Patents

Literature

524results about How to "Consistent performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

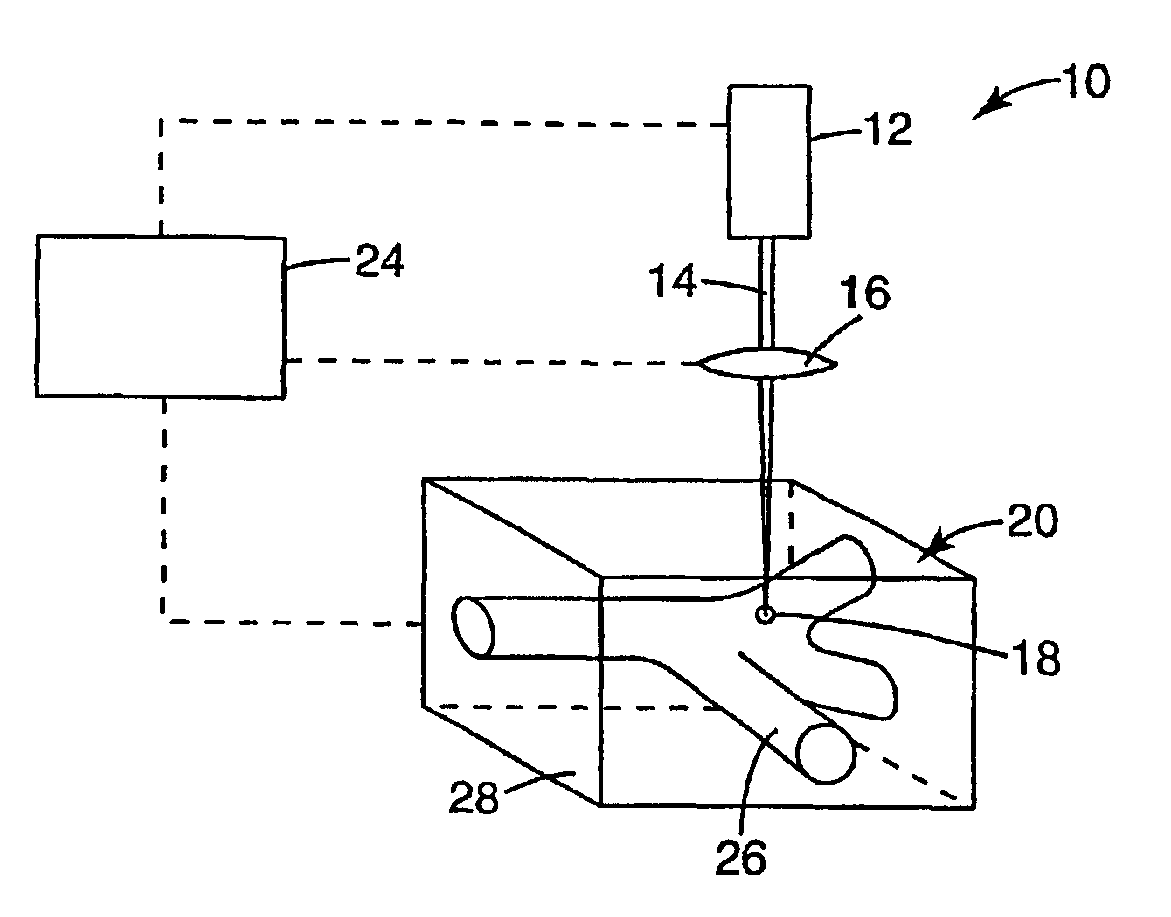

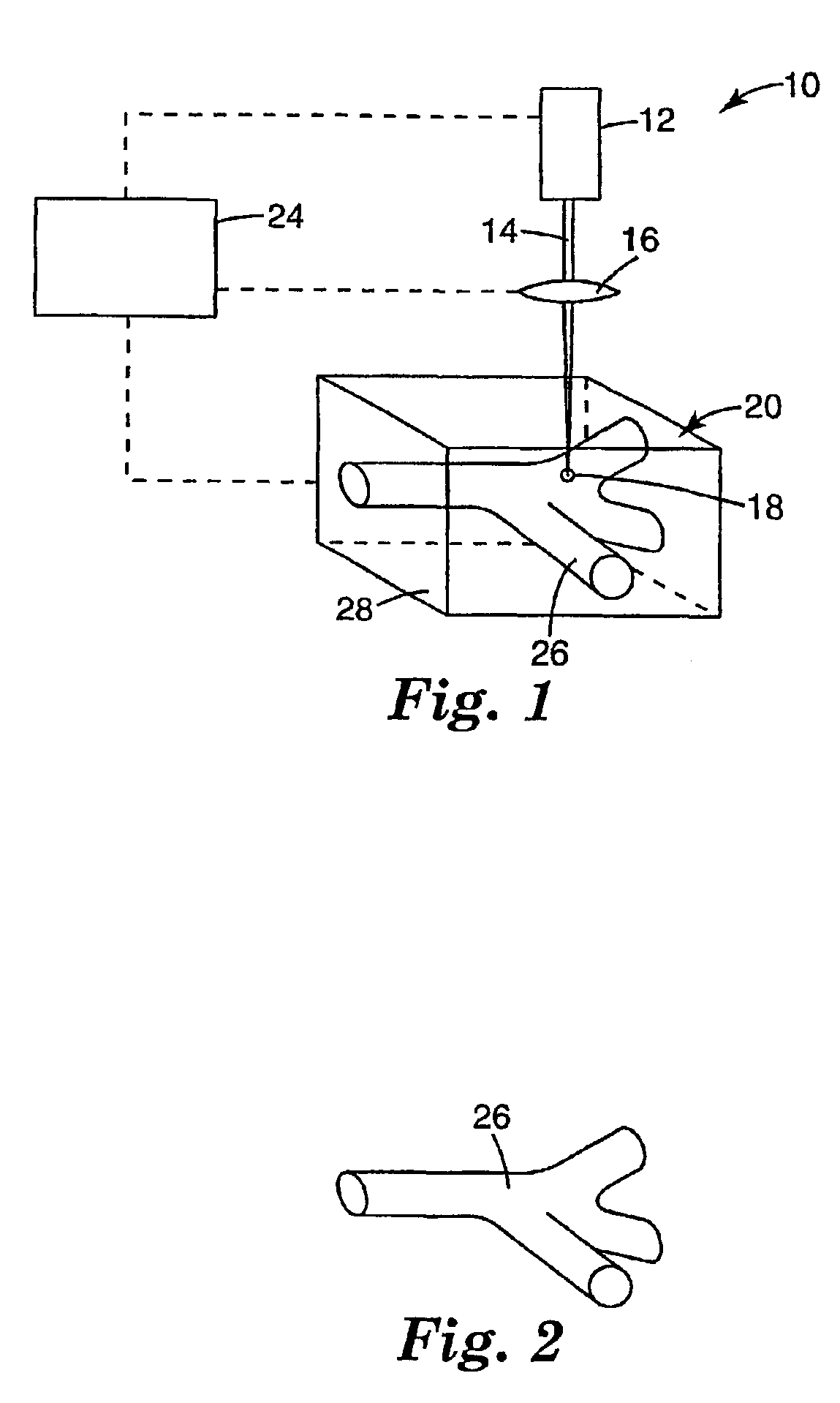

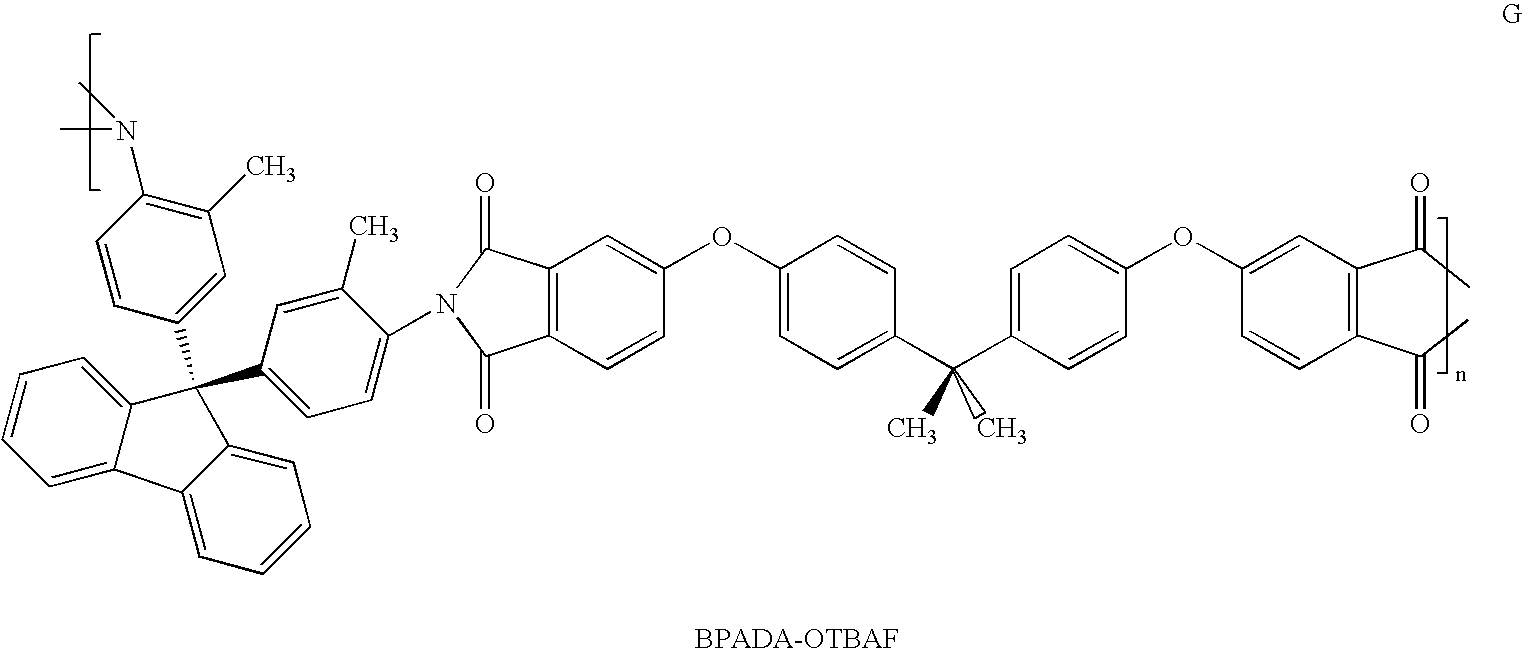

Microfabrication of organic optical elements

InactiveUS6855478B2Good optical stabilityConsistent optical performanceAdditive manufacturing apparatusPhotosensitive materialsMicrofabricationPhotoinitiator

Method of fabricating an optical element. A photodefinable composition is provided that includes (i) a hydrophobic, photodefinable polymer, said photodefinable polymer having a glass transition temperature in the cured state of at least about 80° C.; and (ii) a multiphoton photoinitiator system comprising at least one multiphoton photosensitizer and preferably at least one phtoinitiator that is capable of being photosensitized by the photosensitizer. One or more portions of the composition are imagewise exposed to the electromagnetic energy under conditions effective to photodefinably form at least a portion of a three-dimensional optical element.

Owner:3M INNOVATIVE PROPERTIES CO

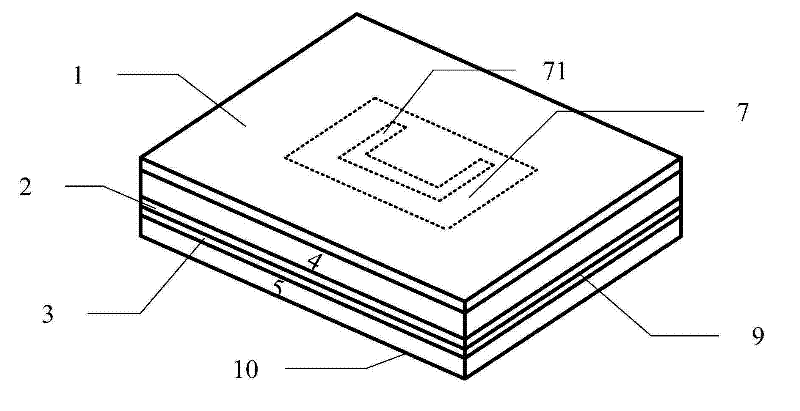

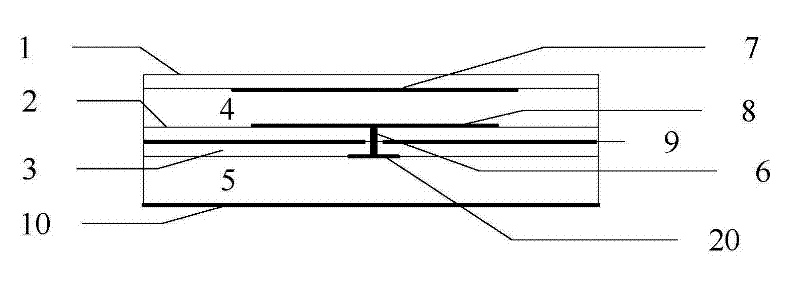

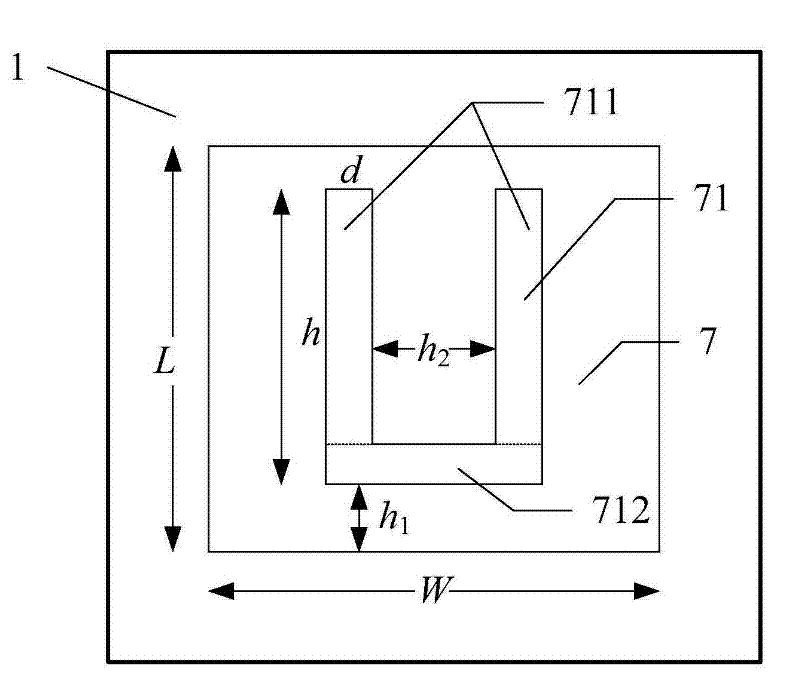

Multilayer Broadband Microstrip Antenna

InactiveCN102299418ADirectionalHigh bandwidthRadiating elements structural formsBroadband microstrip antennaAntenna gain

The invention discloses a multilayer broadband microstrip antenna, comprising an upper dielectric baseplate, a middle dielectric baseplate, a lower dielectric baseplate, an upper low dielectric constant insulating dielectric layer, a lower low dielectric constant insulating dielectric layer, a reflection plate and a feed probe, wherein rectangle radiators of metallic copper pasters are arranged on the lower surface of the upper dielectric baseplate and the upper surface of the middle dielectric baseplate and provided with U-shaped slot structures with different sizes respectively. Due to a special double-layer inverted U-shaped slot coupling feed way, the symmetry of directional diagrams on an E surface or H surface of the antenna is good, thus ensuring that the antenna has more consistent performances in more directions, and having more actual meanings as an exploration antenna and a communication antenna. The reflection plate with an EBG (electromagnetic band gap) structure can preferably restrain backward radiation in the specified frequency relative to a traditional metal reflection plate, thus improving the directivity of the antenna, thereby further improving the gain of theantenna.

Owner:JIMEI UNIV

Continuous production of silica-based microgels

A continuous process is provided for preparing silica microgels using carbon dioxide as a gel initiator at a pressure of at least about 172 kPa (about 25 psig). Consistent performance of microgel can be produced with varying production rates.

Owner:THE CHEMOURS CO FC LLC

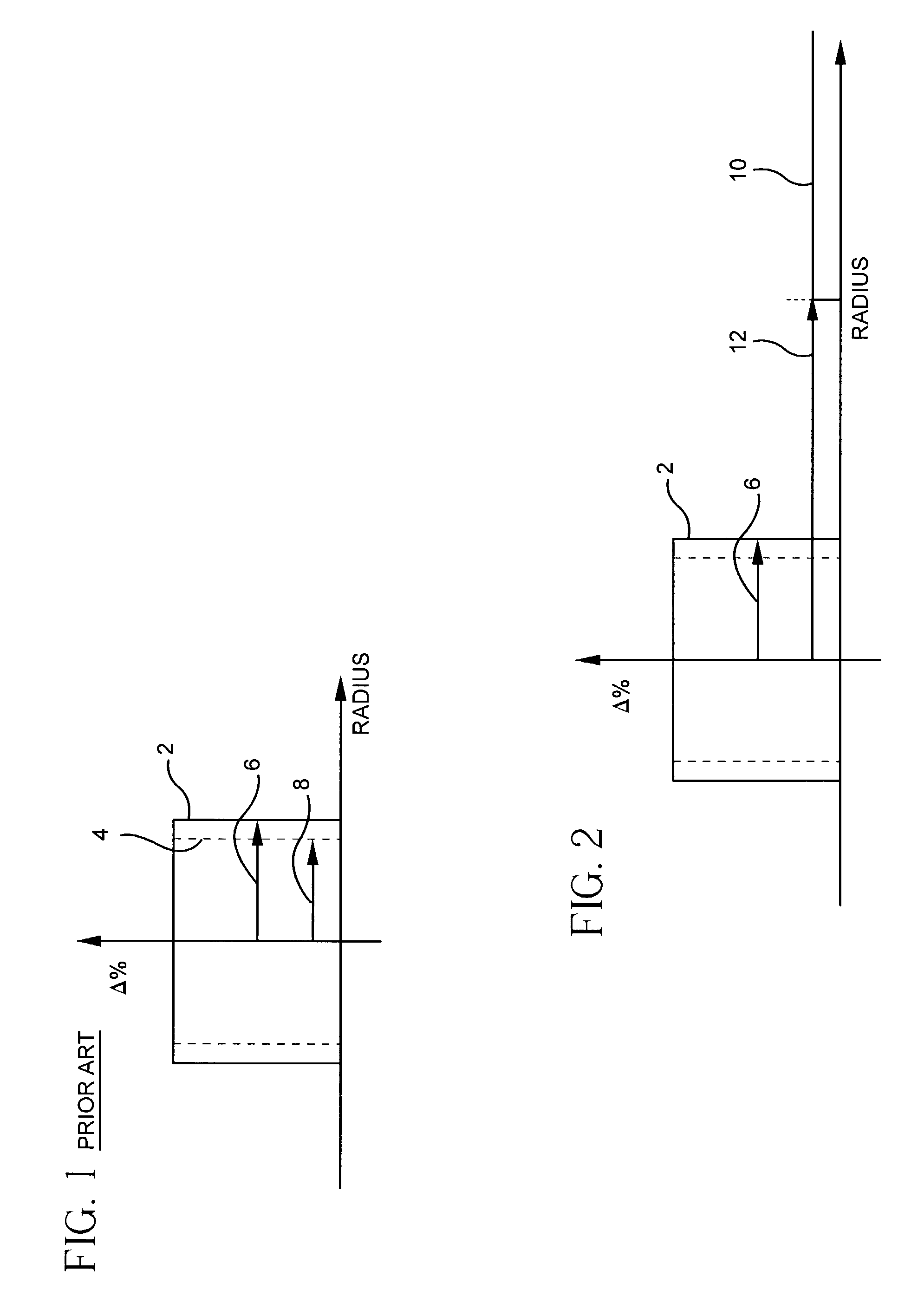

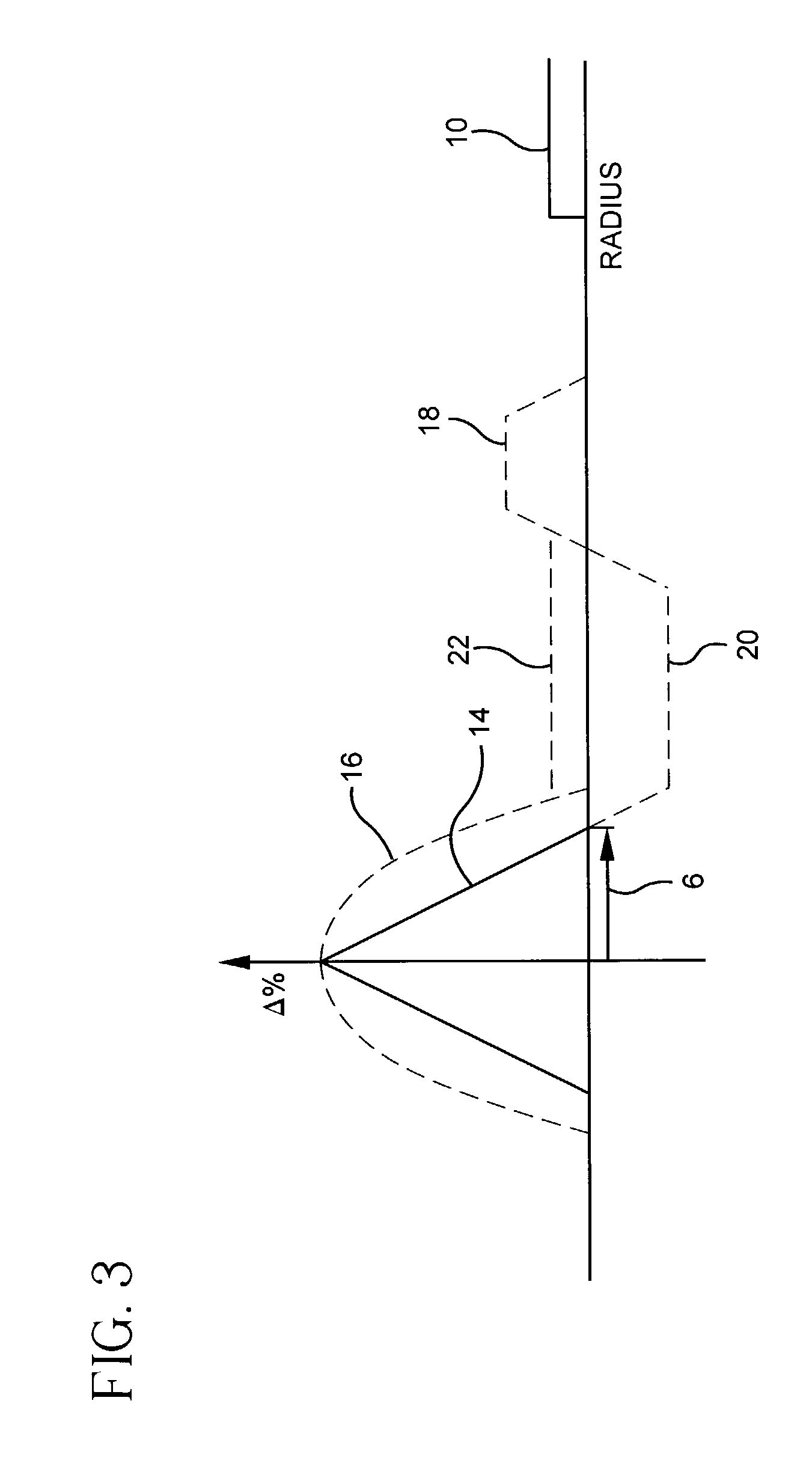

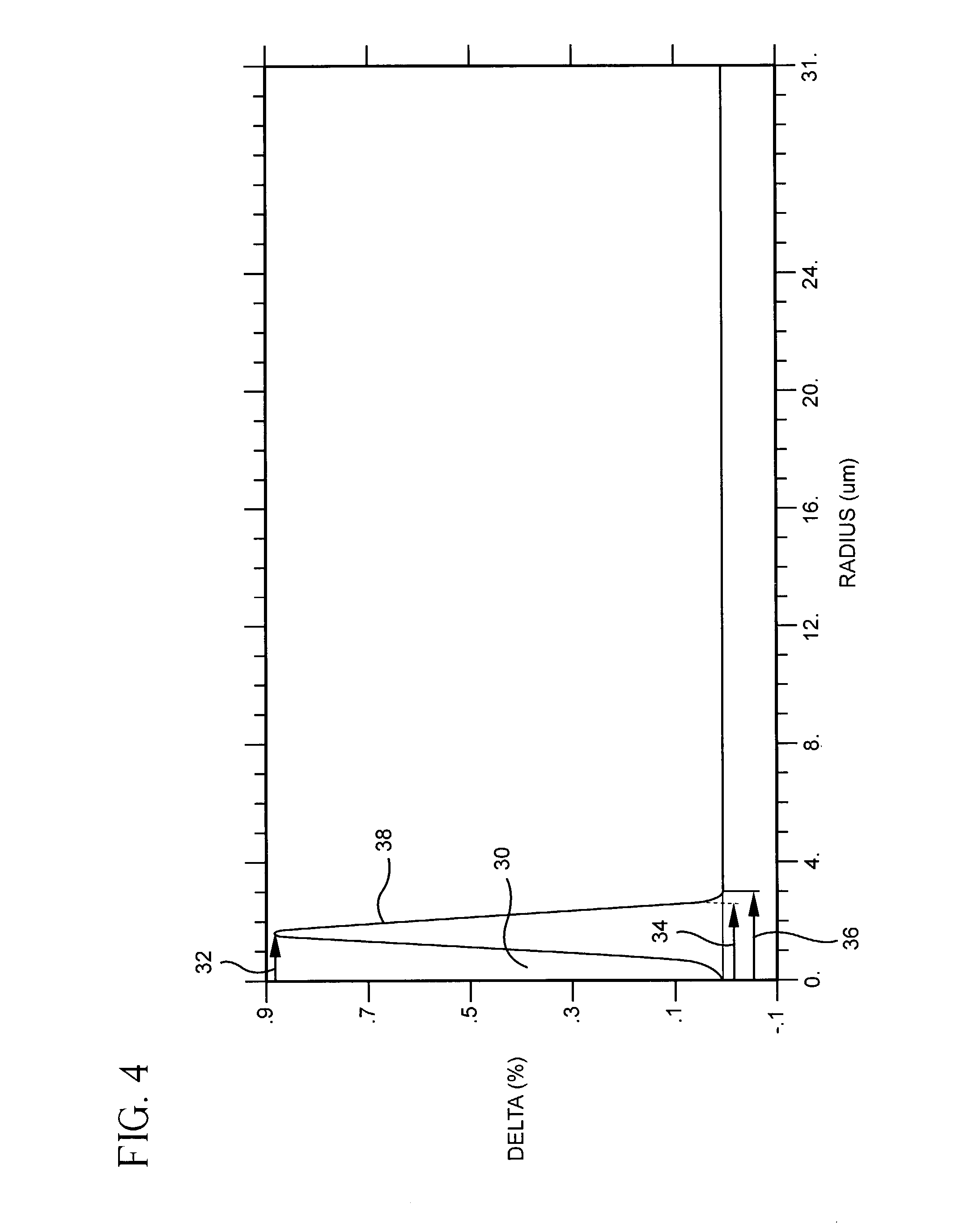

Optical waveguide fiber for local access

InactiveUS7043125B2Consistent performancePower Loss MinimizationLaser detailsOptical fibre with graded refractive index core/claddingDistributed feedback laserRefractive index

Disclosed is a single mode optical waveguide fiber having a low cut off wavelength, and mode field diameter and bend resistance similar to step index single mode optical waveguide fiber designed for use at 1310 nm. By including a clad region of raised refractive index spaced apart from the core region of the single mode optical waveguide fiber, the cut off wavelength can be reduced to 850 nm. The single mode optical waveguide fiber in accord with the invention may also have a core region having a reduced refractive index on centerline surrounded by a region of higher refractive index and a clad region which is substantially uniform. The single mode optical waveguide fiber is thus ideally suited for use with the low cost, reliable VCSEL operating at 850 nm, a Fabry-Perot laser operating at 1310 nm, or a distributed feedback laser operating at 1550 nm thereby enabling low cost, easily installed, home access portions of the broadband telecommunications system.

Owner:CORNING INC

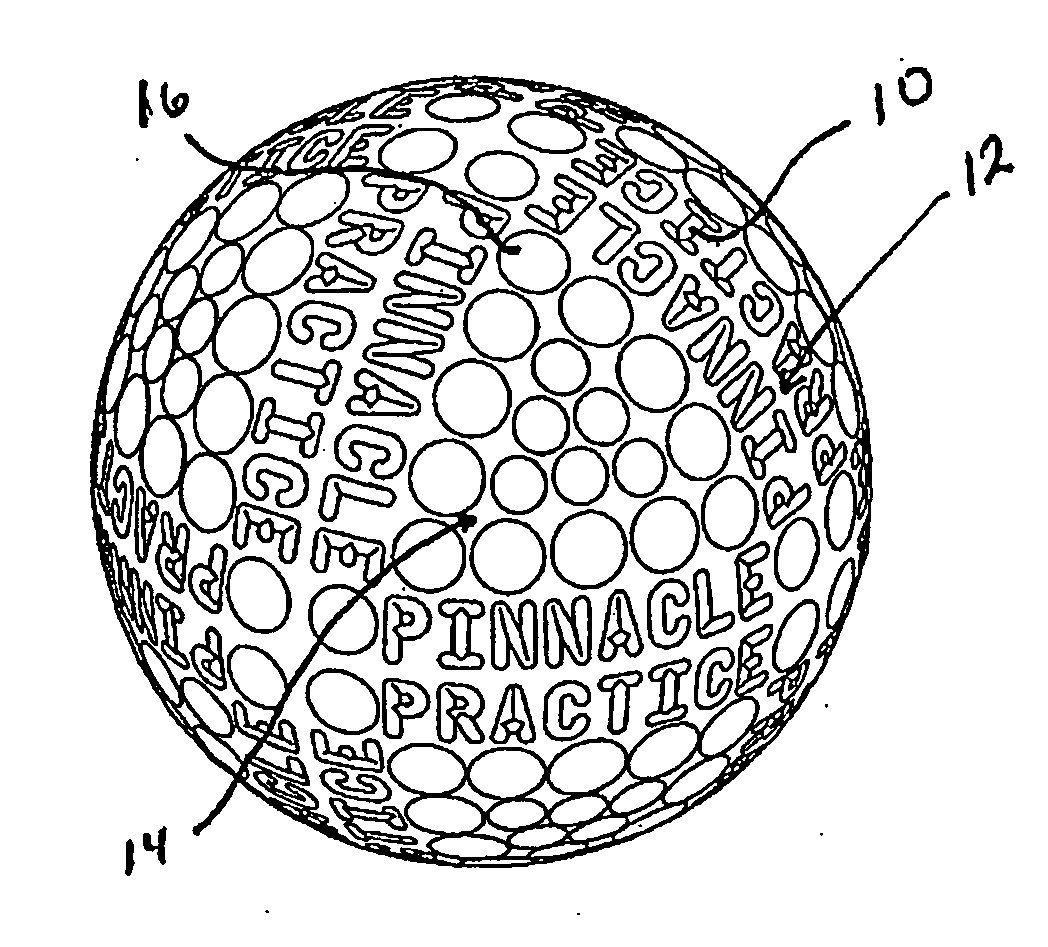

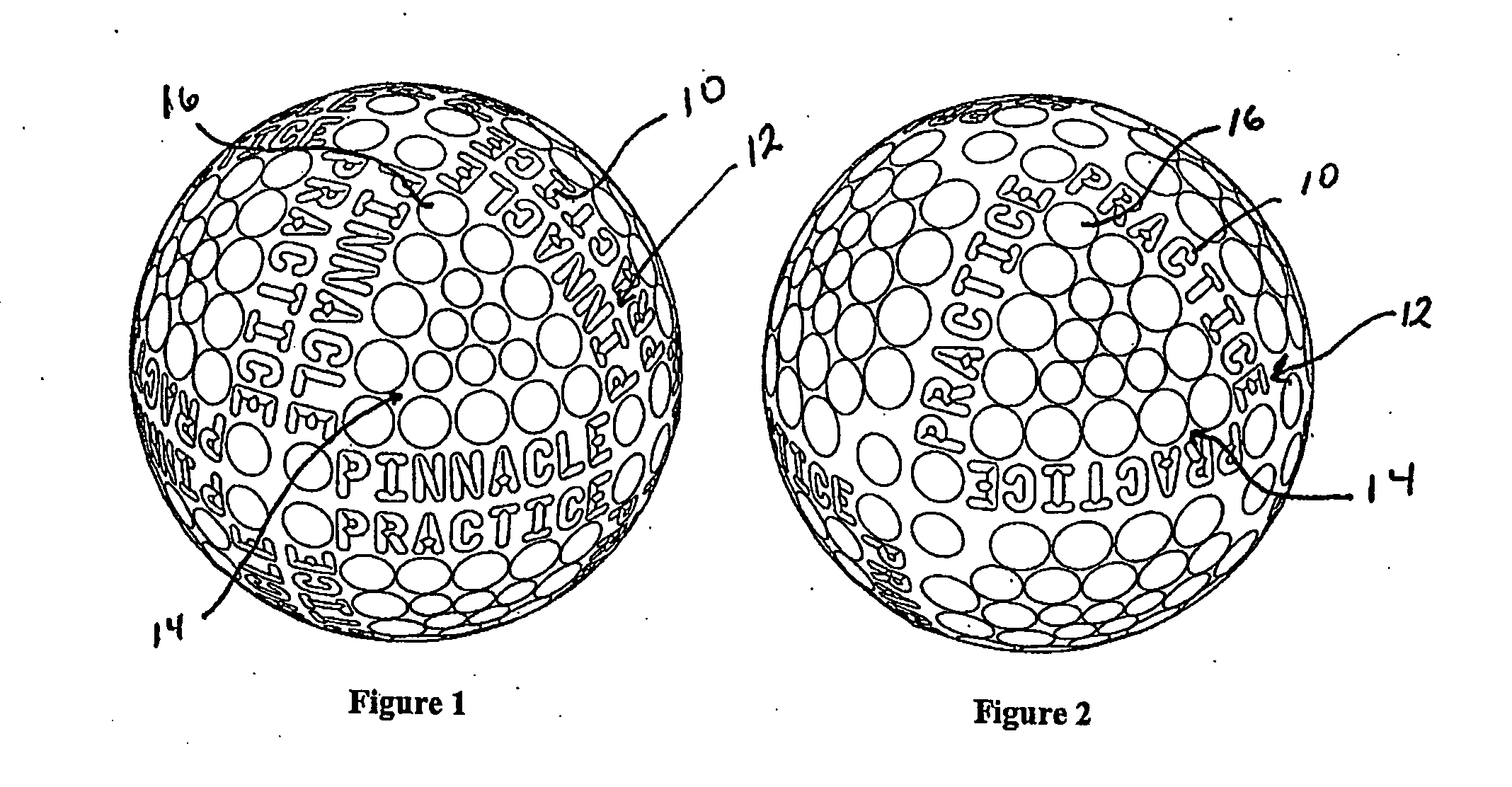

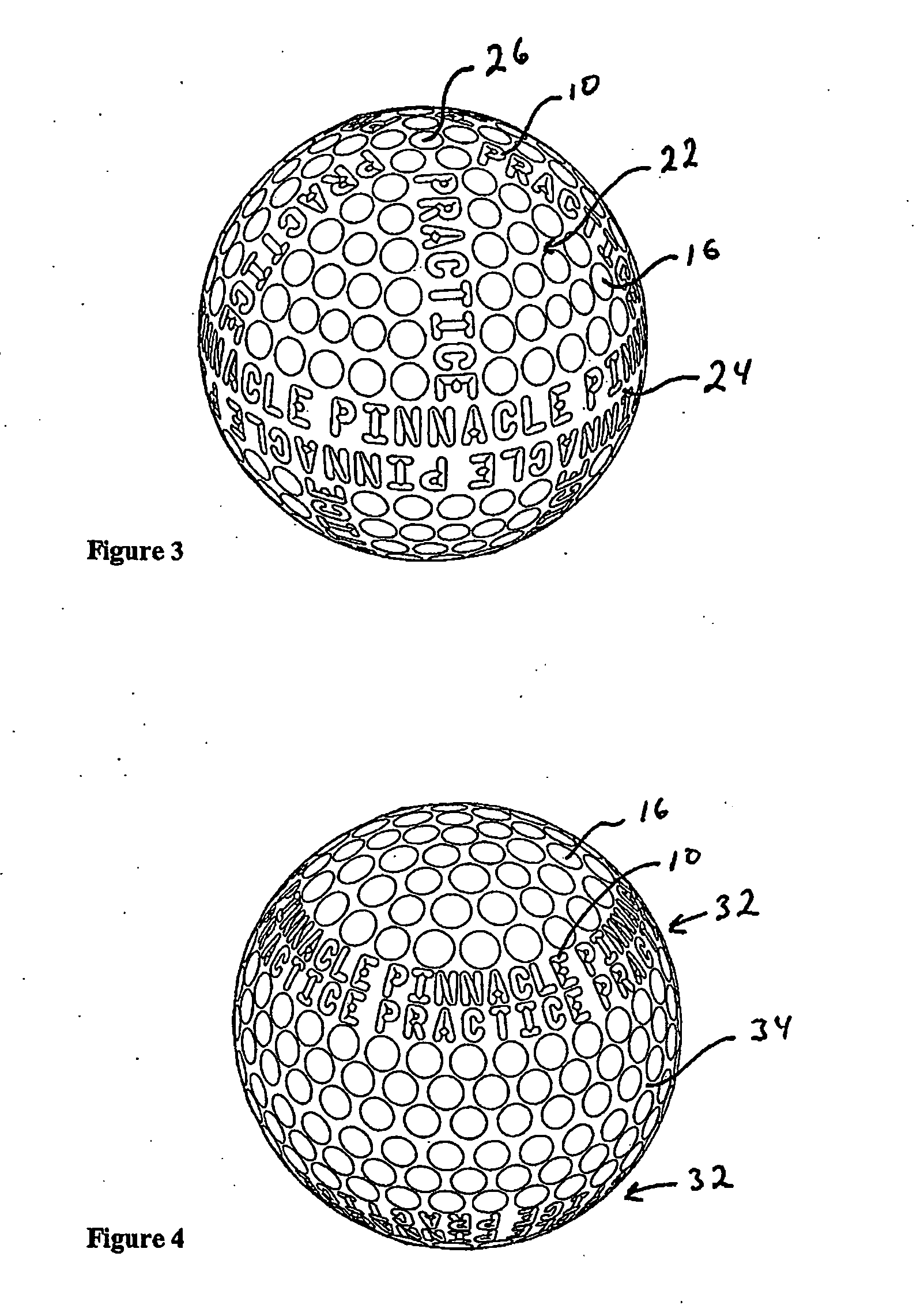

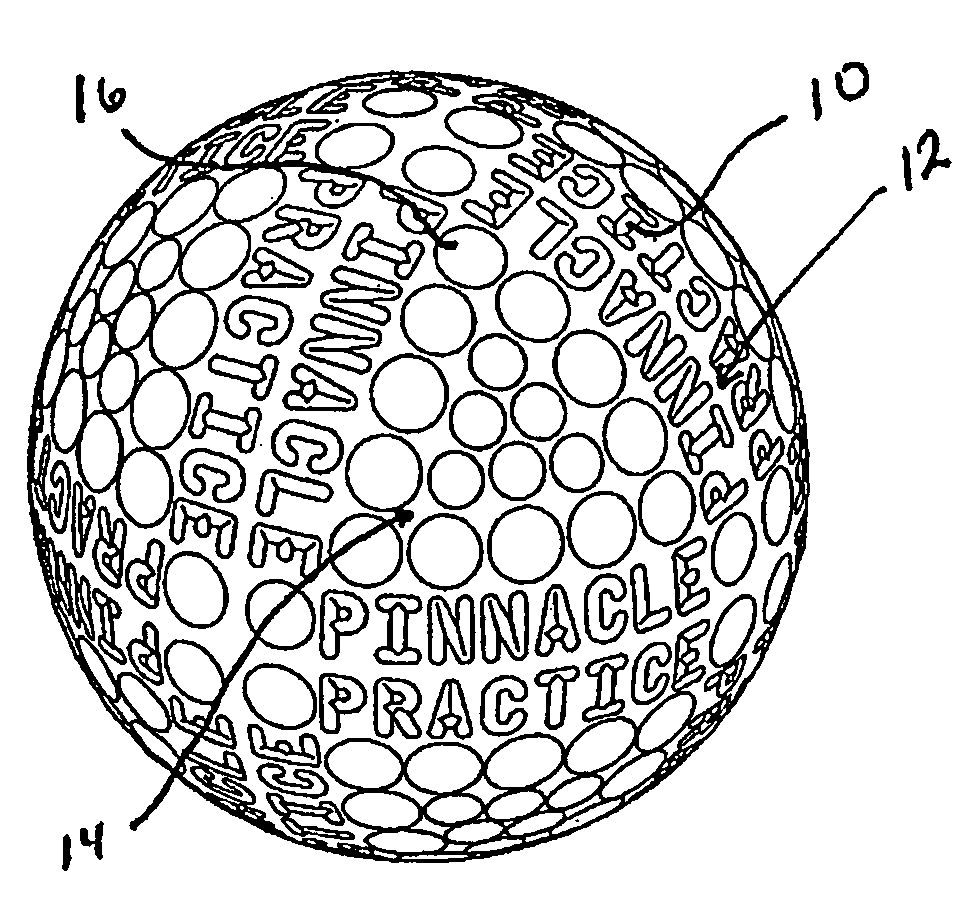

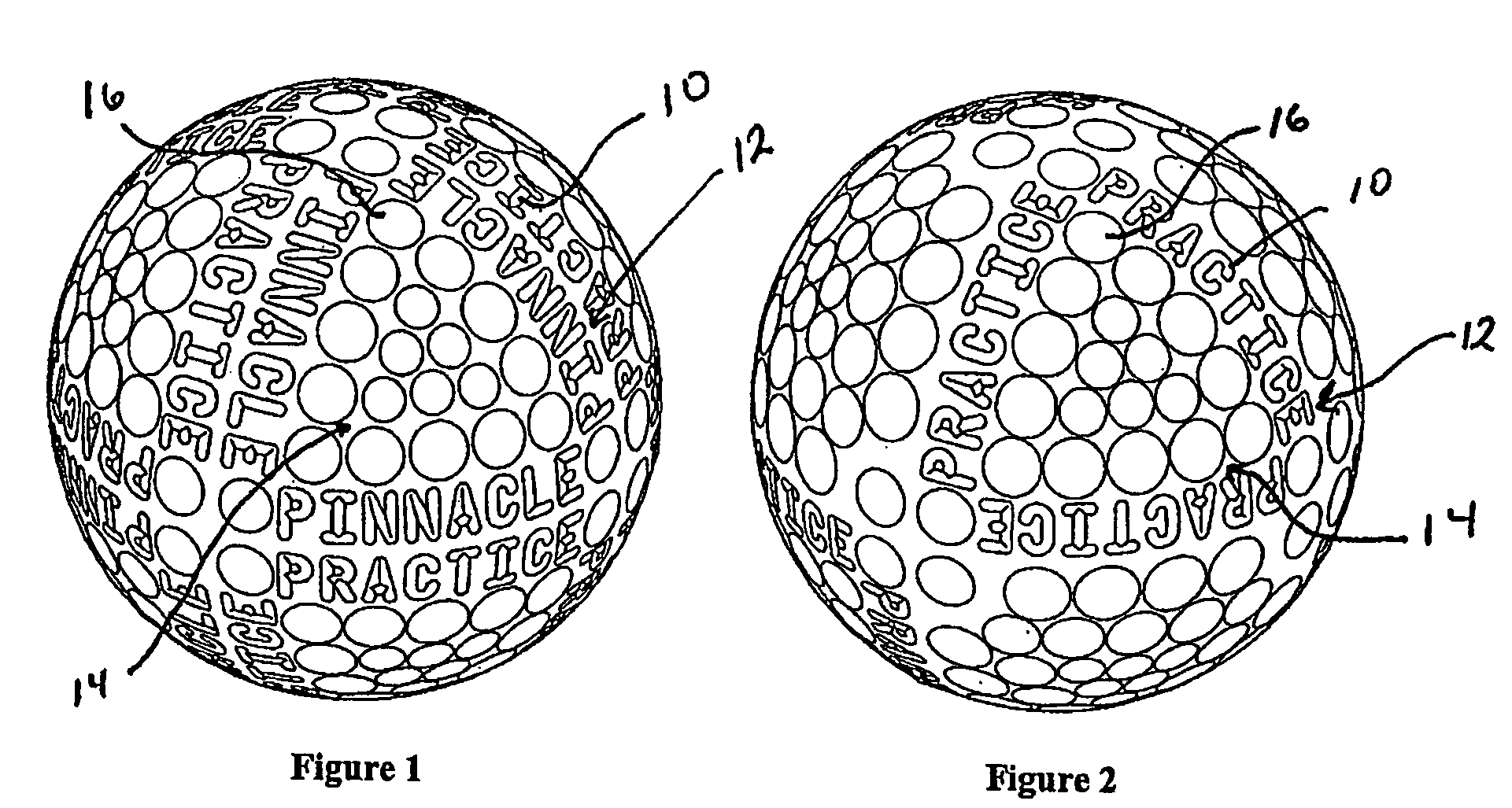

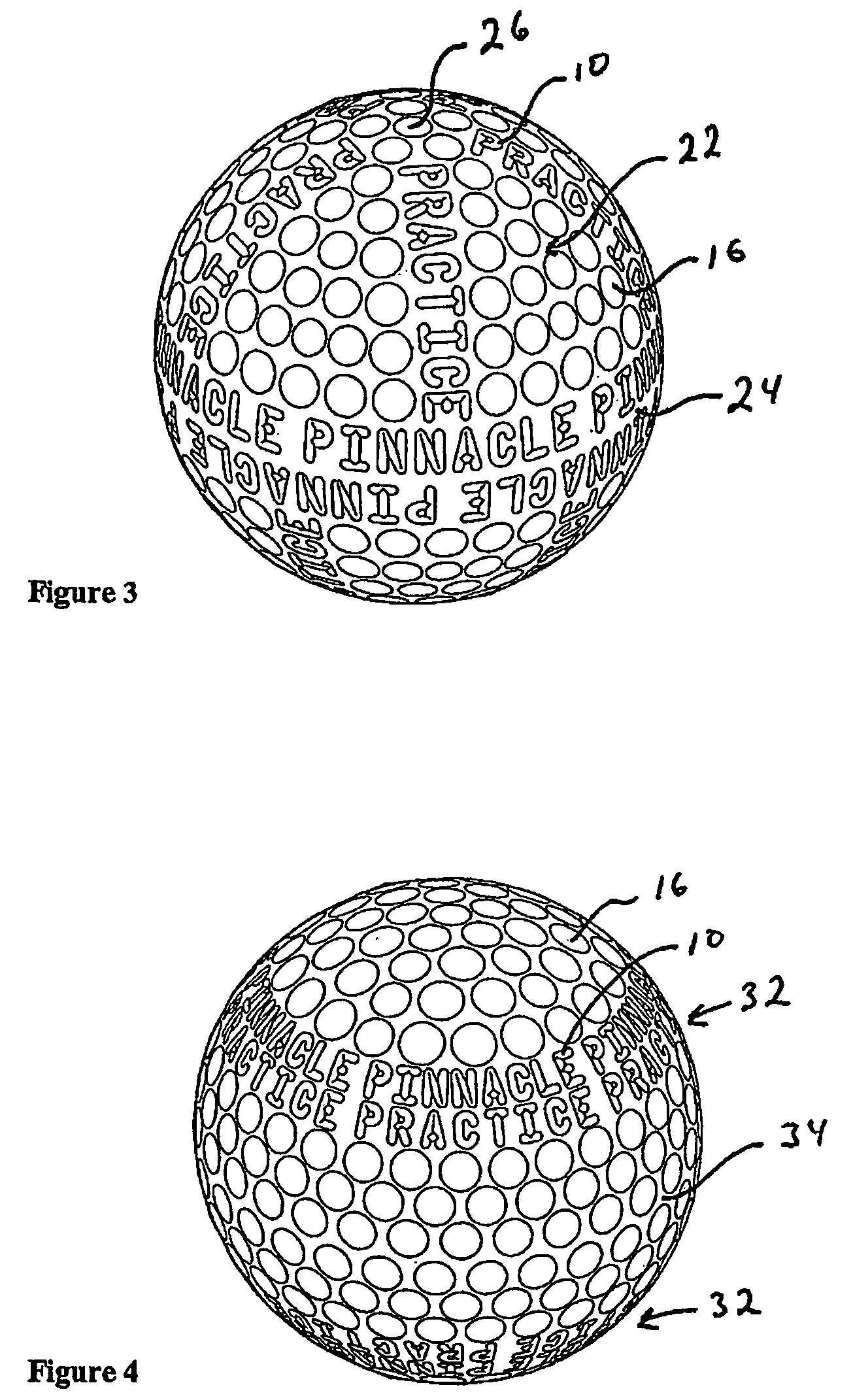

Golf ball dimples forming indicia

A golf ball comprising an outer surface including a plurality of dimples that form indicia. The plurality of dimples take the form of text letters, characters or other symbols and are relatively similar in size to a plurality of conventional shaped dimples or larger. The plurality of dimples occupy a substantial portion of the ball's surface in a repeating, distributed pattern

Owner:ACUSHNET CO

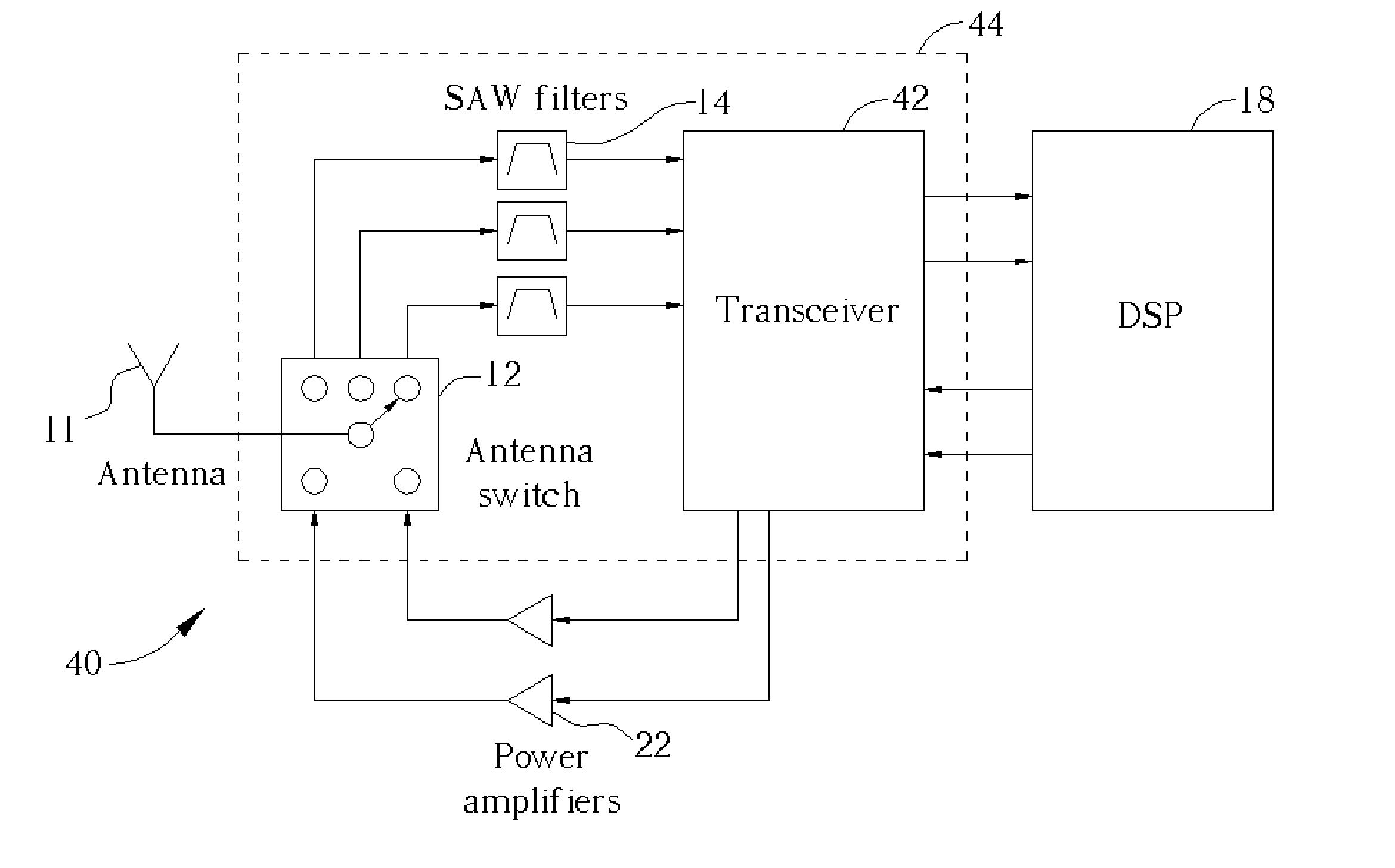

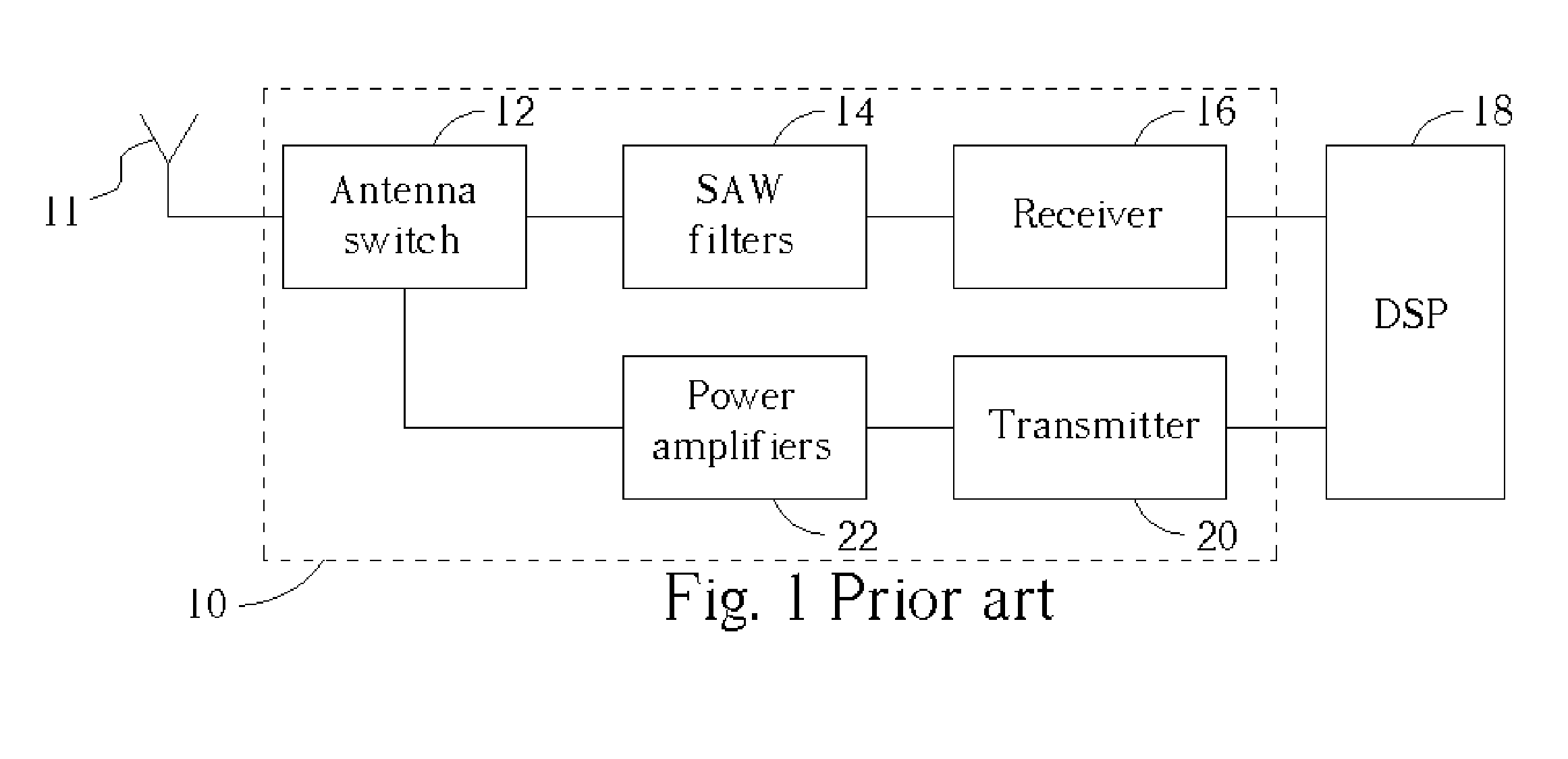

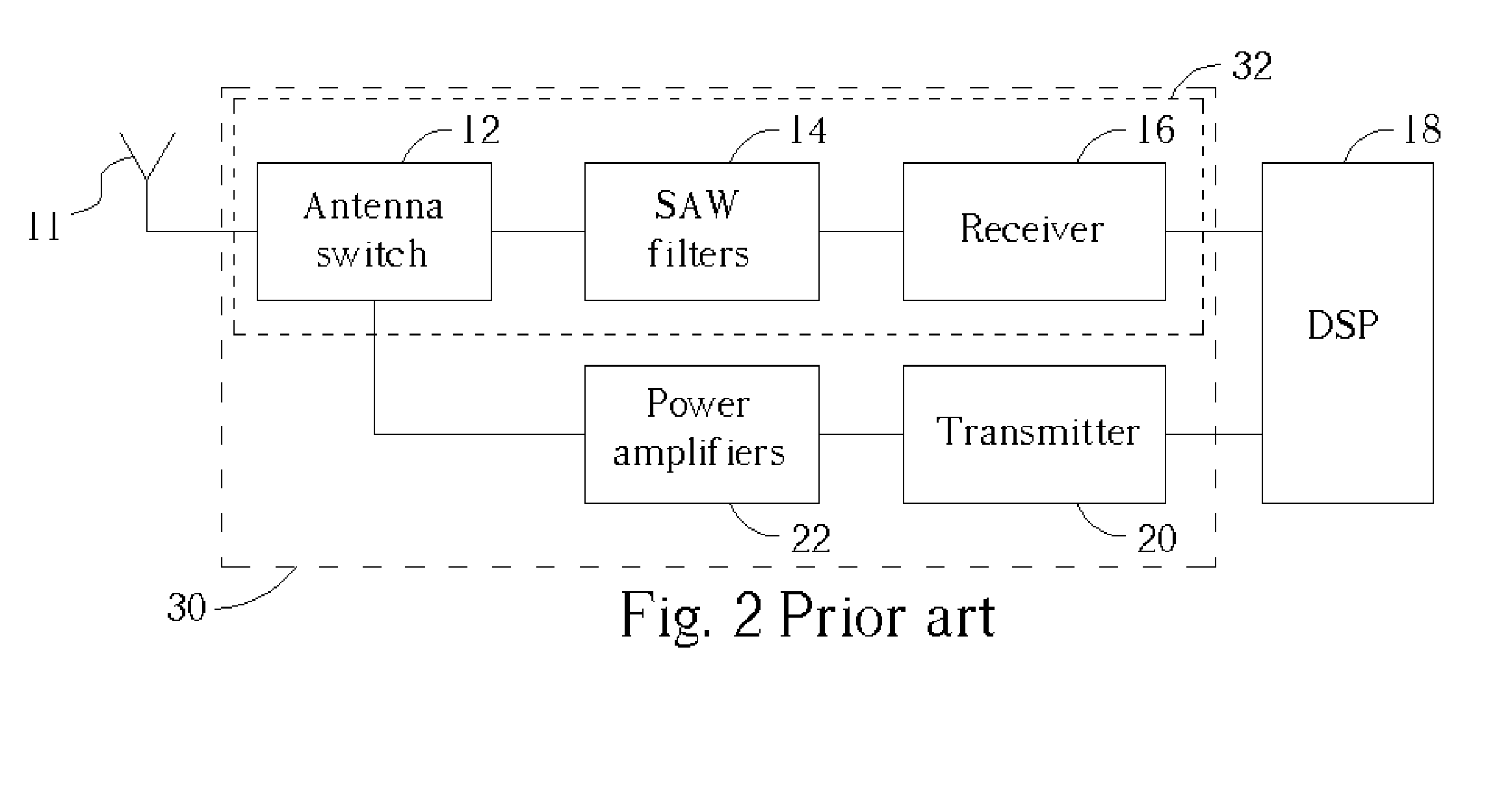

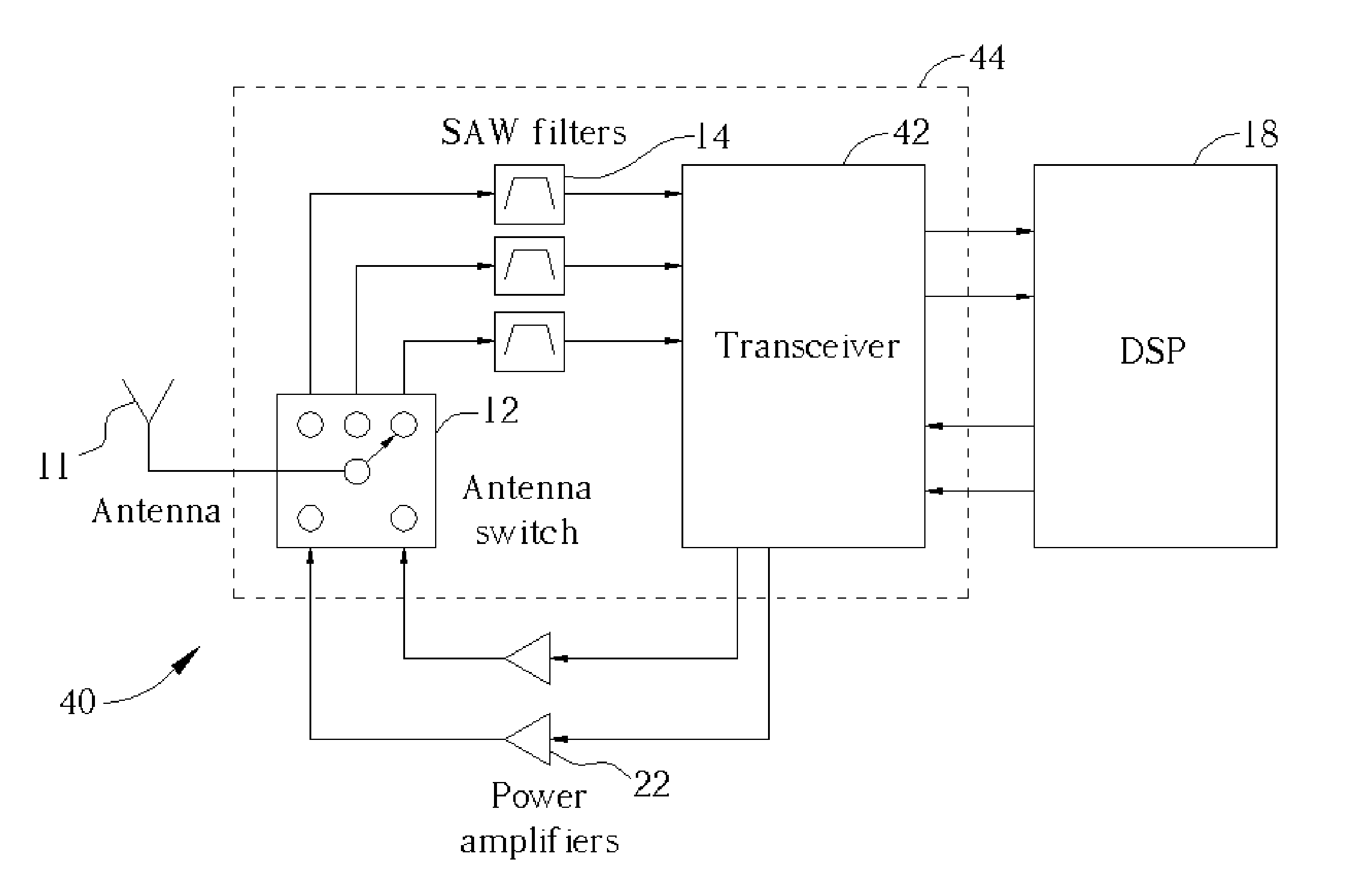

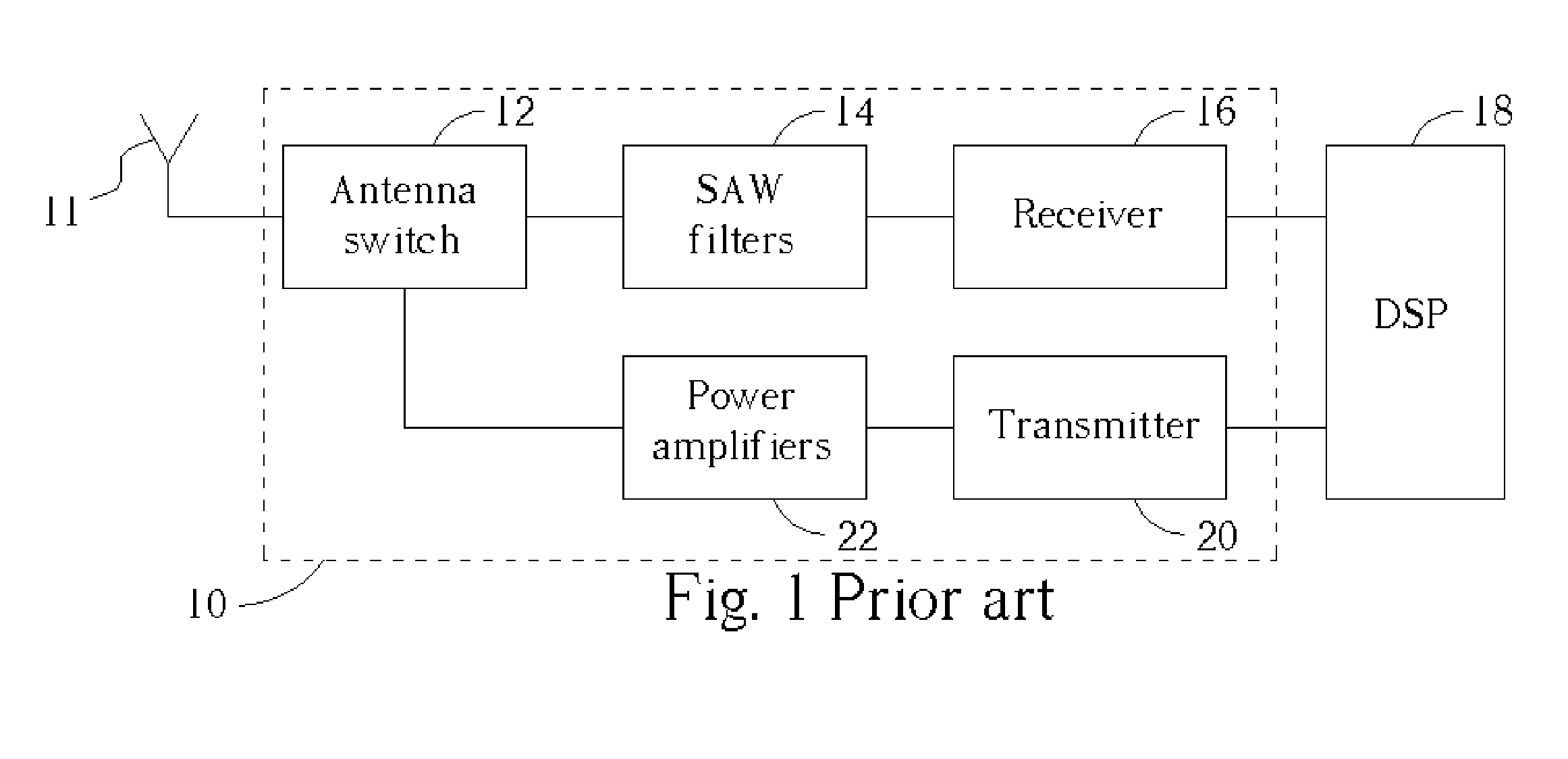

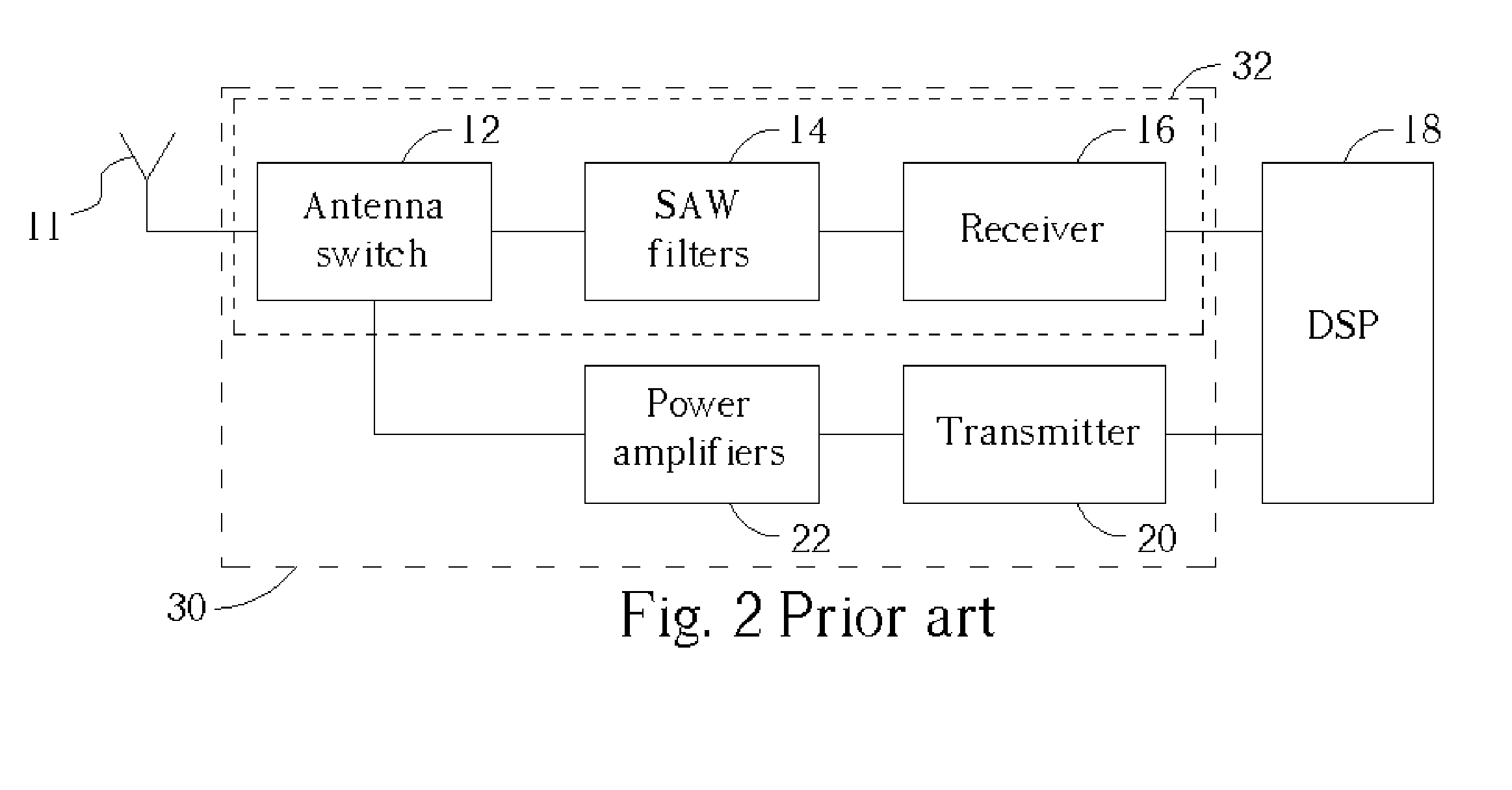

RF transceiver module formed in multi-layered ceramic

InactiveUS20050026647A1Reduce circuit areaReduce the number of partsResonant long antennasModulation with suppressed carrierTransceiverAudio power amplifier

An RF transceiver module for wireless communication devices includes a multi-layered substrate, an RF transceiver IC mounted on the multi-layered substrate for receiving and transmitting voice or data signals, at least one band selection filter mounted on the multi-layered substrate for filtering received RF signals, an antenna switch integrated in the multi-layered substrate which can be switched to transmit RF signals generated by the power amplifiers to the external antenna or to receive RF signals from an external antenna to the RF transceiver IC through the band selection filter, a plurality of passive devices embedded in the multi-layered substrate, and wiring embedded in the multi-layered substrate for electrically connecting the passive devices, the RF transceiver IC, and the band selection filter.

Owner:CHI MEI COMM SYST INC

RF transceiver module formed in multi-layered ceramic

InactiveUS7167688B2Reduce areaShorten the counting processResonant long antennasModulation with suppressed carrierAudio power amplifierTransceiver

An RF transceiver module for wireless communication devices includes a multi-layered substrate, an RF transceiver IC mounted on the multi-layered substrate for receiving and transmitting voice or data signals, at least one band selection filter mounted on the multi-layered substrate for filtering received RF signals, an antenna switch integrated in the multi-layered substrate which can be switched to transmit RF signals generated by the power amplifiers to the external antenna or to receive RF signals from an external antenna to the RF transceiver IC through the band selection filter, a plurality of passive devices embedded in the multi-layered substrate, and wiring embedded in the multi-layered substrate for electrically connecting the passive devices, the RF transceiver IC, and the band selection filter.

Owner:CHI MEI COMM SYST INC

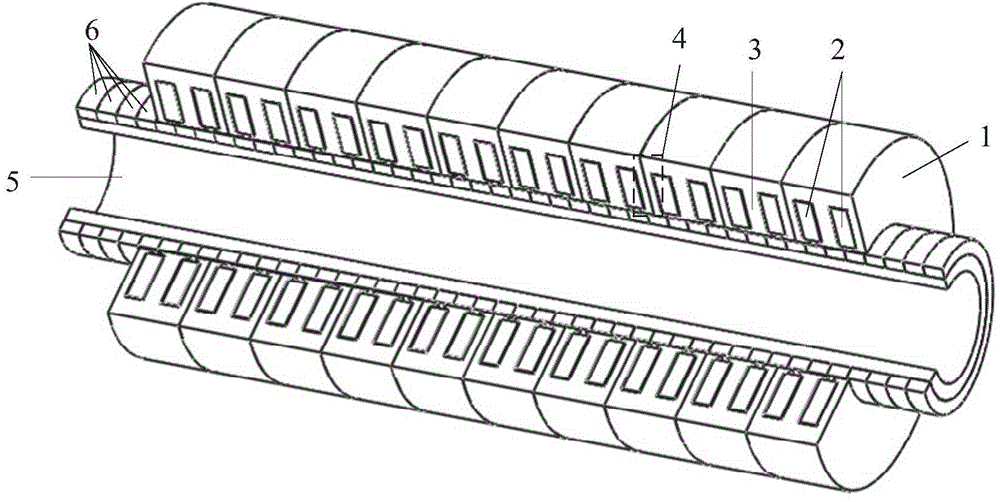

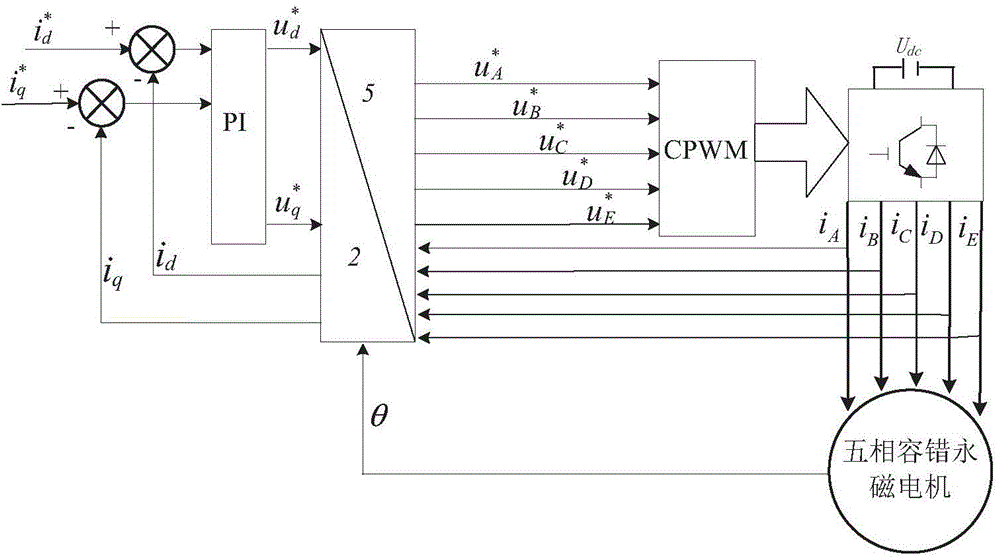

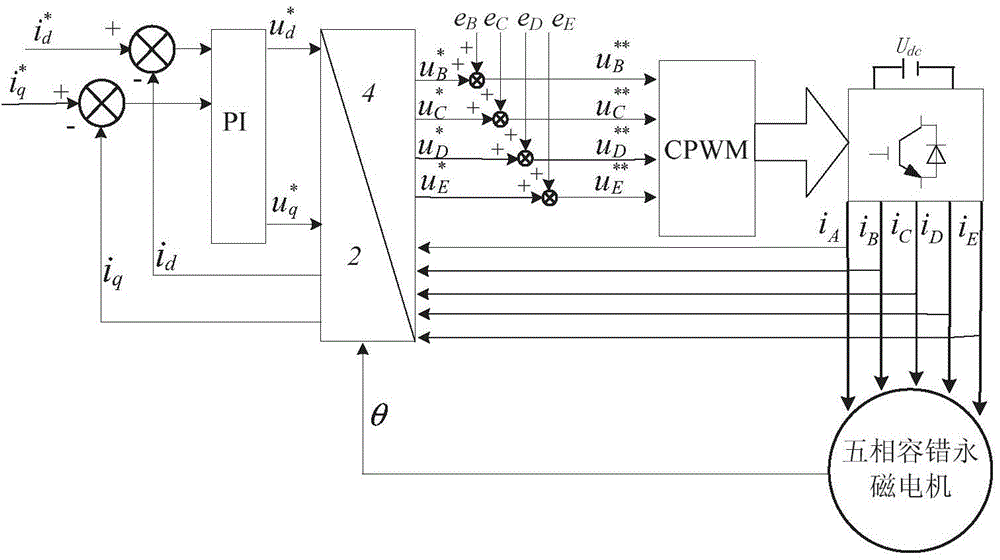

Fault-tolerant control method for five-phase fault-tolerant permanent magnet linear motor

InactiveCN104682820AVersatilityConsistent dynamic performanceElectronic commutation motor controlAC motor controlPhysicsTransformation matrix

The invention discloses a fault-tolerant control method for a five-phase fault-tolerant permanent magnet linear motor. Fault-tolerant current is calculated according to the rule that the magnetomotive force amplitude values and phase angles of rotation before and after the motor is faulted are constant and the current amplitude values of the normal phases are equal; two pieces of orthogonal basis of a fundamental wave space are obtained, and a park transformation matrix is deduced and popularized, so that coordinate transformation of voltage and current is realized; instruction voltage and inverted potentials of all the phases are summarized to obtain expected phase voltages of all the phases under a natural coordinate system of the motor; the expected phase voltages are modulated by a voltage source inverter CPWM to realize interference-free fault-tolerant operation after the five-phase fault-tolerant permanent magnet linear motor is faulted. On the premise of ensuring that the output thrusts or torques of the motor are consistent before and after a certain phase of the motor is in open-circuit fault, the motor thrust or torque pulse can be effectively suppressed; further, more importantly, the dynamic performance of the faulted motor is consistent with that of the normal motor, so that high-dynamic-performance fault-tolerant operation of the motor is realized, and the algorithm has certain universality.

Owner:JIANGSU UNIV

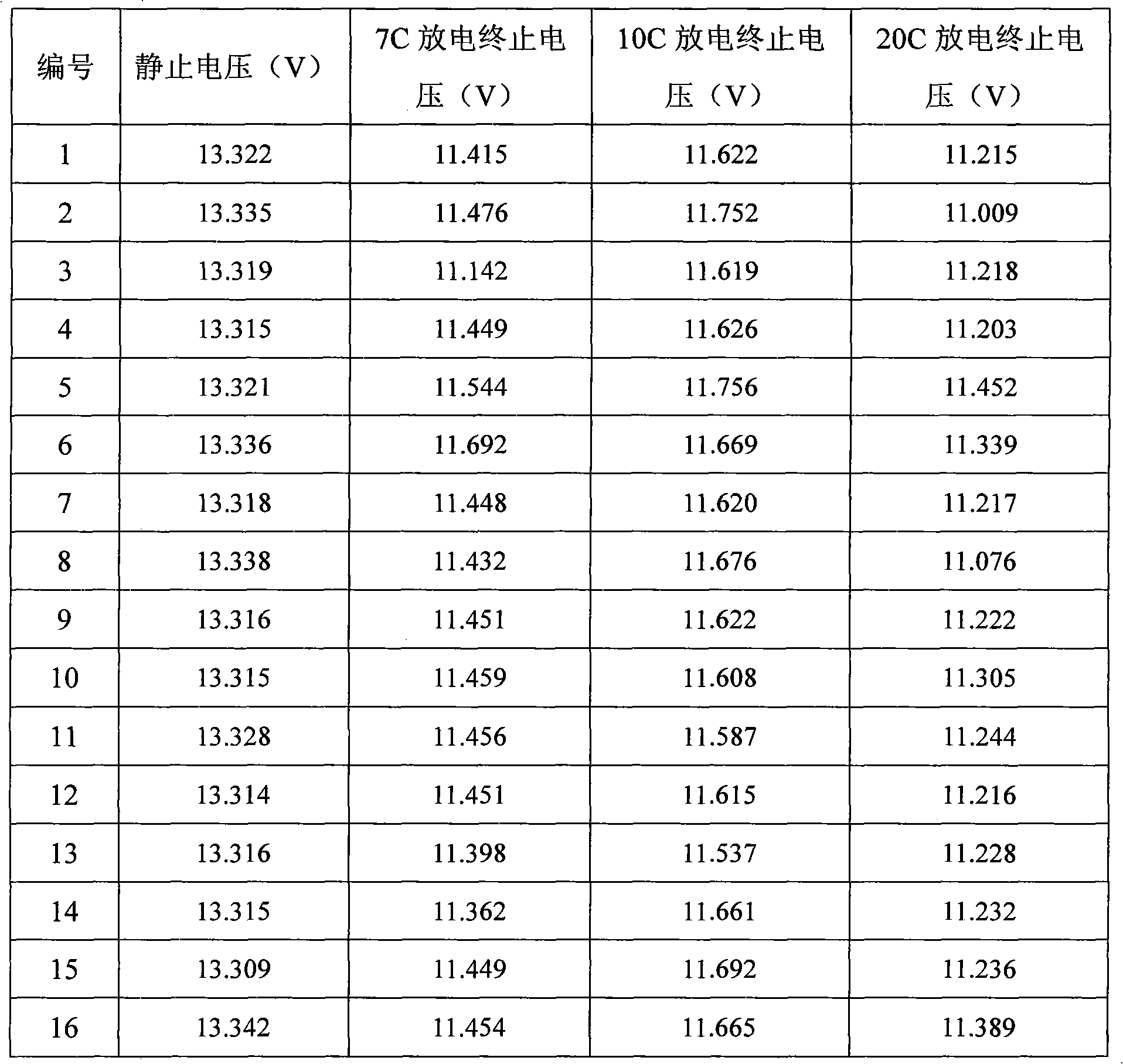

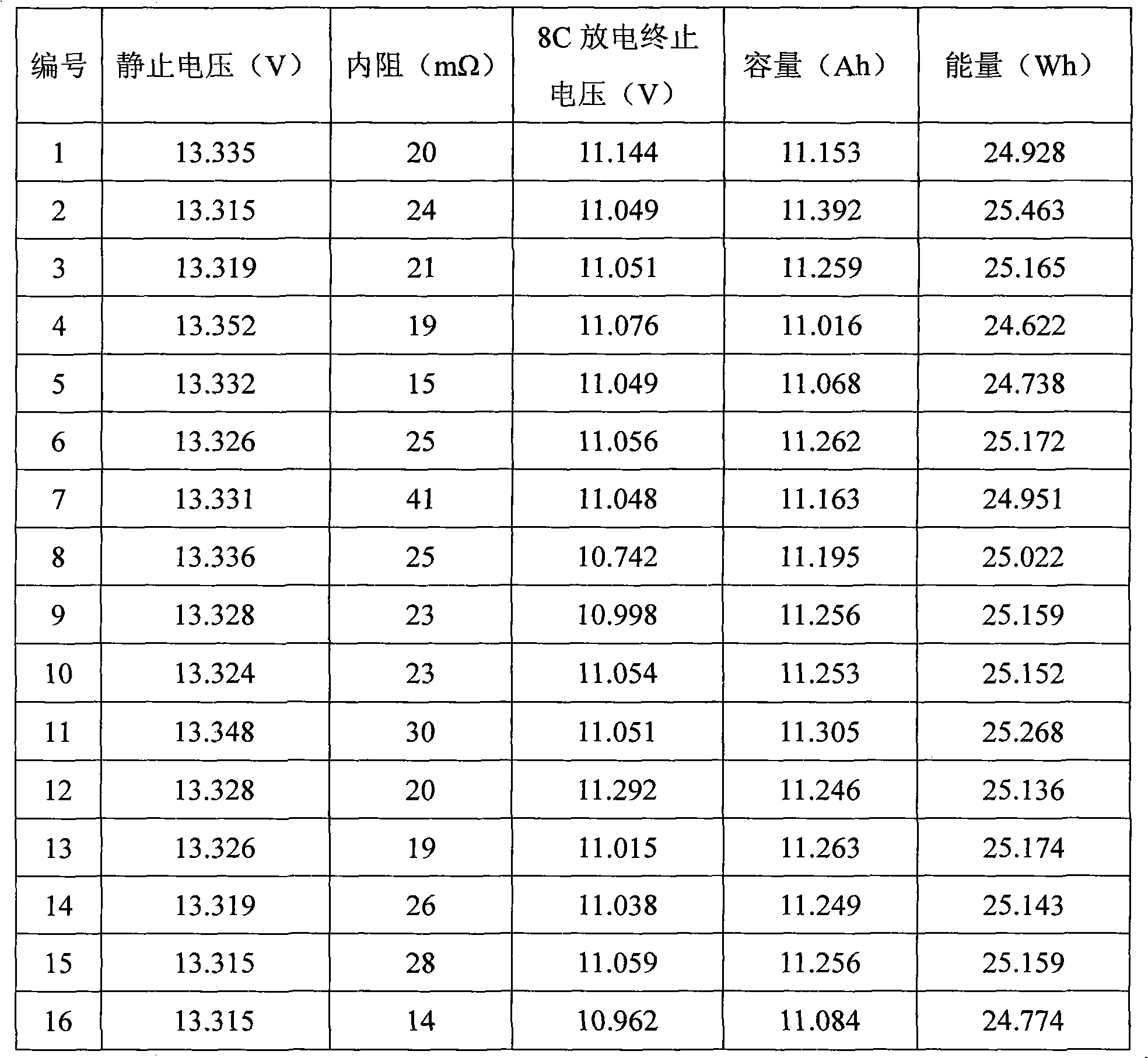

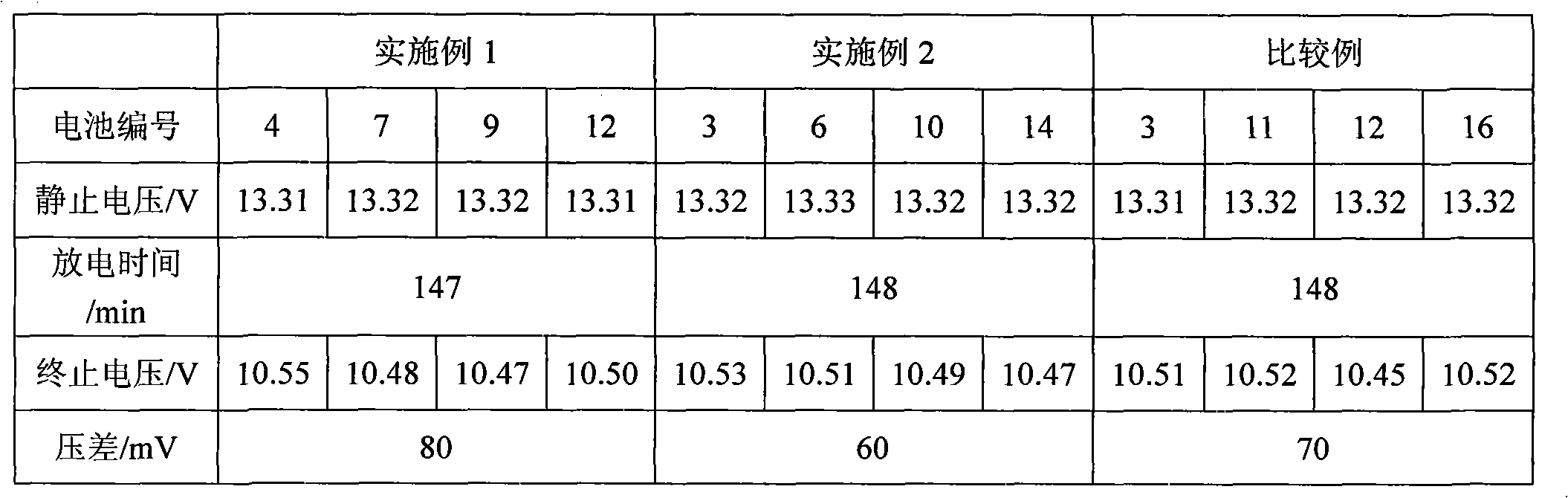

Lead-acid cell grouping method

InactiveCN101924257APerformance is not affectedConsistent performanceLead-acid accumulatorsElectrical testingInternal resistanceTerminal voltage

The invention discloses a lead-acid cell grouping method, comprising the following steps: detecting and recording static the voltage of a cell; detecting and recording the internal resistance of the cell; carrying out transient pulse discharging for one or more times on the lead-acid cell at different currents and discharging times; recording one or more data of discharging terminal voltage, discharging volume and discharging energy each time; after discharging detection, grouping the cell according to the difference range of one or more parameters of static voltage, internal resistance, discharging terminal voltage, discharging volume and discharging energy. The grouped cell group has high uniformity and long service life; the method is simple; and the required test device is easily realized and has strong operability.

Owner:JIANGSU SHUANGDENG GROUP

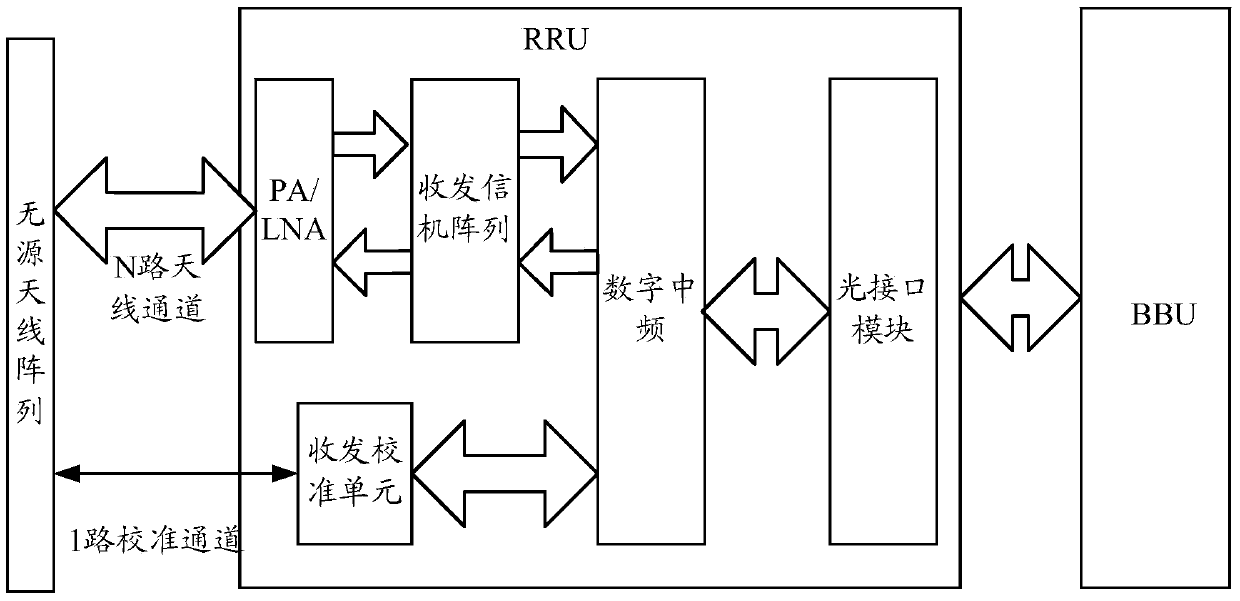

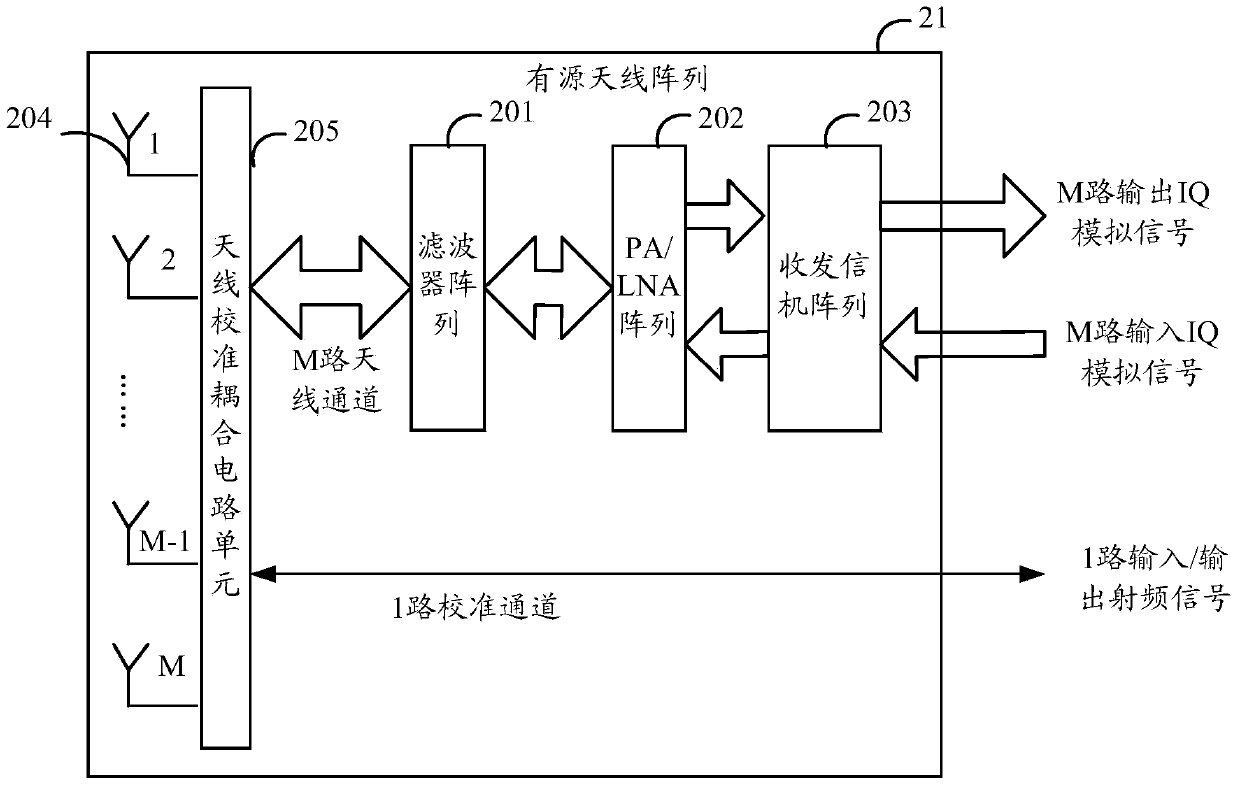

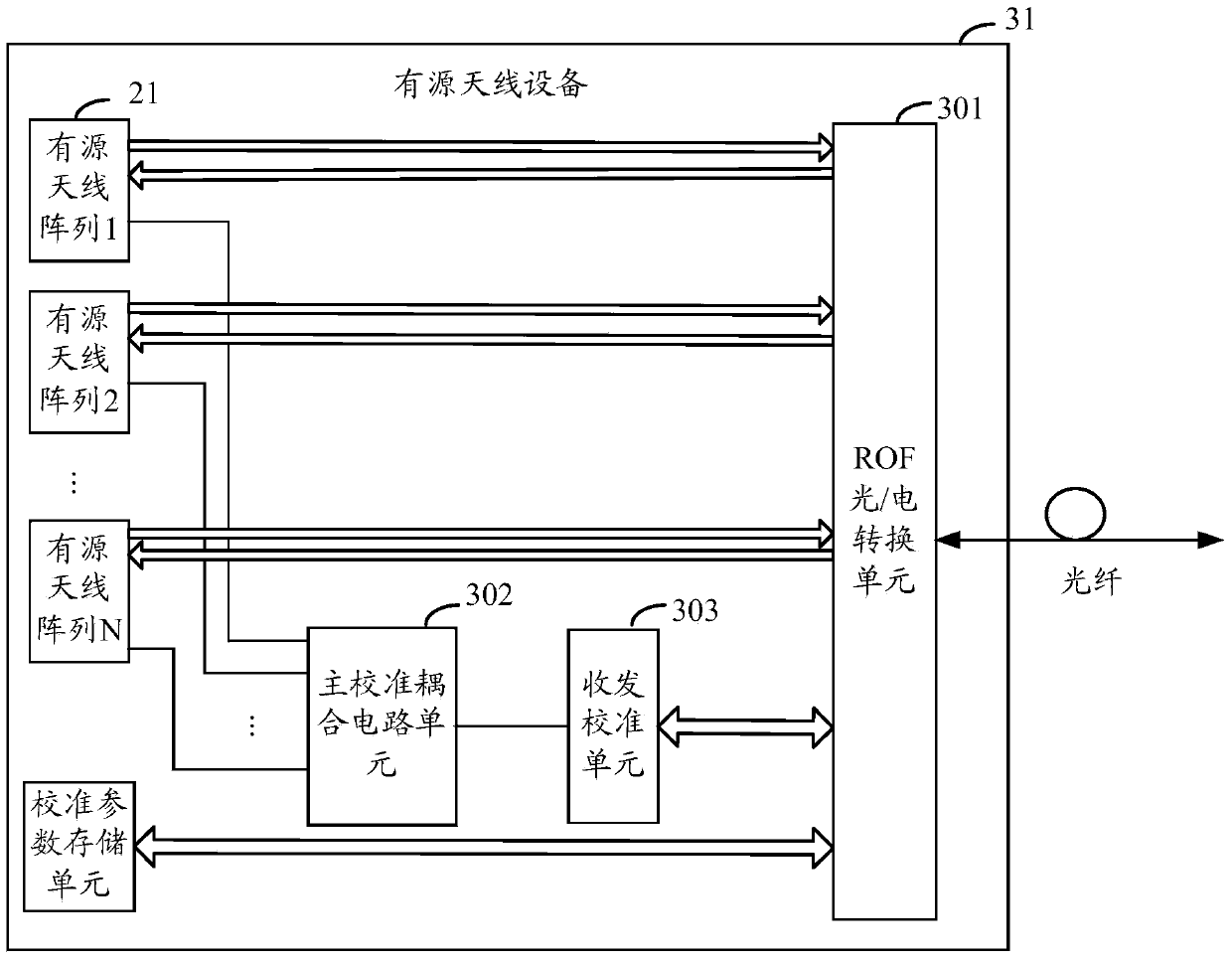

Active antenna associated equipment, system and transmitting and receiving calibration method

ActiveCN103997352AConsistent performanceReduce the difficulty of implementationTransmitters monitoringSimultaneous aerial operationsRadio over fiberScalable design

The invention discloses active antenna associated equipment, a system and a transmitting and receiving calibration method. Extensible design of an antenna array is achieved, construction implementation difficulty is reduced, and meanwhile construction implementation reliability is provided. The active antenna equipment comprises N active antenna arrays, a main calibration coupling circuit unit, a transmitting and receiving calibration unit, a calibration parameter storage unit and a radio over fiber (ROF) photoelectricity conversion unit, wherein the N is larger than 1. Each active antenna array at least comprises an antenna coupling circuit unit and M antenna oscillators connected to the antenna coupling circuit unit, wherein the M is larger than 1. Antenna calibration coupling circuit units of the active antenna arrays are connected to the main calibration coupling circuit unit through a calibration channel. The main calibration coupling circuit is connected with the transmitting and receiving calibration unit. The transmitting and receiving calibration unit and the calibration parameter storage unit are respectively connected to the ROF photoelectricity conversion unit.

Owner:DATANG MOBILE COMM EQUIP CO LTD

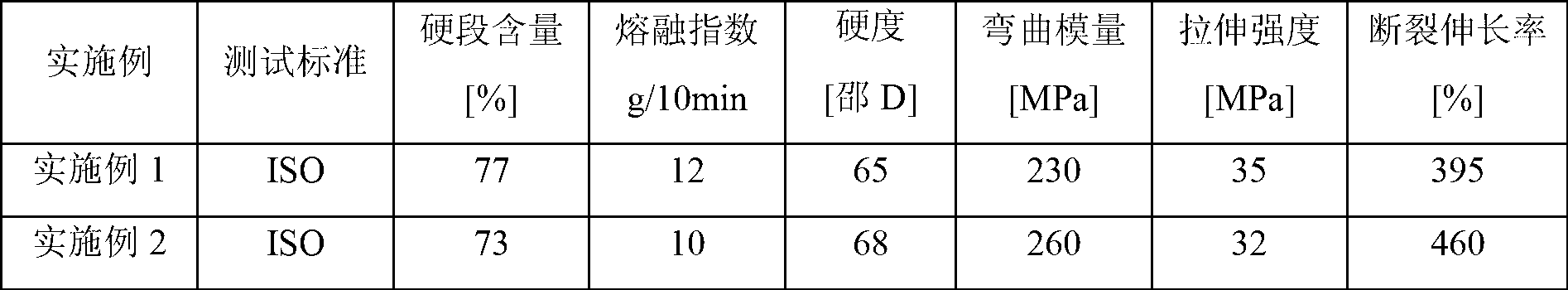

Method for preparing copolyether ester elastomer

The invention discloses a method for preparing copolyether ester elastomer. The method comprises the following steps of mixing aromatic binary acid, polyether glycol and micromolecule glycol to carry out an esterification reaction, removing by-products of tetrahydrofuran and water to obtain carboxylate after the reaction is finished; transferring the obtained carboxylate into a pre-polycondensation reactor, adding an antioxidant and a catalyst to react for 1-2 hours, so as to obtain a prepolymer; transferring the prepolymer to a polycondensation kettle, wherein the polymerization time is 1.5-3 hours and the pressure is 100-200Pa; and obtaining the copolyether ester elastomer after the reaction is finished. By adopting the method disclosed by the invention, the copolyether ester elastomer is prepared from terephthalic acid as a raw material; the cost is low; and the by-product tetrahydrofuran generated by reaction is rectified and purified to obtain the high-purity tetrahydrofuran. The method has no negative effect on the cost of synthetizing TPEE (thermoplastic polyeher ester elastomer); the performance of the synthetized copolyether ester elastomer is consistent with that of the product prepared from dimethyl terephthalate.

Owner:KINGFA SCI & TECH CO LTD +1

Method for producing diamond tool for grinding concrete floor

InactiveCN101518890ALow priceImprove stabilityAbrasion apparatusGrinding devicesHot pressHot pressing

The invention discloses a method for producing a diamond tool for grinding a concrete floor, which comprises the following steps: proportional irregular glomerocryst diamond and man-made diamond are uniformly distributed on the surface of a tire casing; a gap between the diamond is filled with metallic bond, and according to the ratio by weight, the metallic bond comprises 40 to 70 percent of cobaltco, 10 to 20 percent of copper, 15 to 20 percent of tungsten carbide, 5 to 10 percent of stannum and 0.5 to 3 percent of trace element; the operation of cold press molding is carried out, sections formed by the cold press molding are delivered to a vacuum hot press sintering furnace to be sintered, and the temperature is kept from 850 DEG C to 900 DEG C and the pressure from 10 to 15 tons; and the sintered sections are welded on a metal base body. The diamond tool produced by the method not only can increase the grinding efficiency and maintain the stable performance, but also can greatly prolong the service life.

Owner:邓国川 +2

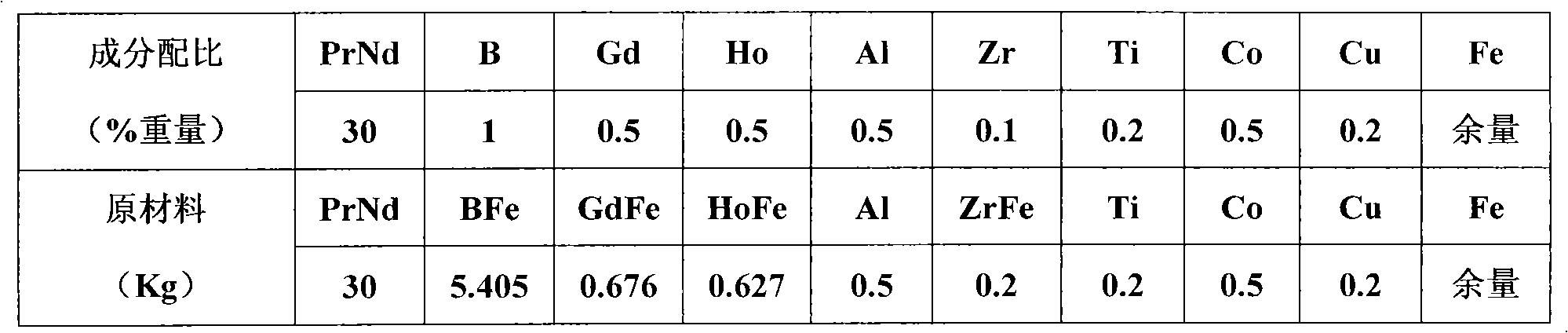

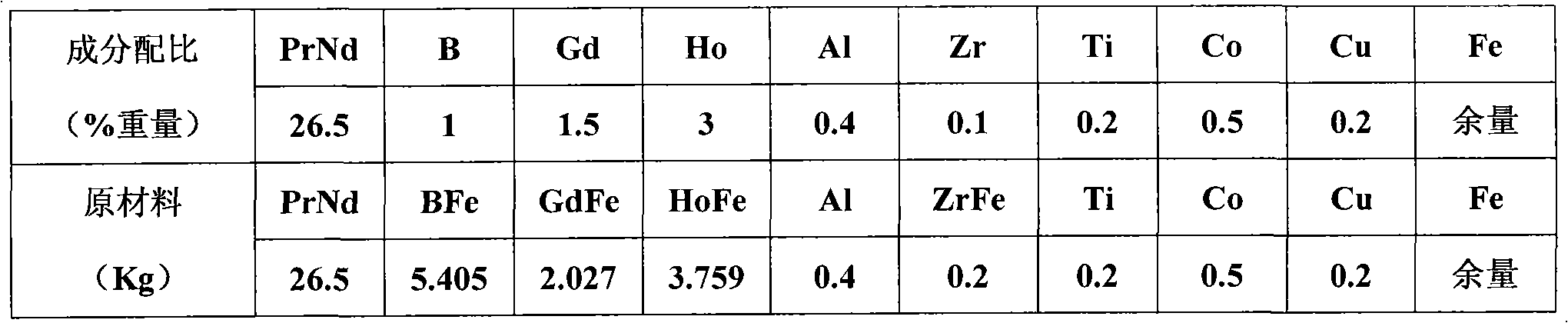

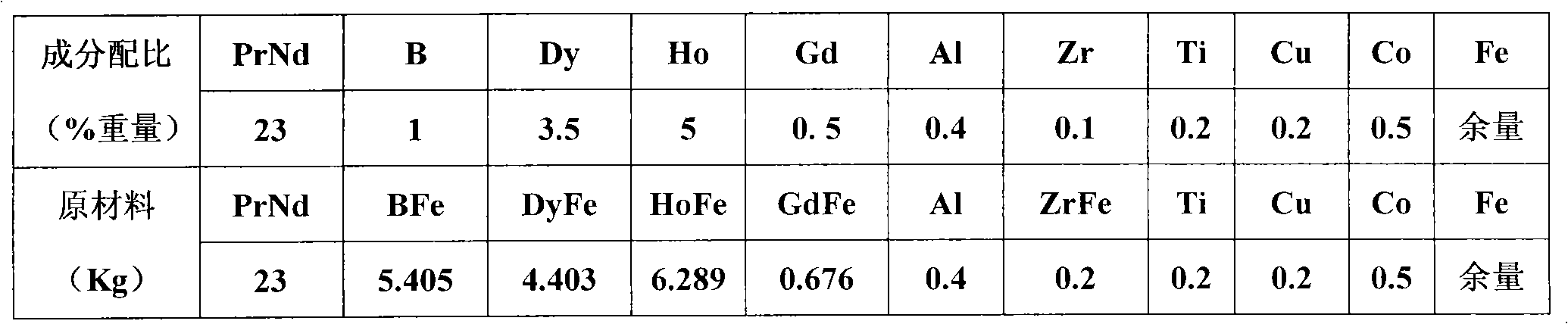

Medium-to-high grade neodymium-iron-boron magnet with composite addition of gadolinium and holmium

InactiveCN101552062AAlleviate shortagesPowder speed increasedInductances/transformers/magnets manufactureMagnetic materialsCobaltImpurity

The invention discloses a medium-to-high grade neodymium-iron-boron magnet with composite addition of gadolinium and holmium, which is composed of the following components by weight percentage: 20 percent-33 percent of praseodymium-neodymium alloy, 0.5 percent-10 percent of gadolinium, 0.5 percent-10 percent of holmium, 0.9 percent-1.2 percent of boron, 0.1 percent-0.8 percent of aluminum, 0.1 percent-0.5 percent of copper, 0.1 percent-0.5 percent of zirconium, 0.1 percent-0.5 percent of titanium, 0 percent-10 percent of dysprosium, 0 percent-3.0 percent of cobalt and the balance of iron and a small amount of inevitable impurities in materials. The medium-to-high grade neodymium-iron-boron magnet with composite addition of gadolinium and holmium has high corrosion resistance, square degree and magnetic energy product; furthermore, the powder discharging speed of the powder production procedure in the preparation process is fast, thereby shortening the production cycle, improving the magnetic performances of the magnet and enhancing the enterprise competitiveness.

Owner:宁波同创强磁材料有限公司

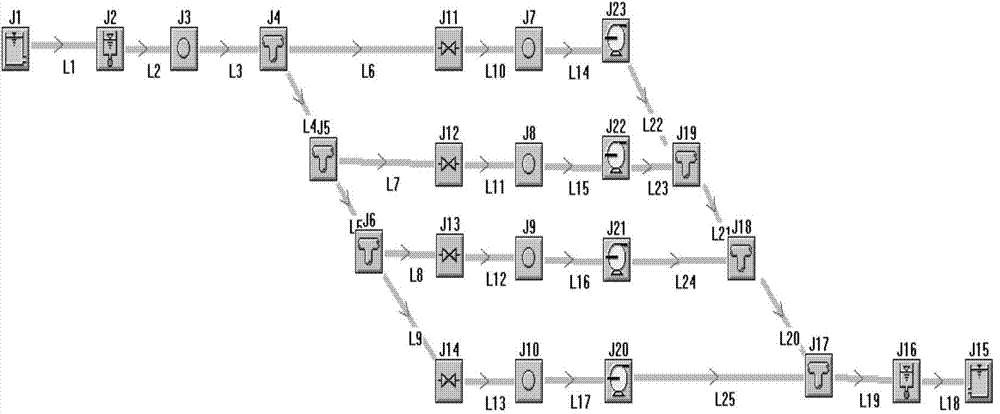

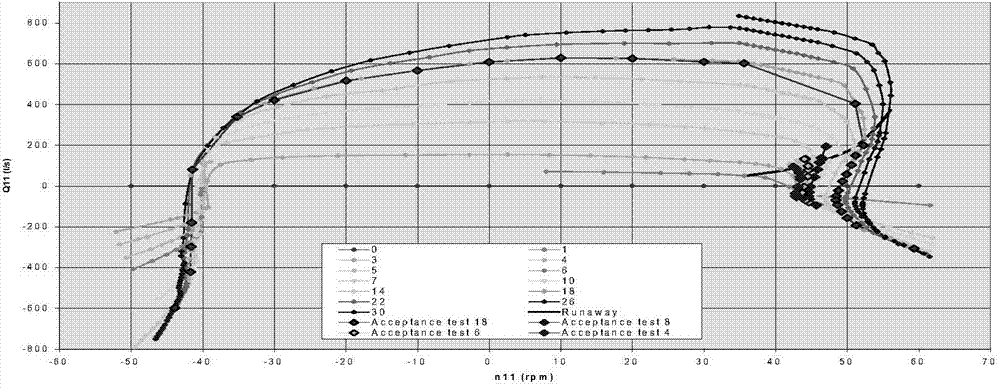

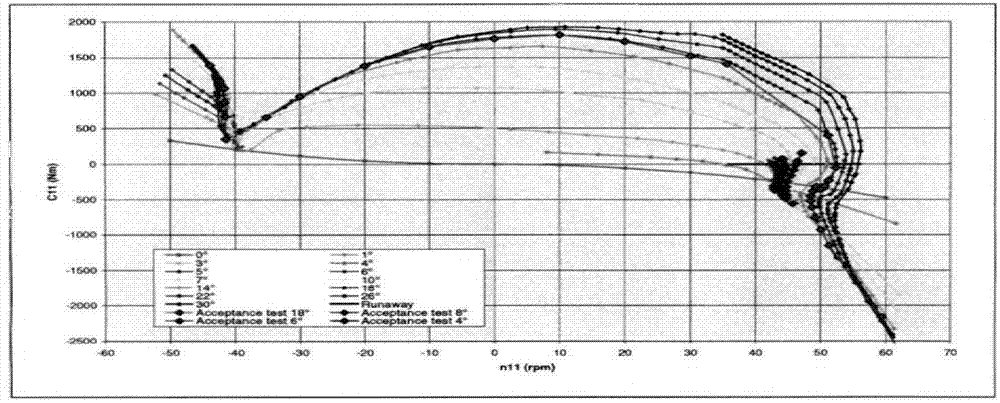

Universal simulation platform for large-sized pumped storage power stations

InactiveCN103593508AConsistent performanceInteractiveSpecial data processing applicationsPower stationWater reservoir

A universal simulation platform for large-sized pumped storage power stations is characterized in that a hydraulic-mechanical-electric system mathematical model is established under a Matlab / Simulink environment; a one-pipe four-unit arrangement form is adopted, an upstream reservoir is connected with an upstream surge shaft through a long guide tunnel, the upstream reservoir is then communicated with three parallel Y-shaped high-pressure bifurcated pipes through a long high-pressure tunnel, a 300MW water pump turbine is disposed behind each high-pressure bifurcated pipe, and water flows pass the water pump turbines, enter the parallel Y-shaped tail water bifurcated pipes, gather at a tail water branch pipe, flow by the downstream purge shaft and a tail water tunnel, and reach a downstream reservoir. The universal simulation platform for large-sized pumped storage power stations is characterized in that universality is fully considered and overall change responses of curves can be optionally checked in real time.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

Golf ball dimples forming indicia

A golf ball comprising an outer surface including a plurality of dimples that form indicia. The plurality of dimples take the form of text letters, characters or other symbols and are relatively similar in size to a plurality of conventional shaped dimples or larger. The plurality of dimples occupy a substantial portion of the ball's surface in a repeating, distributed pattern.

Owner:ACUSHNET CO

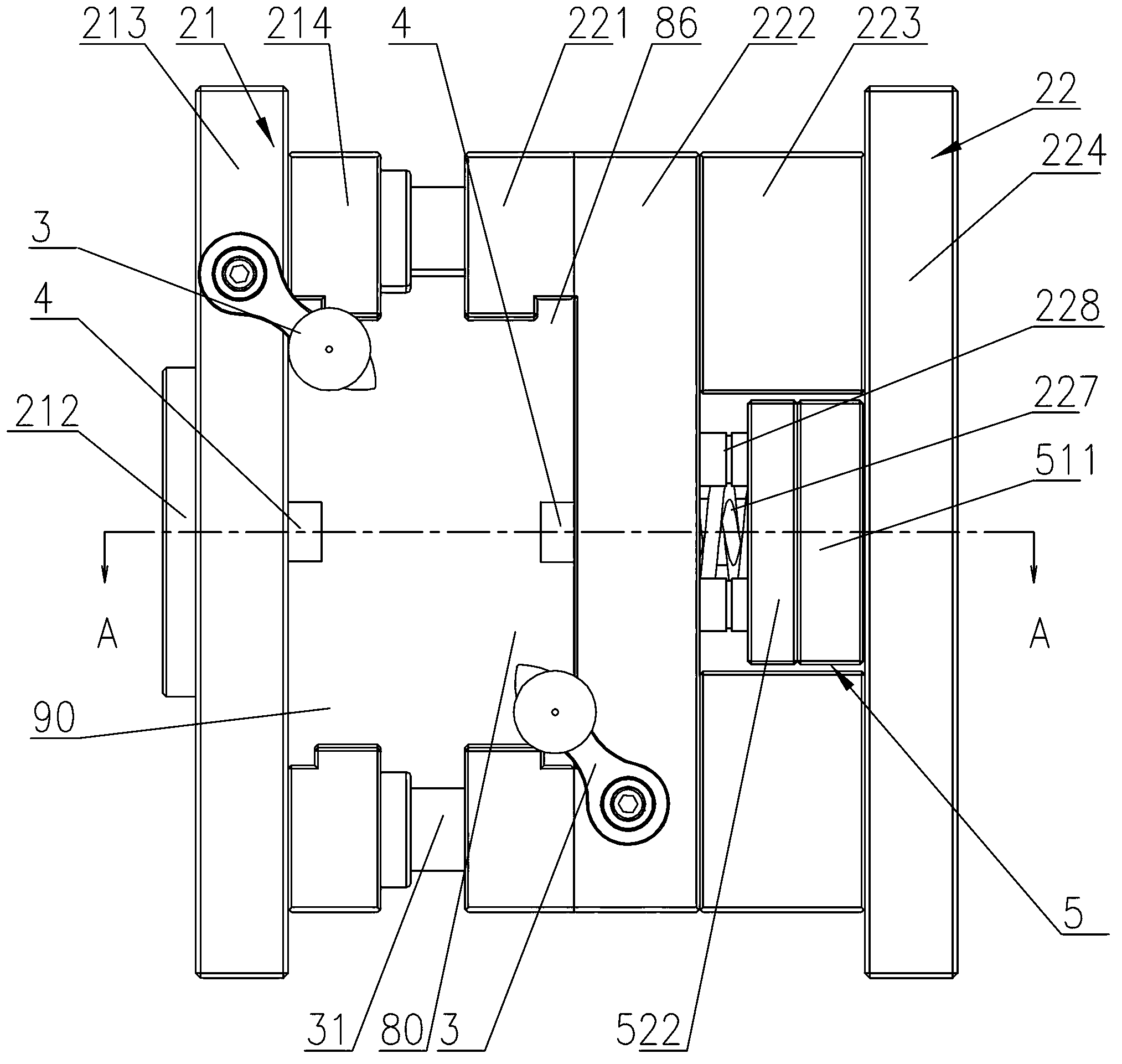

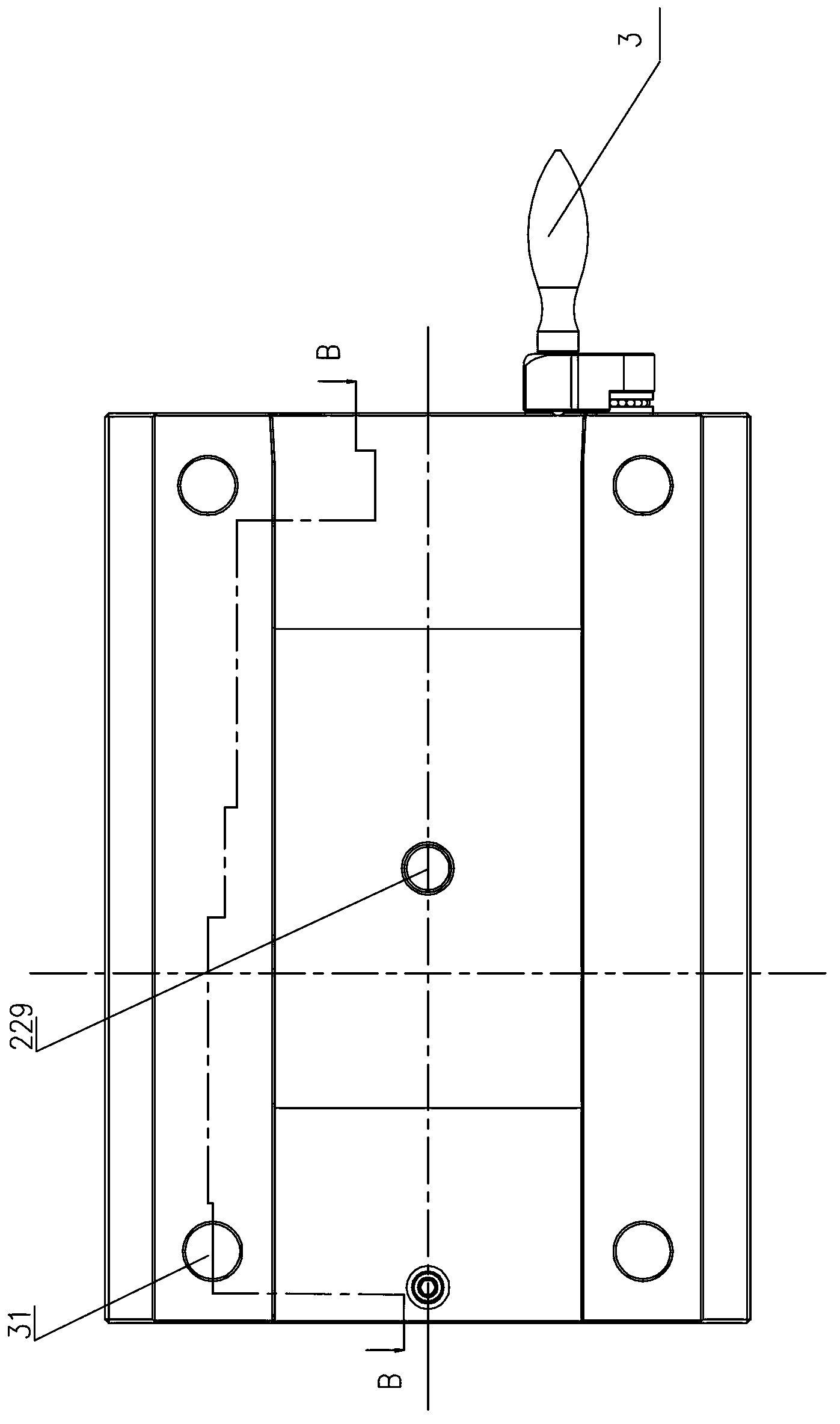

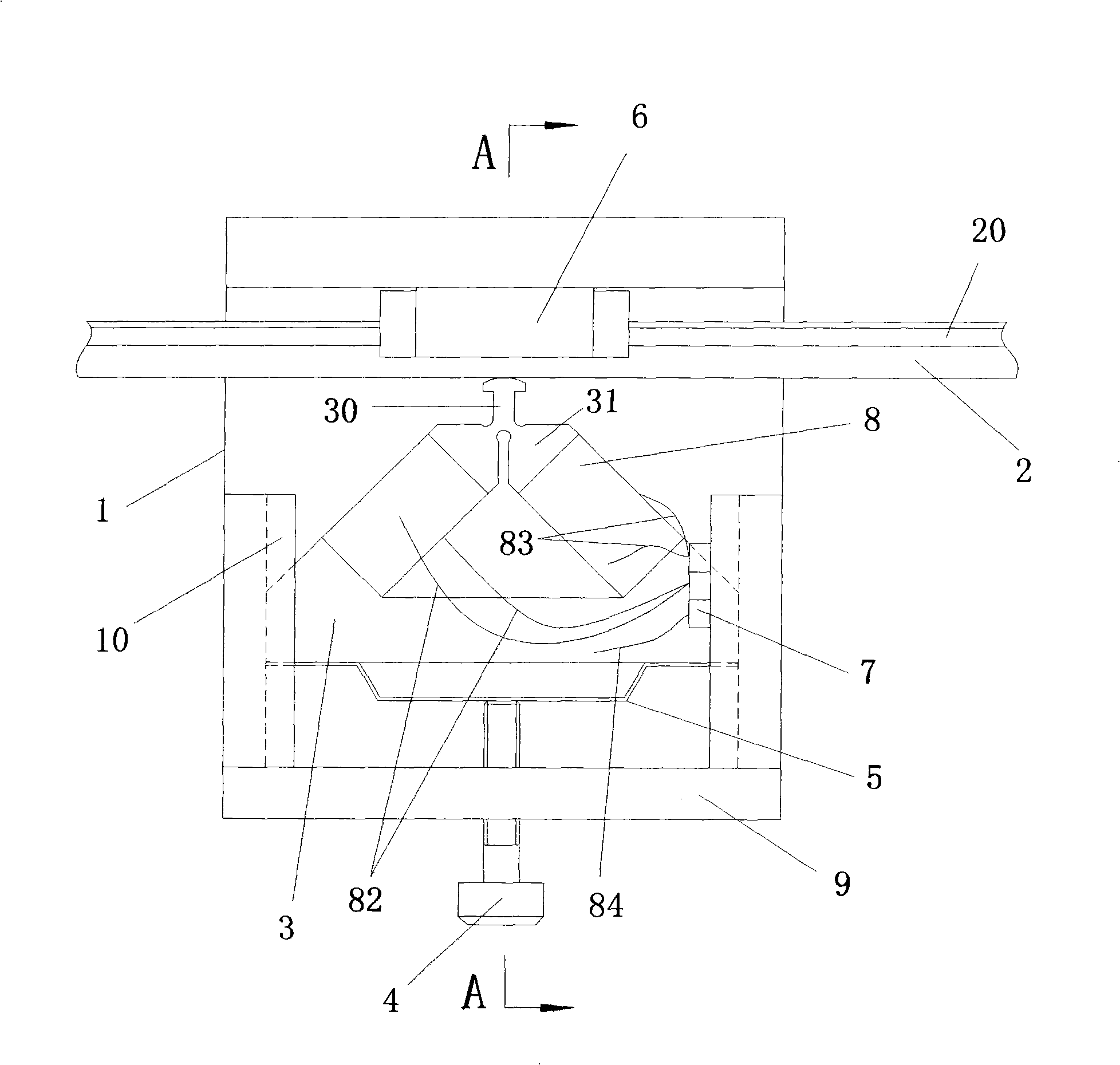

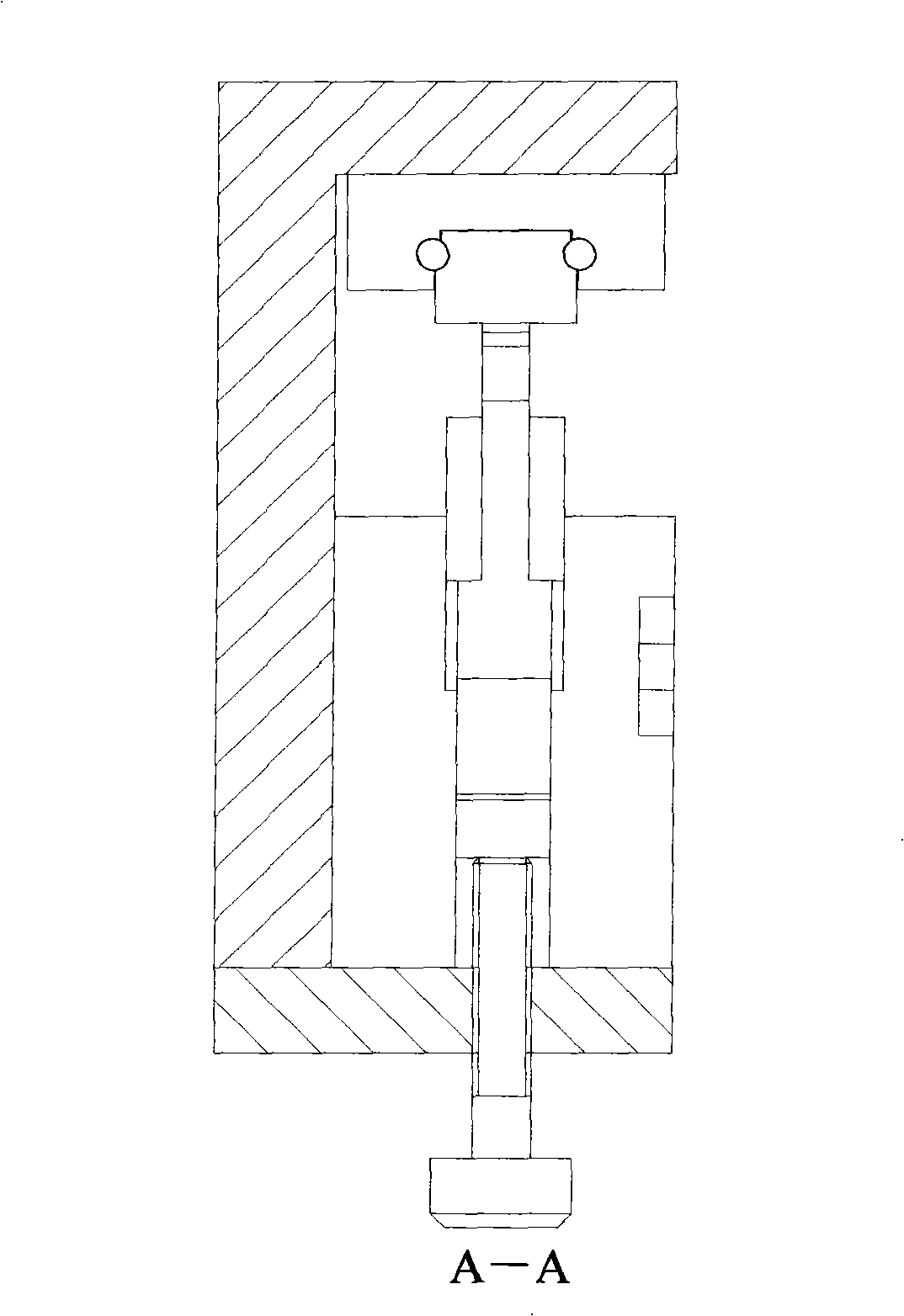

Injection mould with rapidly-replaced mould cores

The invention discloses an injection mould with rapidly-replaced mould cores. The injection mould is composed of a movable mould and a stationary mould, wherein a main body of the movable mould is composed of a movable mould base and a movable mould core movably arranged on the movable mould base; a main body of the stationary mould is composed of a stationary mould base and a stationary mould core movably arranged on the stationary mould base; the butt joint faces of the movable mould base and the stationary mould base are respectively provided with a mould core mounting sliding chute which horizontally extends from front to back; at least the front ends of the mould core mounting sliding chutes are provided with plug-in mounting holes for mounting or dismounting the mould cores; the mould cores are provided with tracks matched with the mould core mounting sliding chutes so as to move along the mould core mounting sliding chutes; and the mould cores are inserted to or dismounted from the mould core mounting sliding chutes on the mould bases through the plug-in mounting holes, thus the mould cores are replaced. According to the invention, only one set of mould base needs to be manufactured to be matched with the mould cores of different cavities which are manufactured according to spline standards tested based on different performance indexes; the mould replacing operation is easier and more convenient than that of the prior art, so that the mould replacing time is greatly shortened; and the manufacturing cost of various test spline moulds can also be greatly reduced.

Owner:广州现代塑料有限公司

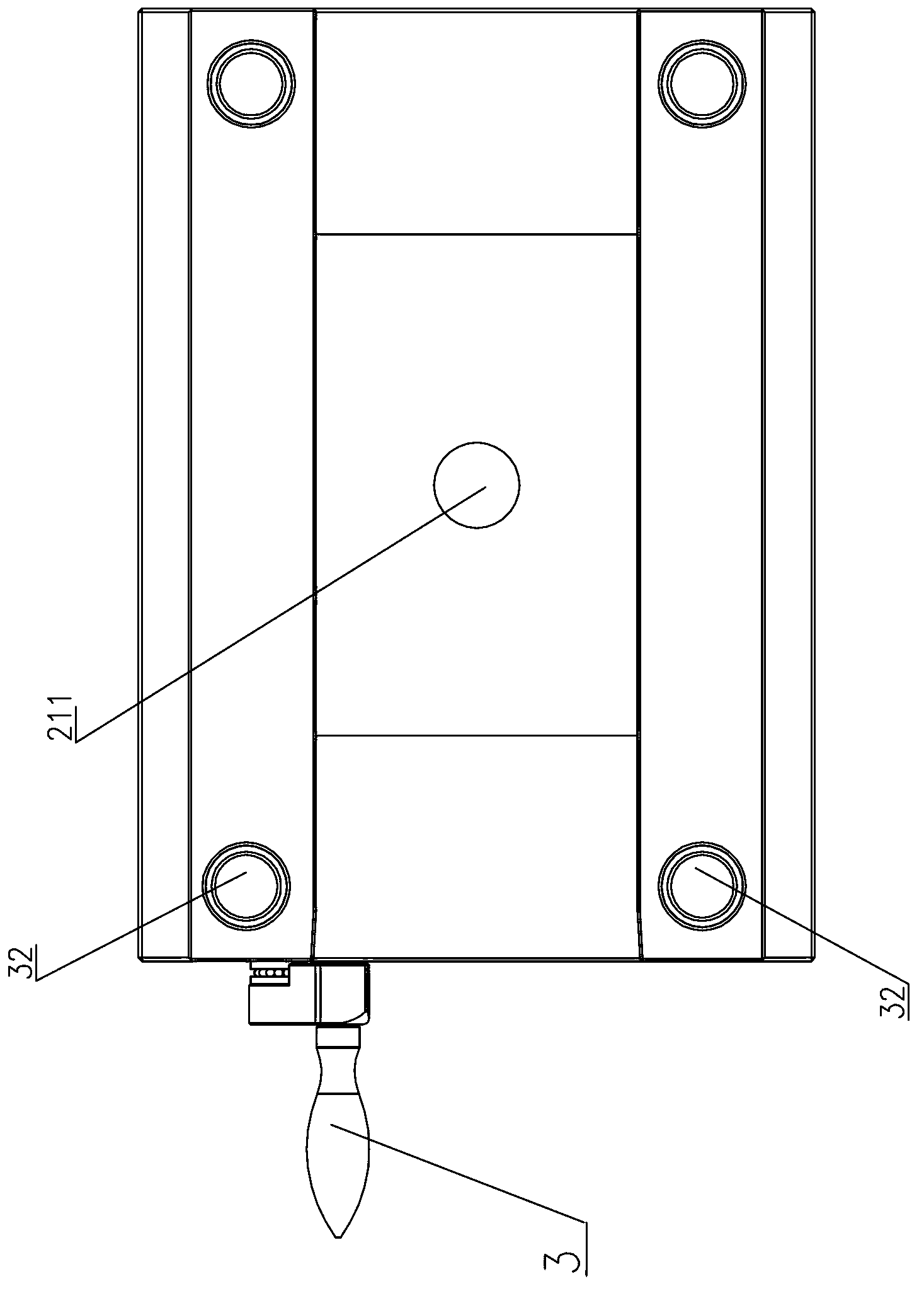

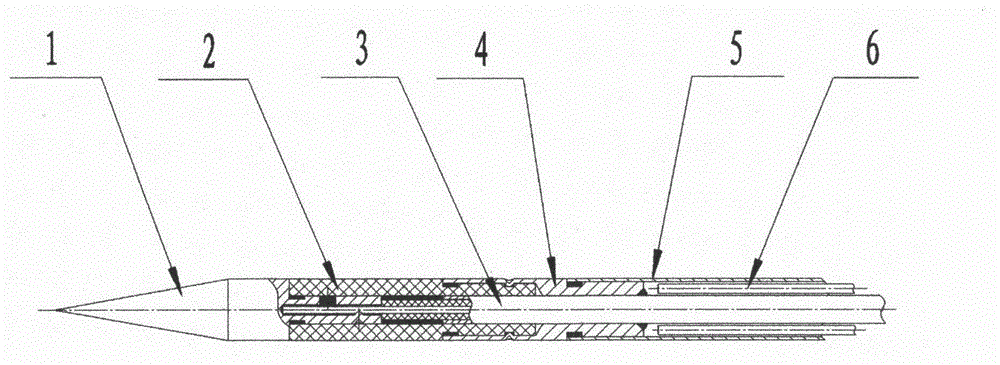

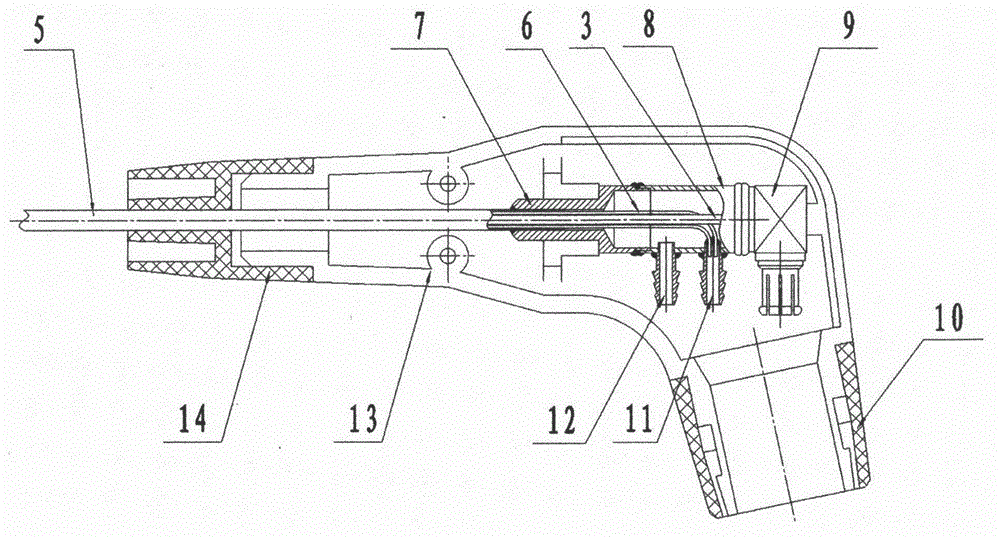

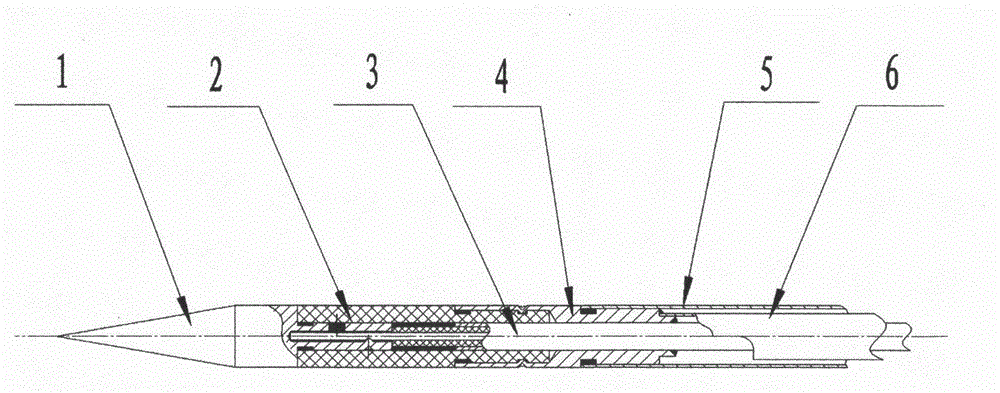

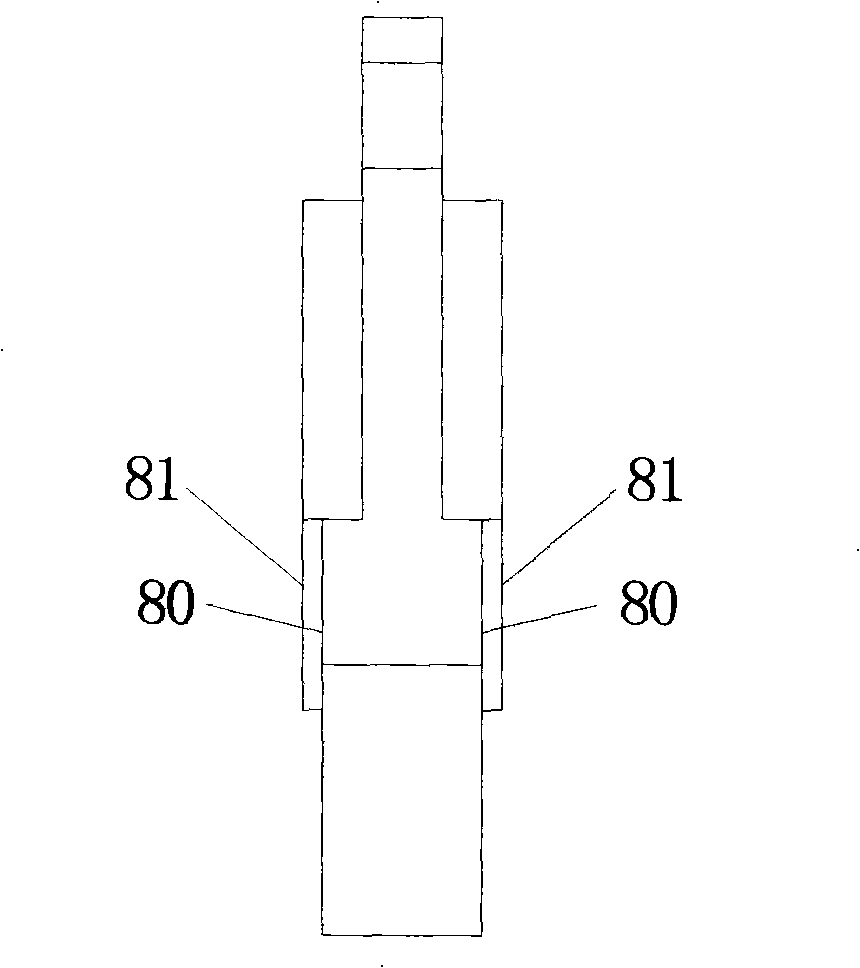

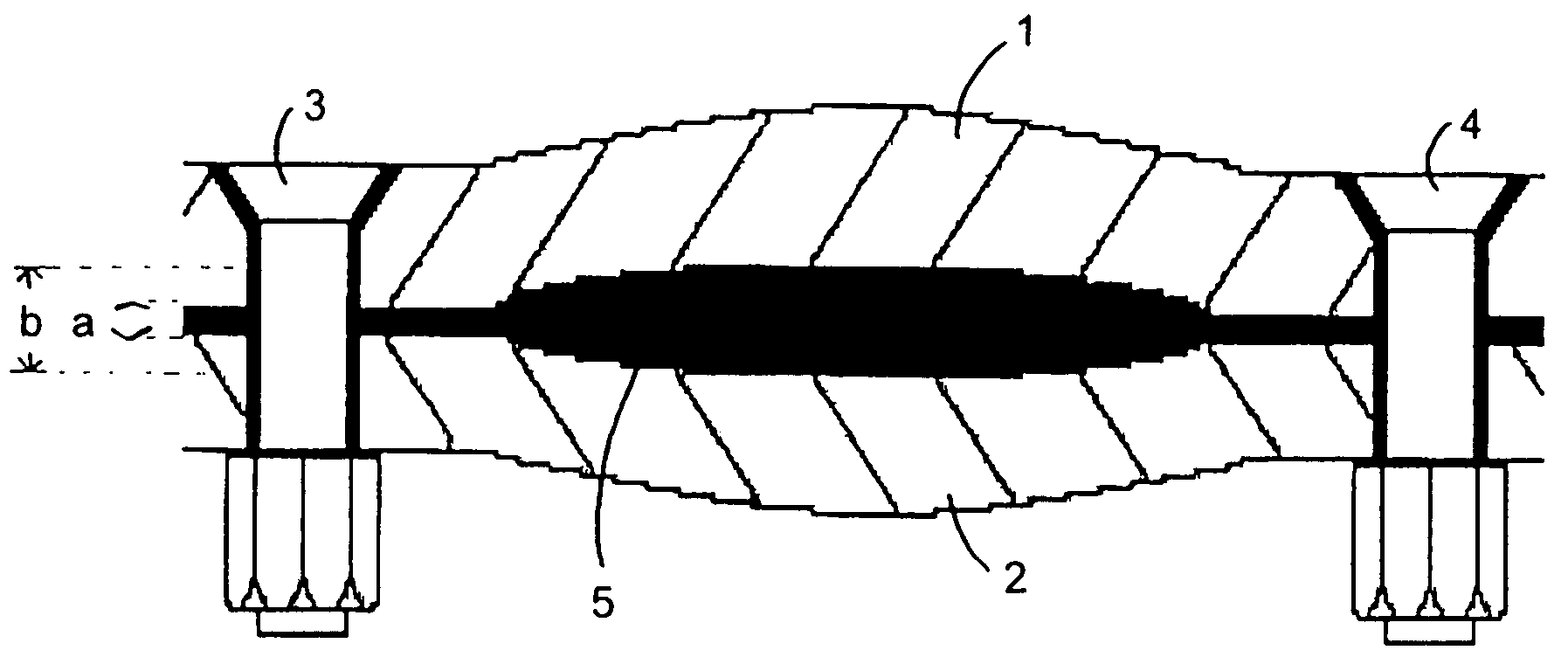

High-performance water-cooled microwave ablation antenna

InactiveCN103142307ASolve the problem of head falling offSolve the leakSurgical instrument detailsElectrical conductorCoaxial cable

The invention discloses a high-performance water-cooled microwave ablation antenna, comprising a radiation head, a medium pipe, a semi-rigid coaxial electric cable, a needle rod, and a metal outer guide bush sleeved on the tail part of the medium pipe, wherein the semi-rigid coaxial electric cable penetrates through the axis hole of the metal outer guide bush and then is connected with the radiation head, the front end of the metal outer guide bush is sleeved on the medium pipe, the front end of the needle rod is sleeved on the excircle of the tail part of the outer guide bush, and the outer guide bush is in ohmic contact with the outer conductor of the semi-rigid coaxial electric cable and the needle rod. According to the high-performance water-cooled microwave ablation antenna disclosed by the invention, the needle rod and the medium pipe are connected together through the metal outer guide bush, the outer guide bush is in ohmic contact with the outer conductor of the semi-rigid coaxial electric cable and the needle rod, so that the structure precision of the microwave ablation antenna is improved, the boundary condition of the spatial electromagnetic field source of the antenna is not instable and unknown any more, and therefore, the performance and the main property parameters of the ablation antenna tend to be consistent and have certainty, so that the stability, efficiency and reliability of the ablation antenna are further improved.

Owner:杨兴瑞

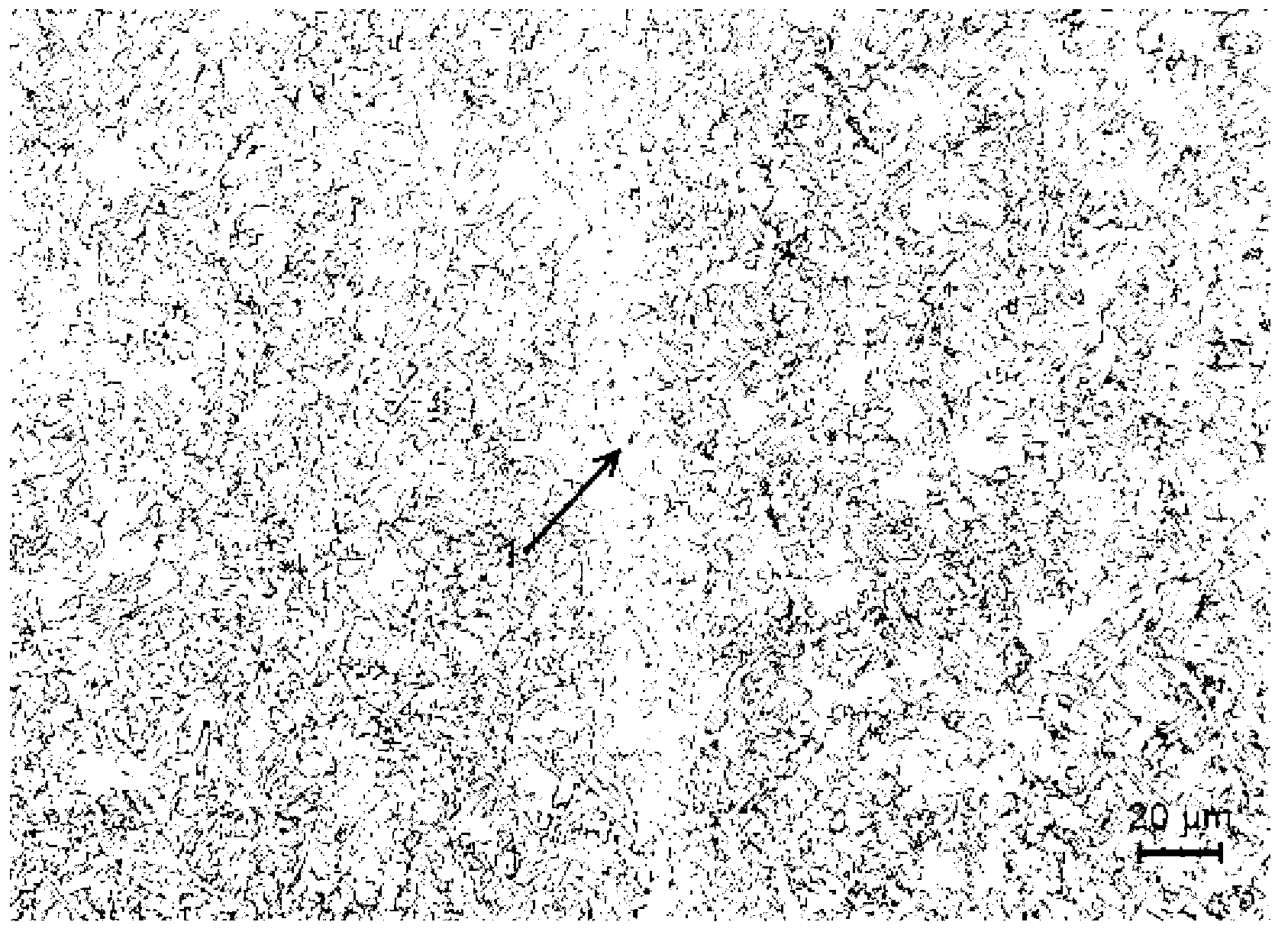

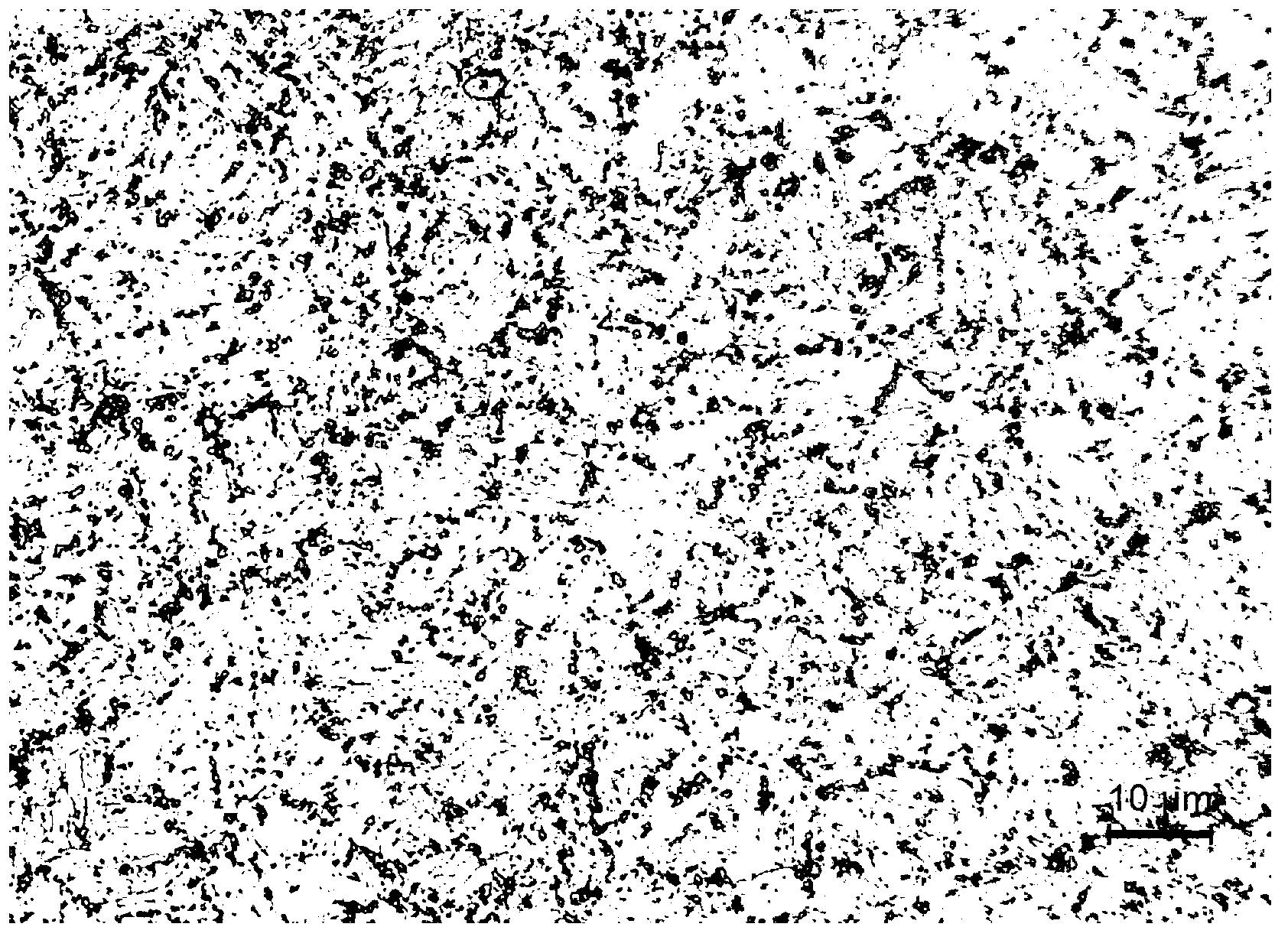

Control method for bearing steel network carbides and banded carbides and bearing steel

ActiveCN105648170AReduce formation effectReduce the formation effect of bearing steel network carbides and banded carbides Significant formation effectTemperature controlCarbide

The invention discloses a control method for bearing steel network carbides and banded carbides and bearing steel. The temperature of a finishing pass during hot rolling of the bearing steel is controlled to be within the range of 830 to 870 DEG C, and a large number of carbides are prevented from being separated out; then cooling equipment is utilized for performing water cooling on eventually rolled bar materials, the temperature of the bar materials is made to rapidly pass through the temperature range being 700 to 850 DEG C, the carbides are forcefully inhibited from being separated out, and the proportion of cementite in pearlite is increased; and meanwhile, the temperature of the bar materials after water cooling is controlled to be 600 DEG C to 650 DEG C, and a bainite or martensite structure is prevented from being generated. Production proves that the effect on reducing formation of the bearing steel network carbides and banded carbides is remarkable through the method, the grade of the network carbides in the bearing steel is decreased to the second grade or third grade from above third grade in GB / T18254 and the metallographic phase form of the carbides is a semi-net shape or a mass point shape, and the grade of the banded carbides in the bearing steel reaches the first grade in GB / T18254.

Owner:SUZHOU SUXIN SPECIAL STEEL +2

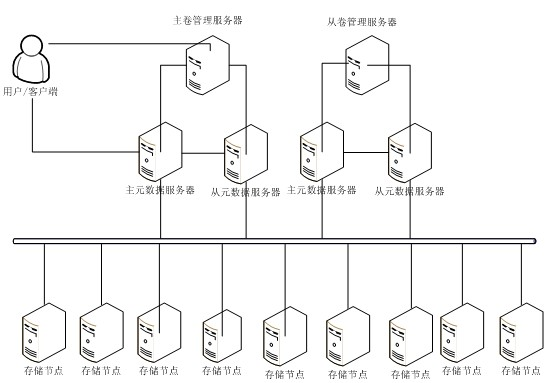

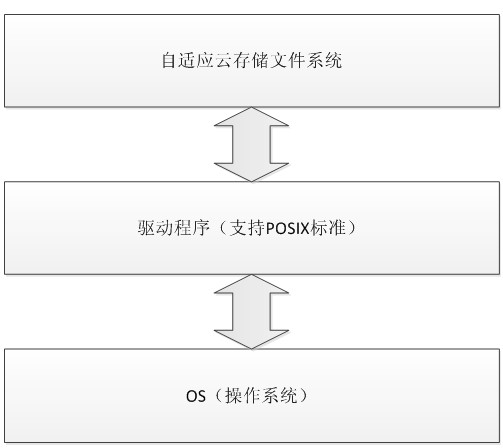

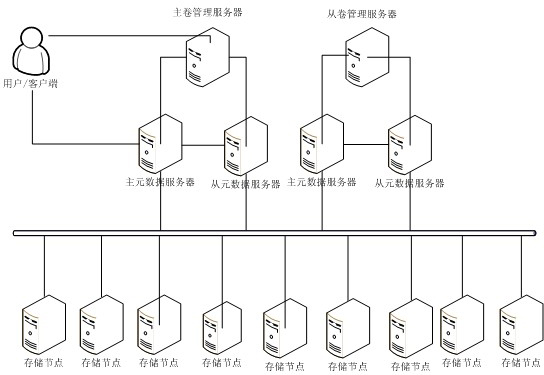

File storage management system of cloud storage system

The invention provides a file storage management system of a cloud storage system. The system comprises one or a plurality of management nodes, and one or a plurality of storage nodes (data nodes); in data establishment and storage, the system distributively establishes and stores the data on each storage node; in data establishment and storage, a system external interface supports a POSIX (Portable Operating System Interface of Unix) standard protocol, and the system controls a data diffluent mode through a master file management server, balances the load of each storage server, and keeps the performance and a primary storage data saving path of the server permanent.

Owner:NANJING YUNCHUANG LARGE DATA TECH CO LTD

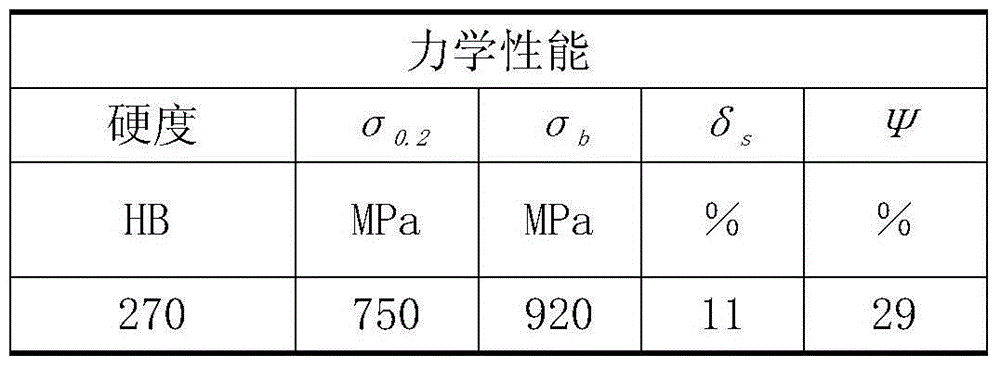

High-strength and high-toughness oil casing and manufacturing method thereof

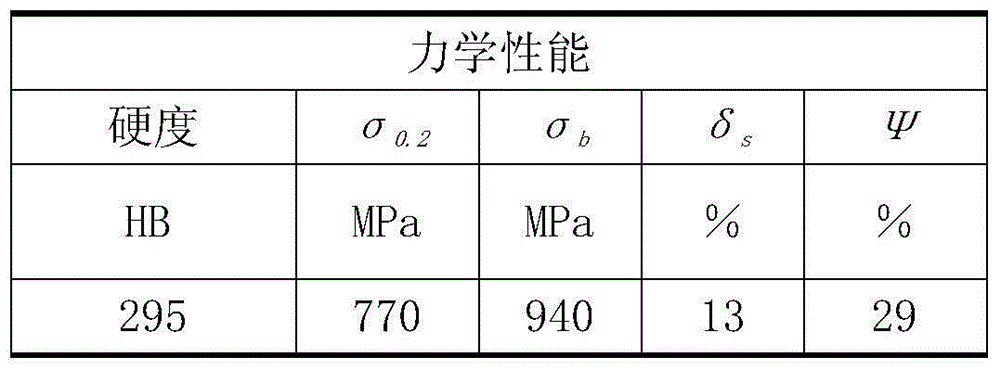

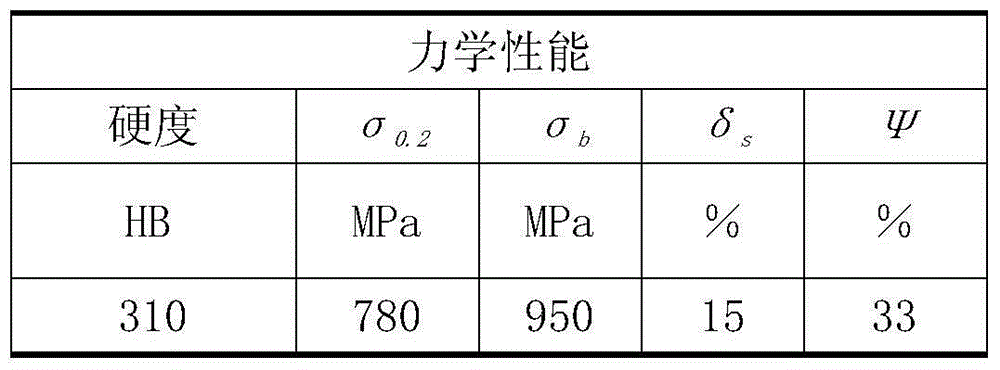

ActiveCN103194693ARefine the grain sizeConsistent performanceDrilling rodsDrilling casingsChemical compositionThermal treatment

The invention discloses a high-strength and high-toughness oil casing and a manufacturing method thereof. A 'HFW(High Frequency Welding)+welding line on-line thermal treatment+hot tension reducing+whole casing thermal treatment' technology is used for manufacturing a Q125 steel grade oil casing, and the weight percentage of chemical components are as follows: C: 0.18-0.30; Sh: 0.10-0.35; Mn: 1.00-1.30; P: not more than 0.018; S: not more than 0.008; Cr: 0.20-1.20; Mo: 0.20-0.55; Nh: 0.10-0.56; B: 0.0010-0.0015; Nb+V+Ti: not more than 0.08; and the balance of Fe and unavoidable impurities. For the Q125 oil casing produced by the manufacturing method, the yield strength is not less than 865MPa, the tensile strength is not less than 940MPa, the specific elongation is not less than 23.2%, at 0 DEG C, the full-scale transverse impact energy is not less than 105J and the longitudinal impact energy is not less than 110J. The Q125 steel grade oil casing produced by the technology is excellent in comprehensive performance, and has excellent high toughness and high plasticity.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

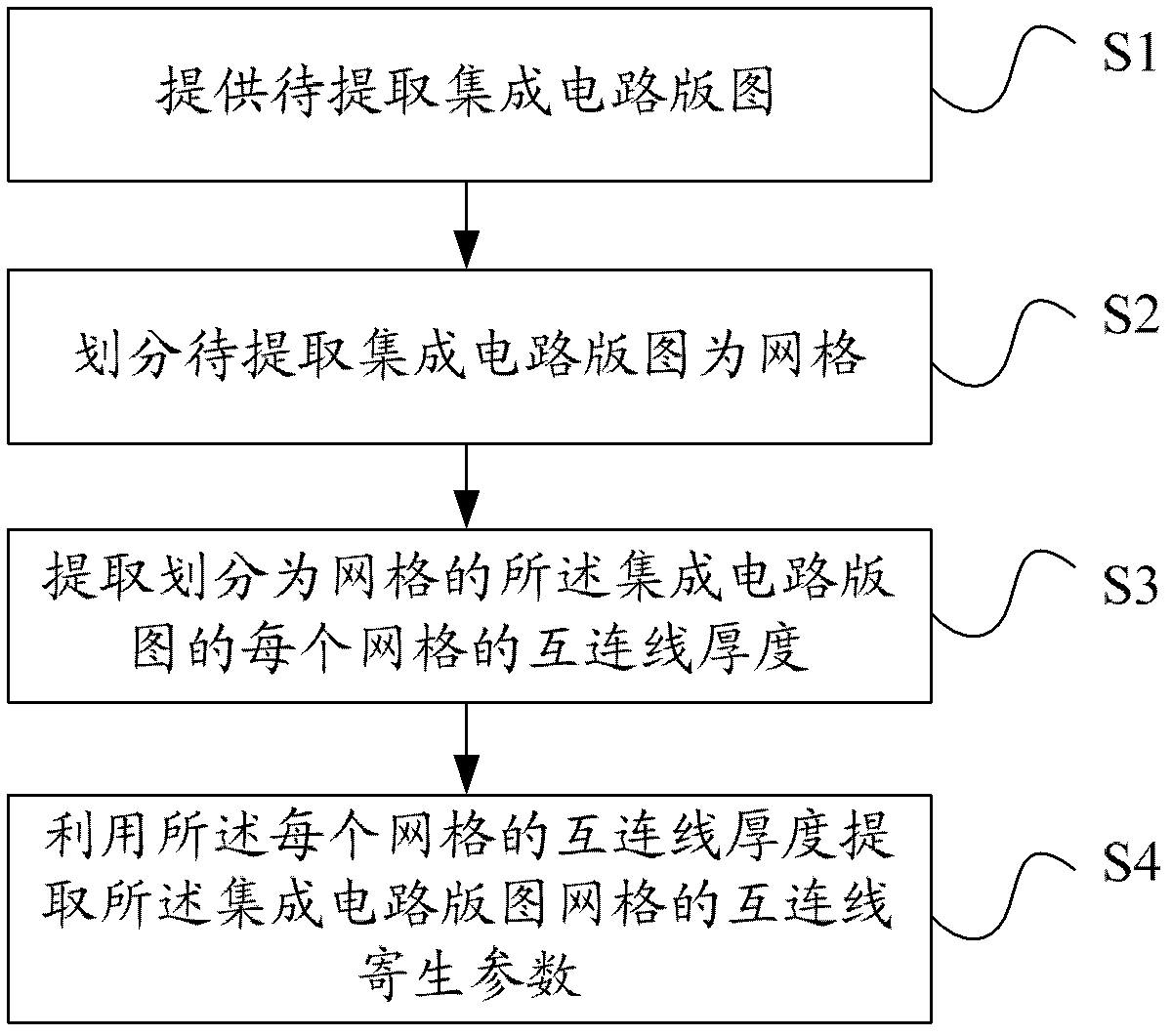

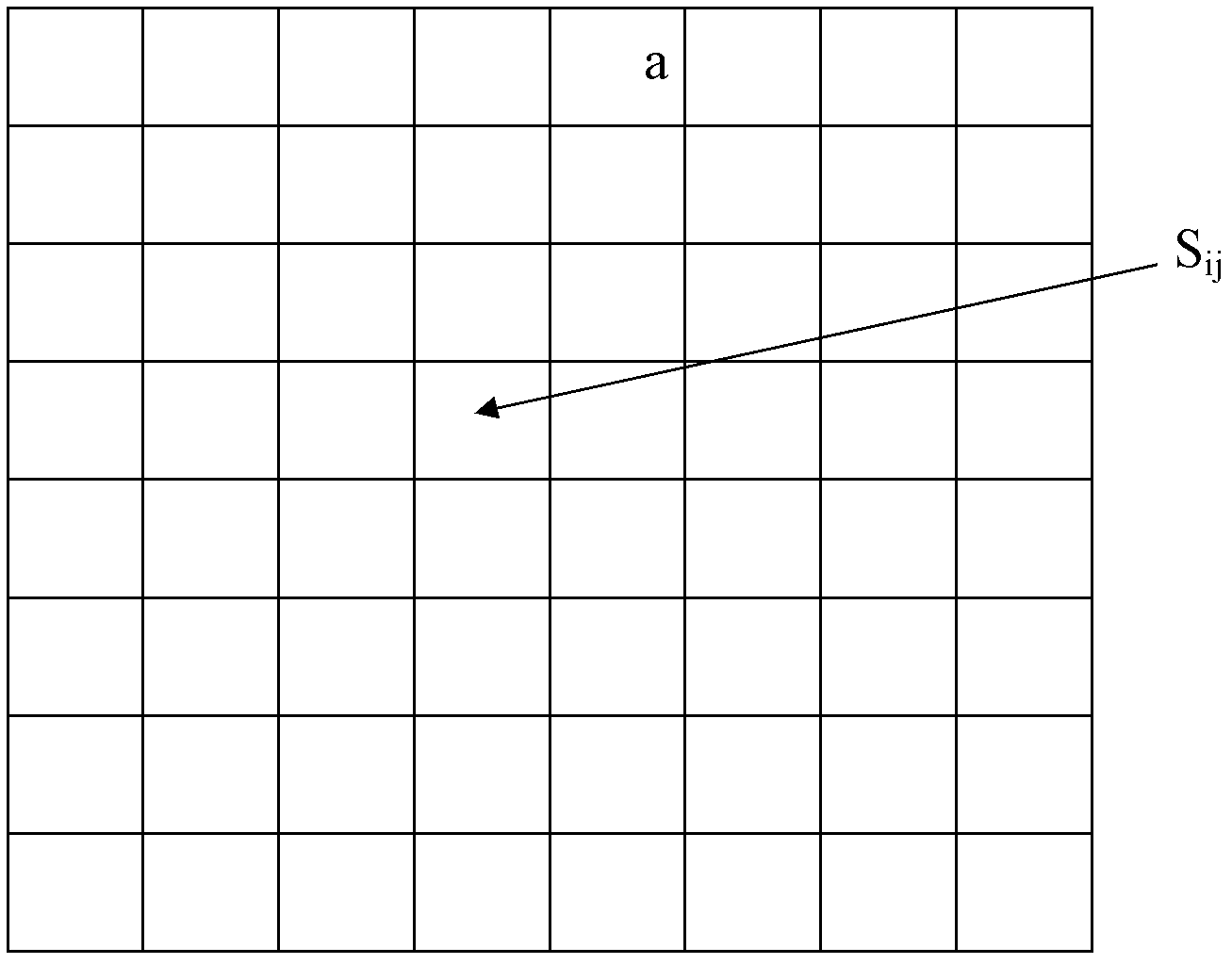

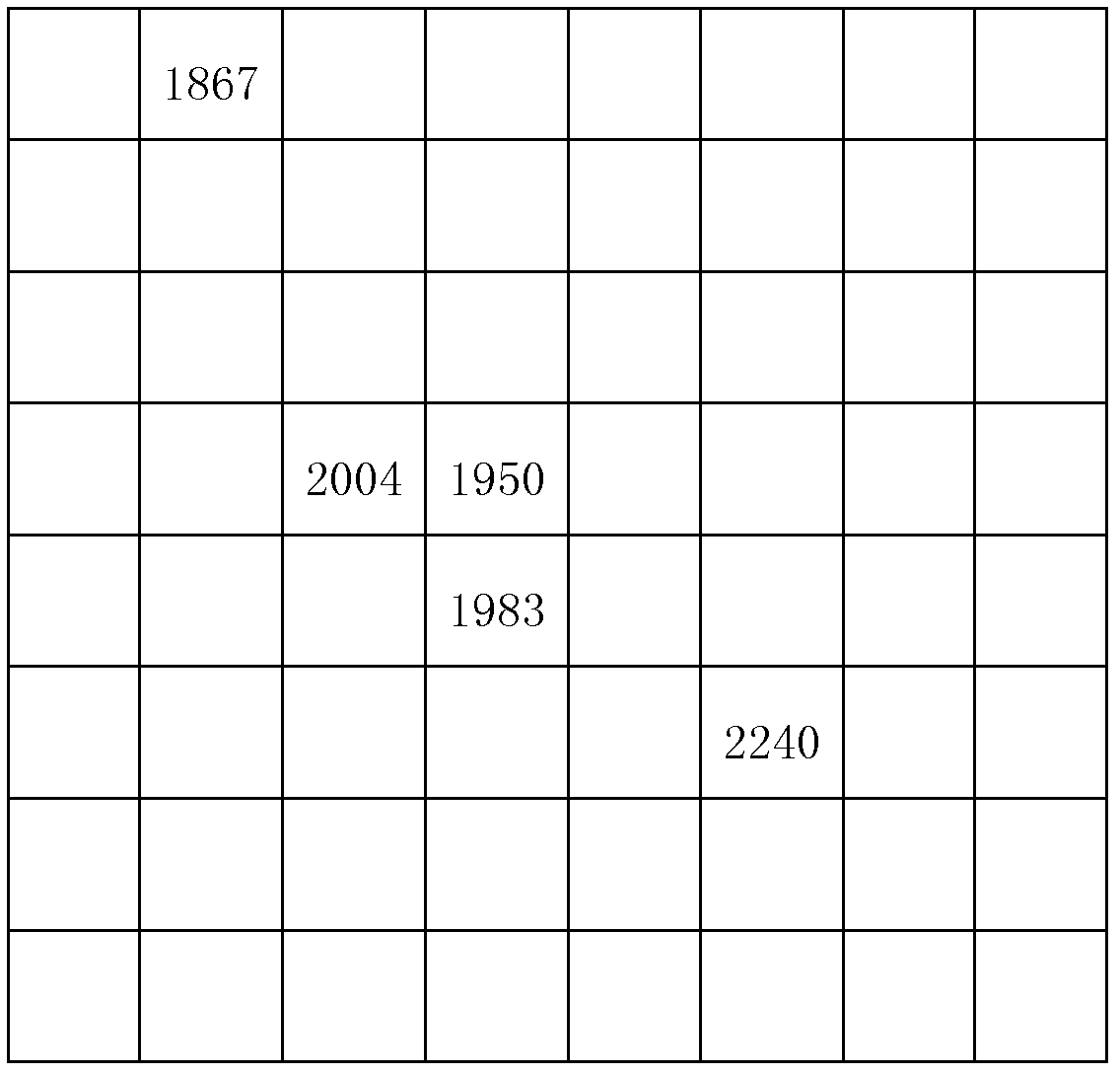

Method for extracting parasitic parameters of interconnection lines and device

ActiveCN102521468AAvoid miscalculationsConsistent performanceSpecial data processing applicationsEngineeringIntegrated circuit layout

The invention provides a method for extracting parasitic parameters of interconnection lines. The method includes obtaining the thickness of each interconnection line of each grid of a layout after the integrated circuit layout is divided into the grids in a parasitic parameter extraction process; extracting the parasitic parameters of the interconnection lines of the grids of the layout according to the obtained thicknesses of the interconnection lines so as to obtain parasitic parameter extraction results with consideration of thickness differences. Correspondingly, the invention further provides a device for extracting the parasitic parameters of the interconnection line. The thickness differences of the interconnection lines caused by CMP (chemical mechanical polishing) process are taken into consideration in the method, more accurate geometric information of the interconnection lines is adopted in the parasitic parameter extraction process, and accordingly more accurate parasitic parameters can be obtained.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

High-temperature resistant turbine blade and production process thereof

ActiveCN104099516AImprove performanceImprove impact toughnessBlade accessoriesSolid state diffusion coatingChemical compositionSteam turbine blade

The invention discloses a high-temperature resistant turbine blade. The turbine blade comprises the following chemical components in percentage by weight: 0.19-0.21% of C, 0.55-0.57% of Mn, 0.20-0.22% of Si, 0.38-0.40% of Al, 0.30-0.32% of V, 0.40-0.42% of Ti, 0.12-0.14% of Ni, 0.06-0.08% of Sn, 0.25-0.27% of Zr, no more than 0.025% of S, no more than 0.025% of P, no more than 0.20% of Cu, 0.20-0.22% of lanthanide serial rare earth, and the balance Fe. The invention further designs a production process of the turbine blade. The production process has the advantages of simplicity and low cost, helps to largely improve the impact toughness of the blade, enhance the high temperature resistance of the blade and prolong the service life of the blade through the nitridation surface treatment.

Owner:南京赛达科技有限公司

Compound vibrator line ultrasonic electromotor

InactiveCN101262182ASimple structural designSimple designPiezoelectric/electrostriction/magnetostriction machinesElastomerPrism

The invention discloses a linear ultrasonic motor with composite vibrators. The linear ultrasonic motor comprises a frame, a mover, a vibrator and a pre-fastening mechanism, wherein, a sliding base and a hub are fixed inside the frame, the mover is arranged and capable of moving on the sliding base, the vibrator is an elastic metal body taking the shape of a right angled isosceles triangle, shifting teeth which contact the mover are arranged at the right angle part, the front surface and the back surface of the two right-angle side parts are provided with four piezoelectric ceramic pieces and the bottom surface of the vibrator contacts the pre-fastening mechanism. The motor has easy design, simple structure, convenient installation, large push force, long stroke and high working efficiency; with the two prism-shaped composite vibrator and that the shifting teeth with micro-displacement amplification function contact the surface of the mover, and that the two longitudinal prism-shaped composite vibrators are combined into a longitudinal bending composite vibrator of the shifting teeth, the longitudinal bending composite vibrator drives the mover to do a macro movement, thereby obtaining large drive force, comparatively longer working stroke, comparatively higher working rate and comparatively higher disconnection and self-locking capacity.

Owner:SOUTH CHINA AGRI UNIV

Preparation method of light calcium-alginate-base sponge body functional material

The invention discloses a preparation method of a light calcium-alginate-base sponge body functional material. The preparation method comprises the following steps: in room temperature, evenly mixing sodium alginate powder with soluble calcium salt, magnesium salt or aluminum salt, a reinforcing agent, peroxide and a catalyst to obtain a mixture; moistening with an alcohol-water solution to form paste; rolling by molding equipment to form a film material or a plate material; and then sequentially performing infiltration, complexation for pore formation, and expansion for pore formation. The preparation method has the characteristics of simple technology, low control difficulty, low equipment investment, energy-saving effect, low production cost and the like and is applicable to large-scaled industrial production; the prepared light calcium-alginate-base sponge body functional material is the same in structure and composition regardless of interior or exterior, good in quality, light in weight, high in mechanical strength, and excellent in imbibition performance and air permeability, and can be widely applicable to the fields of antibacterial materials, flame-resistant materials, adsorbing materials, acoustic materials, vibration-absorptive materials and the like; the market prospect is extensive.

Owner:QINGDAO UNIV

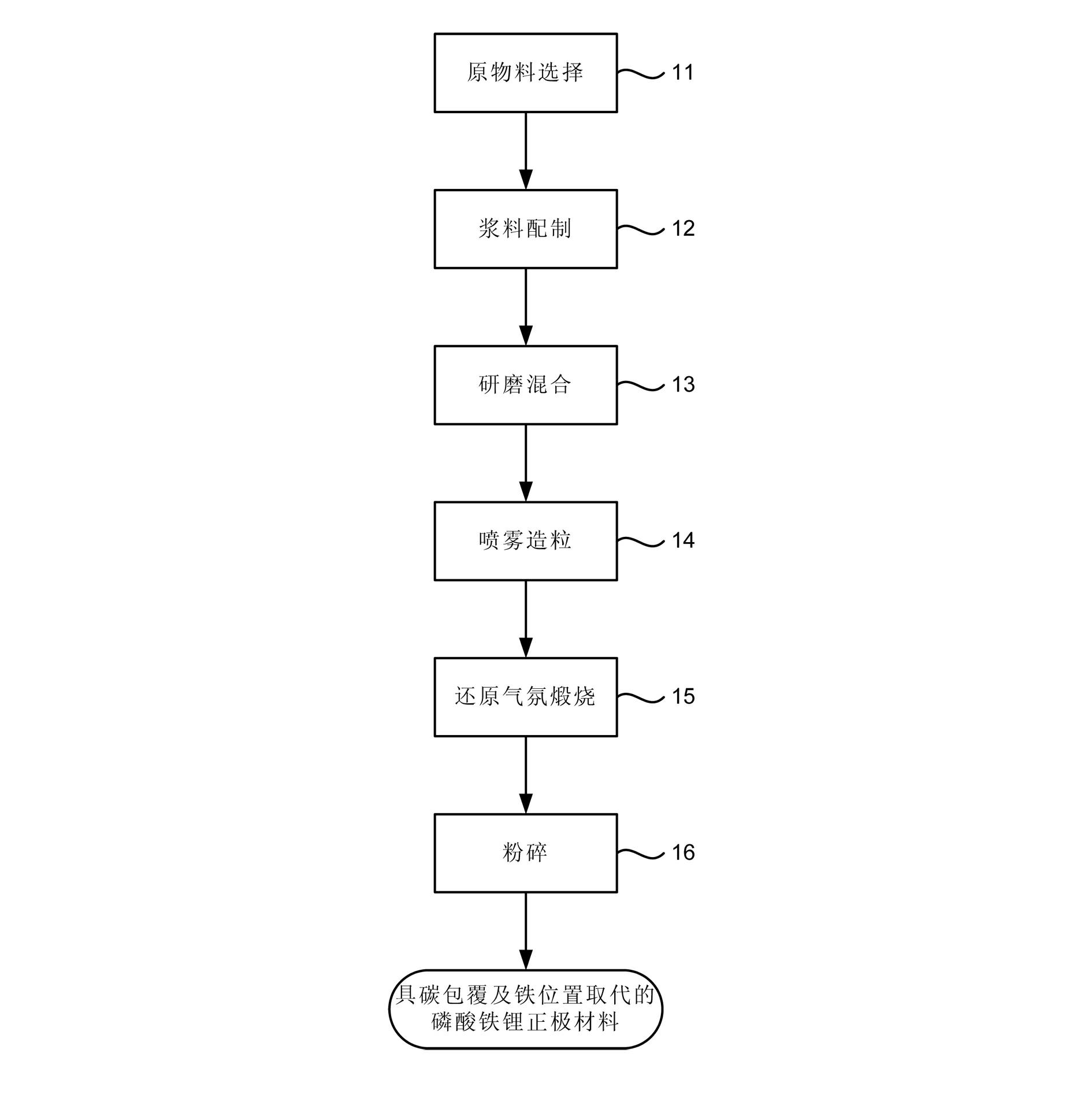

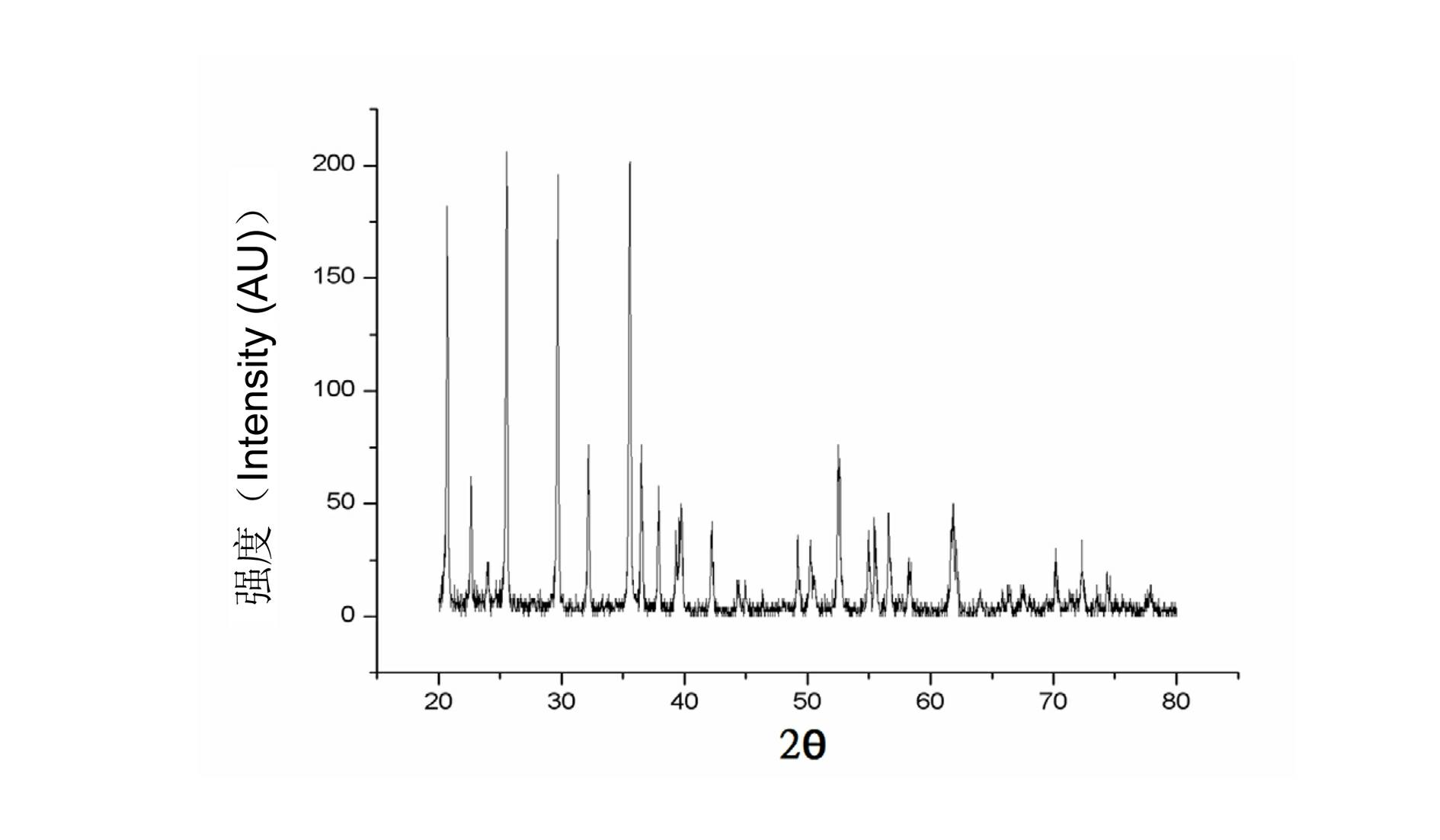

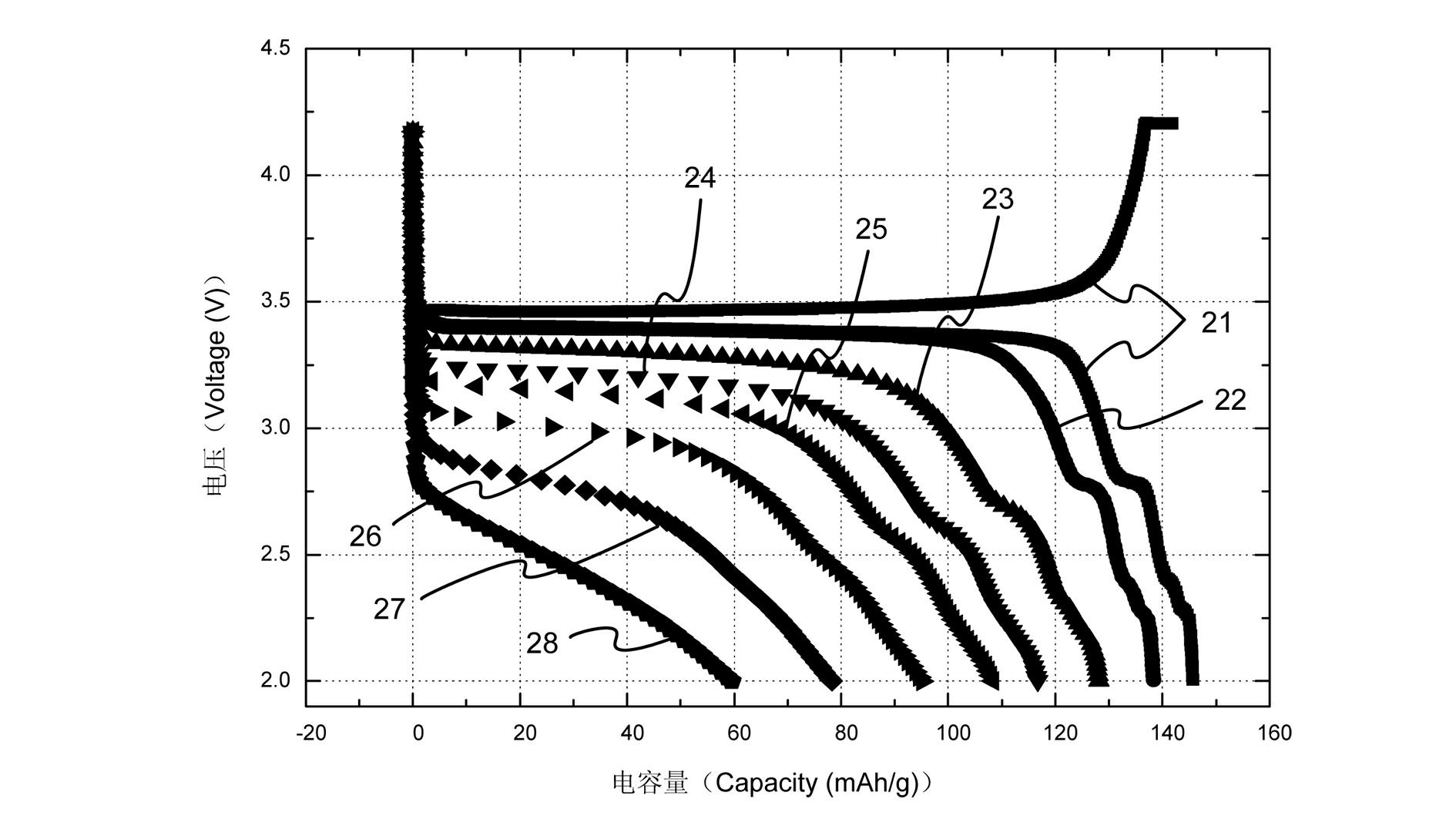

Manufacturing method for lithium iron phosphate cathode material

InactiveCN102468479ASimplify the process technologyWell mixedCell electrodesPhosphorus compoundsWater solubleCarbon source

The invention relates to a manufacturing method for a lithium iron phosphate cathode material. The reactivity and the uniformity of raw materials are improved by adopting a semi-chemical method, and the raw materials used for manufacturing lithium iron phosphate materials are divided into water-soluble raw materials and water-insoluble raw materials. The manufacturing method comprises the following steps of: firstly, dissolving the water-soluble raw materials into water, adding the water-insoluble raw materials, adding a dispersing agent, a carbon source and a compound of iron position substituting elements, and grinding and uniformly mixing the raw materials to form slurry with all components of lithium iron phosphate; secondly, preparing the uniformly mixed slurry into precursor powder in a spray granulation manner; and finally, calcining the precursor powder at the temperature of between 600 and 800 DEG C for 1 to 24 hours in reducing atmosphere, and crushing the calcined powder to obtain finished products. The manufacturing process is simple and suitable for mass production, the raw materials are uniformly mixed, the properties of the products are consistent, the prepared lithium iron phosphate has stable quality characteristics, and the products have long charge and discharge service life and higher charge and discharge capacity, so that related problems of the conventional lithium iron phosphate production are solved.

Owner:GREEN ENERGY ELECTRODE

Steel ring billet casting technique based on casting and rolling combined forming

ActiveCN104439219AReduce heating timesSave blankingMolten metal pouring equipmentsFurnace typesTemperingCasting mold

The invention discloses a steel ring billet casting technique based on casting and rolling combined forming. The steel ring billet casting technique based on casting and rolling combined forming comprises the steps that firstly, a casting mold is manufactured by means of water glass sand, the casting mold is dried and sprayed with painting, casting raw materials of a steel ring are smelted and are poured into the casting mold, and normalizing, tempering and quenching-tempering heat treatment are conducted on a steel ring billet formed through pouring; secondly, the steel ring billet is cooled to the room temperature, and polishing and machining are conducted on the cooled steel ring billet; finally, the steel ring billet which can be directly used for casting and rolling combined forming is obtained. According to the steel ring billet cast according to the technique, the defects, such as shrinkage cavities, shrinkage porosity and segregation, appearing in the steel ring billet casting process can be reduced, grains are refined to the maximum extent, and the high-quality steel ring billet capable of meeting the requirement for the ring rolling performance is manufactured; due to the fact that the processes of the casting and rolling combined forming technique are simplified, the quality and performance of the ring rolling technique and a ring workpiece are guaranteed.

Owner:盐城市大丰区生产力促进中心

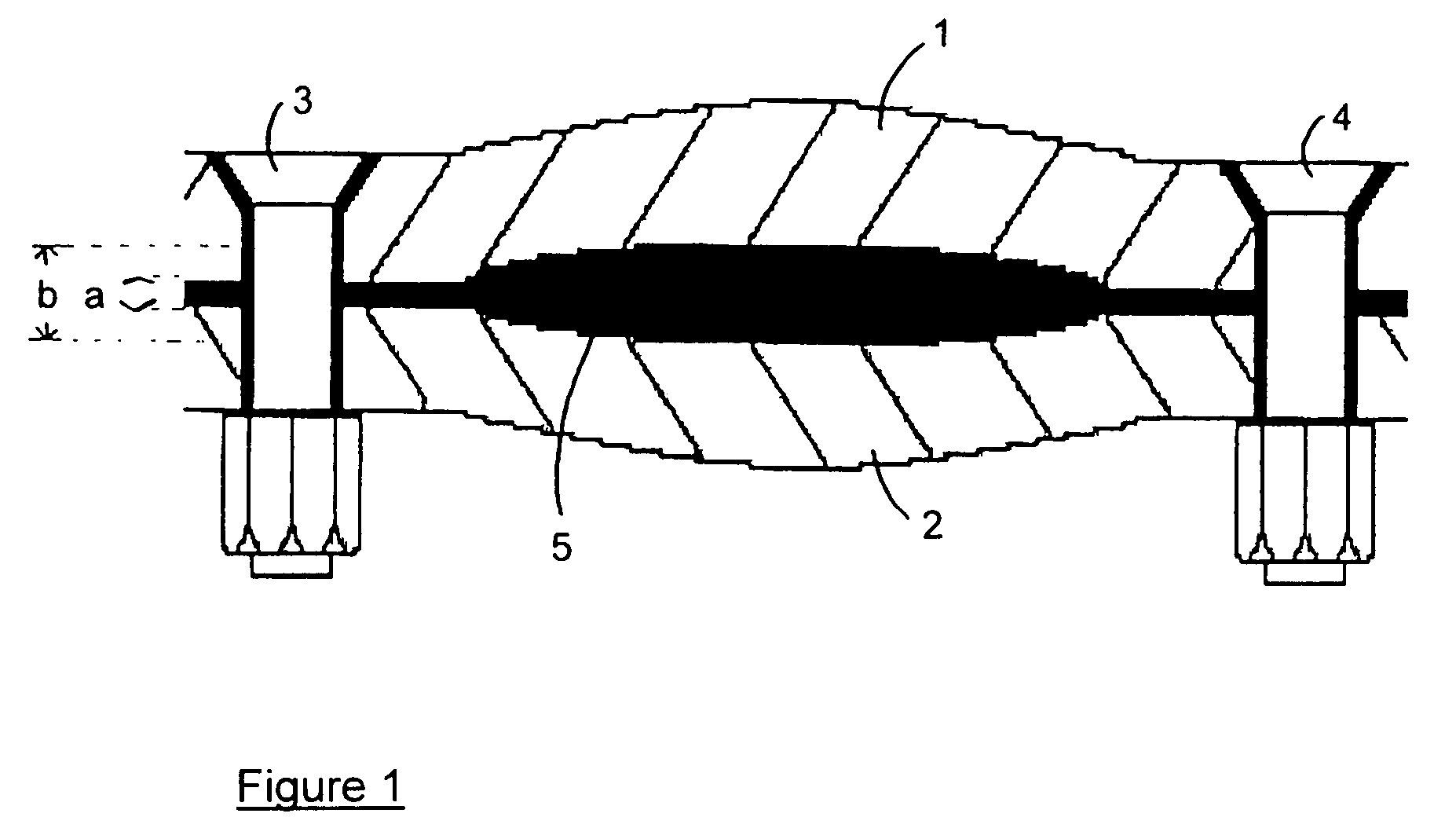

Method of sealing a joint

InactiveUS7708281B2Improve fatigue resistanceHigh load-transferringFuselage framesEngine sealsEngineeringMechanical engineering

A method of sealing a joint between components especially in an aircraft comprises the steps of identifying the sealing gap to be sealed; selecting a suitable sealing material having a fractional maximum sealing thickness and a fractional fully-compressed thickness and selecting a suitable thickness of that sealing material, based on a consideration of the fractional maximum sealing thickness and the fractional fully-compressed thickness of the sealing material and on the sealing gap; locating, between the mating surfaces of the components to be sealed, the suitable thickness of the suitable sealing material; and fastening the components together.

Owner:AIRBUS OPERATIONS LTD

Method for preparing calcium alginate based cavernous body functional material

The invention discloses a method for preparing a calcium alginate based cavernous body functional material. The method comprises the following steps of: uniformly mixing sodium alginate powder with a soluble calcium salt, magnesium salt or aluminum salt and an enhancer; sequentially forming into membranes and pieces by virtue of equipment; performing infiltration reaction and pore formation reaction to obtain the material, wherein the sodium alginate powder, the soluble calcium salt, magnesium salt or aluminum salt and the enhancer are 10-65 to 7-30 to 15-35 to 10-30 in percentage by weight. The method is simple in process control and has less equipment investment, and sewage discharge is basically avoided; the prepared functional material is a cavernous body having a nanometer structure, has the characteristics of high consistency of internal structure and external structure and composition, high imbibition air permeability, powerful mechanical strength, high flexibility and elasticity and the like, and can be used as medical auxiliaries, antibacterial materials, flame-resistant materials, absorption materials and sound-absorbent materials, vibration-absorptive materials and the like.

Owner:QINGDAO UNIV

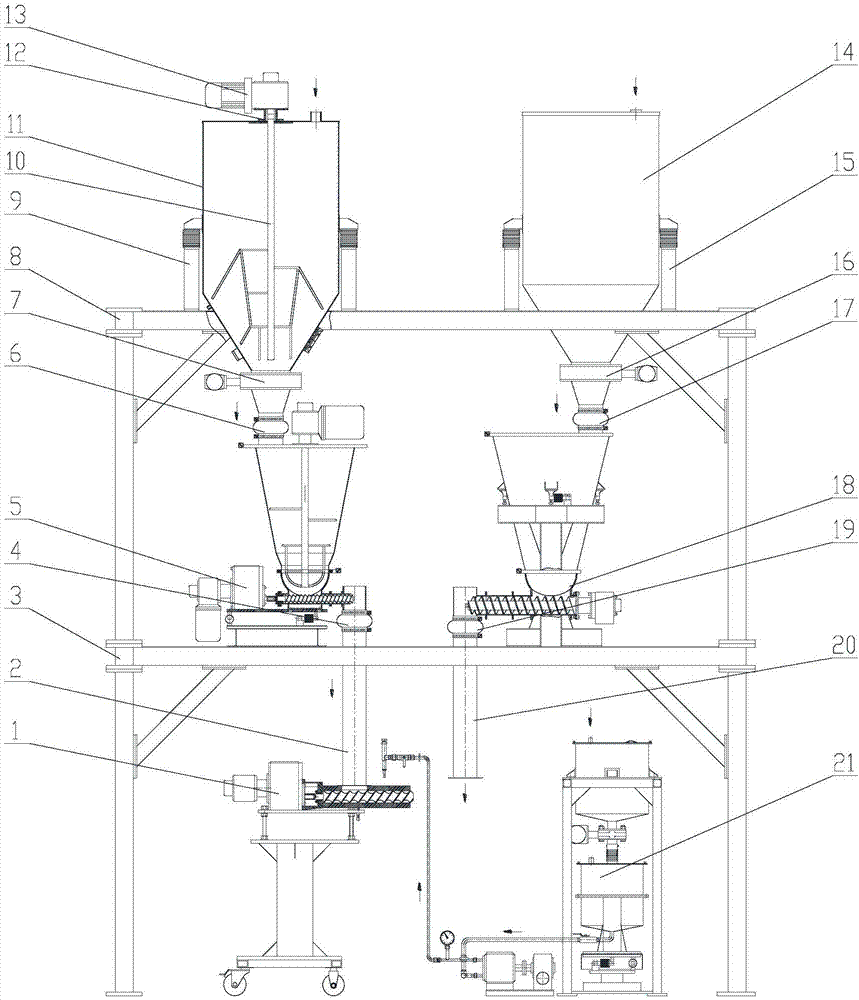

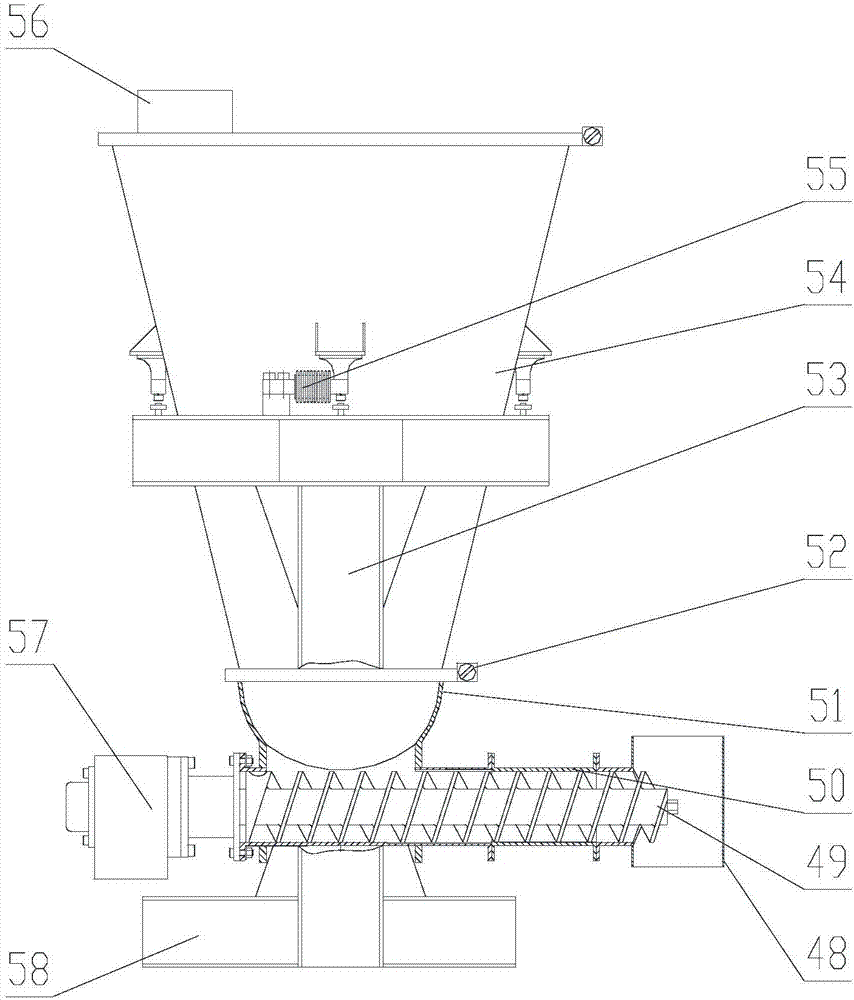

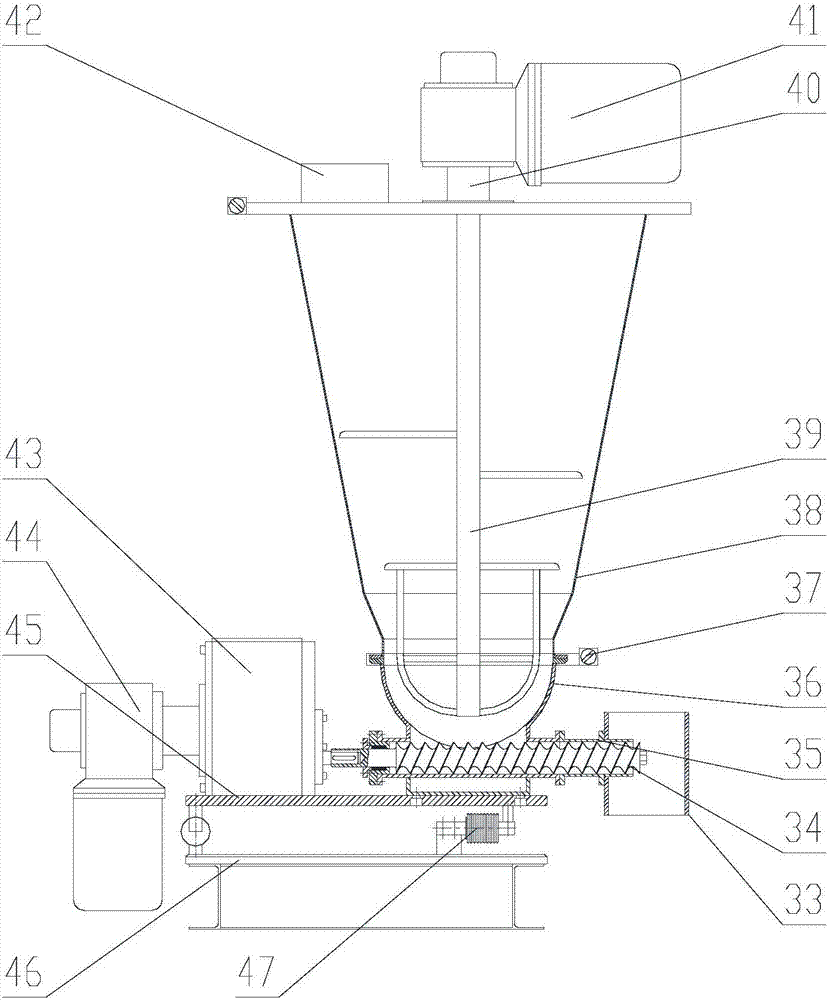

Lose-in-weigh continuous weighing-metering feeding system

The invention discloses a lose-in-weigh continuous weighing-metering feeding system. The lose-in-weigh continuous weighing-metering feeding system comprises a raw material bin II, a raw material bin I, a lose-in-weigh single-screw metering feeding machine, a lose-in-weigh double-screw metering feeding machine, a forcible side feeding machine and a lose-in-weigh liquid metering feeding machine, wherein the lose-in-weigh single-screw metering feeding machine comprises a weighing hopper II, a single-screw spherical feeding body, a single-screw feeding barrel and a weighing sensor II; the lose-in-weigh double-screw metering feeding machine comprises a weighing hopper I, a double-screw spherical feeding body, a double-screw feeding barrel and a weighing sensor I; the forcible side feeding machine comprises a side feeding barrel; and the lose-in-weigh liquid metering feeding machine comprises a liquid raw material bin, a weighing hopper III, a liquid metering pump and a weighing sensor III. The feeding system disclosed by the invention is adaptive to meet many weighing-metering feeding machines with different material states, high in shock resistance, and capable of preventing the 'bridging' phenomenon of powder materials, and ensuring the feeding continuity.

Owner:NANJING GIANT MACHINERY

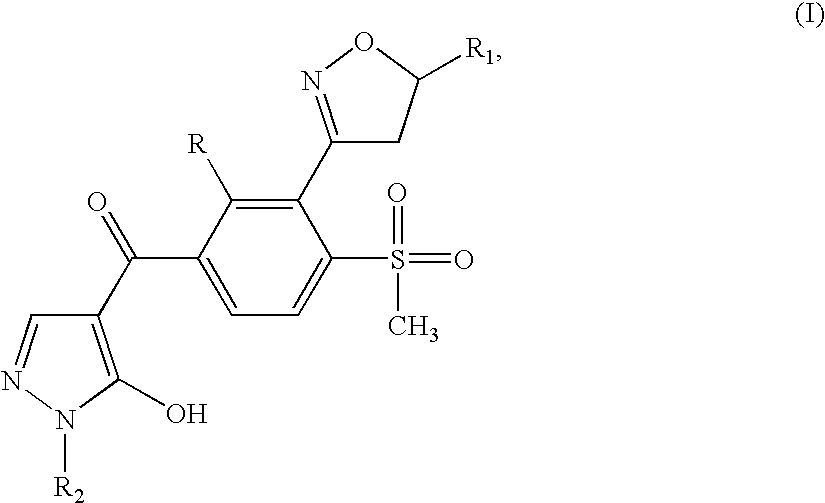

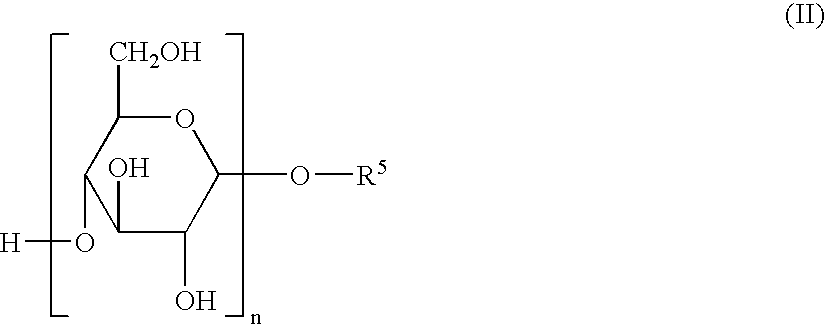

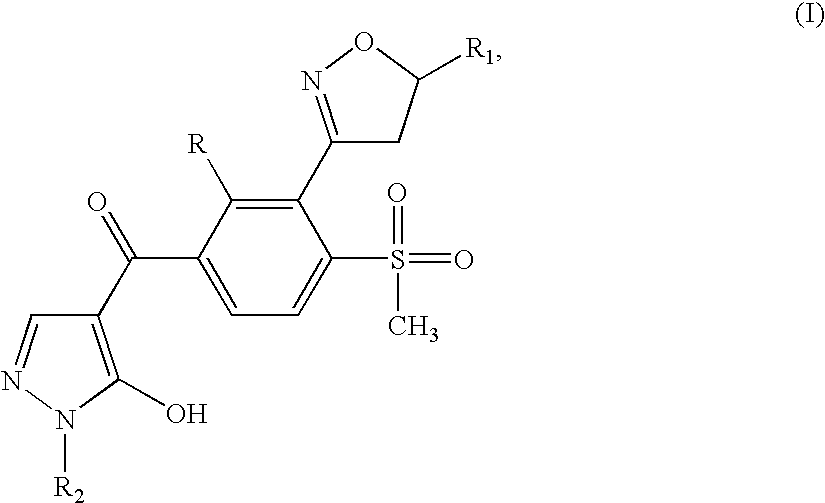

Herbicidal Composition

ActiveUS20070197387A1Consistent performanceBe consistentBiocideDead animal preservationPharmaceutical preservativesParaffin oils

A herbicidal composition comprising, in addition to customary inert formulation excipients, as a mixture of at least one soil-applied herbicide and a lipophilic additive consisting of a paraffin oil derived from the refined fraction of petroleum oil with a distillation range at 10 mm Hg of about 190 °C. to about 280 °C. and with a carbon number distribution from about C13 to about C55.

Owner:SYNGENTA CROP PROTECTION INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com