Patents

Literature

54results about How to "Same depth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

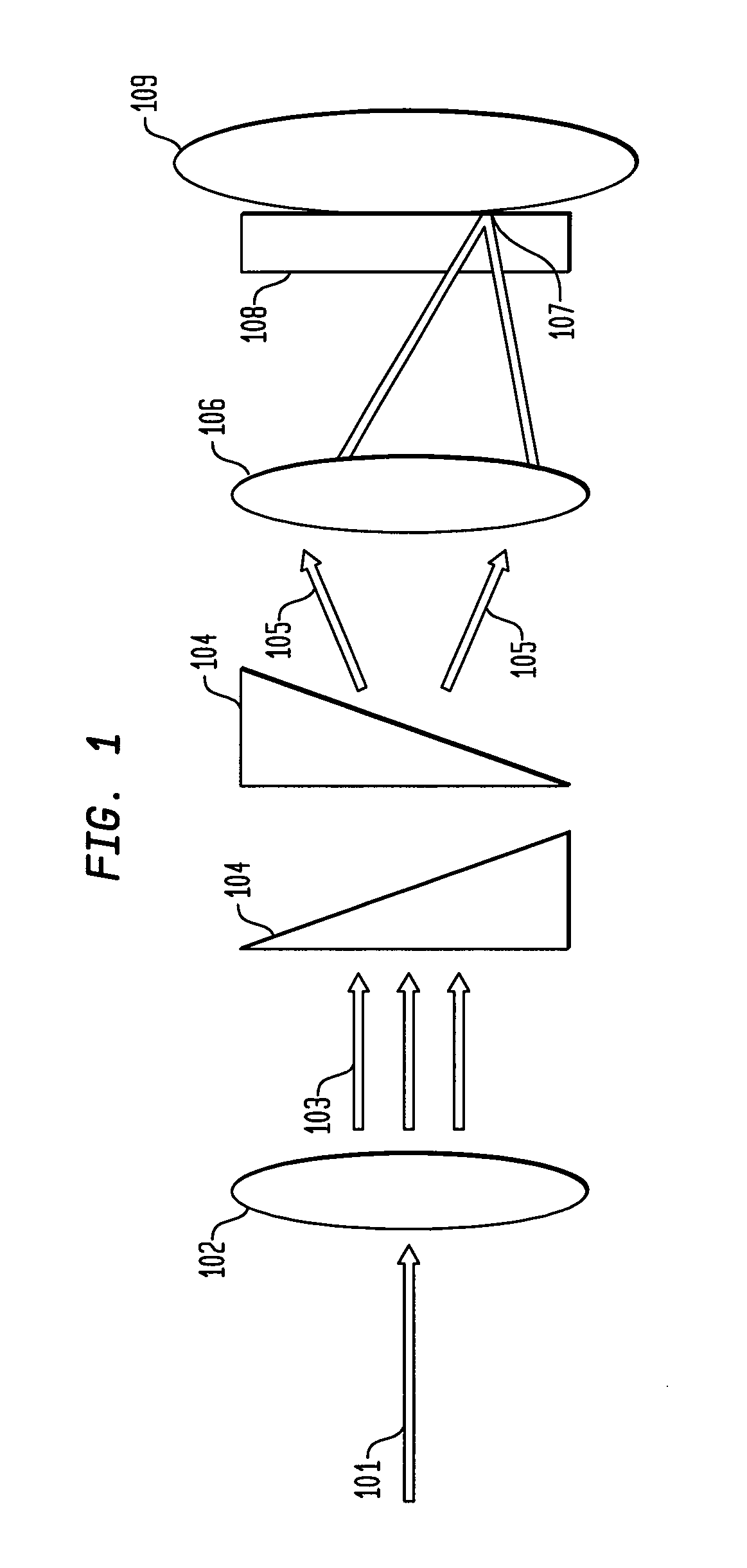

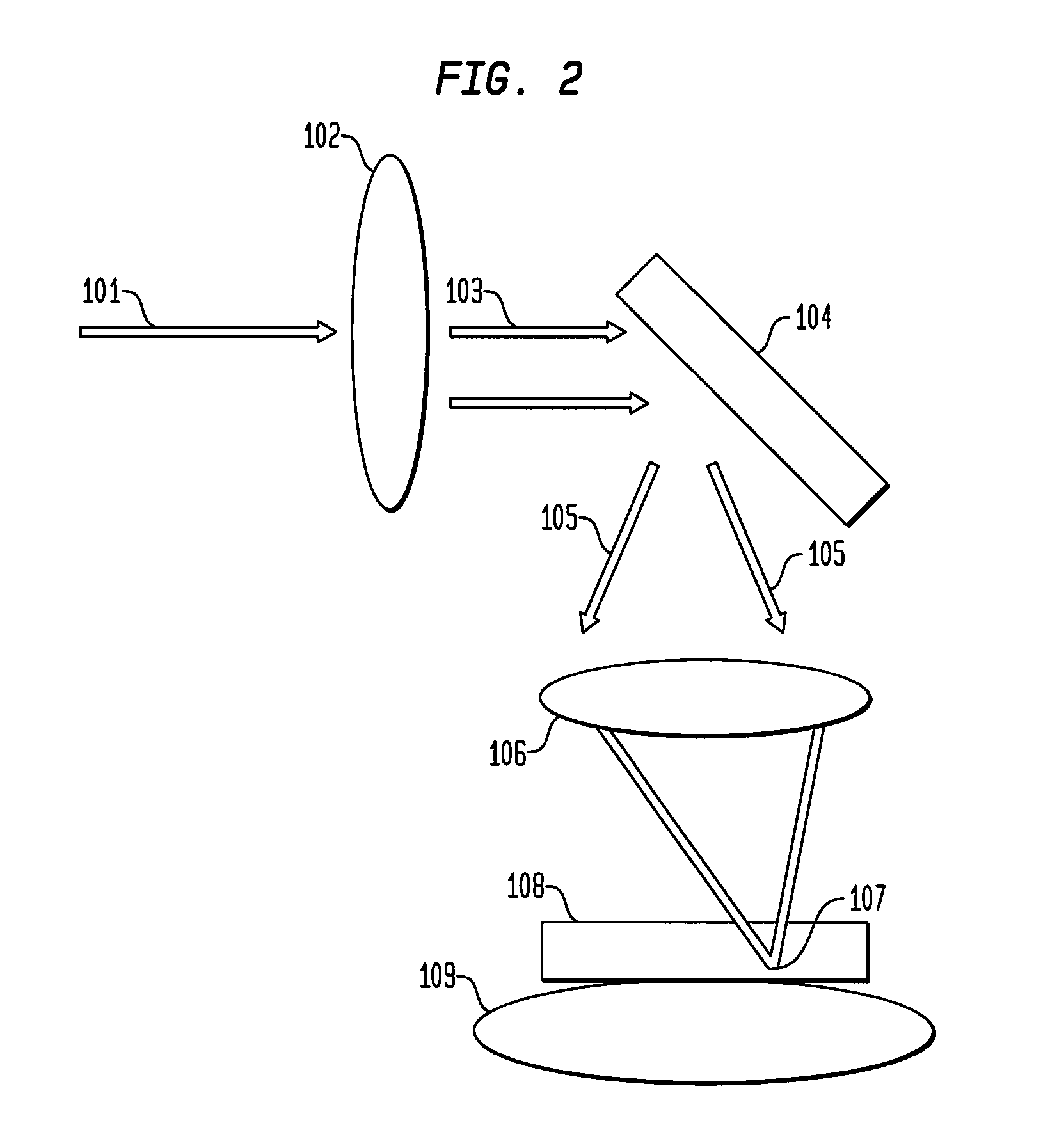

System and method for creating a stable optical interface

ActiveUS20070219437A1Simple interfaceOptical coupling efficiency is decreasedDiagnostic recording/measuringSensorsSkin surfaceRefractive index

A system and a method for creating a stable and reproducible interface of an optical sensor system for measuring blood glucose levels in biological tissue include a dual wedge prism sensor attached to a disposable optic that comprises a focusing lens and an optical window. The disposable optic adheres to the skin to allow a patient to take multiple readings or scans at the same location. The disposable optic includes a Petzval surface placed flush against the skin to maintain the focal point of the optical beam on the surface of the skin. Additionally, the integrity of the sensor signal is maximized by varying the rotation rates of the dual wedge prisms over time in relation to the depth scan rate of the sensor. Optimally, a medium may be injected between the disposable and the skin to match the respective refractive indices and optimize the signal collection of the sensor.

Owner:MASIMO CORP

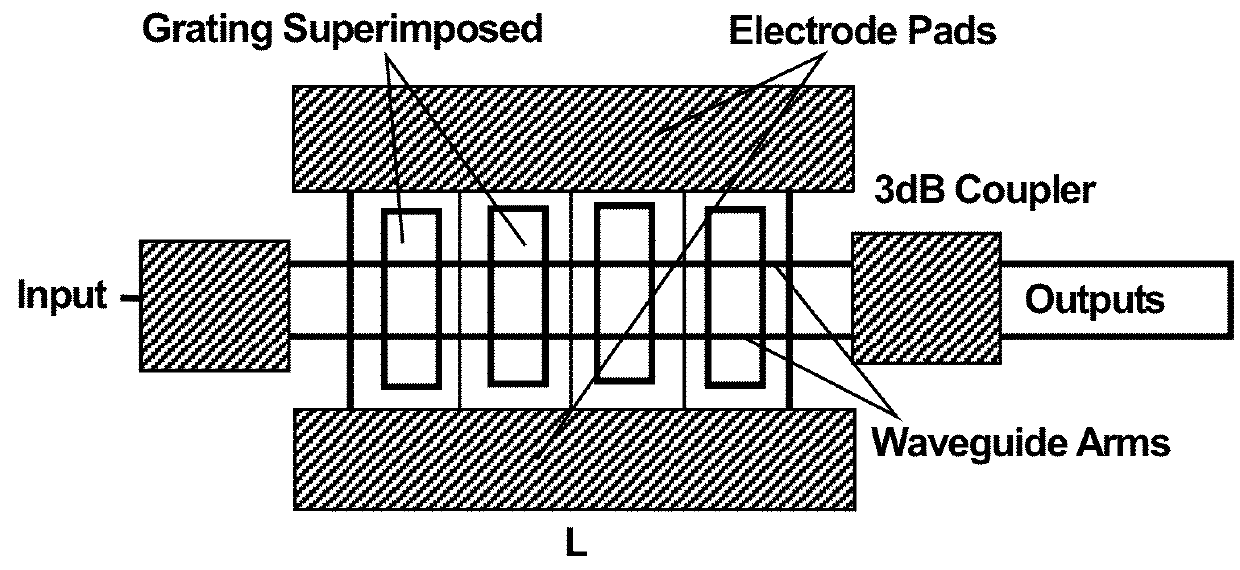

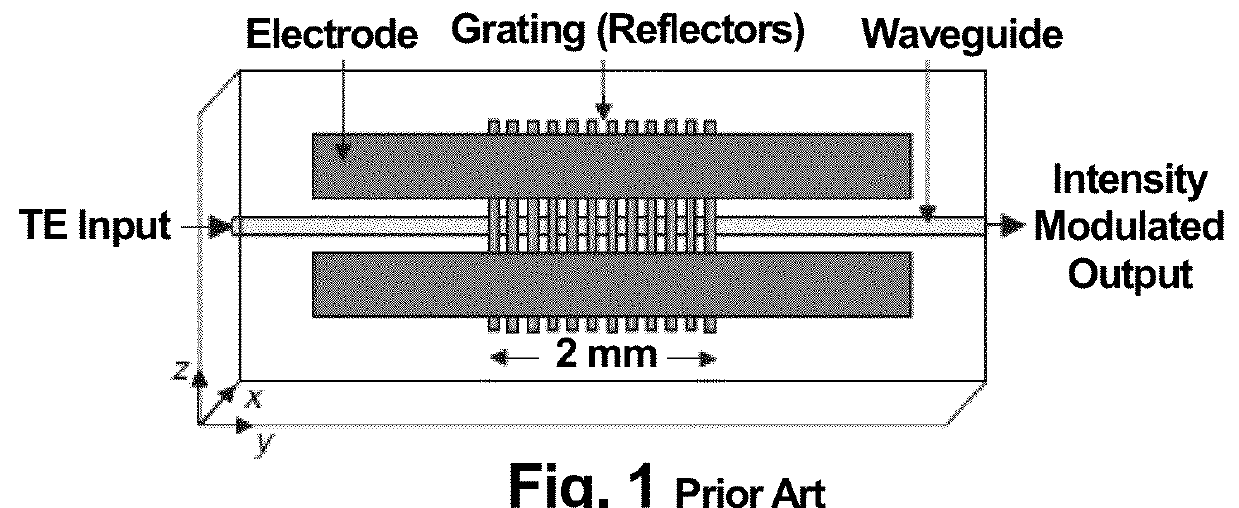

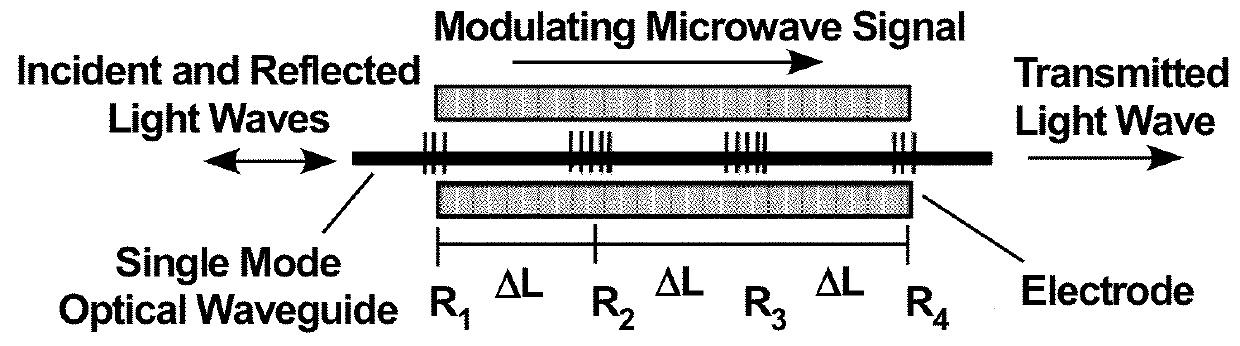

Electro-optic grating modulator

ActiveUS9335568B1Strong modulation depthSignificant changeNon-linear opticsWaveguide gratingHigh frequency

An optical-waveguide grating modulator is compatible with high-frequency electrical modulation signals of limited bandwidth. The modulator comprises an optical grating formed in an optical waveguide constructed from electro-optic (EO) material and an electrode that is an RF waveguide or RF transmission line that conducts a traveling-wave electromagnetic (EM) field and that contains a portion of the optical-grating waveguide with a continuous grating. The RF input modulation signal is coupled into an RF EM field that propagates through the RF waveguide or transmission line in a direction that is parallel to the direction the light propagates in the optical-grating waveguide and that EM field overlaps the optical-grating waveguide. The light travels along the optical-grating waveguide preferably at the same velocity as the RF EM field travels along the RF waveguide or transmission line.

Owner:HRL LAB

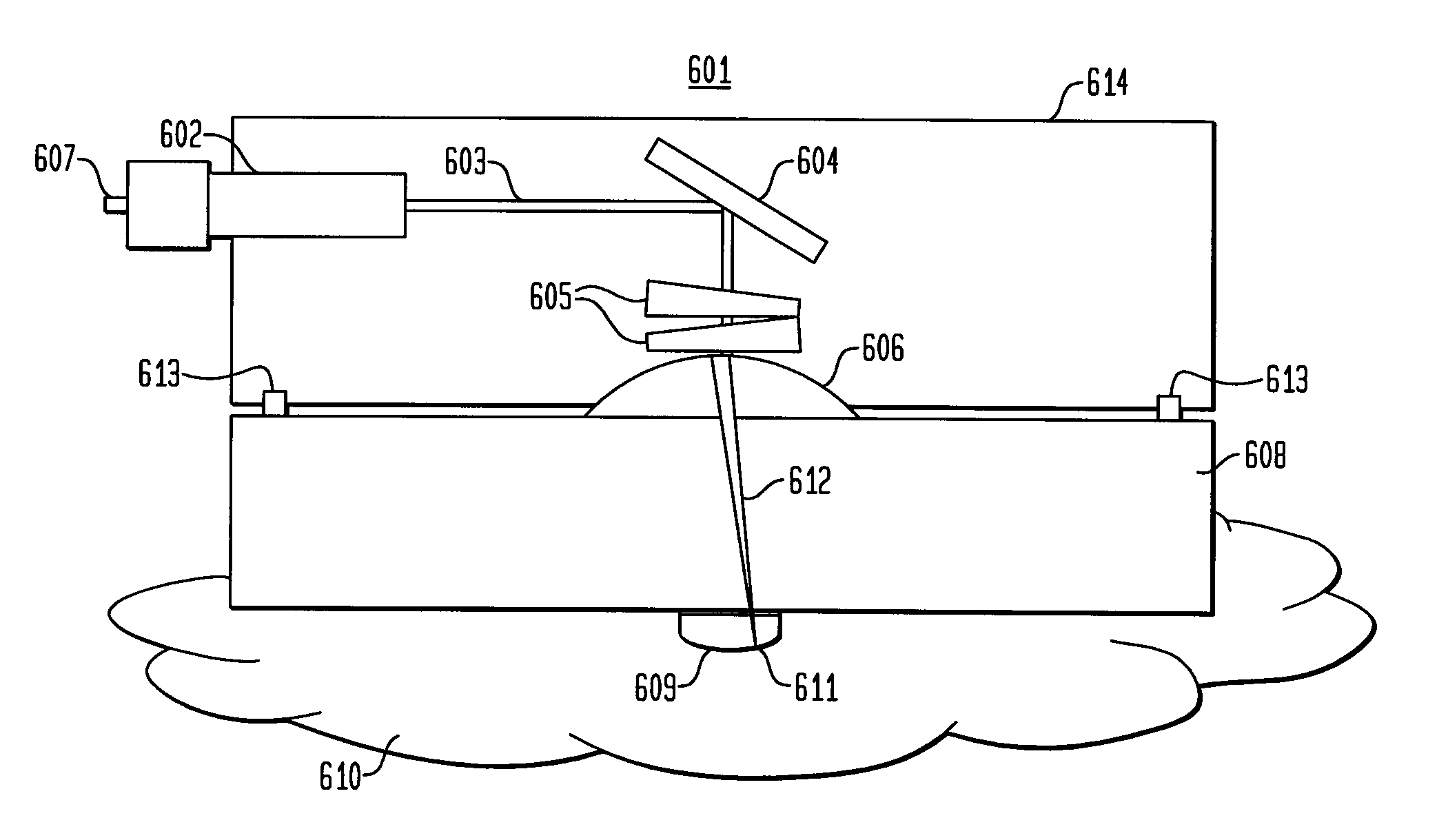

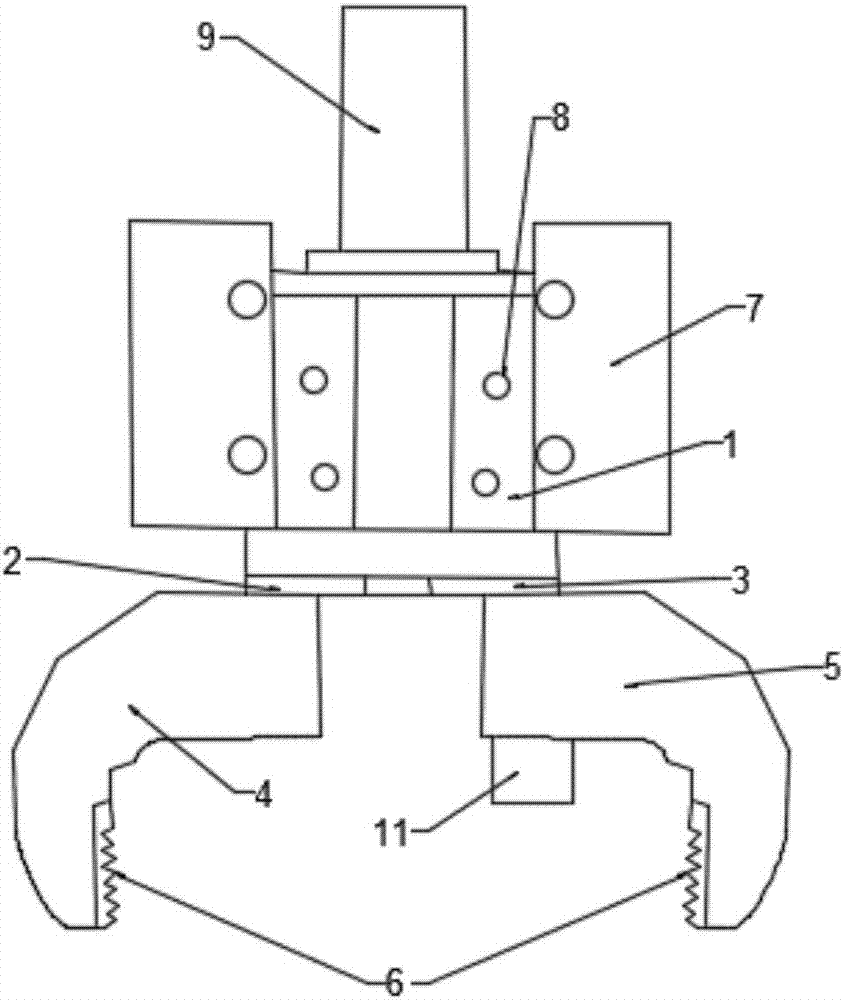

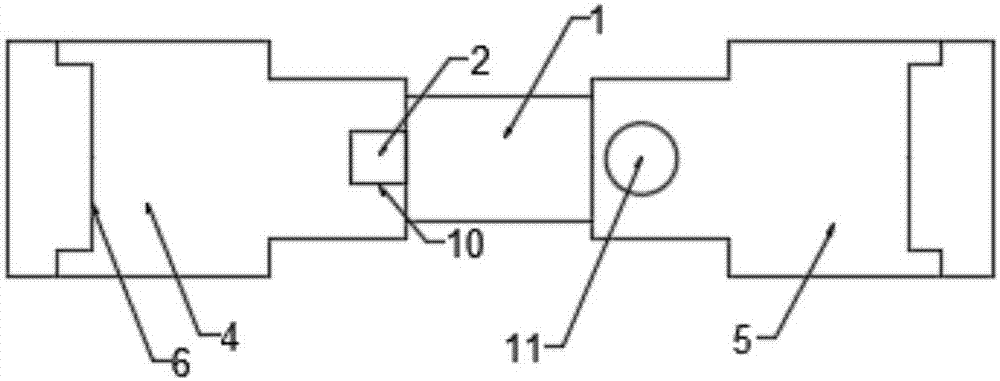

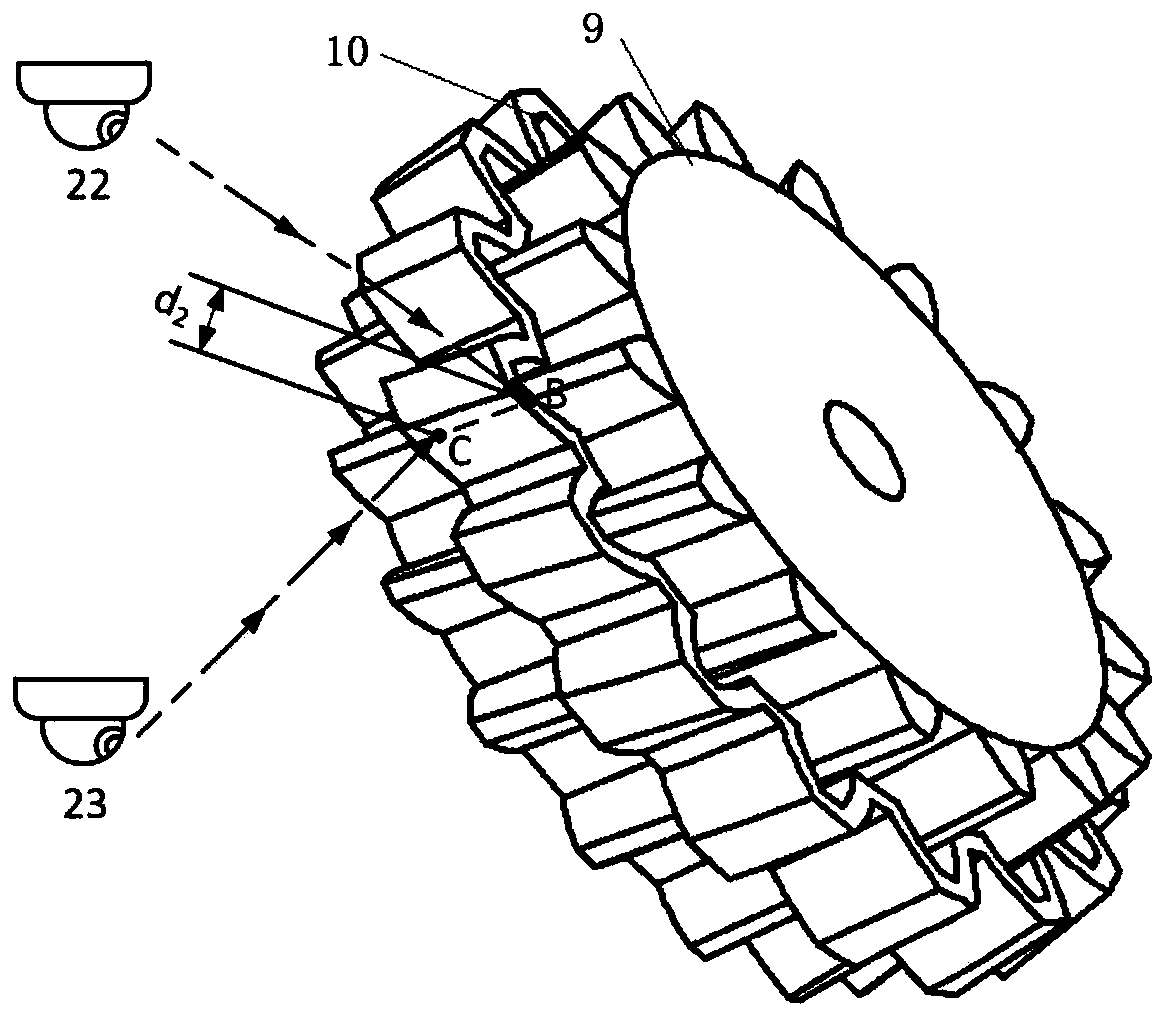

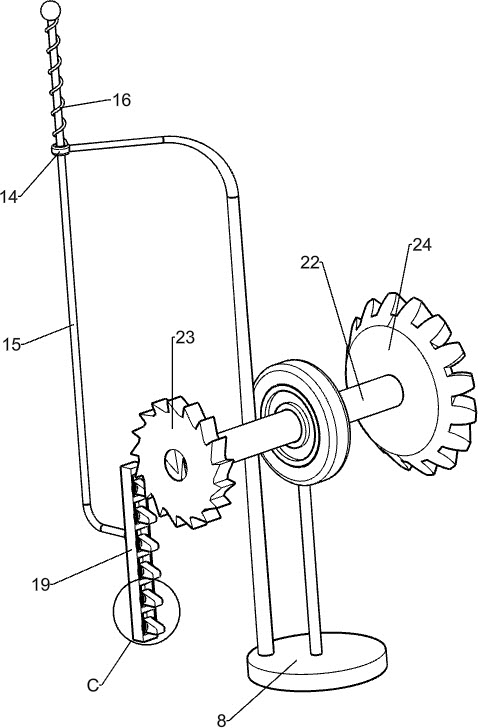

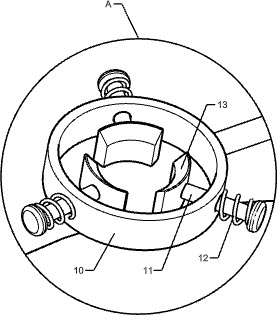

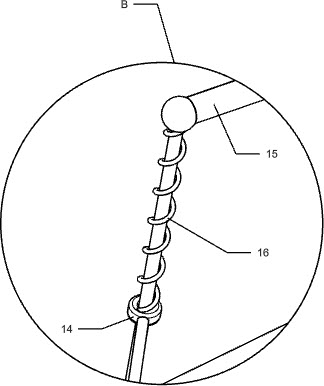

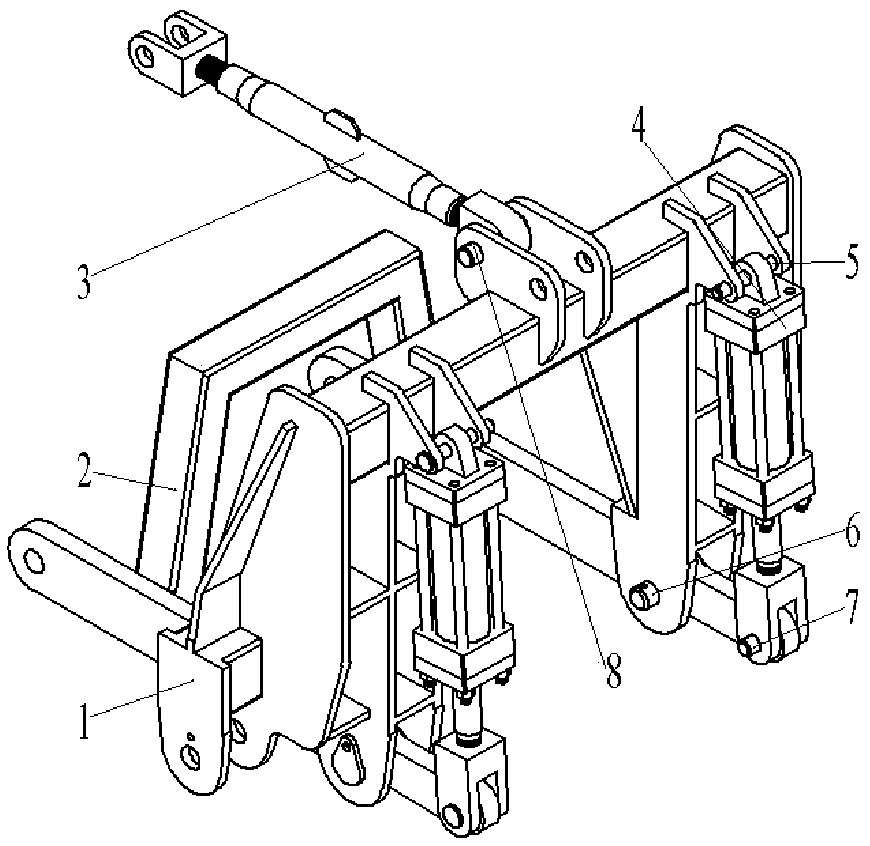

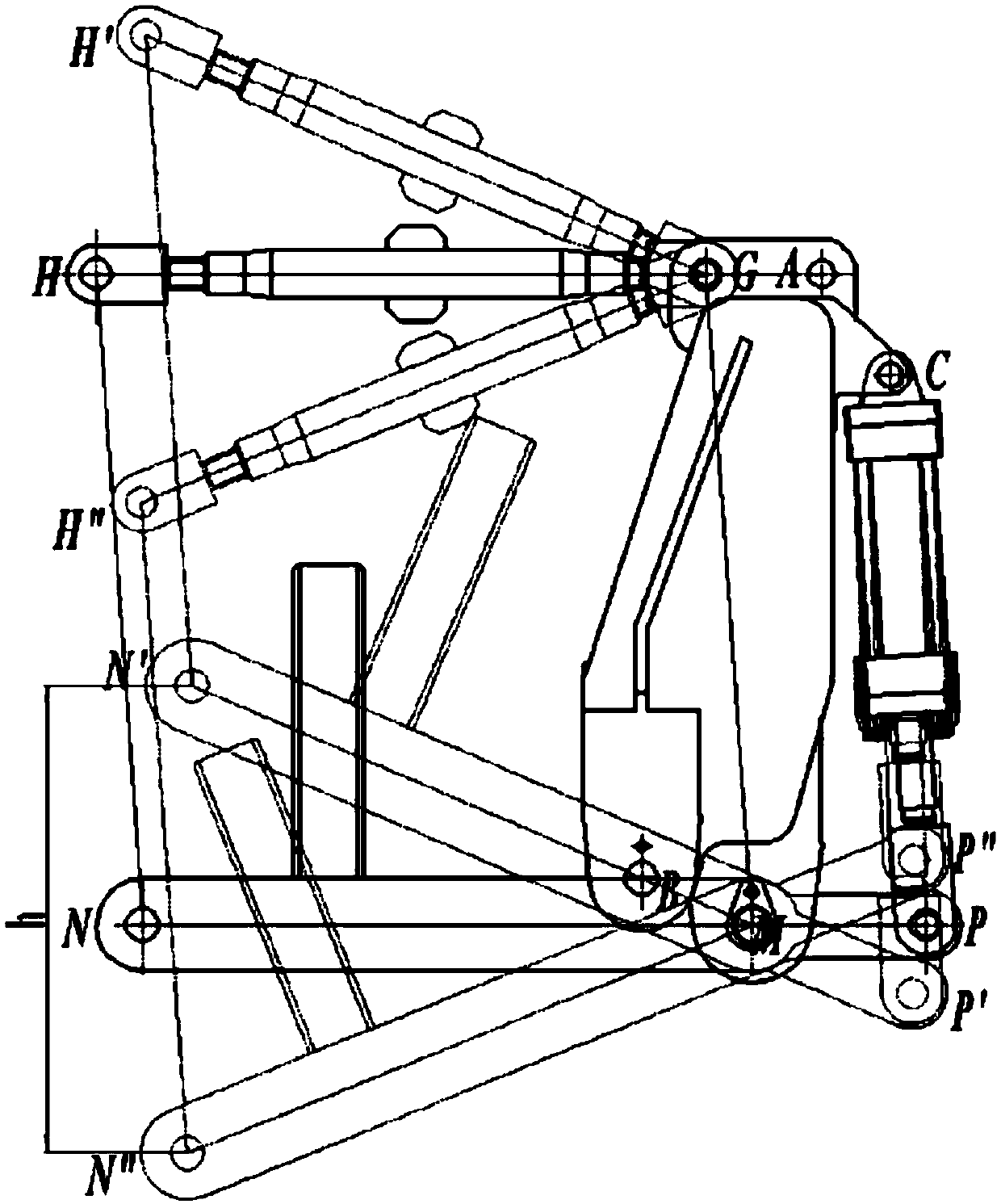

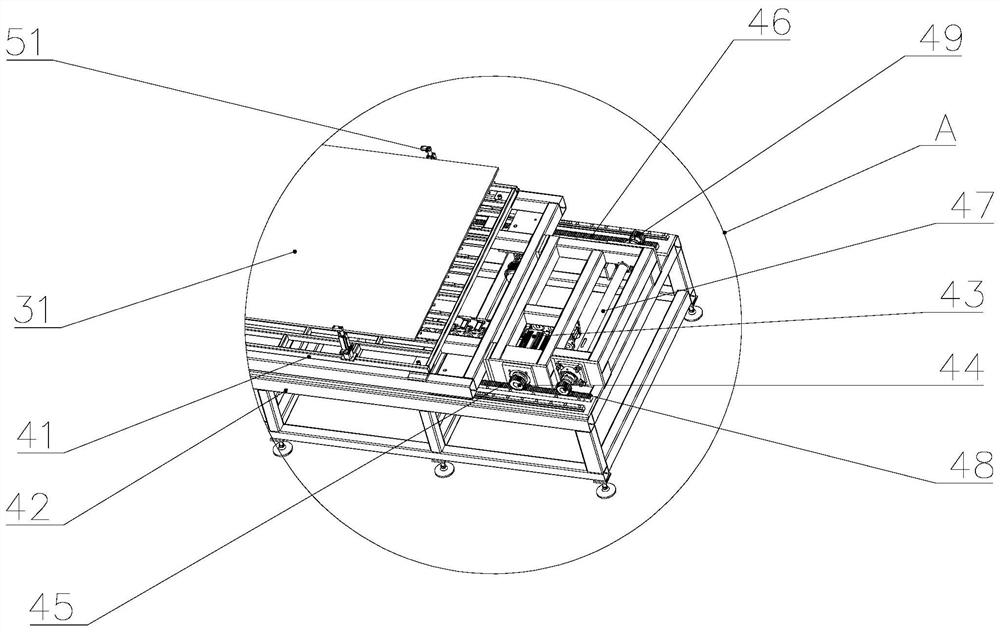

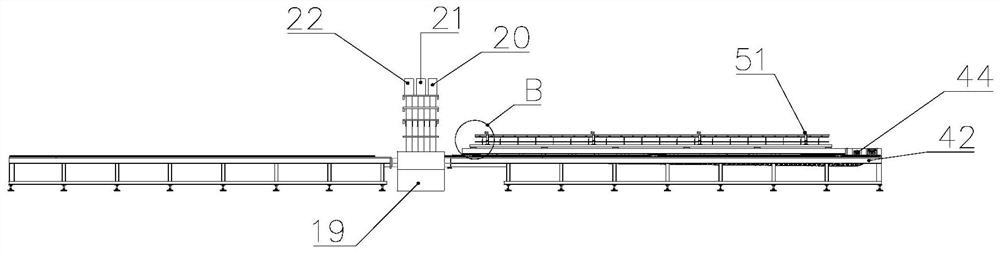

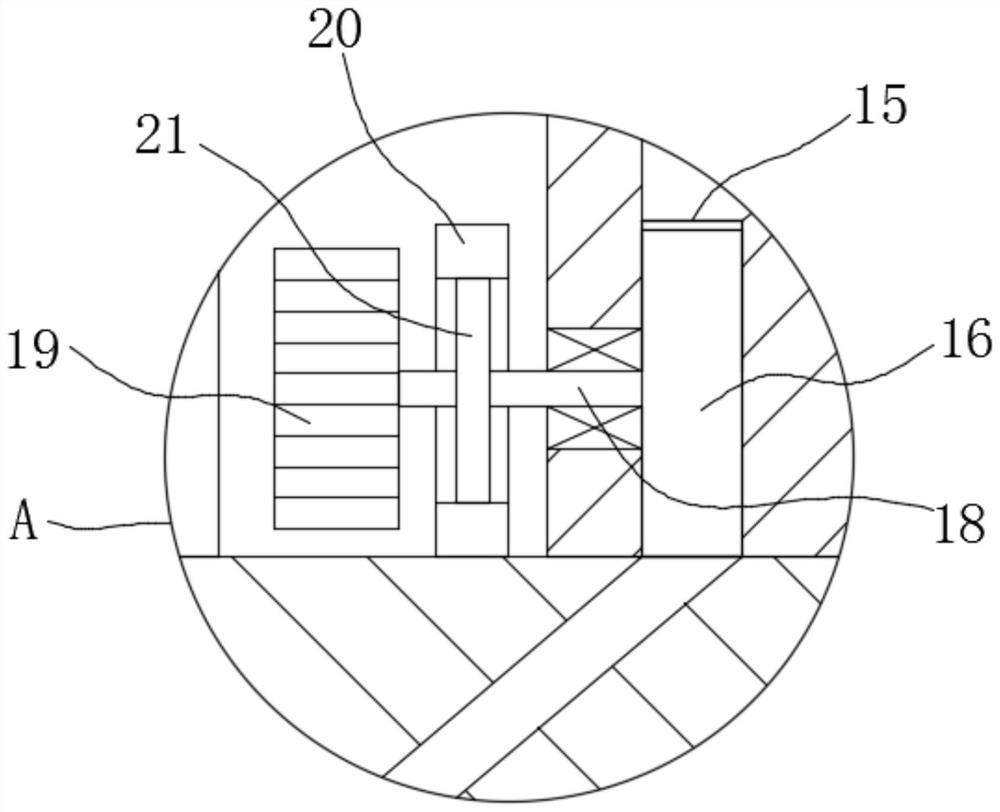

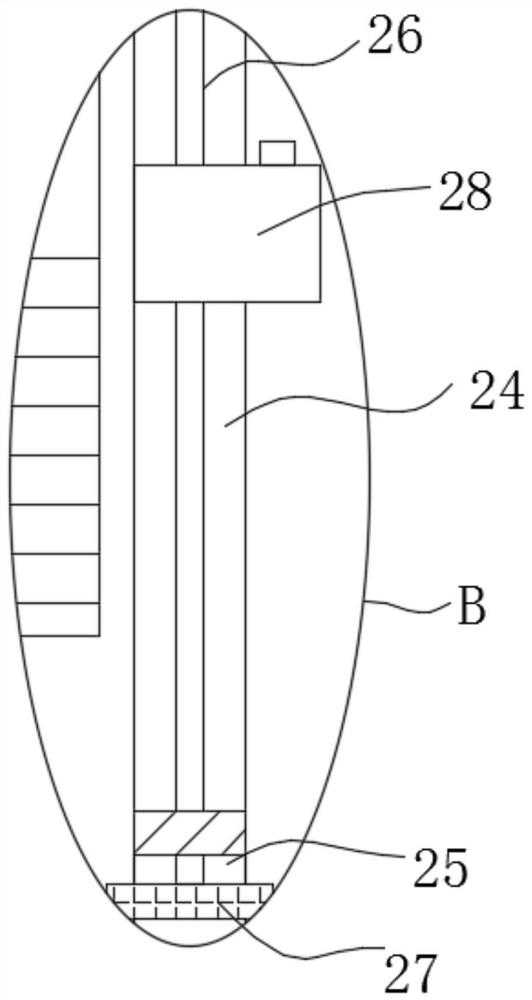

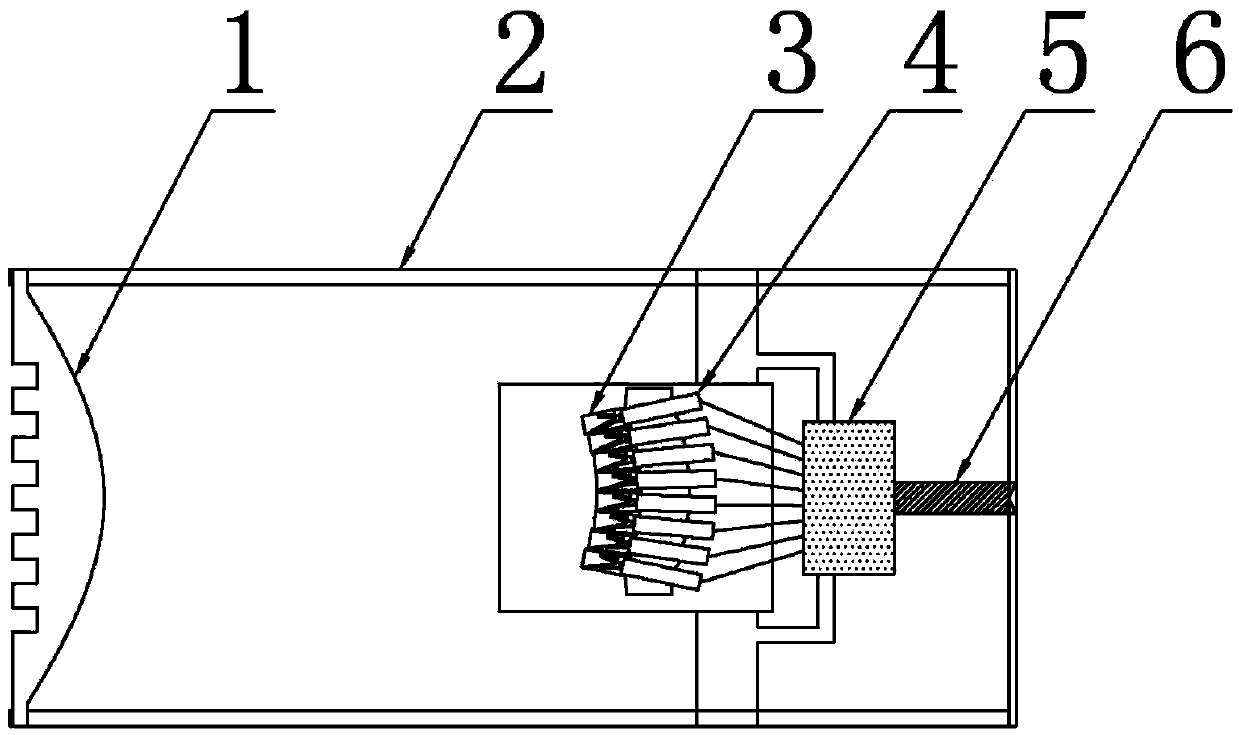

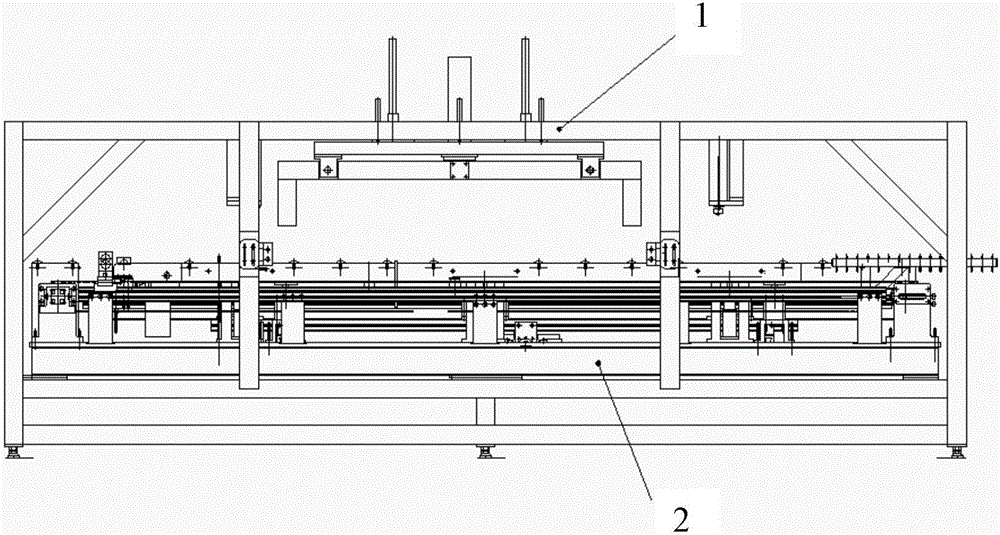

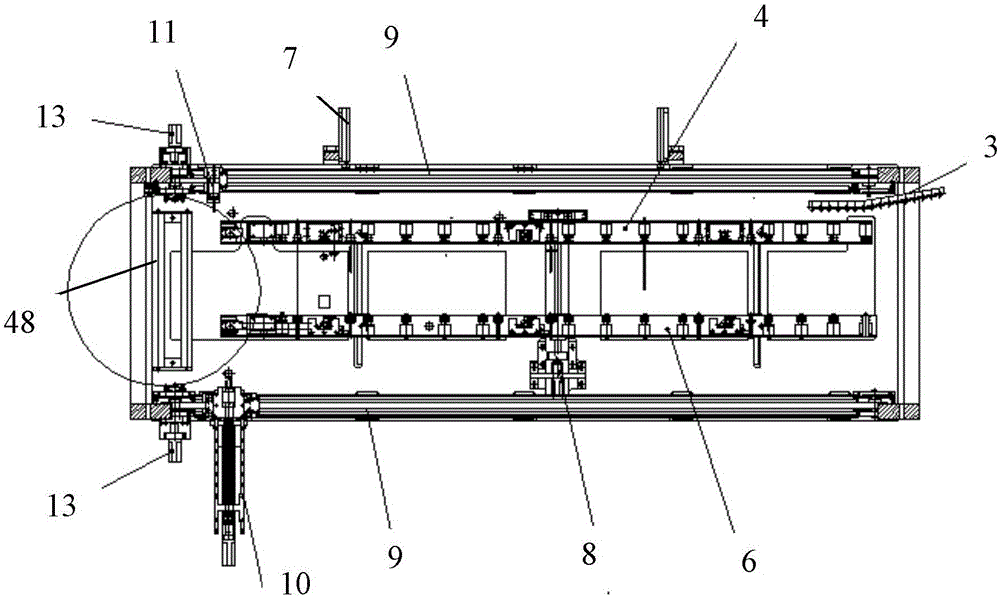

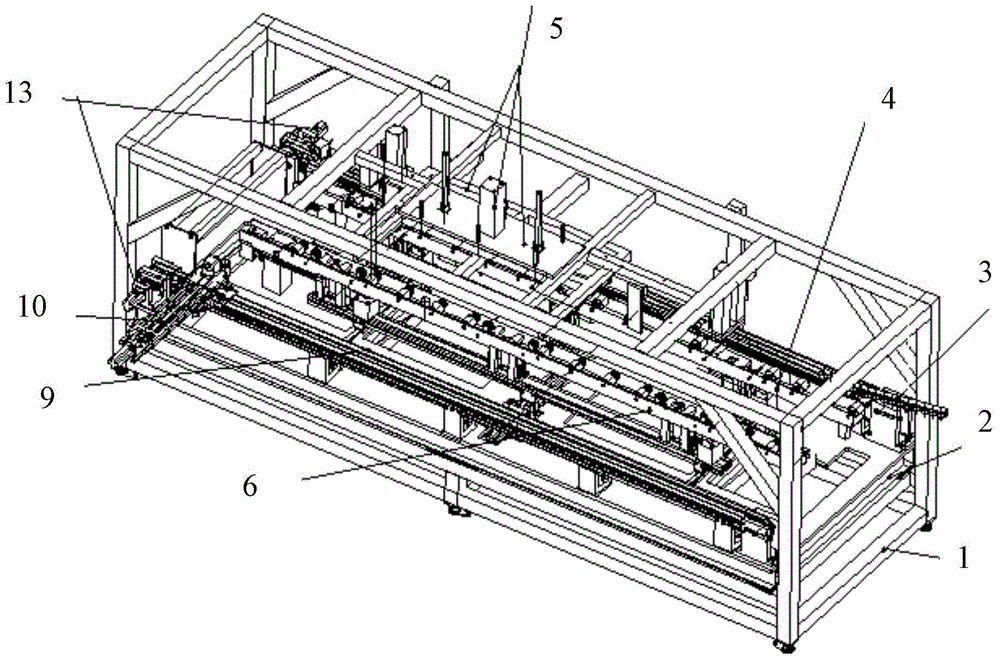

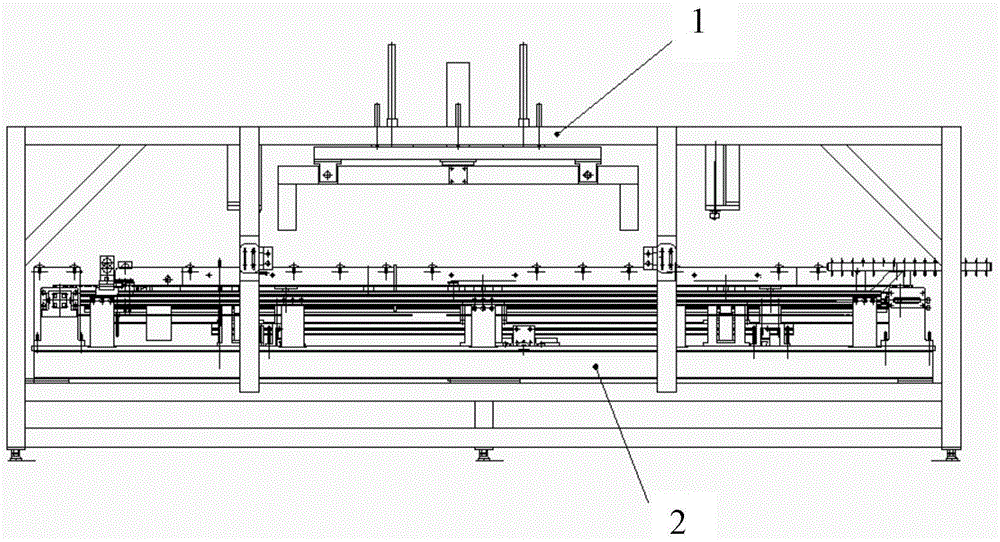

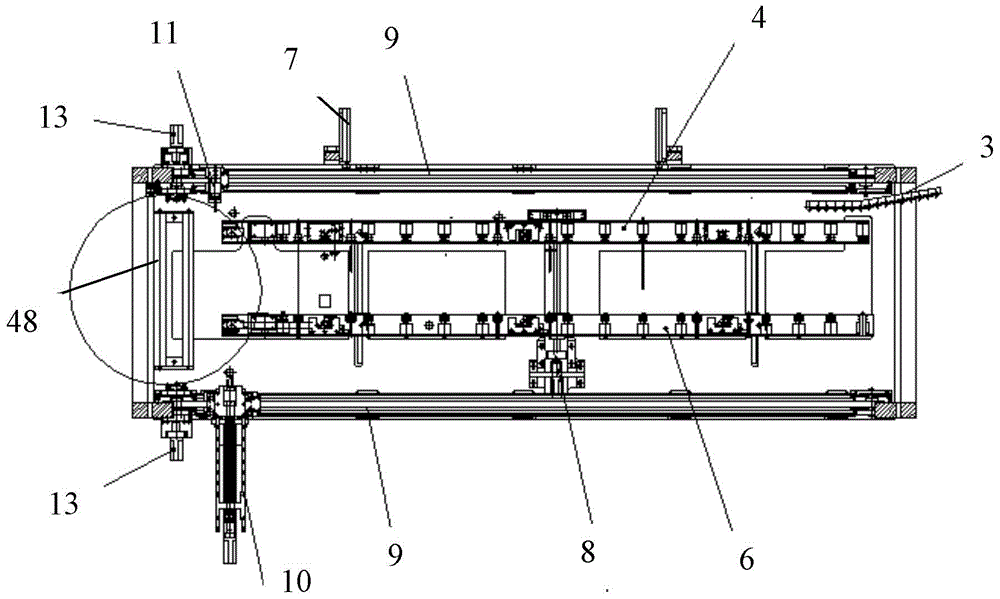

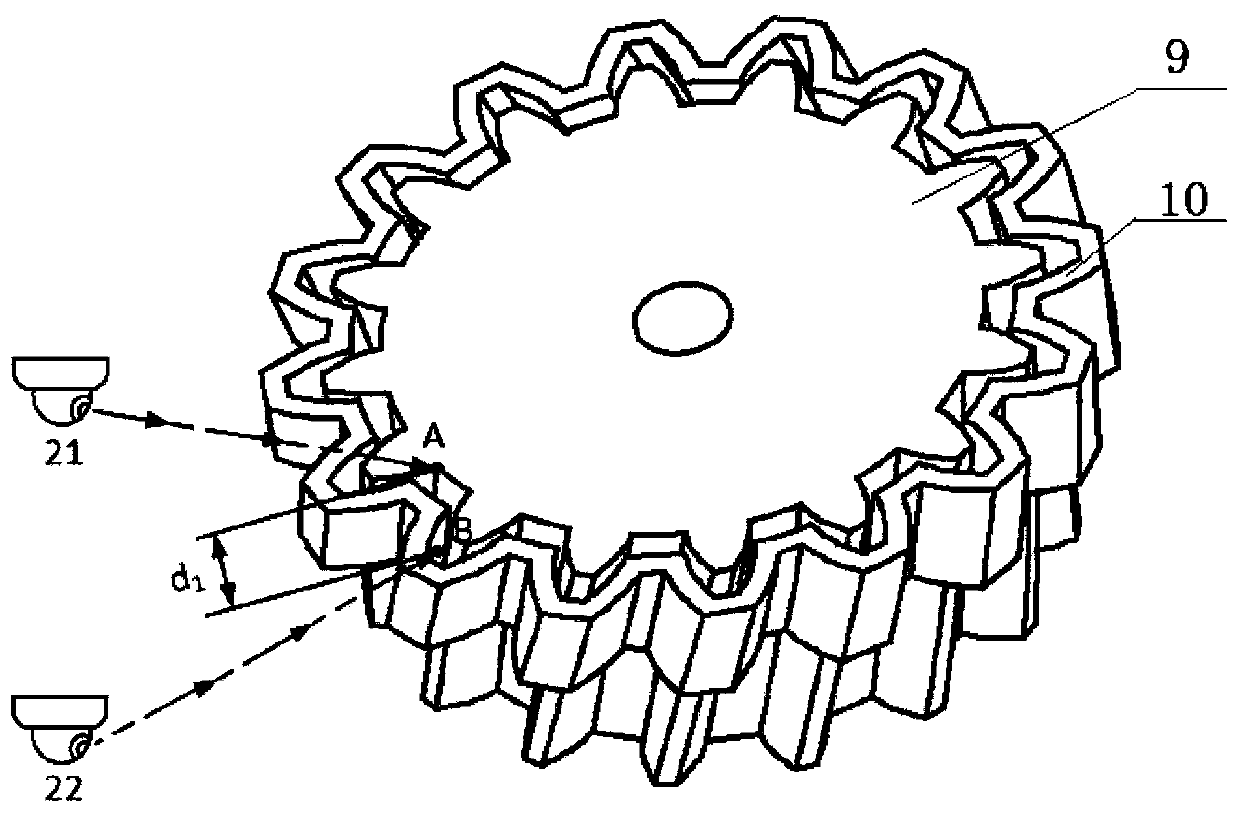

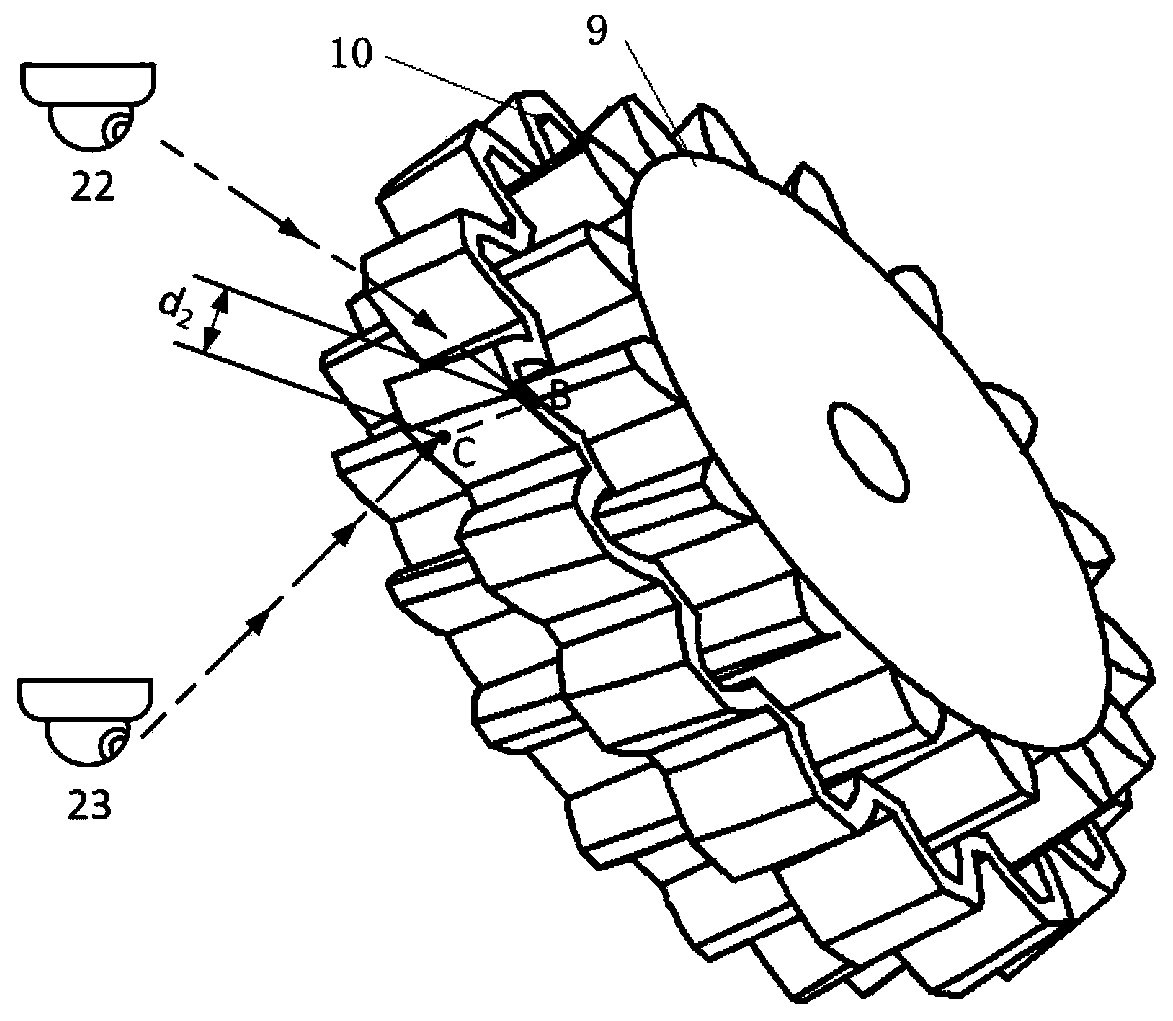

Battery clamping device and replacing device and method applied to autonomous cruising of unmanned aerial vehicle

ActiveCN106864766AAvoid changeReliable cooperationAnchoring installationsRemote controlled aircraftElectrical batteryUncrewed vehicle

The invention discloses a battery clamping device and a replacing device and method applied to autonomous cruising of an unmanned aerial vehicle to clamp and replace an unmanned aerial vehicle battery stably. Saw-toothed blocks are arranged on grippers and can be used for clamping the battery in a fastened mode, downward slipping of the battery during moving is effectively avoided, it can be guaranteed that the clamping depths and positions of the two sides of the battery are the same, and the situation that the clamping depths and positions are different, and consequentially the clamped battery deflects and cannot be mounted in a battery box or the unmanned aerial vehicle is avoided. According to the technical scheme, the battery clamping device comprises a clamping claw mechanism which comprises a clamping claw body; the clamping claw body is connected with a first clamping claw part and a second clamping claw part; the first clamping claw part is fixedly connected with the first gripper, and the second clamping claw part is fixedly connected with the second gripper; and the saw-toothed blocks are arranged on the opposite faces of the first gripper and the second gripper in a matched mode.

Owner:SHANDONG UNIV +1

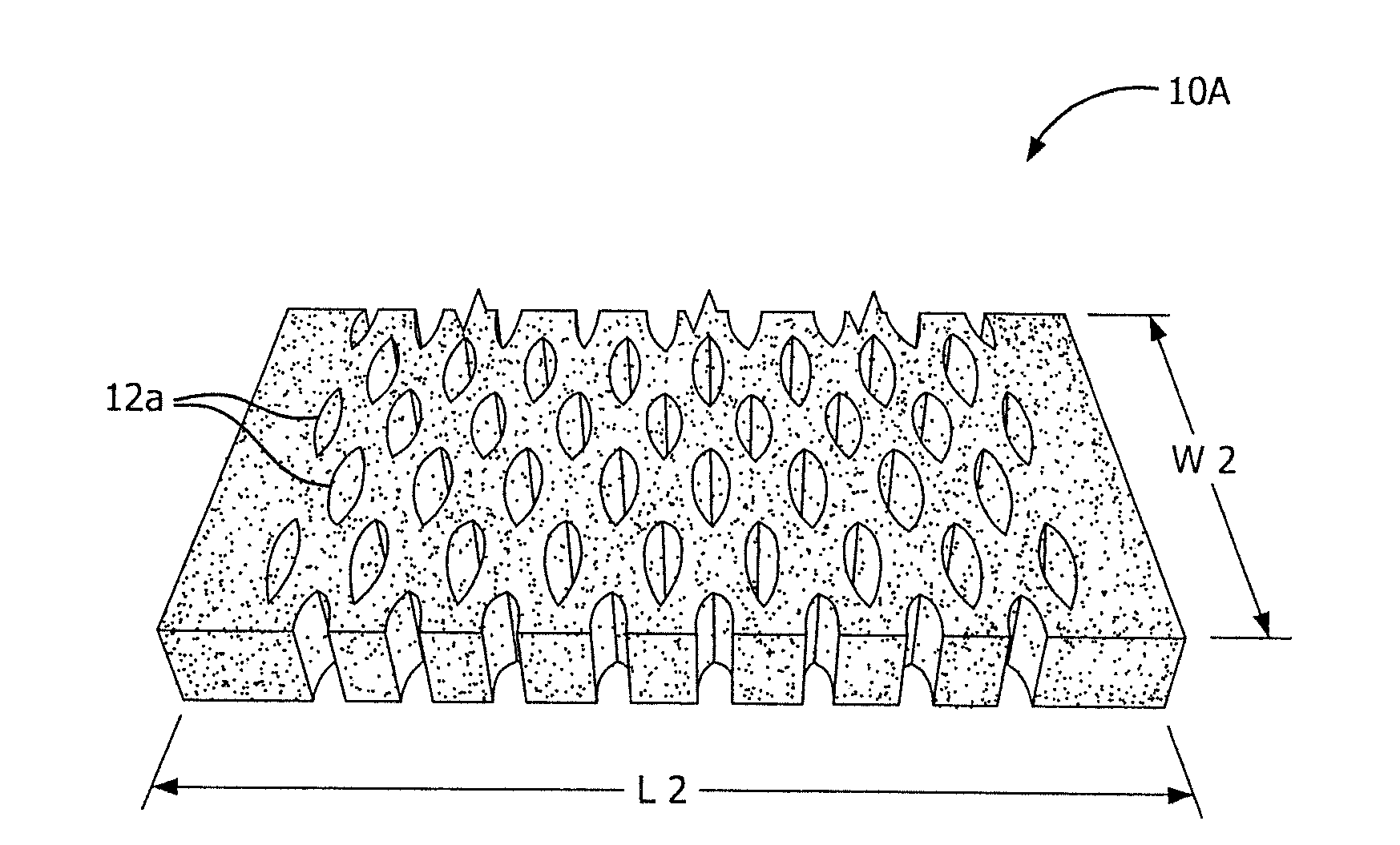

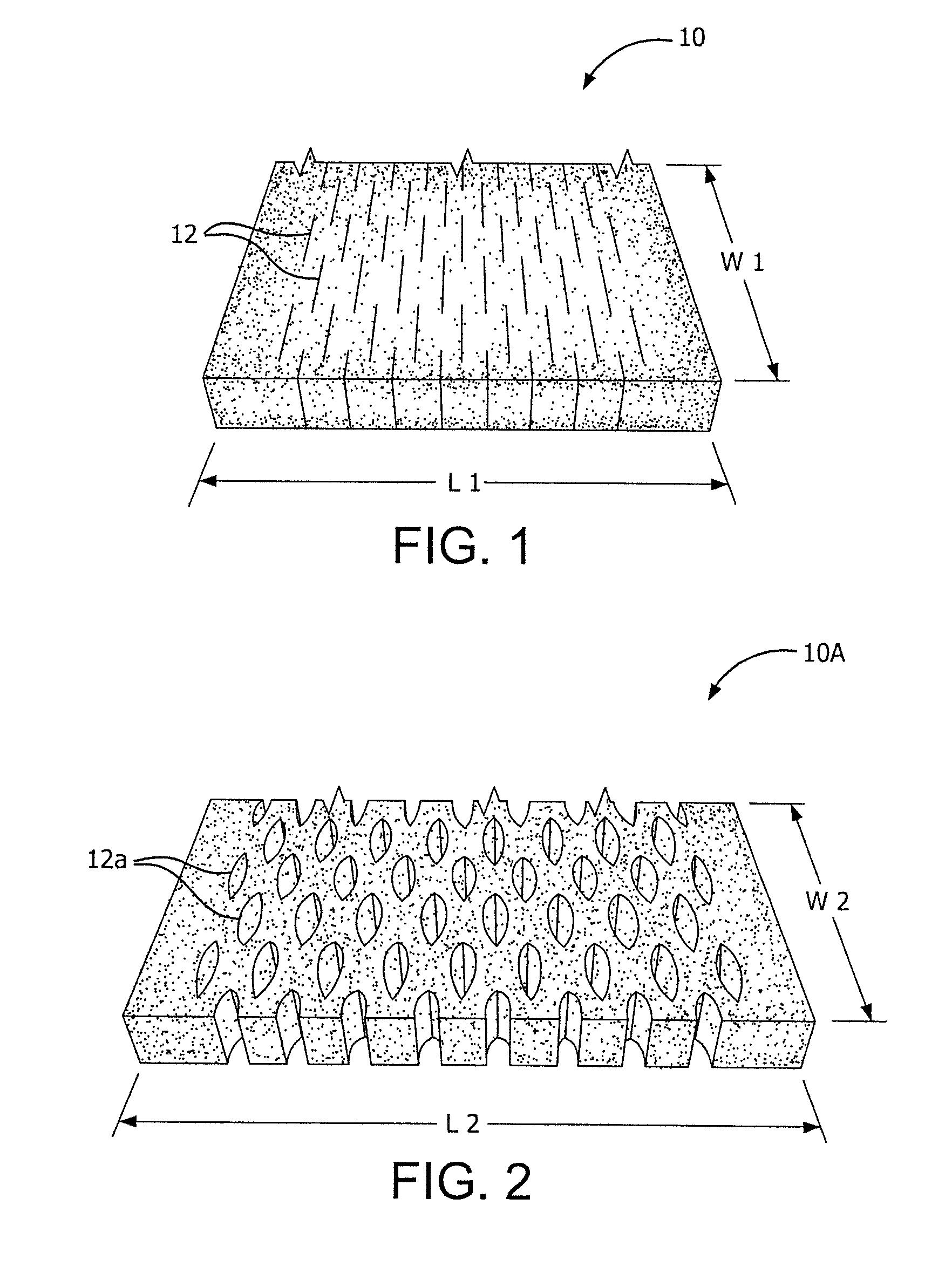

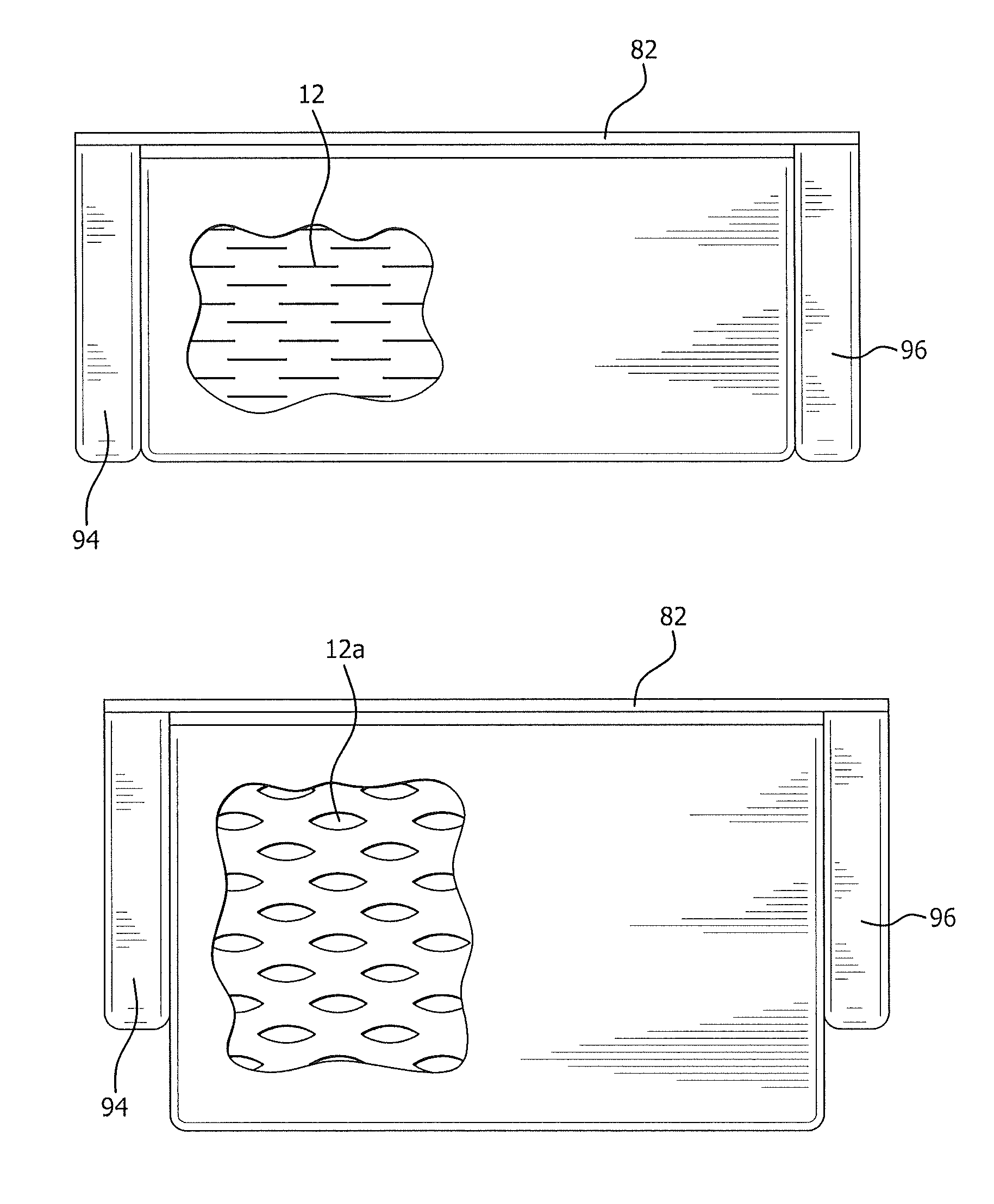

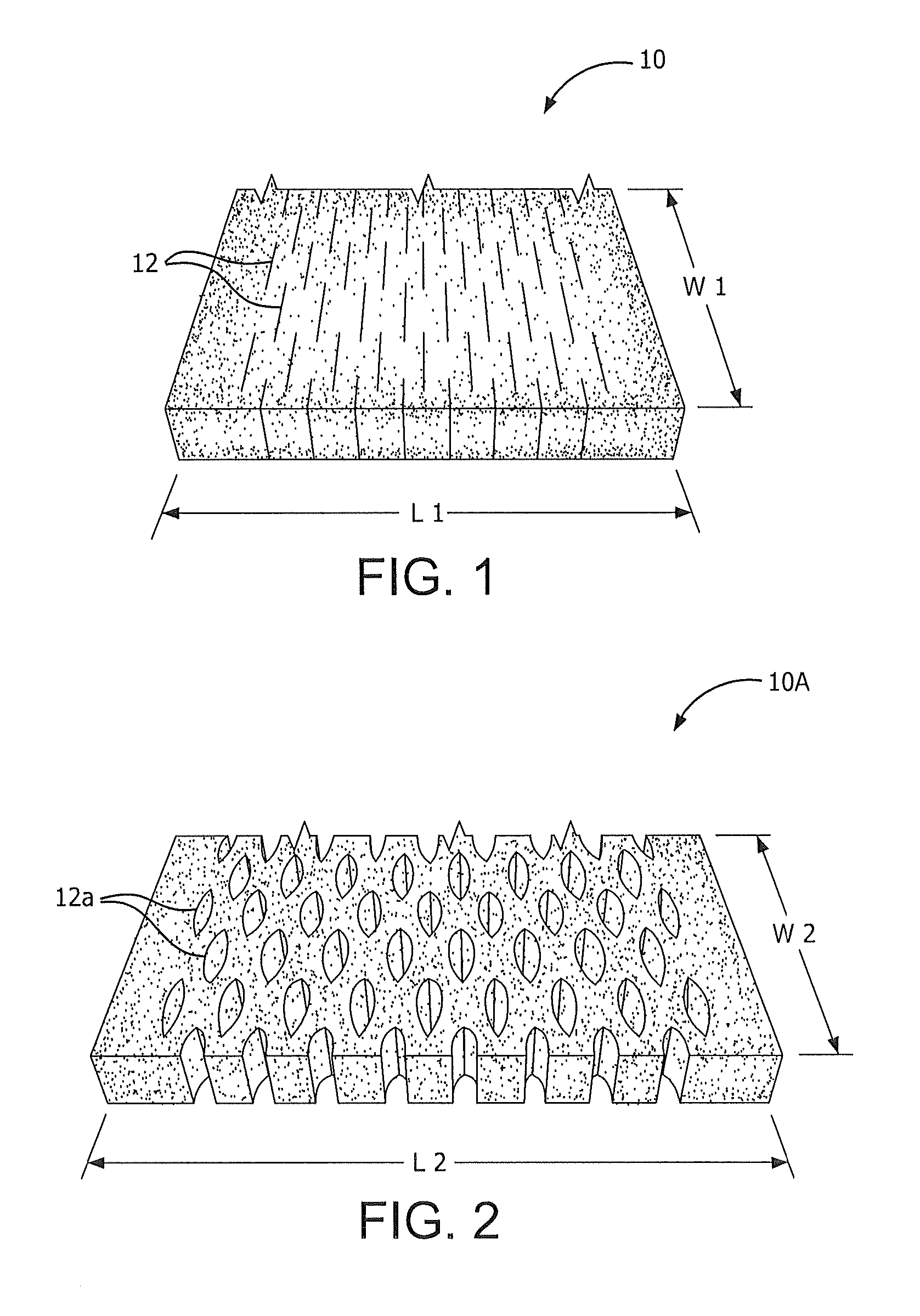

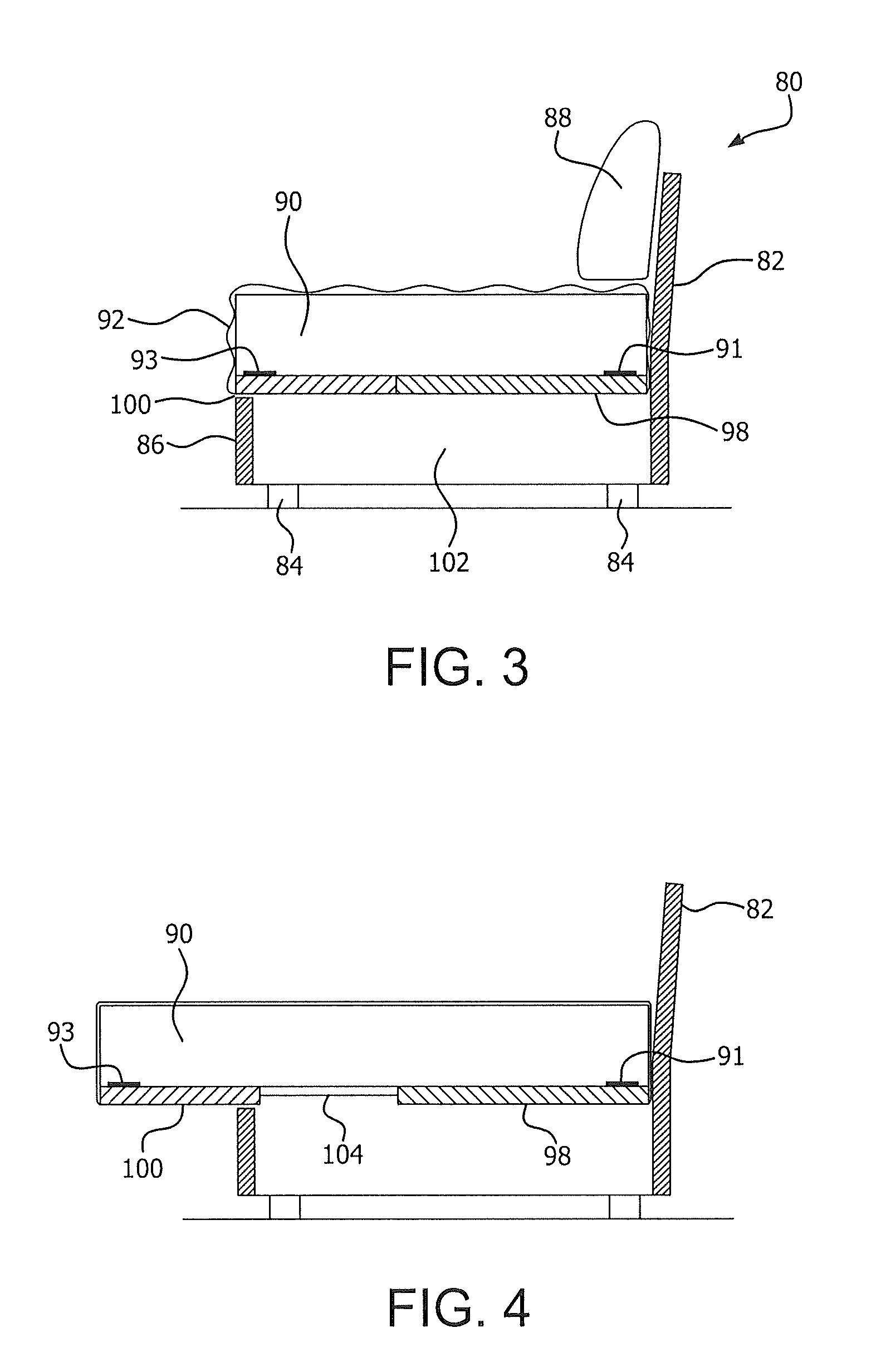

Convertible furniture with selectively expandable mattress cushion section(s)

InactiveUS20150305513A1Quantity minimizationSame depthStuffed mattressesSpring mattressesEngineeringCushion

A cushion, mattress or mattress section for a convertible furniture article defines a plurality of apertures, such as slits or slots or recesses, extending into or through the cushion or mattress section that are cut in a direction at an angle to the first length of the mattress section. The cushion or mattress section expands from its first length to a second length that is longer than the first length upon applying a stretching force to the cushion or mattress section and thereby positioning the mattress section into the open or sleeping configuration. Expansion is due to resilience of the material forming the mattress or mattress section in combination with opening of the apertures. The sleeping surface of the mattress or mattress section may remain substantially planar in both the open (sleeping) position and closed (seating) position.

Owner:TIFFANY & TIFFANY DESIGNERS

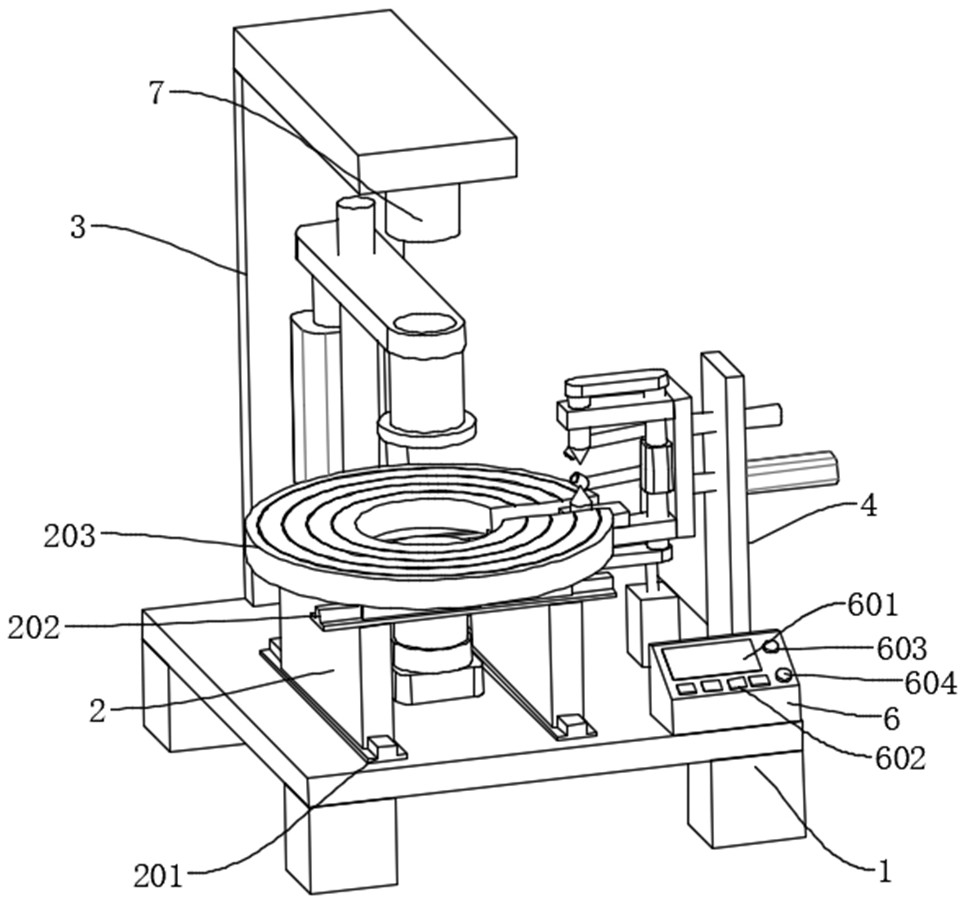

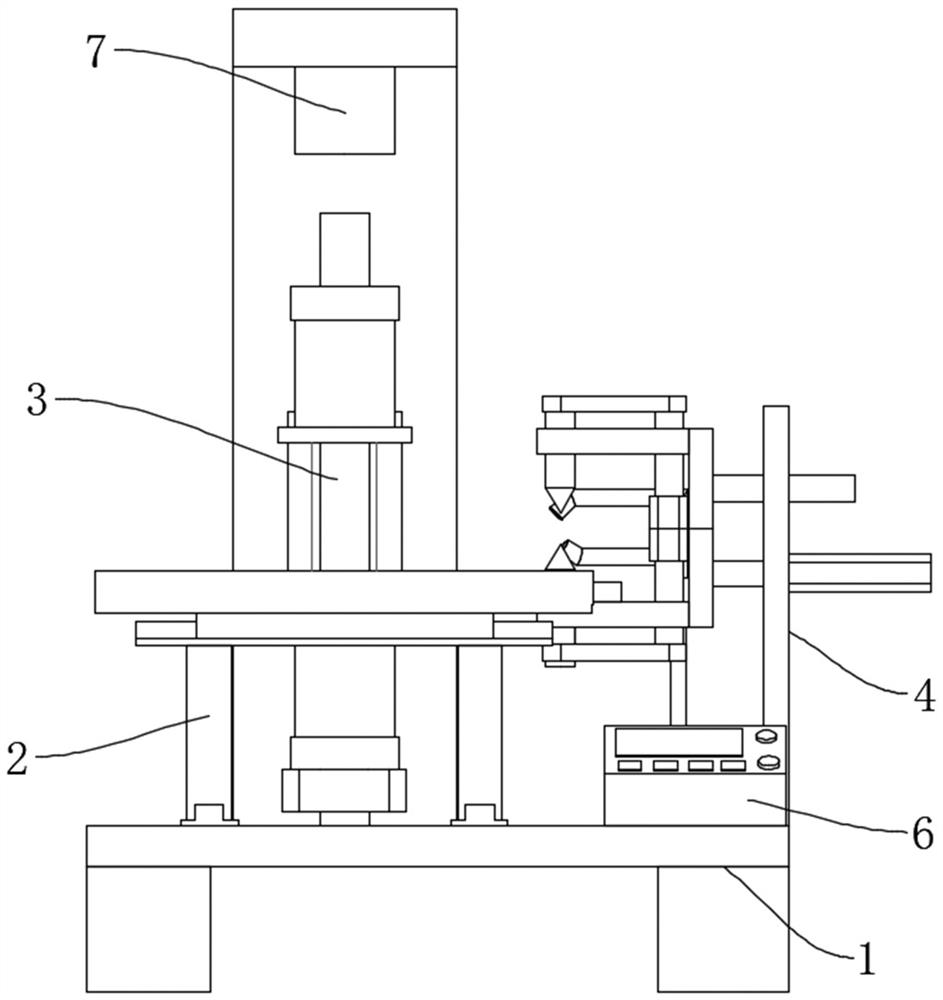

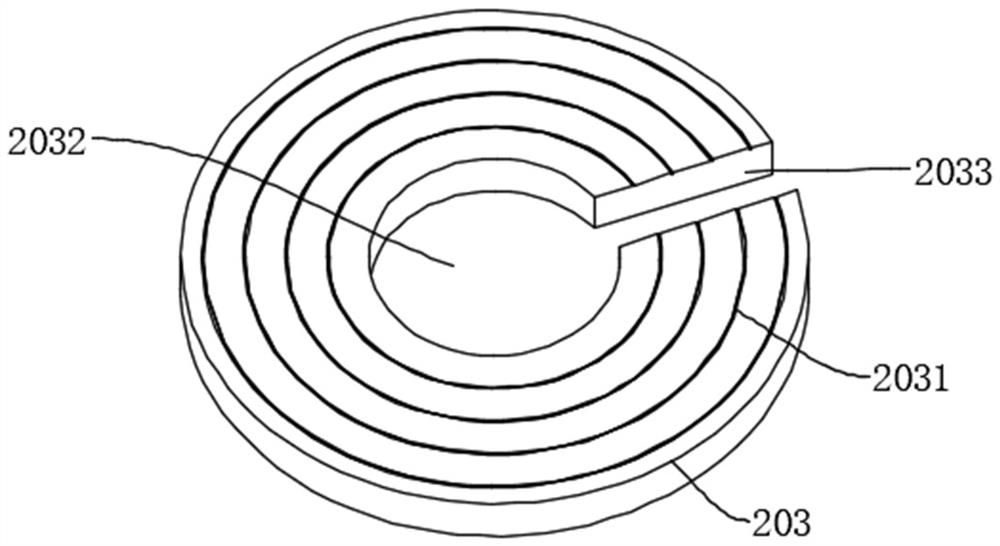

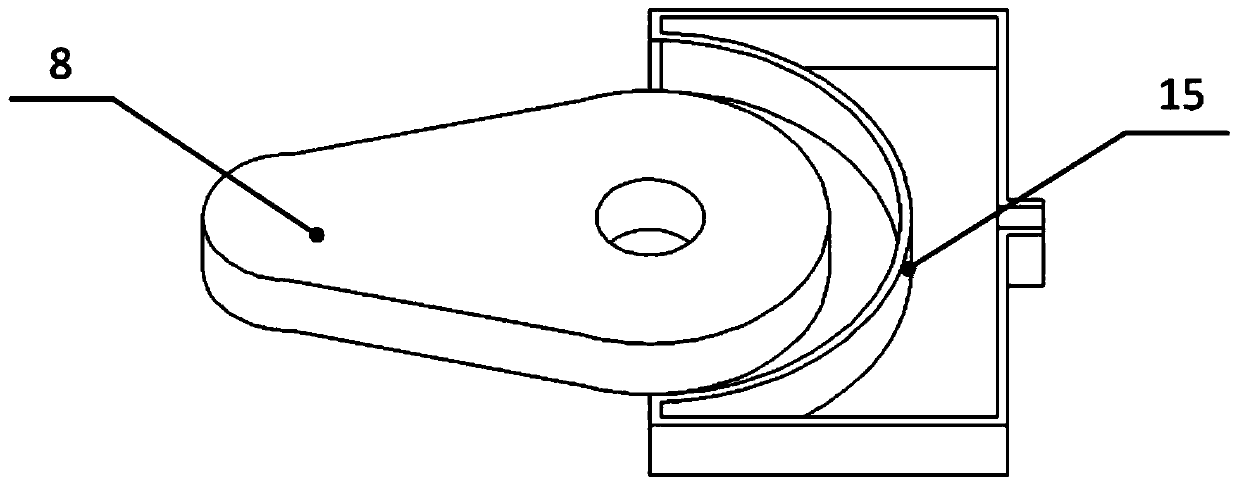

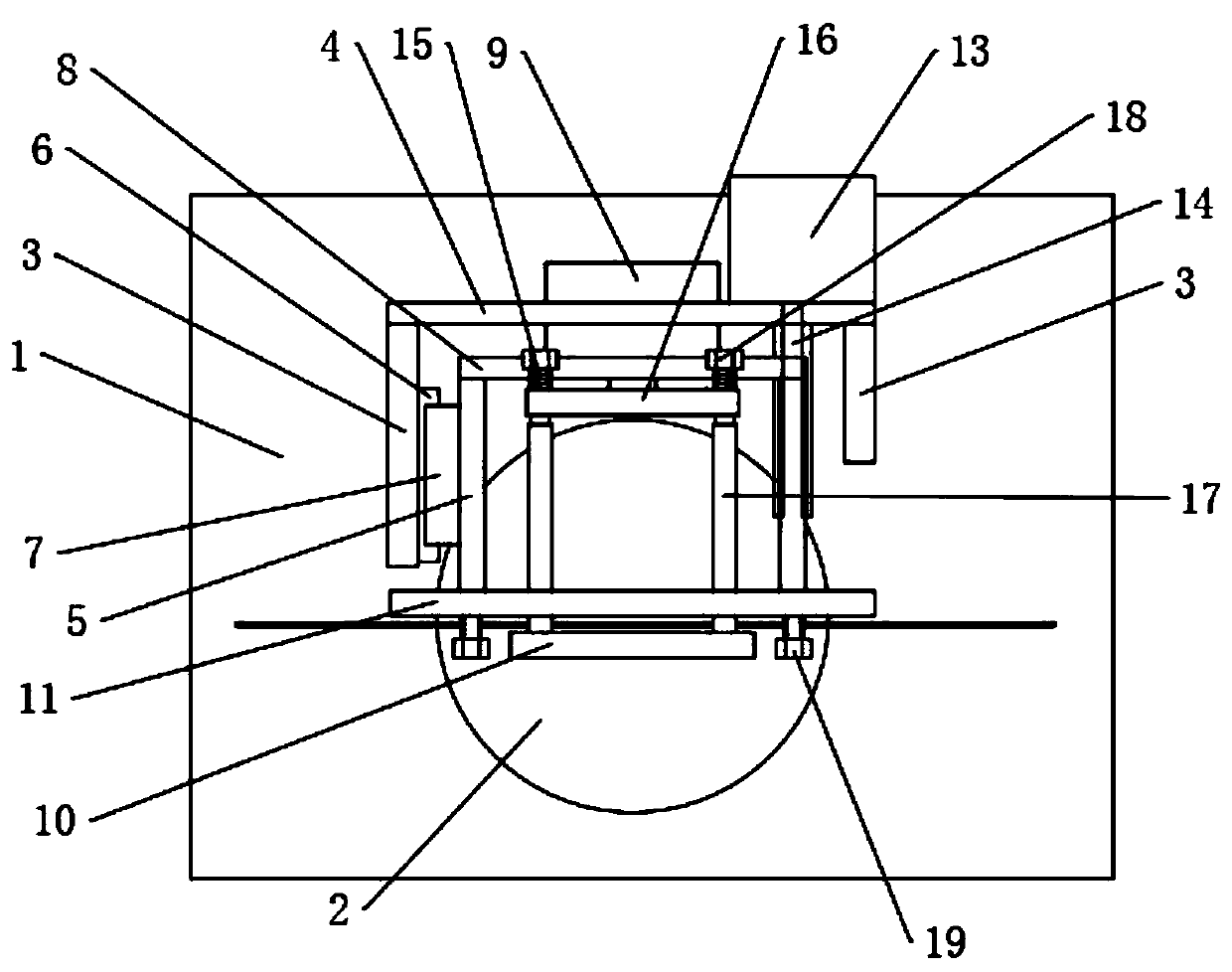

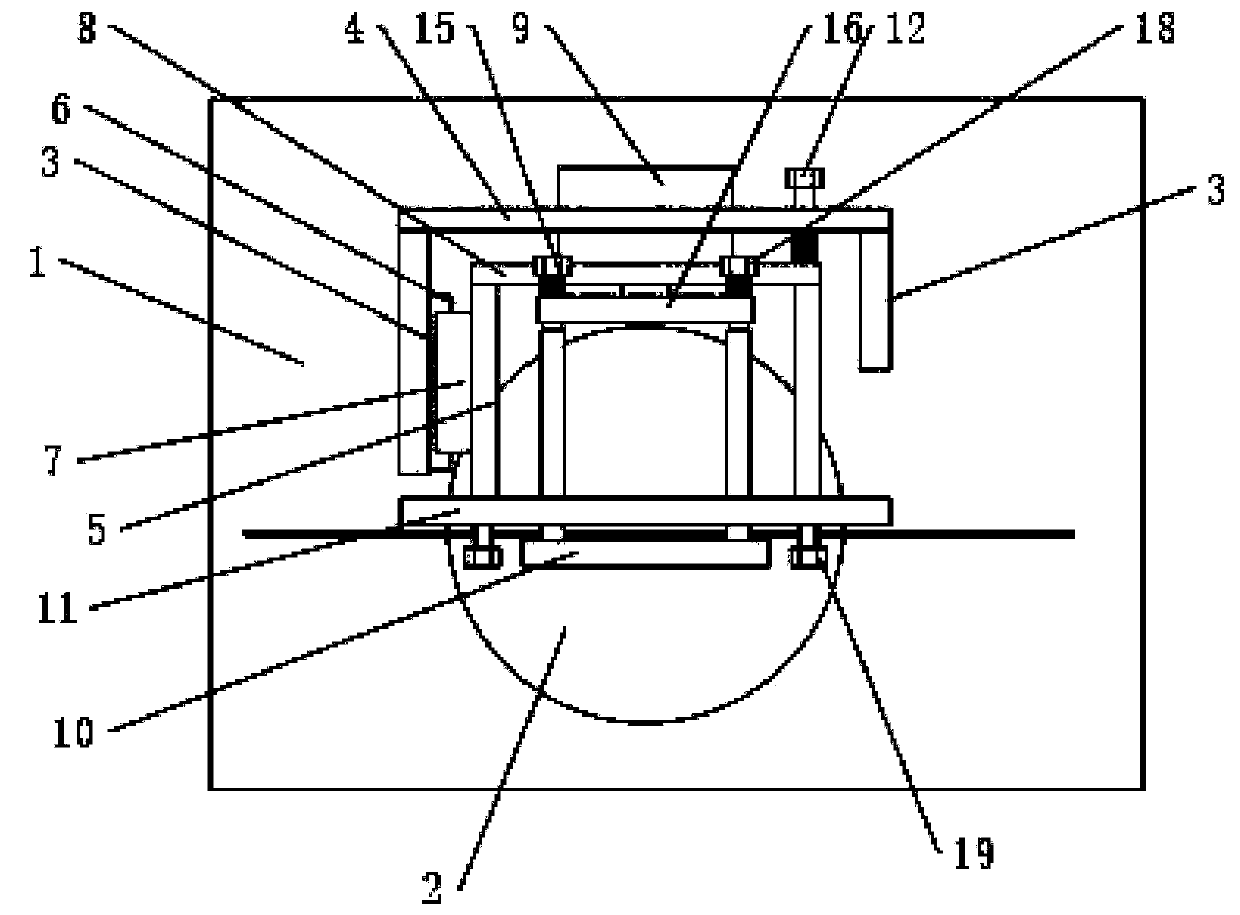

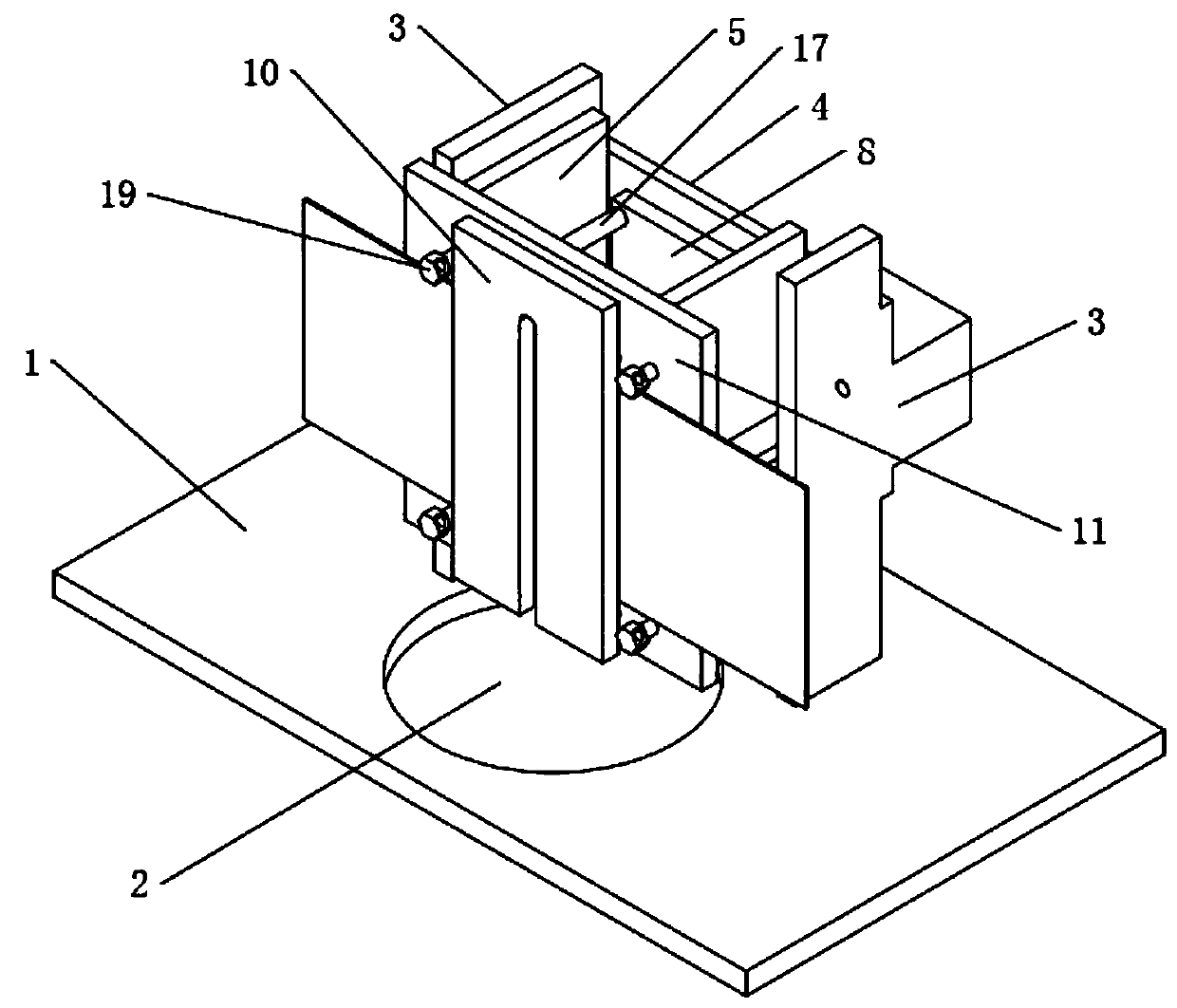

Wafer scribing device for machining and using method thereof

InactiveCN113571453ARealize the function of alignmentEasy to placeSemiconductor/solid-state device manufacturingWaferMachining

The invention discloses a wafer scribing device for machining and a using method thereof. The wafer scribing device comprises a base, wherein an adjusting mechanism is arranged in the center of the top of the base, a control panel is connected to one side of the front end of the top of the base through screws, the adjusting mechanism comprises a longitudinal linear sliding rail pair, a transverse linear sliding rail pair and a placement disc, and the transverse linear sliding rail pair is arranged at the top of the longitudinal linear sliding rail pair. Through transverse movement of the longitudinal linear sliding rail pair, longitudinal movement of the transverse linear sliding rail pair and cooperation with the alignment equipment body, the wafer alignment function is achieved, initial placement of wafers is facilitated through arrangement of annular scales and receding holes, and then alignment work of the wafers is facilitated; and the wafer can be fixed and driven to rotate through a clamping assembly, and a scribing assembly which moves up and down synchronously is matched to rapidly complete scribing of the two sides of the wafer, so that the scribing efficiency is improved, and it can be guaranteed that the scribing depths of the front and the back are the same.

Owner:ZHENGZHOU UNIV OF IND TECH

Convertible furniture with selectively expandable mattress cushion section(s)

InactiveUS9095221B1Quantity minimizationSame depthStuffed mattressesSpring mattressesEngineeringCushion

A cushion, mattress or mattress section for a convertible furniture article defines a plurality of apertures, such as slits or slots or recesses, extending into or through the cushion or mattress section that are cut in a direction at an angle to the first length of the mattress section. The cushion or mattress section expands from its first length to a second length that is longer than the first length upon applying a stretching force to the cushion or mattress section and thereby positioning the mattress section into the open or sleeping configuration. Expansion is due to resilience of the material forming the mattress or mattress section in combination with opening of the apertures. The sleeping surface of the mattress or mattress section may remain substantially planar in both the open (sleeping) position and closed (seating) position.

Owner:TIFFANY & TIFFANY DESIGNERS

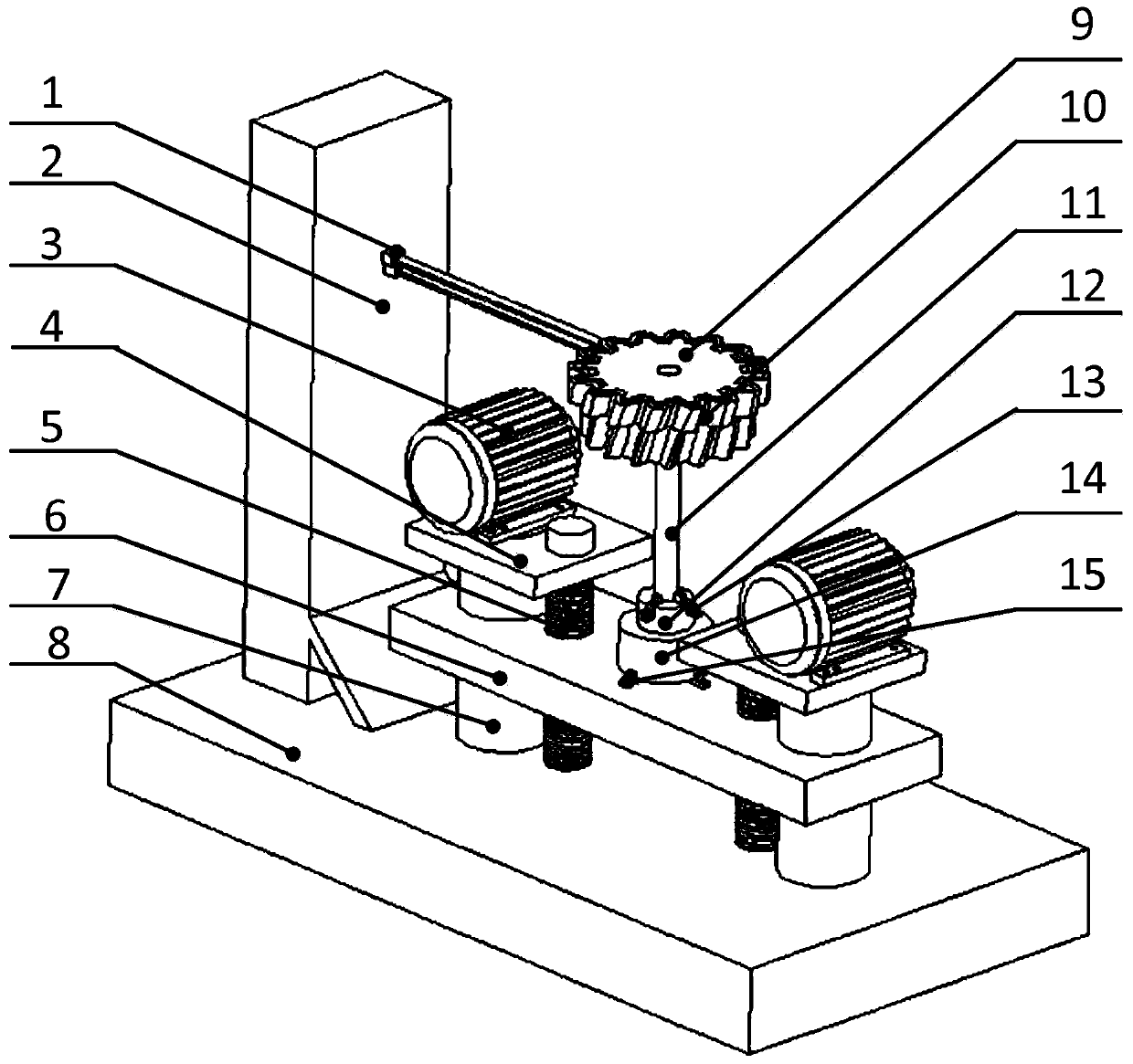

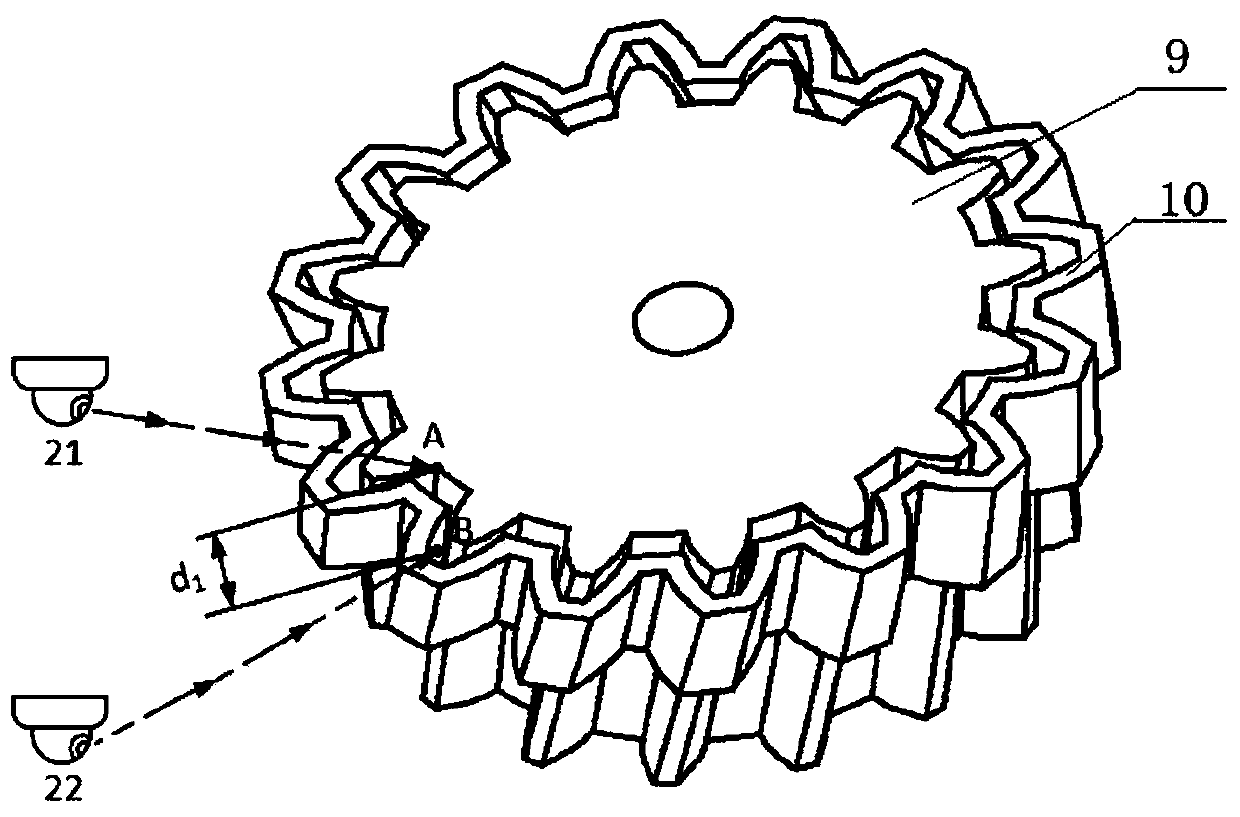

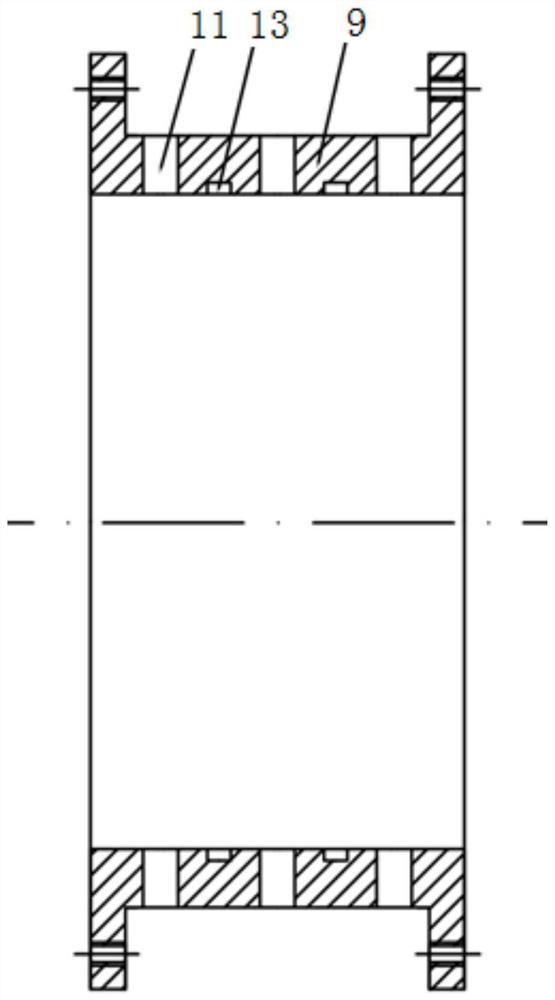

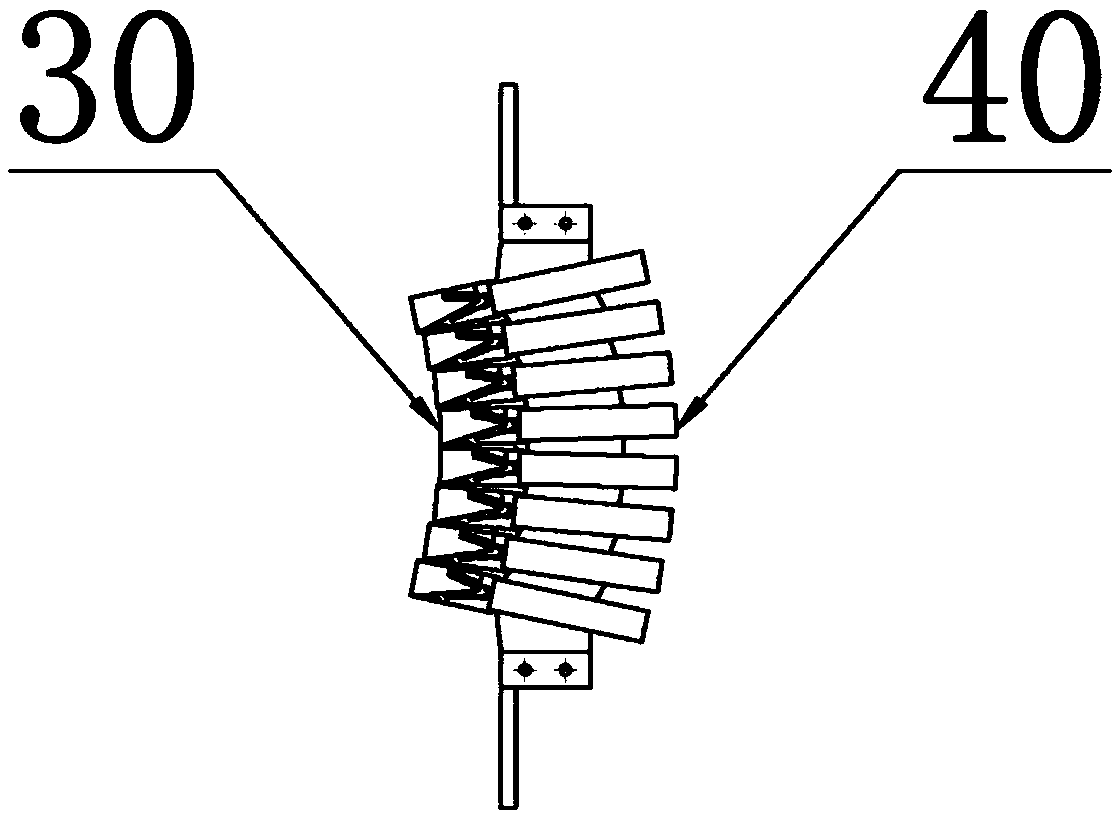

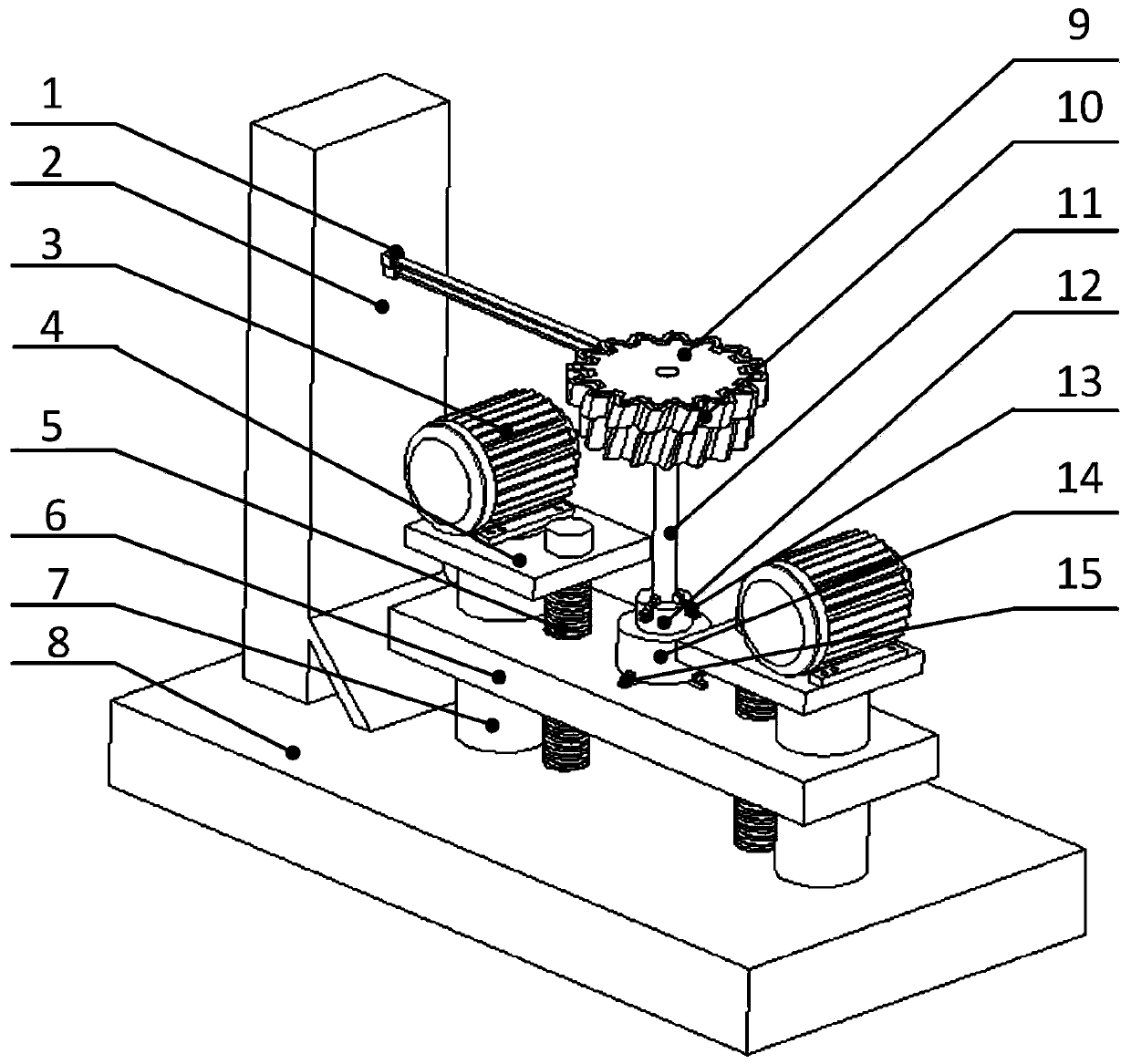

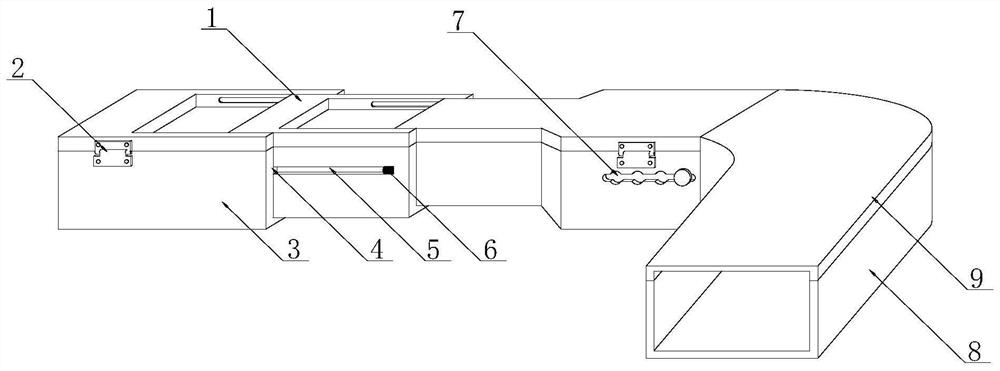

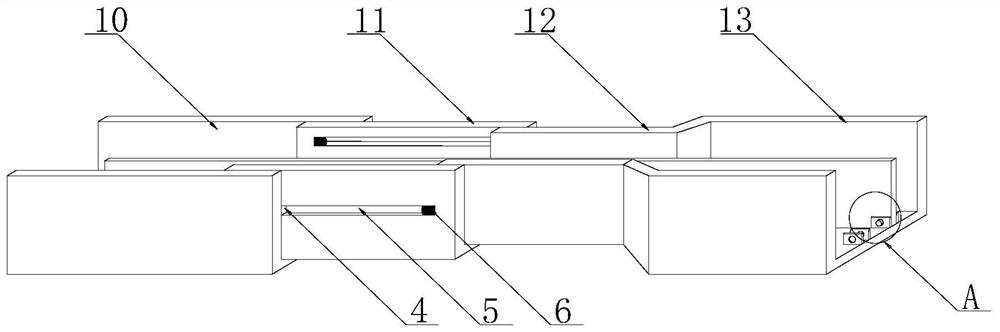

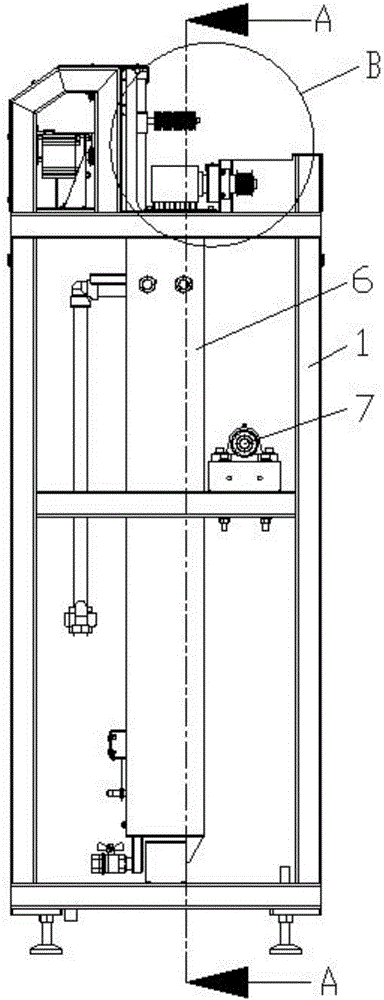

Layer-by-layer heating device for cylindrical bevel gears and method thereof

ActiveCN109825694AGuaranteed uniformityEvenly heatedIncreasing energy efficiencyFurnace typesEngineeringTooth surface

The invention relates to a layer-by-layer heating device for cylindrical bevel gears. The device comprises a heating device, a rotating platform device, a worktable, a lifting device, a vertical powersupply table, a base and multiple infrared temperature measuring cameras; the heating device comprises a profiling induction coil and an induction coil bracket; one end of the induction coil bracketis vertically fixed on the vertical power supply table; the profiling induction coil is fixed at the other end of the induction coil bracket; the profiling induction coil is positioned above the rotating platform device; the rotating platform device is used for fixedly supporting the cylindrical bevel gears; the rotating platform device is mounted on the worktable; the worktable is mounted on thelifting device; the lifting device is fixed on the base; and the vertical power supply table is vertically fixed on the base. The invention further provides a layer-by-layer heating method for the cylindrical bevel gears; the influence caused by the end surface effect is effectively reduced; the depth uniformity of tooth surface hardening layers is improved; and the service life of the cylindricalbevel gears is prolonged.

Owner:TAICANG FANSHENG ELECTRONICS TECH CO LTD

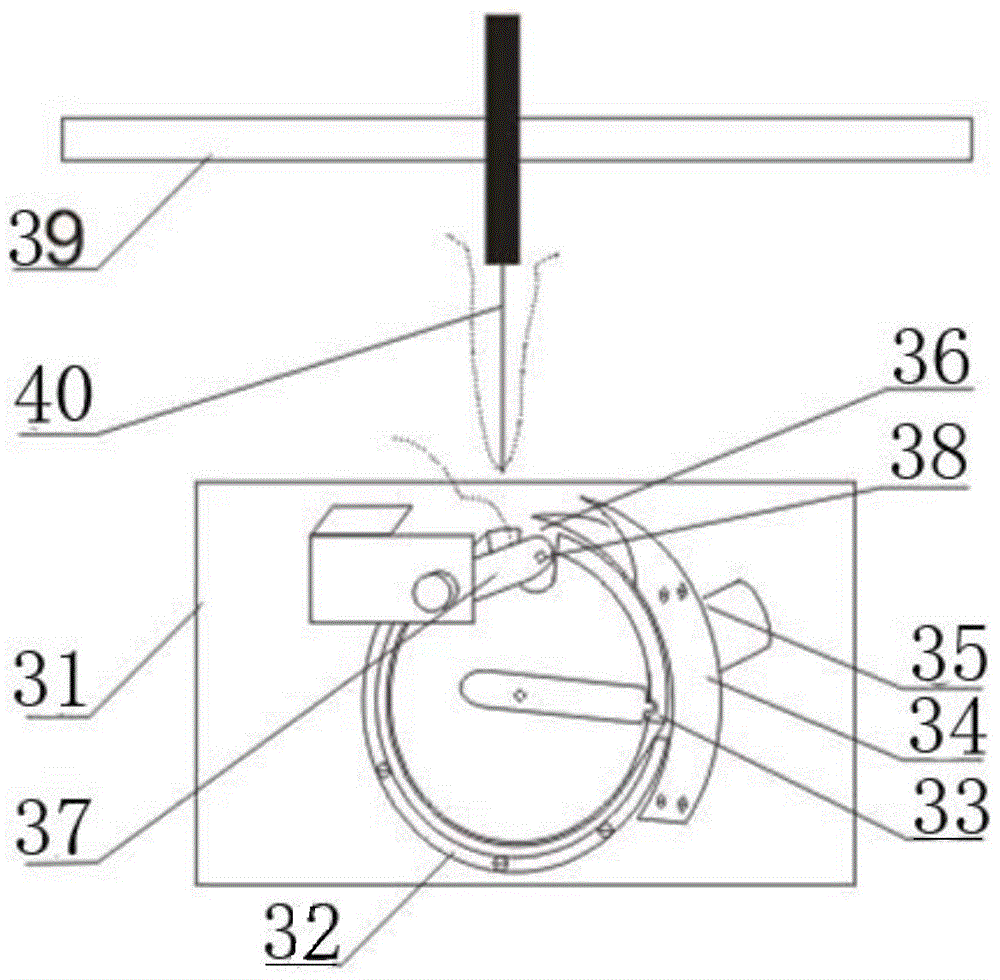

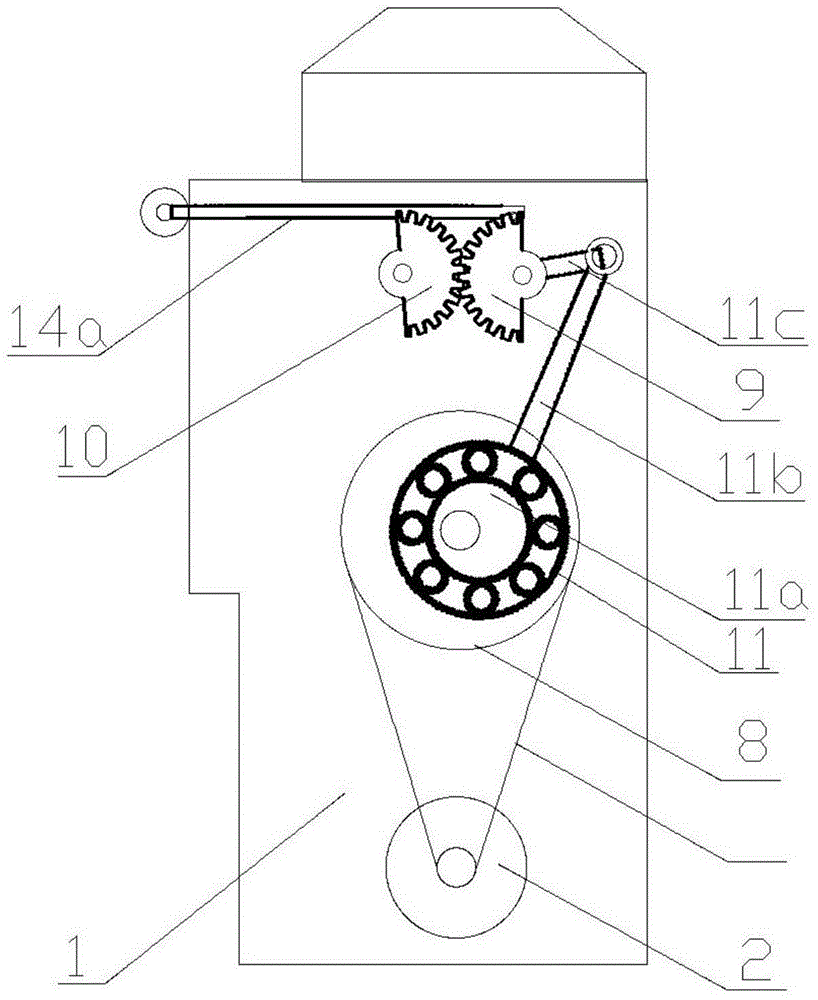

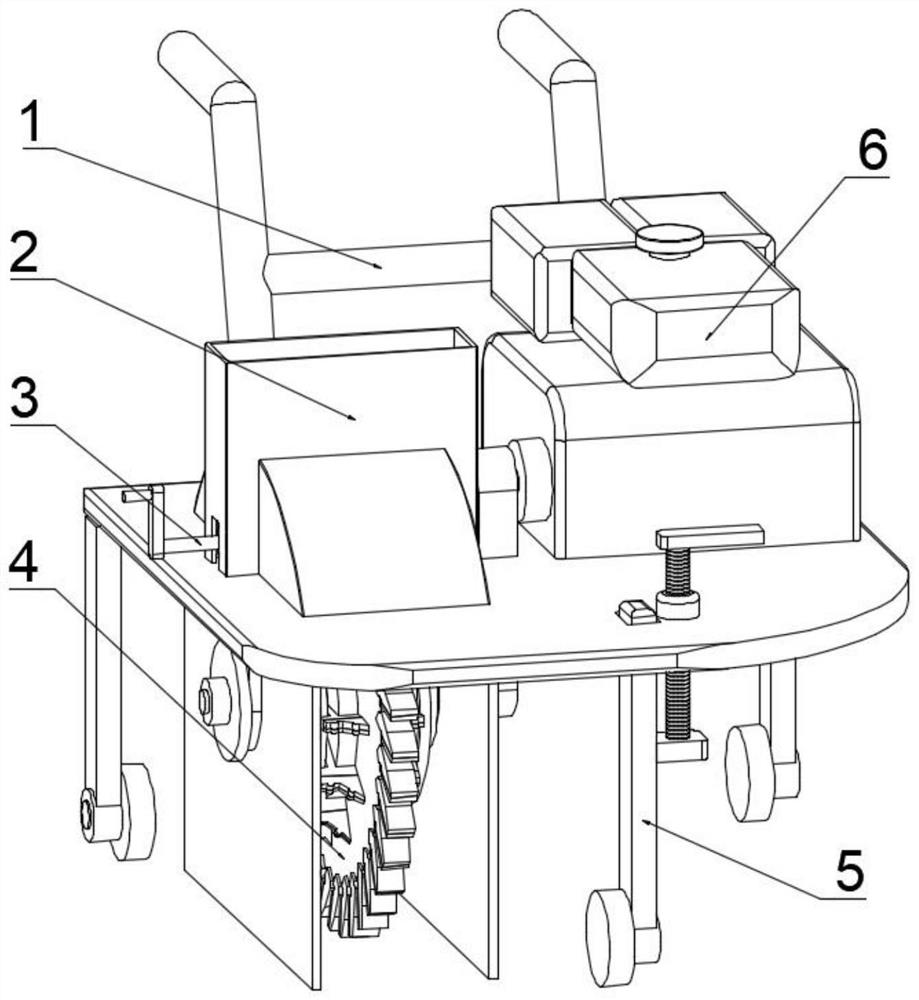

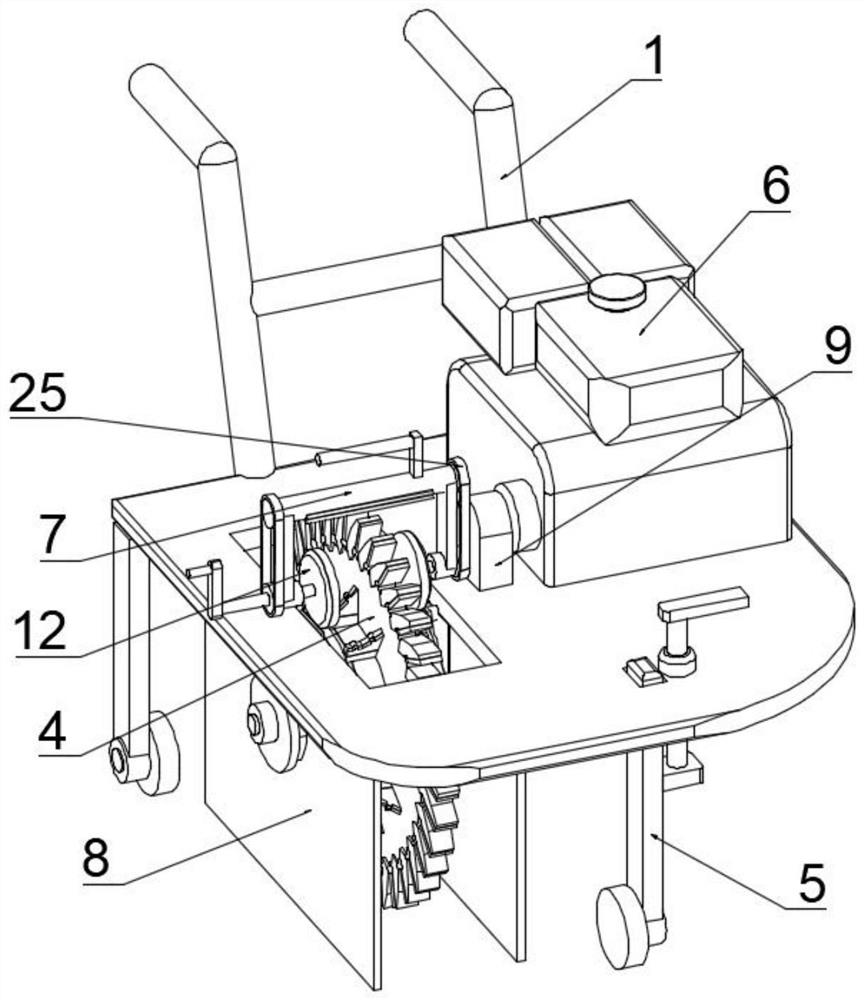

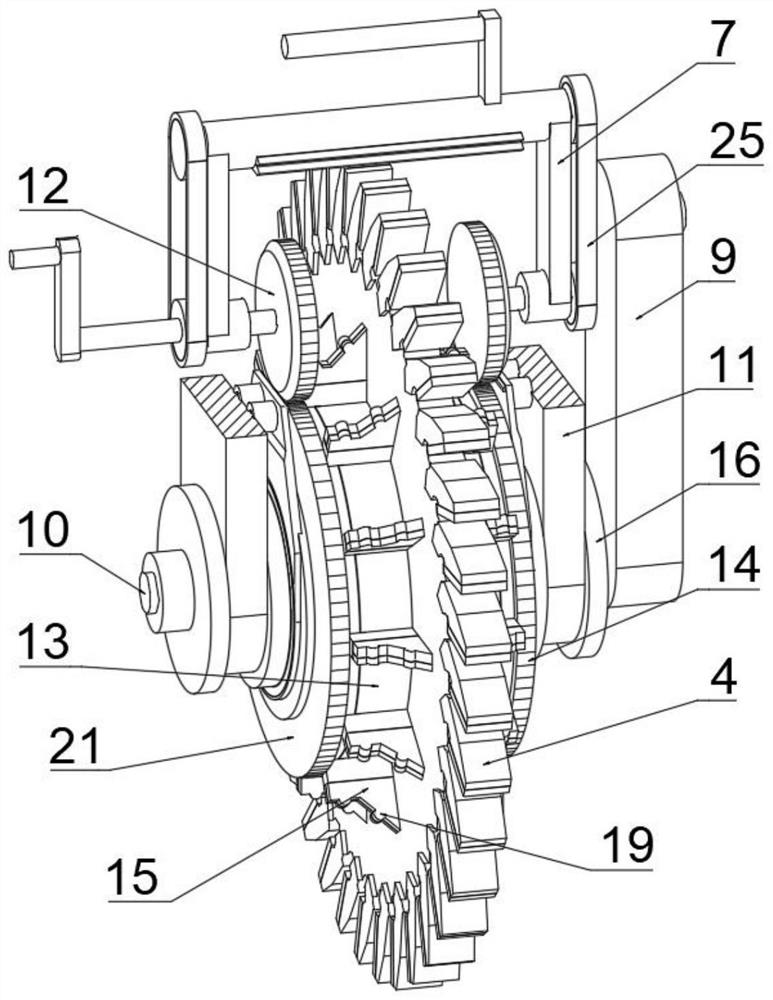

Steel pipe end grooving device

The invention relates to a grooving device, in particular to a steel pipe end grooving device. According to the technical problem, the steel pipe end grooving device saves manpower, can erect a steelpipe straightly and has the same grooving depth. The steel pipe end grooving device comprises a mounting frame, a grooving assembly and a rotary clamping assembly, wherein the grooving assembly is mounted on the mounting frame and is used for grooving in a sliding manner; and the rotary clamping assembly is mounted on the mounting frame and is used for clamping in a sliding manner. According to the steel pipe end grooving device, the steel pipe can be grooved through the grooving assembly, people can use the steel pipe end grooving device more conveniently, the steel pipe needing to be groovedcan be clamped by the rotary clamping assembly, people can take down the grooved steel pipe to conduct replacement through the rotary clamping assembly while grooving is conducted, and through wedge-shaped teeth, a ratchet wheel, a first bevel gear and a second bevel gear, people do not need to manually rotate a circular ring to replace the steel pipe when grooving the end part of the steel pipeby using equipment.

Owner:佛山市南海岐丰钢管有限公司

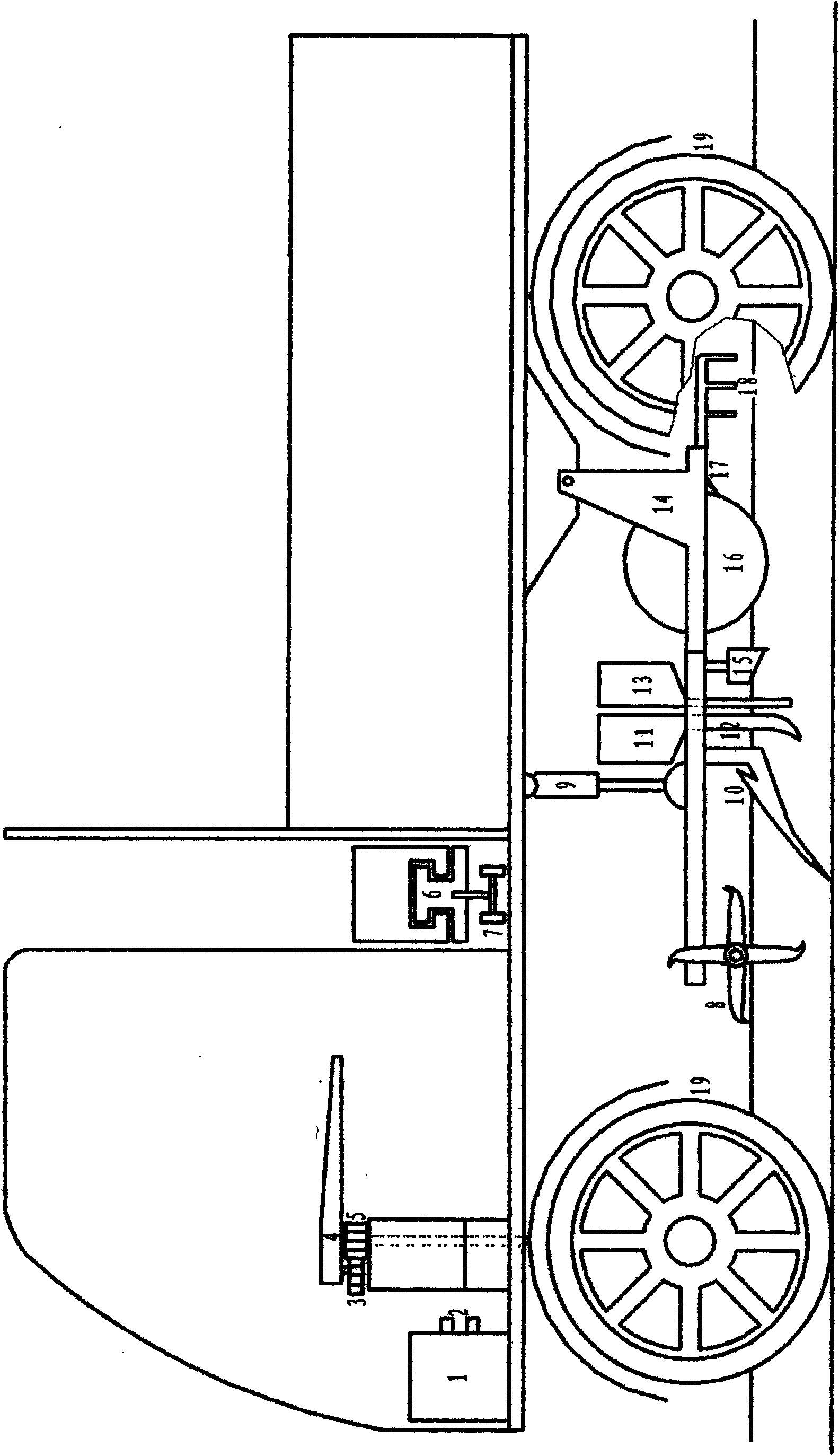

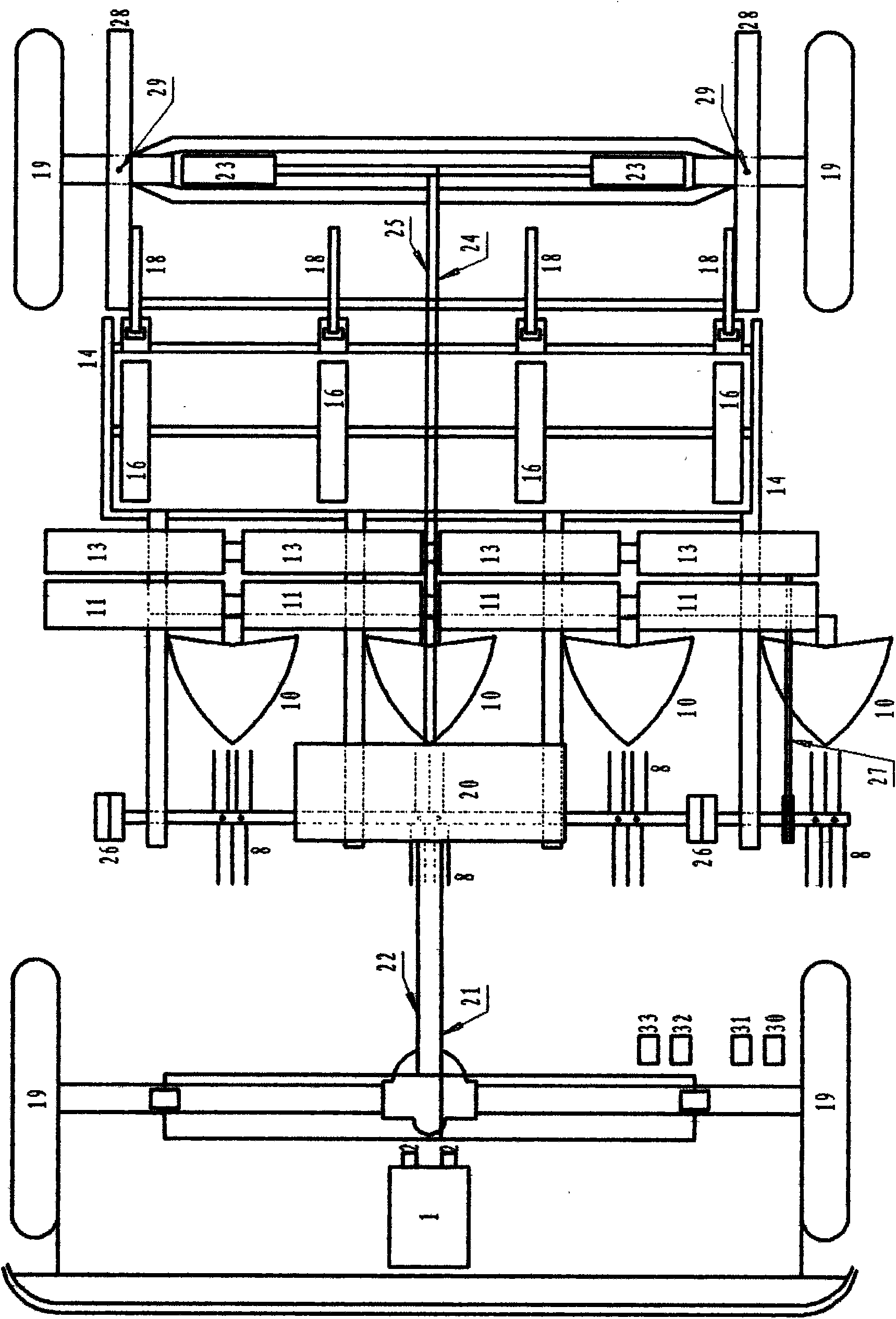

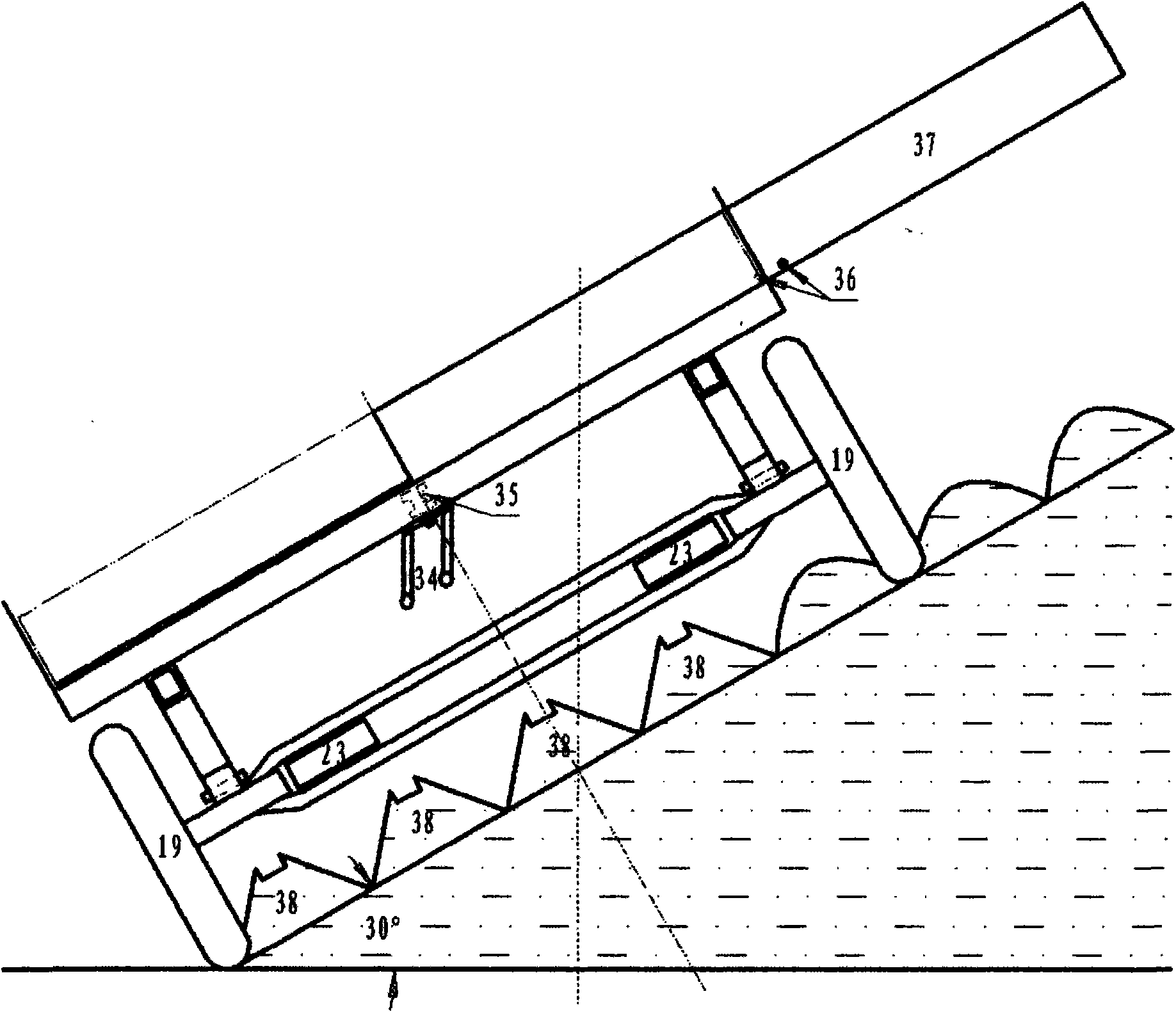

Multifunction hydraulic agricultural vehicle

The mechanical transmission of the vehicle all adopts hydraulic transmission. A walking part of the vehicle adopts a single coupling shaft and a double coupling shaft and forms the situation of being wheel-by-wheel and power-by-power (four-wheel and four-drive). A front shaft is a single coupling shaft, an arch bridge is upward and the central part is provided with a vertical shaft. The function of the vertical shaft is to move two wheels from transverse to consequent to 90 degrees, the wheels rotates under stress application, the vehicle body can be pulled, a back wheel is taken as a central point to change the front of the vehicle into the back thereof, thus completing 180-dgree turn and ensuring that the vehicle takes place exactly and returns back to the cultivated direction and position after the turn. A back shaft is the double coupling shaft. In order to reduce water loss and soil erosion and increase the buffering power of soil against rain water, the cultivation crossing to mountains is adopted for hilly lands. Therefore, the vehicle body can be inclined to heavier side when cultivating the hilly lands, the weight of the vehicle body is moved to low wheels and the high wheels losing gravity and adhesion to the ground slide and idle, thus causing the phenomenon of deviating from a cultivation ridge path or not walking of a rotary vehicle and bringing great difficulty for implementing mechanization. Consequently, in order to adapt the cultivation in a mountain area, the middle position of the length of the vehicle body is specially and additionally provided with a sliding iron counterweight accounting for 30 percent of the total weight of the vehicle body. When the vehicle cultivates the hilly lands transversely, the sliding iron counterweight can correspondingly move to a higher position under the control of a vertical automatic switch and presses the weight on the high wheels so as to lead the gravities of high and low wheels to be the same or similar.

Owner:徐强 +1

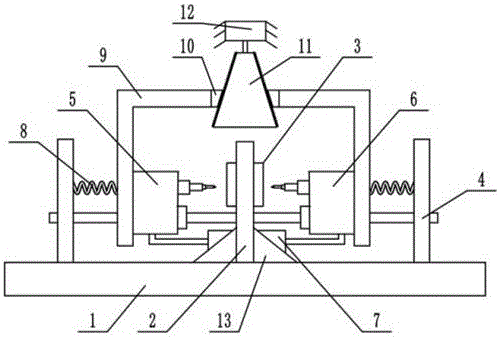

Drilling equipment for drilling center hole of motor shaft

The invention belongs to the field of mechanical grinding, and concretely discloses drilling equipment for drilling a center hole of a motor shaft. The drilling equipment for drilling the center hole of the motor shaft comprises a base and a support plate. A through hole is formed in the support plate; a clamping device is arranged in the through hole and is coaxial to the through hole; a sliding support penetrates through the bottom part of the support plate; a first drilling machine is slidably connected to one end of the sliding support; a second drilling machine is slidably connected to the other end of the sliding support; the first drilling machine and the second drilling machine are jointly connected with a first motor; elastic elements are connected between the first drilling machine and one side wall of the sliding support as well as between the second drilling machine and the other side wall of the sliding support; drill bits of the first drilling machine and the second drilling machine are coaxial to the clamping device; connecting rods are connected onto the first drilling machine and the second drilling machine; threaded plates are arranged on opposite end faces of the two connecting rods; and a threaded cone is matched between the threaded plates. The scheme can prevent the occurrence of the problems that the motor shaft is eccentric during a drilling process, holes in two ends of the motor shaft are non-coaxial, and the like.

Owner:CHONGQING QIANYAN MACHINERY CO LTD

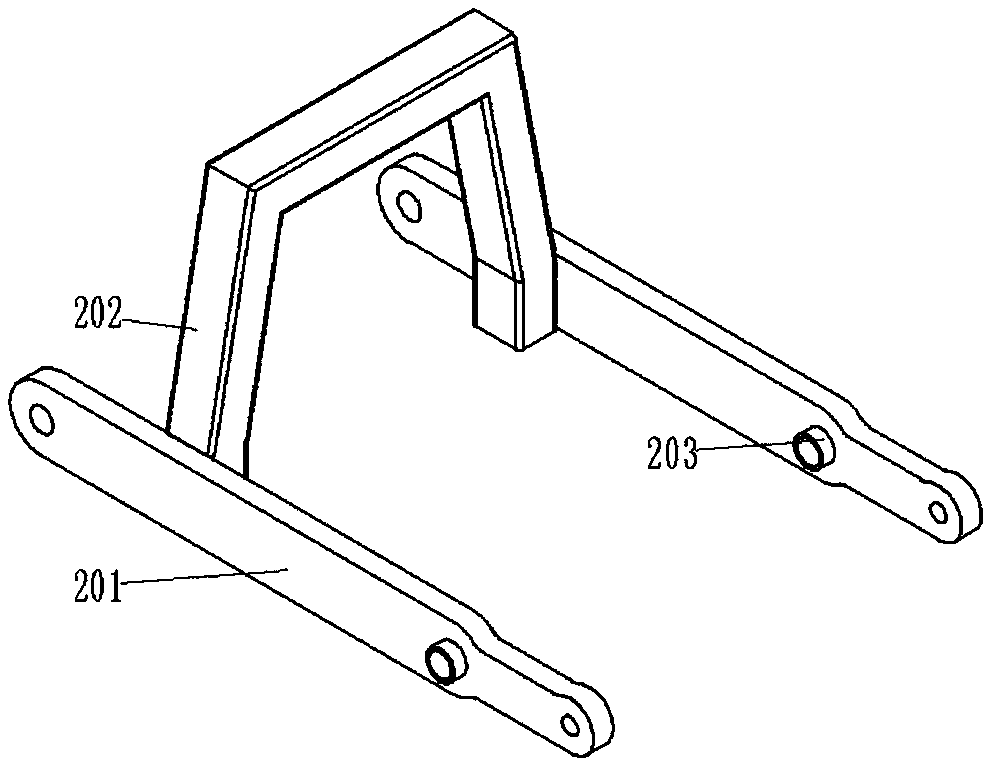

Continuous machine elevation adjusting mechanism and automatic tilling depth adjusting method thereof

The invention relates to a continuous machine elevation adjusting mechanism and belongs to the technical field of agricultural tilling and land preparation machines. The mechanism comprises an elevation adjusting support, a lower lifting support, an upper pull rod and an elevation oil cylinder, wherein the elevation adjusting support comprises a transverse part extending bilaterally and a longitudinal part for erecting the transverse part; the connecting point of the upper pull rod and a machine, the connecting point of the upper pull rod and the elevation adjusting support, the connecting point of the lower lifting support and the elevation adjusting support and the connecting point of the lower lifting support and the machine form a parallelogram, so that the machine, the upper pull rod,the elevation adjusting support and the lower lifting support constitute a parallelogram mechanism. The invention also relates to an automatic tilling depth adjusting method of the continuous machineelevation adjusting mechanism. By means of the mechanism, the operation quality and the operation efficiency can be improved, and damage to a tractor and the machine due to overload flameout in the operation process of the machine can be reduced.

Owner:SOUTH CHINA AGRI UNIV

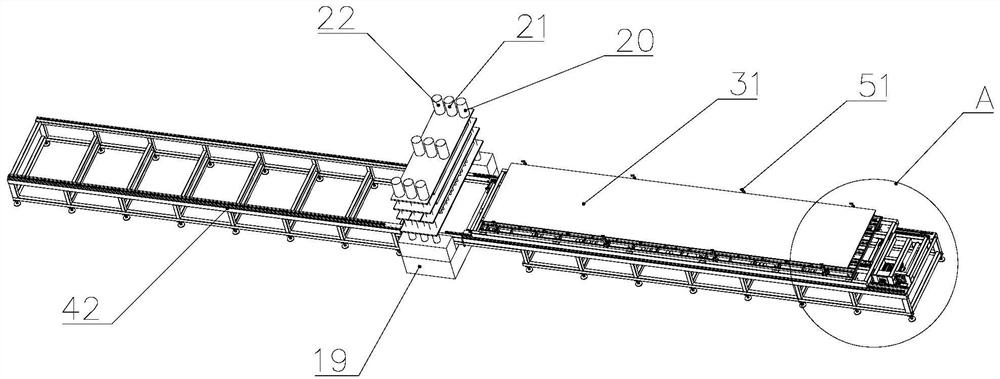

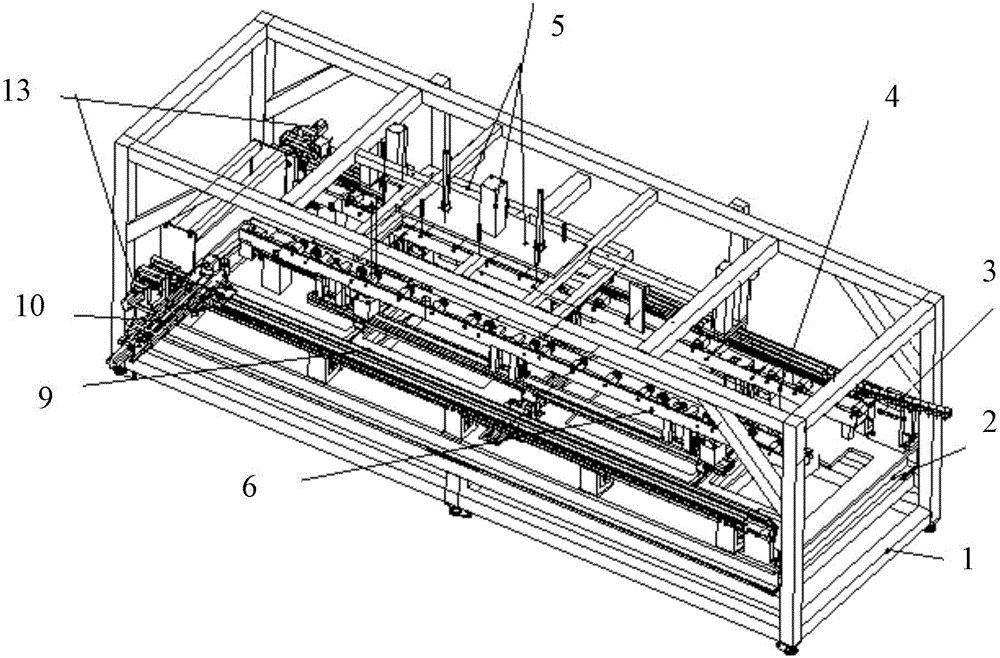

Truss 3D floor plate perforating machine

ActiveCN113020653AReduce damageReduce the breakage rateMetal working apparatusStone-like material working toolsFloor levelFloor plate

The invention discloses a truss 3D floor plate perforating machine, and belongs to the field of floor plate production equipment. The perforating machine comprises a screw feeding mechanism, wherein the screw feeding mechanism comprises a first perforating assembly, a second perforating assembly and a screw feeding assembly, the first perforating assembly comprises a plurality of first perforating drill bits, and the first perforating drill bits are used for perforating a first workpiece; the second perforating assembly comprises a plurality of second perforating drill bits, and the second perforating drill bits are used for perforating a second workpiece; the screw feeding assembly comprises a plurality of screw feeding heads, and the screw feeding heads are used for fastening the first workpiece and the second workpiece; and under the action of a conveying mechanism, the first perforating assembly is used for perforating the first workpiece to form a first hole, the second perforating assembly is used for continuously perforating the second workpiece along the first hole to form a second hole, and then the second workpiece is conveyed to the screw feeding assembly to connect the first hole with the second hole.

Owner:山东七星绿色建筑科技有限公司

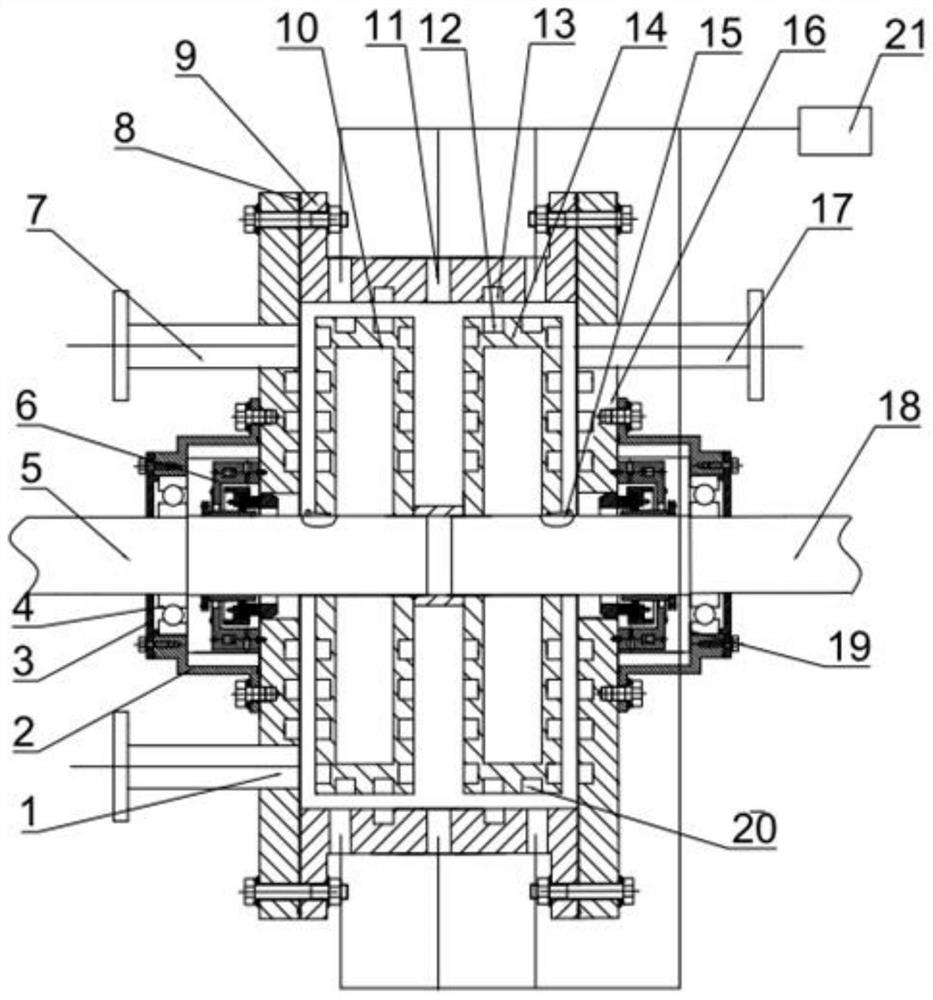

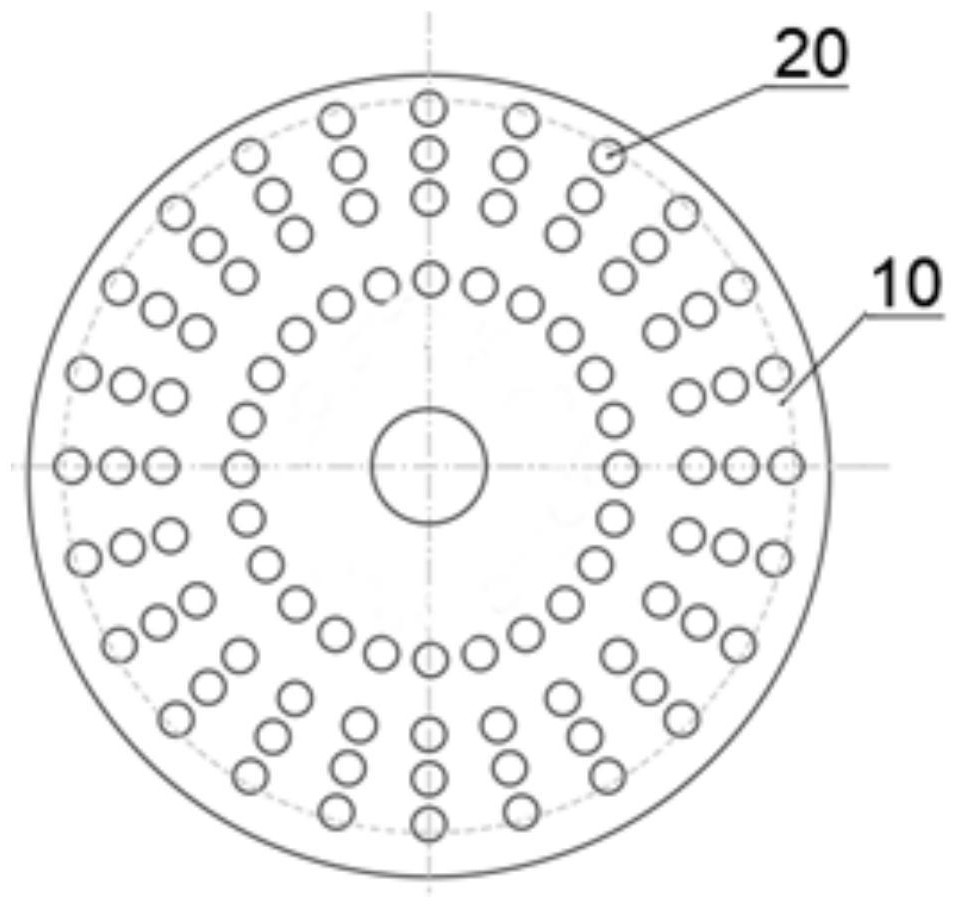

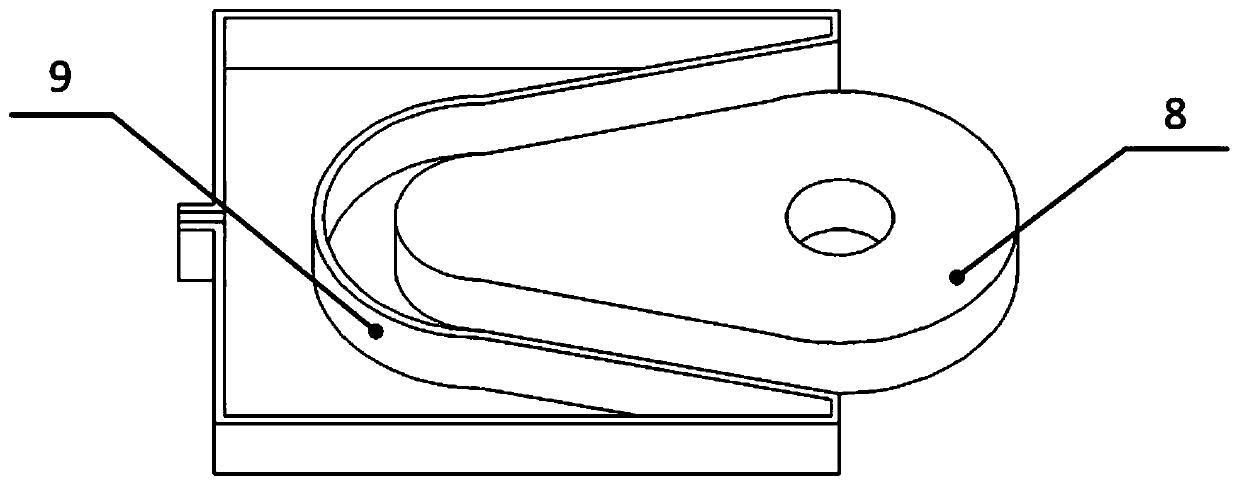

Antibiotic wastewater degradation device coupled with hydraulic, ultrasonic cavitation and oxidation processes

InactiveCN111807459ASame depthUniform cavitation intensityWater treatment compoundsWater contaminantsUltrasonic cavitationMechanical engineering

The invention provides an antibiotic wastewater degradation device coupled with hydraulic, ultrasonic cavitation and oxidation processes. The device comprises a stator, a rotor, an ultrasonic generator and an ultrasonic transducer. The stator is a hollow sealed cylinder, and the ultrasonic transducer extending into an inner cavity of the stator is arranged on the outer wall of the stator; stator cavitation holes are distributed in the inner wall of the stator. Two wheel discs are arranged in the stator, and each wheel disc is fixedly connected to one rotating shaft; the two rotating shafts aresymmetrically installed at the two ends in the stator respectively. Wheel disc cavitation holes are distributed in the circumferential direction and the end face of each wheel disc. One end of the stator is provided with a wastewater inlet pipe and an oxidant pipe, and the other end is provided with a liquid outlet pipe. According to the device, the antibiotic wastewater is degraded by coupling hydraulic power, ultrasonic cavitation and an oxidizing agent, the cavitation energy density is enhanced, the effect of the oxidizing agent is improved, the antibiotic wastewater is degraded efficiently and synergistically, the effect is good, the amplification performance is good, the treatment capacity is large, continuous operation can be achieved, the cost is low, secondary pollution is avoided, and the device has wide application prospects in the field of wastewater degradation.

Owner:SHANDONG UNIV

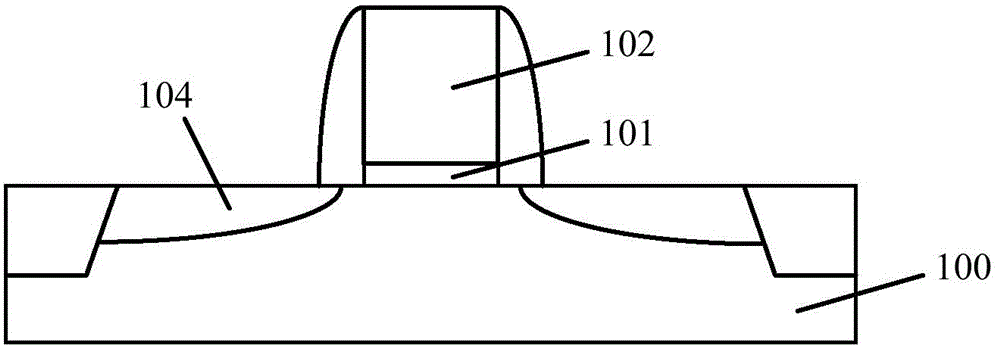

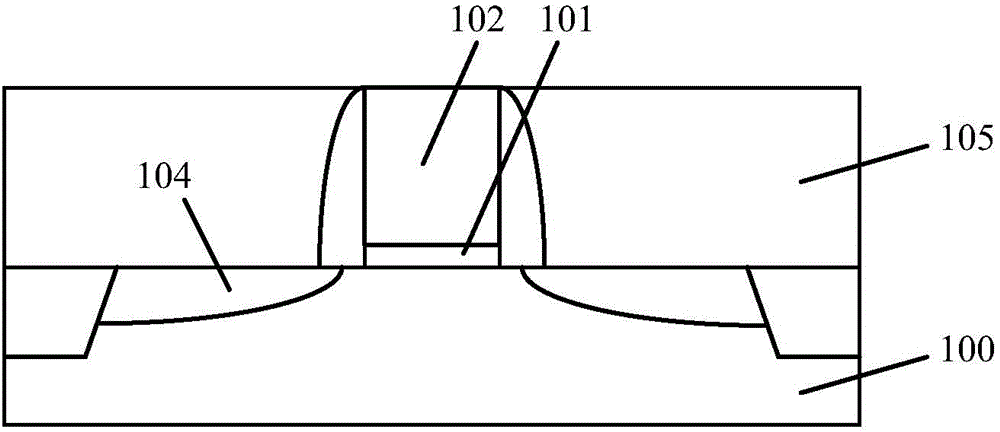

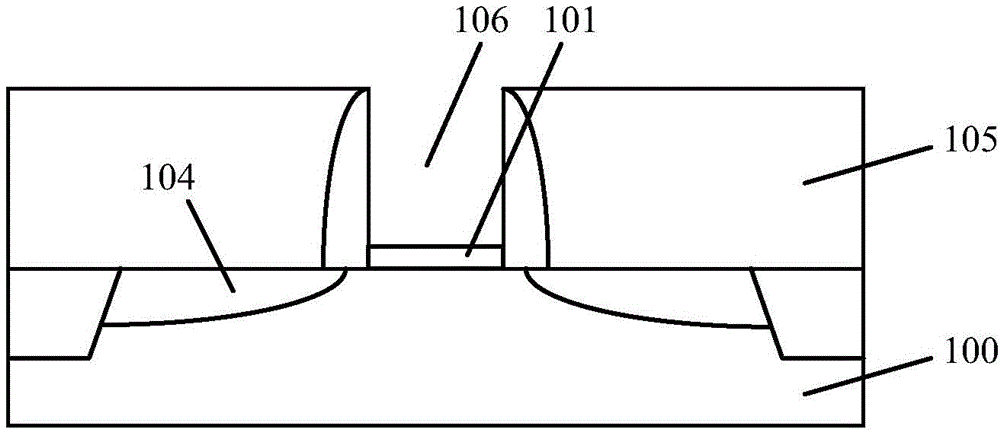

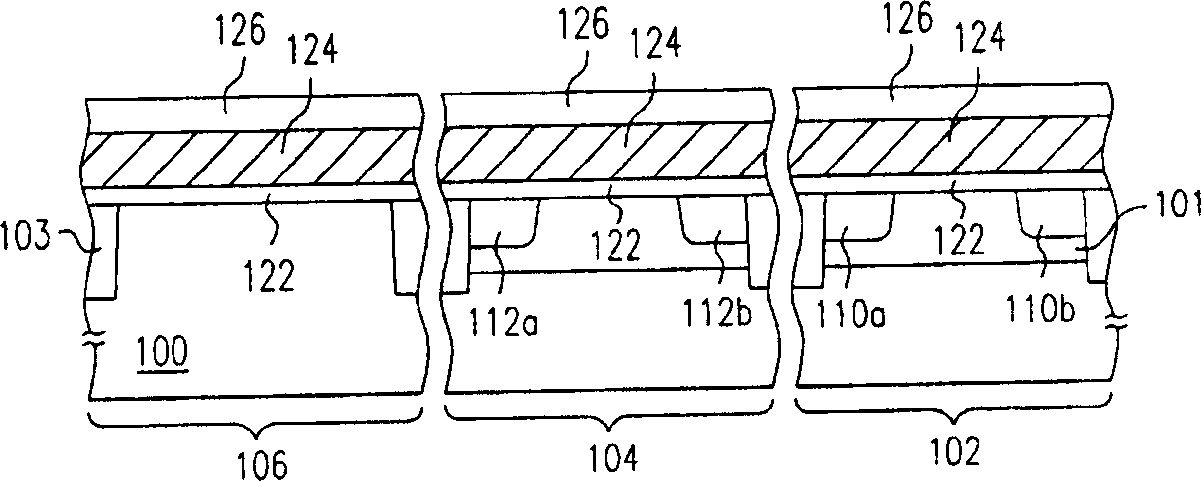

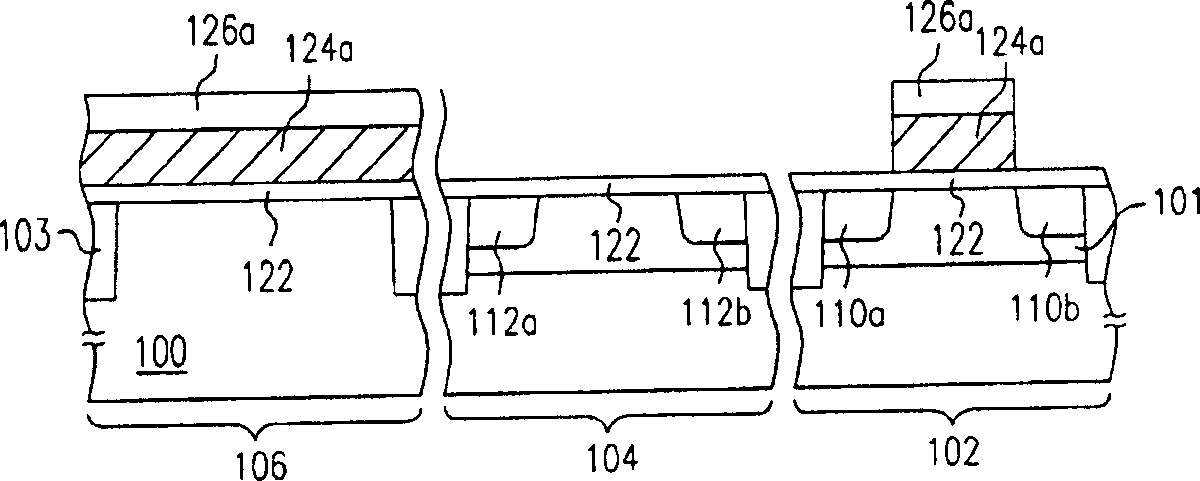

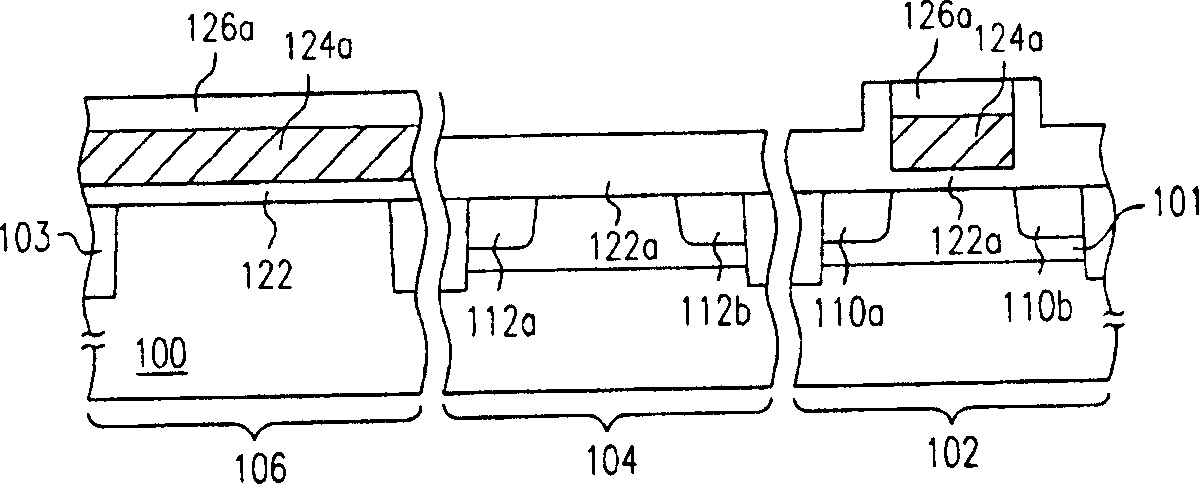

Semiconductor structure and formation method thereof

ActiveCN105826176AGood lookingImprove electrical performanceSemiconductor/solid-state device manufacturingSemiconductor devicesDielectricGate dielectric

The invention relates to a semiconductor structure and a formation method thereof. The formation method comprises the steps of providing a substrate, wherein the surface of the substrate is provided with a pseudo gate dielectric film, and the surface of the pseudo gate dielectric film is provided with a pseudo gate film; forming a mask layer at part of the surface of the pseudo gate film, carrying out a first etching process on the pseudo gate film by taking the mask layer as a mask so as to form a first trench in the pseudo gate film, wherein the side wall of the first trench is vertical with the surface of the substrate, carrying out a second etching process on the pseudo gate film at the bottom of the first trench until the surface of the pseudo dielectric film is exposed, forming a second trench at the bottom of the first trench, forming a pseudo gate layer adjacent to the left pseudo gate film between the first trench and the second trench, wherein the top of the second trench is less than the bottom of the second trench in size, and the angle between the side wall of the second trench and the bottom surface of the second trench is an acute angle, and carrying out a third etching process on the exposed pseudo gate dielectric film until the surface of the substrate is exposed so as to form a pseudo gate dielectric layer. The formed semiconductor structure is good in appearance and improved in performance.

Owner:SEMICON MFG INT (SHANGHAI) CORP

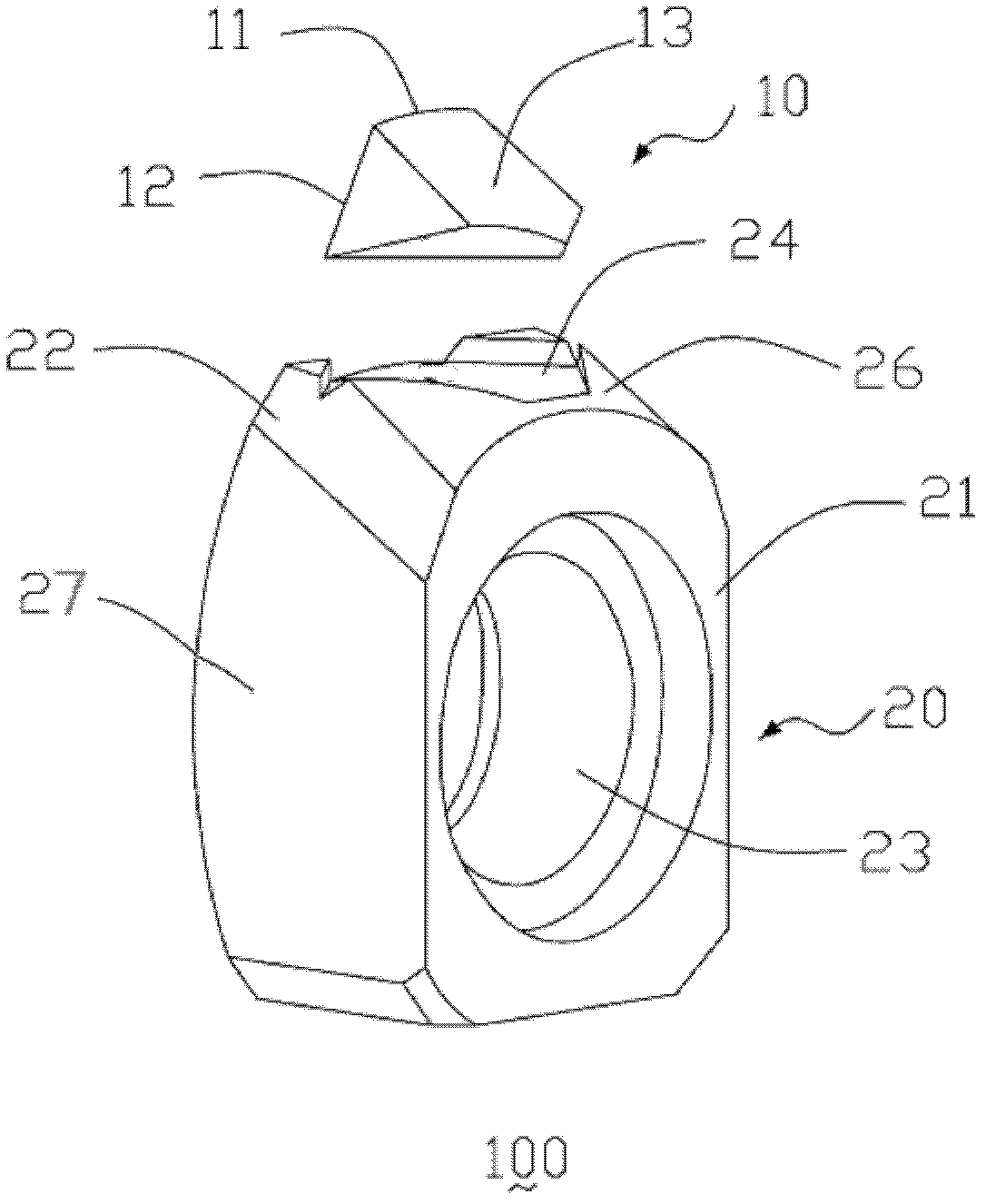

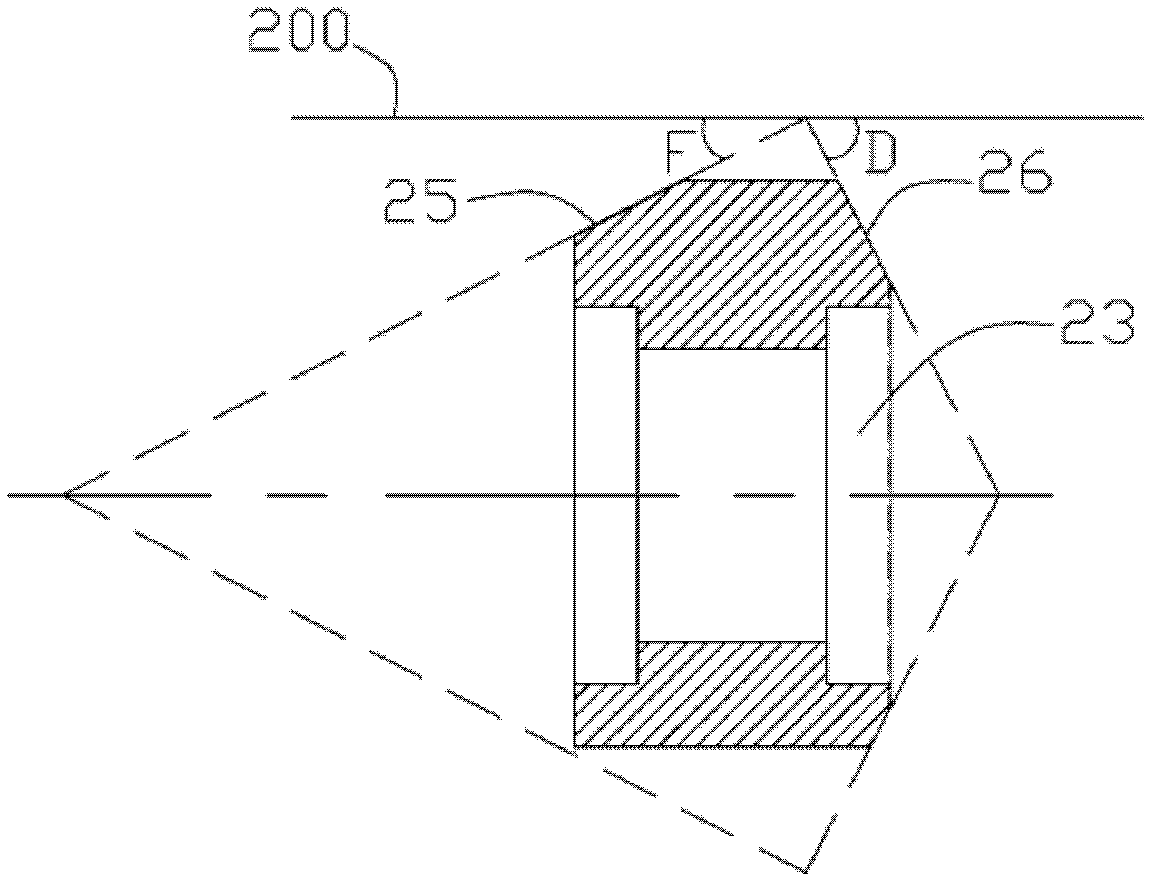

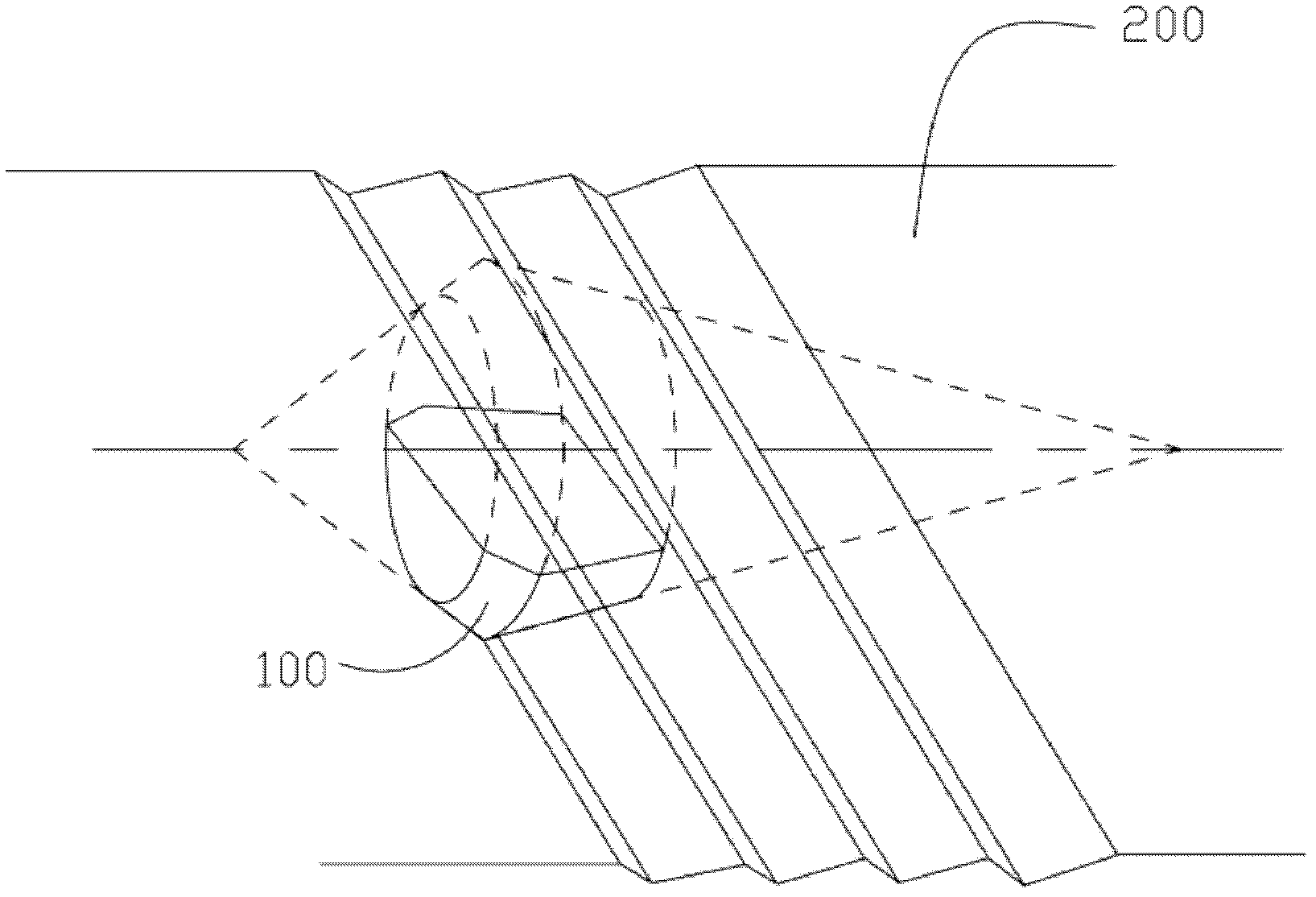

Grating ruling cutter and cutter body thereof

The invention provides a grating ruling cutter, which comprises a cutter body and a diamond biconical cutter bit welded and grinded on the cutter body. The cutter body is provided with at least one end face and a uniform datum hole perpendicular to the end faces, the uniform datum hole serves as a uniform datum for cutter grinding, grating ruling and online blade changing, and the axis of the uniform datum hole is perpendicular to the end faces. The grating ruling cutter has the uniform datum for cutter grinding, grating ruling and online blade changing, and the radian of the height of a blade line consisting of a biconical surface, and coaxiality of grating ruling and online blade changing are ensured during cutter grinding, so that the uniform datum can serve as an online blade changing center for the grating ruling cutter to facilitate online blade changing when the cutter wears.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

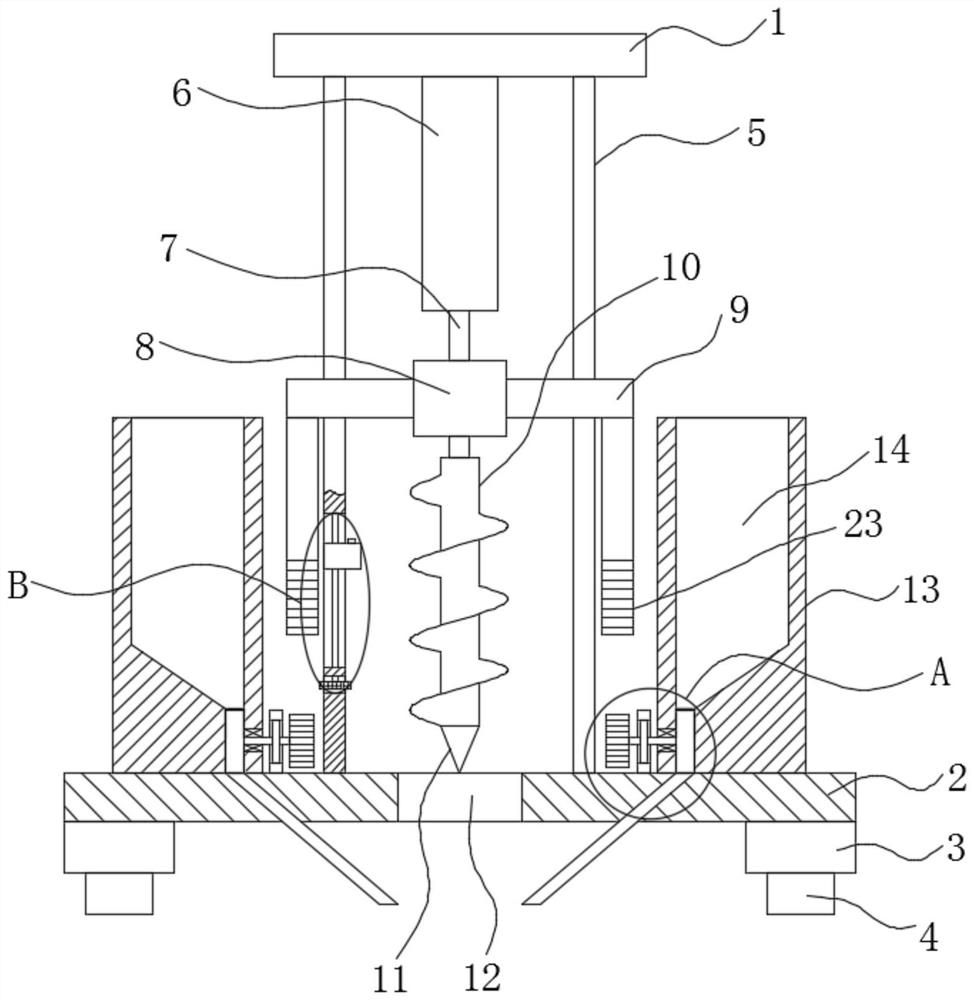

Agricultural pit digging and seeding device

PendingCN112753320AEasy to operateMeet growth needsPlantingWatering devicesAgricultural engineeringElectric machinery

The invention discloses an agricultural pit digging and seeding device. The agricultural pit digging and seeding device comprises a top plate and a platform which are arranged in parallel up and down, two guide columns are vertically and fixedly connected between the top plate and the platform, a double-shaft motor is vertically arranged between the two guide columns, and an upper output shaft of the double-shaft motor is fixedly connected with a first threaded rod; the first threaded rod is sleeved with a threaded sleeve in a threaded mode, the upper end of the threaded sleeve is fixedly connected with the midpoint of the top plate, a lower output shaft of the double-shaft motor is fixedly connected with a drill rod, the lower end of the drill rod is fixedly connected with a drill bit, and sliding plates are fixedly connected to the two sides of the double-shaft motor correspondingly; the sliding plates are slidably sleeved on the corresponding guide columns, and a drilling groove coaxial with the first threaded rod is formed in the upper end of the platform. The agricultural pit digging and seeding device has the advantages that the structure is simple and reasonable, in addition, the drilling depth of the drill bit and the drill rod can be set, the same depth of planting pits is guaranteed, sowing, fertilizing and watering are achieved in one step, and the planting efficiency is greatly improved.

Owner:黄新宇

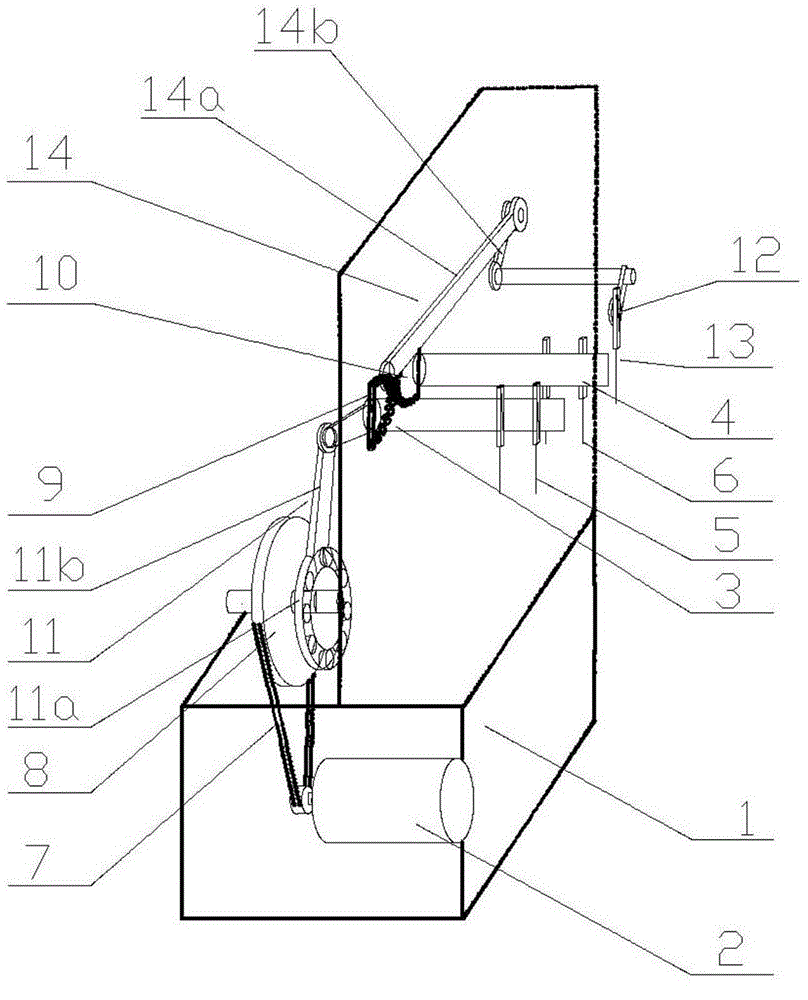

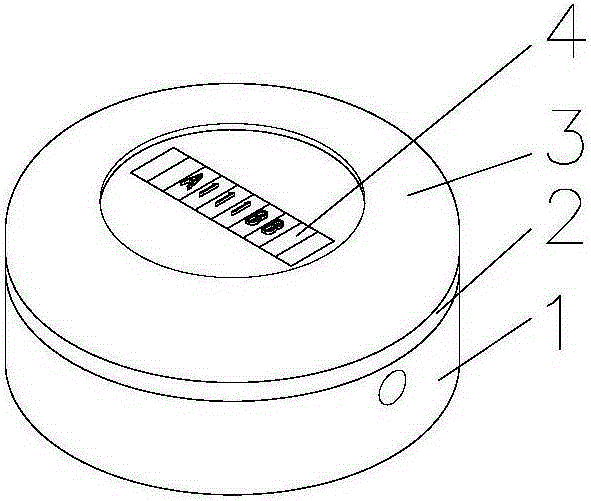

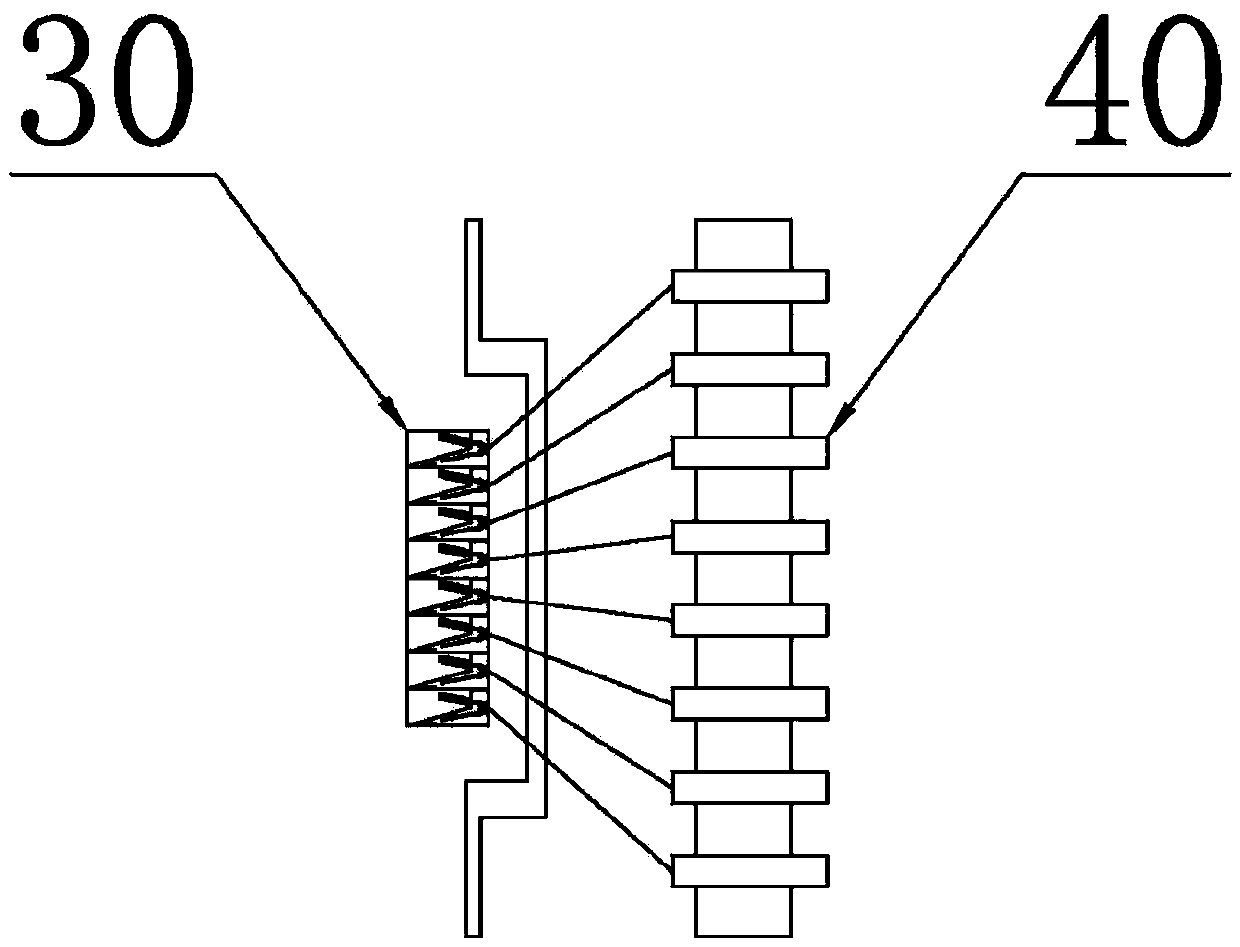

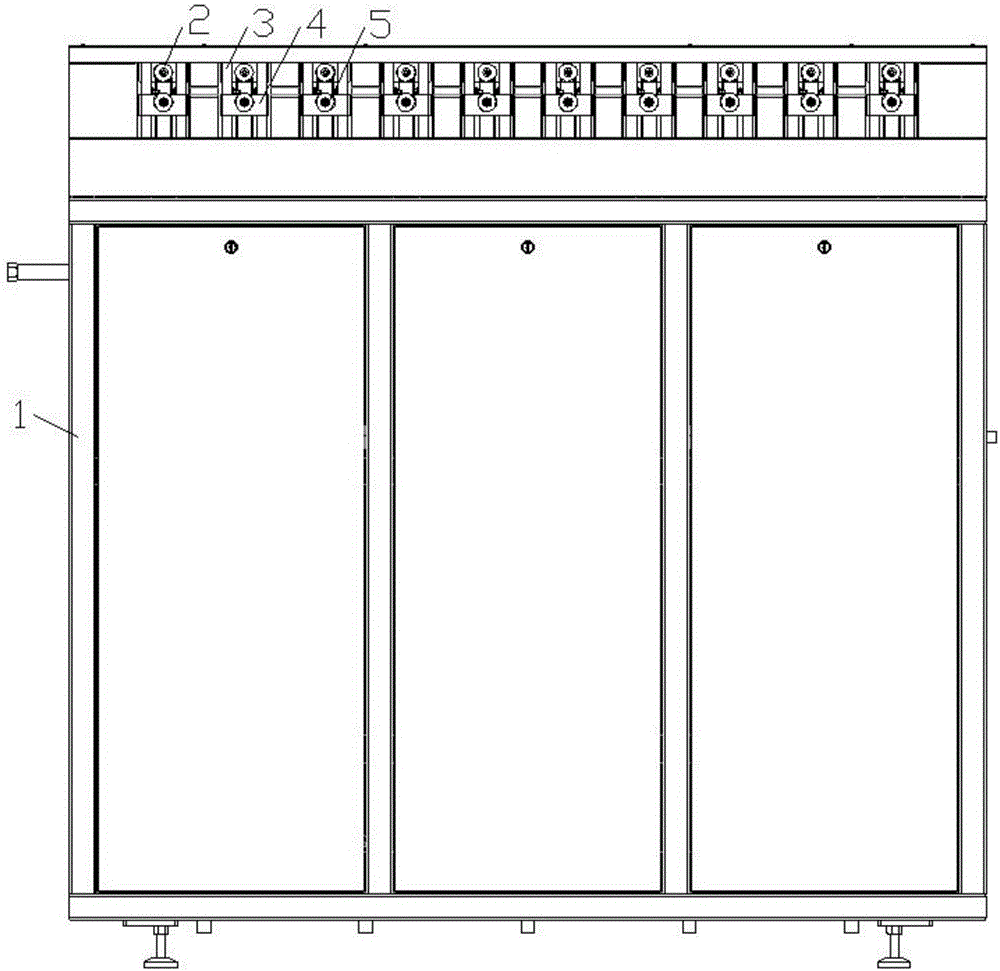

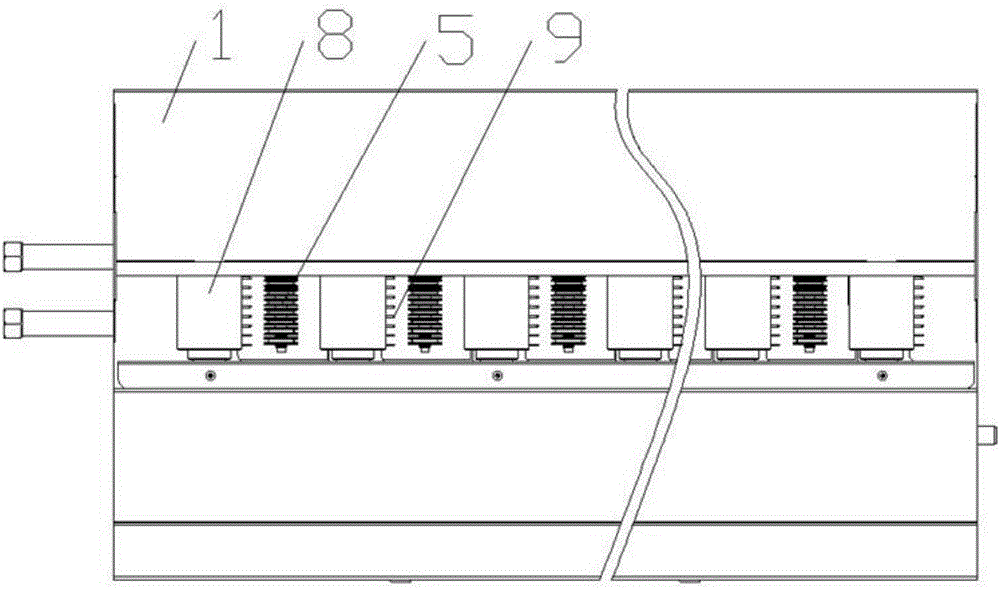

Quilting machine

InactiveCN105019145ASame depthEvenly spacedSewing-machine elementsMattress sewingElectric machineryDrive motor

The invention discloses a quilting machine needle rod stroke system which comprises a rack. The rack is provided with a front-row-needle mounting beam capable of sliding up and down, a rear-row-needle mounting beam and a machine needle drive system. The machine needle drive system comprises a drive motor, a transmission wheel, a front-row-needle transmission gear and a rear-row-needle transmission gear, wherein the front-row-needle transmission gear and the rear-row-needle transmission gear are matched with each other. The drive motor drives the transmission wheel to rotate through a belt transmission structure. The transmission wheel drives the front-row-needle transmission gear and the rear-row-needle transmission gear to swing synchronously through a connection rod mechanism. The front-row-needle transmission gear drives the front-row-needle mounting beam to swing up and down through a front-row-needle transmission mechanism. The rear-row-needle transmission gear drives the rear-row-needle mounting beam to swing up and down through a rear-row-needle transmission mechanism. The machine needle rod stroke system is more steady, high in production efficiency and low in energy consumption.

Owner:NAIMAN BANNER GRASSLAND SHOW CASHMERE PROD

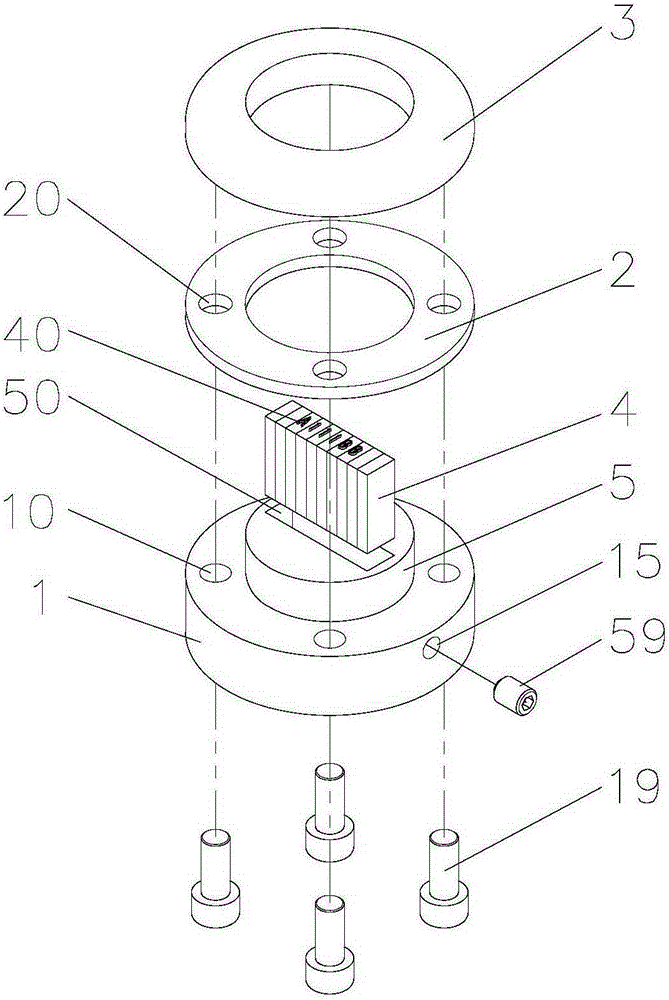

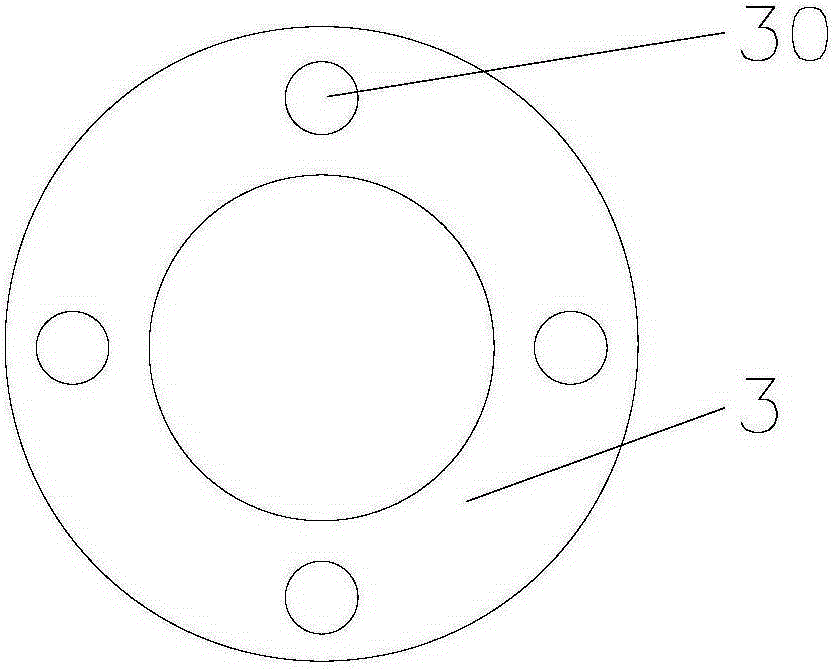

Stamping die with replaceable characters

The invention discloses a stamping die with replaceable characters. The stamping die with the replaceable characters comprises a die main body, steel stamps, an elastic ring and an upper cover, the die main body is provided with a boss, the outer side of the boss is sleeved with the elastic ring and the upper cover, the elastic ring is on the lower portion of the upper cover, a groove is formed in the boss, the bottom of the groove is in the die main body, multiple steel stamps are neatly arranged in the groove, and the tops of the steel stamps are provided with protruding stamped characters. According to the stamping die with the replaceable characters, the steel stamps are arranged in the groove, the stamping die can stamp different characters by replacing the steel stamps easily, and the stamped characters are clear and neat; a side hole is matched with a socket head cap set screw to be capable of effectively fixing the steel stamps, and the stamping effect is prevented from being affected due to looseness of the steel stamps.

Owner:安歌科技(集团)股份有限公司

Portable millimeter wave passive focal plane imaging system

InactiveCN105371962AHighly integratedReduce volumeRadiation pyrometryAntenna supports/mountingsSignal conditioning circuitsRadiometer

The invention provides a portable millimeter wave passive focal plane imaging system. The portable millimeter wave passive focal plane imaging system comprises a cylinder of which one end is equipped with a lens antenna, wherein the cylinder is internally fixed with a focal plane feed source array opposite to the lens antenna, the focal plane feed source array is connected with a radiometer reception set, the radiometer reception set is connected with a signal conditioning circuit, and the signal conditioning circuit is connected with a switching circuit having a signal output port and a power supply input port. The portable millimeter wave passive focal plane imaging system has properties of small volume and light weight, can be held by a single person to scan a target scene for imaging and can realize millimeter wave imaging of building and ground vehicle targets all day long.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

A laser scribing device for coating material and adjustable scribing distance

InactiveCN104908108BGuaranteed shape regularitySame depthMetal working apparatusEngineeringLaser scribing

A scratching-distance adjustable laser film scratching device used for film materials comprises a rack, a carrier, guide rails, a roller platform fixed end component, an upper centering-pressing mechanism, a roller platform moving end component, two side-wall pressing parts, a lower centering mechanism, two slide rail platforms, a movable laser fixing base, a laser fixing base and a controller. The scratching-distance adjustable laser film scratching device used for film materials can automatically adjust processing distance according to width of a product to be processed, so that emitted laser can be always close to the edge of the product, uniform shapes and same depths of scratches can be guaranteed, films can be directly torn off, and operation efficiency can be improved while the product surface can be protected from being scratched.

Owner:HANGCHENG TIANJIN TECH

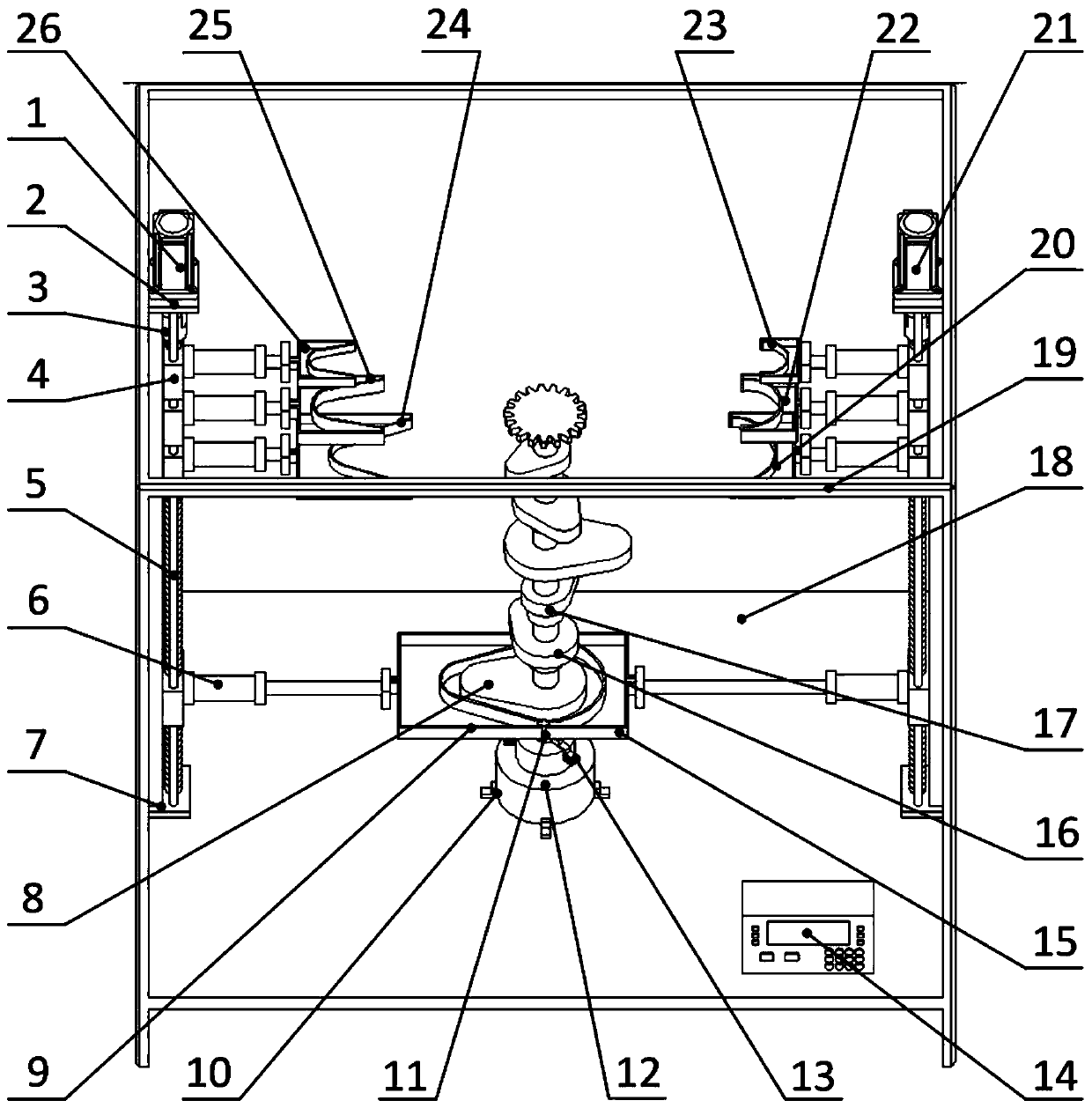

A device and process for thermal processing of camshafts with small batches and multiple specifications

ActiveCN110172547BConstant spacingEvenly heatedIncreasing energy efficiencyFurnace typesHot workEngineering

The invention discloses a device and a process for hot working of small-batch multi-specification camshafts, and belongs to the field of camshaft heat treatment. The device comprises a steel frame anda workbench, wherein two lifting devices are symmetrically arranged on the steel frames located on the two sides of the workbench, a rotary platform device is arranged on the workbench, the camshaftis movably connected in the rotary platform device, a cam is arranged on the camshaft, the lifting devices are correspondingly connected with telescopic rods, the tail end of one telescopic rod is connected with a peach tip induction coil, the tail end of the other telescopic rod is connected with a base circle induction coil, an isolation plate is arranged between the peach tip induction coil andthe base circle induction coil, and the workbench is provided with a PLC which is electrically connected with the lifting devices and the rotary platform device correspondingly. According to the device for hot working of the small-batch multi-specification camshafts and the process adopting the device, the quenching temperature and the depth of the hardened layer after quenching of the peach tippart of the cam are correspondingly same as the quenching temperature and the depth of the hardened layer after quenching of the base circle part of the cam, and the cams with different specificationscan be continuously heated.

Owner:兰溪正昂汽配有限公司

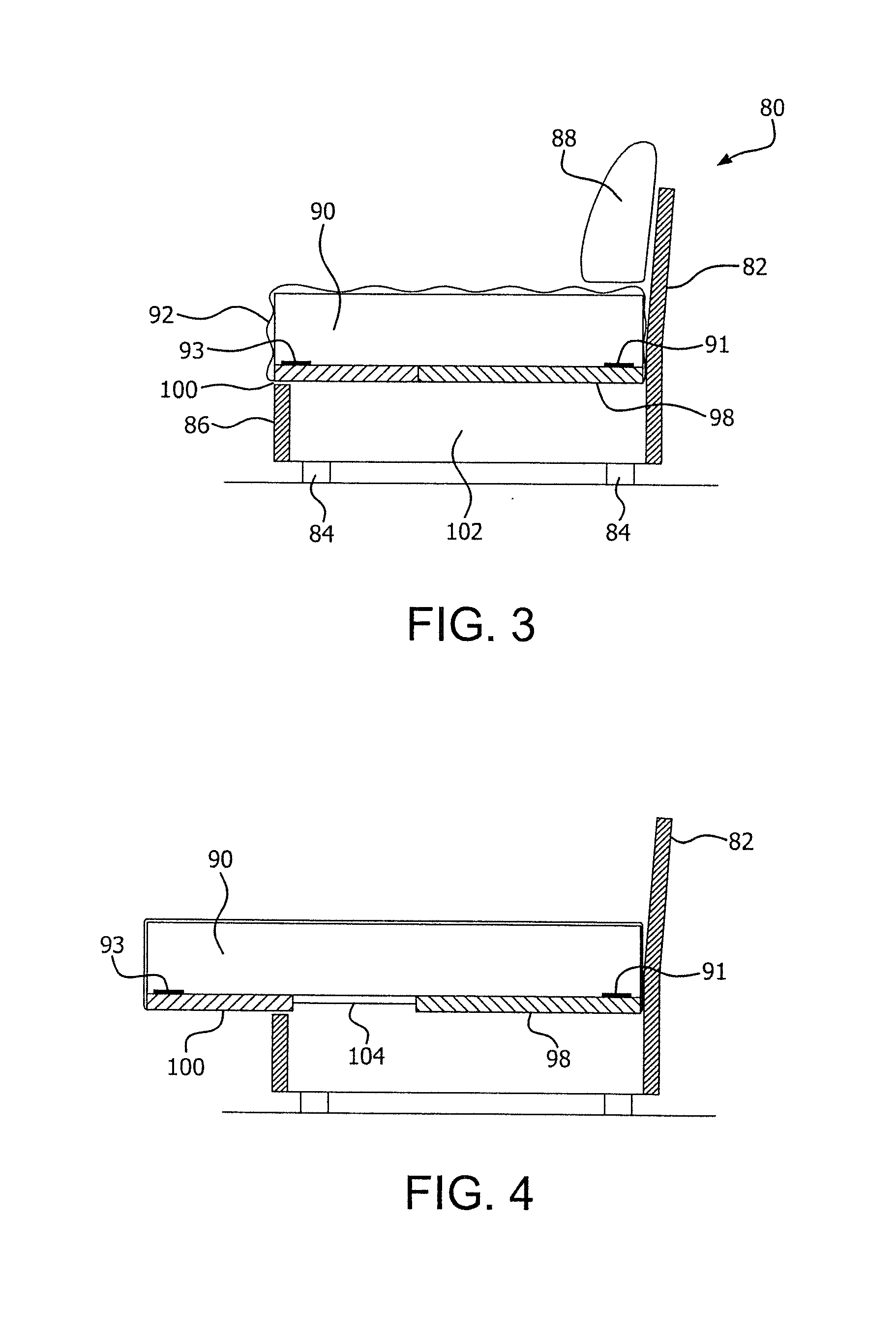

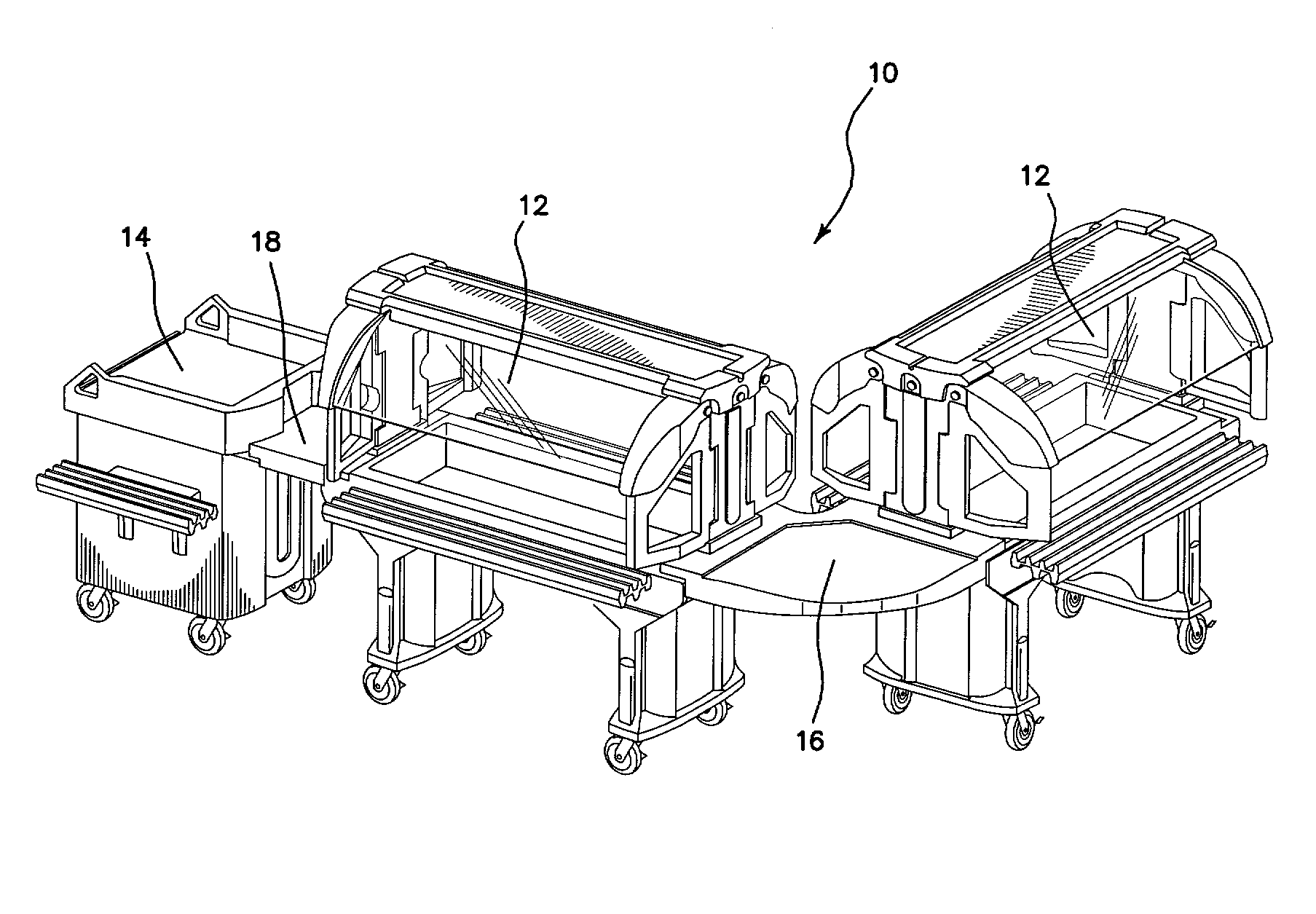

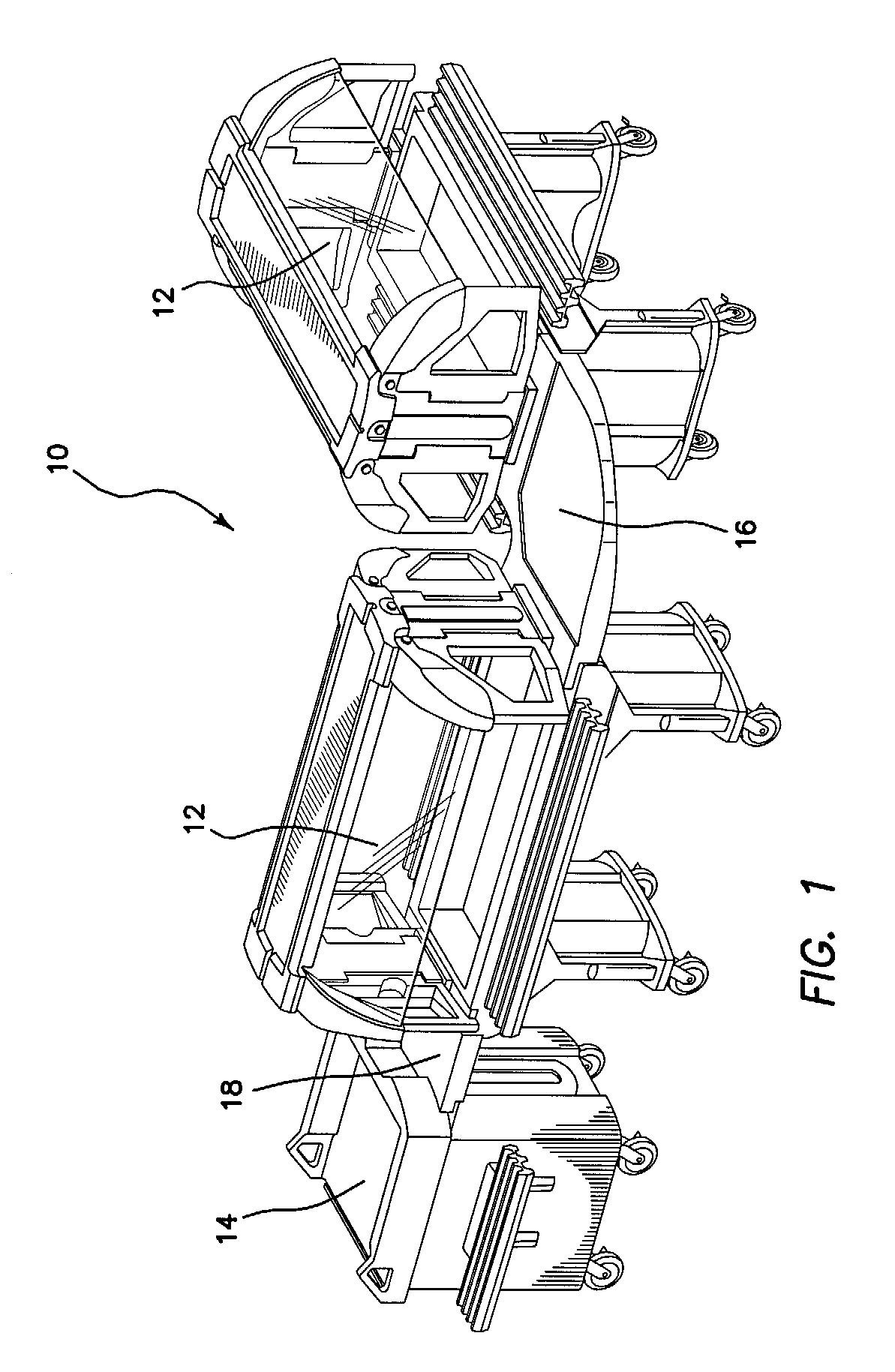

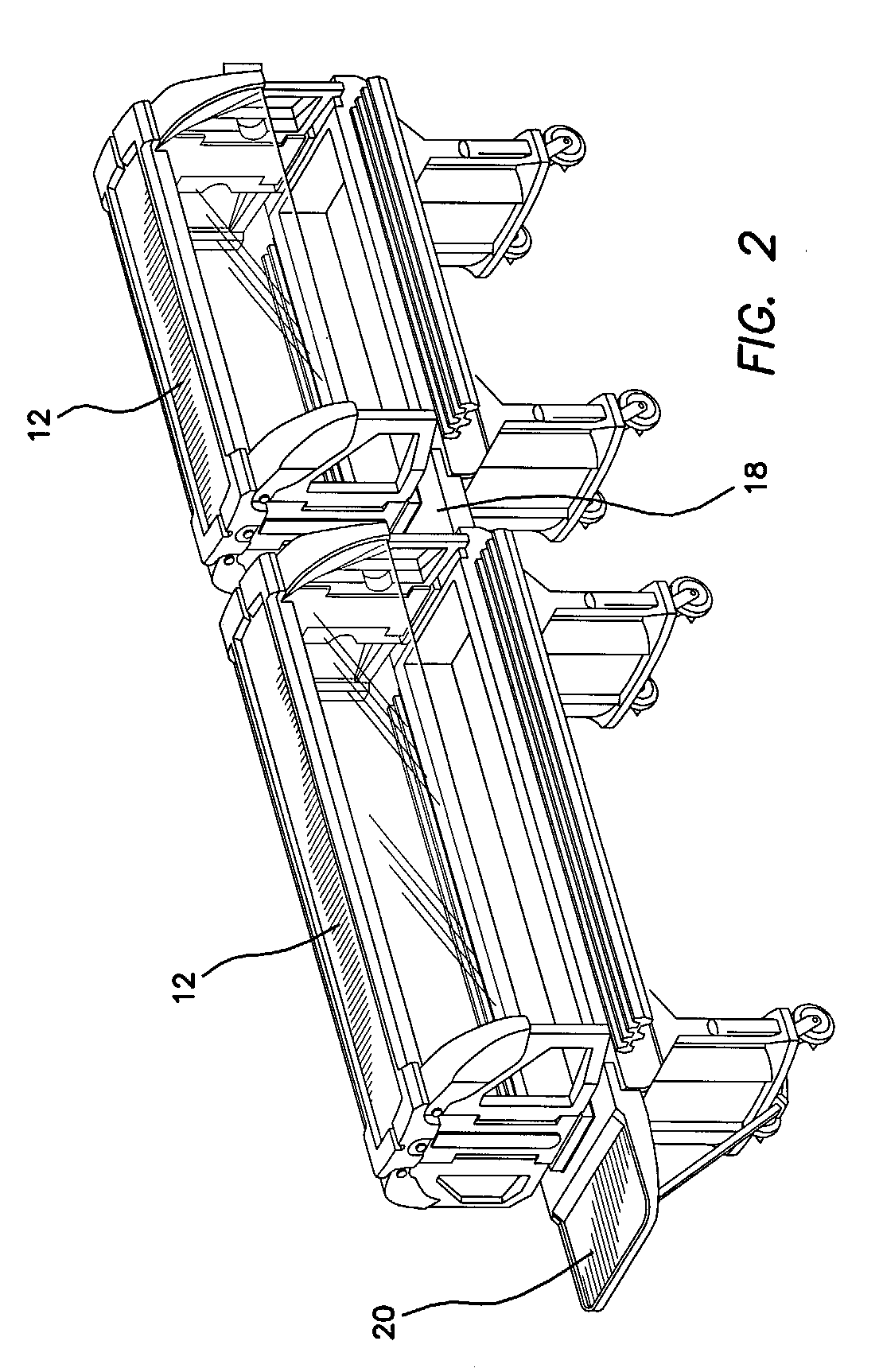

Collapsible Food Service System

ActiveUS20110109207A1Same depthAccessibleShow cabinetsLighting and heating apparatusEngineeringCaster

A food service system is formed using a plurality of units capable of being interlocked together in a variety of customizable configurations. The units of the food service system include a food service bar with buffet pan chillers, a work table, a cashier station, and variety of connecting pieces for linking each of the units together. The food service bar comprises a sneeze guard that protects the food contained within the bar on three sides and can be broken down and folded down and into itself when the bar is being transported or stored. The buffet pan chillers are double sided and configured such that when frozen, may accommodate a shallow food pan on one side and then flipped over to accommodate a deep food pan on the other side while still maintaining the same serving height. Each unit is configured to receive multiple sizes of wheels or casters.

Owner:CAMBRO MFG

Scratching-distance adjustable laser film scratching device used for film materials

ActiveCN104908108AGuaranteed shape regularitySame depthMetal working apparatusFilm materialScratching

A scratching-distance adjustable laser film scratching device used for film materials comprises a rack, a carrier, guide rails, a roller platform fixed end component, an upper centering-pressing mechanism, a roller platform moving end component, two side-wall pressing parts, a lower centering mechanism, two slide rail platforms, a movable laser fixing base, a laser fixing base and a controller. The scratching-distance adjustable laser film scratching device used for film materials can automatically adjust processing distance according to width of a product to be processed, so that emitted laser can be always close to the edge of the product, uniform shapes and same depths of scratches can be guaranteed, films can be directly torn off, and operation efficiency can be improved while the product surface can be protected from being scratched.

Owner:HANGCHENG TIANJIN TECH

Layer-by-layer heating for cylindrical helical gears

ActiveCN109825694BGuaranteed uniformityEvenly heatedFurnace typesIncreasing energy efficiencyGear wheelBevel gear

The invention relates to a layer-by-layer heating device for cylindrical bevel gears. The device comprises a heating device, a rotating platform device, a worktable, a lifting device, a vertical powersupply table, a base and multiple infrared temperature measuring cameras; the heating device comprises a profiling induction coil and an induction coil bracket; one end of the induction coil bracketis vertically fixed on the vertical power supply table; the profiling induction coil is fixed at the other end of the induction coil bracket; the profiling induction coil is positioned above the rotating platform device; the rotating platform device is used for fixedly supporting the cylindrical bevel gears; the rotating platform device is mounted on the worktable; the worktable is mounted on thelifting device; the lifting device is fixed on the base; and the vertical power supply table is vertically fixed on the base. The invention further provides a layer-by-layer heating method for the cylindrical bevel gears; the influence caused by the end surface effect is effectively reduced; the depth uniformity of tooth surface hardening layers is improved; and the service life of the cylindricalbevel gears is prolonged.

Owner:TAICANG FANSHENG ELECTRONICS TECH CO LTD

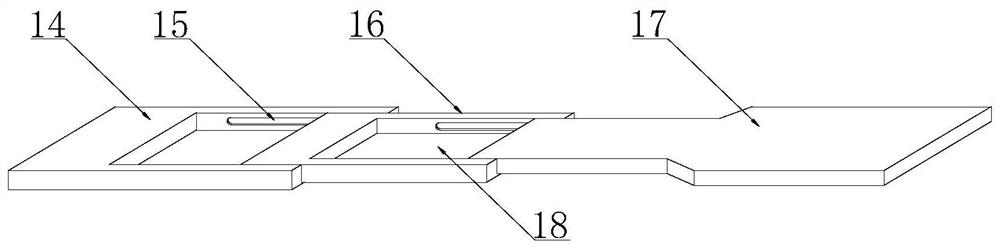

Bidirectional telescopic cable bridge and use method thereof

InactiveCN113889933ASame widthSame depthElectrical apparatusVibration suppression adjustmentsCable trayEngineering

The invention discloses a bidirectional telescopic cable bridge and a use method thereof, and belongs to the technical field of cable bridges. The bidirectional telescopic cable bridge comprises a telescopic bridge main body, a telescopic cover plate covers the top of the telescopic bridge main body, a hinge is arranged between the telescopic bridge main body and the telescopic cover plate, an elbow is inserted into one side of the telescopic bridge main body, and a plurality of clamping plates are arranged in the telescopic bridge body at equal intervals; partition plates are inserted into the clamping plates, and mounting grooves are formed in the attached positions of the partition plates and the clamping plates in the width direction of the partition plates and the clamping plates. The bidirectional telescopic cable bridge is composed of the first bridge, the adjusting frame, the buffer frame and the second bridge, so that bidirectional free adjustment can be performed, compared with an existing bidirectional bridge, the adjusting length is longer, fine adjustment during assembly is more facilitated, the telescopic cover plate can prevent dust and can synchronously contract along with the telescopic bridge body, and the internal space of the telescopic bridge main body can be divided through the partition plates, so effective distinguishing is realized.

Owner:江苏汉兴电气有限公司

Road and bridge shallow crack repairing device

PendingCN114753271AIncrease shallow connection surface areaImprove connection stabilityBridge erection/assemblyRoads maintainenceArchitectural engineeringStructural engineering

The invention discloses a road and bridge shallow crack repairing device, and relates to the field of crack repairing, the road and bridge shallow crack repairing device comprises a main frame, the upper part of the main frame is provided with a driving machine, the lower part of the main frame is rotatably provided with a rotating shaft, a transmission member is arranged between the rotating shaft and the driving machine, and the outer side of the rotating shaft is sleeved with a cutting wheel. By arranging the two sets of cutting blades rotating along with the cutting wheels, a gap can be widened slightly, meanwhile, a conical transition groove is synchronously formed in a roadbed on the surface layer, on the premise that the bonding strength of the inner layer of the roadbed is not damaged, the shallow layer connecting surface area of the sealing gap is greatly increased, and the connecting stability of a rear sealing object and an original road surface is effectively improved; and therefore, the repairing effect is good.

Owner:安徽虹达道路桥梁工程有限公司

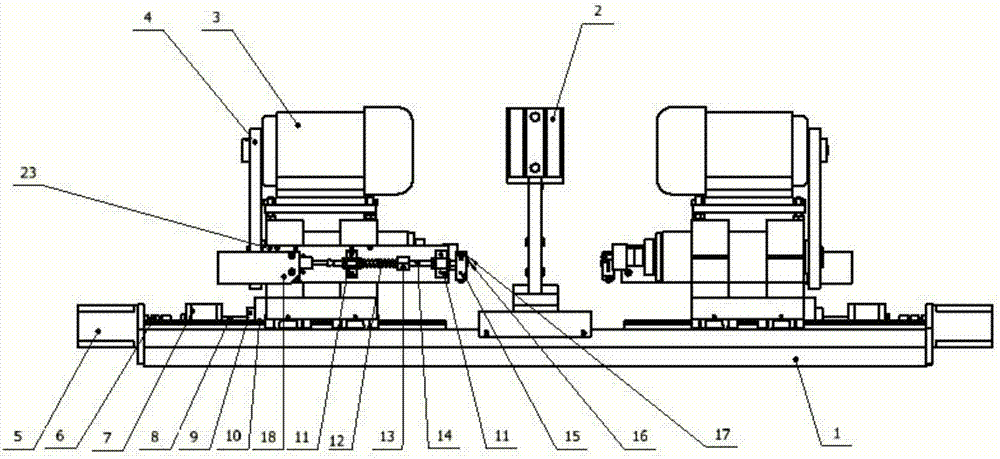

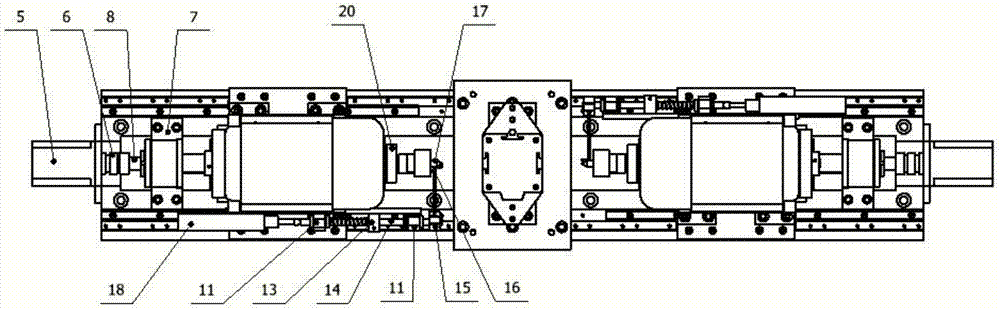

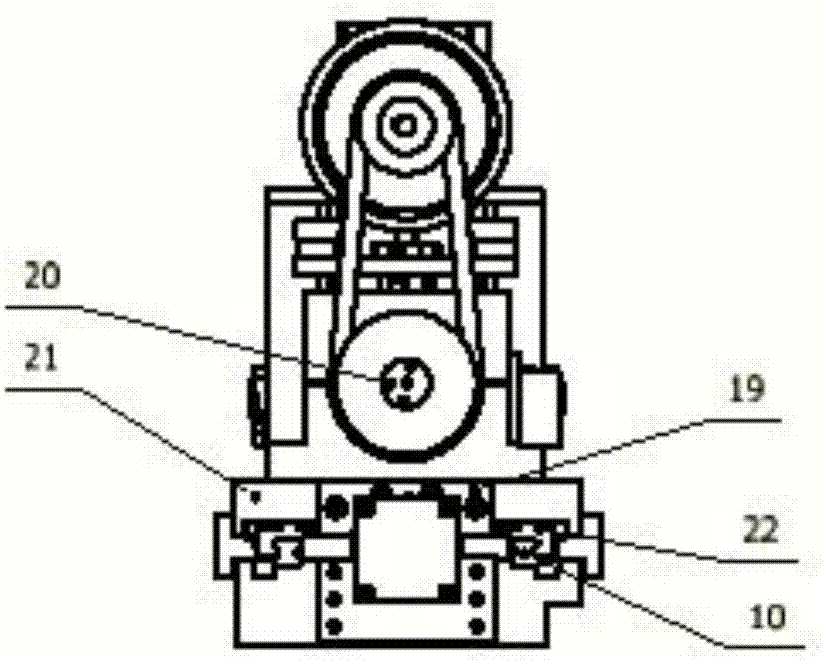

Method for drilling center holes in two end faces of cylindrical roller by using depth control device

ActiveCN107378039ASame speedSame depthMeasurement/indication equipmentsFeeding apparatusBall screwElectric machine

The invention relates to a method for drilling center holes in two end faces of a cylindrical roller by using a depth control device. The depth control device overall comprises a pedestal, a workpiece clamping device, a first motor, a belt, a center drill, a nut base, a drilling shaft, a sliding base, a sliding block, a second motor, a shaft coupler, a bearing pedestal, a ball screw, a screw nut, a guide rail, a linear guide sleeve, a reset spring, a bar hoop, a measuring bar, a rod clamp, a touch rod, a measuring head and a measuring head base. The depth control device accepts effective control of a controller, provides good guarantee for drilling the center holes in the two end faces of the cylindrical roller, and has the characteristics of simple structure, easiness in manufacturing and convenience in use. Through the depth control device, the center holes can be drilled in the two end faces of the cylindrical roller simultaneously, equal work speed and equal work depth can be guaranteed, the center holes in the two end faces of the cylindrical roller have high coaxiality, the processing process is simplified, and the processing precision and the production efficiency are improved.

Owner:LUOYANG LIBO NUMERICAL CONTROL TECH CO LTD

Hollow semipermeable fibrous membrane silk cleaning device

ActiveCN106245124AReduce cross section flowReduce usageArtificial filament washing/dryingFiberCantilever

The invention belongs to the technical field of spinning and discloses a hollow semipermeable fibrous membrane silk cleaning device used for solving problems of high operation cost of an existing cleaning device in a utilization process and high construction and operation cost of matched dustless rooms. The hollow semipermeable fibrous membrane silk cleaning device comprises a frame, a head end water washing tank and a tail end water washing tank are arranged on the frame, and a plurality of middle water washing tanks are abreast arranged between the head end water washing tank and the tail end water washing tank. The head end water washing tank is provided with a water drain pipe, the tail end water washing tank is provided with a water inlet pipe, and the water washing tanks form water tank systems which are independent but communicated sequentially. Silk pressing guide rails are mounted on inner walls of the water washing tanks respectively, silk pressing sliders capable of sliding on the silk pressing guide rails are mounted on the silk pressing guide rails respectively, and cantilever silk pressing wheels used for taking hollow semipermeable fibrous membrane silks into bottoms of the water washing tanks are mounted on the silk pressing sliders respectively.

Owner:CHENGDU HEDA AUTOMATION EQUIP

Semiconductor element and making method

ActiveCN1815717ASame depthSame concentrationSolid-state devicesSemiconductor/solid-state device manufacturingManufacturing cost reductionEngineering

The method includes following steps: providing a substrate with storage unit zone and high voltage circuit zone; forming first, second source poles / drain poles zones on the two pieces of zone in the substrate; forming oxidizing layer, first conductive layer and topping layer in sequence on the substrate; defining floating grid on the storage unit zone, and removing out the topping layer and the first conductive layer from the high voltage circuit zone; thickening exposed the oxidizing layer; removing out the topping layer, and forming barrier layer on the exposed surface of floating grid; forming second conductive layer, defining out grid pole in the high voltage circuit zone, and defining out control grid pole in storage unit zone. Combining procedure for preparing storage unit and high voltage components, the method does not need to increase number of using photoresist so as to shorten fabricating flow and lowering fabricating cost.

Owner:UNITED MICROELECTRONICS CORP

An adjustable clamping device

ActiveCN110814818BGuaranteed verticalityReduce shade errorOther manufacturing equipments/toolsPositioning apparatusEngineeringWorkbench

The invention provides an automatic adjusting and clamping device which comprises a workbench. A through hole for running through a cutter is formed in the workbench. Parallel body fixing plates are arranged on the workbench. A fastening fixing plate is arranged at the rear ends of the body fixing plates. The front ends of the fixing plates are open. Connecting plates are slidingly installed between the body fixing plates. The inner ends of the connecting plates are provided with a power fixing plate close to the fastening fixing plate. The outer ends of the connecting plates are provided witha clamping rear plate. A power part is arranged at the center of the power fixing plate. The power part is in power connection with a clamping front plate. The clamping front plate is located on theouter side of the clamping rear plate. A gap for clamping aluminum plates is formed between the clamping front plate and the clamping rear plate. An adjusting part for adjusting the distance between the power fixing plate and the fastening fixing plate is arranged on the fastening fixing plate. The automatic adjusting and clamping device has the technical advantages of being simple in structure, convenient to popularize, capable of conveniently clamping and adjusting the clamped aluminum plates, suitable for clamping different types of aluminum plates, and capable of providing a proper cuttingdepth for bending.

Owner:潍坊达创数控设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com