Method for machining circular hole alloy steel cage with inner-and-outer double fore shafts

A processing method and technology of alloy steel, which is applied in the processing field of structural bearing cages, can solve problems such as high wear rate of milling cutters, failure to fit into the outer casing, and difficulty in ensuring the angle, so as to improve production efficiency and improve surface roughness. , The effect of reducing the processing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

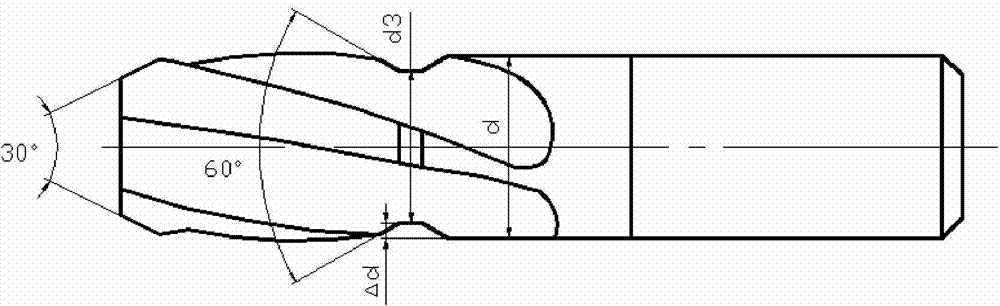

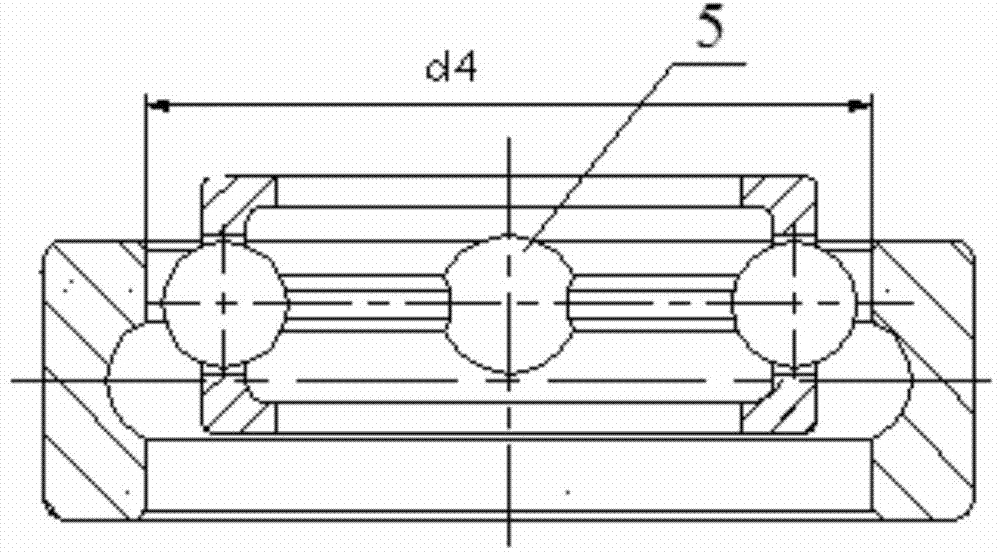

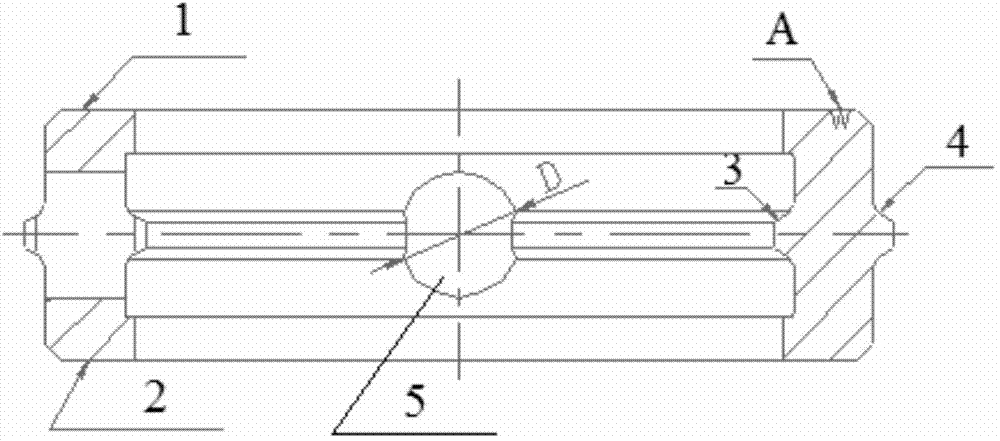

[0046] Specific implementation mode 1: The processing method of an alloy steel cage with inner and outer double locking round holes in this embodiment is carried out according to the following steps:

[0047] 1. Turning forming: Turning the alloy steel with a hard alloy inner diameter turning tool to obtain an alloy steel with an inner diameter of 52.8mm to 53mm, and then using a hard alloy outer diameter turning tool to turn the outer surface of the alloy steel with an inner diameter of 52.8mm to 53mm diameter, to obtain alloy steel pipes with an inner diameter of 52.8mm to 53mm and an outer diameter of 67.2mm to 67.4mm, and then use a carbide end face turning tool to turn the alloy steel pipe with an inner diameter of 52.8mm to 53mm and an outer diameter of 67.2mm to 67.4mm The end face is cut off with a cutting knife to obtain an alloy steel cage with a formed wide band size of 16.3mm to 16.5mm;

[0048] 2. Quenching and tempering treatment: perform quenching and tempering ...

specific Embodiment approach 2

[0079] Embodiment 2: This embodiment is different from Embodiment 1 in that: the cutting speed in step 1 is 120m / min-260m / min, and the feed rate is 0.2mm / r-0.25mm / r. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0080] Specific Embodiment 3: The difference between this embodiment and specific embodiment 1 or 2 is that the quenching and tempering treatment process described in step 2 is: cleaning first, and then quenching in a vacuum oil quenching furnace at a temperature of 835°C Treat for 40min to 45min, clean after quenching, and then temper in a vacuum tempering furnace at a temperature of 580°C for 120min to 130min to obtain a quenched and tempered alloy steel cage. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com