Fuel cell based on in-plate counter-flow flow field

A fuel cell, countercurrent technology, applied in the direction of fuel cells, fuel cell additives, fuel cell grouping, etc., can solve the problems of concentration drop, concentration difference, uneven current density distribution, etc., to overcome the gradual increase or decrease , to promote the effect of uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

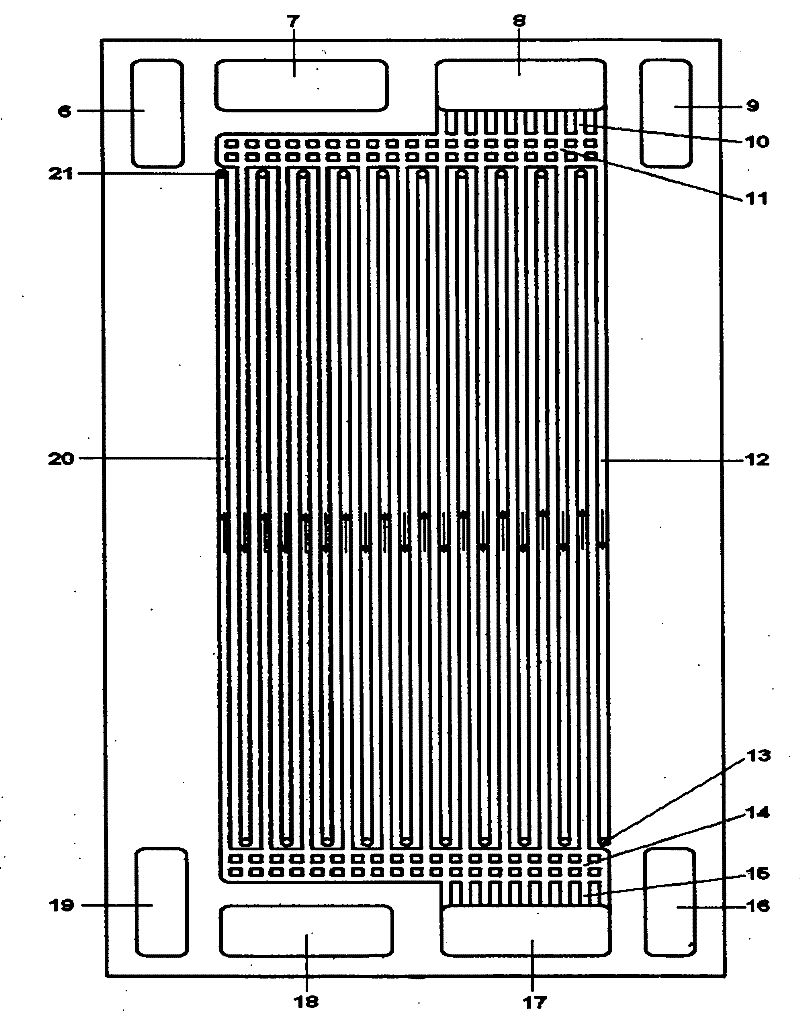

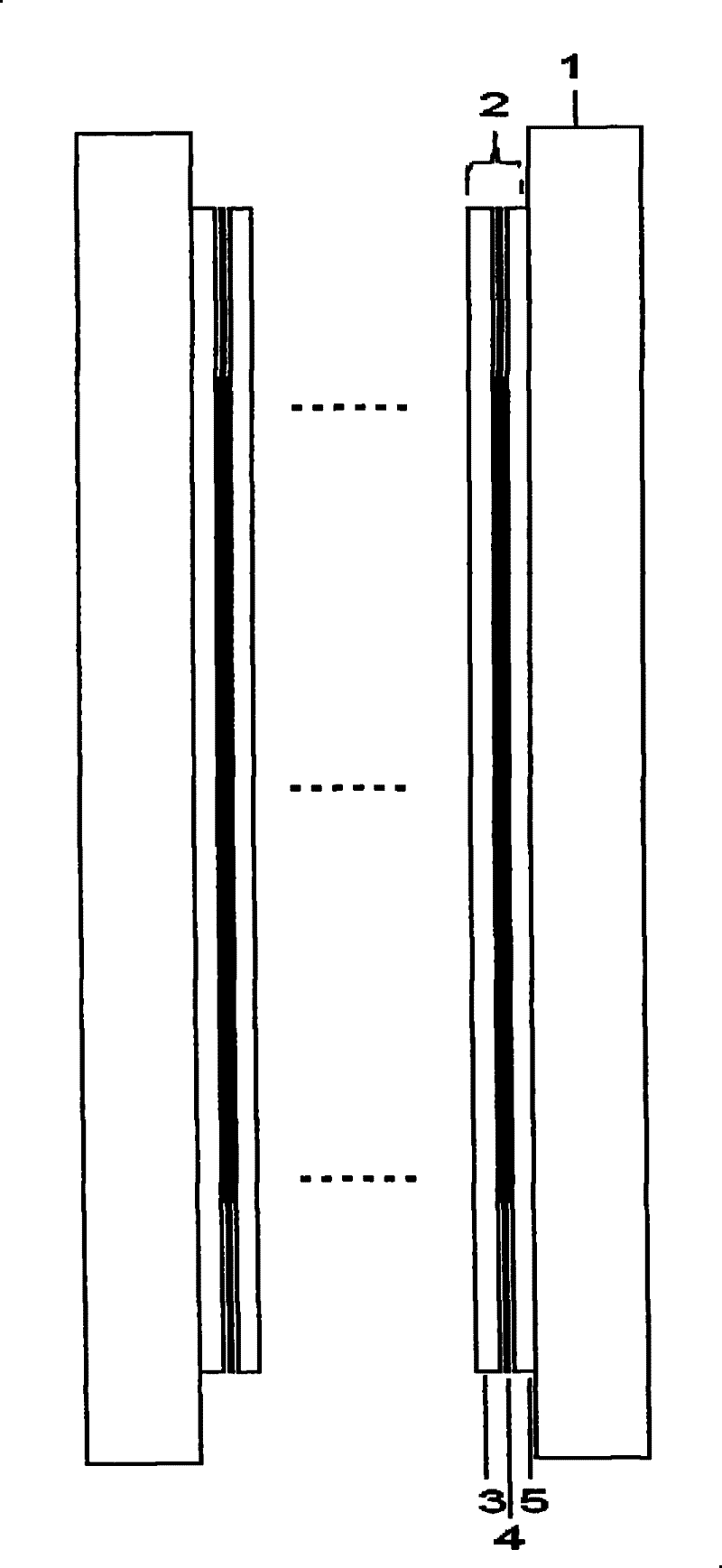

[0015] The fuel cell based on the countercurrent flow field in the plate proposed by the present invention has a structure such as figure 1 As shown, it includes a splint 1 and a plurality of battery cells 2 , and the plurality of battery cells 2 are sandwiched between two splints 1 after being connected in series. The battery unit 2 includes an air flow field plate 3 , a fuel flow field plate 5 and a membrane electrode 4 , and the air flow field plate 3 and the fuel flow field plate 5 are respectively placed on both sides of the membrane electrode 3 .

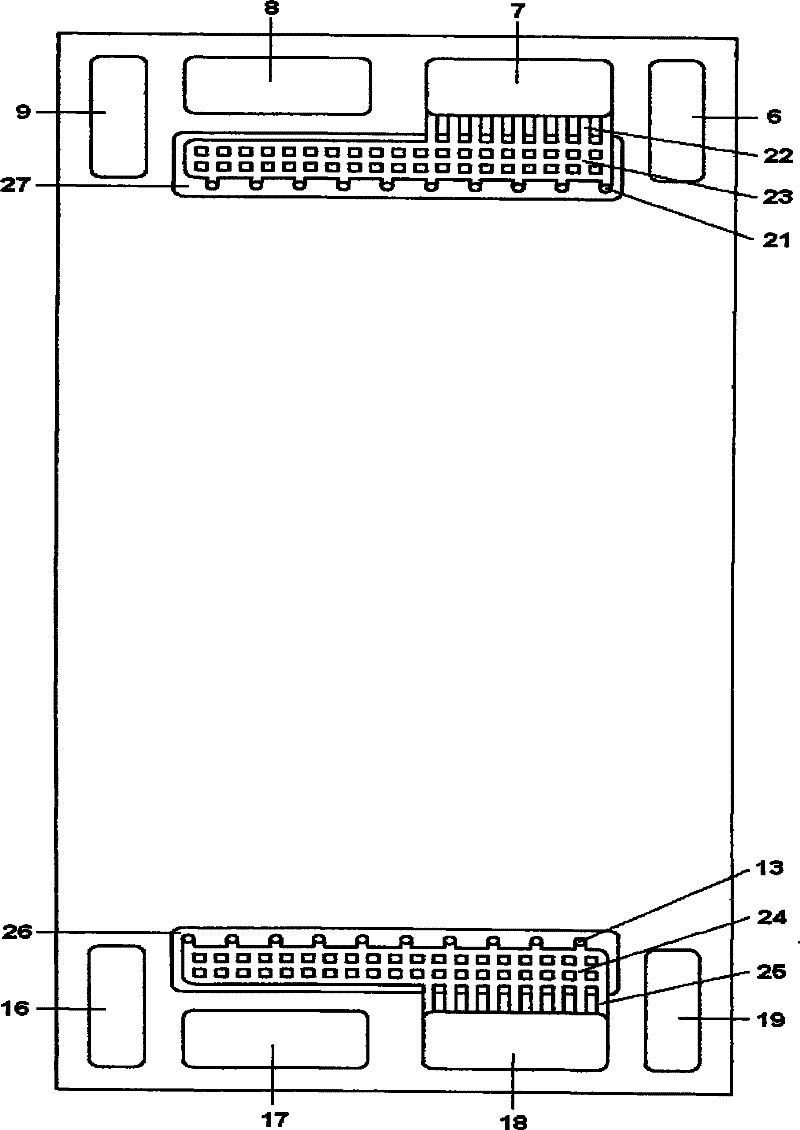

[0016] The structure of the above-mentioned air flow field plate 3 is as follows: figure 2 As shown, the first fuel inlet 6, the second air outlet 7, the first air inlet 8 and the second fuel outlet 9 are sequentially opened on the upper end from left to right, and the second group of air flow field plates are opened on the lower side. The air passes through the hole 21 . The lower end of the air flow field plate is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com