High-strength and high-toughness oil casing and manufacturing method thereof

A technology of oil casing and manufacturing method, which is applied in the direction of casing, drill pipe, earthwork drilling, etc., which can solve the problems of increased raw material cost, difficult control, poor dimensional accuracy of the pipe body, etc., and achieves consistent performance and high dimensional accuracy , Eliminate the effect of weld streamline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

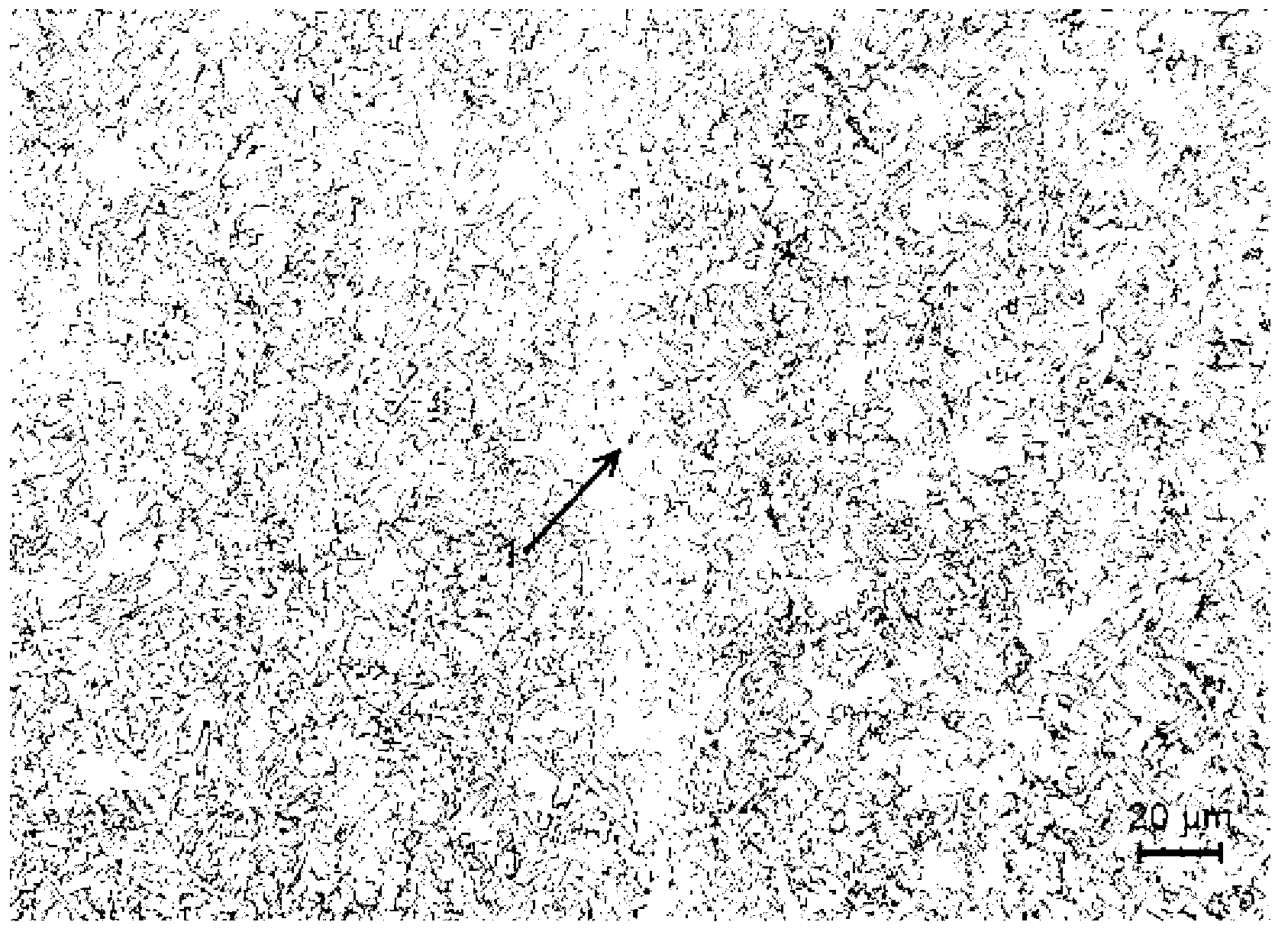

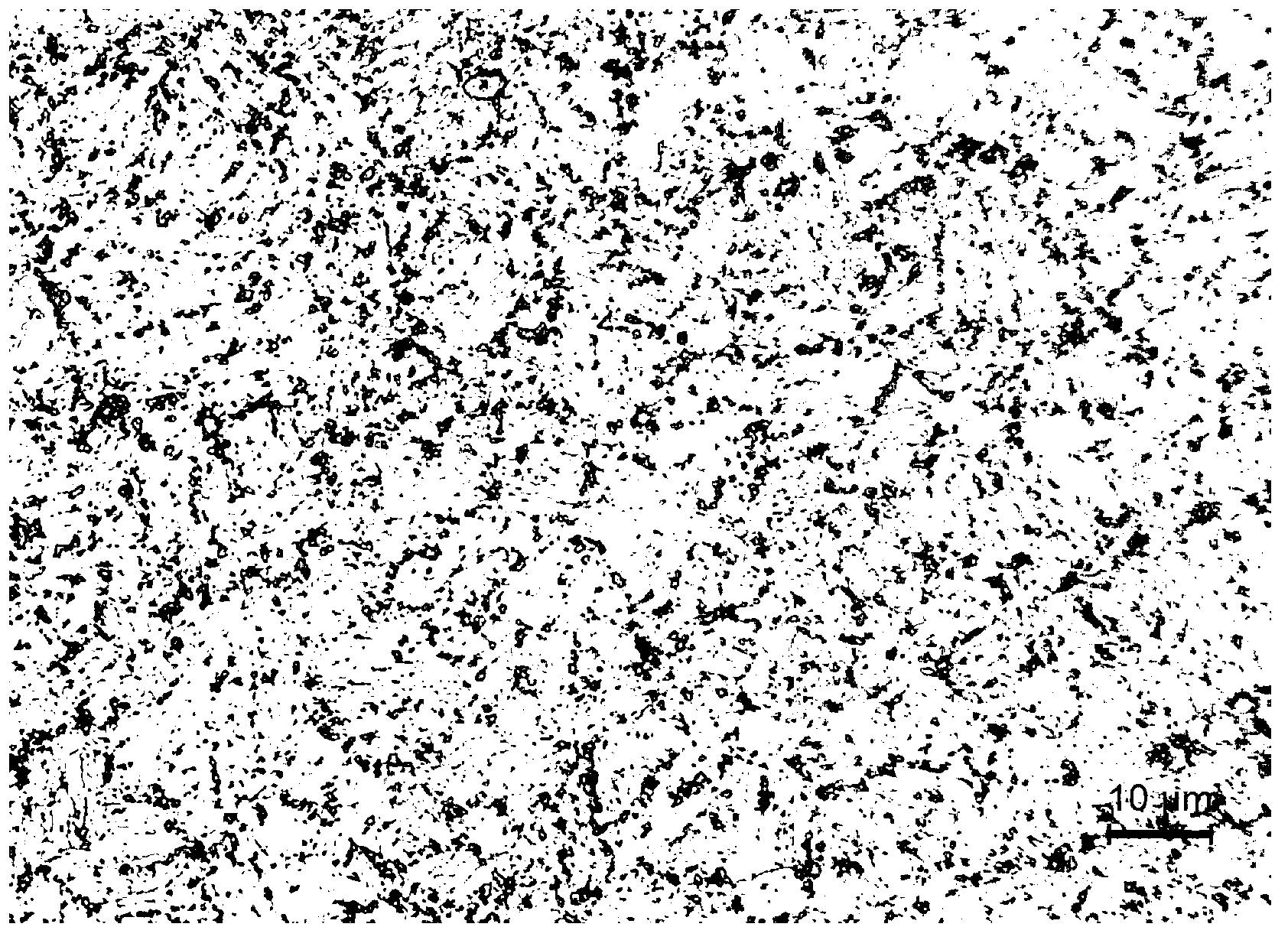

[0028] see Figure 1-5 , TMCP hot-rolled coil raw material composition (wt%): C: 0.26, Si: 0.25, Mn: 1.25, P: 0.011, S: 0.002, Cr: 0.55, Mo: 0.3, Ni: 0.22, B: 0.0012, Nb +V+Ti≤0.08.

[0029] First, prepare the HFW welded pipe: the TMCP hot-rolled coil with the above-mentioned chemical composition and high dimensional accuracy with a wall thickness deviation of -0.15 ~ +0.15 mm is subjected to longitudinal shearing of the steel strip, ultrasonic testing of the steel strip, edge milling, FFX forming and HFW Welding, adjusting the forming process (opening angle 5°, extrusion amount 3mm), controlling welding parameters (welding power 390KW, welding speed 18m / min) to weld a straight seam welded pipe with a specification of Φ193.7×10.05mm, and proceed immediately after welding The internal and external weld burrs are trimmed, the internal burr scraping groove and the external burr residual height are both ≤0.20mm, so that the weld bead and the inner and outer surfaces of the pipe a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| Circularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com