Non-joint single hydraulic prop for blasting mining

A single hydraulic prop and joint gun technology, applied in mining equipment, props/supports, earthwork drilling, etc., can solve the problems of many processing procedures, poor anti-eccentric load capacity, and many equipment, reducing labor intensity, resisting Strong eccentric load capacity and the effect of expanding the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

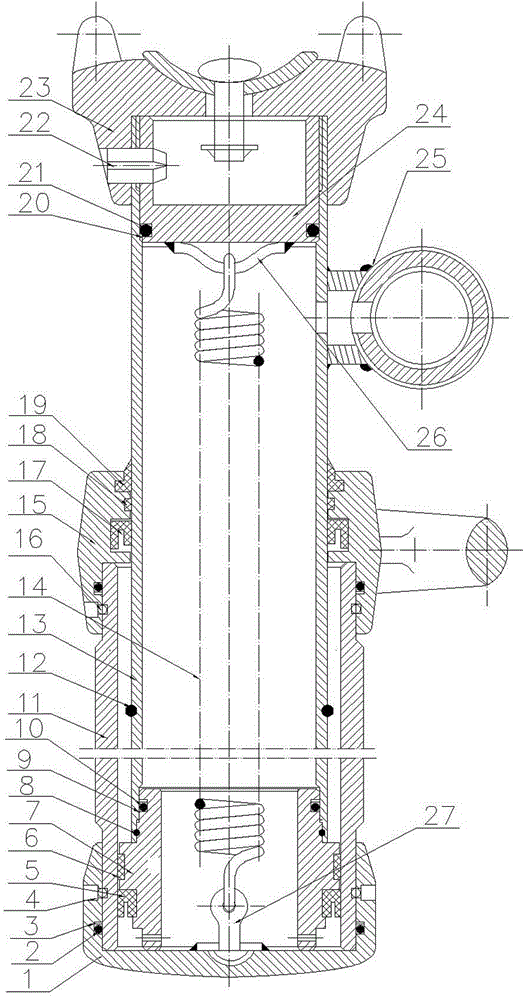

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

[0024] As shown in the accompanying drawings, the present invention is mainly composed of a base 1, an oil cylinder 11, a live cylinder 13, a return spring 14, a handle body 15, a top cover 23, a three-purpose valve seat body 25 and a seal, and the whole is streamlined. The oil cylinder 11 with an inner diameter of 90 or 100 mm is one of the important parts of the pillar, and its main function is to store liquid and bear the expansion force of the hydraulic pressure and the tension and tension from the external force of the pillar.

[0025] The live cylinder 13 is a hollow cylindrical body, and its main function is the lifting and lowering of the pillar, and the transmission of pressure from the top plate. Its lower end is softly connected to the hollow piston body 7 through an O-shaped sealing ring III10. The piston body 7 is a dirt storage type, which can store impu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com