Patents

Literature

319results about How to "High geometric accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

System and method for fabricating or repairing a part

InactiveUS7020539B1Improve accuracyHigh geometric accuracyAdditive manufacturing apparatusTool changing apparatusMulti axisMachining

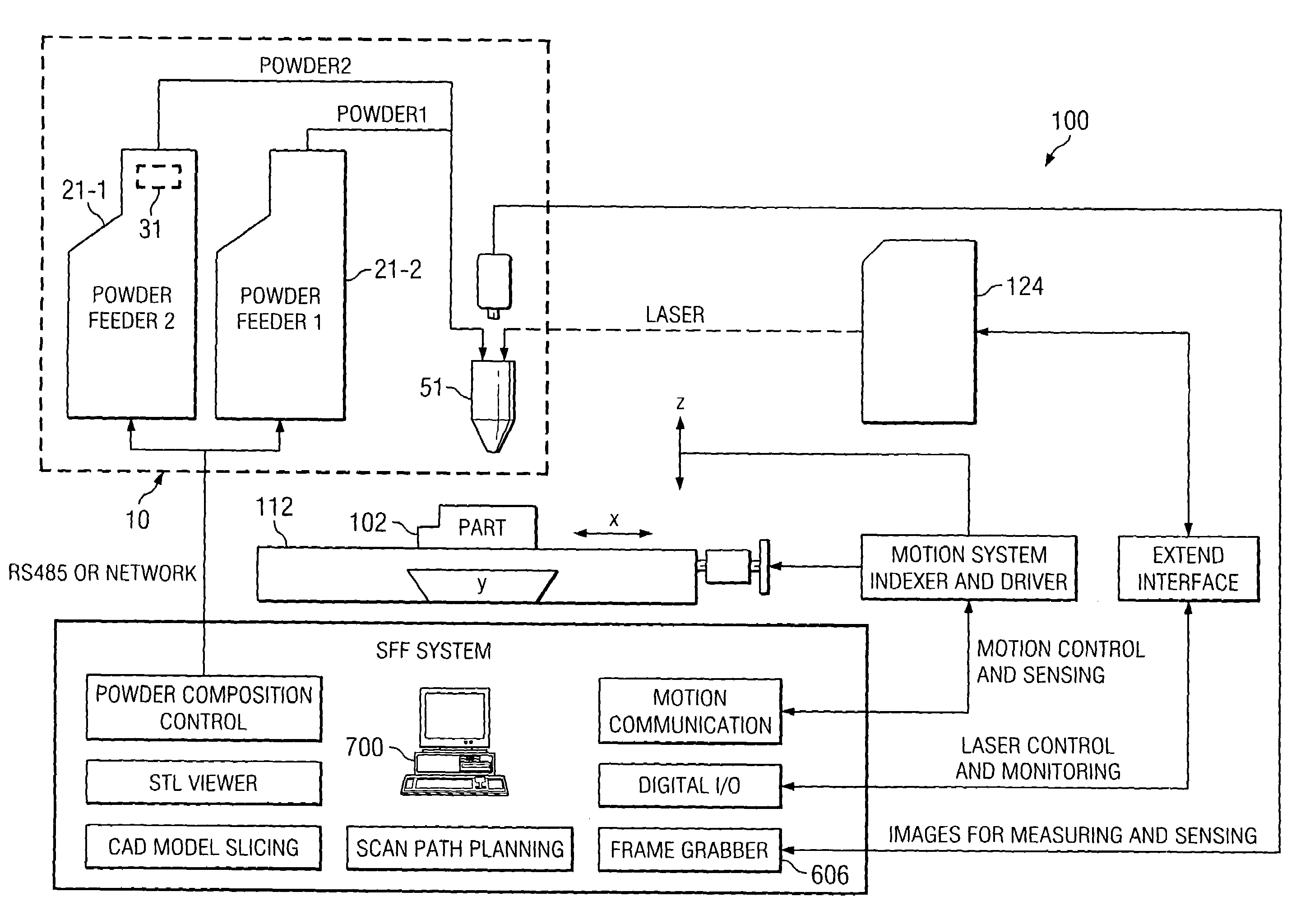

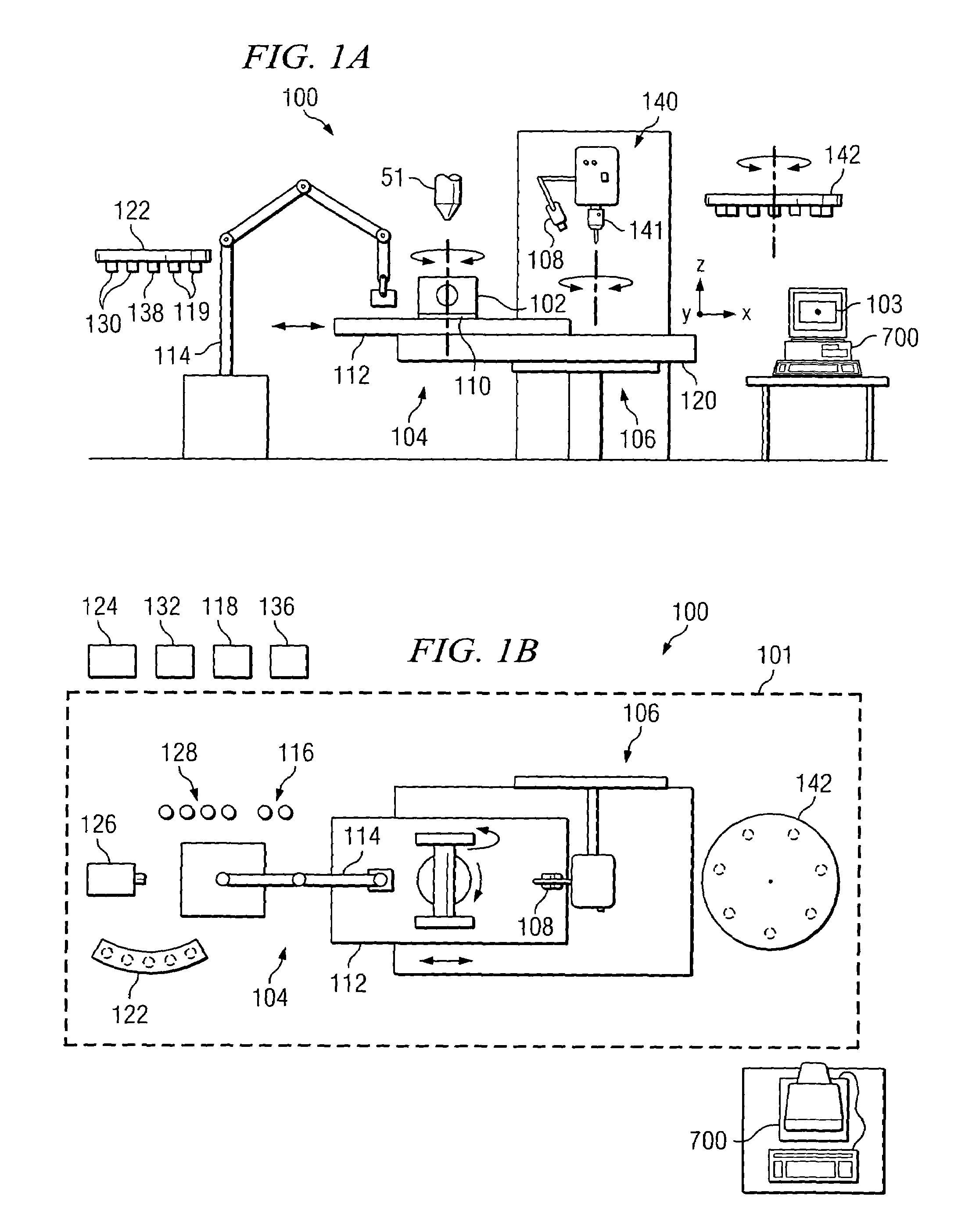

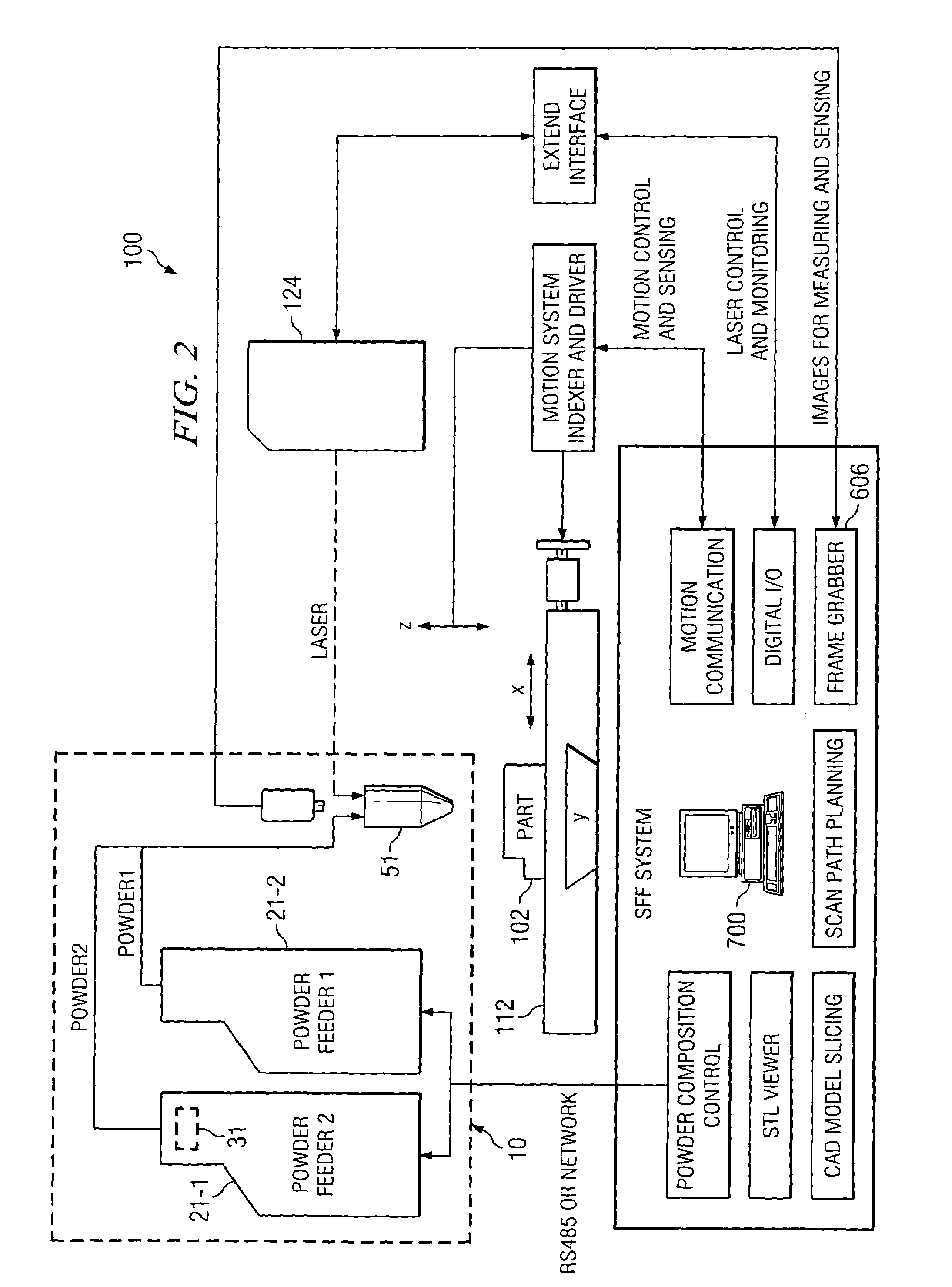

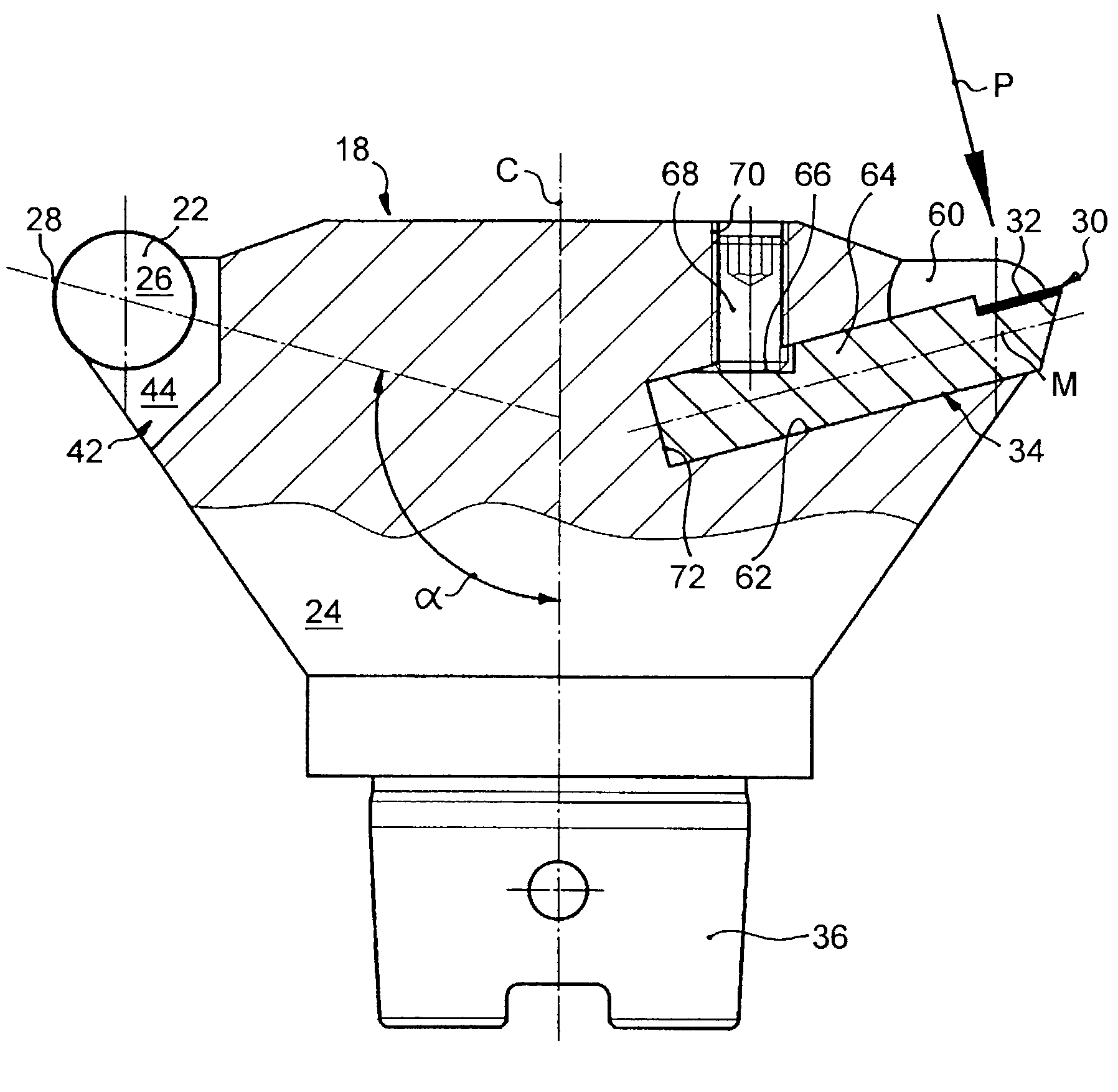

According to one embodiment of the invention, a system for fabricating a part includes a computer operable to control the fabrication of a three-dimensional part using a solid CAD model, a deposition station operable to deposit successive two-dimensional layers of material to fabricate the three-dimensional part, and a machining station operable to remove at least a portion of one or more of the deposited two-dimensional layers of material. The deposition station includes a substrate on which to fabricate the three-dimensional part, a welding-based deposition system having a welding torch, a laser-based deposition system having a laser head, a plasma powder cladding system having a plasma torch, and a multi-axis robot operable to, when directed by the computer, utilize one of the welding-based deposition system, laser-based deposition system, and plasma powder cladding system to deposit any of the two-dimensional layers of material. The machining station includes a multi-axis milling machine and an automatic tool changer. The milling machine is operable to, when directed by the computer, select from a plurality of machining tools associated with the automatic tool changer for use in the milling machine.

Owner:SOUTHERN METHODIST UNIVERSITY

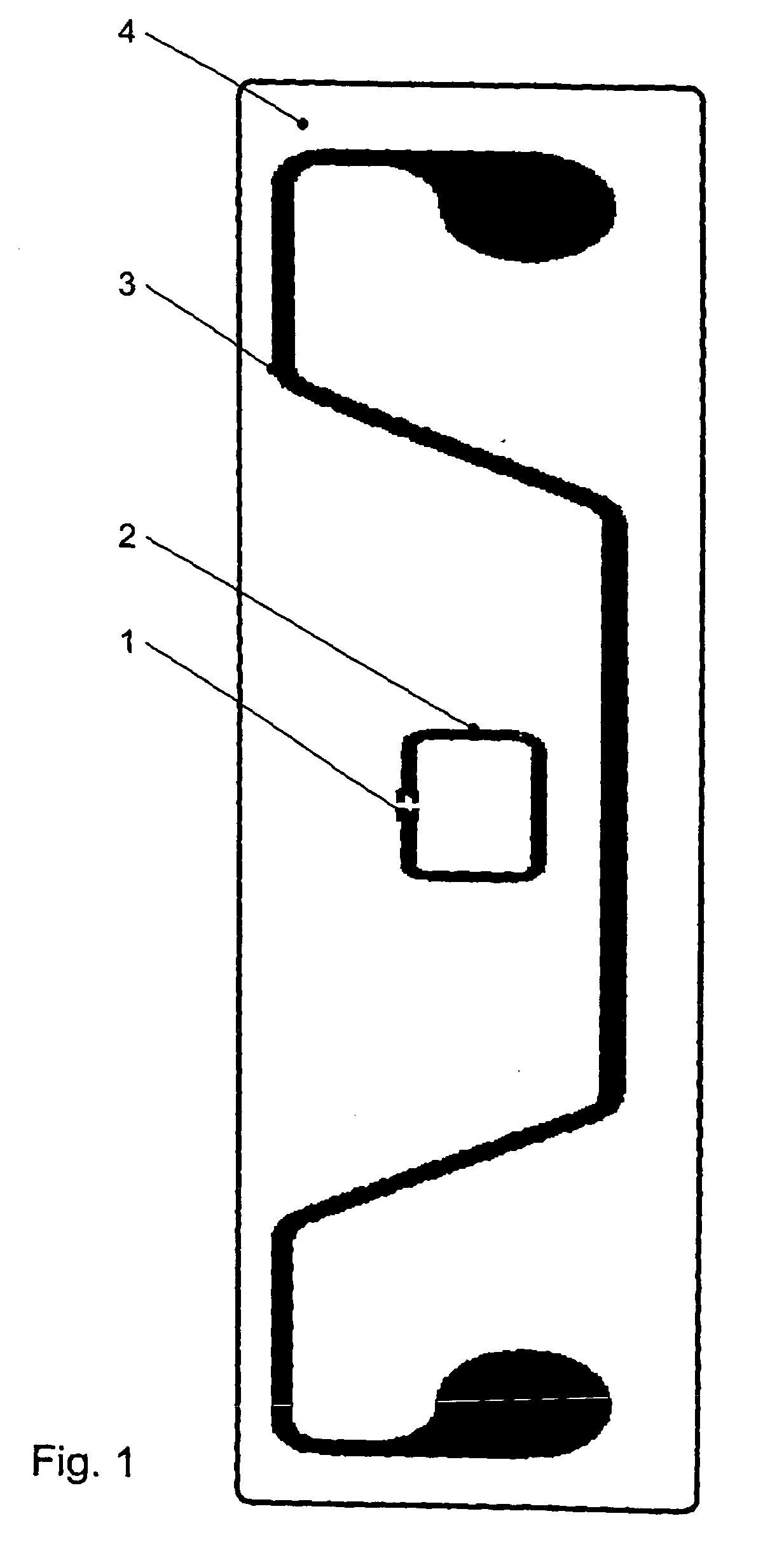

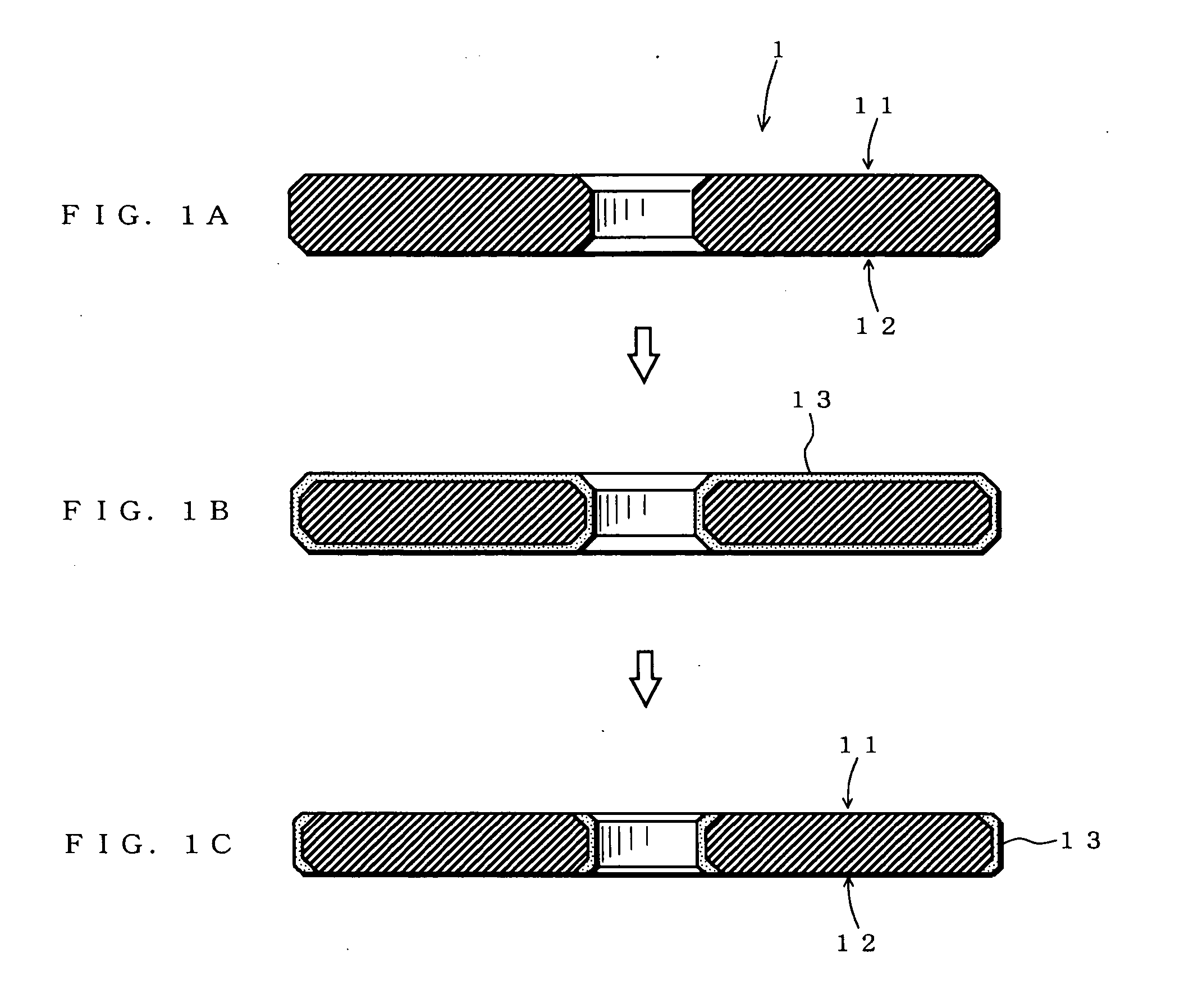

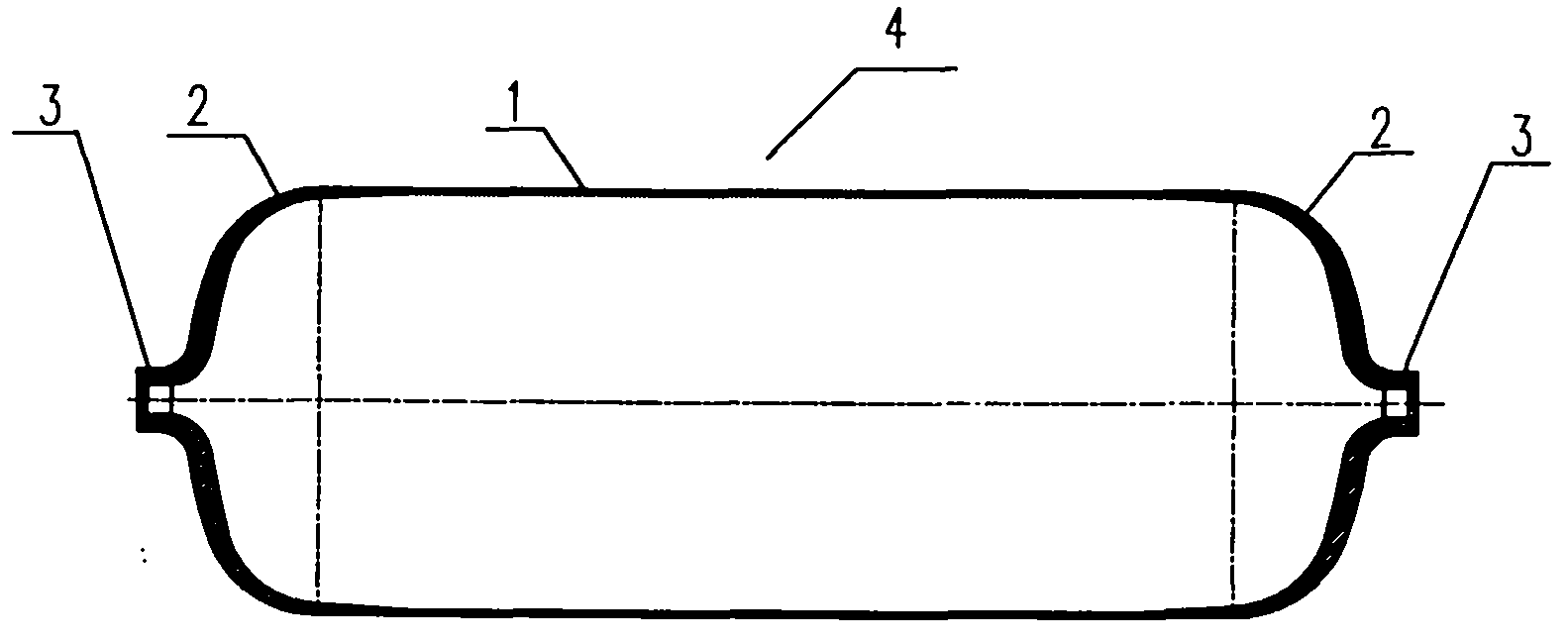

Radio frequency identification transponder antenna

ActiveUS20070052613A1Lower input impedanceLower resistanceRadiating elements structural formsAntennas earthing switches associationImpedance matchingElectric field

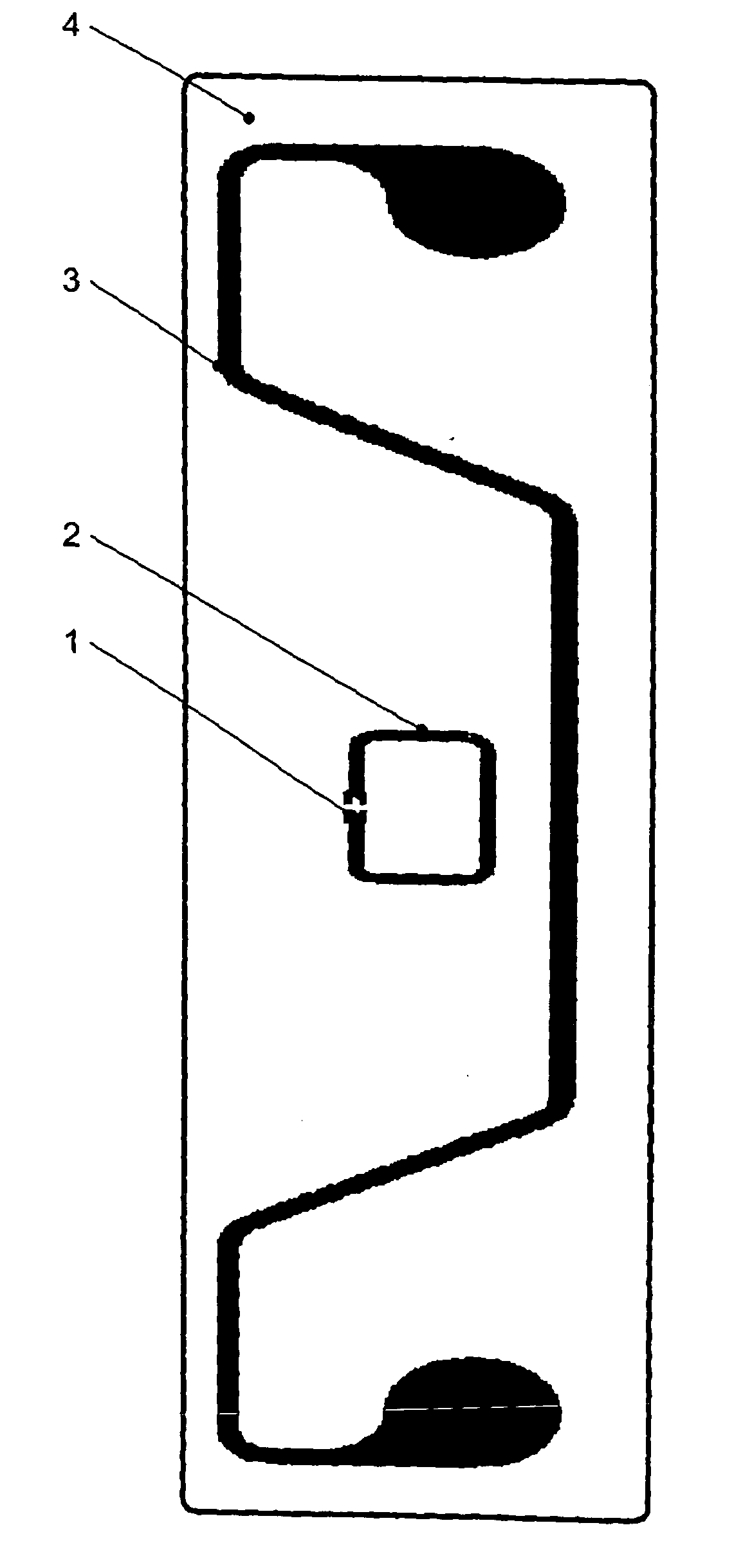

A RFID transponder having a microchip or integrated circuit, an impedance-matching structure and a resonant structure mounted on at least one substrate and connected to each other by an electric field.

Owner:SMARTRAC TECHNOLOGY GMBH

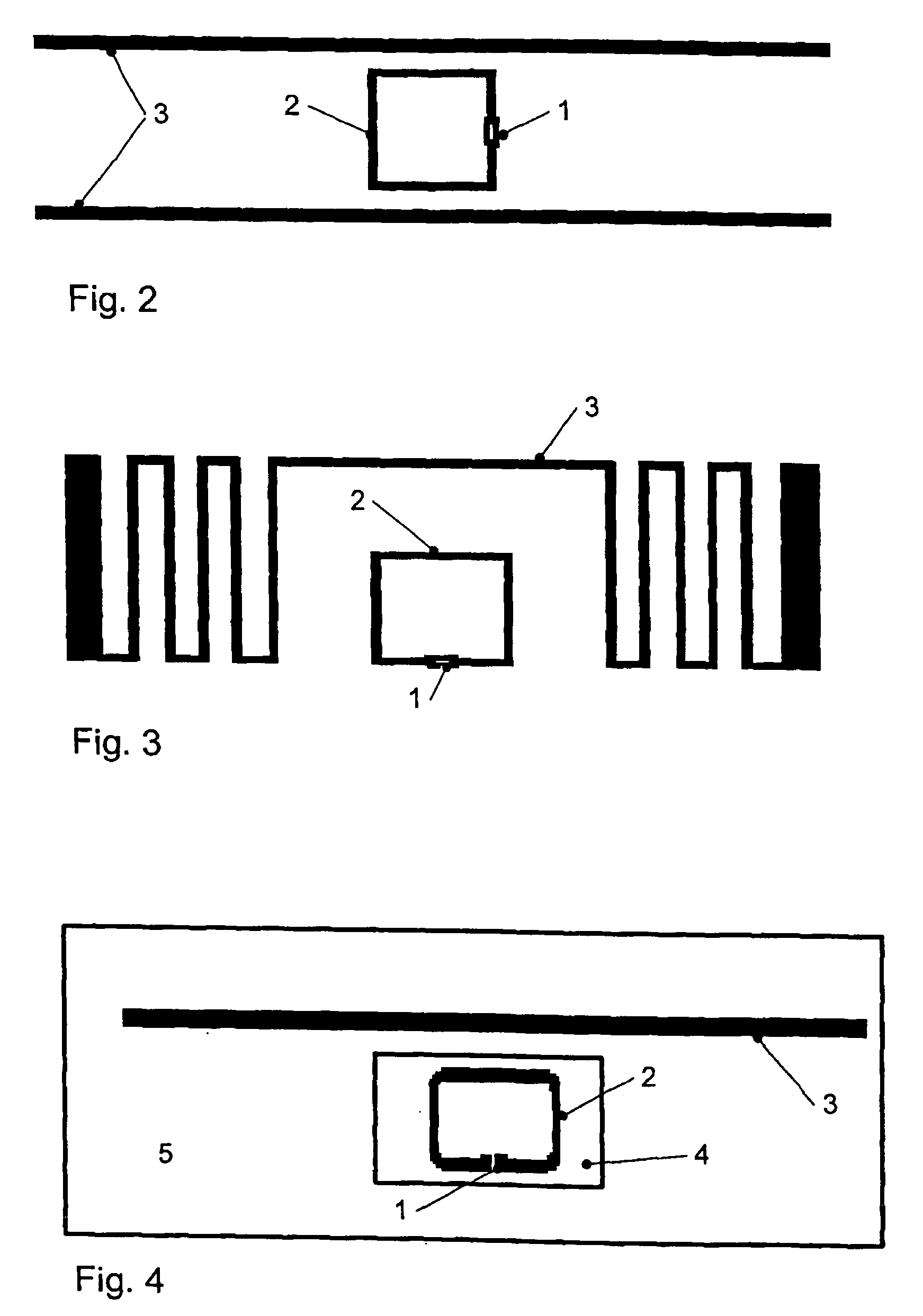

Method for stitching partial radiation images to reconstruct a full image

InactiveUS6895106B2High geometric accuracyImprove image qualityCharacter and pattern recognitionImage data processing detailsComputer graphics (images)Radiology

A method of forming a composite digital image comprising: providing 1-N digital images formed from 1-N contiguous segments of a larger radiographic image recorded in 1-N overlapping storage phosphor screens wherein N is equal to or greater than 2 and wherein the image content in the overlapped region of contiguous images is the same, and the end edge of a screen nearest an x-ray source is present in both contiguous images; selecting a pair of contiguous digital images, wherein one image is closer to said x-ray source than said other image; correcting for any geometric distortion if applicable in said pair of digital images based on the distance between x-ray source and said storage phosphor screen; determining any rotational displacement and any vertical displacement between said pair of digital images by matching said end edge of said one image present in said pair of images correcting for image orientation if applicable based on any said rotational displacement; determining any horizontal displacement between said pair of digital images by correlating the image content in said overlapping regions of said pair of digital images; stitching said pair of digital images together to form a larger composite digital image along said one image edge based on any said horizontal and vertical displacement; and repeating said correcting for any geometric distortion to said stitching with the larger composite image and the next consecutive overlapping digital image until all N digital images are stitched together to form a full composite image.

Owner:CARESTREAM HEALTH INC

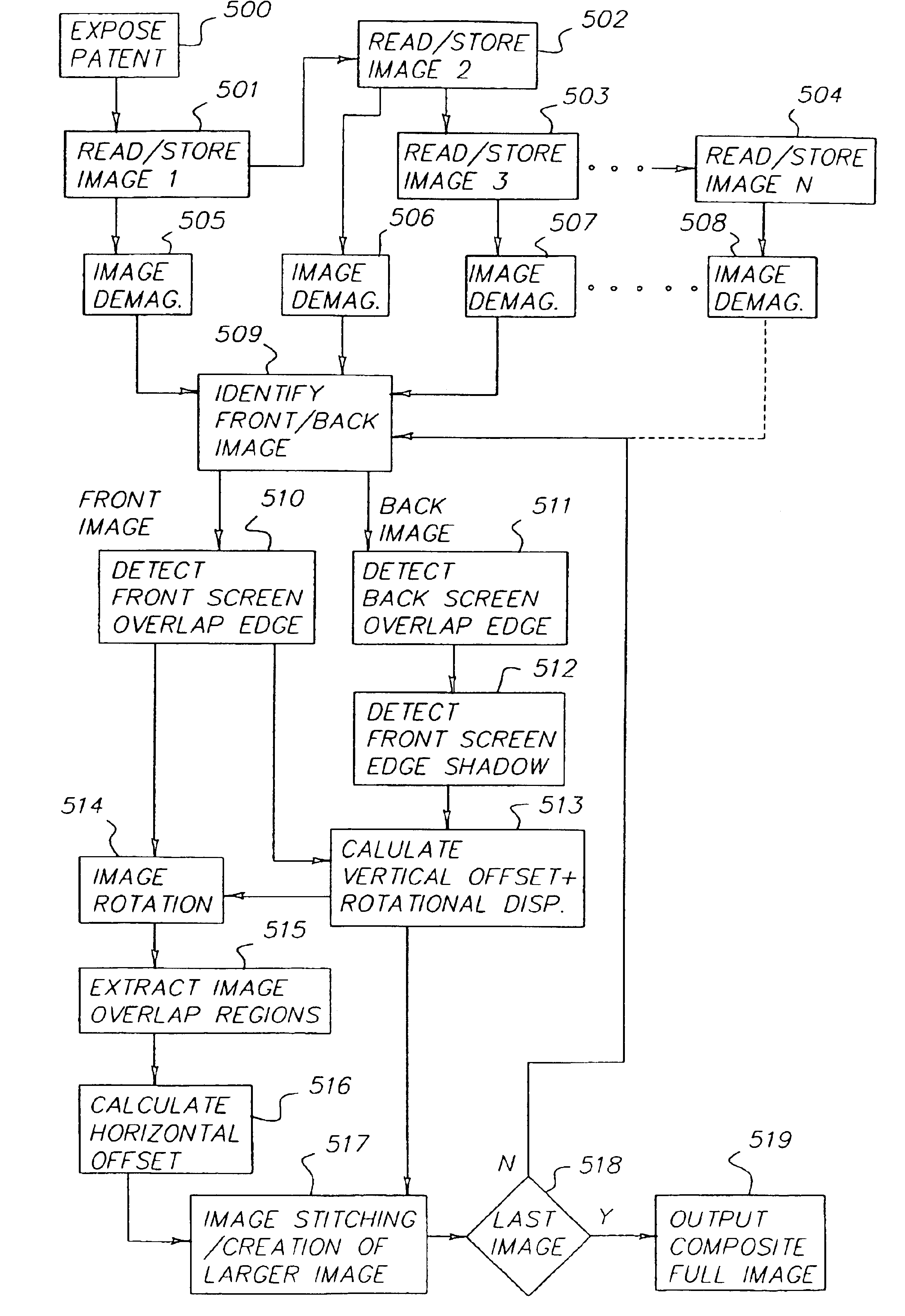

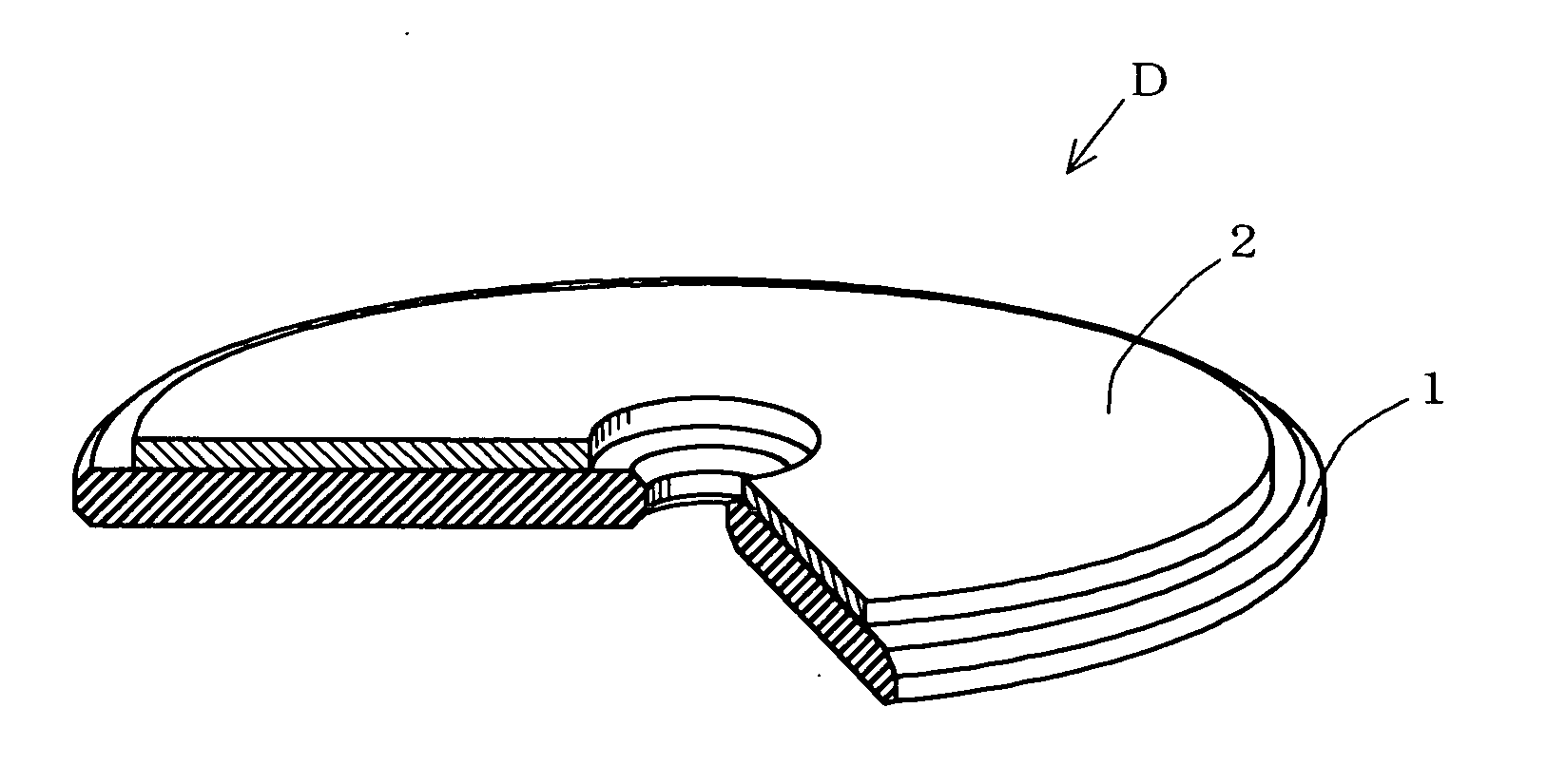

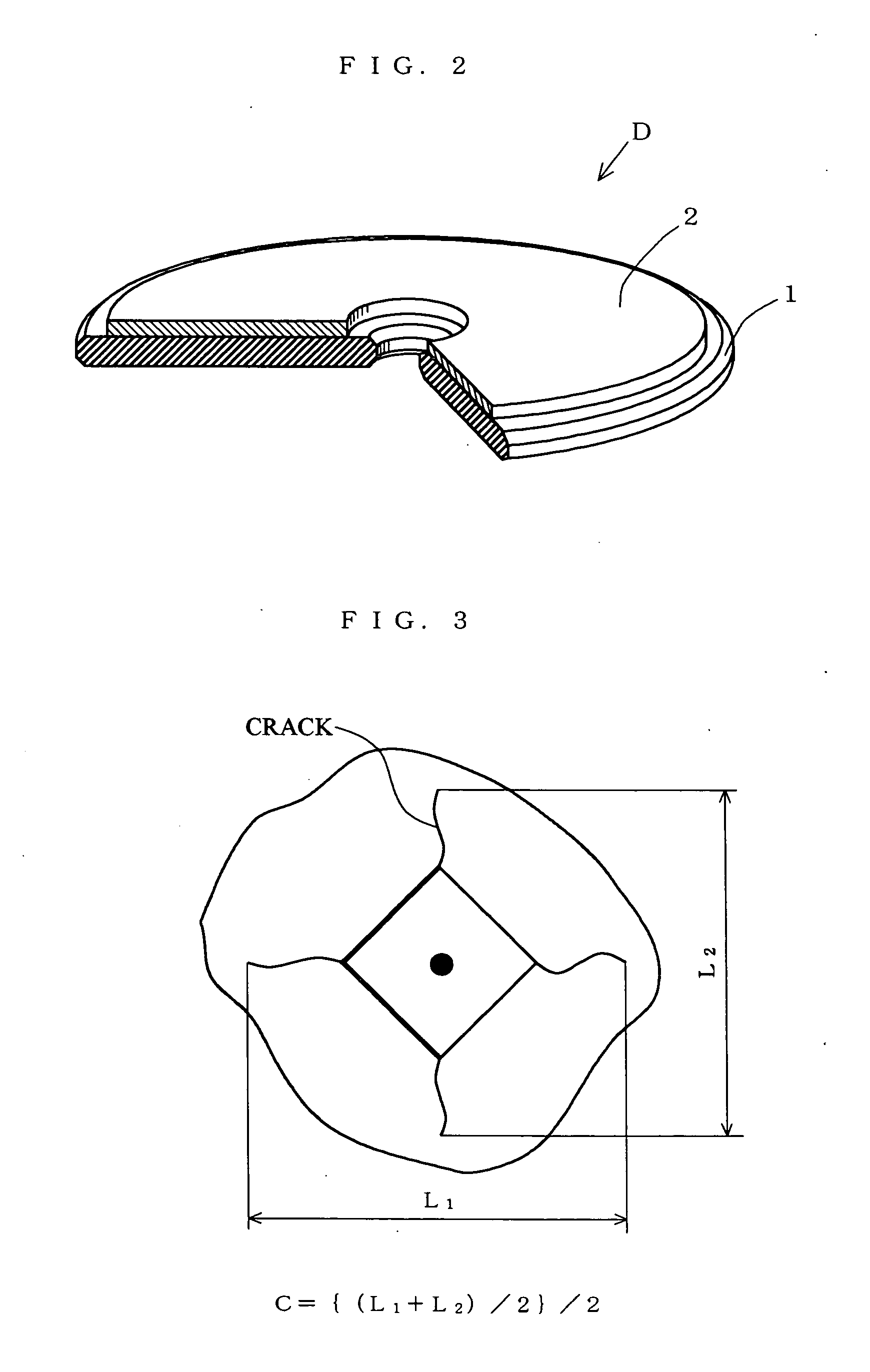

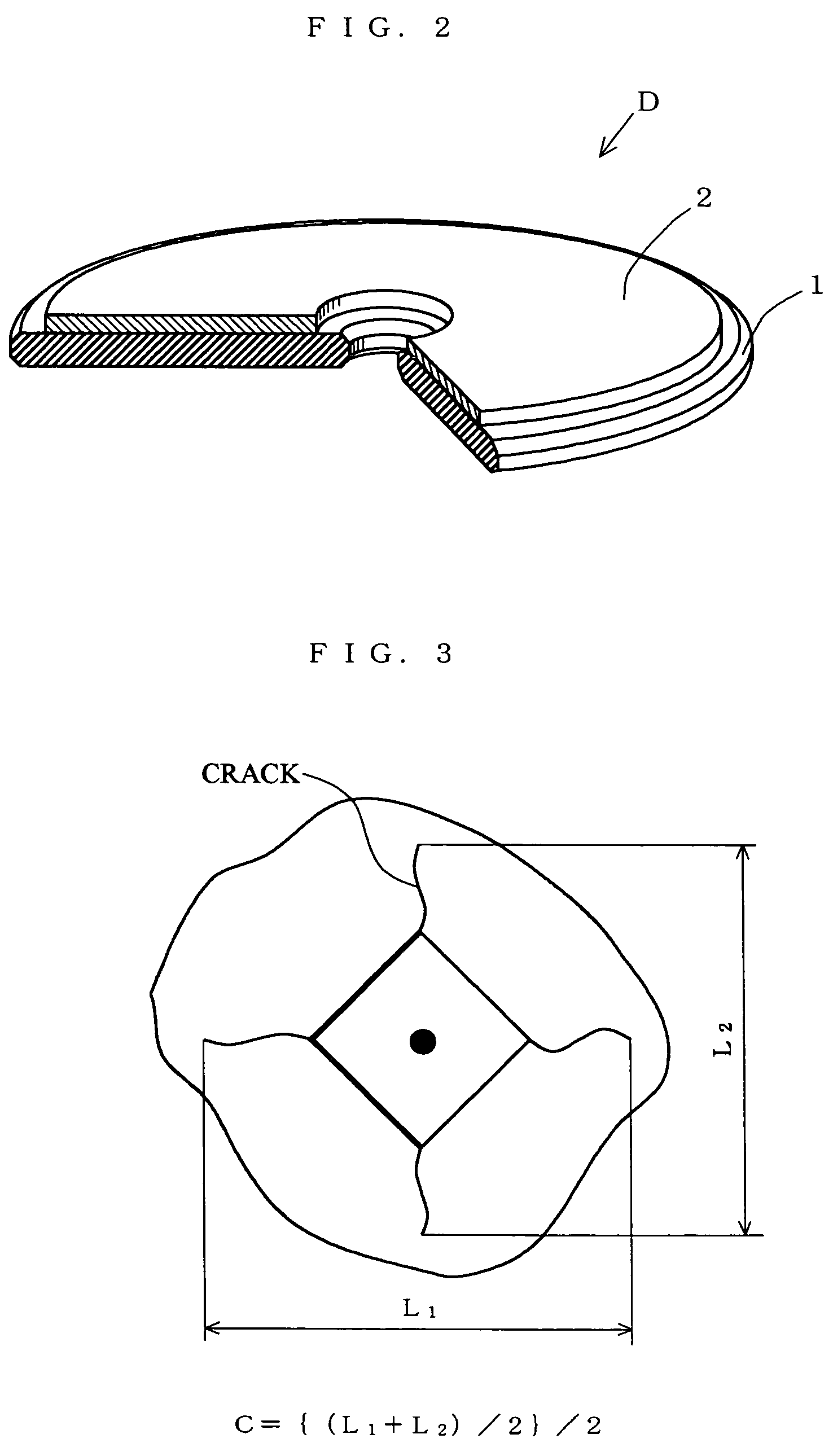

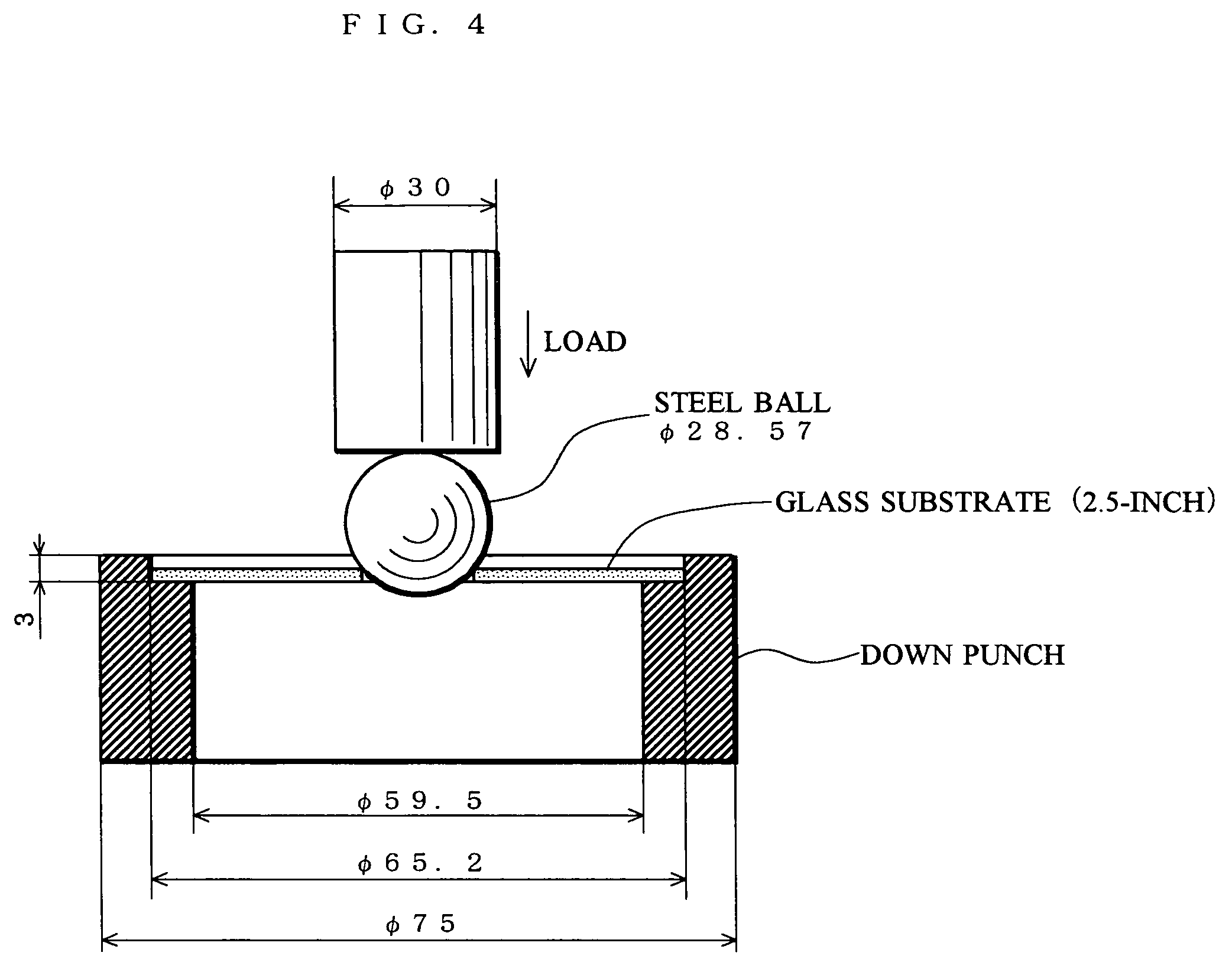

Glass substrate for an information recording medium and information recording medium employing it

InactiveUS20050096210A1Improve yieldIncreased durabilityMagnetic materials for record carriersBase layers for recording layersEdge surfaceRecording layer

A chemically strengthened glass substrate for use as the substrate of an information recording medium such as a magnetic disk, magneto-optical disk, DVD, or MD, wherein a strengthened layer formed by chemical strengthening exists on the outer edge surface and on the inner edge surface but substantially not on a surface on which an information recording layer is formed.

Owner:HOYA CORP

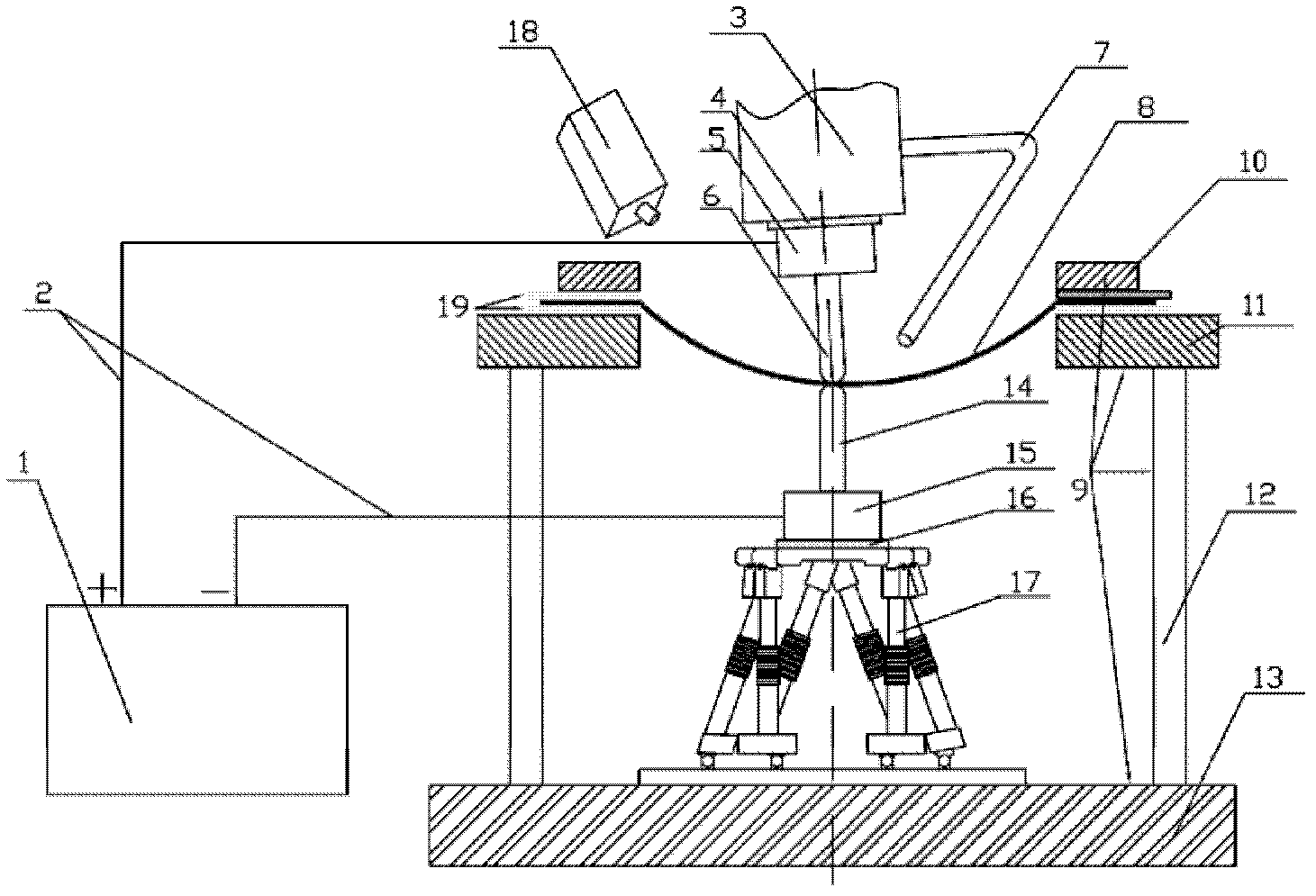

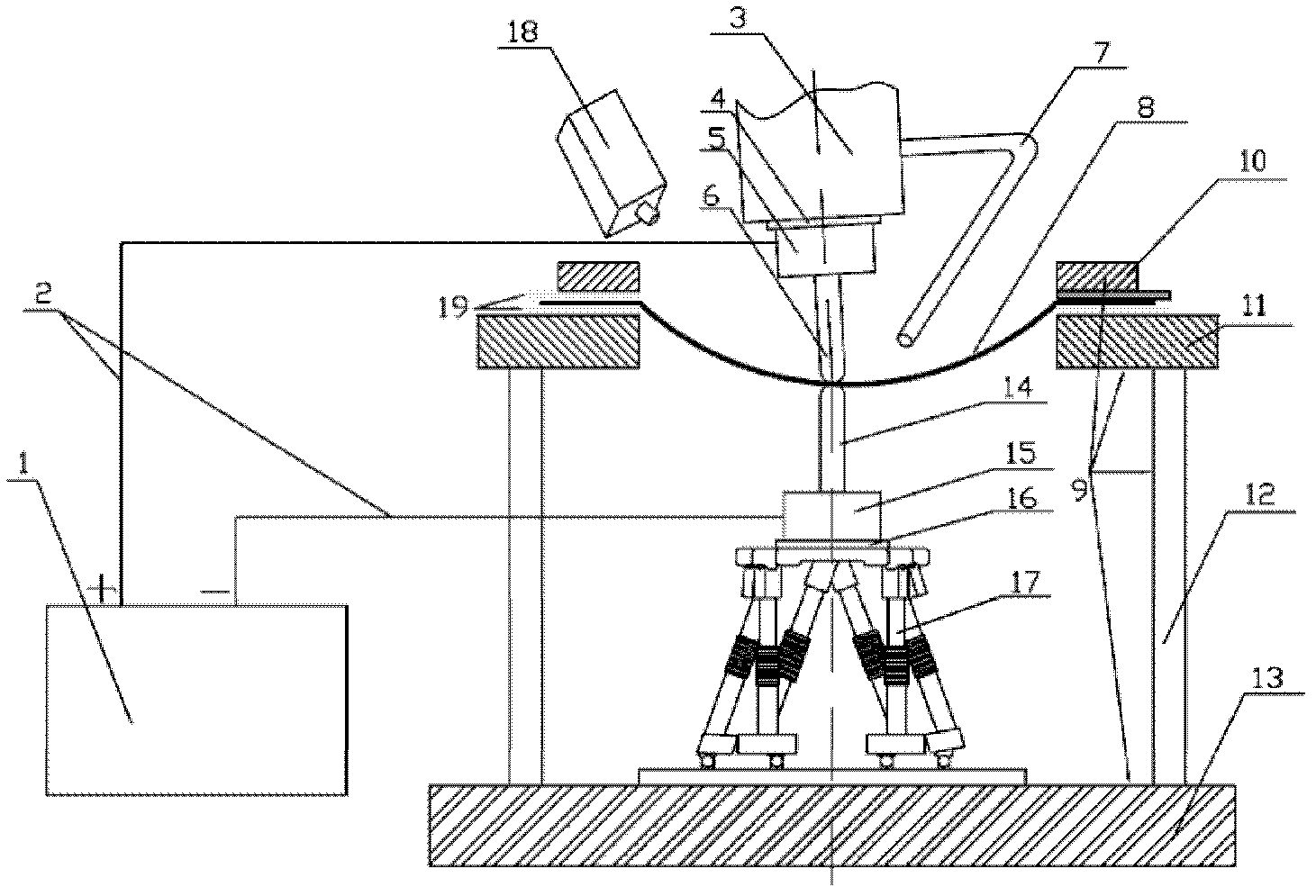

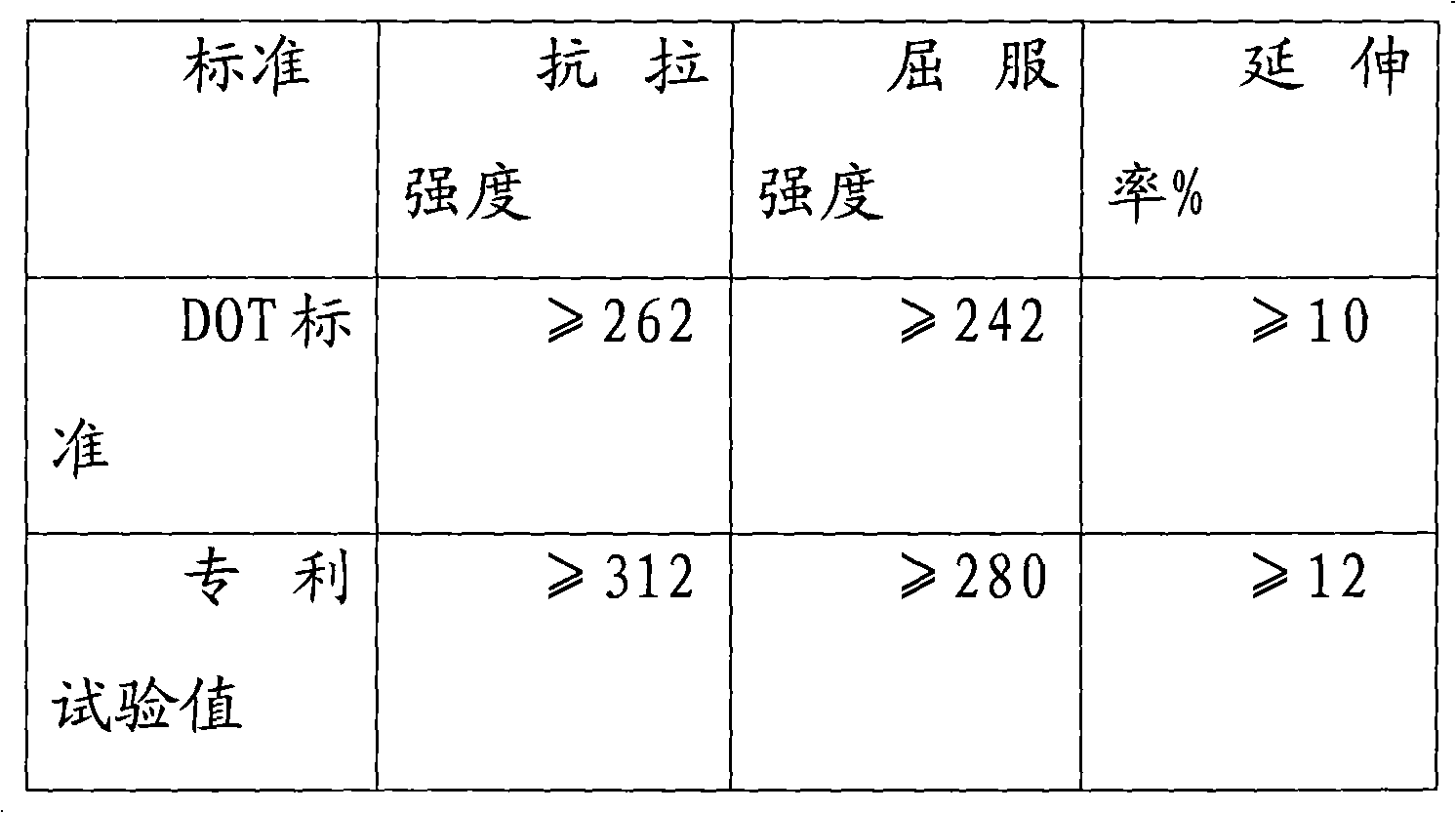

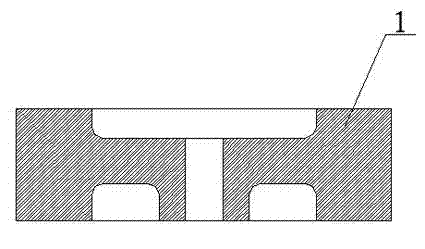

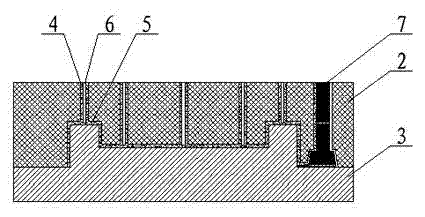

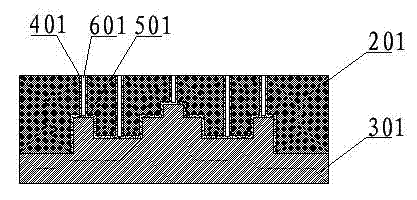

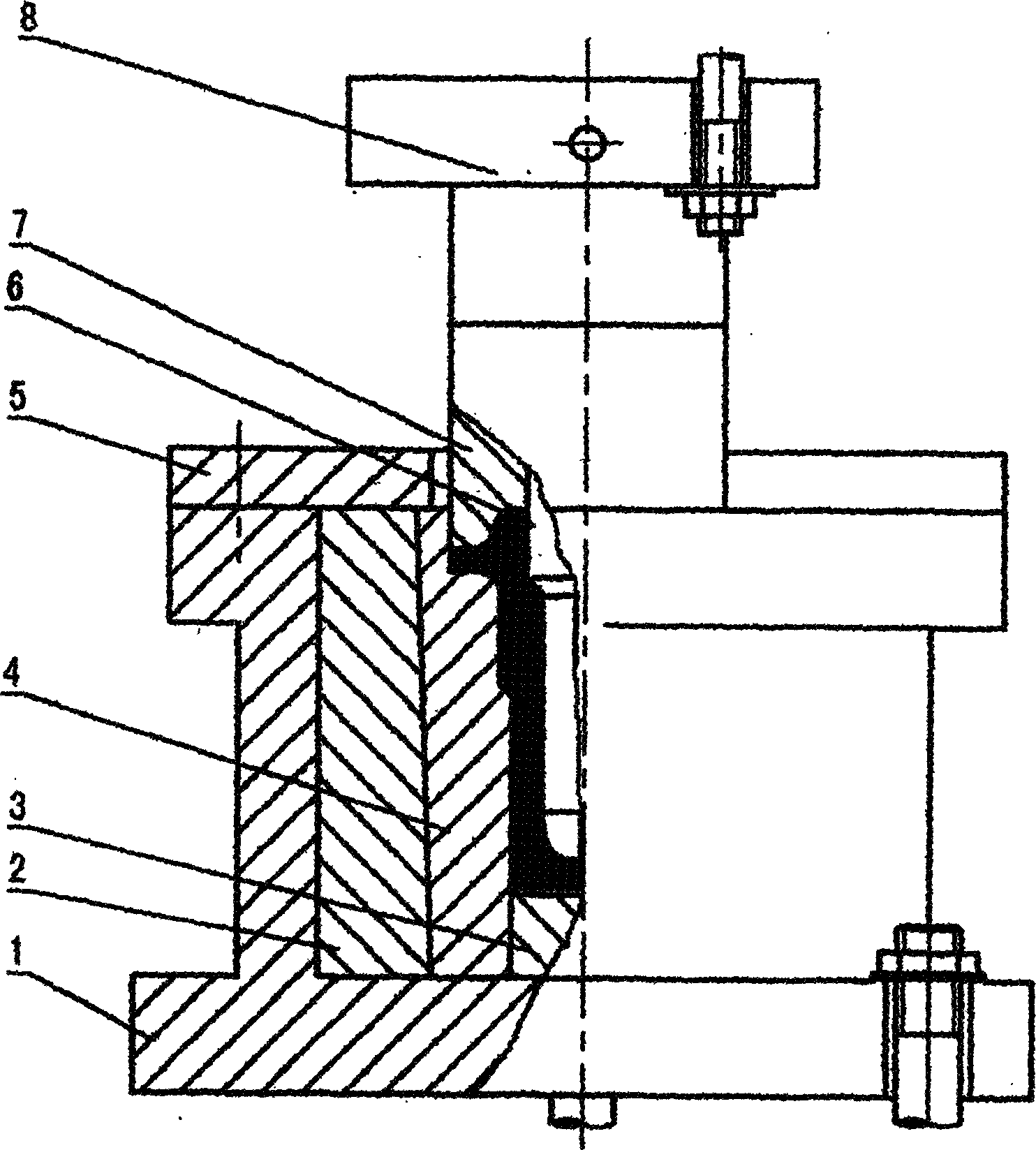

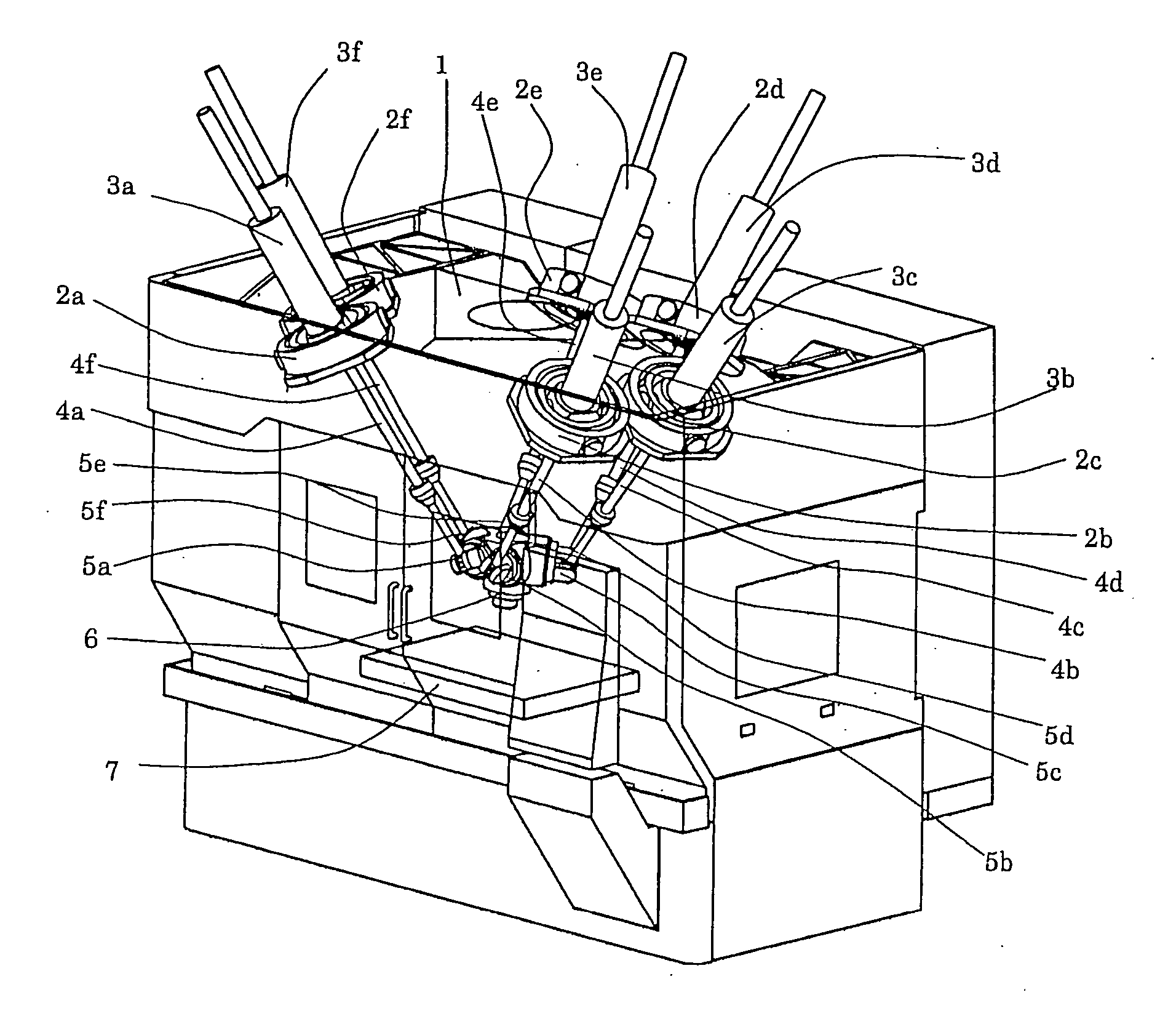

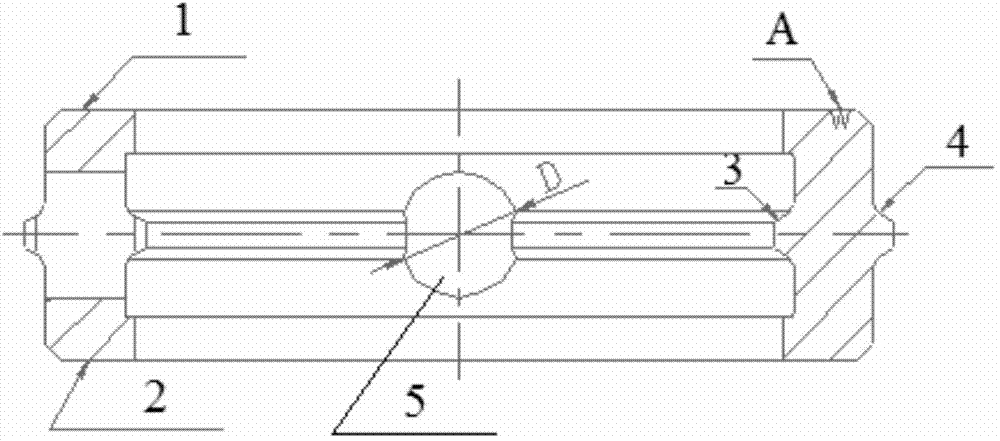

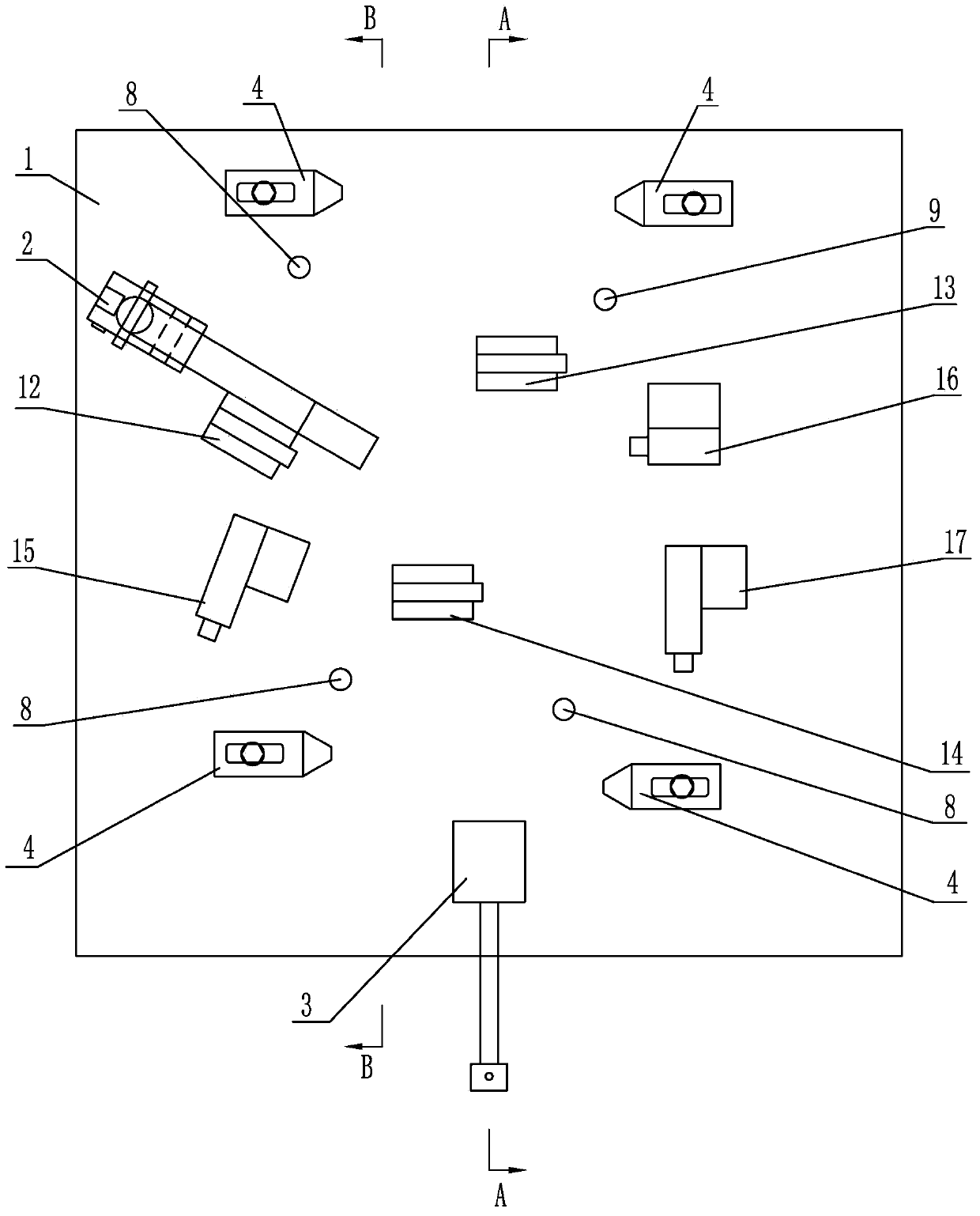

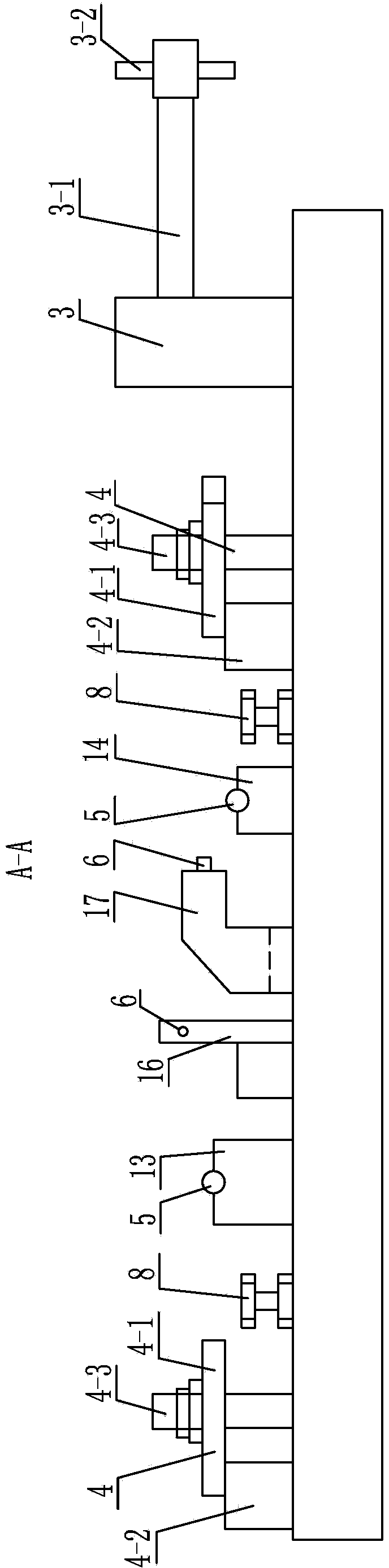

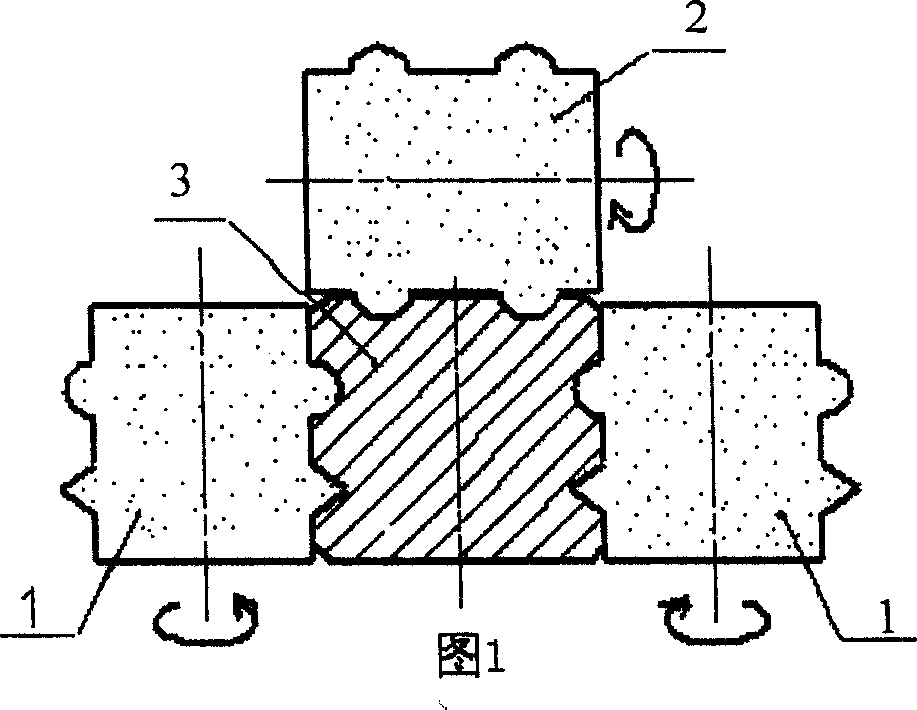

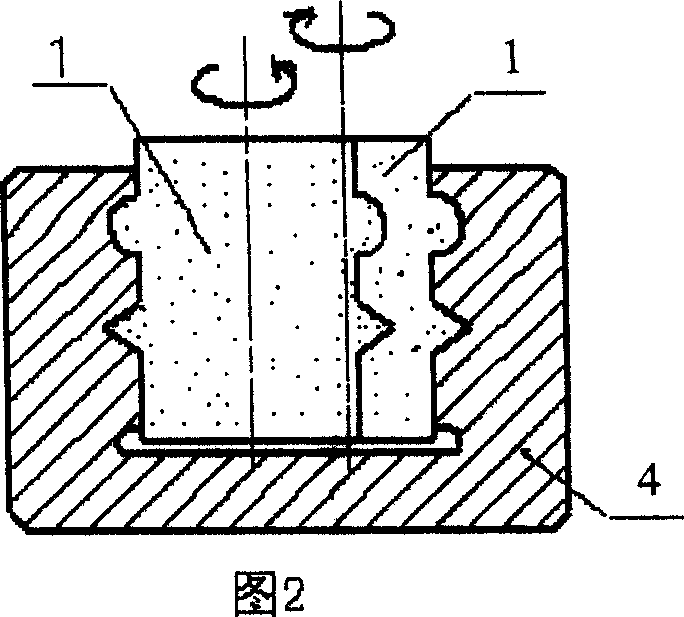

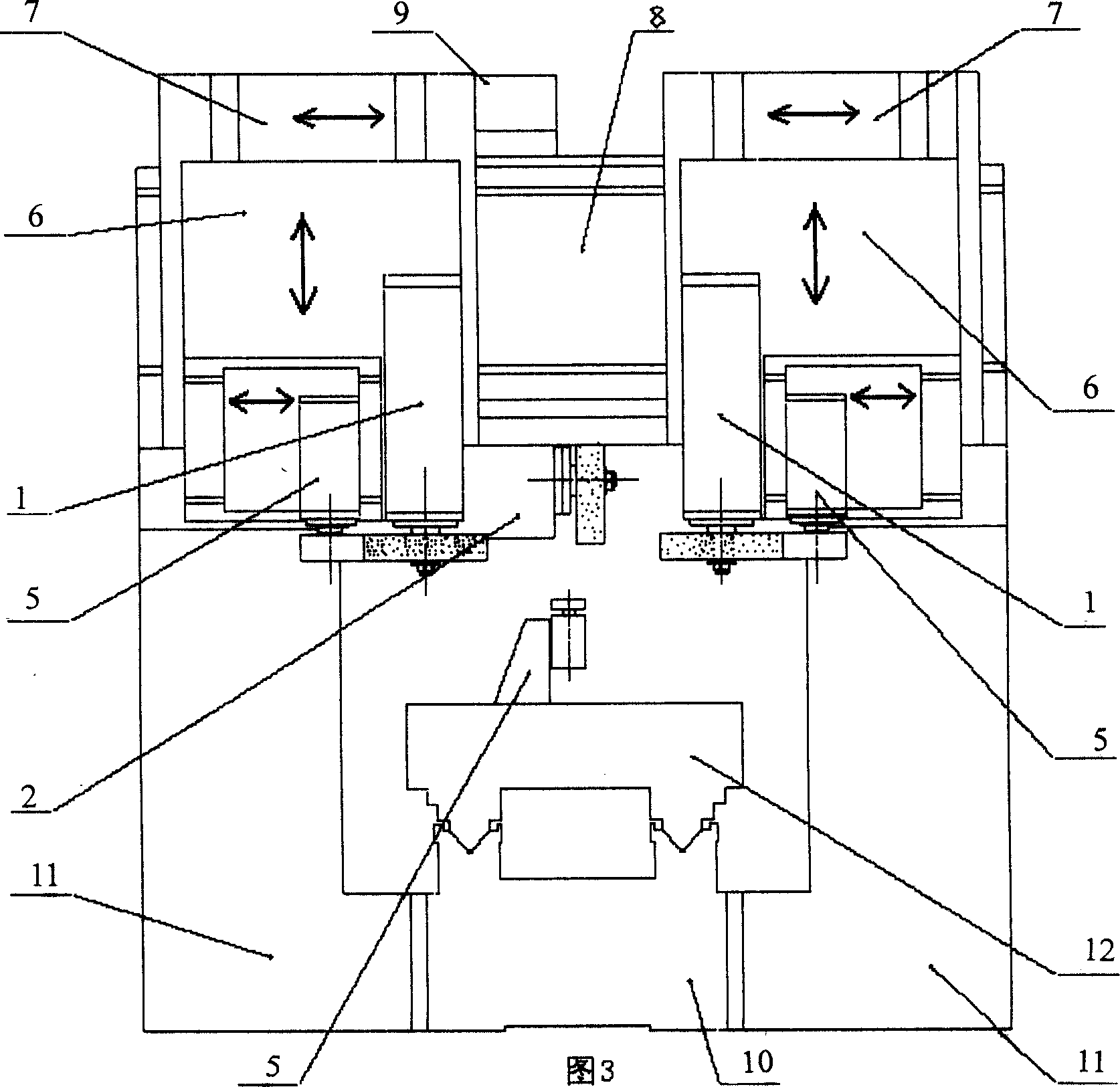

Electroplastic incremental forming device and method for plates

ActiveCN102527830ALower yield stressHigh geometric accuracyMetal-working feeding devicesPositioning devicesNumerical controlHigh energy

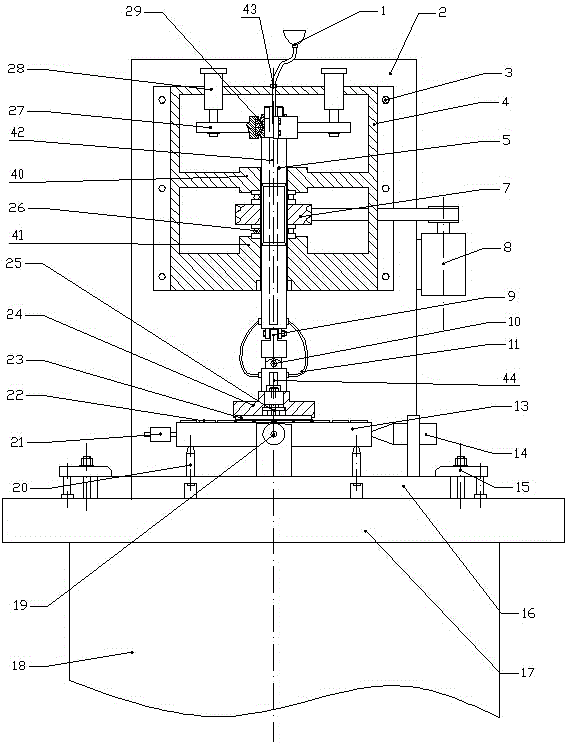

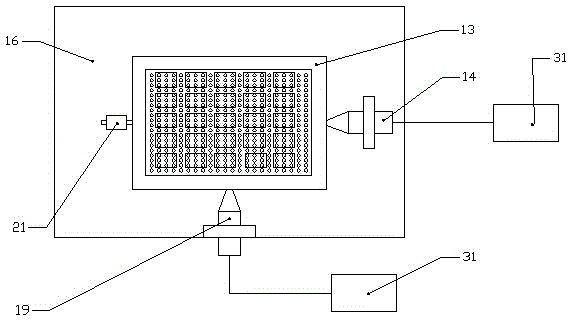

The invention relates to an electroplastic incremental forming device and an electroplastic incremental forming method for plates. The device comprises a five-axis numerical control forming machine tool, a six-axis parallel robot machining system, a plate forming clamp, a high energy pulse power supply, an infrared thermometer, and a compressed air cooling system embedded in the machine tool, wherein an upper forming pressing head is arranged at the tail end of a spindle of the five-axis numerical control forming machine tool; the six-axis parallel robot machining system is arranged on a working table of the machine tool; the top of the six-axis parallel robot machining system is provided with a lower forming pressing head; the plate forming clamp is fixed on the working table of the machine tool; positive and negative poles of the high energy pulse power supply are connected with the upper forming pressing head and the lower forming pressing head through high current-carrying conductors respectively so as to form a current loop among the high energy pulse power supply, the upper forming pressing head, the lower forming pressing head and the plates; a camera of the infrared thermometer is aligned with a central area of each plate; and the compressed air cooling system is aligned with a forming area of each plate. Compared with the prior art, the invention has the advantages of high efficiency, energy conservation, high machining precision, high surface quality and the like.

Owner:SHANGHAI JIAO TONG UNIV

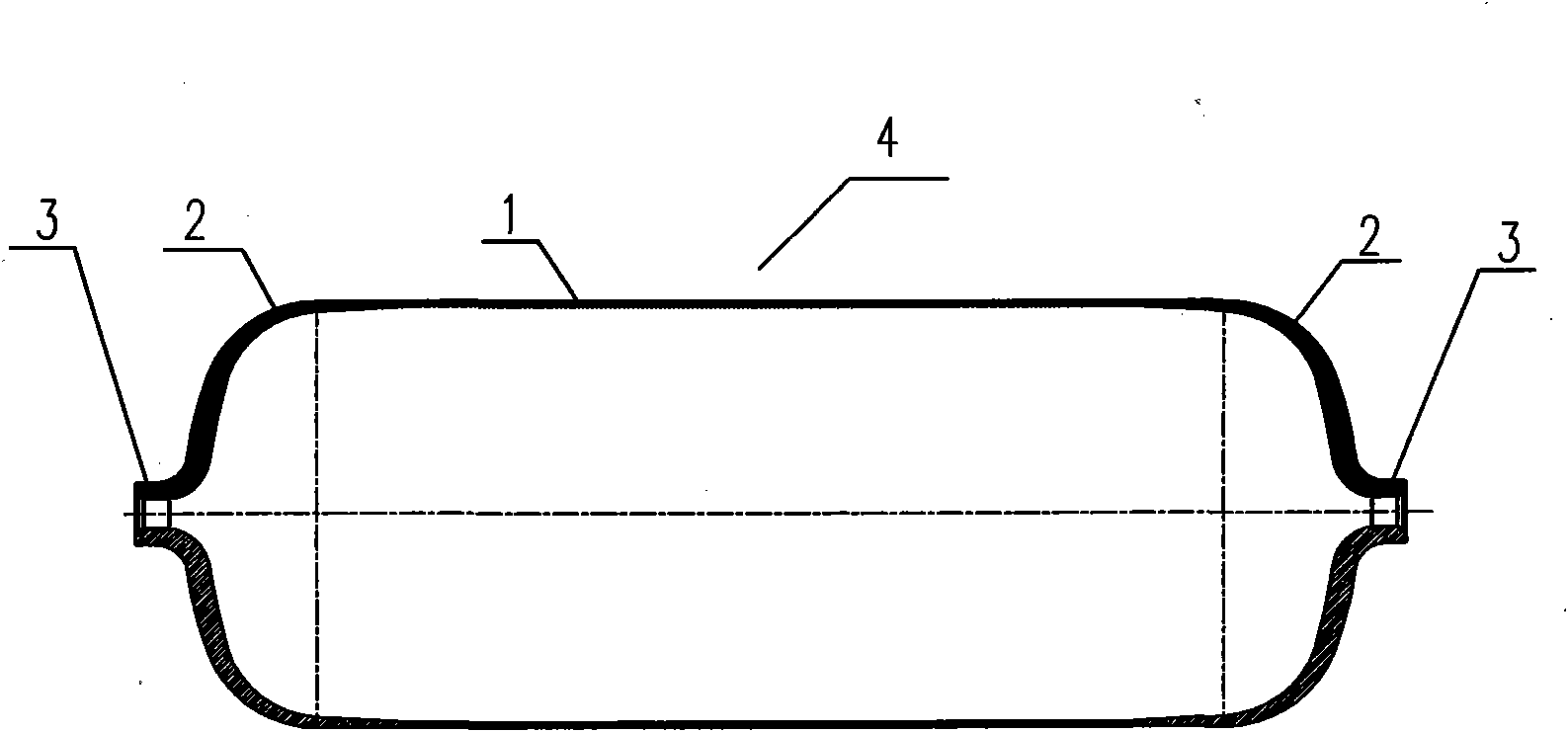

Method for manufacturing aluminum liner of vehicular composite cylinder

The invention discloses a method for manufacturing an aluminum liner of a vehicular composite cylinder, which is used for manufacturing the aluminum liner of the vehicular composite cylinder. The aluminum liner consists of a thin-walled cylinder body of the aluminum liner, an end enclosure gradually thickening part and an opening part. The aluminum liner is manufactured by adopting a method of reducing the wall thickness of a thick-wall aluminum pipe by over 60 percent by one time of rotary pressing by a 450 strong spinning reduction machine, forming the end enclosure part and the opening part by using a 412 spinning necking machine, and machining the connecting threads on the opening part after solution ageing heat treatment. The aluminum liner of the vehicular composite cylinder has the advantages of high quality, large diameter, thin wall thickness, small weight capacity ratio (weight / capacity), high geometric dimensioning accuracy, high quality of inner and outer surfaces and the like, and has the excellent application and market prospects.

Owner:BEIJING TIANHAI IND

Sand-line iron mould casting process for grey cast iron flywheel housing of diesel engine

ActiveCN102728790AGood size consistencyPut an end to the phenomenon of sand swellingFoundry mouldsFoundry coresDieselingSurface roughness

The invention discloses a sand-line iron mould casting process for grey cast iron flywheel housings of diesel engines. In the invention, upper and lower sand-line iron mould processes are used, so that produced grey cast iron flywheel housing blanks have favorable geometric size precision which can be up to CT8 grade, favorable surface roughness which can be up to 12.5 microns and favorable mechanical properties, the blank processing has small allowance which can be controlled in 3mm, small flashing distortion which can be controlled in 0.5mm and small cleaning workload, so that the labor environment is improved, the environmental protection is improved, the yield is high and can be up to 95%, and the national policies of energy conservation, environmental protection and sustainable development are met.

Owner:JIANGSU SONGLIN AUTOMOBILE PARTS

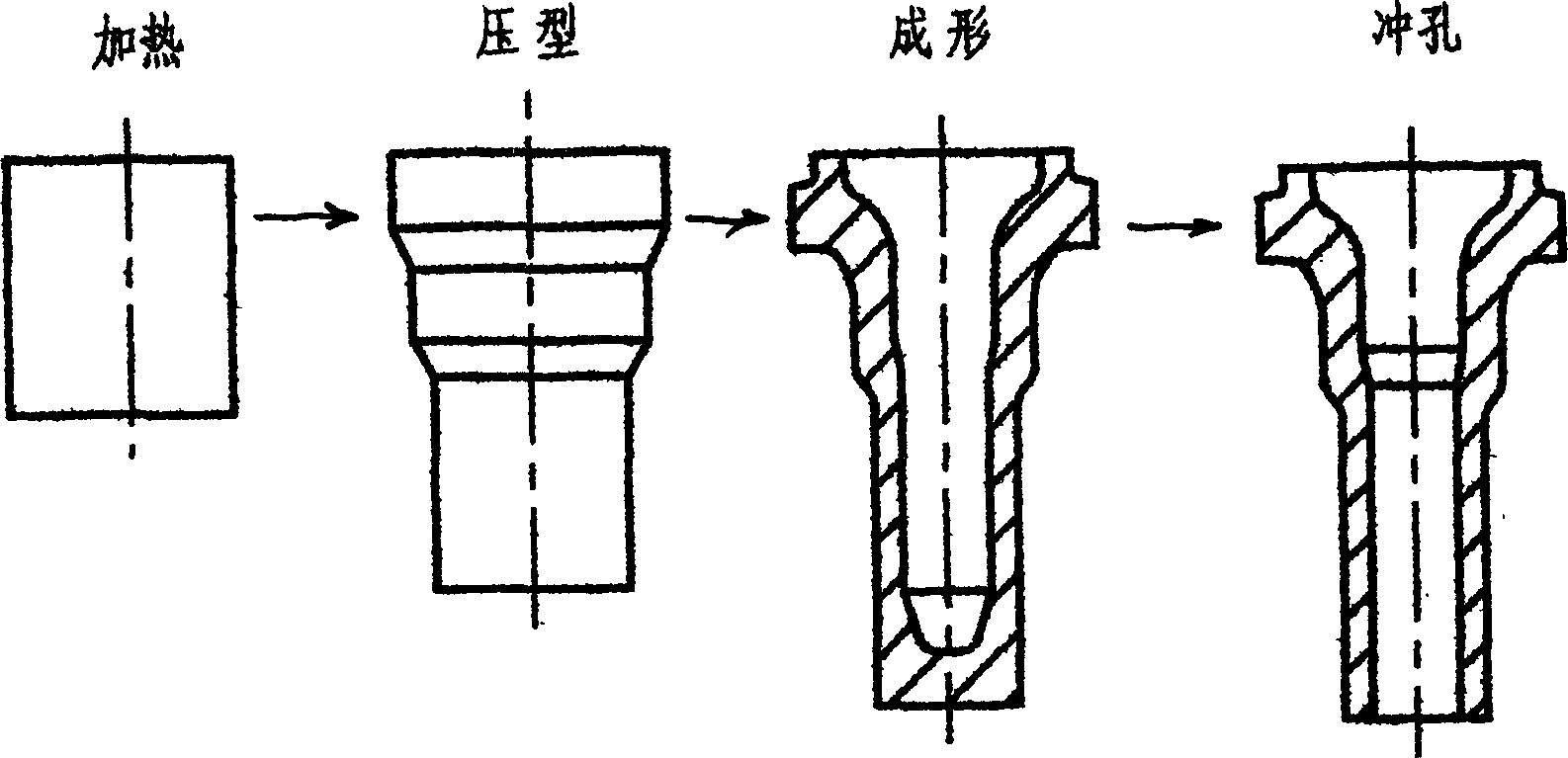

All fiber forging process for load-carrying vehicle hub axle and die therefor

InactiveCN1628921AHigh geometric accuracyGrain refinementForging/hammering/pressing machinesWheelsSurface finishFiber

This invention relates to a load automobile hub axle tube whole fiber forging and shaping process and its mould. It is characterized by the following: adopting solid material; finishing hub axle tube surface and deep hole extrusion shaping to get the whole fiber metal flow wire along axle direction and the inner hole is shaped by extrusion without process.

Owner:李克敏 +3

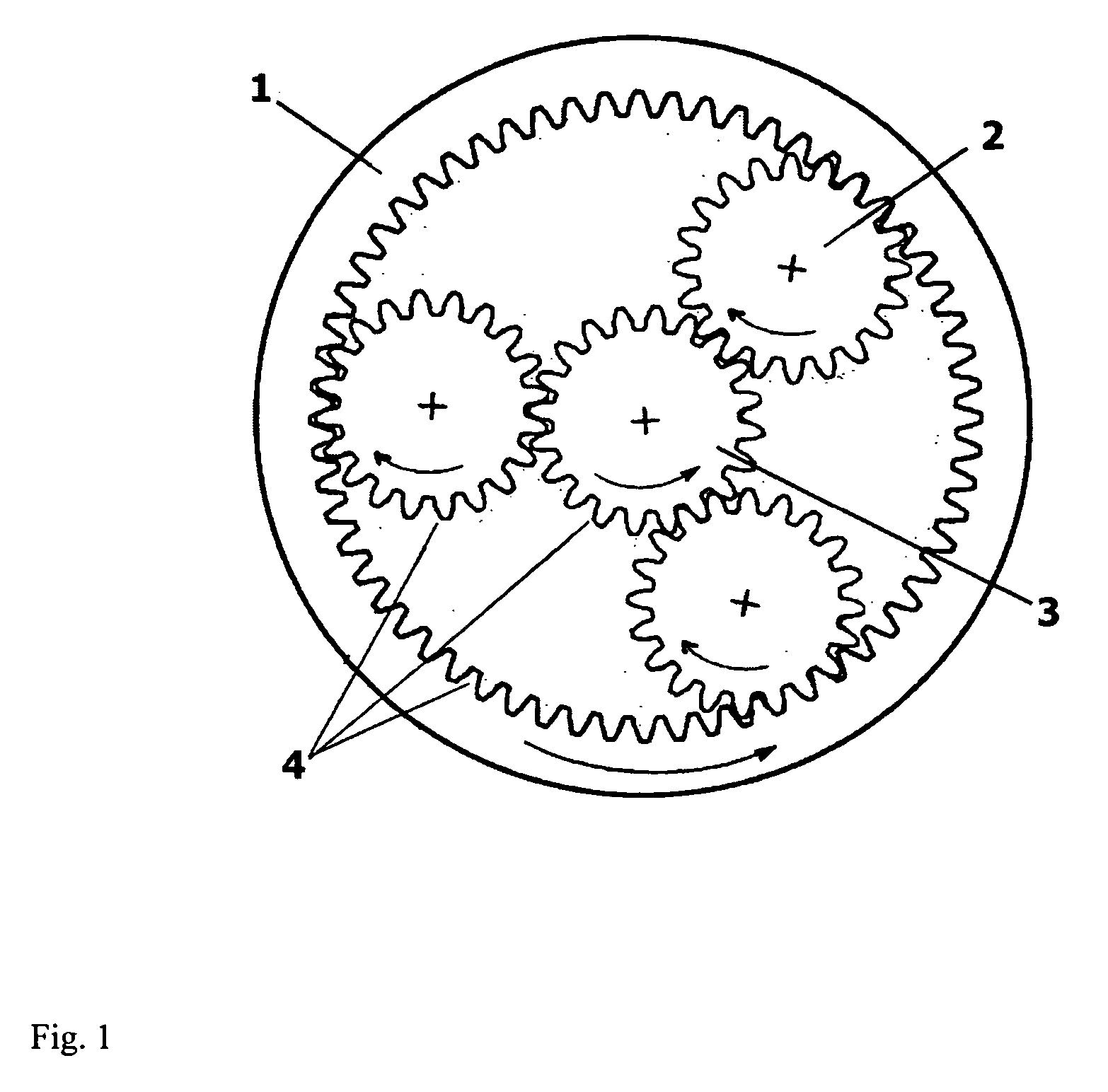

Superfinishing large planetary gear systems

ActiveUS20050014597A1Reduces and eliminates lubricant debrisAvoid damageEdge grinding machinesPolishing machinesGear wheelEngineering

Disclosed herein is a new improved large planetary gear system used on the input stage of wind turbine power generators. This improved planetary gear system reduces or eliminates lubricant debris traditionally generated from the gear teeth, thereby eliminating an initiating source for bearing failure. To achieve these results, some and preferably all of the gear teeth within the planetary gear system are superfinished using chemically accelerated vibratory finishing to a surface roughness of approximately 0.25 micron or less. Several objects and advantages of the invention are to provide a gearbox with reduced metal debris, improved bearing life, reduced wear, reduced vibro-frictional noise, improved contact fatigue, improved fretting resistance, improved lubrication, to simplify the run-in process, and to enhance the durability and efficiency of the gearbox.

Owner:OSRO GMBH +1

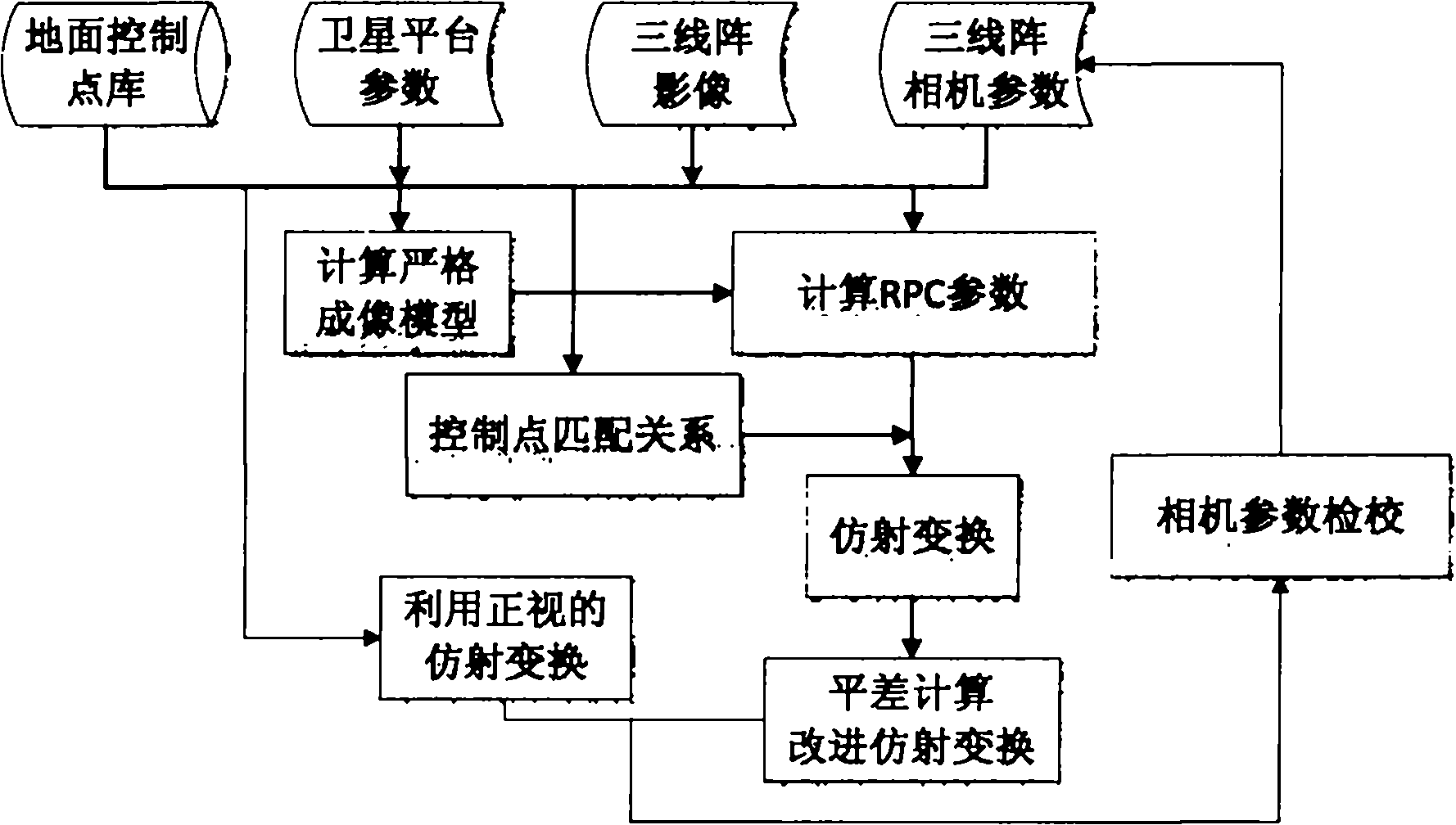

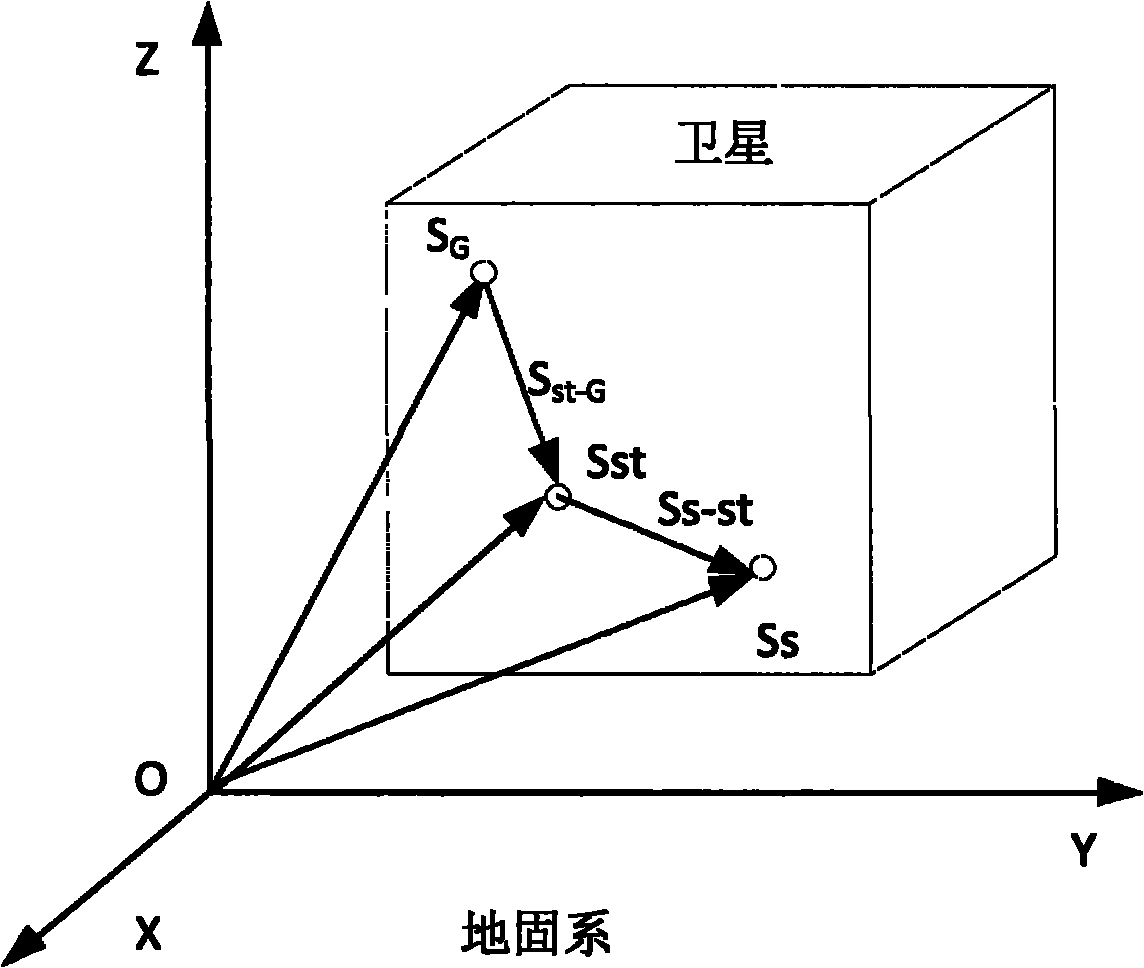

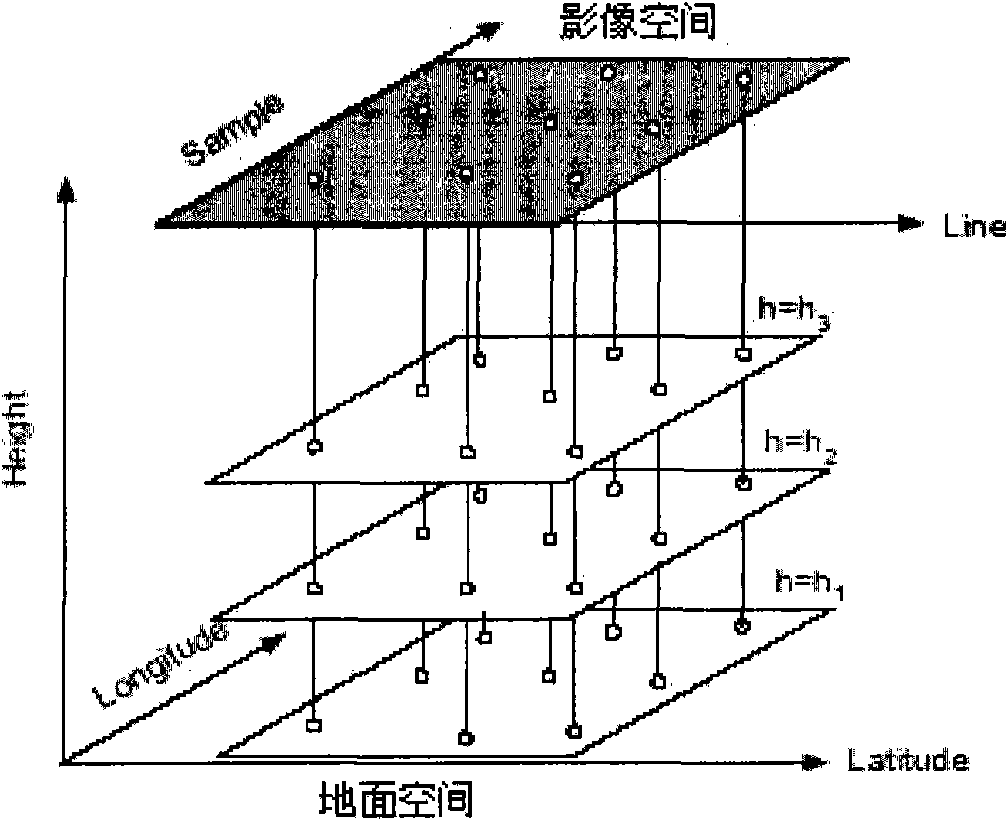

RPC-based method for improving and calibrating block adjustment of three-linear array three-dimensional satellite

ActiveCN102168972ASolve computational difficultiesImprove compatibilityPicture interpretationArea networkImage matching

The invention relates to a rational-polynomial-coefficients (RPC)-based method for improving and calibrating the block adjustment of a three-linear array three-dimensional satellite, which comprises the following steps of: (1) determining the mapping relationship between ground points and image points, namely a strict imaging model; (2) solving RPC parameters of each image in three linear arrays according to the strict imaging model, and searching for connection points among the three linear arrays by image matching; (3) listing three affine transformation formulas of fore sight, front sight and back sight of the three-linear array images; (4) establishing an error equation and solving to acquire corrections of affine transformation parameters, and revising the affine transformation formulas by utilizing the corrections; (5) listing the affine transformation formulas of the fore sight and the back sight again by utilizing camera parameters and the revised affine transformation formula of the front sight; and (6) solving the revised affine transformation formulas of the fore sight and the back sight in the step (4) and the listed affine transformation formulas of the fore sight and the back sight in the step (5) simultaneously to acquire the corrections of the camera parameters, and revising the camera parameters to improve and calibrate the block adjustment of the three-linear array three-dimensional satellite.

Owner:CHINA CENT FOR RESOURCES SATELLITE DATA & APPL

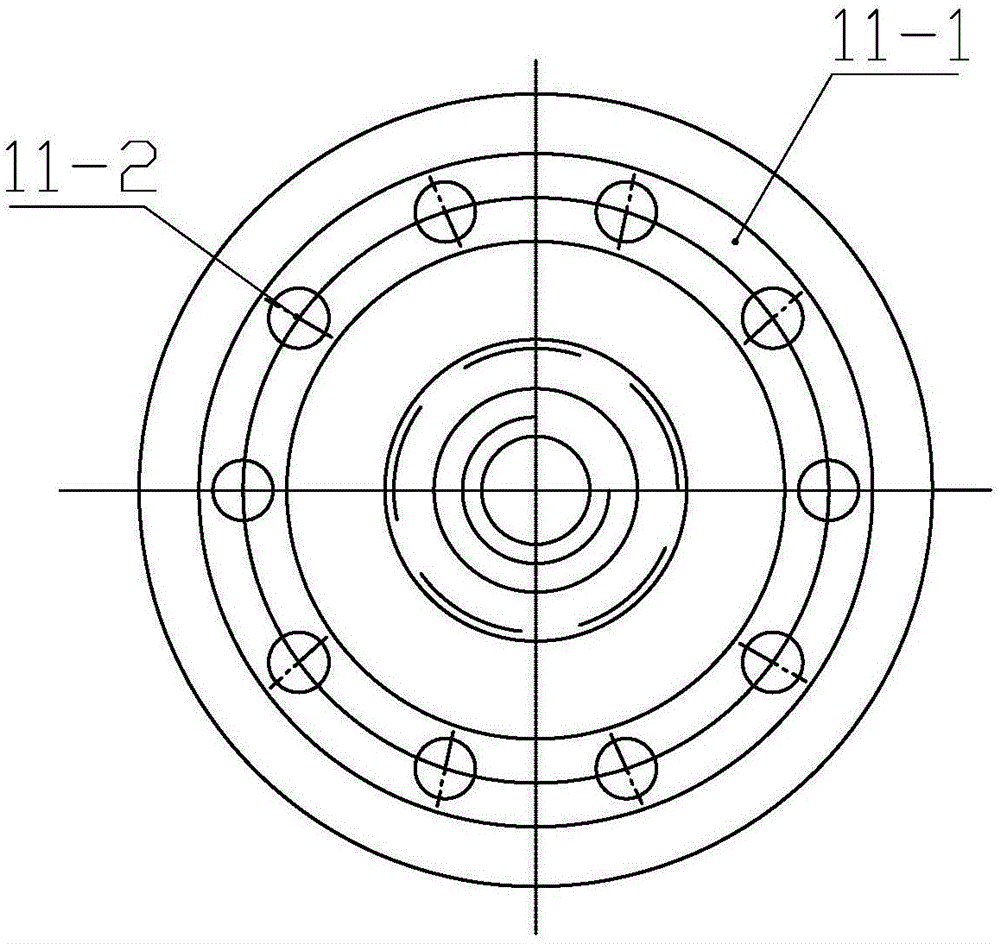

Processing device for ultrasonic grinding on sapphire lenses

ActiveCN104589183AImprove surface roughnessHigh geometric accuracyOptical surface grinding machinesGrinding drivesPhysicsGrinding

The invention discloses a processing device for ultrasonic grinding on sapphire lenses. The processing device comprises a support seat (18) and an ultrasonic vibration loading system, wherein a working table (17) and a machine tool body (2); a grinding head driving system and a grinding liquid supply system which are located above the working table (17) are arranged on the machine tool body (2); a lens fixing and mounting system is arranged on the working table (17); the support seat (18) is provided with an auxiliary moving system used for controlling the working table (17) to horizontally move in an X direction and a Y direction and move up and down in a Z direction. The processing device for the ultrasonic grinding of the sapphire lenses has the advantages that the process is advanced, the processing cost is relatively low, the production efficiency is high, the processing quality is high, and an existing machine tool device and an existing vacuum sucking disc of a research institute are fully utilized; the processing device can be used for grinding and processing the sapphire lenses with increasingly high temperature at high efficiency and high quality; the requirements of enterprises in the future are met.

Owner:KEYIZHAN INTELLIGENT EQUIP CO LTD +1

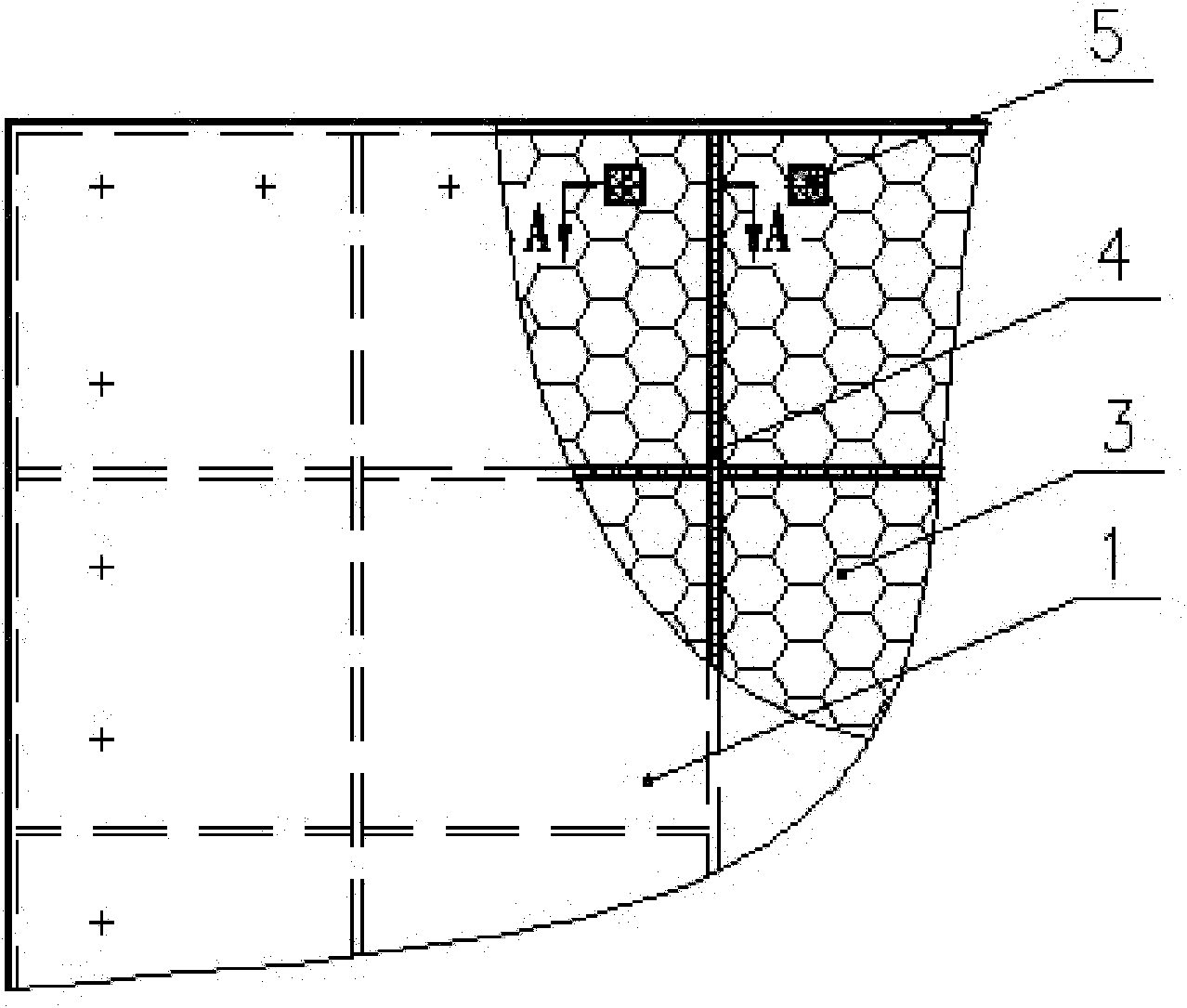

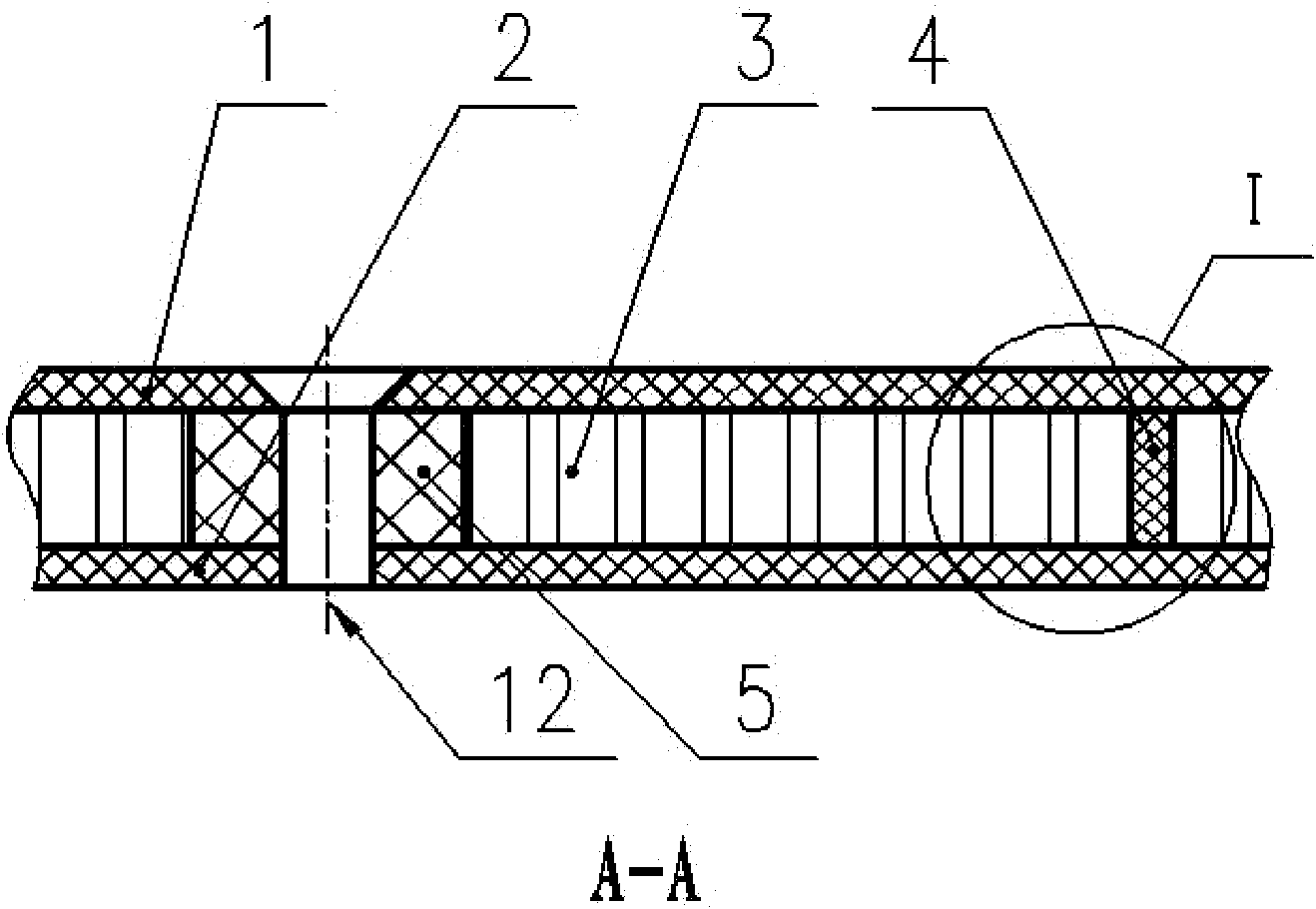

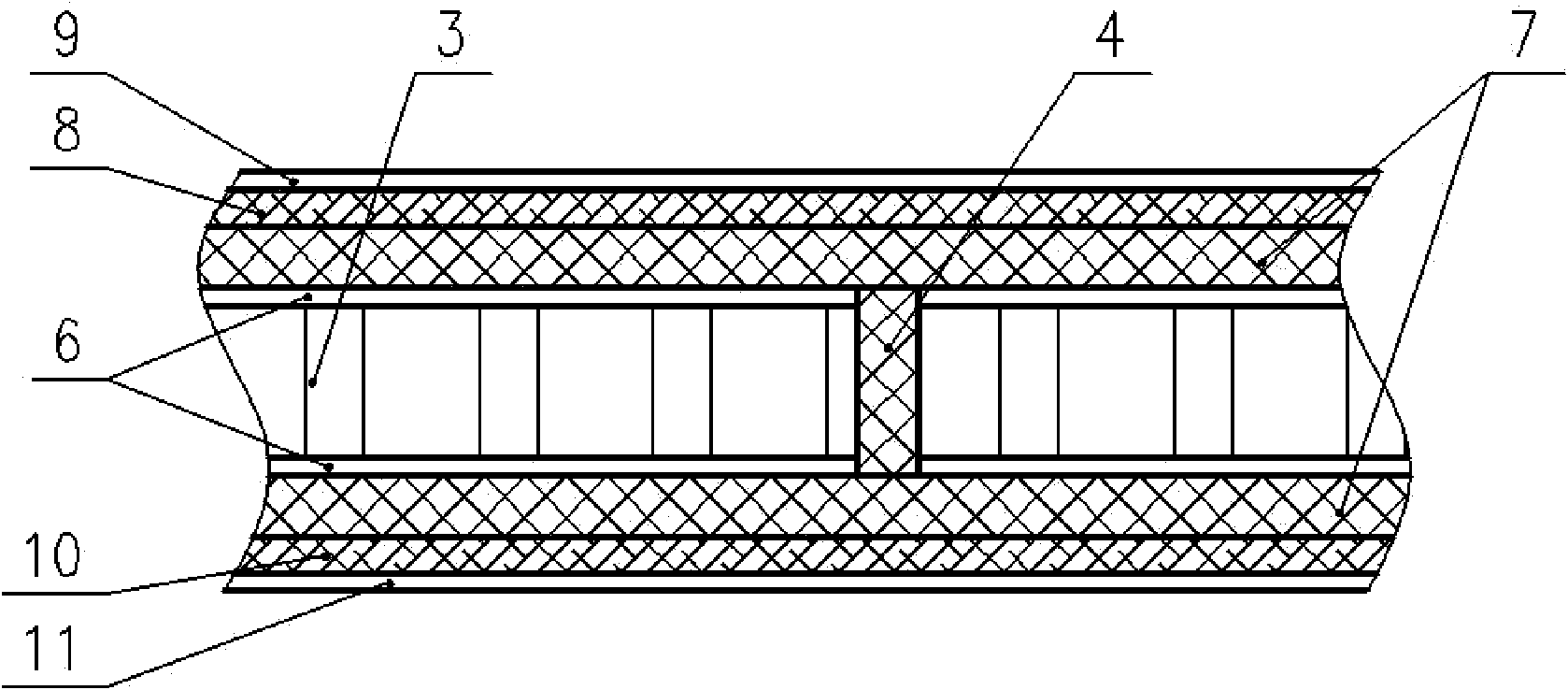

Ultra-large light-transmission-type decorative board

InactiveCN102061790AHigh light transmittanceHigh mechanical strengthCovering/liningsWallsTransmittanceHoneycomb

The invention belongs to building enclosure materials, in particular to a light-transmission-type composite sandwich decorative board with an ultra-large face. In the decorative board, a wholly-reinforced composite sandwich structure of a light-transmission-type FRP (Fiber Reinforced Plastic) panel, a honeycomb core material and latticed FRP reinforcing ribs is adopted, mounting holes are arranged on the periphery and in other specified positions, the product is formed by adopting a die, and the surface is coated with a high-weather-resistant facing layer. The decorative board provided by the invention is suitable for the mass production of boards with ultralarge faces. Compared with hollow glass of a curtain wall, the decorative board provided by the invention has equivalent light transmittance as well as the advantages of great veneer area, light weight, high strength, good impact resistance, sound and heat isolation, good decoration effect, capability of night illumination, easiness for maintenance, long service life, and the like and can meet the demands of curtain walls, enclosures and decoration engineering of buildings and large-scale landscape structures for light-transmission-type decorative boards with ultra-large areas.

Owner:秦皇岛耀华装备集团股份有限公司

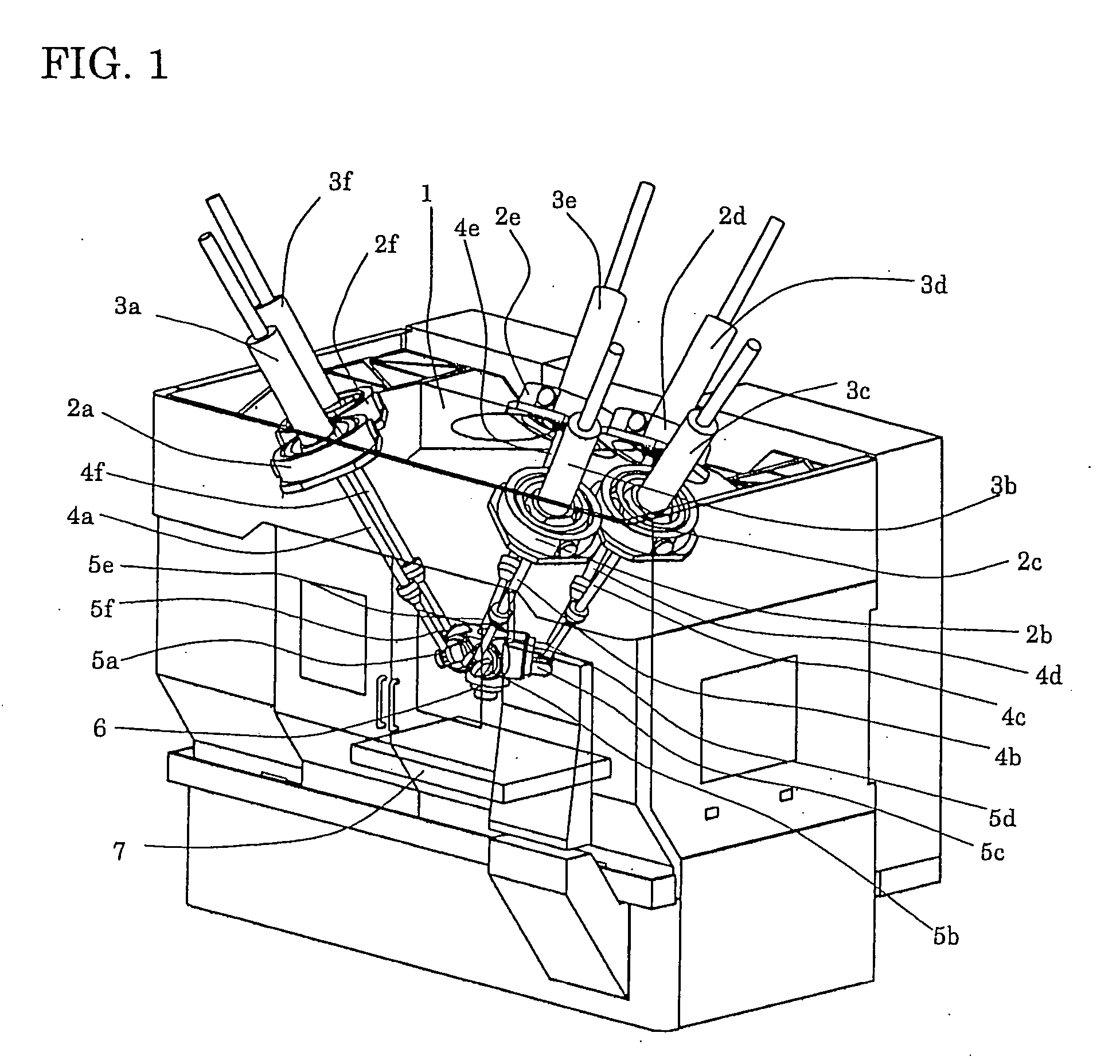

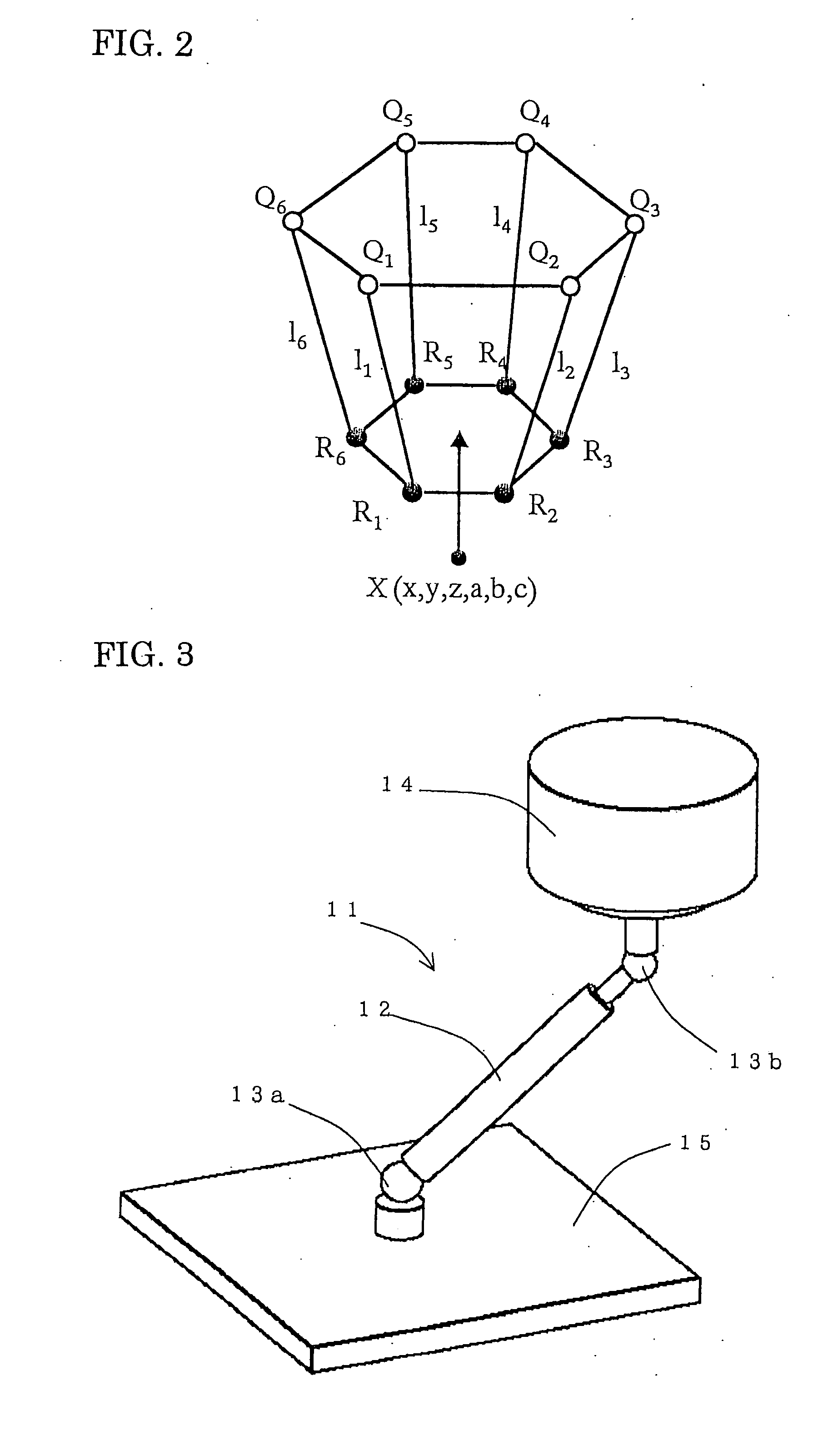

Calibration method for a parallel kinematic mechanism machine

InactiveUS20060254364A1Improve accuracyReproduction errorProgramme-controlled manipulatorForce measurementParallel kinematicsEngineering

Kinematic parameters of a parallel kinematic machine can be estimated with high precision considering thermal displacement and error of a measuring device, in addition to deformation error caused by self-weight of each component. A DBB device is used when end effectors of a parallel kinematic mechanism machine are positioned at plural positions and in plural postures. In the DBB device, a plurality of support bars are provided with rigid balls on the both ends. One of the balls is fixed on a table and the other ball is provided with an end effector. The position, posture, and distance from a fixed position are measured and based on the measured value kinematic parameters are estimated. In estimating the kinematic parameters, any of deformation error caused by self-weight of each component, thermal displacement of each component, error of a measuring device are added for computation by linear approximation.

Owner:OKUMA CORP

Glass substrate for an information recording medium and information recording medium employing it

InactiveUS7566673B2High geometric accuracyHigh strengthMagnetic materials for record carriersBase layers for recording layersEdge surfaceRecording layer

A chemically strengthened glass substrate for use as the substrate of an information recording medium such as a magnetic disk, magneto-optical disk, DVD, or MD, wherein a strengthened formed by chemical strengthening exists on the outer edge surface and on the inner edge surface but substantially not on a surface on which an information recording layer is formed.

Owner:HOYA CORP

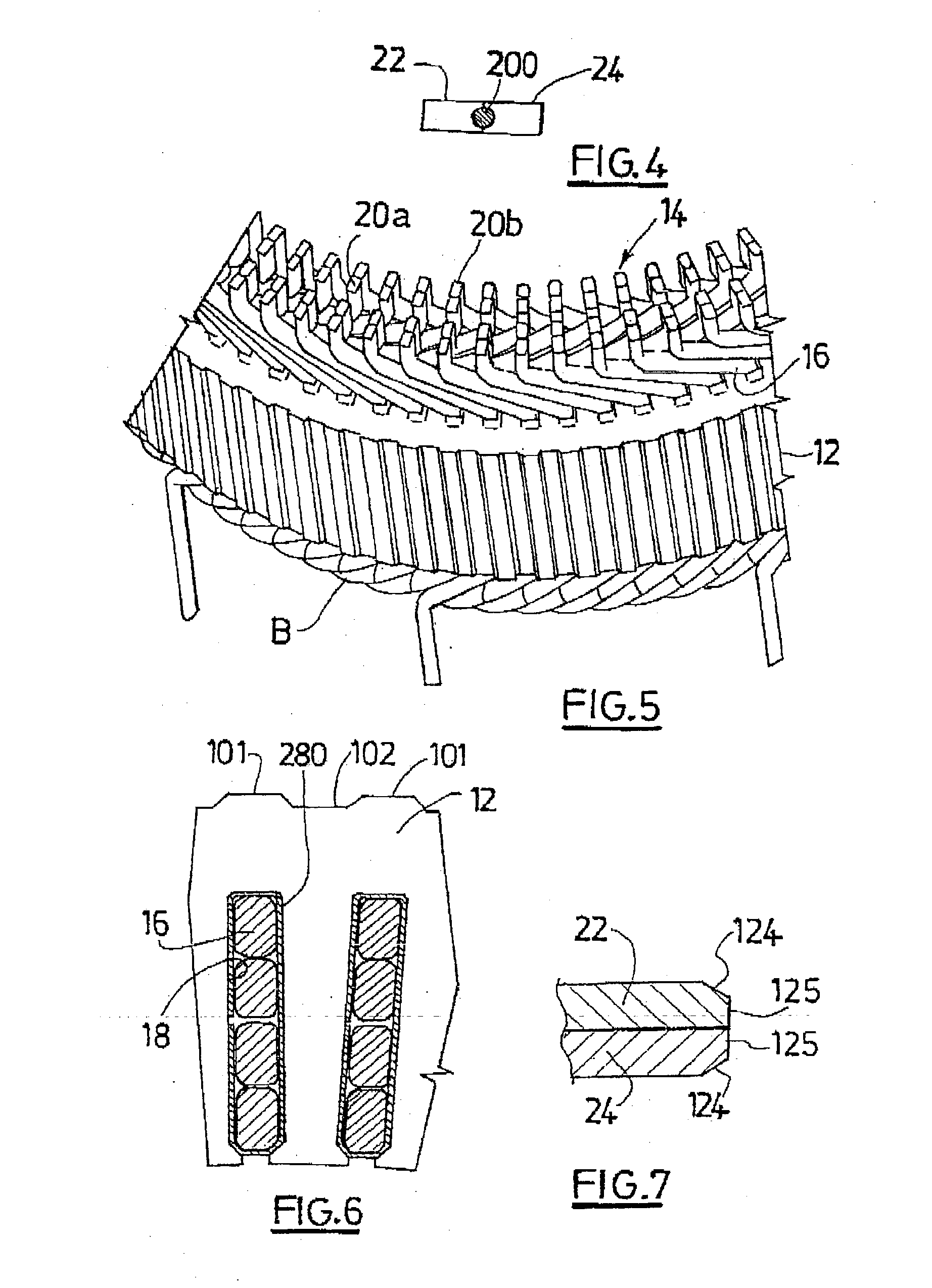

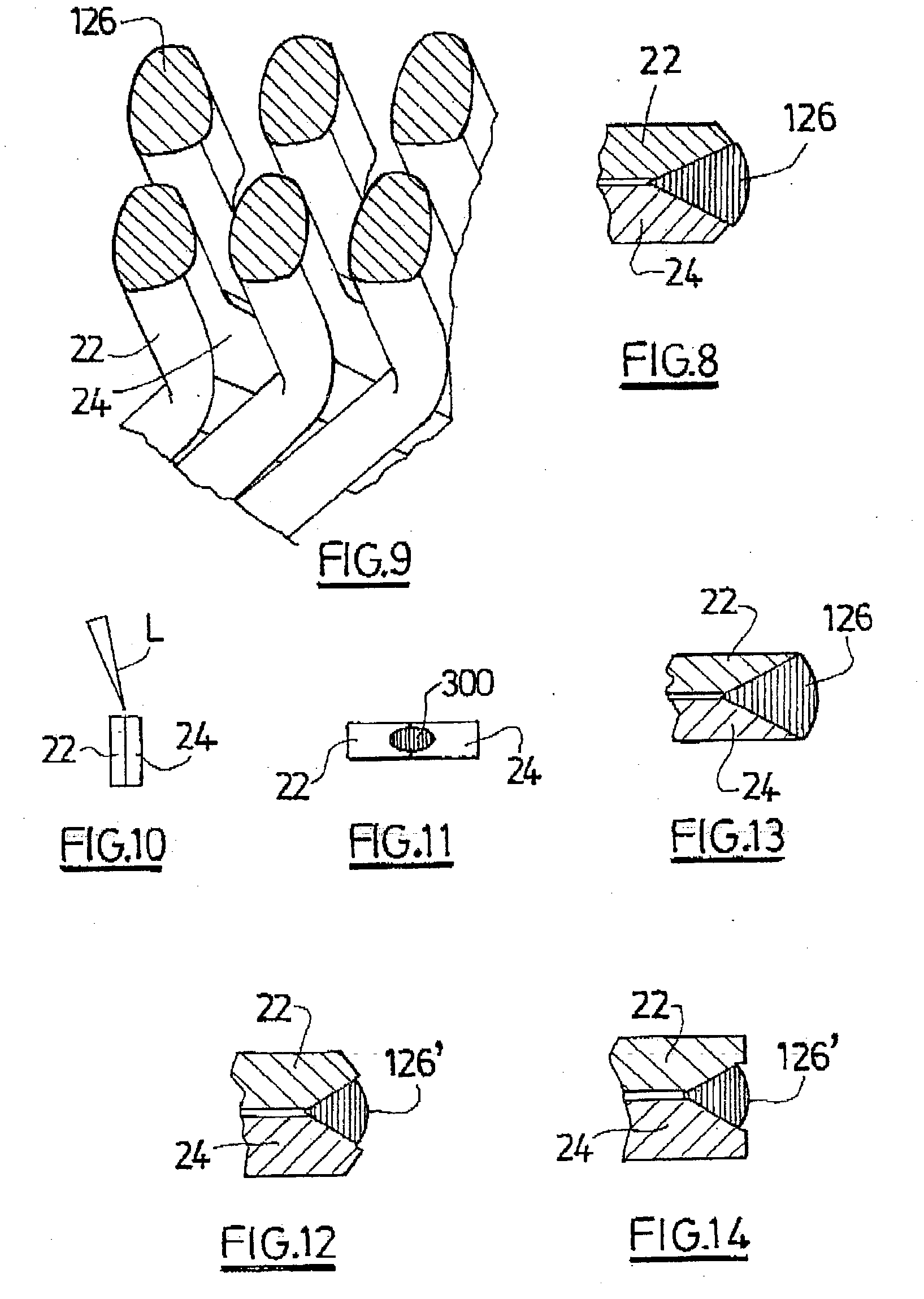

Method for assembling conductive segments of a rotor winding or stator winding in a rotary electric machine

InactiveUS20030159269A1Reduce assemblyRapid and simple and economicalMagnetic circuitSynchronous machinesElectrical conductorAlternator

The inventive method of assembling conductive segments (16) of a rotor winding or a stator winding in a rotary electric machine comprises the following stages: insertion of the conductive segments (16) into slots made in a core (12) of the rotor or stator, whereby the free ends of the conductive segments protrude beyond the latter, and welding of the free ends of the conductive segments in groups of two in order to form a winding (14) around the rotor or stator. The conductor statements are both made of wire which is electrically conductive and coated with an electrically insulating material. The coating of electrically insulating material is removed in the welding zone of the conductive segments by the means used for welding the latter. The invention can be used for conducting segments of a rotor or stator winding in an alternator in a motor vehicle.

Owner:VALEO EQUIP ELECTRIC MOTEUR

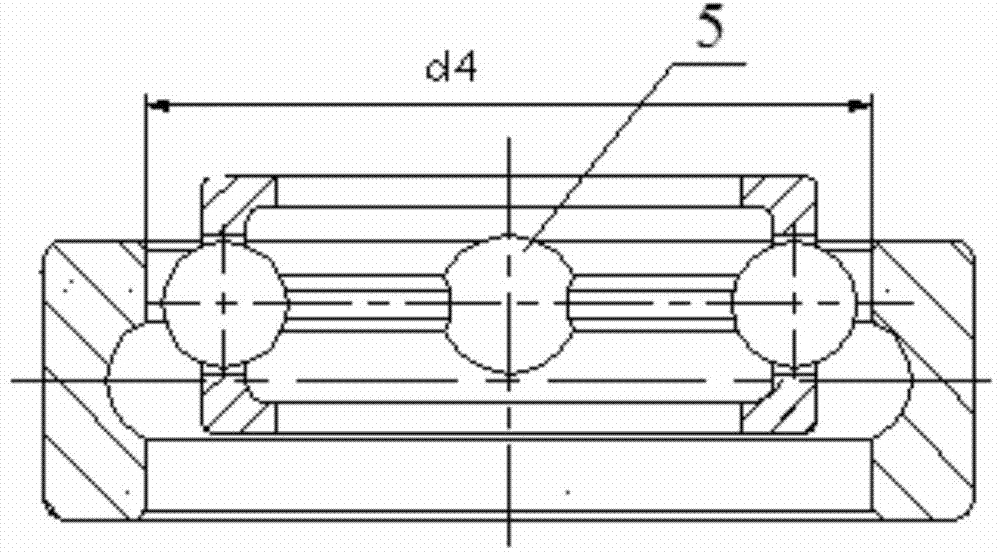

Method for machining circular hole alloy steel cage with inner-and-outer double fore shafts

The invention provides a method for machining a circular hole alloy steel cage with inner-and-outer double fore shafts, relates to a method for machining a bearing cage and aims at solving the problems that the surface roughness of a cage pocket is unqualified, the wear rate of a drill bit and a milling cutter is high, the machining precision of the cage pocket is low, the sizes of the pocket and the inner-and-outer double fore shafts of the pocket are not stable, the inner-and-outer locking angles are difficult to guarantee, and the cage can not be installed in an outer casing when assembled and contact balls are prone to falling off. The method comprises the steps of forming by lathing, thermal refining, finish lathing for a first surface, finish lathing for a second surface, coarse grinding for outer circle, finish lathing for inner circle, uniform grinding for first surface and second surface, printing, lathing for inner step and inner groove, drilling, hole milling, lathing for outer step, finish uniform grinding for first surface and second surface, chamfer lathing, deburring, polishing, washing, final inspection and silver plating.

Owner:AVIC HARBIN BEARING

Forging process of bearing ring

ActiveCN104827245AEliminate Inherent DefectsIncrease tightnessBearing componentsEngine componentsPunchingMedium frequency

The invention relates to a forging process of a bearing ring. The process includes following steps that: 1) in first firing, a medium-frequency induction heating furnace is adopted to heat an ingot to 1200 DEG C, dead head pressing, chamfering and sprue filing are performed; 2) in second firing, re-heating, upsetting and drawing out are performed on the machined ingot; 3) in third firing, re-heating, upsetting, rotary flattening, punching and reaming are performed on the machined ingot; 4) in fourth firing, the machined ingot is re-heated, and upsetting is performed on the machined ingot in a mold ring, so that the machined ingot can be in a technique size, the mold is removed, and reaming is performed on the machined ingot, so that the machined ingot can be in a technique size, and total forging ratio is controlled to be larger than 5; 5) groove turning is performed, the machined ingot is subjected to cold rolling and reeling on a closed shaping and reaming machine, and rolling paths and chamfered angles are molded with one step, truing is performed, and two end surfaces are subjected to soft grinding; 6) the machined ingot is pre-heated to 800 DEG C to 850 DEG C, after crack detection is performed, when the temperature of the machined ingot is lower than 450 DEG C, the machined ingot is put into the furnace so as to pre-heated to 600 DEG C to 650 DEG C, and heat preservation is performed on the machined ingot, and the machined ingot is put in to the furnace of which the temperature ranges from 950 DEC C to 1000 DEC and is rapidly heated to 1140 DEC C to 1200 DEC C, and water quenching is performed, and instantly, tempering from 550 DEC C to 600 DEC C is performed on the machined ingot, and the machined ingot is cooled to 400 DEC C to 450 DEC C in the furnace, and the machined ingot is taken out from the furnace and cooled. With the forging process adopted, inherent defects of metal can be eliminated, and the service life of a bearing can be prolonged.

Owner:JIANGSU JINYUAN FORGE

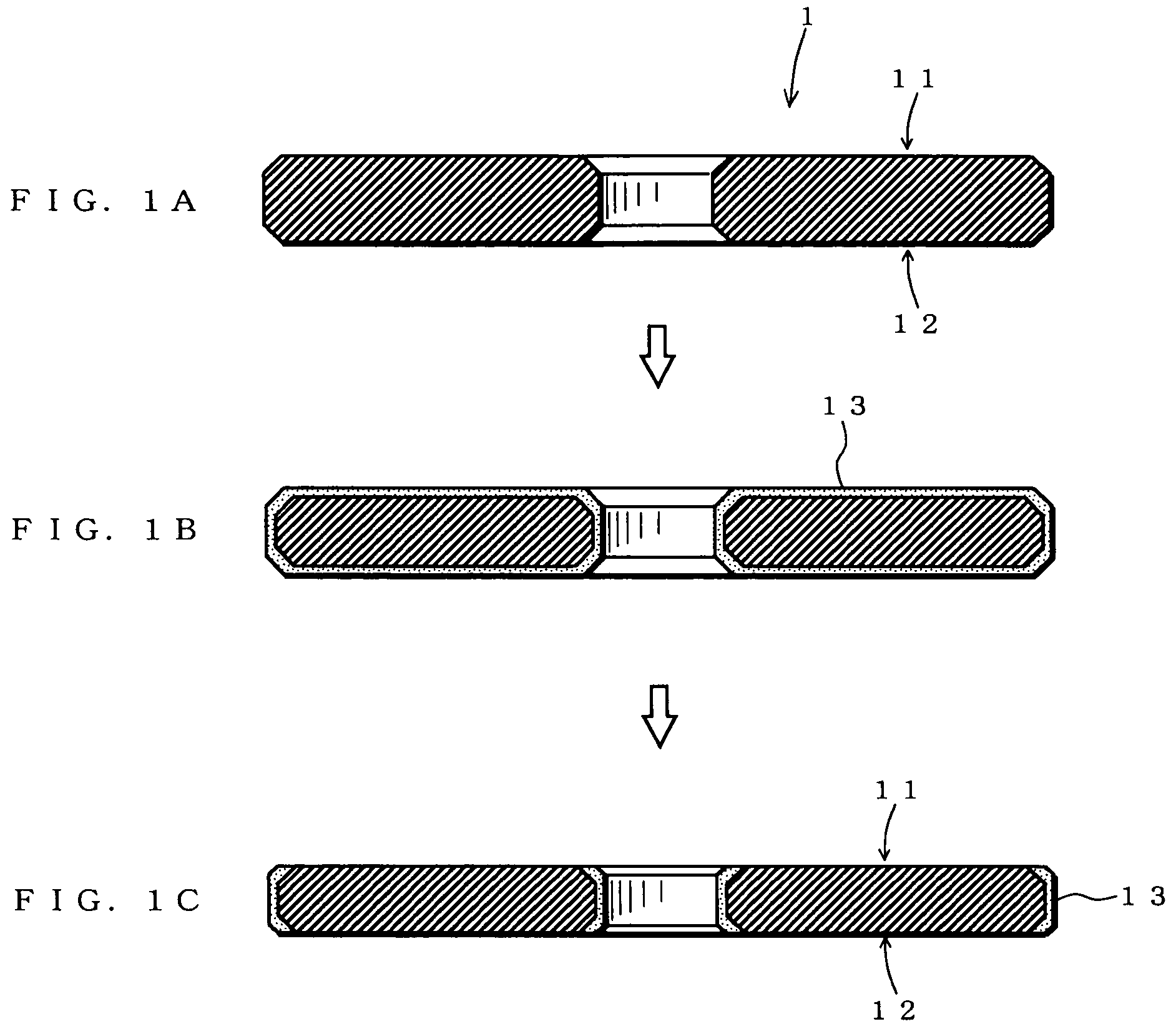

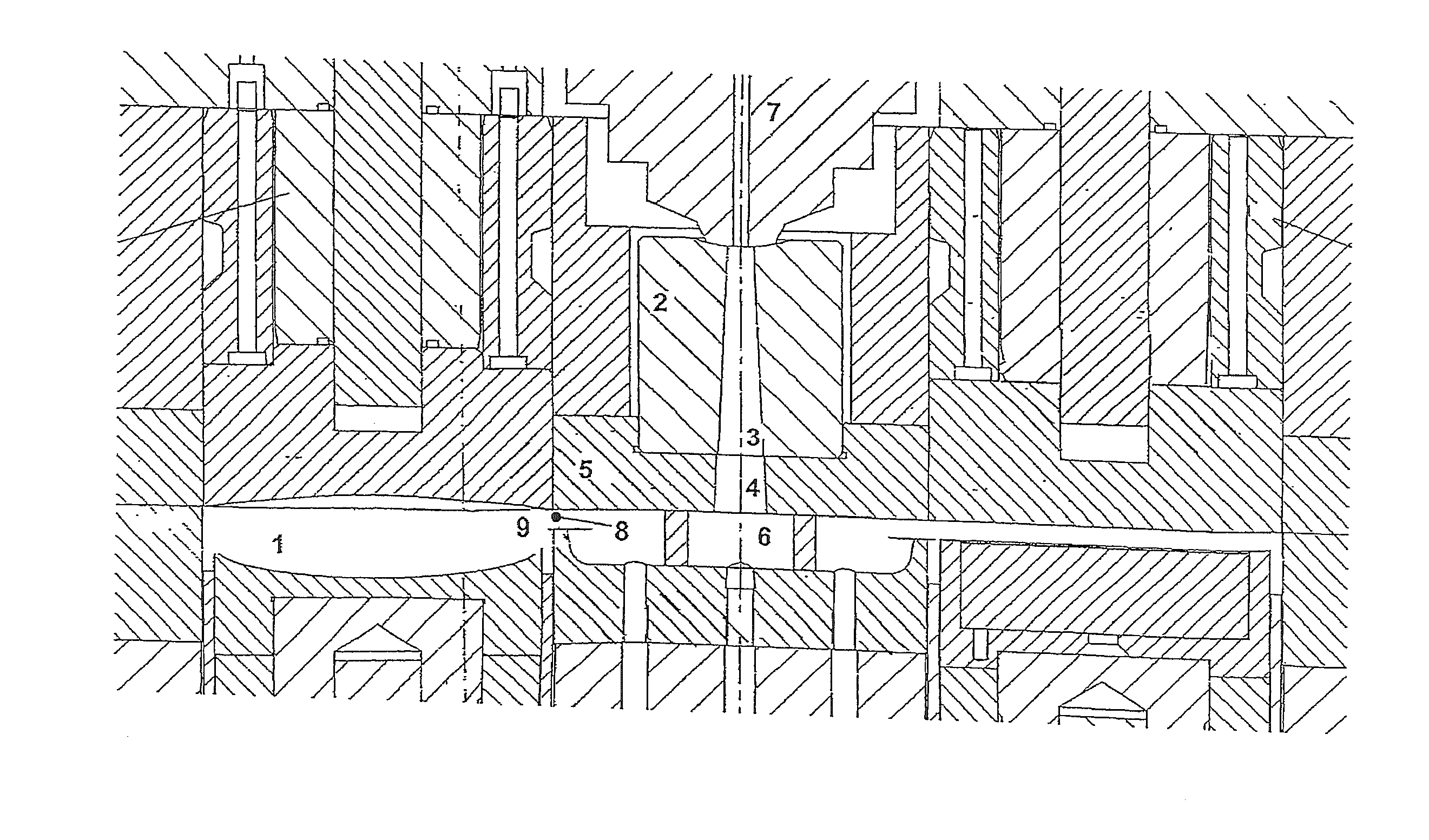

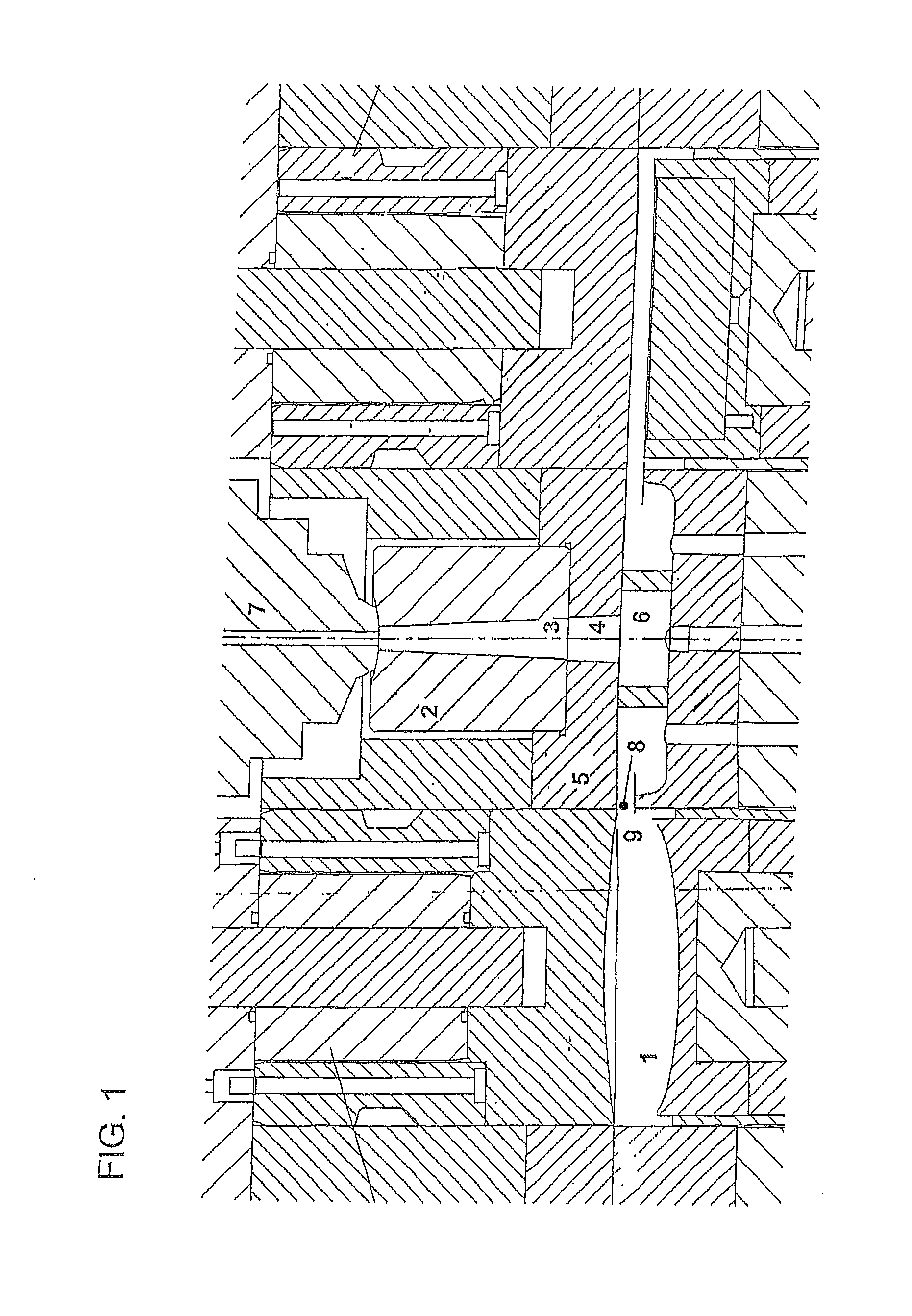

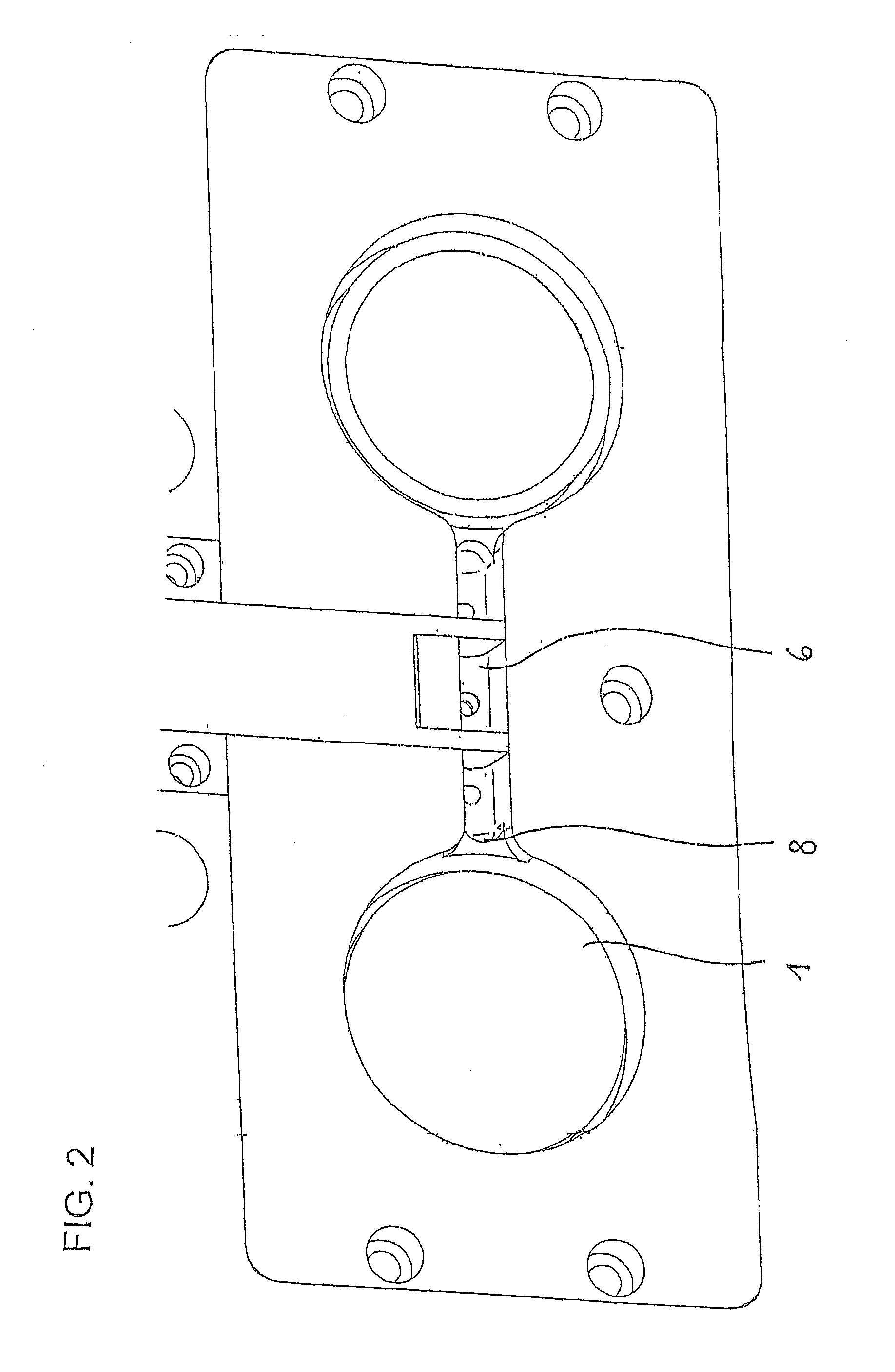

Process and apparatus for producing thick-walled plastic components

InactiveUS20100327470A1Quality improvementLow production costOptical articlesAuxillary shaping apparatusLight guideThick wall

The invention relates to a process for producing plastic components, in particular optical lenses or optical light-guides, wherein plastic melt is injected via a sprue (3, 4, 6, 8) into a cavity (1) of a moulding tool shaping the component and additional plastic melt is after-pressed into the cavity (1) for the purpose of compensating a volume contraction of the injected plastic melt due to cooling. The process is characterised in that the plastic melt located in the sprue (3, 4, 6, 8) is kept flowable by means of energy introduced in the region of the sprue until such time as the molten core of the plastic component has solidified in the course of the after-pressing of plastic melt for the purpose of compensating the volume contraction due to cooling (holding-pressure). The invention further relates to an apparatus for implementing the process.

Owner:BAYER MATERIALSCIENCE AG

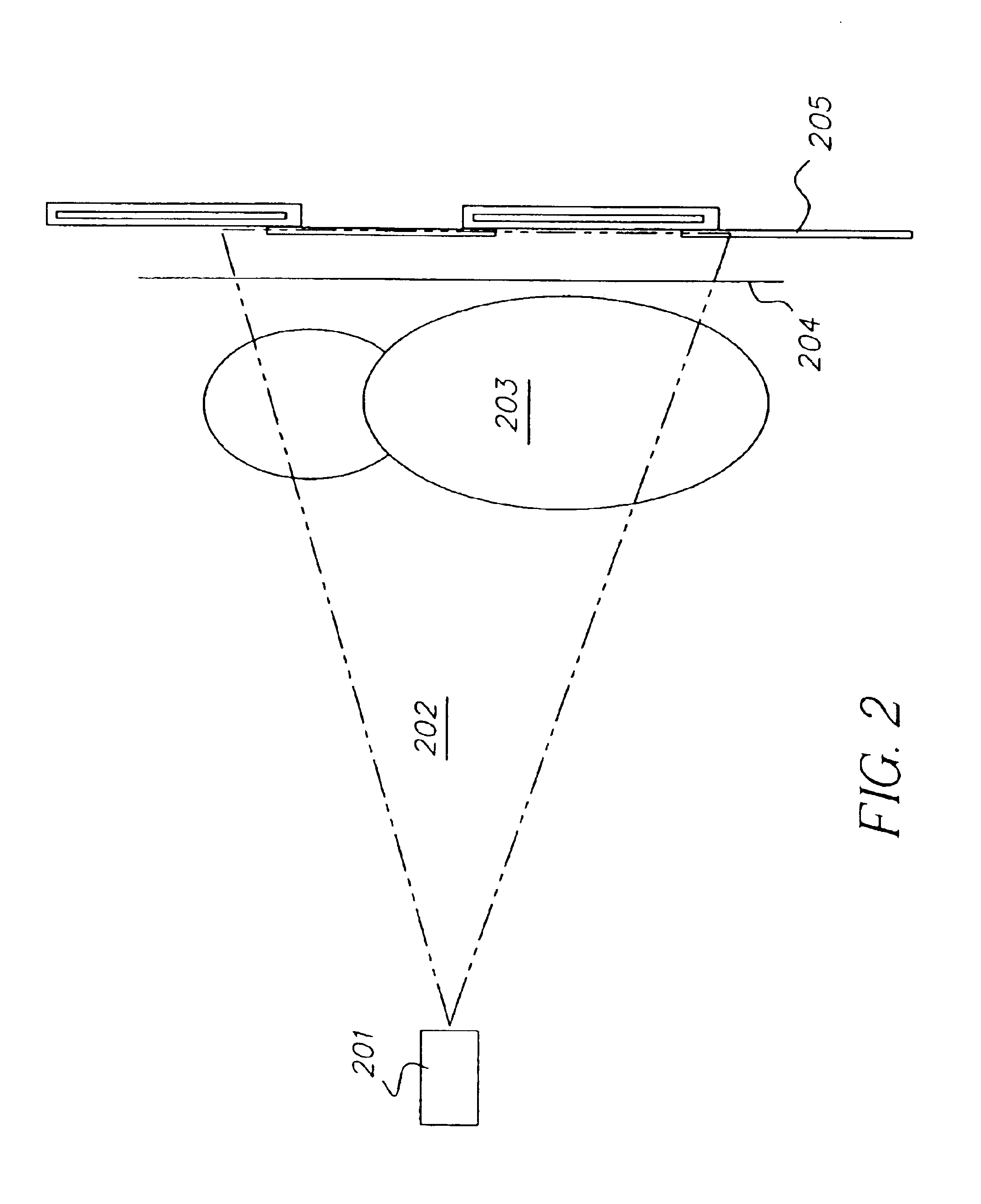

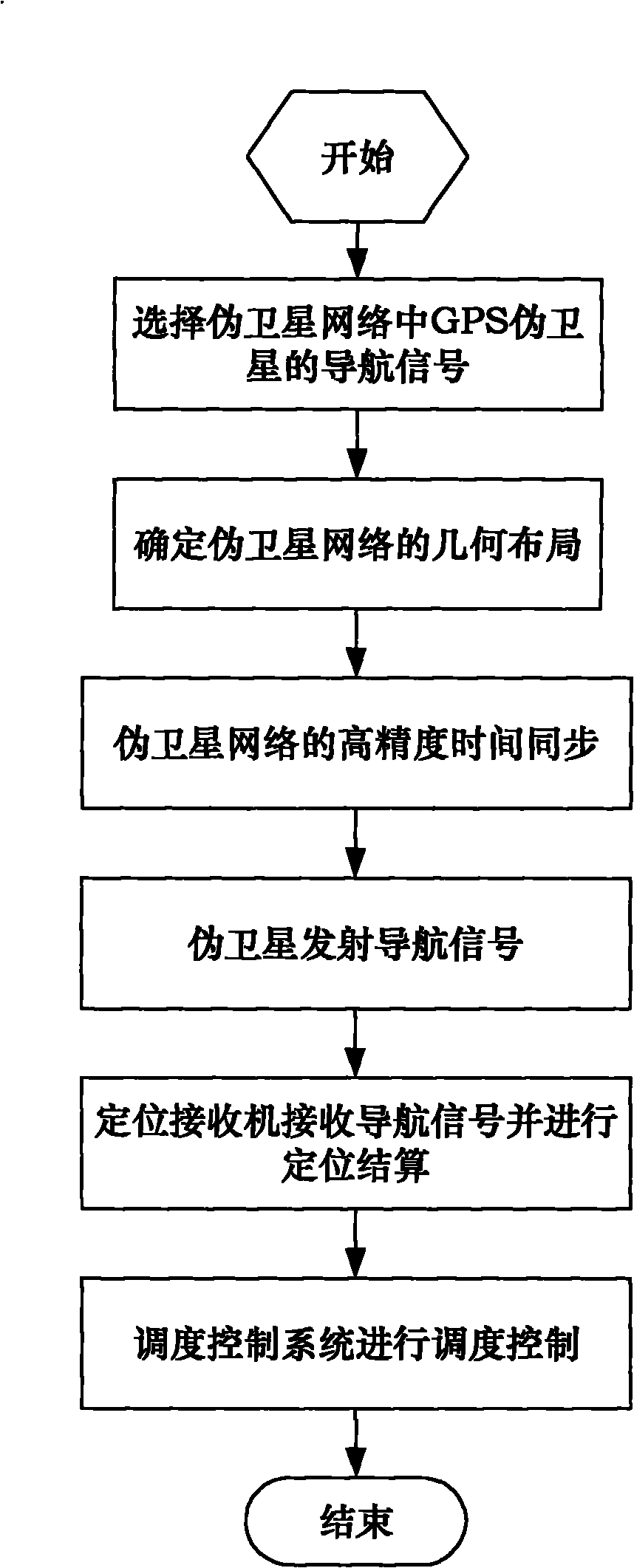

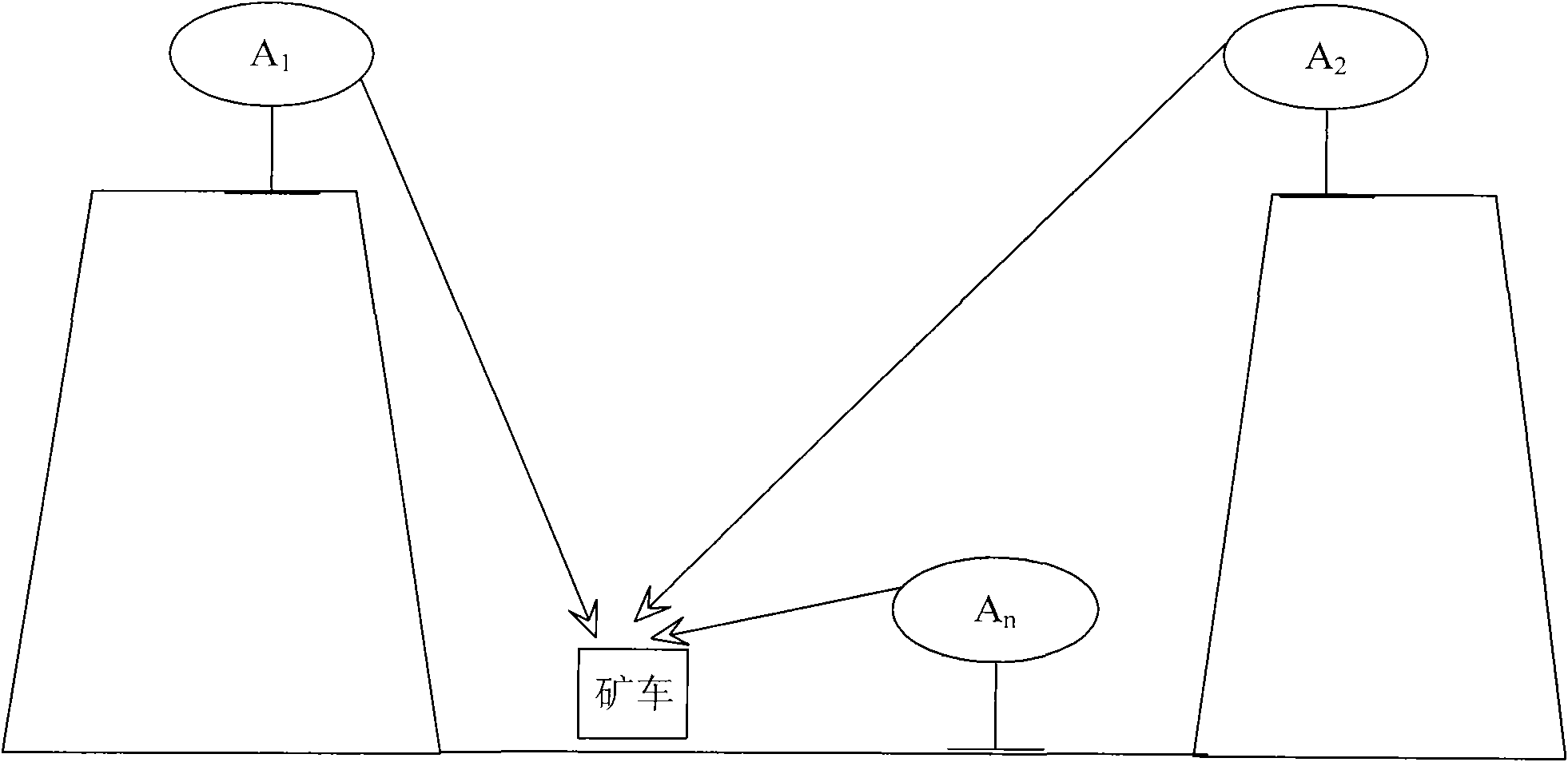

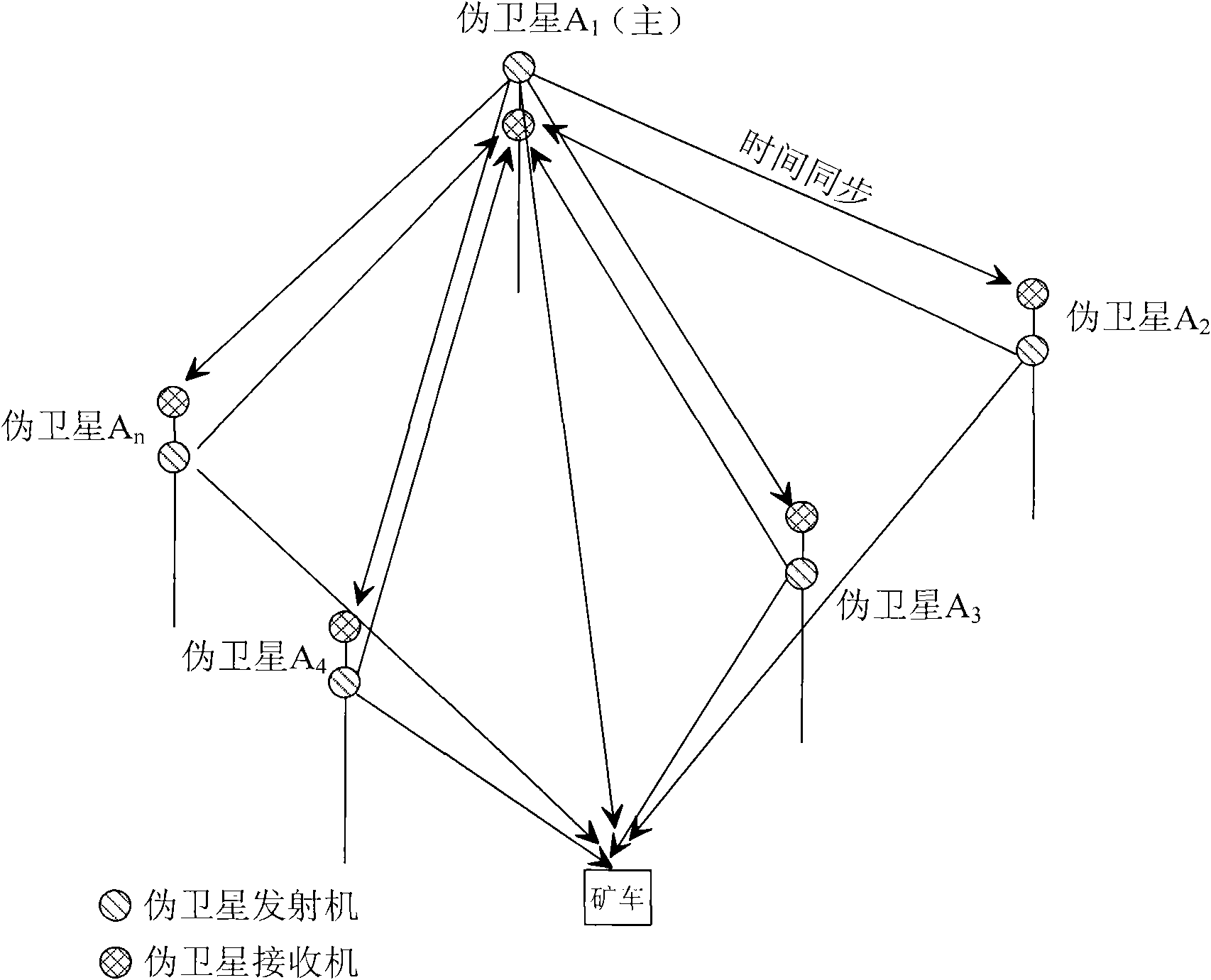

Positioning method of deep open pit based on pseudolite

InactiveCN101833103AOvercome the serious disadvantage of occlusionAchieve positioningSatellite radio beaconingPseudoliteEnvironmental geology

The invention discloses a positioning method of a deep open pit based on a pseudolite, comprising the following steps of: 1. selecting a navigation signal of a GPS (Global Position System) pseudolite in a pseudolite network; 2. determining a geometrical layout of the pseudolite network; 3. carrying out high-precision time synchronization on the pseudolite network; 4. emitting the navigation signal by the pseudolite; 5. receiving the navigation signal by a positioning receiver and carrying out positioning clearing; and 6. carrying out dispatching control by a dispatching control system. The invention overcomes the defects of serious shielding of the deep open pit, realizes pit positioning by adopting the pseudolite, controls the physical position of a pseudolite system and improves the geometrical precision and the positioning precision.

Owner:BEIHANG UNIV

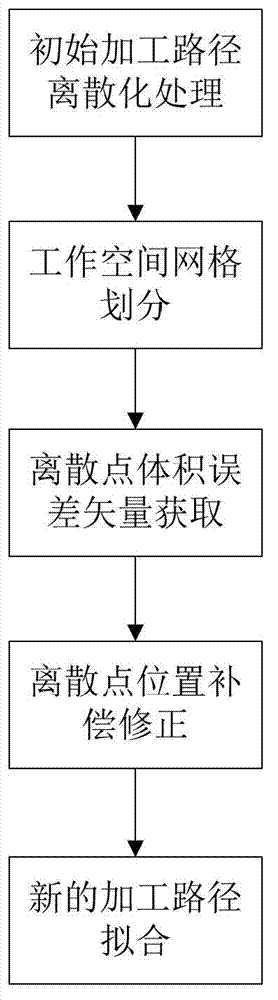

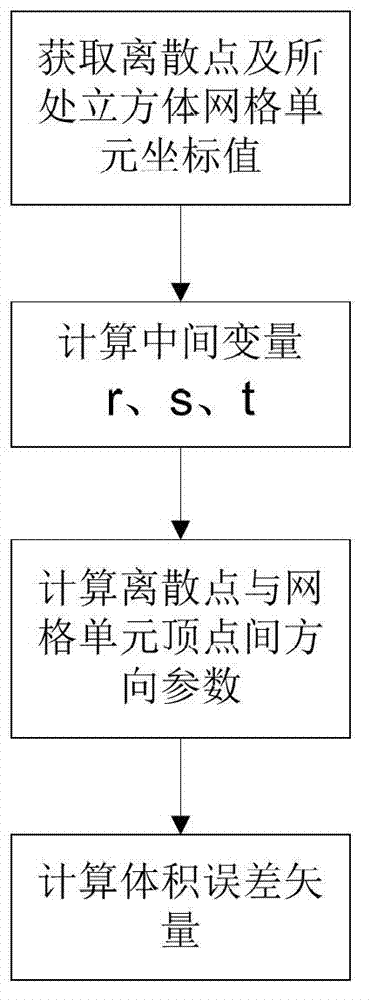

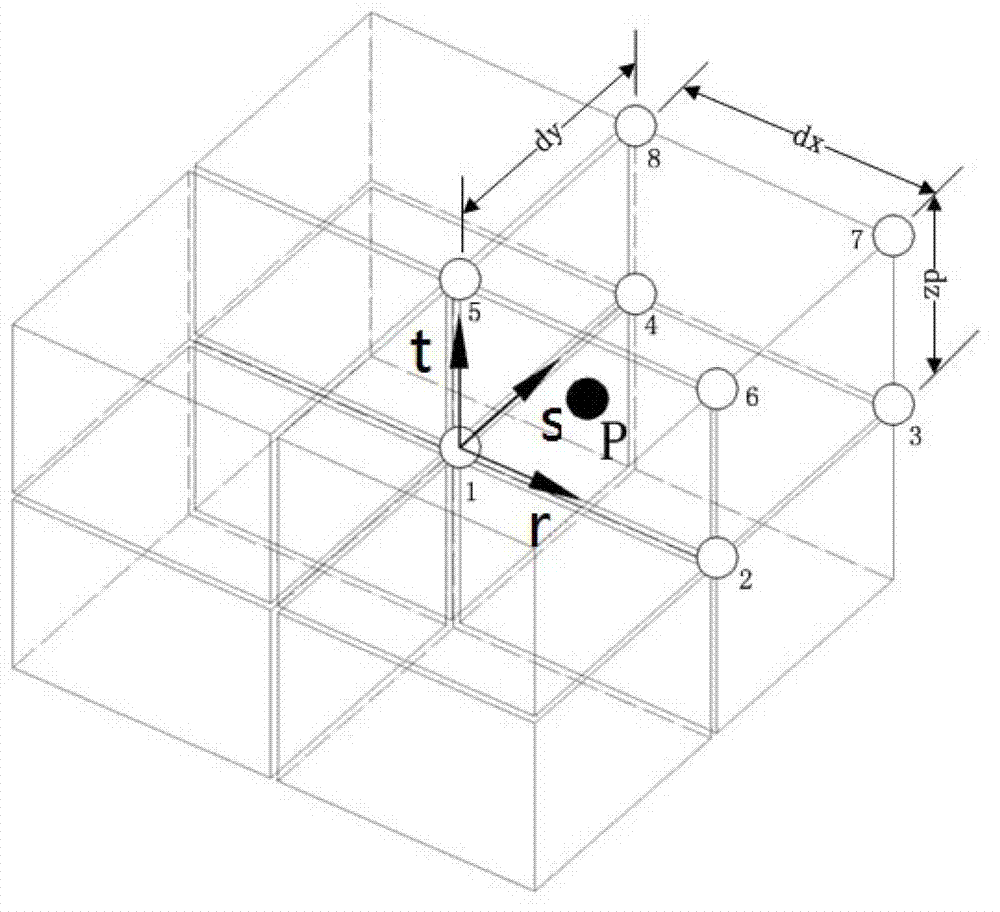

Kinematic transformation based grinding machining method for numerically controlled grinding wheel

The invention discloses a kinematic transformation based grinding machining method for a numerically controlled grinding wheel, which comprises the following steps of: generating an initial grinding wheel machining path and performing discretization treatment to produce a plurality of discrete points; selecting position points within the range of movement of a driving shaft of a grinding wheel rack, and meshing to produce a plurality of cube mesh units based on the position points; finding the cube mesh units respectively comprising the discrete points, and then calculating the volume error vectors of the discrete points in the mesh units; utilizing the volume error vectors to convert each discrete point, and then producing a plurality of new discrete points; and producing a new grinding wheel machining path by a fitting method and performing the corresponding grinding treatment. The invention also discloses an improvement on calculation of volume error vectors and a point compression processing mode. Through the method, the deviation between the actual grinding trajectory and the ideal grinding trajectory caused by the kinematic properties and geometry error of the numerically controlled grinder can be reduced, and the geometric accuracy and dimensional accuracy of machining can be correspondingly improved.

Owner:HUAZHONG UNIV OF SCI & TECH

High-strength and high-toughness oil casing and manufacturing method thereof

ActiveCN103194693ARefine the grain sizeConsistent performanceDrilling rodsDrilling casingsChemical compositionThermal treatment

The invention discloses a high-strength and high-toughness oil casing and a manufacturing method thereof. A 'HFW(High Frequency Welding)+welding line on-line thermal treatment+hot tension reducing+whole casing thermal treatment' technology is used for manufacturing a Q125 steel grade oil casing, and the weight percentage of chemical components are as follows: C: 0.18-0.30; Sh: 0.10-0.35; Mn: 1.00-1.30; P: not more than 0.018; S: not more than 0.008; Cr: 0.20-1.20; Mo: 0.20-0.55; Nh: 0.10-0.56; B: 0.0010-0.0015; Nb+V+Ti: not more than 0.08; and the balance of Fe and unavoidable impurities. For the Q125 oil casing produced by the manufacturing method, the yield strength is not less than 865MPa, the tensile strength is not less than 940MPa, the specific elongation is not less than 23.2%, at 0 DEG C, the full-scale transverse impact energy is not less than 105J and the longitudinal impact energy is not less than 110J. The Q125 steel grade oil casing produced by the technology is excellent in comprehensive performance, and has excellent high toughness and high plasticity.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

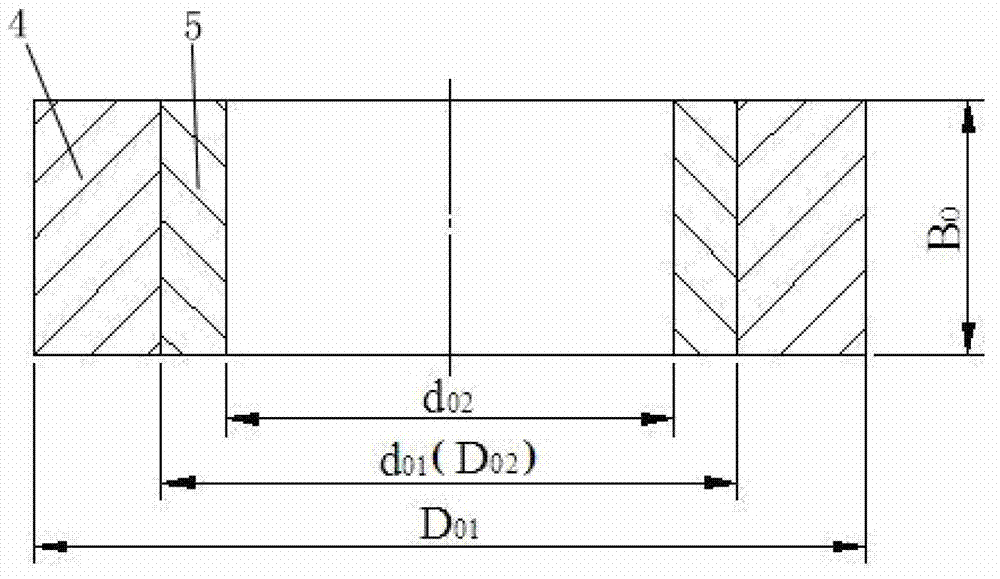

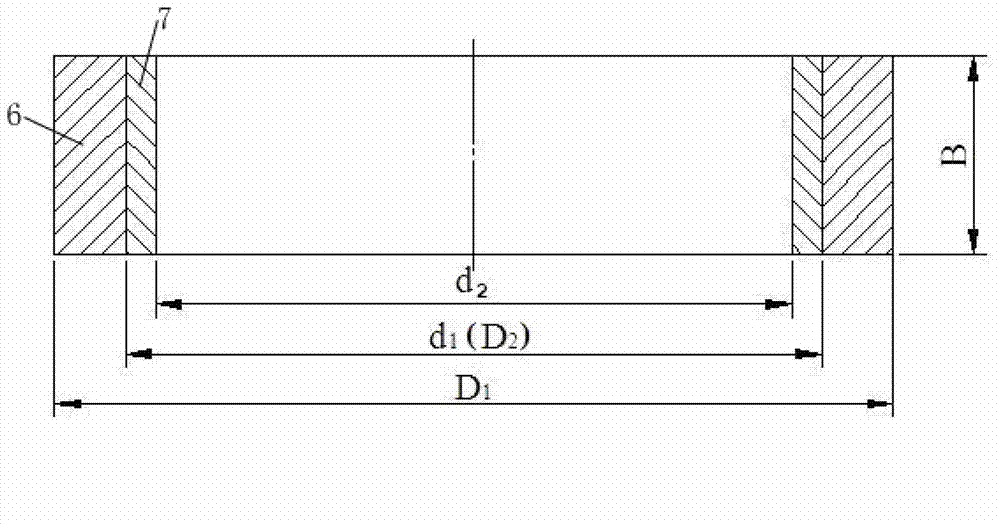

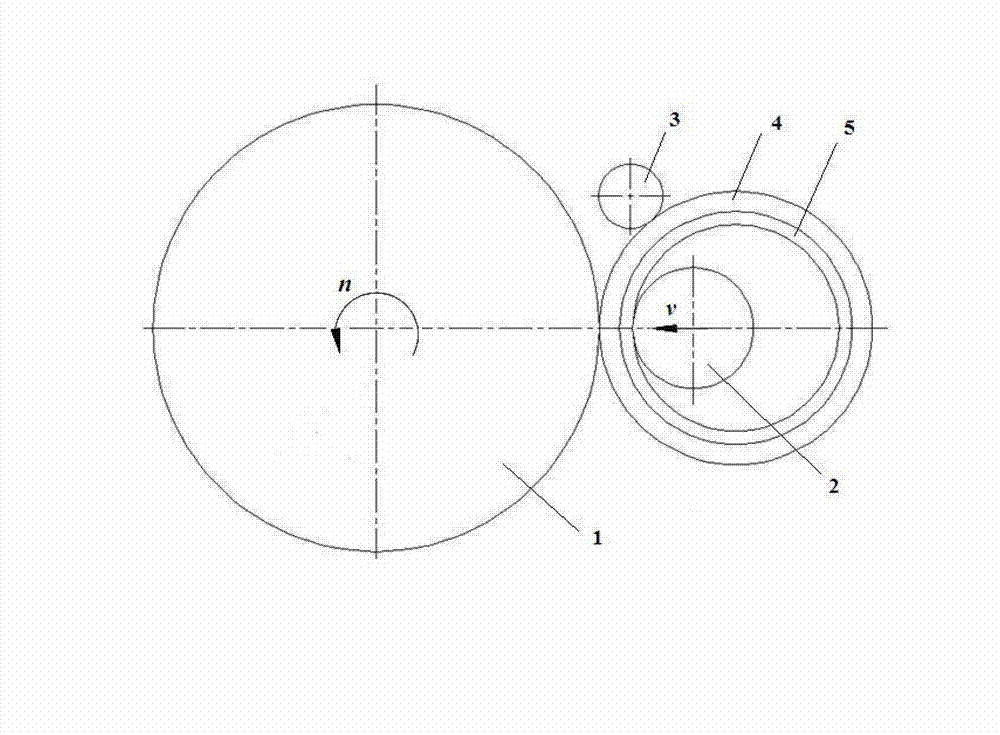

Precise roll forming method for bimetallic rings

ActiveCN103042142ASignificant energy saving and material savingReduce manufacturing costMetal rollingProduction rateRoll forming

The invention relates to a precise roll forming method for bimetallic rings. The method comprises: S1, obtaining an outer ring blank and an inner ring blank; S2, assembling the outer ring blank and the inner ring blank; S3, placing a core roller in the inner ring blank; S4, placing a drive roller outside the outer ring blank; S5, driving the drive roller to rotate through a drive device and driving the core roller to perform linear feed movement radially, wherein the outer ring blank and the inner ring blank are attached closely constantly to produce continuous local plastic deformation with the wall thickness reducing and the diameter expanding; and S6, stopping feed of the core roller and getting the core roller back when the outer diameter of the outer ring blank reaches a preset value of the outer diameter of a bimetallic ring. According to the precise roll forming method, the bimetallic ring is formed integrally through one step through continuous local plastic deformation, so that the method has the advantage that energy and materials are saved, the production cost is reduced, and the yield is improved. The bimetallic ring interface contact quality is good, the connection strength is high, and requirements of service performances and service lives of high-performance bimetallic rings can be met.

Owner:WUHAN UNIV OF TECH

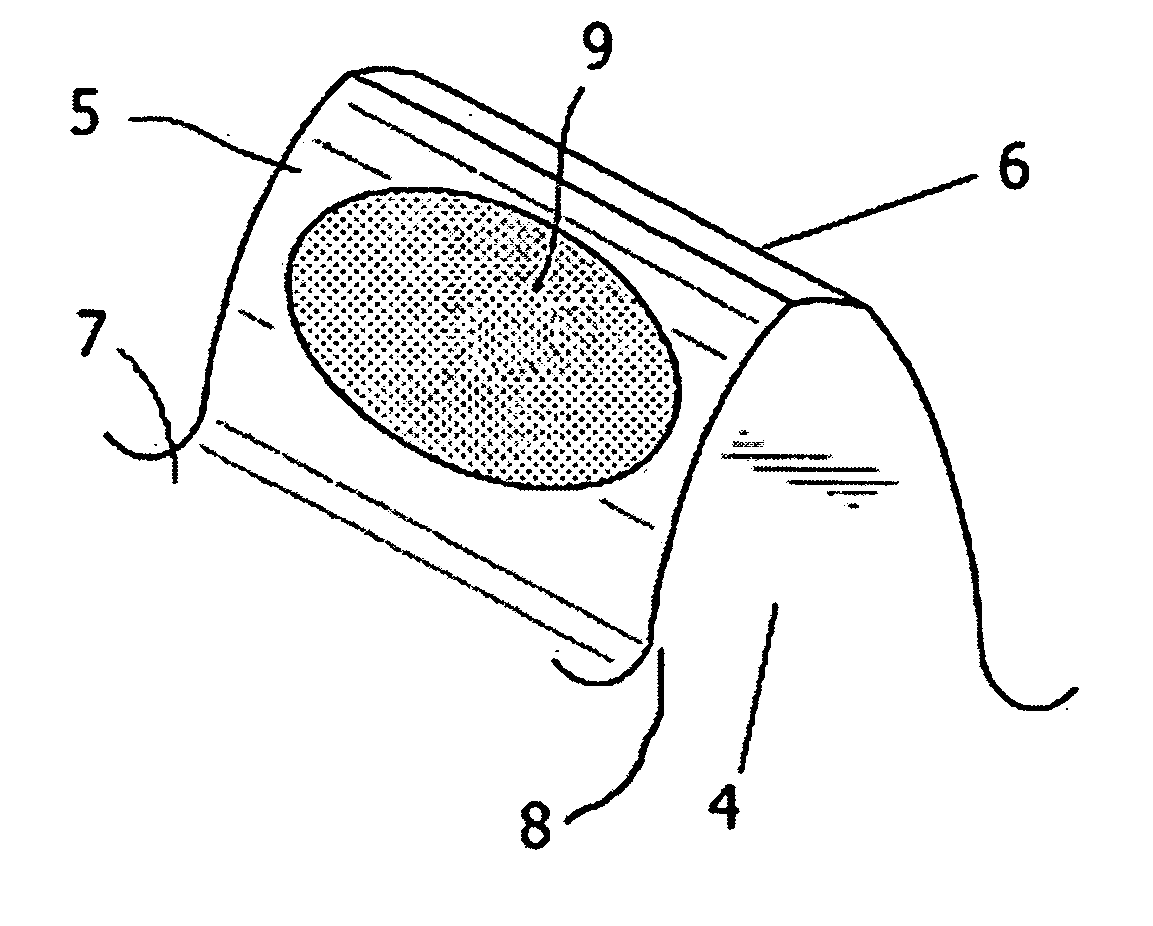

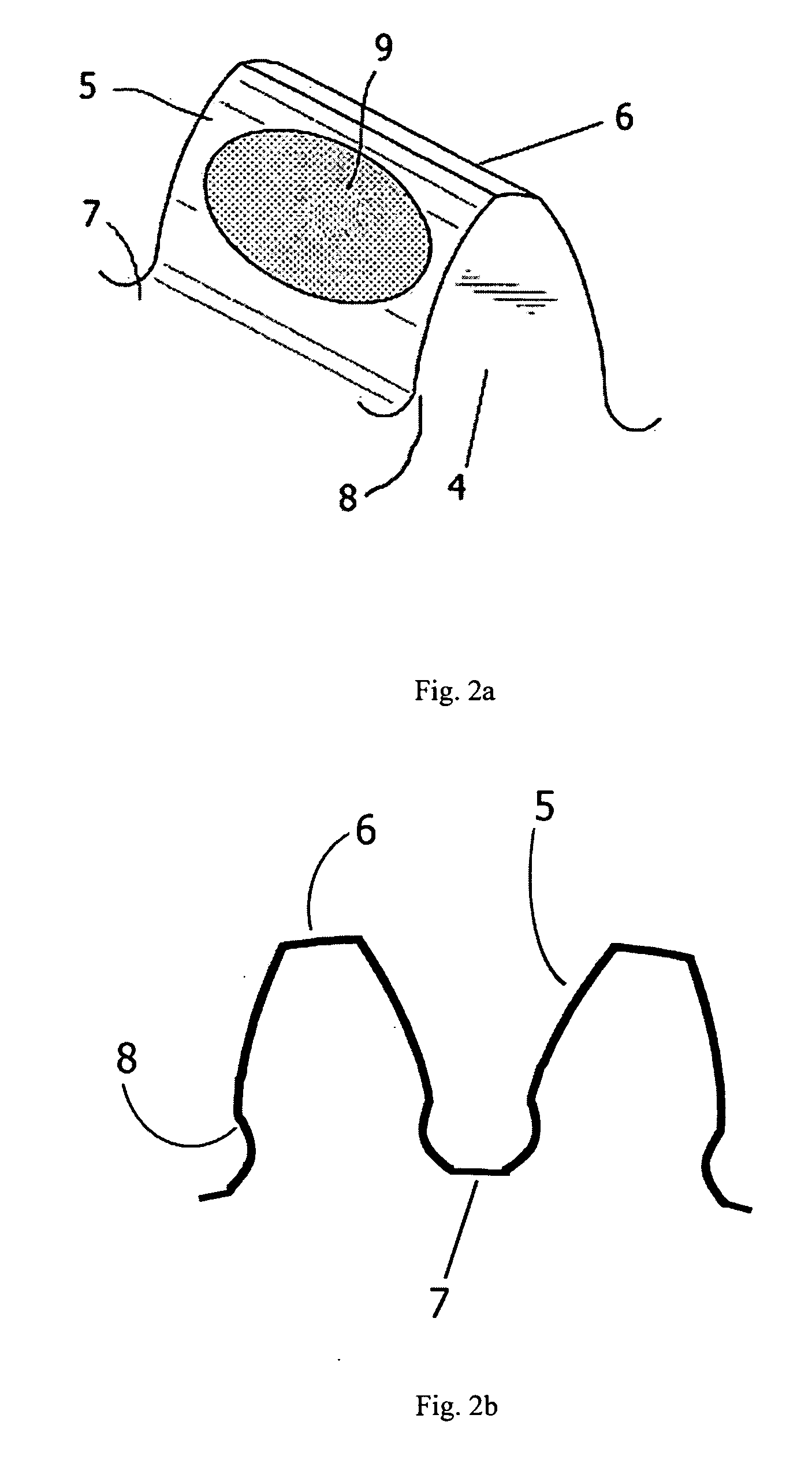

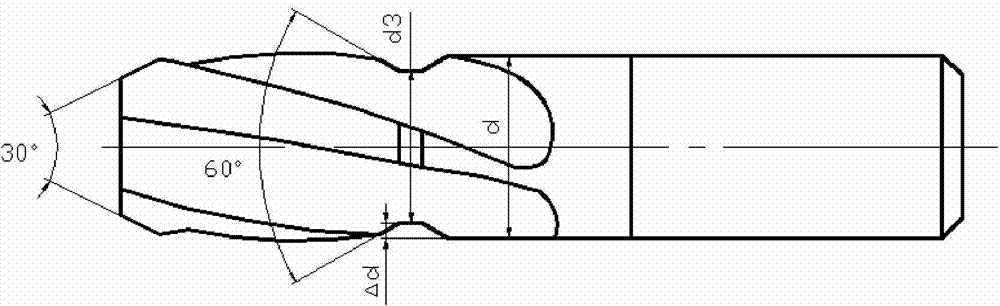

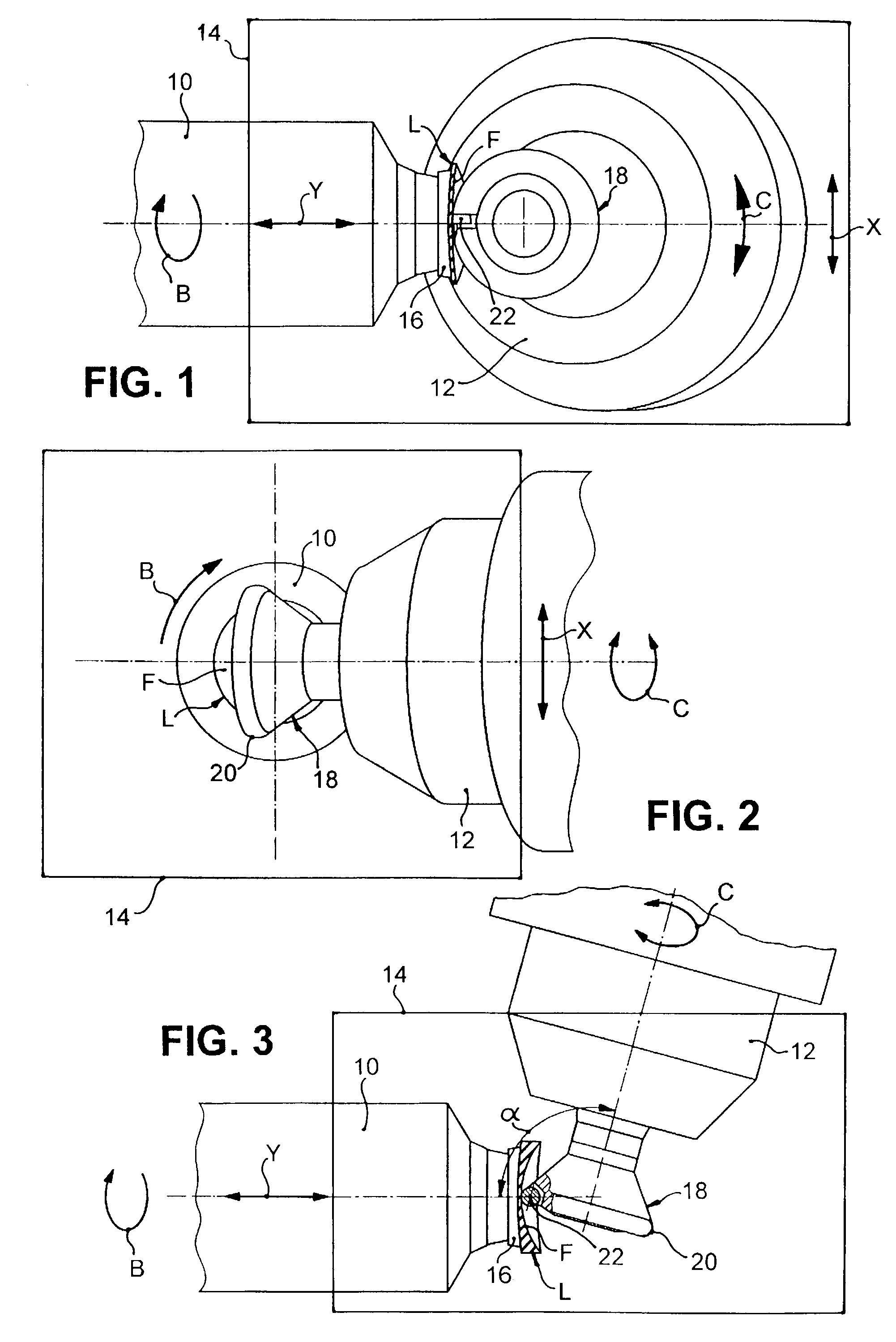

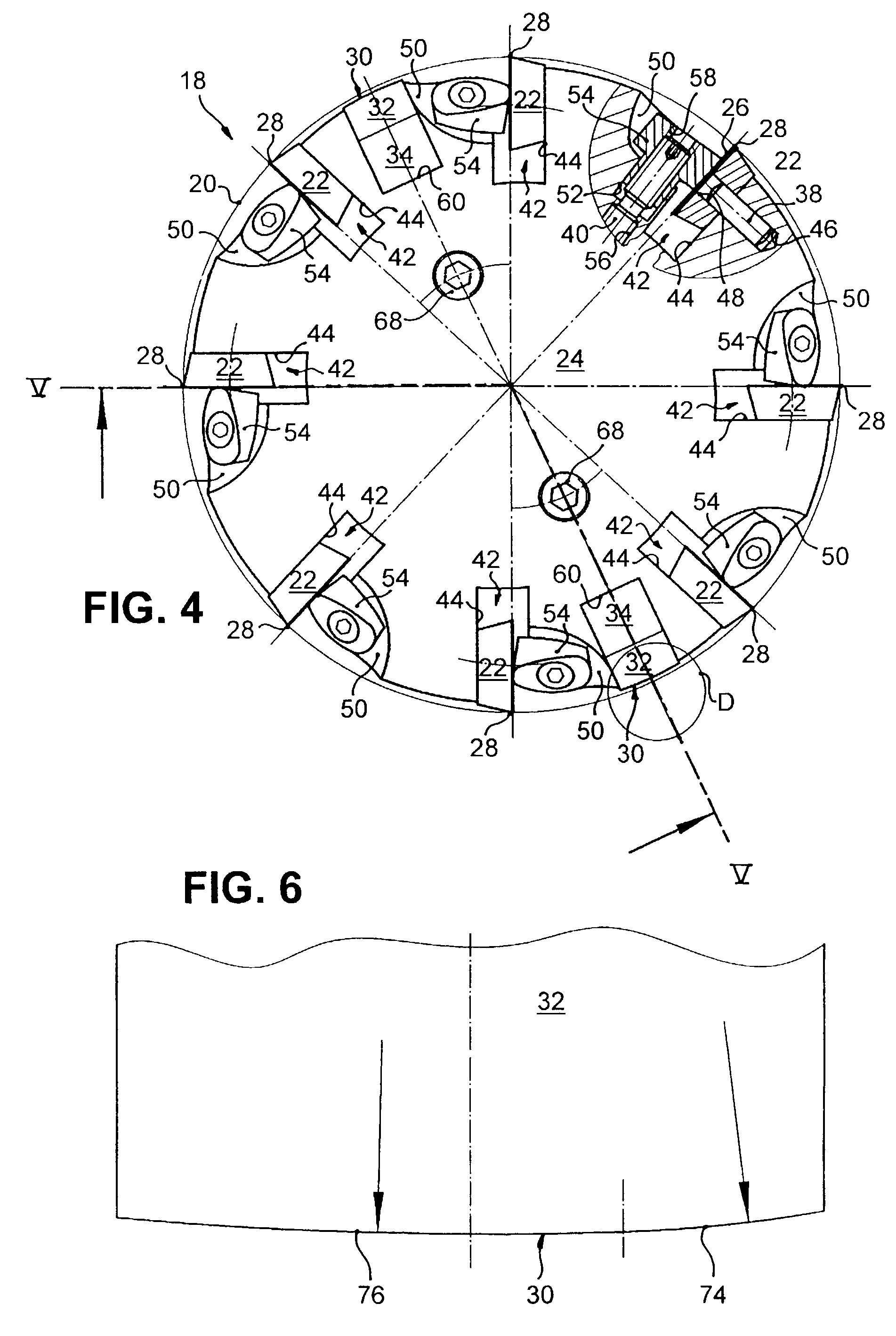

Method and device for the surface machining of workpieces composed of non-brittle materials in optical lens manufacturing and tool for this purpose

InactiveUS6991525B2Easy loadingRapidly and reliably machinedMilling cuttersOptical articlesRotational axisEngineering

A device is disclosed for the surface machining of, among other things, plastic spectacle lenses, which has a work spindle, by means of which the spectacle lens can be driven with a controlled angle of rotation about an axis of work rotation, and a tool spindle, by means of which a tool can be driven to rotate about an axis of tool rotation, work and tool spindle being movable relative to one another with their positions controlled in two axes running at right angles. For rotational machining of the surface of the spectacle lens to be machined, the tool can also be swiveled by means of the tool spindle with a controlled angle of rotation about the axis of tool rotation, so that a rotational cutting edge provided on the tool can be brought into a defined rotational machining engagement with the surface of the spectacle lens to be machined as a function of the angle of rotation of the spectacle lens. Also included is a combined milling and rotational machining tool and a combined milling and rotational machining method. As a result, high cutting rates and very good surface qualities can be easily and efficiently achieved in the surface machining.

Owner:SATISLOH GMBH

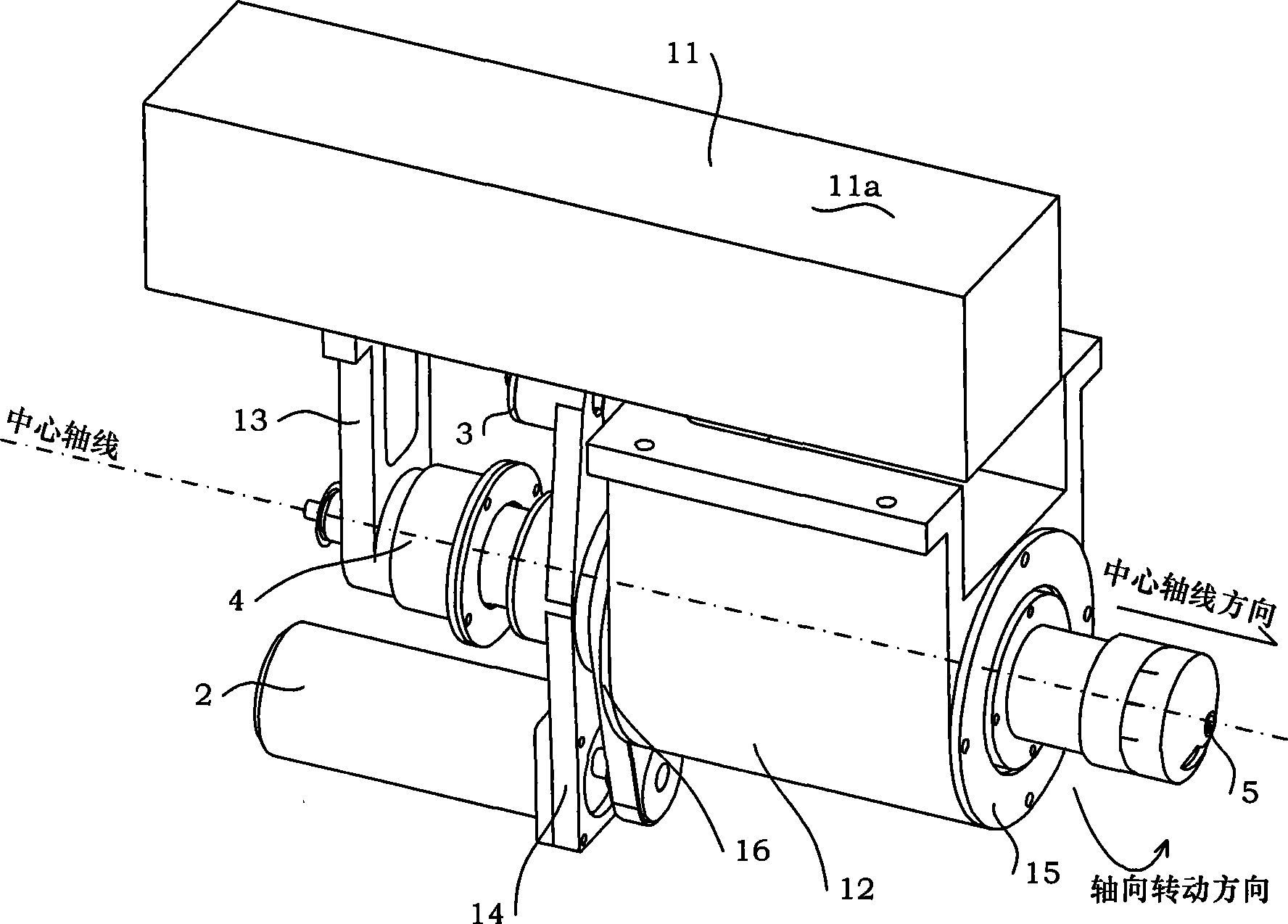

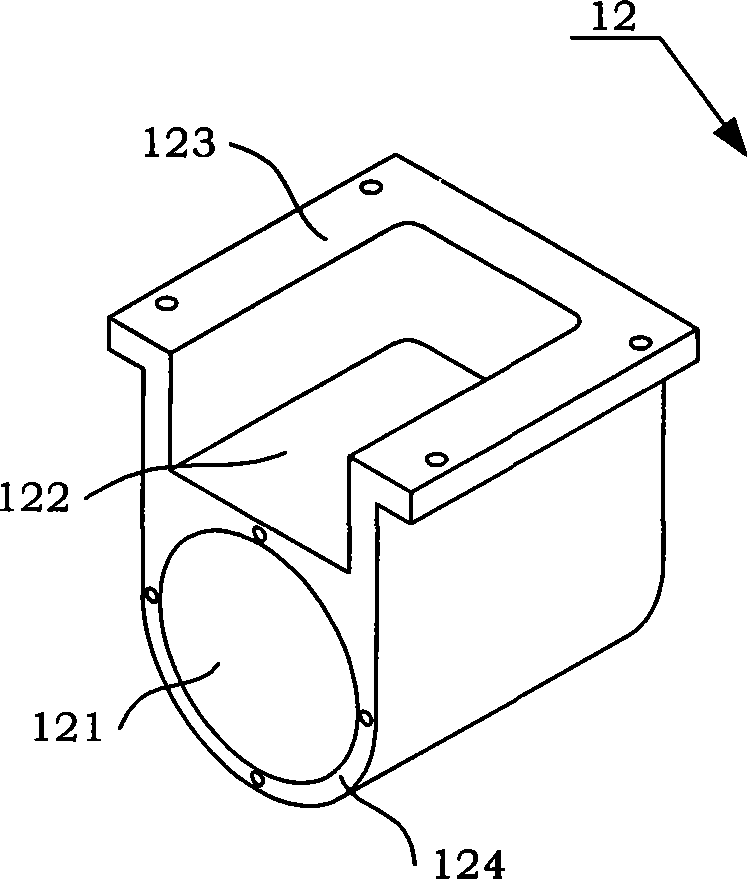

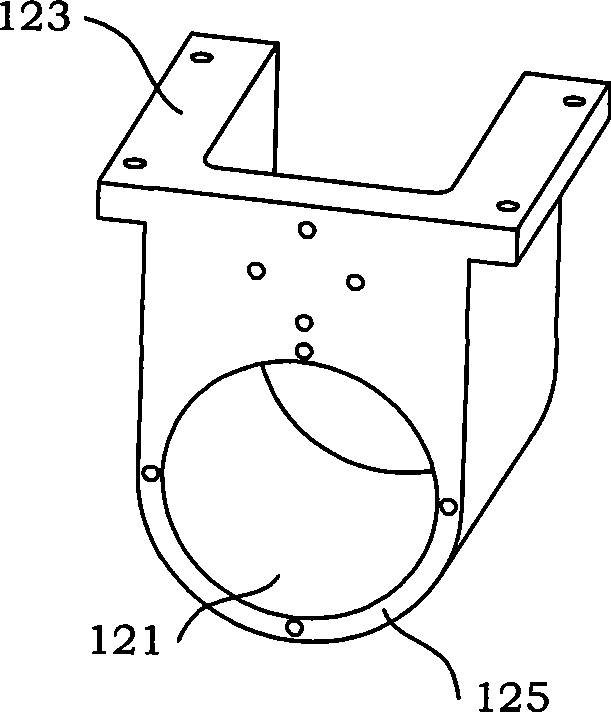

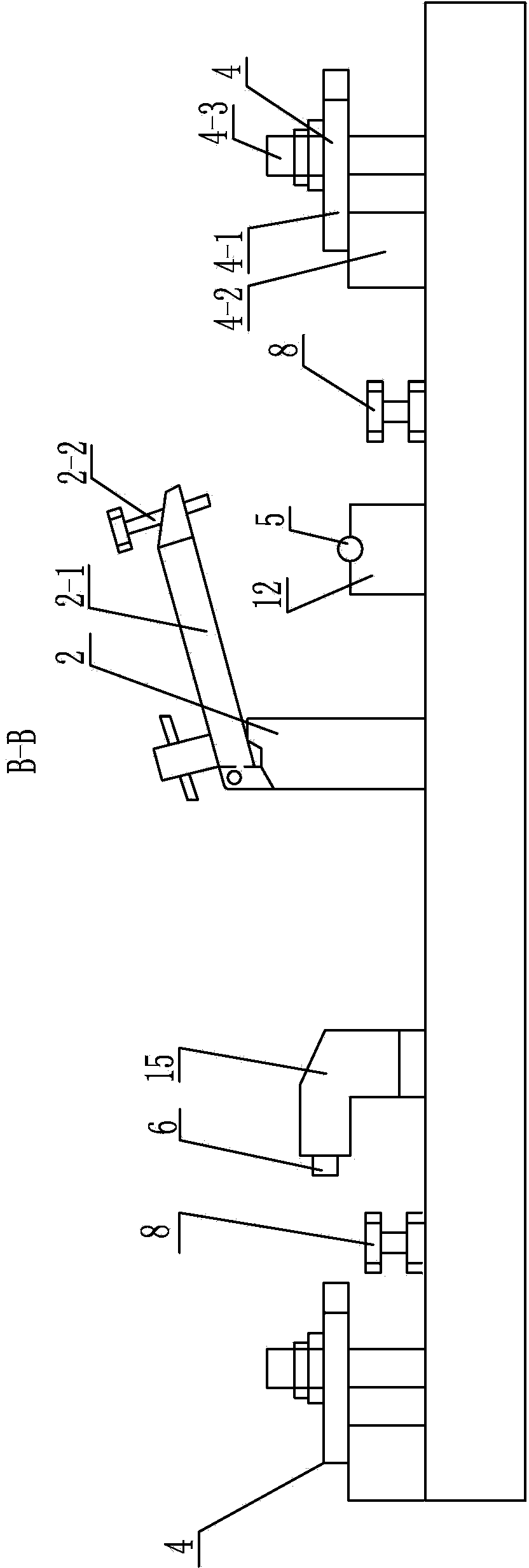

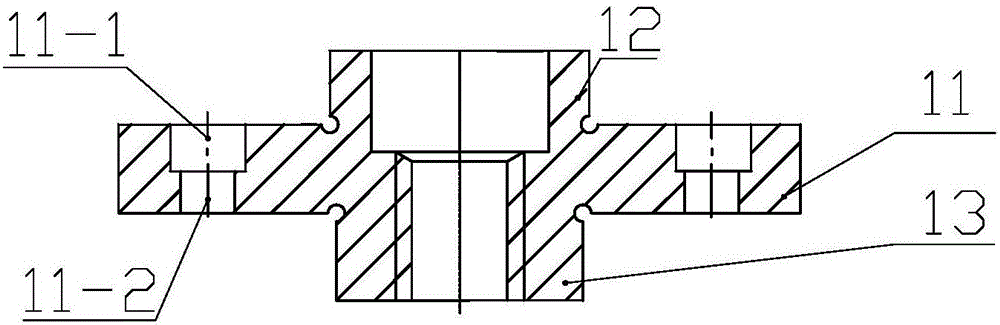

Floating type oval-shaped supersonic vibration micro-engraving device

InactiveCN101376179AMake up for the defect of not being able to rotateDepth remains constantMechanical vibrations separationLarge fixed membersNumerical controlTransducer

The invention discloses a floating elliptical ultrasonic vibration micro-sculpture device, which comprises an installation table (11), a support unit, a driving unit (2), a sliding unit (3), a floating transduction component (4) and a longitudinal bending transducer (1); the support unit is composed of a support base (12), an A bracket (13) and a B bracket (14); the lower installing surface of the installation table (11) is respectively connected with the support base (12) and the A bracket (13); and the upper installing surface (11a) of the installation table (11) is connected with a numerical control table. The cutter of the sculpture device can produce elliptical ultrasonic vibration to realize micro-sculpturing under the drive of an ultrasonic transducer. The micro-sculpture device can ensure that the depth of a processed groove maintains constant through the floating transduction component; then the longitudinal bending transducer causes the cutter to produce ultrasonic elliptical vibration; the characteristics of ultrasonic elliptical vibration which can reduce the cutting force to improve the machining accuracy and reduce the surface roughness are utilized to ensure that the groove on the processed part surface has high geometric accuracy and surface quality without burrs on the edge thereof; and the unitized design of the longitudinal bending transducer and the driving unit remedies the defect that the cutter cannot rotate in the traditional planing process, thereby realizing free-adjusting sculpture process with multiple cutting directions.

Owner:BEIHANG UNIV

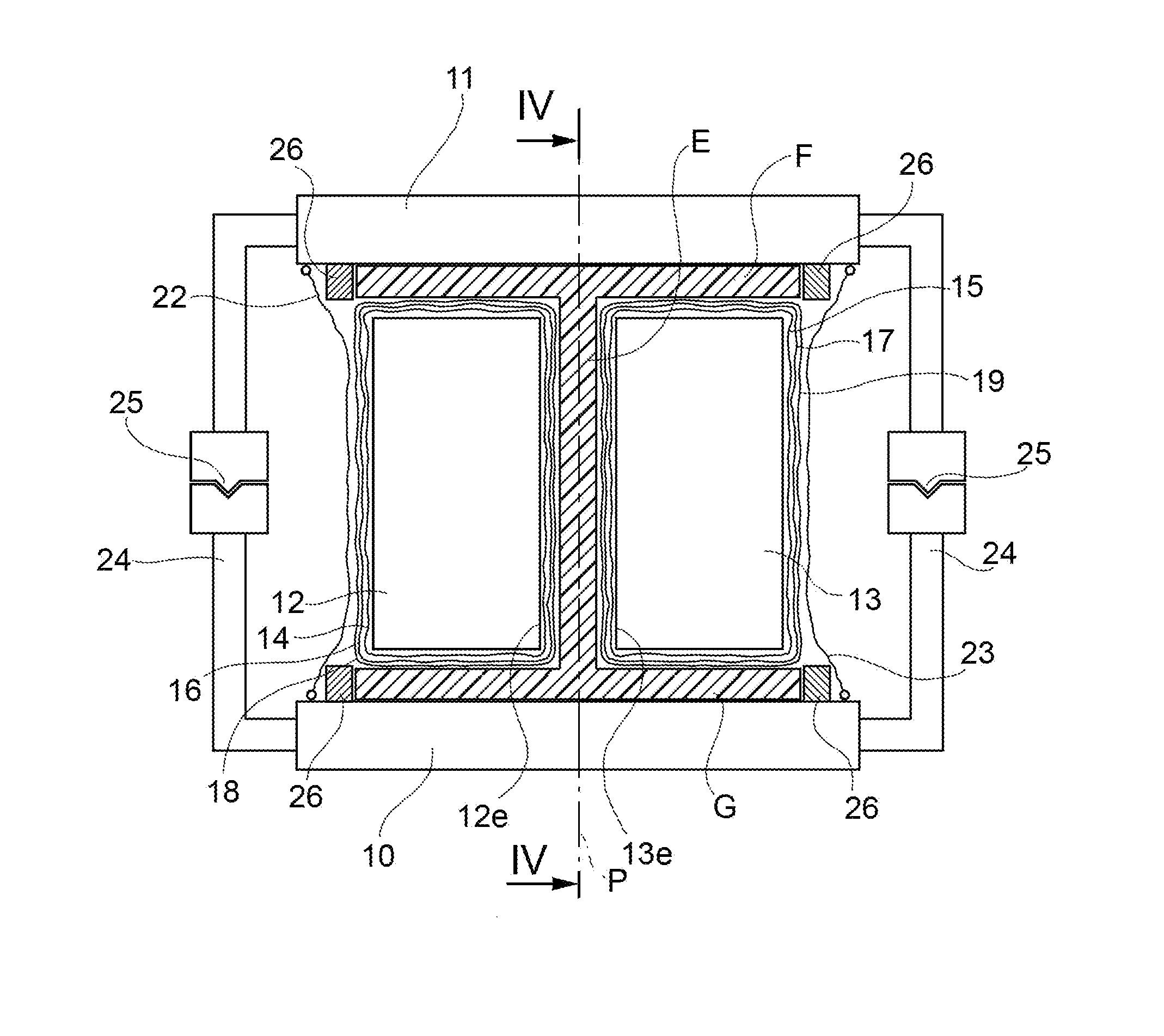

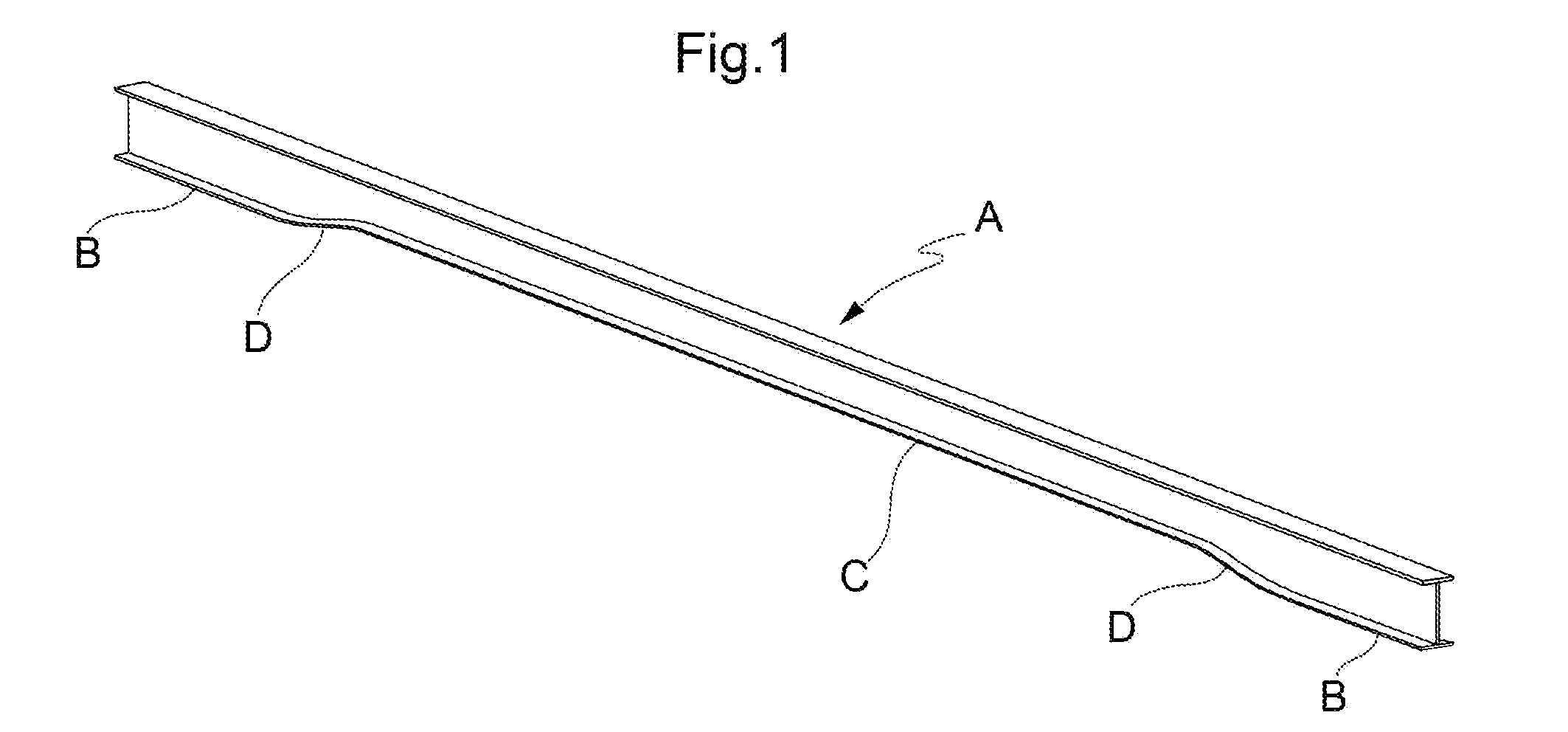

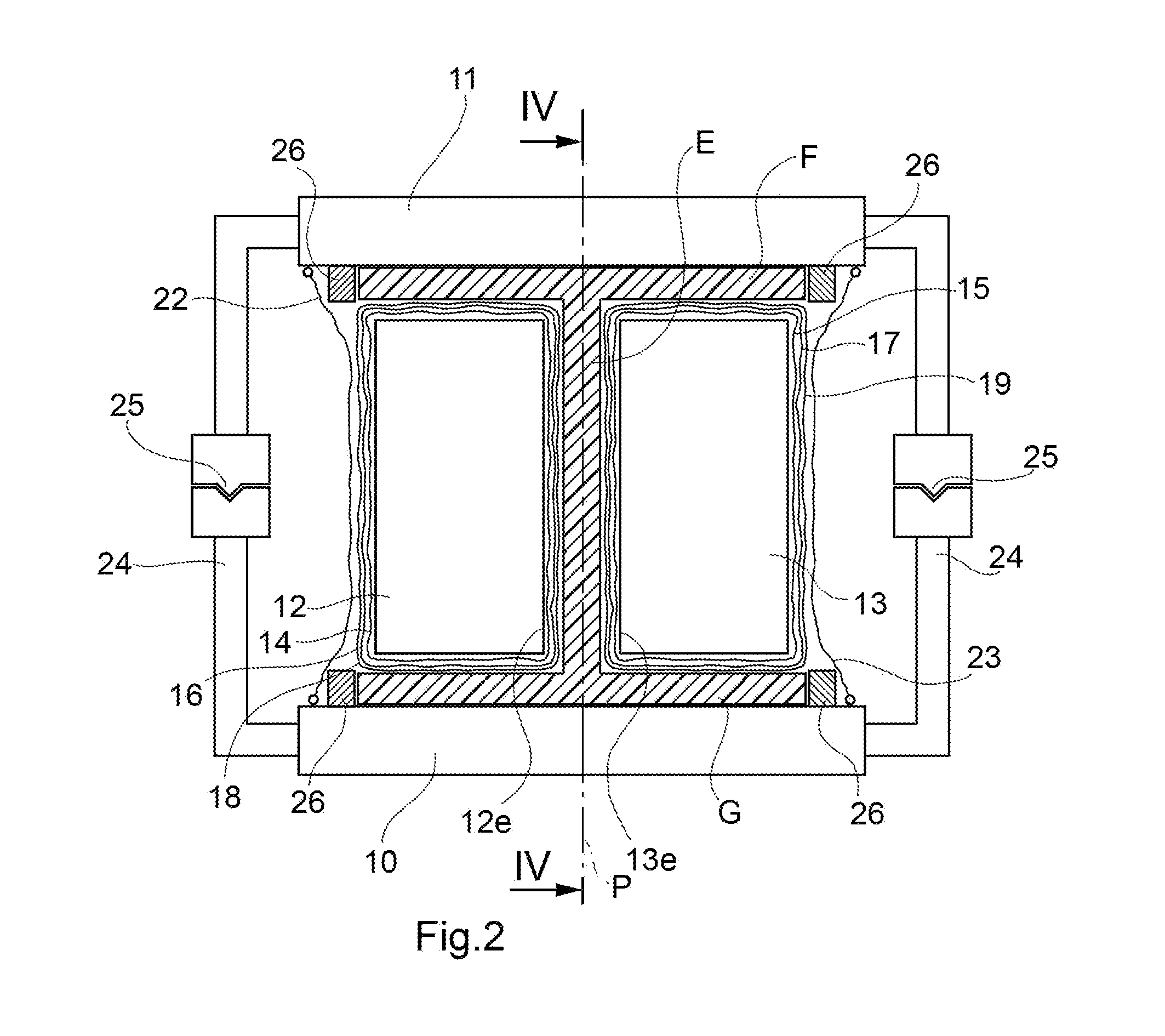

Method of manufacturing spars, longerons and fuselage beams having a variable h cross-section

ActiveUS20110226407A1High geometric accuracyUniform applicationEfficient propulsion technologiesWingsFiberVertical plane

A beam of fibre-reinforced curable thermosetting composite material is preliminarily assembled in an uncured condition. The beam is placed between two forming tools, namely a lower and an upper tool, shaped in such a way as to give the lower and upper flanges a predetermined shape, at least one of the flanges having a non-rectilinear profile viewed in a longitudinal vertical plane. Two longitudinally elongate rigid inserts are placed between the flanges at the sides of the web and are covered in respective airtight tubular bags. The spaces between the upper tool and the lower tool on the two opposite longitudinal sides are sealed. The open opposite ends of the tubular bags are also sealed in such a manner that the pressure applied in an autoclave during the step of curing causes the tubular bags to swell and presses them against the two opposite faces of the web and against the flanges of the beam. On completion of curing, the upper forming tool is removed and the inserts are extracted sideways.

Owner:ALENIA AERONAUTICA SPA

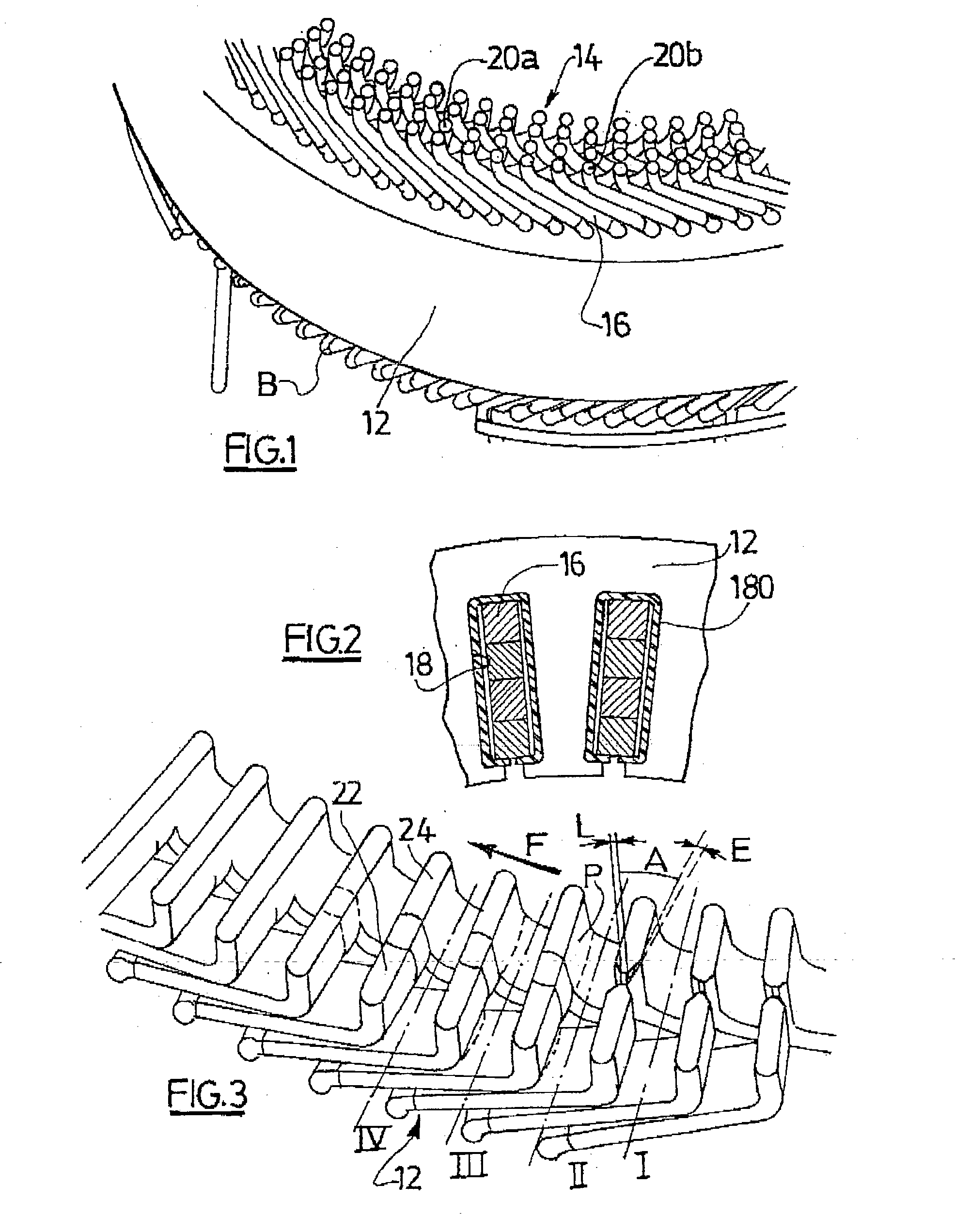

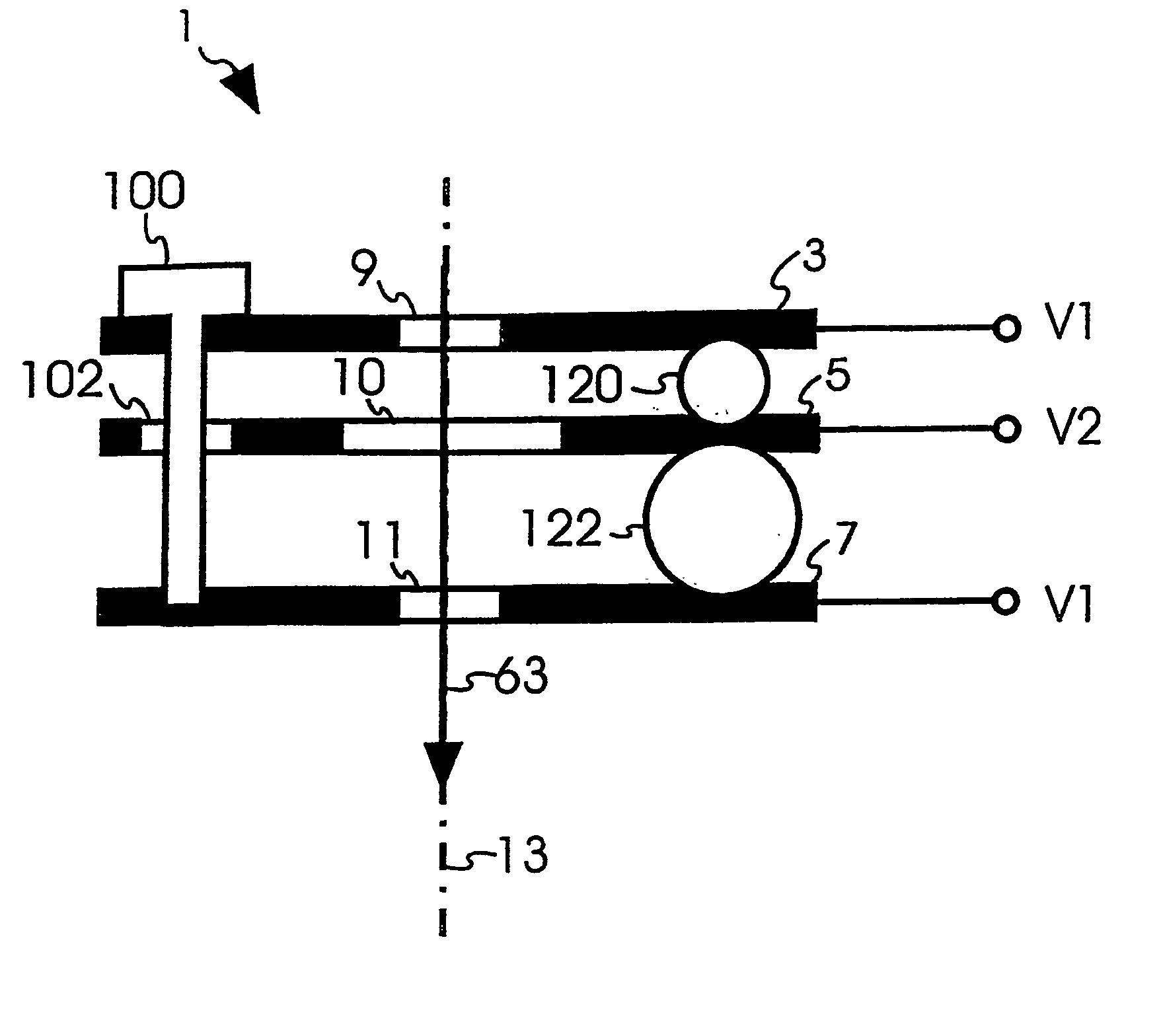

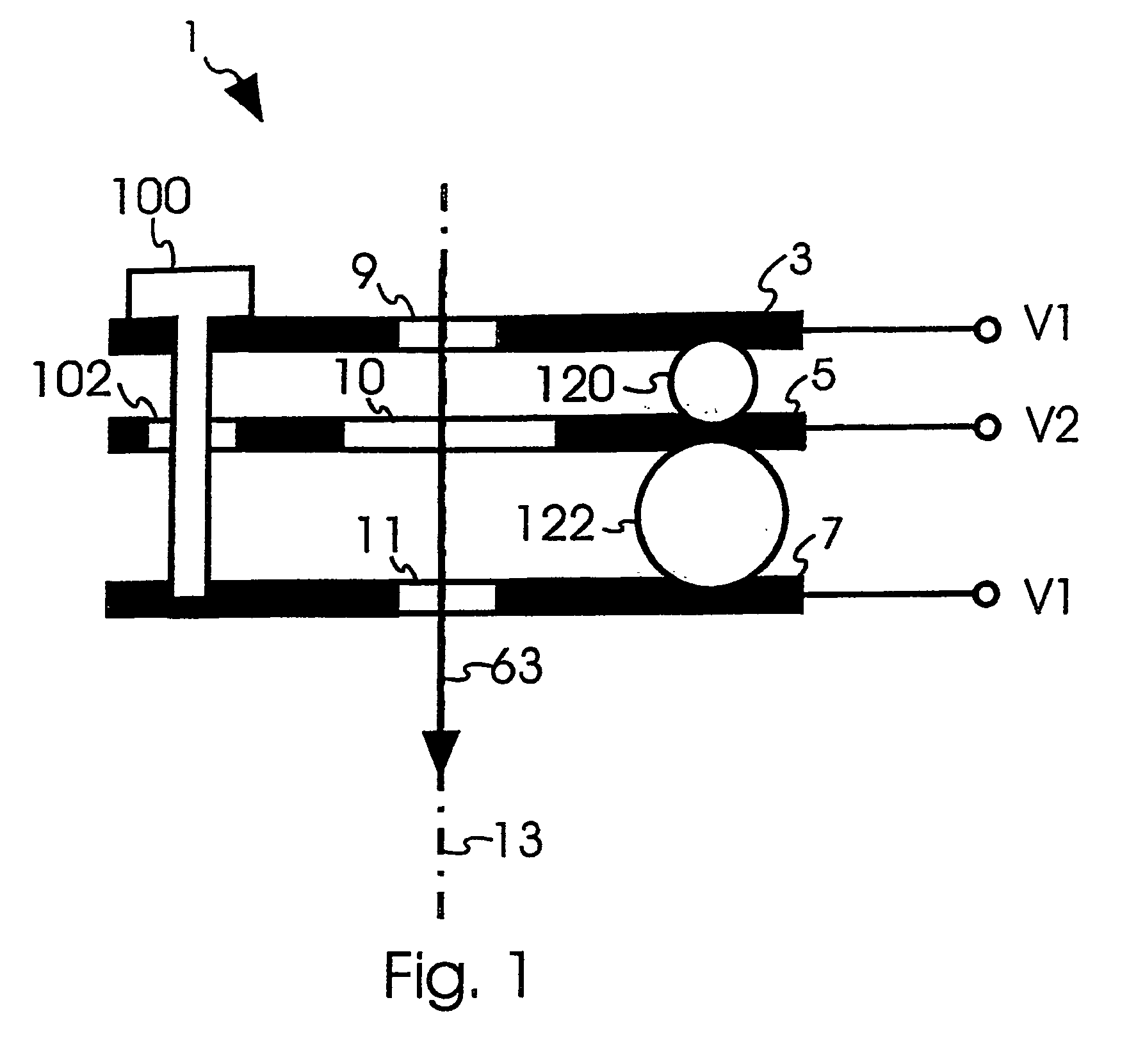

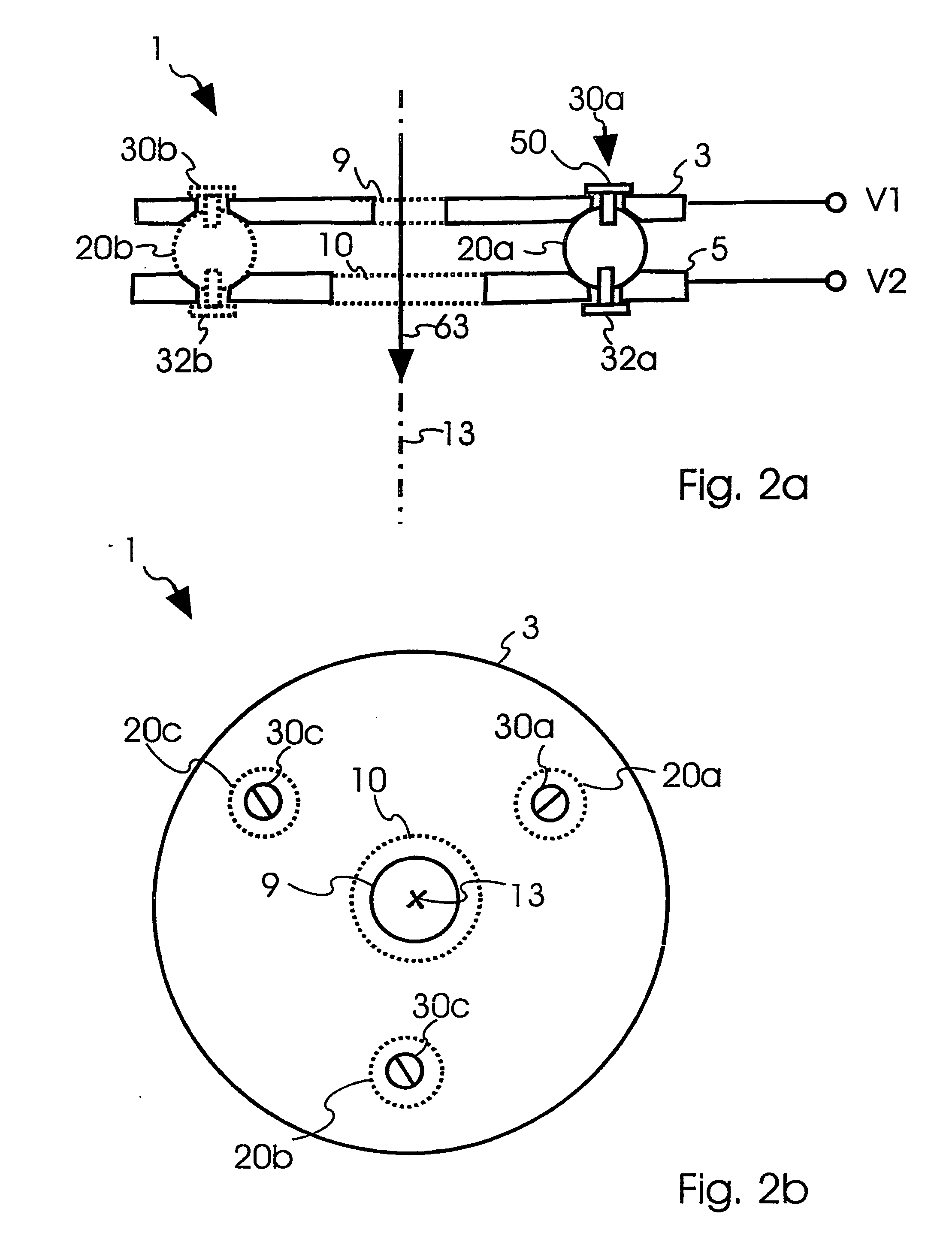

Beam optical component for charged particle beams

ActiveUS20070125954A1Improve focus qualityRemove distortionStability-of-path spectrometersBeam/ray focussing/reflecting arrangementsLight beamMolecular physics

The present invention relates to a beam optical component (1, 201) for acting on a charged particle beam (63) including a first element (3; 203) having a first opening (9; 209) for acting on the charged particle beam (63), at least a second element (5; 205) for acting on the charged particle beam (63); at least one distance piece (20a, 20b, 20c) positioned between the first element (3; 203) and the second element (5; 205) to define a minimum distance between the first element (3; 203) and the second element (5; 205); and a first holding piece (30a; 30b; 30c) for abutting the first element (3) to the at least one distance piece (20a, 20b, 20c), whereby the first holding piece (30a; 30b; 30c) is attached to the at least one distance piece (20a, 20b, 20c). First and second elements (3; 203; 5; 205) are preferably electrodes or pole pieces to act on the charged particle beam by an electrostatic or magnetic force. With the first holding piece (30a; 30b; 30c) attached to the at least one distance piece, distorting mechanical forces on the first and second elements (3, 5) are reduced which improves the performance of the respective beam optical components (1; 201).

Owner:ICT INTEGRATED CIRCUIT TESTING GESELLSCHAFT FUER HALBLEITERPRUEFTECHNIK GMBH

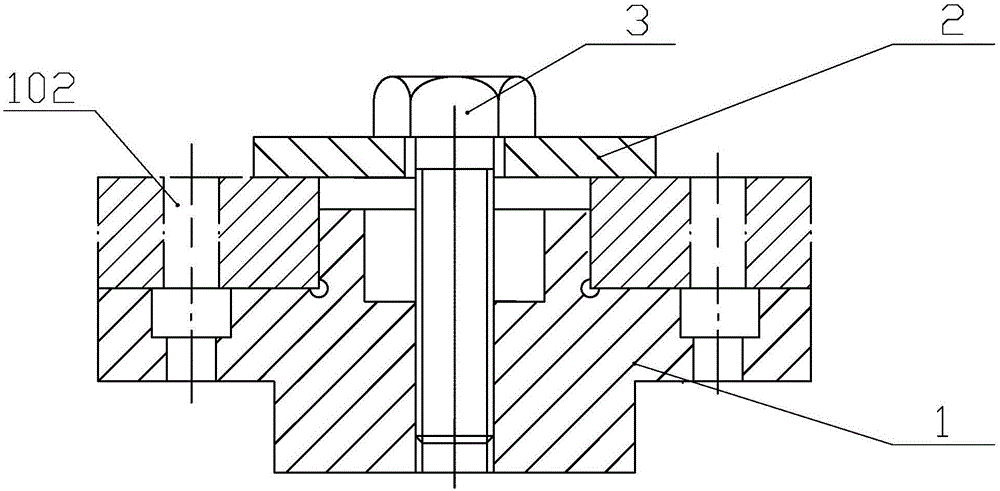

Clamping and positioning device for machining gas turbine power turbine guide vane datum face

ActiveCN104191264AImprove positionHigh geometric accuracyWork clamping meansPositioning apparatusEngineeringMachining process

The invention provides a clamping and positioning device for machining a gas turbine power turbine guide vane datum face, and relates to the clamping and positioning device. The clamping and positioning device aims to solve the problems that no special fixture device exists in the existing machining process of gas turbine power turbine guide vanes, assembling and positioning of steam passages are inconsistent with assembling and positioning of steam passage circular arcs, and the steam passages are damaged. The clamping and positioning device comprises a fixture, a first screwing device, a second screwing device, three positioning cylindrical pins, three positioning round head pins, four auxiliary lifting adjusting and supporting devices, four pressing devices and six positioning bases. The first positioning base, the second positioning base, the third positioning base, the fourth positioning base, the fifth positioning base and the sixth positioning base are correspondingly installed on the upper end face of the fixture according to the positions of six datum points for machining workblanks of the gas turbine power turbine guide vanes. The first screwing device, the second screwing device, the four pressing devices and the four auxiliary lifting adjusting and supporting devices are arranged on the upper end face of the fixture. The clamping and positioning device is used for positioning and machining of the gas turbine power turbine guide vanes.

Owner:HARBIN TURBINE +1

High-grade car precision bearing steel ball fabrication process

The invention discloses a process for manufacturing a precision bearing steel ball used in a high-grade automobile. The process comprises the following steps of the selection of raw materials, the cold heading and forming of ball billets, the heat treatment, the surface strengthening, the preliminary lapping and flaw detection, the super lapping of a resin wheel, the cleaning, the rust protection and the packaging; by technologies of the selection of raw materials, the forming of ball billets, the surface strengthening and the super lapping of a resin wheel, the surface quality and the geometric accuracy of the steel ball are further improved, thereby improving the quality of products.

Owner:JIANGSU LIXING GENERAL STEEL BALL

Machining technology for alloy steel separation type solid retainer

The invention discloses a machining technology for an alloy steel separation type solid retainer, and belongs to the technical field of machining. The machining technology solves the problems that according to an existing machining technology for an alloy steel separation type solid retainer, the roughness of the outer diameter surface and the inner diameter surface of the retainer is disqualified, the machining precision of the outer diameter and the inner diameter of the retainer is poor, and the inner diameter size and the outer diameter size of the retainer are not stable. The machining technology comprises the following steps of turning forming, uniform grinding of two end faces, rivet hole drilling, pin inserting, mark punching, outer diameter grinding, inner diameter final turning and chamfering, hole drilling and milling, deburring, pin dismounting, cavity milling, second rivet hole chamfering, bright polishing, cleaning, flaw detection, final inspection, silver plating and packaging. The machining technology is used for machining the alloy steel separation type solid retainer.

Owner:AVIC HARBIN BEARING

Straight line rolling guiding rail, and guideway slider multiple grinding head combined grinding machine

A combined grinder with multiple grinding heads for grinding the straight rolling track and slide block on the track is composed of a machine body, two vertical columns, a transverse beam installed to said vertical columns, a tool carriage on said transverse beam, 2-4 grinding heads (including vertical and horizontal grinding heads), and an abrasive disc repairing device.

Owner:浙江杭机股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com