high-energy screw press comprises a machine body, a circular guiderail, a circular guide rail cover, a spherical bearing seat, a screw rod, a bearing fixed inner body, a thrust ball bearing, a convex cover, an O-shaped sealing ring, a bearing outer body, a lower sealing ring, a lower sealing ring cover, a deep groove ball bearing, a deep groove ball bearing cover, a main motor, a driving pulley, a driven pulley-type flywheel, a multi-layer positioning plate, aroller bearing seat, a pushing self-aligning roller bearing, an inner sealing ring, a friction clutch disc, a friction block, a pneumatic conical separation-reunion piston, a conical cylinder body, aguide screw rod, a cylinder body fastening nut, an up-down adjusting bolt, a back tightening nut, a copper nut, a top surface baffle plate, a sliding block, a lifting frame, a lifting rod, a return stroke lifting cylinder and an upper sealing ring. According to the energy-saving and environment-friendly high-energy screw press, the output energy is high, the transmission power is small, power is saved, energy saving is remarkable, the return stroke is quick, the production efficiency is high, the anti-bias load ability is high, multi-position die forging is achieved, environmental protection is achieved, the service life is long, and the safety of the whole machine is ensured; and the energy-saving and environment-friendly high-energy screw press can be widely used in the forging pressureforming process.

Owner:青岛浩源益友锻压机械有限公司

Forging press

InactiveCN102259154BSimple structureEasy to operateForging press detailsForging press drivesHydraulic cylinderEngineering

Owner:GUANGDONG HUAYE POWER TECH

A marine weight pipe coating trolley

InactiveCN105643790BQuality improvementHigh precisionSurface layering apparatusHydraulic motorHydraulic cylinder

Owner:SOUTHWEST PETROLEUM UNIV

Preparation method of end-sealed prefabricated concrete enlarged head tubular pile

ActiveCN108842838BImprove bearing strengthImprove bearing capacityFoundation testingBulkheads/pilesArchitectural engineeringPipe

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com