Medium-to-high grade neodymium-iron-boron magnet with composite addition of gadolinium and holmium

A compound additive and high-grade technology, applied in the direction of magnetic objects, magnetic materials, inductors/transformers/magnets, etc., can solve the problem of increasing the production cost of medium and high-performance NdFeB magnets, and can not effectively reduce production costs, squareness and magnetic energy To solve the problem of low product quality, to alleviate the shortage of raw materials, shorten the production cycle, and improve the powder output speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

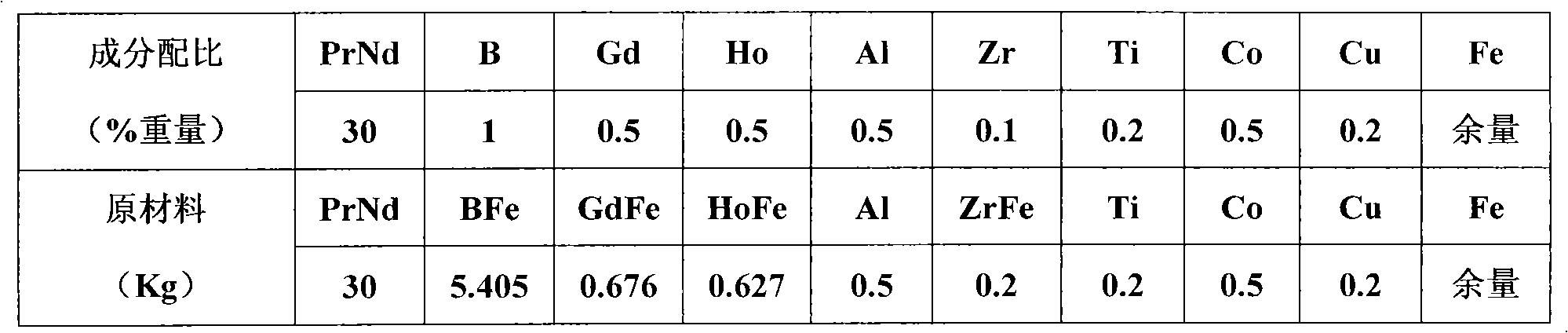

[0026] Ingredients: ingredients according to the following ratio (each component is weight percentage): 30% praseodymium neodymium alloy (praseodymium content is 25%), 1% boron, 0.5% gadolinium, 0.5% holmium, 0.5% aluminum, 0.1% zirconium , 0.2% titanium, 0.5% cobalt, 0.2% copper, and the balance is a small amount of unavoidable impurities in iron and materials; in order to reduce the melting point of the ingredients, boron, gadolinium, holmium, zirconium and other substances are used to ensure the weight of each of the above ingredients in the ingredients When the percentage is constant, it is added in the form of alloy; boron iron alloy, wherein the weight percentage of boron is 18.5%; gadolinium iron alloy, wherein the weight percentage of gadolinium is 74%; holmium iron alloy, wherein the weight percentage of holmium is 79.8%; zirconium Iron alloy in which zirconium is 50% by weight.

[0027] Taking the smelting of 100Kg NdFeB alloy as an example, the distribution ratio of...

Embodiment 2

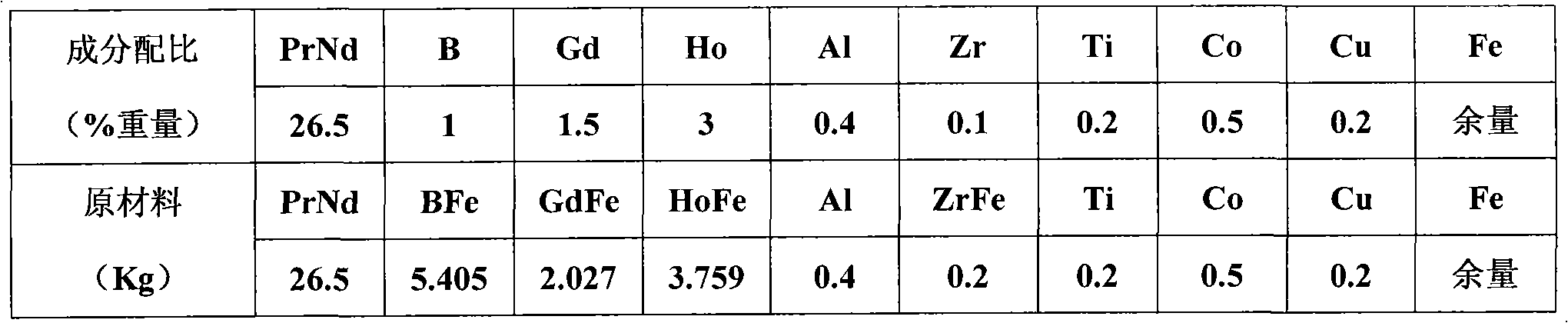

[0040]Ingredients: ingredients according to the following ratio: 26.5% praseodymium neodymium alloy (wherein the weight percentage of neodymium is 75%), 1% boron, 1.5% gadolinium, 3% holmium, 0.4% aluminum, 0.1% zirconium, 0.2% titanium, 0.5% % cobalt, 0.2% copper, and the balance is iron; in order to reduce the melting point of the ingredients, boron, gadolinium, holmium, zirconium and other substances are added in the form of alloys under the condition that the above-mentioned respective weight percentages in the ingredients are kept constant; boron Iron alloys containing 18.5% by weight of boron; iron-gadolinium alloys containing 74% by weight of gadolinium; iron-holmium alloys containing 79.8% by weight of holmium; iron-zirconium alloys containing 50% by weight of zirconium.

[0041] Taking the smelting of 100Kg NdFeB alloy as an example, the distribution ratio of each component is shown in Table 2-1:

[0042] Each component distribution ratio in the embodiment one of tabl...

Embodiment 3

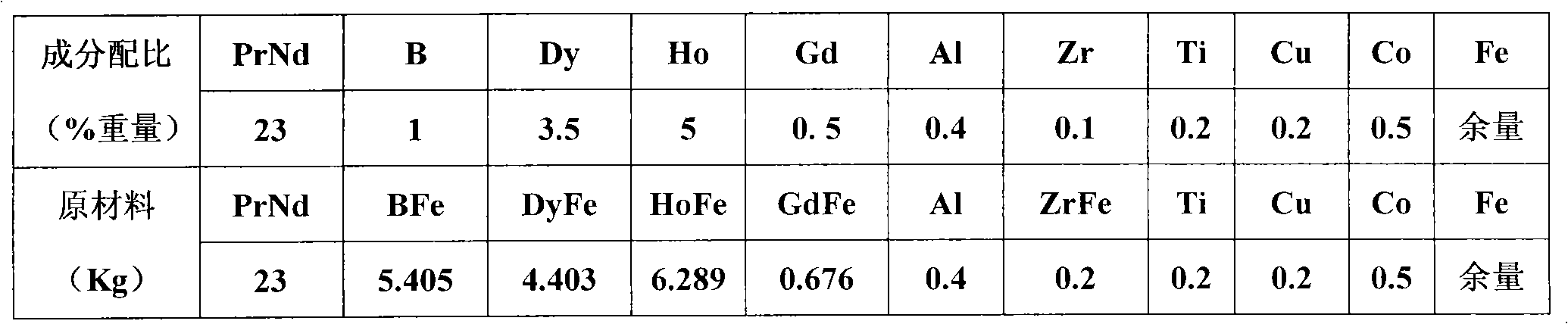

[0051] Ingredients: ingredients according to the following ratio: 23% praseodymium neodymium alloy (wherein the weight percentage of neodymium is 75%), 1% boron, 3.5% dysprosium, 5% holmium, 0.5% gadolinium, 0.4% aluminum, 0.1% zirconium, 0.2 %titanium, 0.2% copper, 0.5% cobalt, and the balance is iron; in order to reduce the melting point of ingredients, boron, dysprosium, gadolinium, holmium, zirconium and other materials are used under the condition that the above-mentioned respective weight percentages in the ingredients are constant. The form of alloy is added; Boron iron alloy, wherein the weight percentage of boron is 18.5%; Dysprosium iron alloy, wherein the weight percentage of dysprosium is 79.5%; Gadolinium iron alloy, wherein the weight percentage of gadolinium is 74%; Holmium iron alloy, wherein the weight percentage of holmium is 79.8%; zirconium iron alloy, wherein the weight percentage of zirconium is 50%.

[0052] Taking the smelting of 100Kg NdFeB alloy as an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com