Electroplastic incremental forming device and method for plates

An electroplastic and progressive forming technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve problems such as difficult and low cost, high-efficiency processing of high surface quality, reduction of deformation resistance of sheet metal, reduction of processing force, etc., to achieve Avoid surface oxidation and excessive softening, improve geometric accuracy and surface quality, and improve plastic deformation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

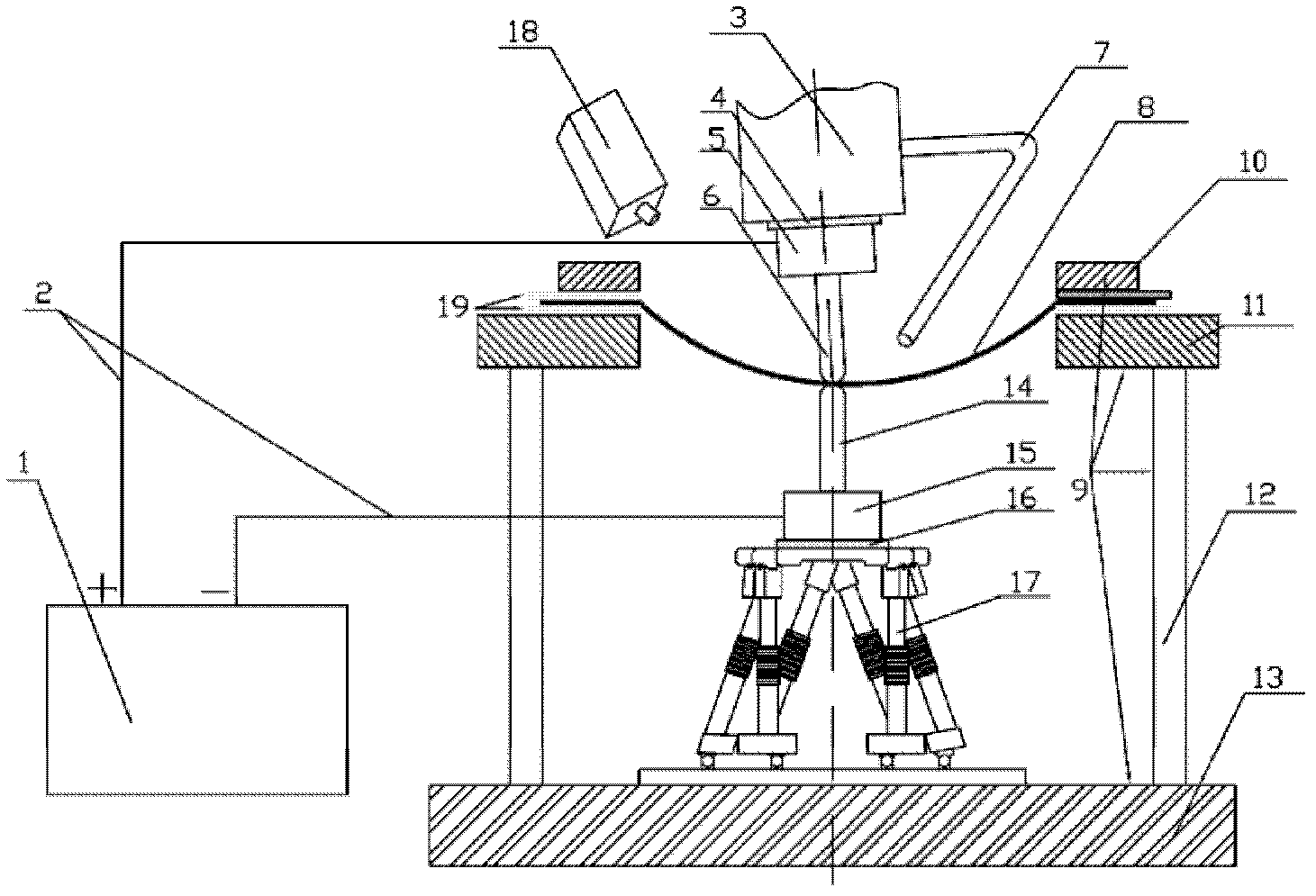

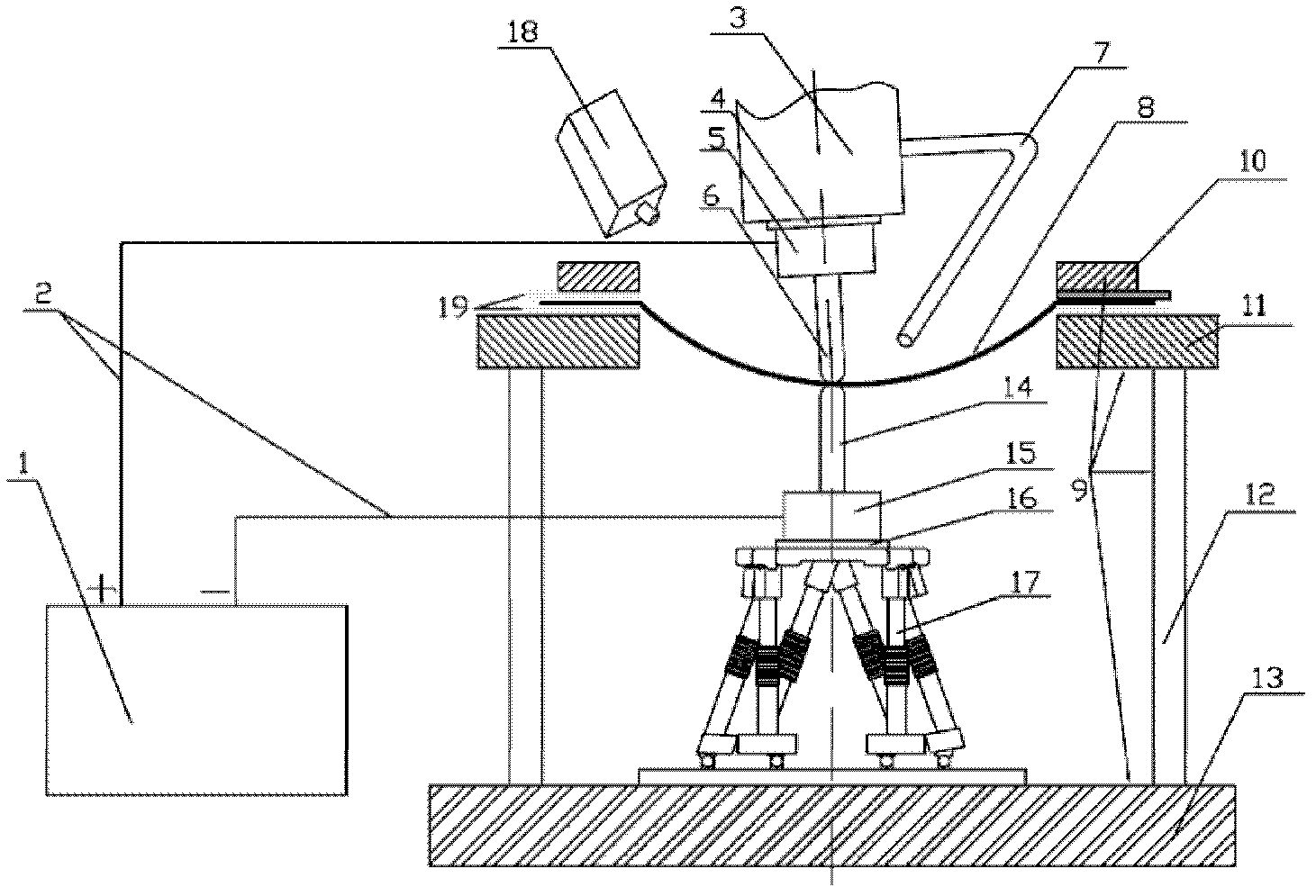

[0024] as attached figure 1 As shown, the electroplastic progressive forming device for sheet metal includes: five-axis CNC forming machine tool 3, six-axis parallel robot processing system 17, sheet metal forming fixture 9, high-energy pulse power supply 1, infrared thermometer 18, and compressed air built into the CNC machine tool Cooling system 7, wherein: the end of the main shaft of the five-axis CNC forming machine tool 3 is equipped with an upper forming indenter 6, and the upper forming indenter 6 is fixed on the end of the main shaft of the five-axis CNC forming machine tool 3 through the upper forming indenter fixing block 5, and on the upper An upper insulating gasket I4 is provided above the forming indenter fixing block 5, and the sheet material 8 is located below the upper forming indenter 6 and fixed by the sheet material forming fixture 9, which is installed on the workbench of the five-axis CNC forming machine tool 3 Above, the sheet material forming jig 9 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com