Membrane catalytic reactor

A technology of reactor and membrane catalysis, which is applied in chemical instruments and methods, chemical/physical processes, petroleum industry, etc., can solve the problems of difficult recycling of catalyst inorganic alkali, high price of immobilized enzyme, increased reaction cost, etc., and achieves manufacturing The process is simple, the concentration is the same, and the effect of expanding the production scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

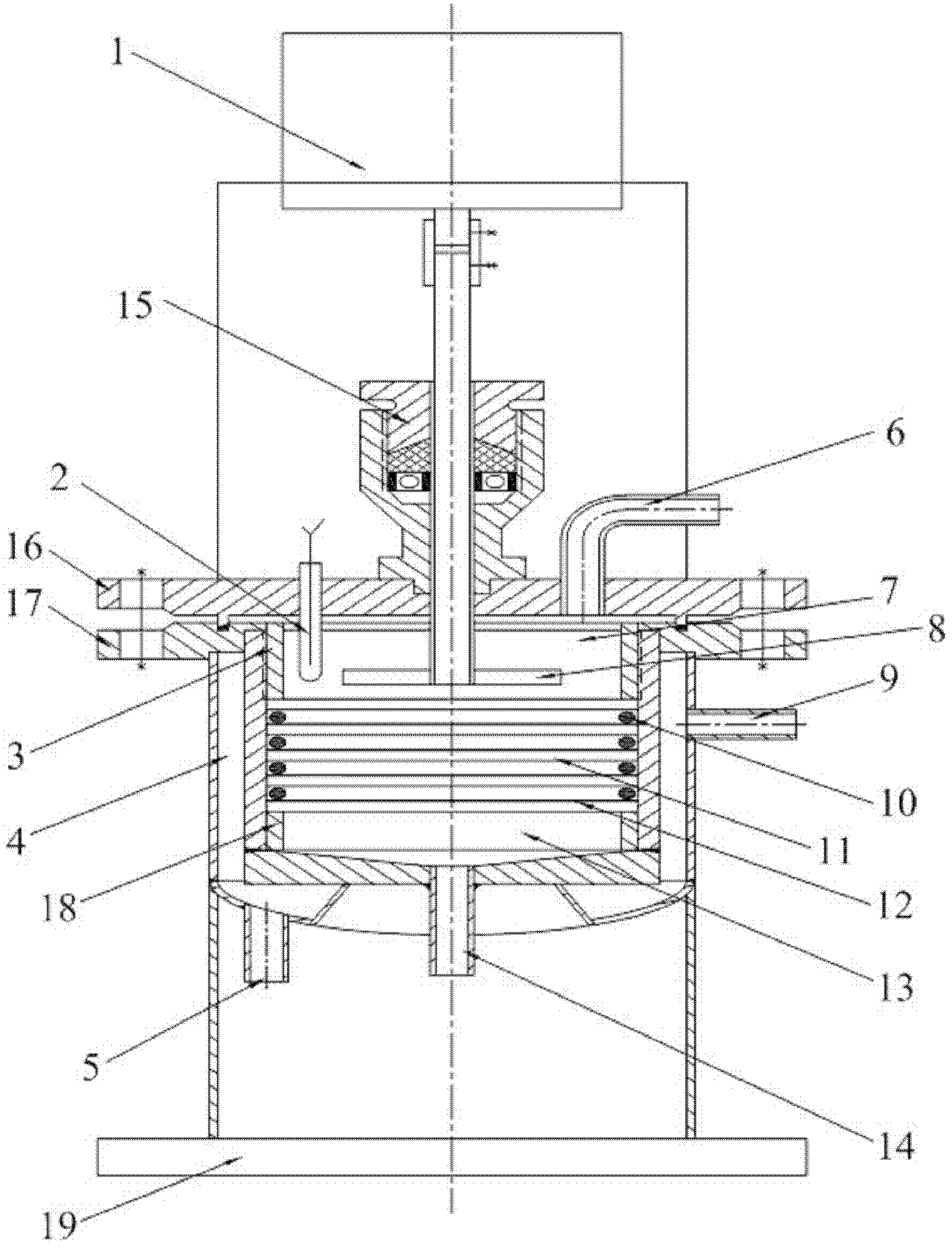

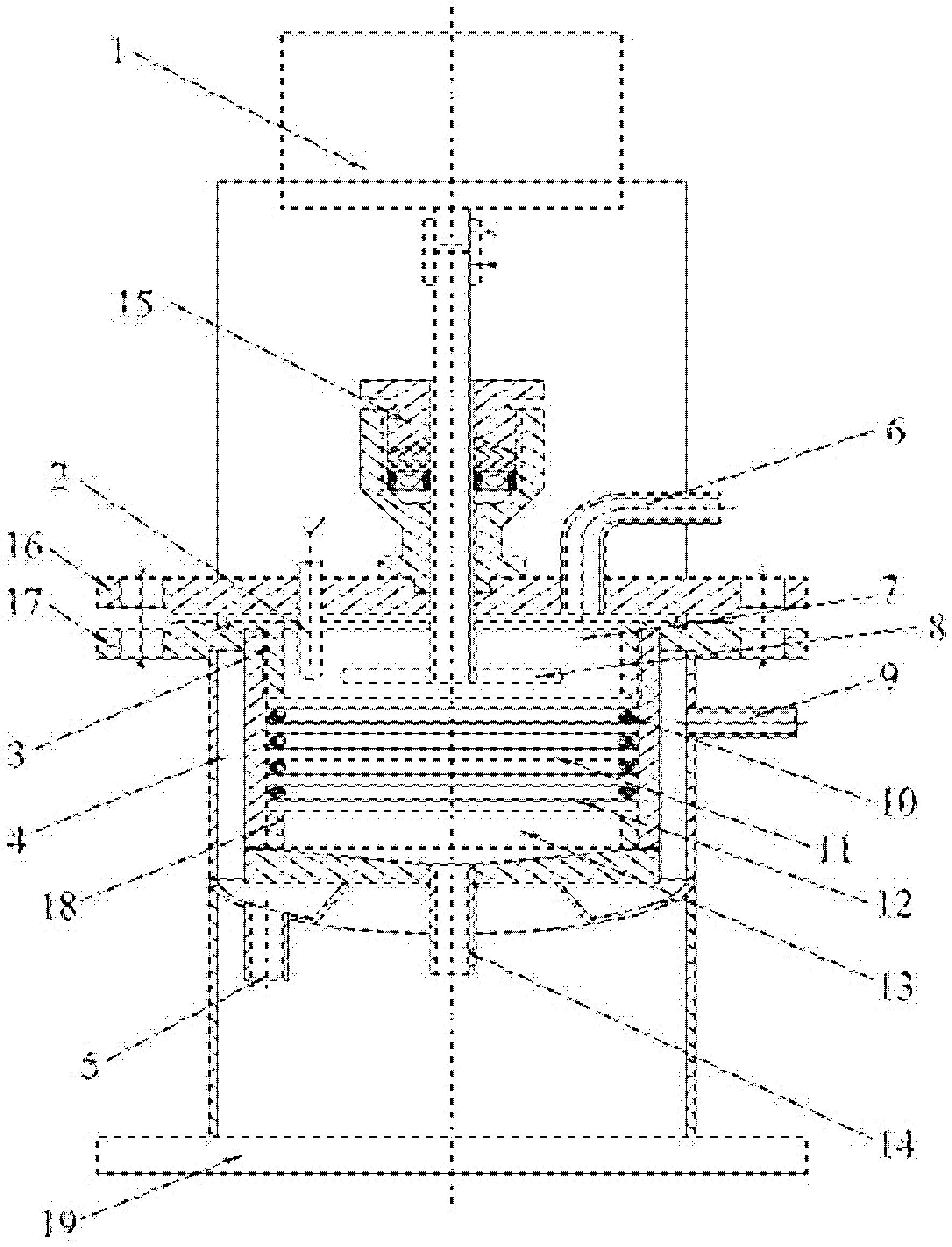

[0021] Further illustrate the present invention below in conjunction with accompanying drawing.

[0022] Such as figure 1 As shown, the present invention comprises feed inlet 6, feed outlet 14, raw material chamber 7, product chamber 13, jacket 4, electric stirrer 1 and catalytic membrane 12, and electric stirrer 1 is arranged on raw material chamber 7 tops, stirring paddle 8 enters the inside of the raw material chamber 7, the catalytic membrane 12 is arranged between the raw material chamber 7 and the product chamber 13, the feed inlet 6 is arranged at the top of the raw material chamber 7, the discharge port 14 is arranged at the bottom of the product chamber 13, and the jacket 4 is arranged at the bottom of the product chamber 13. The outside of the raw material chamber 7 , the catalytic membrane 12 and the product chamber 13 . The catalytic membrane 12 is sheet-shaped and supported by the catalytic membrane support plate 11 . The catalytic membrane 12 and the catalytic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com