Grating ruling cutter and cutter body thereof

A grating scoring and tool body technology, which is applied to lathe tools, manufacturing tools, accessories of tool holders, etc., can solve the problems of easy wear of split scoring knives, inability to change blades online, deep grating grooves, etc. , to achieve the effect of improving the grinding accuracy and turning edge accuracy, improving the repeat positioning accuracy and large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure, features and effects of the grating marking tool proposed according to the present invention are as follows: Details are as follows.

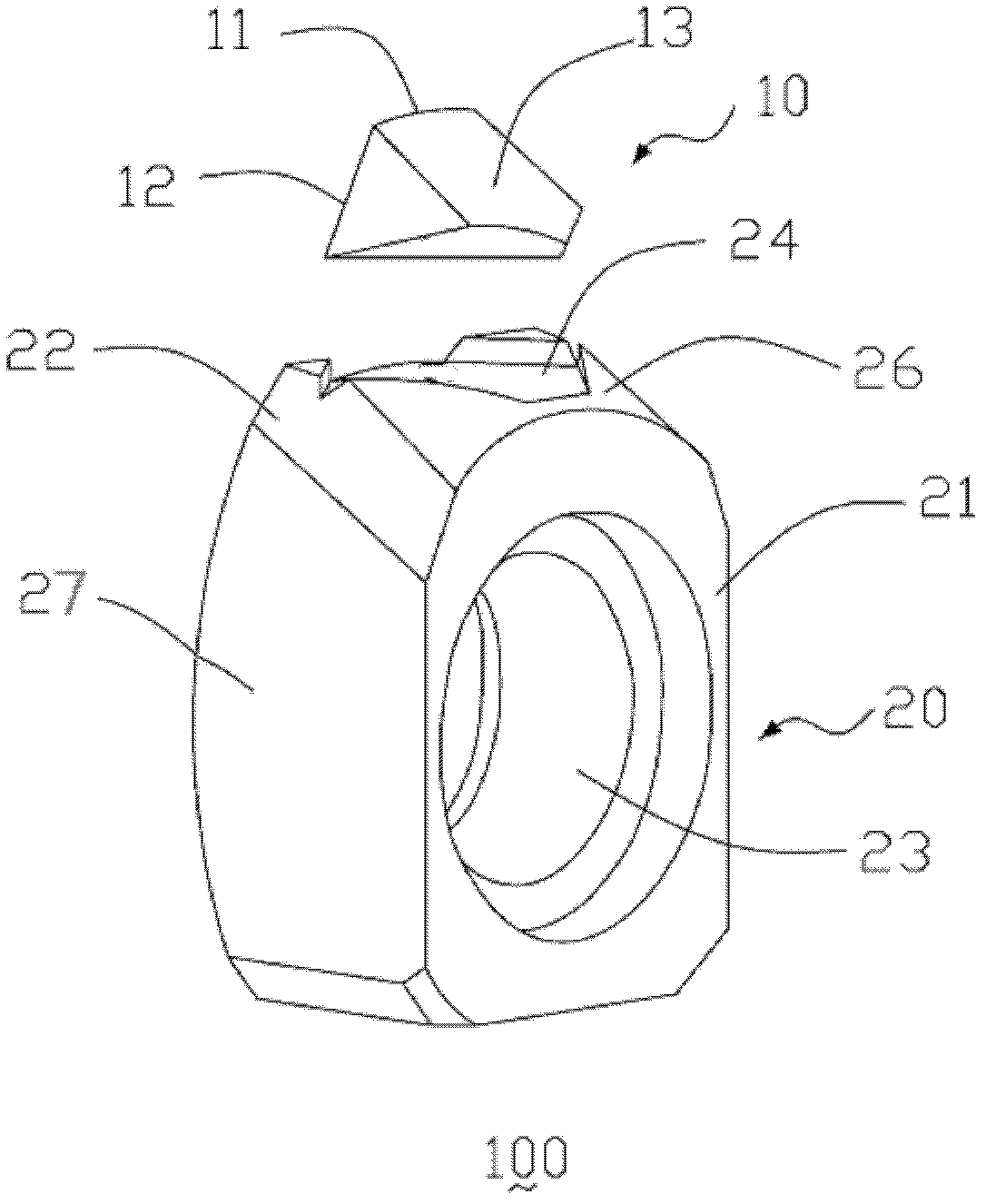

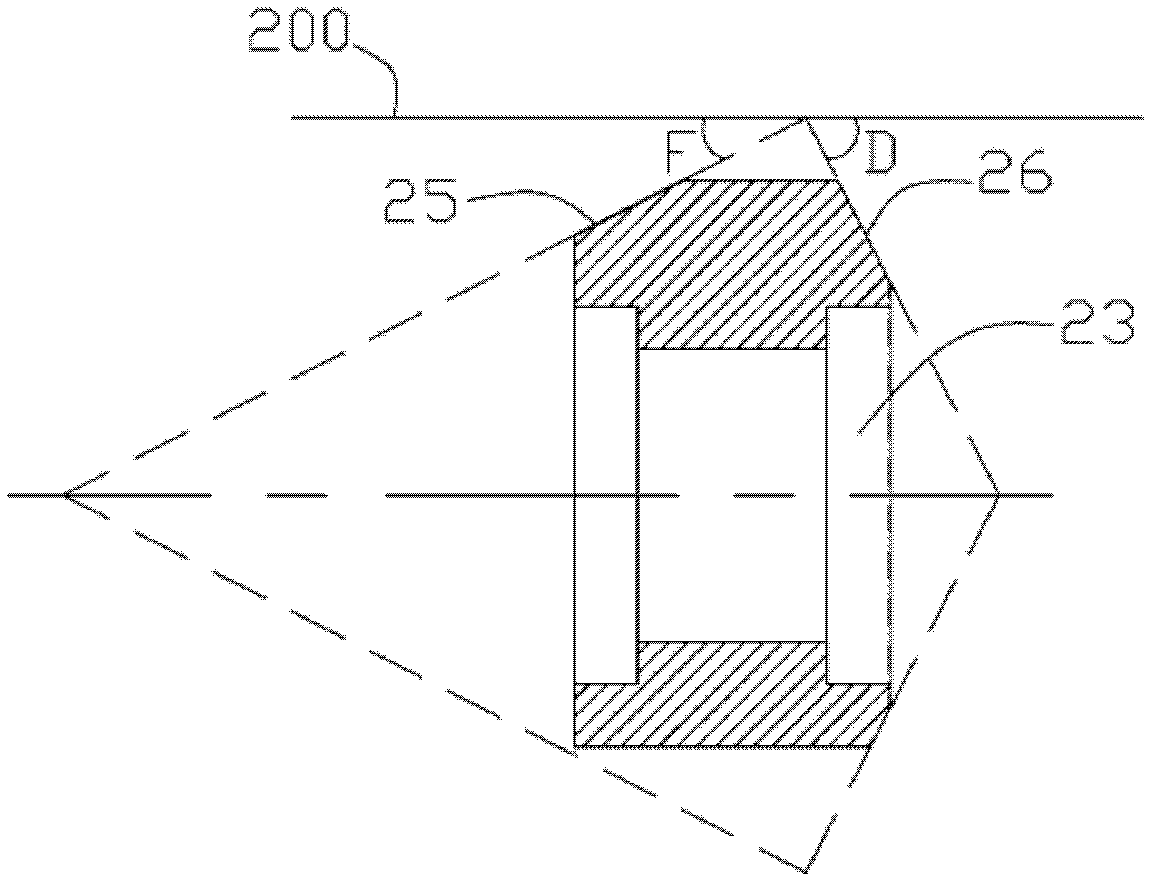

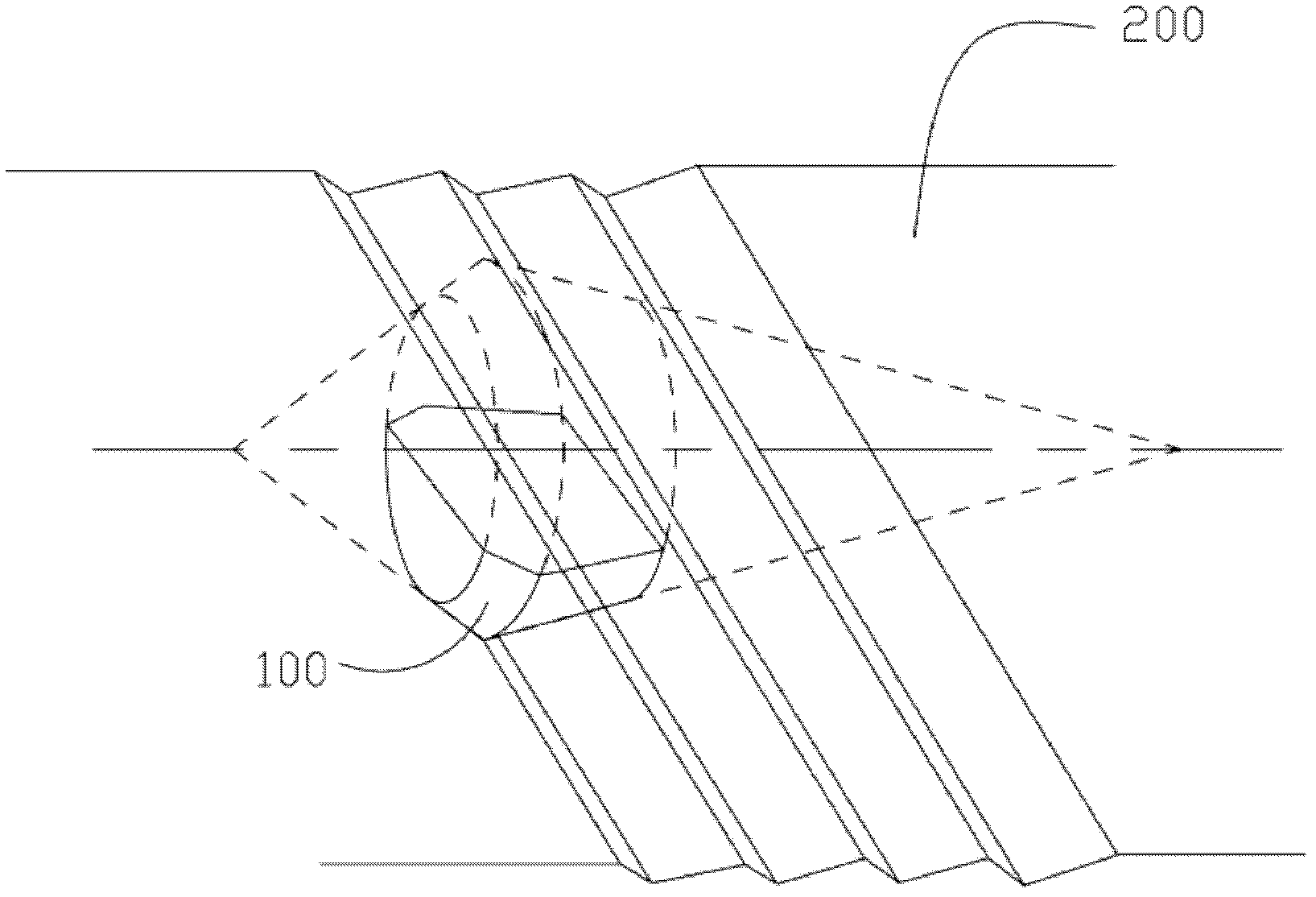

[0018] figure 1 Shown is a three-dimensional schematic view of the grating marking tool of the present invention. figure 2 Shown is a schematic cross-sectional view of the grating scribing tool of the present invention. Such as figure 1 and figure 2 As shown, the grating marking tool 100 includes a tool head 10 , a tool body 20 and a tool mounting shaft (not shown).

[0019] The cutter head 10 is a natural diamond double-conical cutter head, and the above-mentioned diamond double-conical cutter head is welded on the cutter body 20 after grinding. An arc-shaped knife ridge 11 is formed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com