Machining technology for alloy steel separation type solid retainer

A solid cage and processing technology technology, applied in the field of machining, can solve the problems of unstable inner and outer diameters of the cage, poor machining accuracy of the outer and inner diameters of the cage, unqualified roughness of the cage, etc. Dimensional stability, avoiding chipping, and improving the effect of mutual difference between pockets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

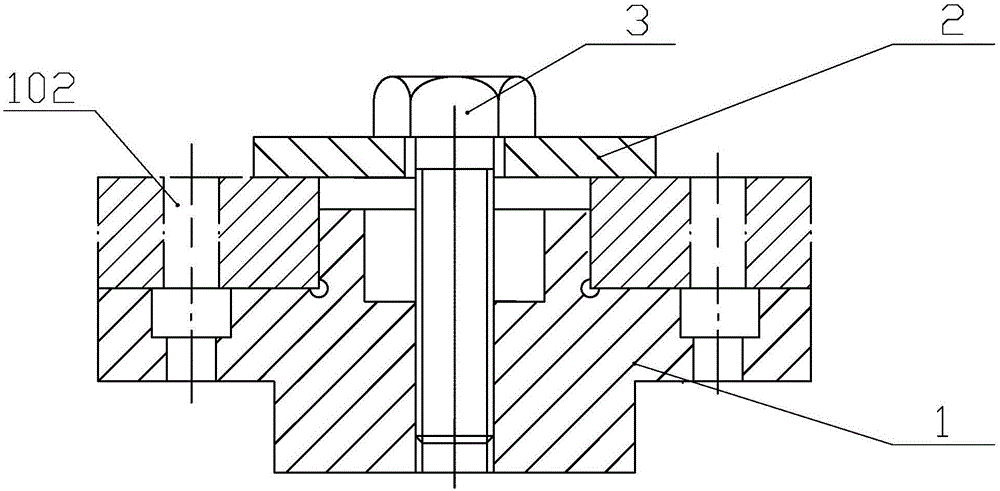

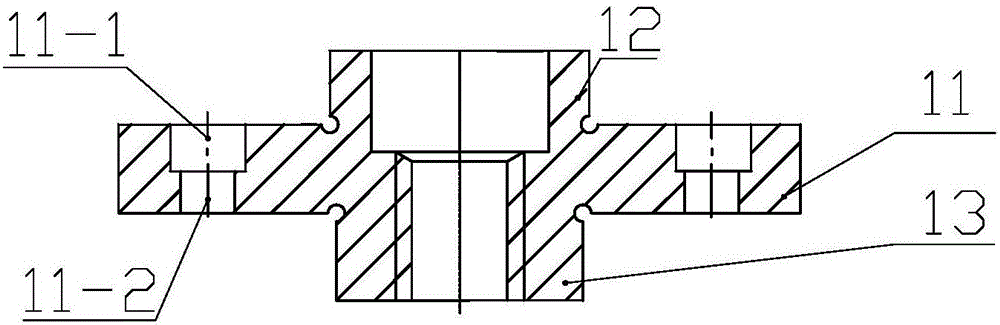

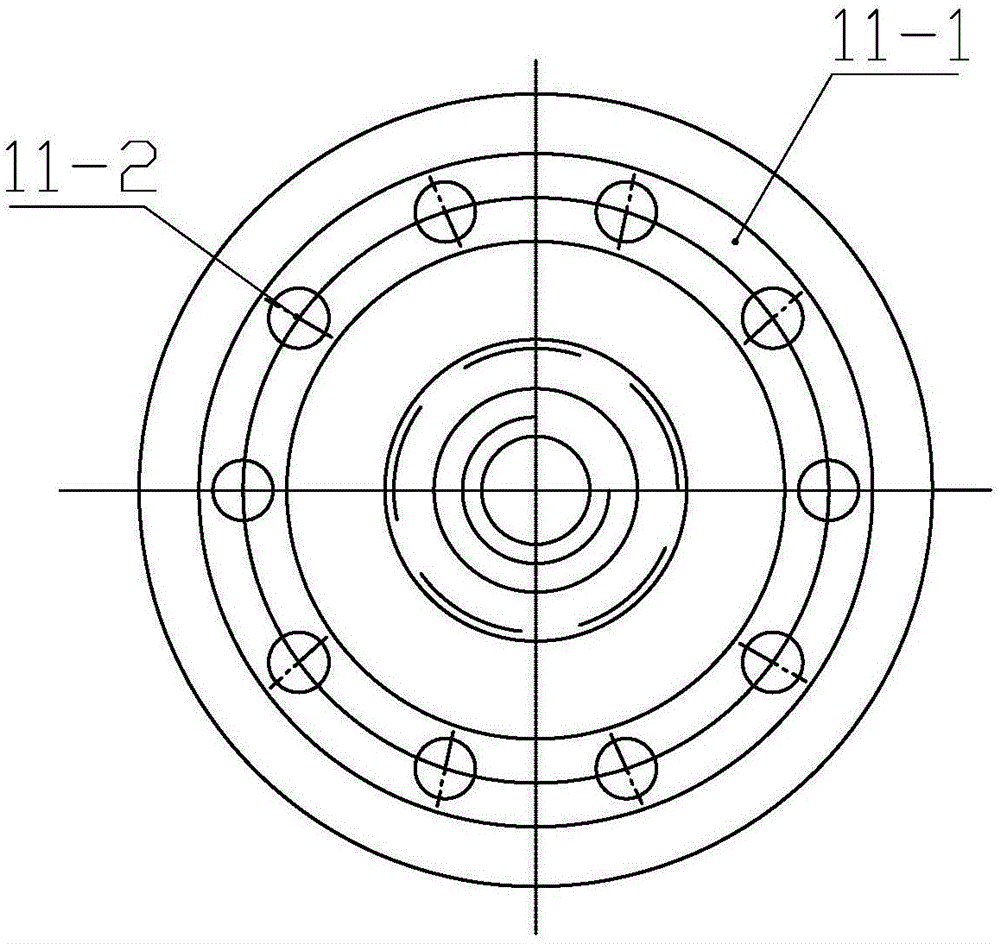

[0044] Specific implementation mode one: combine Figure 1 to Figure 11 Describe this embodiment, the processing technology of a kind of alloy steel separation type entity cage of this embodiment, the steps are as follows:

[0045] 1. Car forming: the cage adopts forgings or bars for feeding and processing, the forgings are ring-shaped workpieces, and the bars are cylindrical workpieces;

[0046] a) When using forgings for feeding processing, the workpiece is first rough-turned into shape, then quenched and tempered, and finally fine-turned into shape. The specific method is:

[0047] 1. First, the two ends of the workpiece, the inner diameter, the outer diameter, and the chamfered inner and outer corners are rough-turned. The size of the workpiece obtained after rough turning is the machining allowance left for the finished cage: outer diameter allowance 1.5-1.6mm, inner diameter allowance 1.1 ~ 1.3mm, end face allowance 0.7 ~ 0.8mm, and then quench and temper the workpiece ...

specific Embodiment approach 2

[0070] Specific implementation mode two: combination Figure 11 To illustrate this embodiment, the cage with an outer diameter ≤ 40 mm is processed by bar feeding, and the cage with an outer diameter > 40 mm and inner diameter ≥ 30 mm is processed by forging. With such a design, if the size of the workpiece is too small, forgings cannot be made, and only bar stock can be used. The advantages of forgings can eliminate internal defects of parts or blanks; forgings have good shape and dimensional stability, and have high comprehensive mechanical properties; the biggest advantages of forgings are good toughness, reasonable fiber structure, and small performance changes between forgings. Other compositions and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0071] Embodiment 3: The drill bit selected in step 3 is a cobalt-containing high-speed steel drill bit with a diameter ranging from 2 to 2.05 mm. With this design, the alloy steel material is hard and sticky, and the hardness reaches 37-38HRC after quenching and tempering treatment. The rivet hole processing belongs to deep hole processing, and the processing depth of the hole is 7-8 times the diameter of the hole. It is easy to fold the drill bit during processing. The drill bit made of cobalt material has the characteristics of high temperature resistance and wear resistance. It has good toughness and sharp cutting edge, which can avoid the generation of sticky chips and built-up edge. materials and difficult-to-process materials. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com