Compound vibrator line ultrasonic electromotor

A linear ultrasonic motor and composite vibrator technology, applied in the field of electric motors, can solve the problems of difficult to achieve linear ultrasonic motor thrust, small elliptical motion trajectory of the driving head, low motor working efficiency, etc., and achieve a simple structure, large driving force and consistent performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with drawings and embodiments.

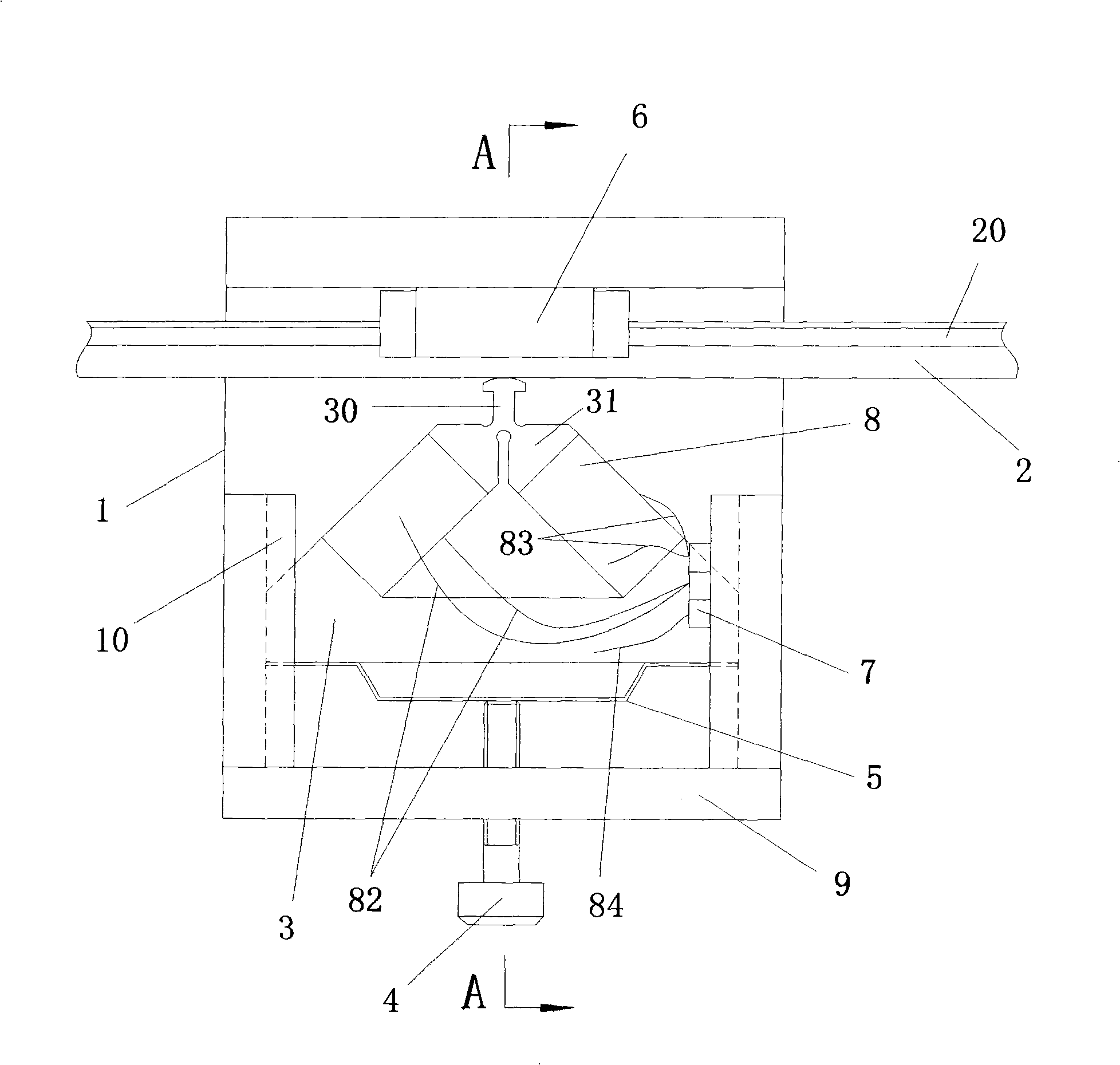

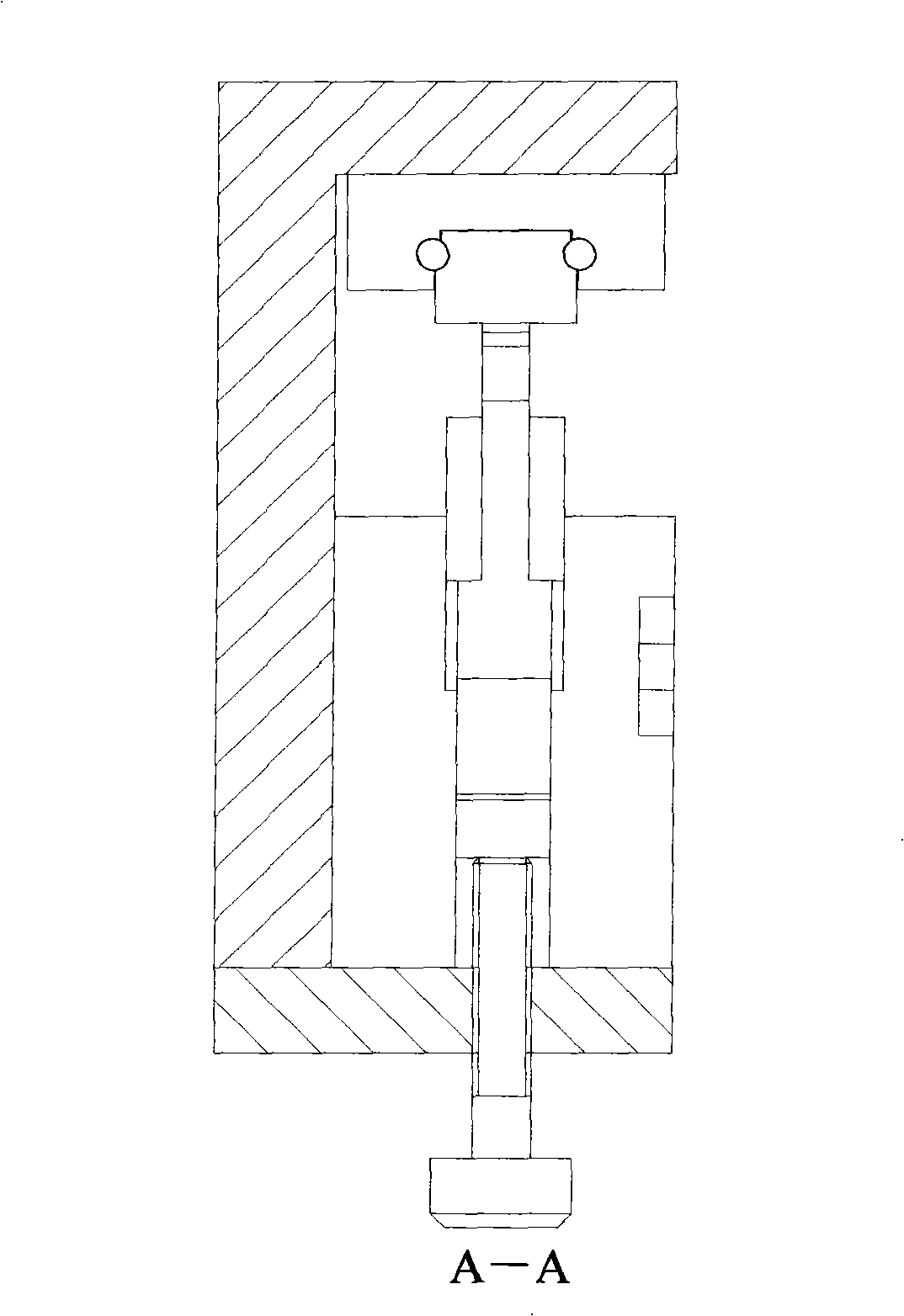

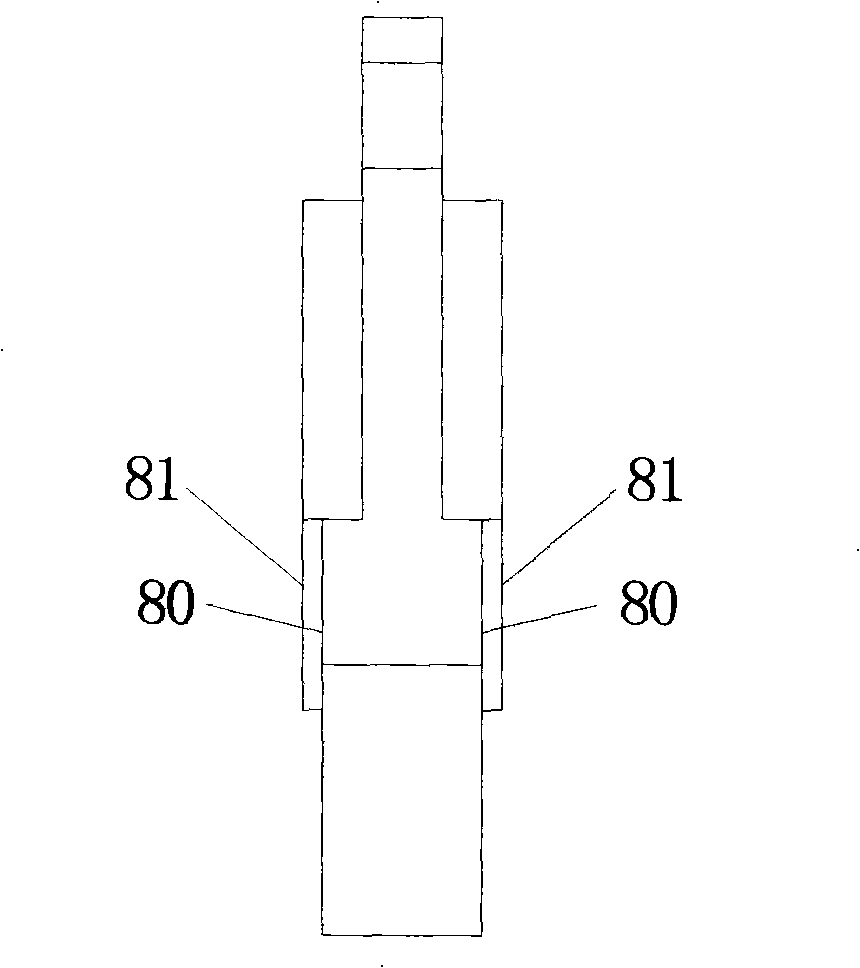

[0023] Such as figure 1 , figure 2 The composite vibrator linear ultrasonic motor shown includes frame 1, mover 2, vibrator 3, pre-tightening screw 4 and leaf spring 5, slide seat 6 and hub 7 are fixed inside frame 1, and mover 2 is movable and installed On the sliding seat 6 , the mover 2 is a linear slide rail with guide grooves 20 on the front and rear surfaces, and the guide grooves 20 cooperate with the sliding seat 6 . The vibrator 3 is a metal elastic body of a right-angled isosceles triangle, and a shifting tooth 30 is provided at the right angle. In contact with the leaf spring 5 , the pre-tightening screw 4 is installed on the lower cover plate 9 of the frame 1 and contacts with the leaf spring 5 .

[0024] The two side plates of the frame 1 are provided with installation grooves 10 , and the vibrator 3 is placed in the two installation grooves 10 . The t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com