Method for preparing copolyether ester elastomer

A technology of copolyetherester and elastomer, which is applied in the field of preparation of copolyetherester elastomer, can solve the problems of high price, difficult separation and extraction of tetrahydrofuran, etc., and achieve the effect of low cost and consistent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

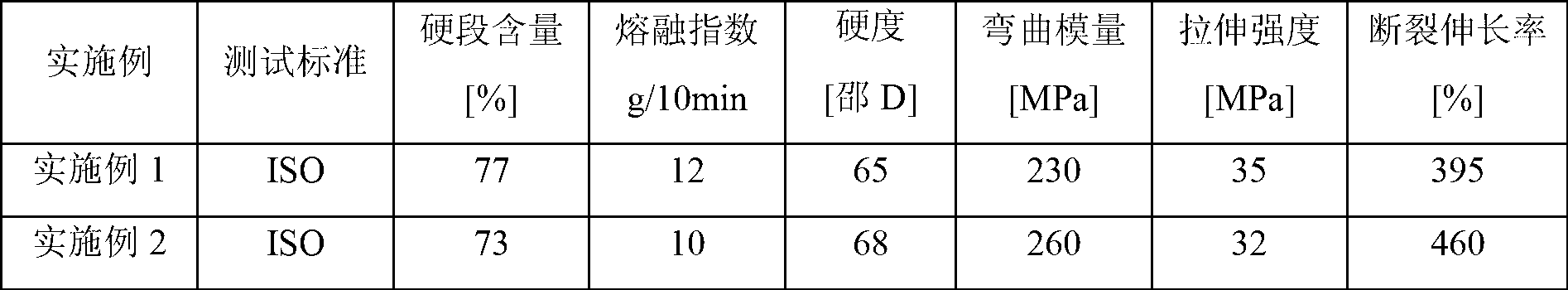

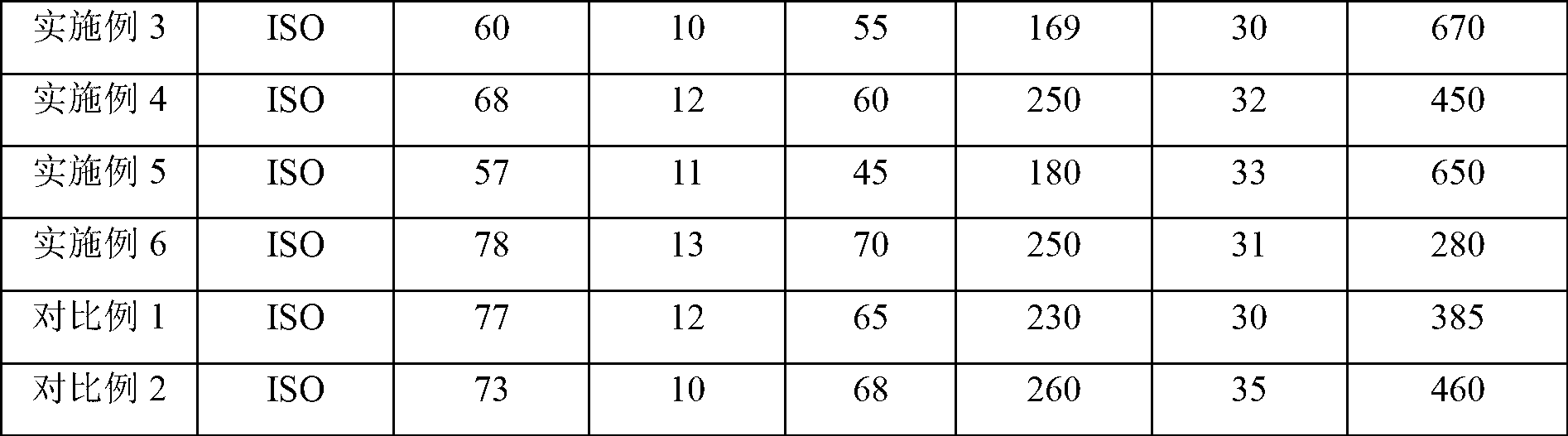

Examples

Embodiment 1

[0033] A method for preparing copolyetherester elastomer, comprising the following steps:

[0034] (1) Esterification: Add 26g (0.126mol) of terephthalic acid (PTA), 25g (0.278mol) of 1,4-butanediol (BDO) and polytetramethylene ether glycol (Mn= 1000) 10g (0.01mol), at the same time add 10mg tetrabutyl titanate and raise the temperature at 235-240°C and carry out the esterification reaction under the pressure of 80kPa, and the reaction time is two hours. After the reaction is completed, the by-product tetrahydrofuran and water are removed to obtain an esterified product; the mixture of tetrahydrofuran and water is purified by rectification to obtain high-purity tetrahydrofuran;

[0035] (2) Prepolymerization reaction: After the esterification reaction, 10 mg of antioxidant 1010 and 10 mg of tetrabutyl titanate were added to the esterified product, the temperature was 238° C., the pressure was 6 kPa, and the reaction was carried out for 1 hour.

[0036] (3) Polycondensation reac...

Embodiment 2

[0038] A method for preparing copolyetherester elastomer, comprising the following steps:

[0039] (1) Esterification: Add 46g (0.277mol) of PTA, 60g (0.666mol) of BDO and 10g (0.01mol) of polytetramethylene ether glycol (Mn=1000) into the flask, and add 20mg of tetrabutyl titanate at the same time Elevate the temperature at 235-240° C. and carry out the esterification reaction at a pressure of 80 kPa, and the reaction time is two hours. After the reaction is completed, the by-product tetrahydrofuran and water are removed to obtain an esterified product; the mixture of tetrahydrofuran and water is purified by rectification to obtain high-purity tetrahydrofuran;

[0040] (2) Prepolymerization reaction: After the esterification reaction, 20 mg of antioxidant 1010 and 20 mg of tetrabutyl titanate were added to the esterified product, the temperature was 238° C., the pressure was 6 kPa, and the reaction was carried out for 1 hour.

[0041] (3) Polycondensation reaction: transfer ...

Embodiment 3

[0043] A method for preparing copolyetherester elastomer, comprising the following steps:

[0044] (1) Esterification: Add 5.8kg (34.9mol) of PTA, 0.2kg (1.2mol) of isophthalic acid, 7kg (77.8mol) of BDO and 5kg of polytetramethylene ether glycol (Mn=1000) into the flask (5mol), while adding 5g of tetrabutyl titanate, the temperature is raised at 235-240°C and the pressure is 80kPa to carry out the esterification reaction, and the reaction time is two hours. After the reaction is completed, the by-product tetrahydrofuran and water are removed to obtain an esterified product; the mixture of tetrahydrofuran and water is purified by rectification to obtain high-purity tetrahydrofuran;

[0045] (2) Prepolymerization reaction: After the esterification reaction, 10 g of antioxidant 1010 and 20 g of tetrabutyl titanate were added to the esterified product at a temperature of 238° C. and a pressure of 6 kPa for 1 hour of reaction.

[0046] (3) Polycondensation reaction: transfer the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com