Wafer scribing device for machining and using method thereof

A mechanical processing and scribing technology, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of increasing the work of grinding, difficult to control the scribing depth, and affecting the alignment of wafers, so as to improve efficiency , The effect of convenient alignment work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

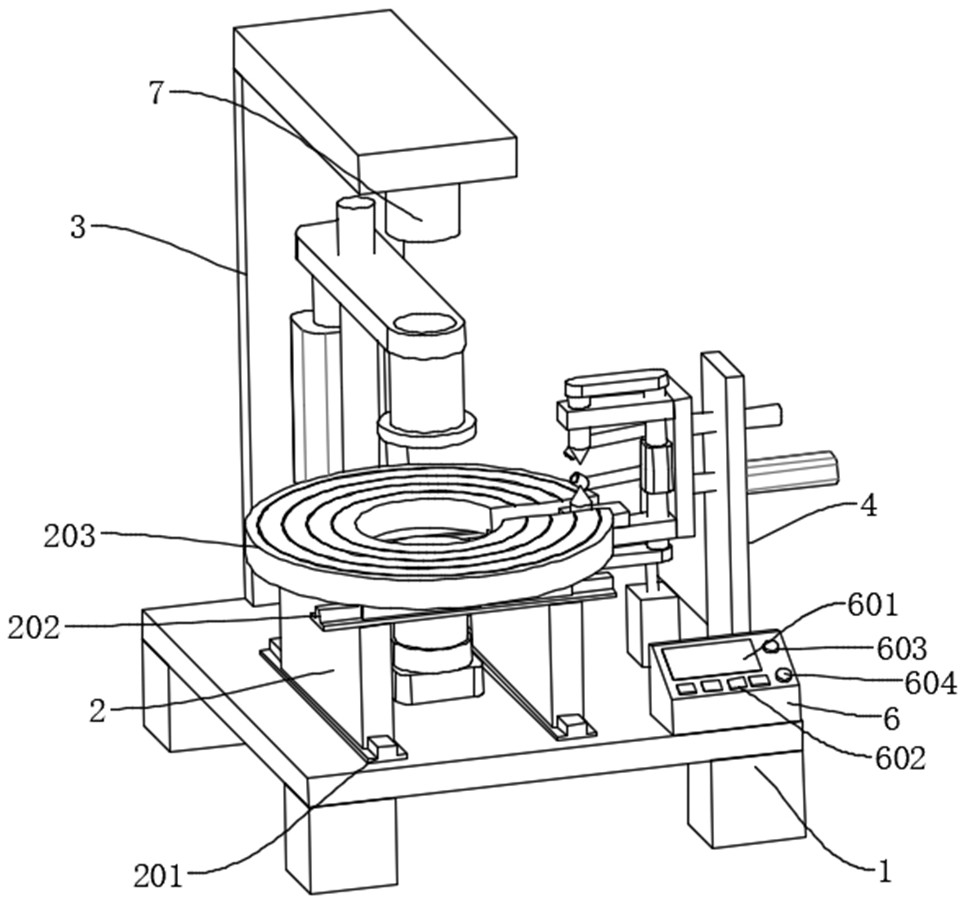

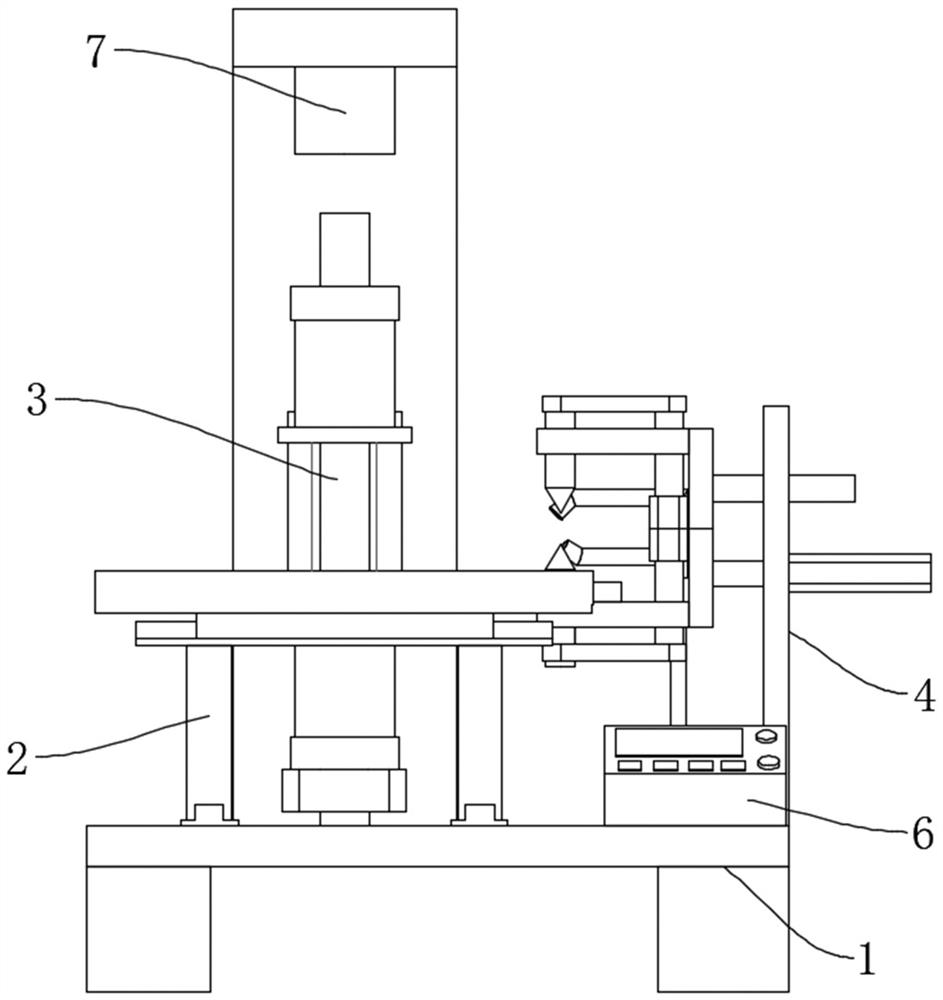

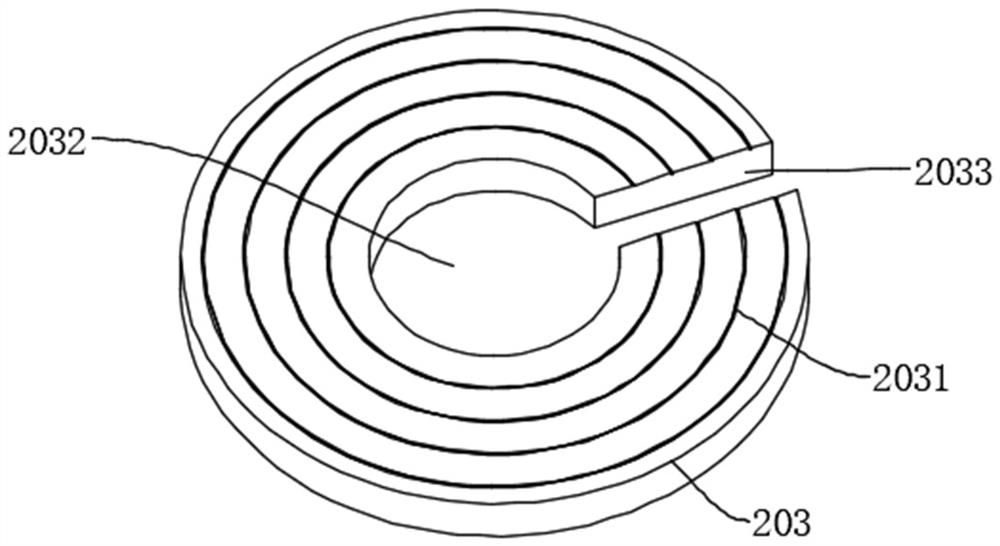

[0038] Such as Figure 1-7 As shown, a wafer dicing device for mechanical processing includes a base 1, an adjustment mechanism 2 is arranged in the center of the top of the base 1, a control panel 6 is connected to the front end side of the top of the base 1 by screws, and the adjustment mechanism 2 includes a vertical linear slide rail Pair 201, horizontal linear slide rail pair 202, placement plate 203, the top of vertical linear slide rail pair 201 is provided with horizontal linear slide rail pair 202, and the top of horizontal linear slide rail pair 202 is connected with a placement plate 203 by bolts, and the center of the top of the placement plate 203 There is a relief hole 2032, and the top of the placement plate 203 is etched with several annular scales 2031 concentric with the relief hole 2032. One side of the placement plate 203 is provided with a relief groove 2033 that runs through the placement plate 203 up and down, and the relief groove 2033 and the The relie...

Embodiment 2

[0046] Such as Figure 8As shown, the difference between Embodiment 2 and Embodiment 1 is that the scribing assembly that moves up and down synchronously includes a third support plate 405, a scribing knife 408, a positive and negative lead screw 41, an adjustment motor 42, a moving plate 43, and a third support plate 405. There are two support plates 405, and they are arranged up and down. The third support plate 405 is connected to one side of the push plate 403 by bolts, and the side of the third support plate 405 close to the push plate 403 is connected with a positive and negative lead screw 41 through a bearing. , the upper end of the positive and negative lead screw 41 passes through the third support plate 405, and the adjustment motor 42 is connected through the coupling, and the outer side of the positive and negative lead screw 41 is threaded with two moving plates 43, and the moving plate 43 is located on the two third support plates. Between the plates 405, the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com