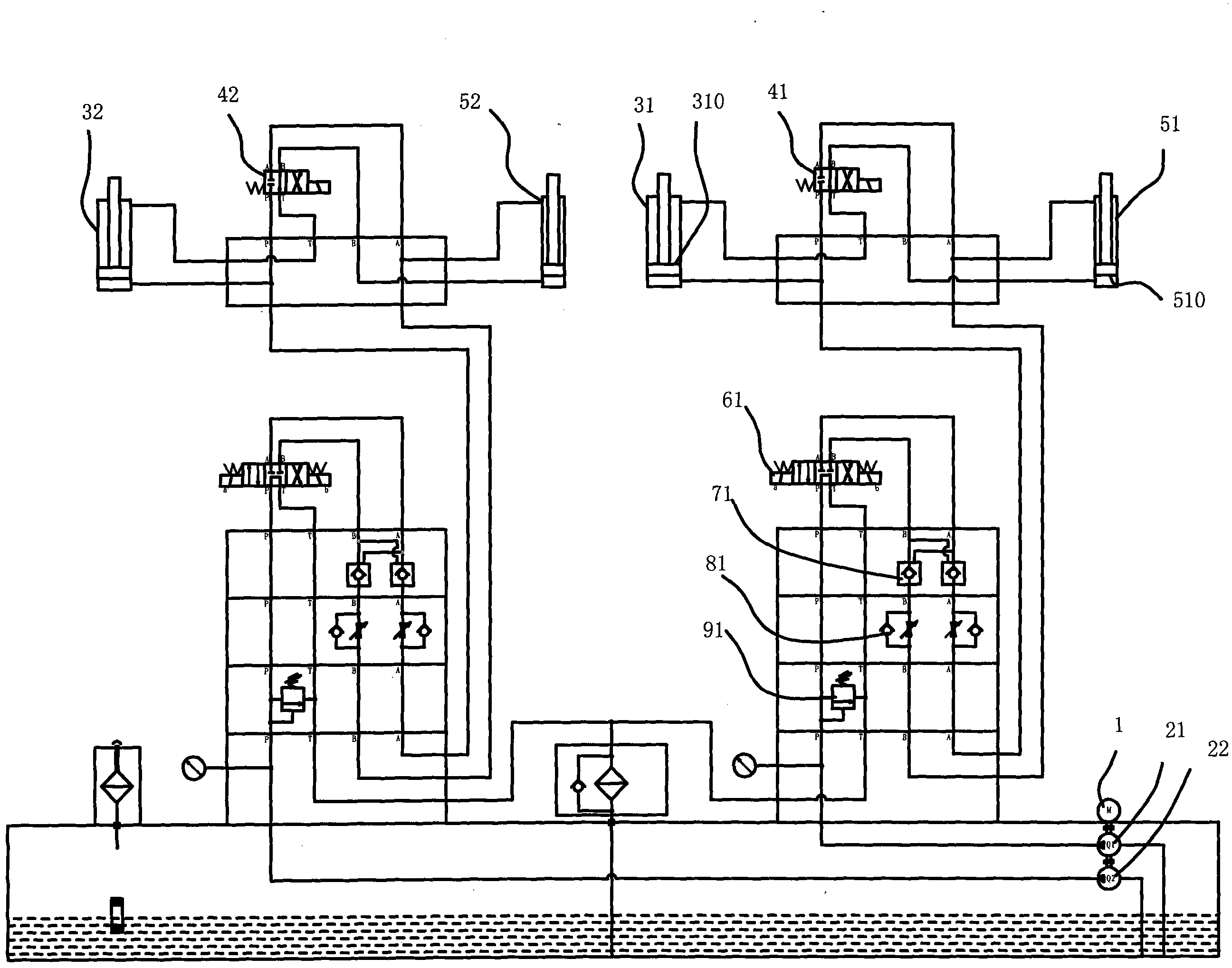

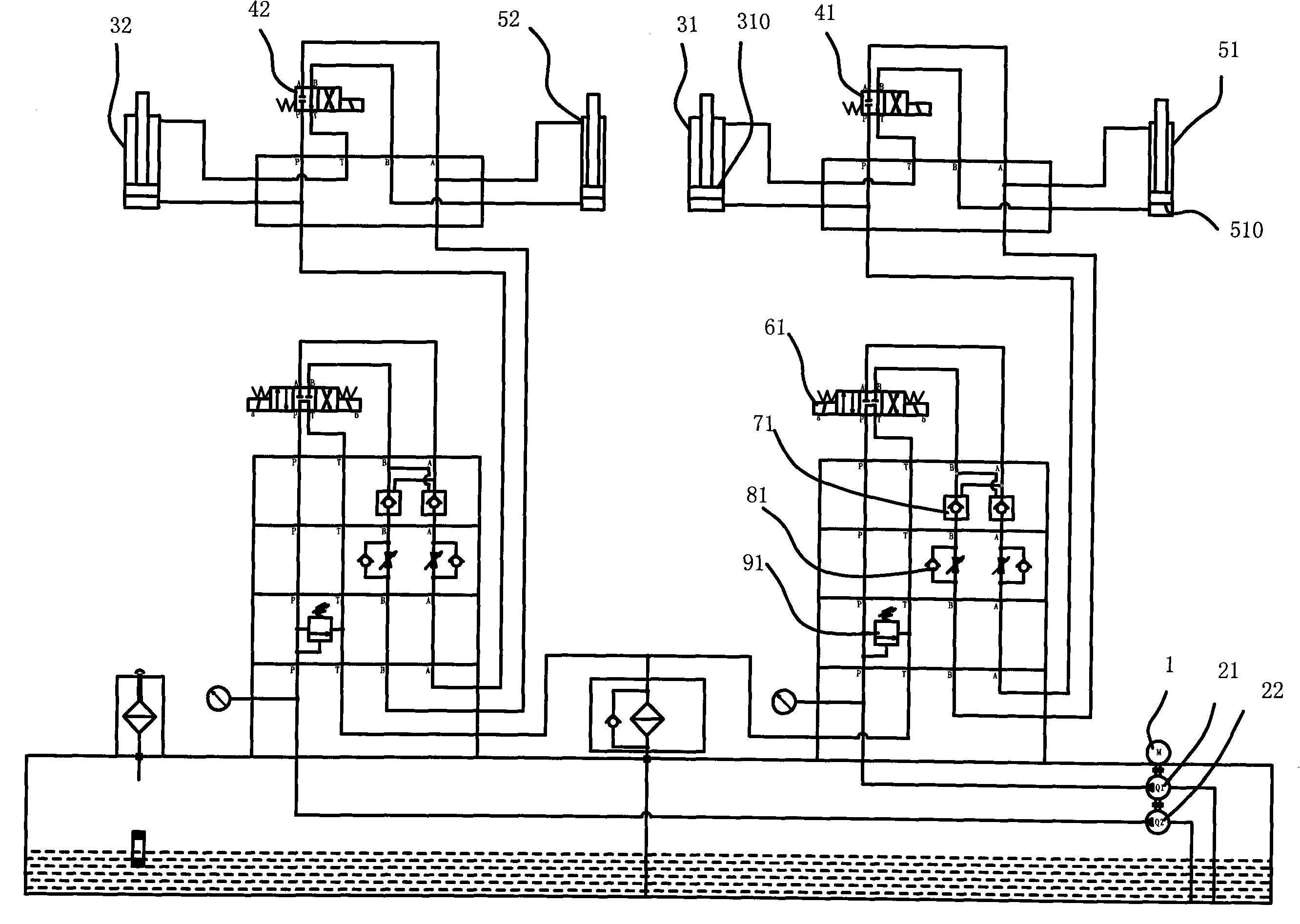

Four-cylinder synchronous hydraulic system

A hydraulic system and auxiliary cylinder technology, applied in the field of stroke control hydraulic circuit, can solve the problems of poor anti-eccentric load capacity, large synchronization error, large power loss, etc., and achieve strong anti-eccentric load capacity, small power loss, and small temperature rise. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The invention as figure 1 As shown, it includes master cylinder A31, auxiliary cylinder A51, master cylinder B32 and auxiliary cylinder B52 respectively driving the four corners of a horizontal platform, oil pump A21, oil pump B22 (double pump is preferred, and the double pump with the same displacement can realize two circuits. The oil supply is the same, so as to realize the synchronization of four cylinders), the two oil circuit reversing control valve groups between the oil pump and the main and auxiliary cylinders 31, 32, 51, 52, and the hydraulic oil tank, the The rod chambers and rodless chambers of the master cylinders 31, 32 and the rodless chambers and rod chambers of the auxiliary cylinders 51, 52 realize serial and parallel switching connections through two-position four-way solenoid valves 41, 42; The working areas of the rod chambers 31 and 32 are equal to the working areas of the rodless chambers 51 and 52 of the auxiliary cylinders.

[0012] The two oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com