Lose-in-weigh continuous weighing-metering feeding system

A technology for metering and feeding, which is applied in the field of loss-in-weight continuous weighing and metering feeding systems, can solve the problems of inconvenient disassembly and installation of metering feeders, shaking of weighing hoppers, and prolonging the feeding process, so as to facilitate assembly and assembly. And dismantling maintenance and cleaning, feeding stability, ensure the effect of continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further explained below in conjunction with the drawings.

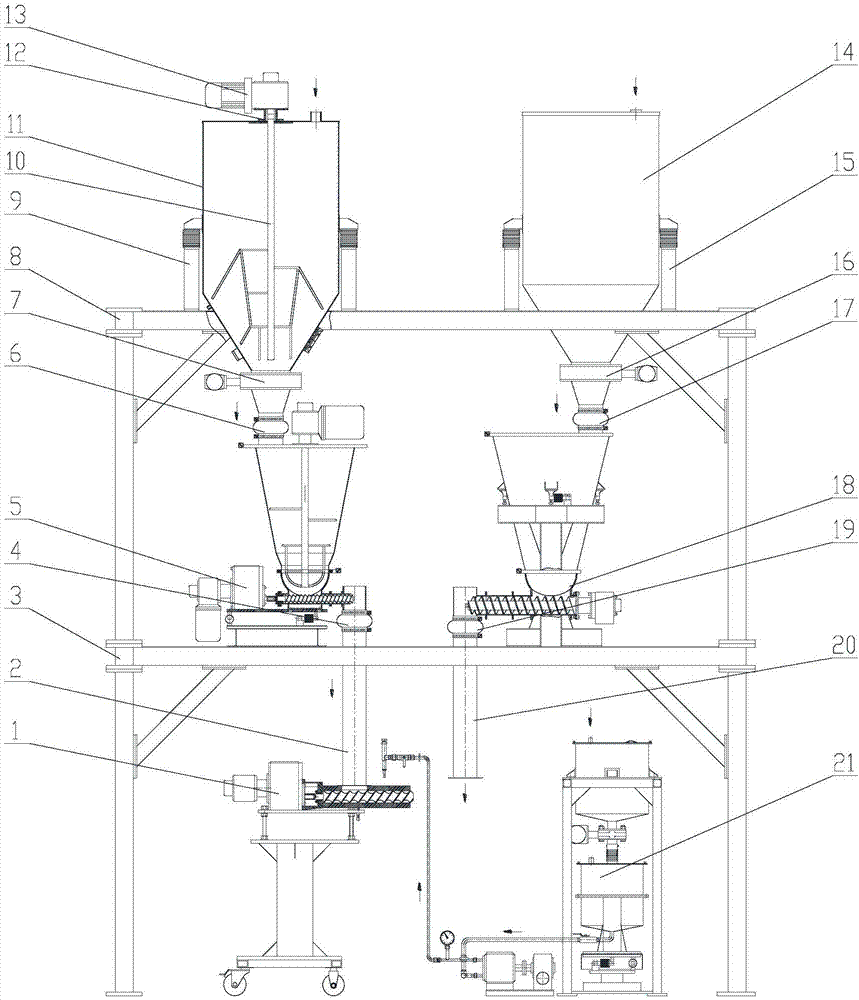

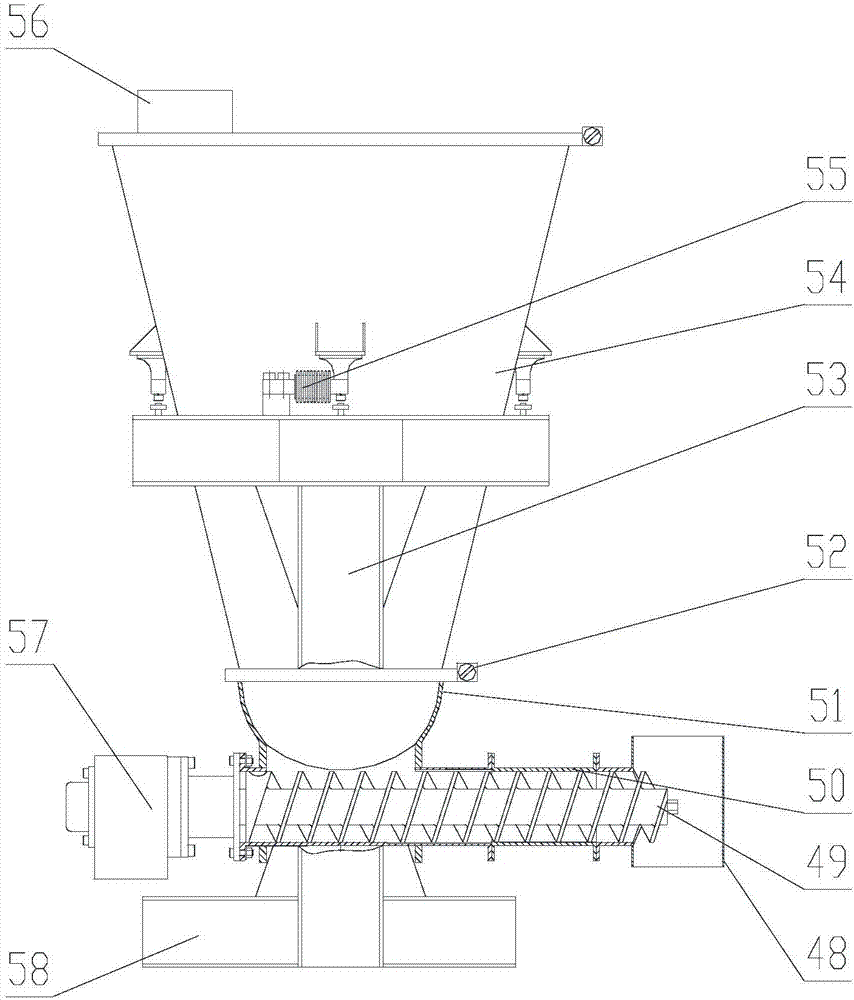

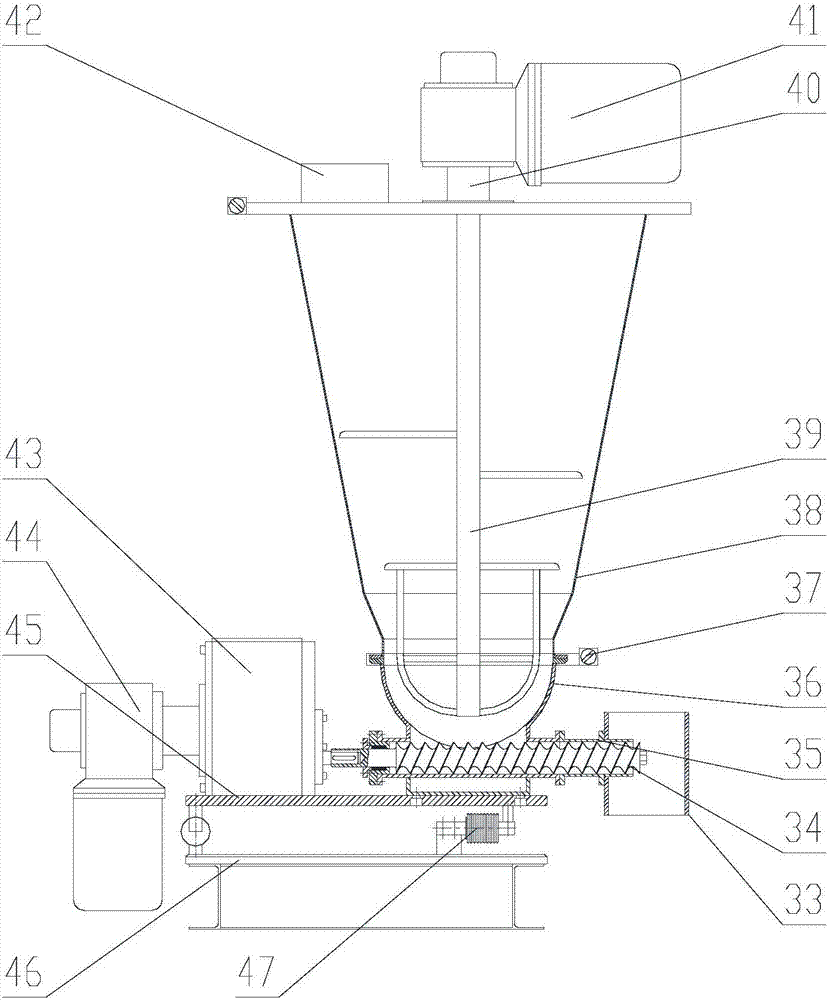

[0038] Such as Figure 1 to 5 As shown, a loss-in-weight continuous weighing metering feeding system of the present invention includes a raw material warehouse II14, a loss-in-weight single screw metering feeder 18, a raw material warehouse I11, a loss-in-weight twin screw metering feeder 5, and a forced side feeding Feeder 1, loss-in-weight liquid metering feeder 21, wherein the raw material warehouse II14 is installed on the platform of the two-story steel frame platform 8 through the support column II15, and the loss-in-weight single-screw metering feeder 18 passes through the single-screw feeder base 58 is installed on the platform of the steel frame platform 3 on the first floor, the raw material warehouse I11 is installed on the platform of the steel frame platform 8 on the second floor through the support column I9, and the loss-in-weight twin-screw metering feeder 5 is install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com