Drilling equipment for drilling center hole of motor shaft

A technology of drilling equipment and motor shaft, which is applied in drilling/drilling equipment, boring/drilling, metal processing equipment, etc. The effect of simplicity, improved accuracy, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below through specific implementations:

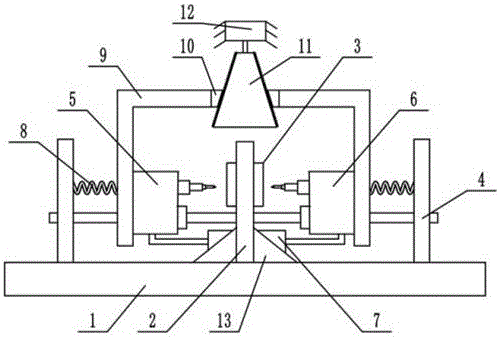

[0022] The reference signs in the drawings of the specification include: base 1, support plate 2, clamping device 3, sliding frame 4, first drilling machine 5, second drilling machine 6, first motor 7, elastic member 8, connecting The rod 9, the threaded plate 10, the threaded cone 11, the second motor 12, and the reinforcement device 13.

[0023] The embodiment is basically as attached figure 1 Shown:

[0024] The drilling equipment used to drill the center hole of the motor shaft is mainly composed of the base 1, the supporting plate 2, the clamping device 3, the sliding frame 4, the first drilling machine 5, the second drilling machine 6, the thread plate 10, and the thread cone. Body 11 constitutes. A support plate 2 is welded to the middle of the base 1, and a reinforcement device 13 is installed at the lower part of the support plate 2, and the reinforcement device 13 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com