Bidirectionally-flowing nanofiltration membrane water treatment system and method

A water treatment system, bi-directional flow technology, applied in the direction of osmosis/dialysis water/sewage treatment, chemical instruments and methods, membrane technology, etc., can solve the problems of high operating cost, reduced water production of membrane elements, and pollution of nanofiltration membrane treatment technology The degree of increase and other problems can be achieved to save the initial investment cost, reduce the pressure requirements, and prolong the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

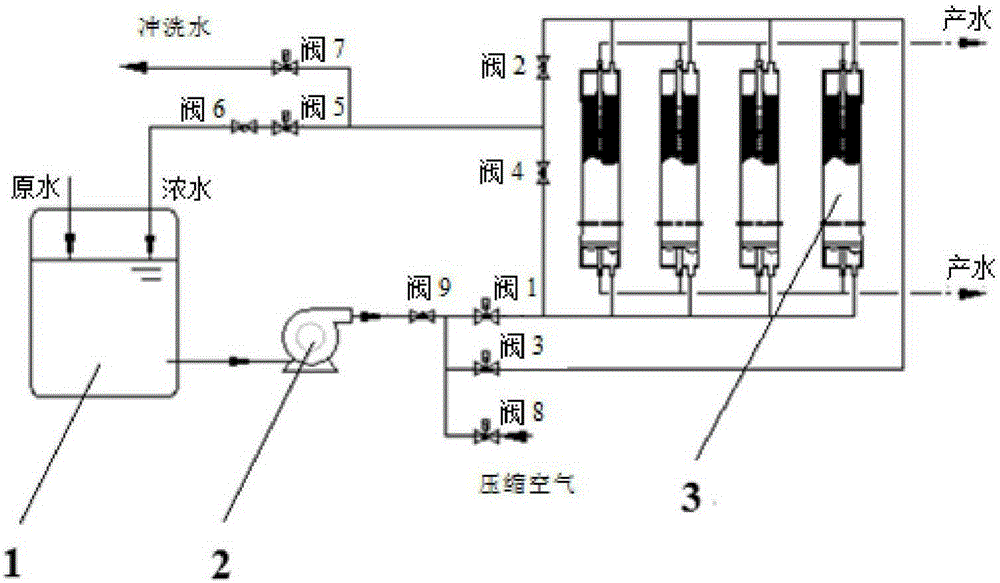

[0058]The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

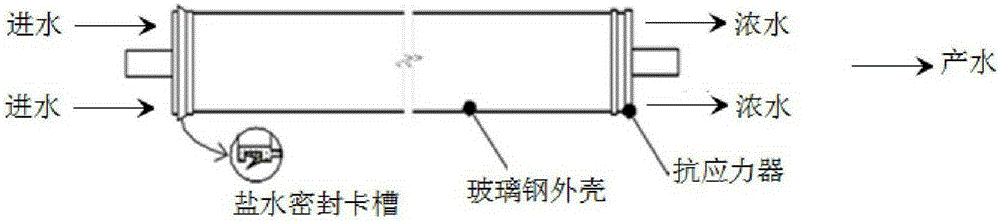

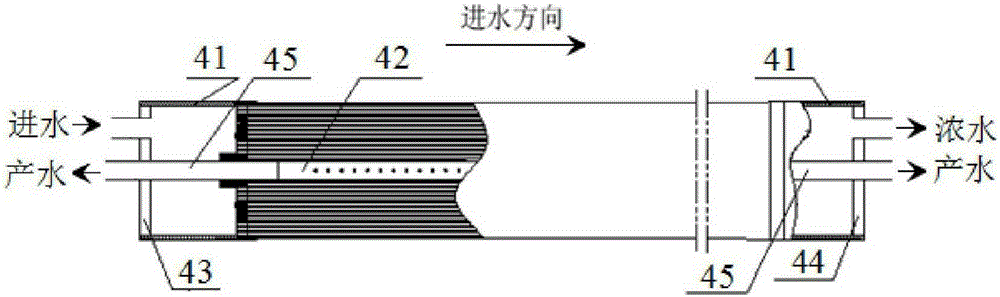

[0059] The structure of the membrane element of the existing nanofiltration membrane module is as follows figure 2 As shown, one end of the main body of the membrane element is the water inlet, and the other end is the concentrated water end (that is, connected to the water inlet of the next stage). The groove and the anti-stress device are connected with the main body;

[0060] The multi-segment series connection between traditional membrane elements is specifically: multiple membrane elements are connected in series in the pressure vessel, the two ends of the pressure vessel are sealed by end plates, the membrane elements are connected by inner joints, and the end plates are connected to each other by end plate adapters. The membrane elements at both ends are connected.

[0061] It can be seen that the existing m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com