Patents

Literature

373results about How to "Low equipment cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

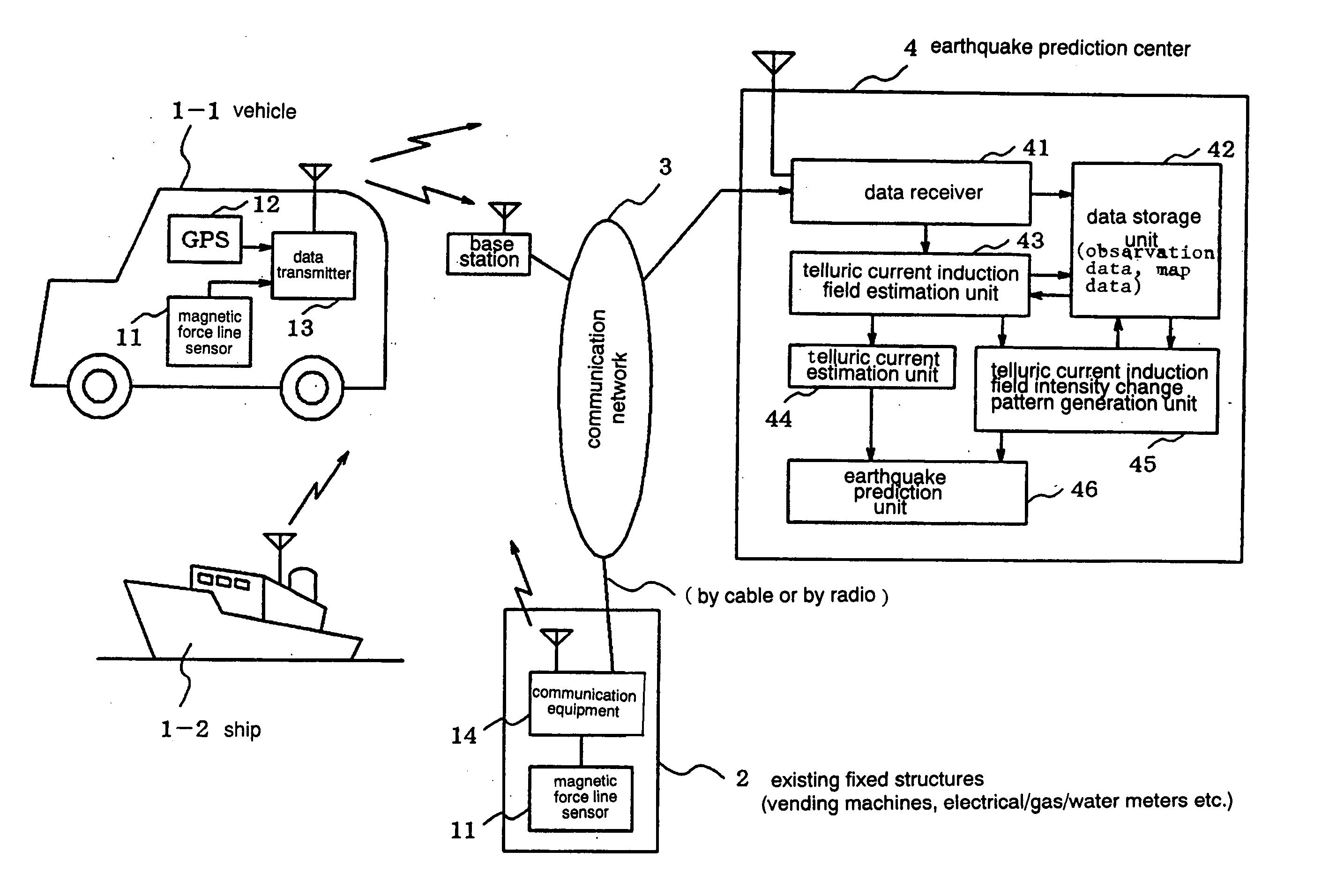

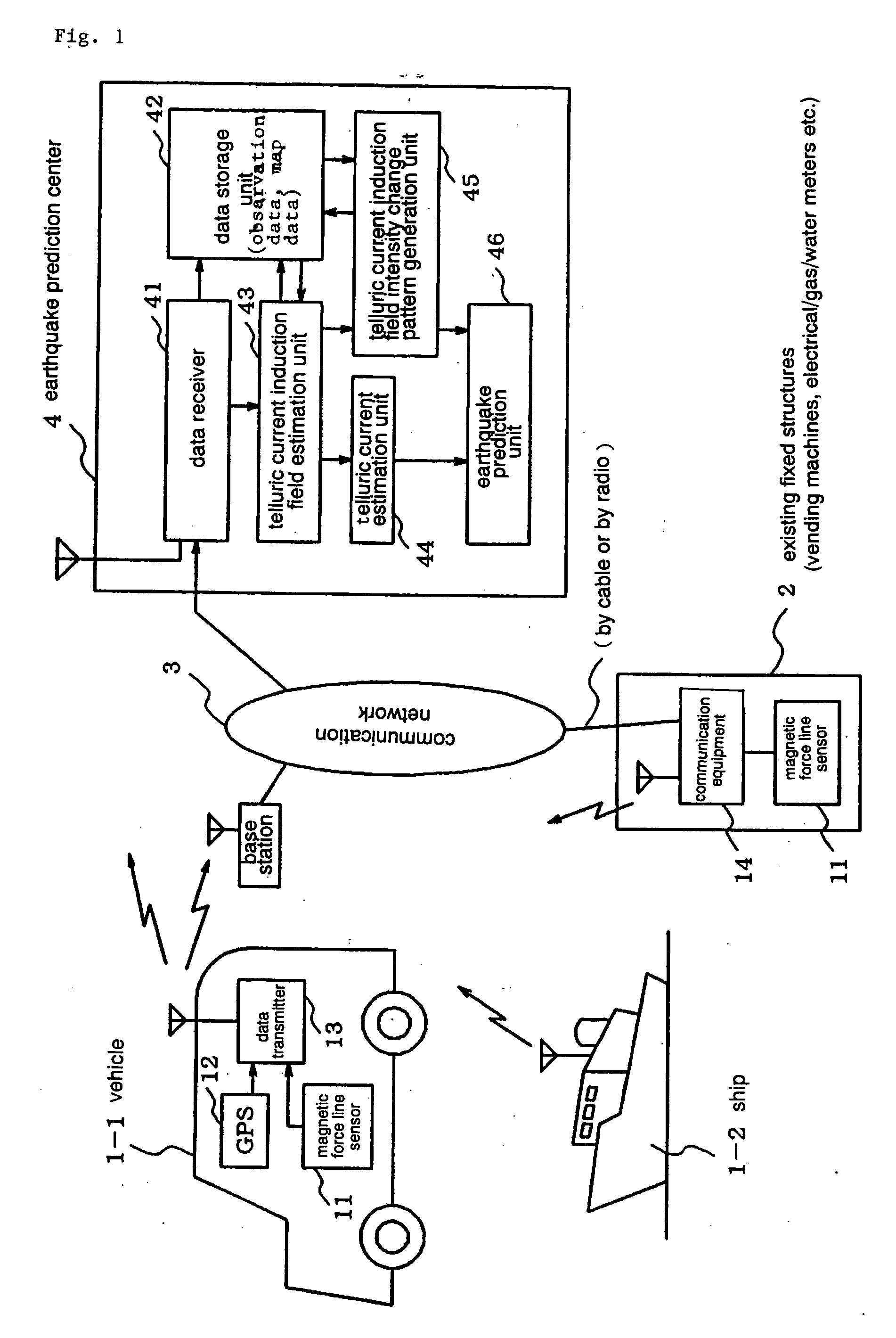

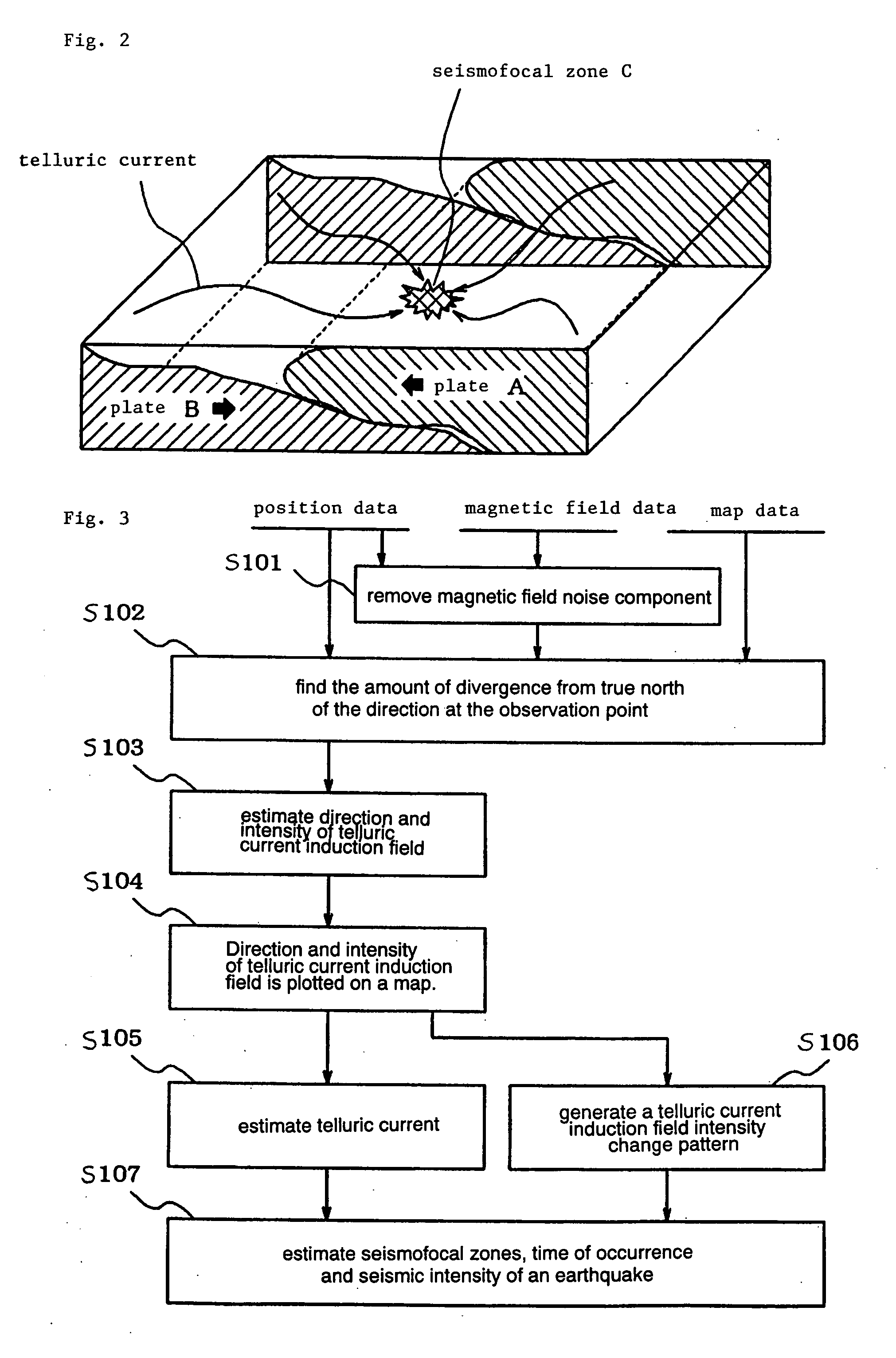

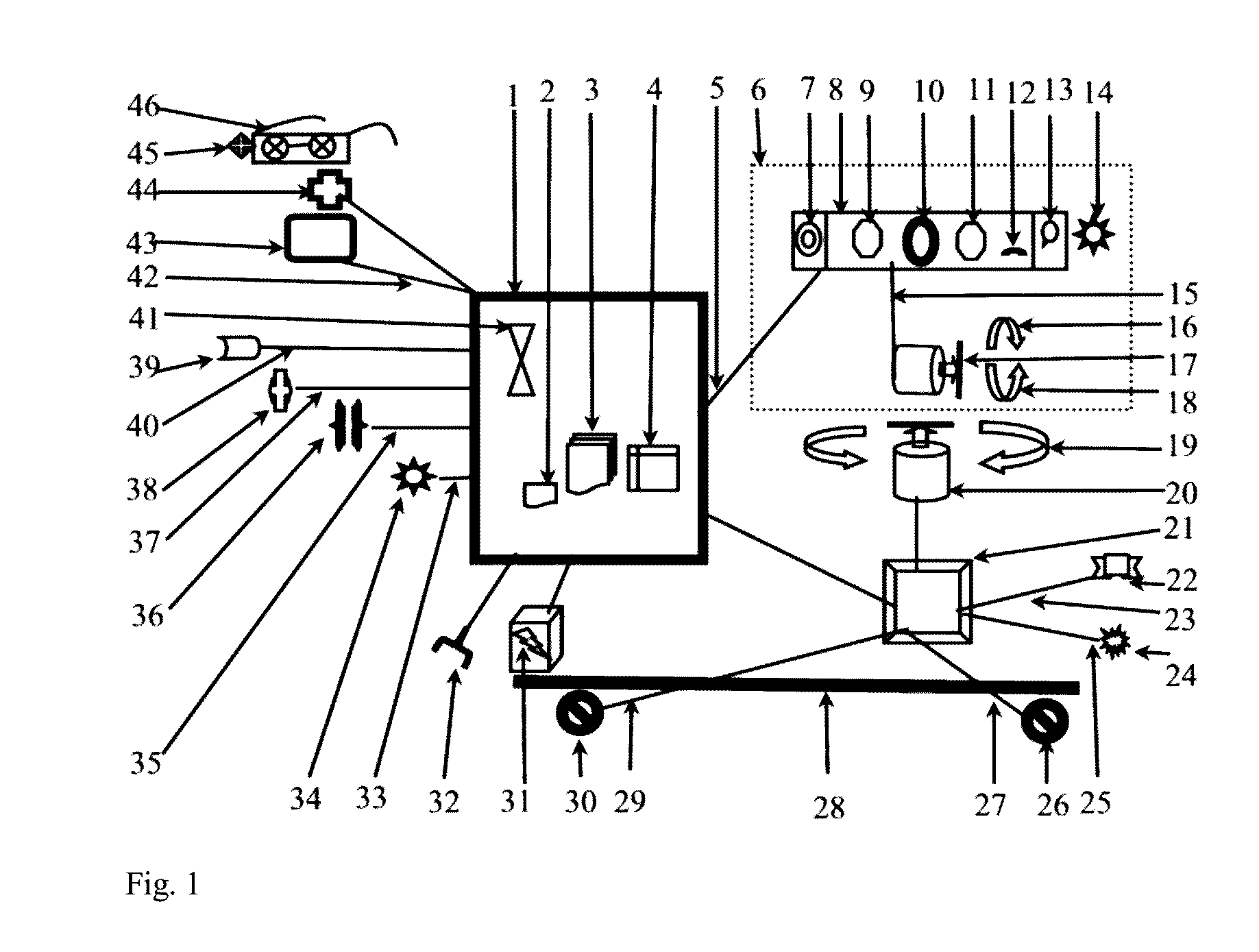

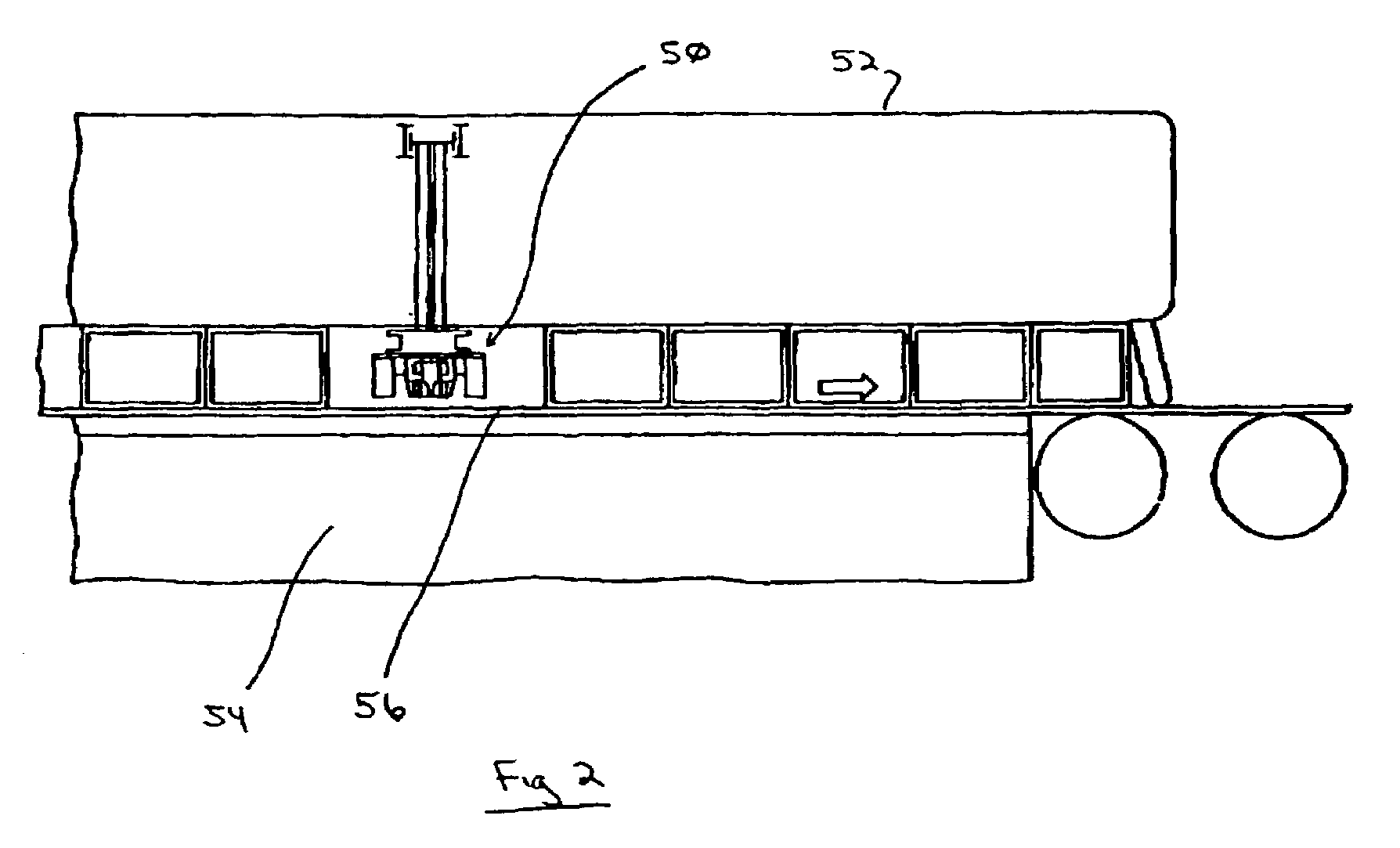

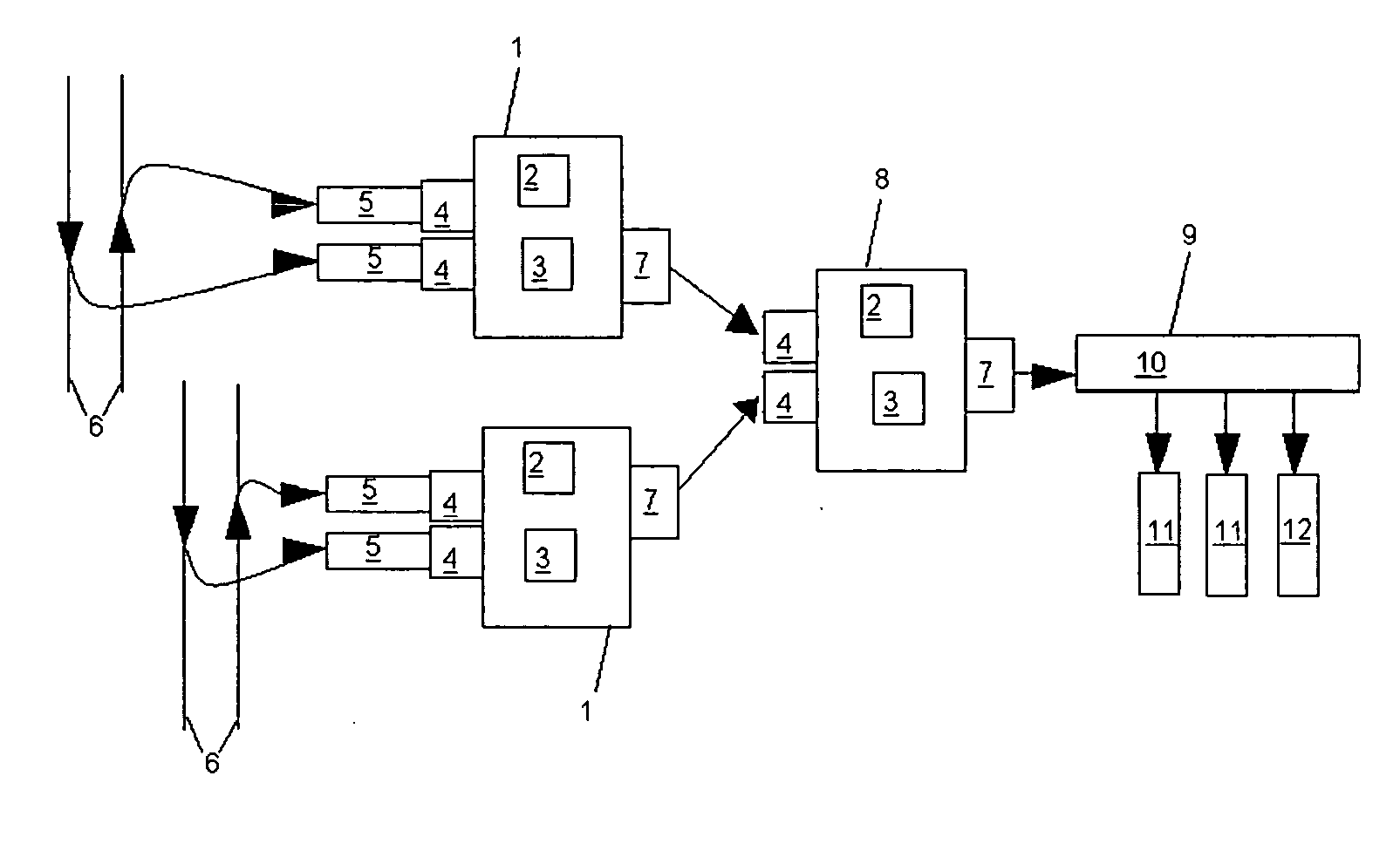

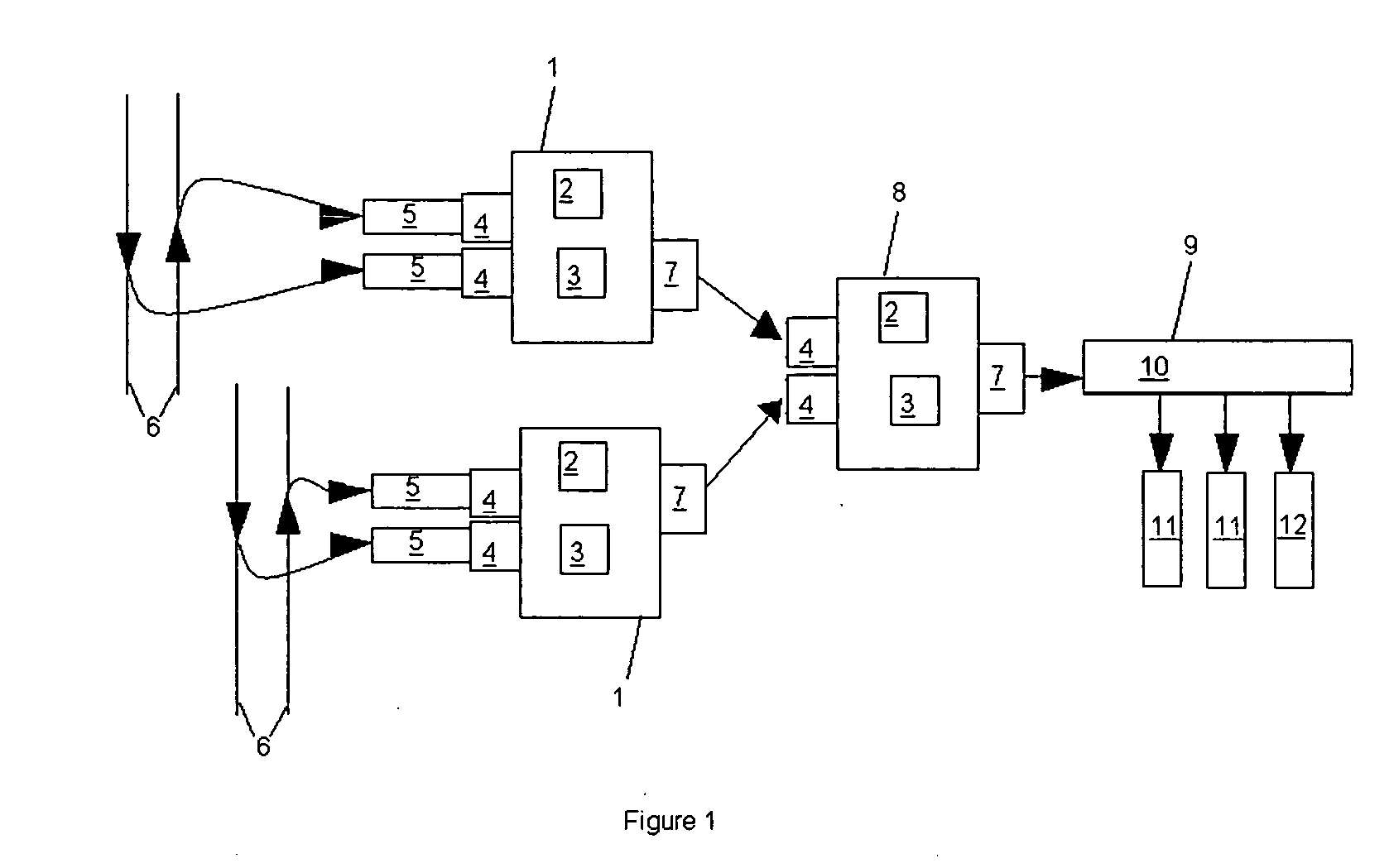

Earthquarke prediction method and system thereof

InactiveUS20050280421A1Low costAccurate predictionEarthquake measurementSeismic signal processingEarthquake predictionTransmitter

Vehicles (1-1) or ships (1-2) each carry a magnetic force line sensor (11), a GPS position detector (12), and a data transmitter (13) and travel within an observation area transmitting magnetic field data and position data of each point to an earthquake prediction center (4). A telluric current induction field estimation unit (43) of the earthquake prediction center (4) estimates telluric current induction fields based on the observation data that it receives and collects. A telluric current estimation unit (44) estimates telluric currents based on the results of estimating the telluric current induction fields. A telluric current induction field intensity change pattern generation unit (45) generates patterns that indicate the change over time of the intensity of telluric current induction fields. An earthquake prediction unit (46) analyzes the state of distribution of the telluric currents and the patterns of change in the intensities of the telluric current induction fields and estimates a seismofocal zone, seismic intensity, and time of occurrence of a seismic event.

Owner:NEC MOBILING LTD

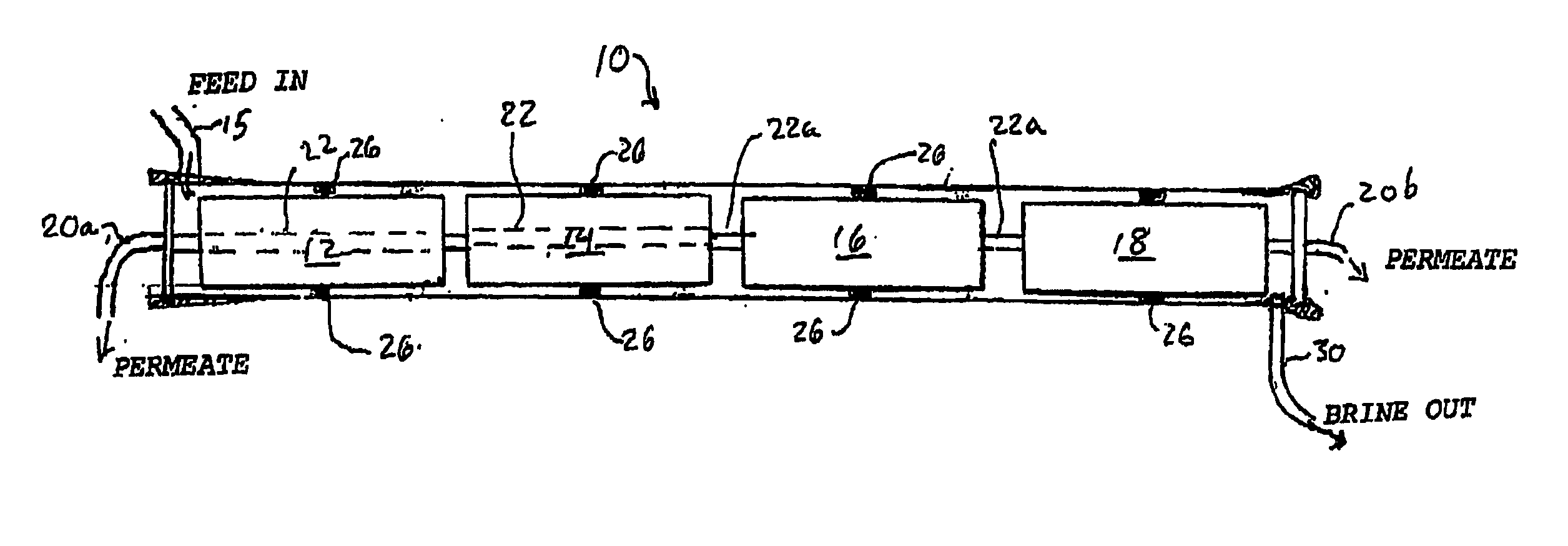

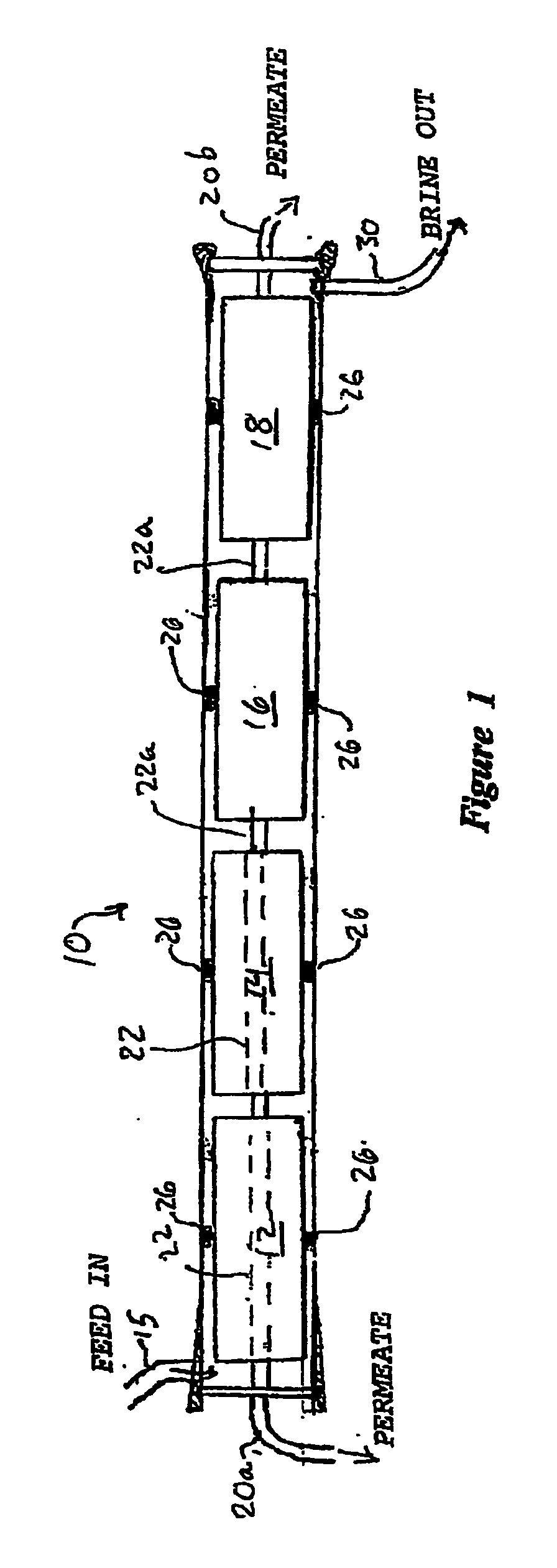

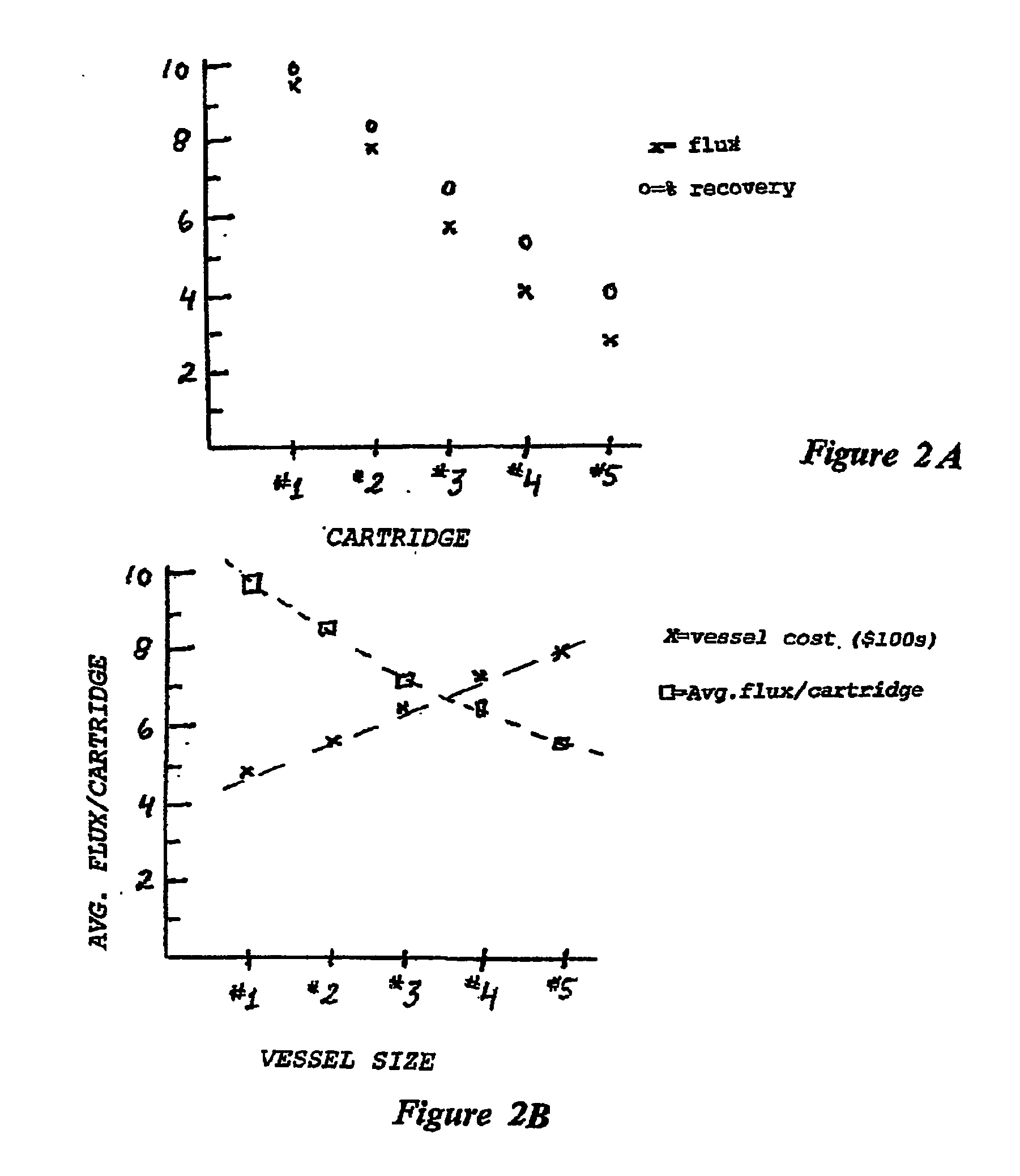

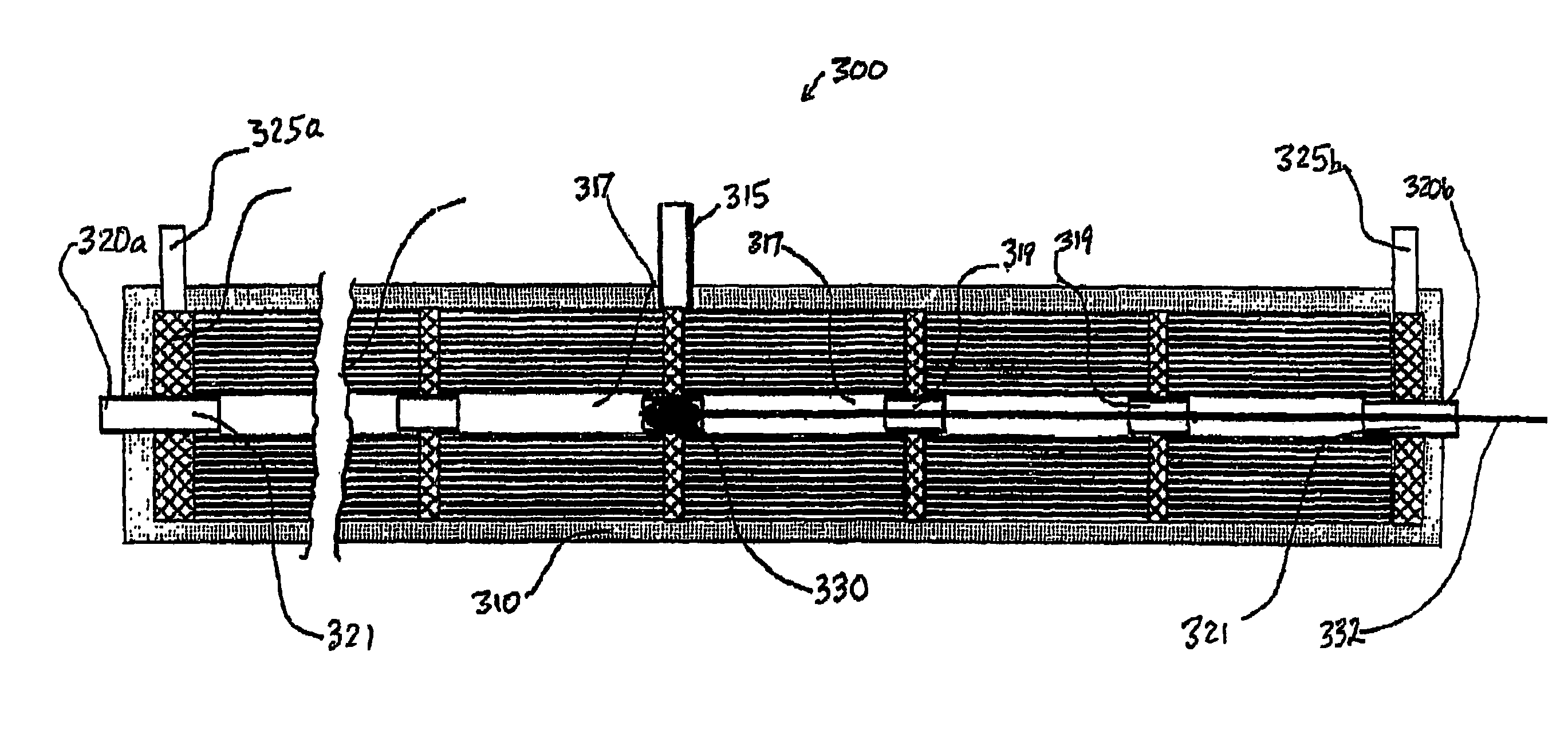

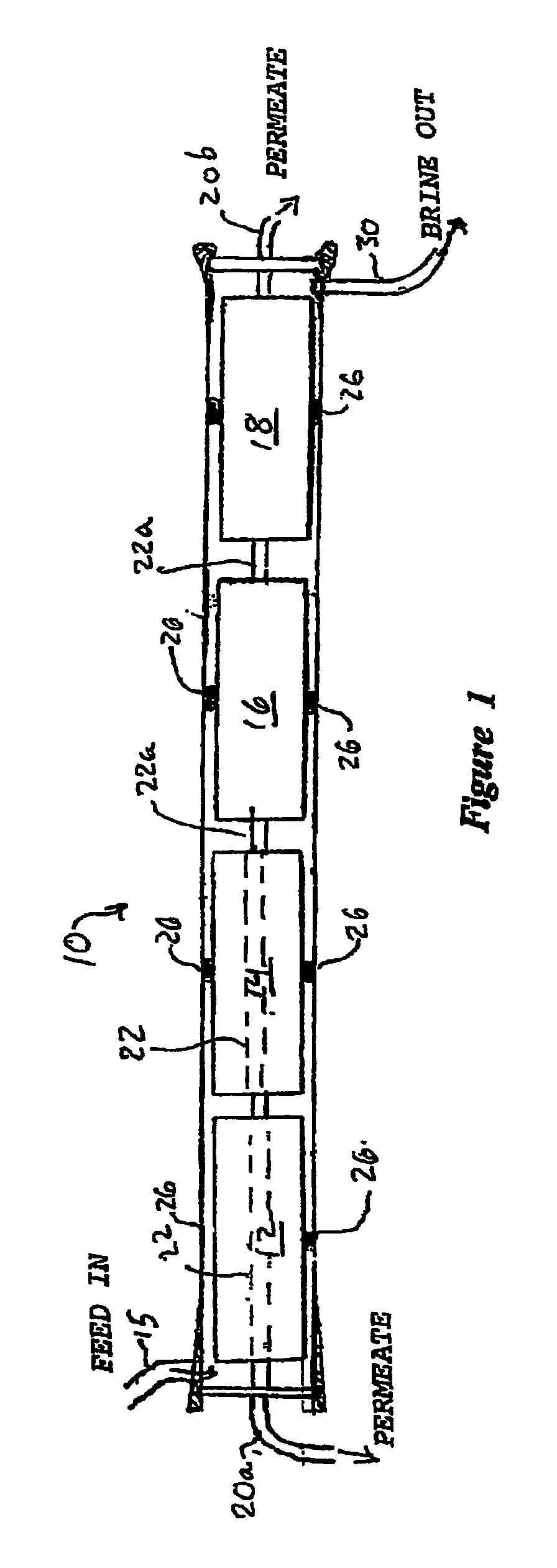

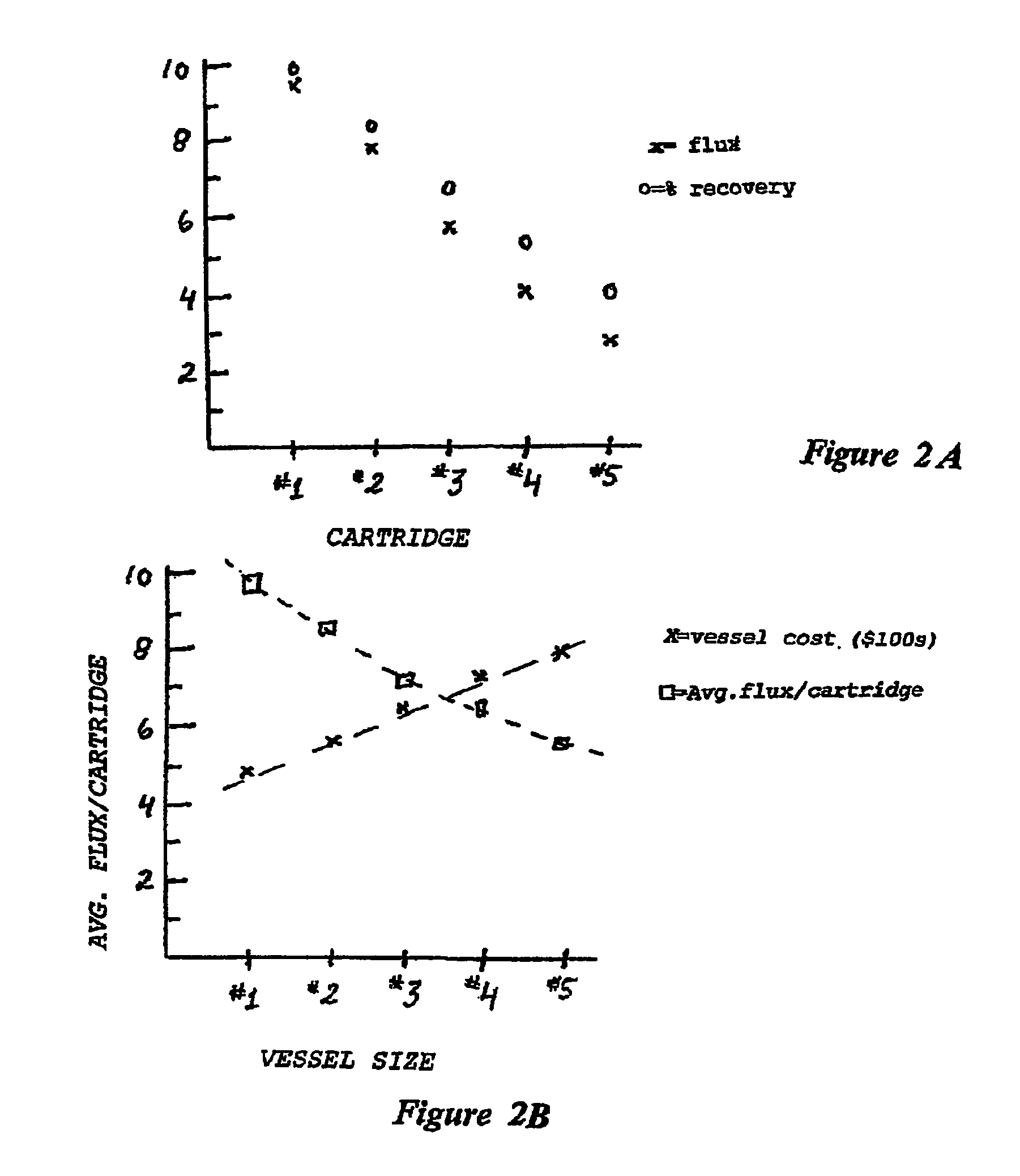

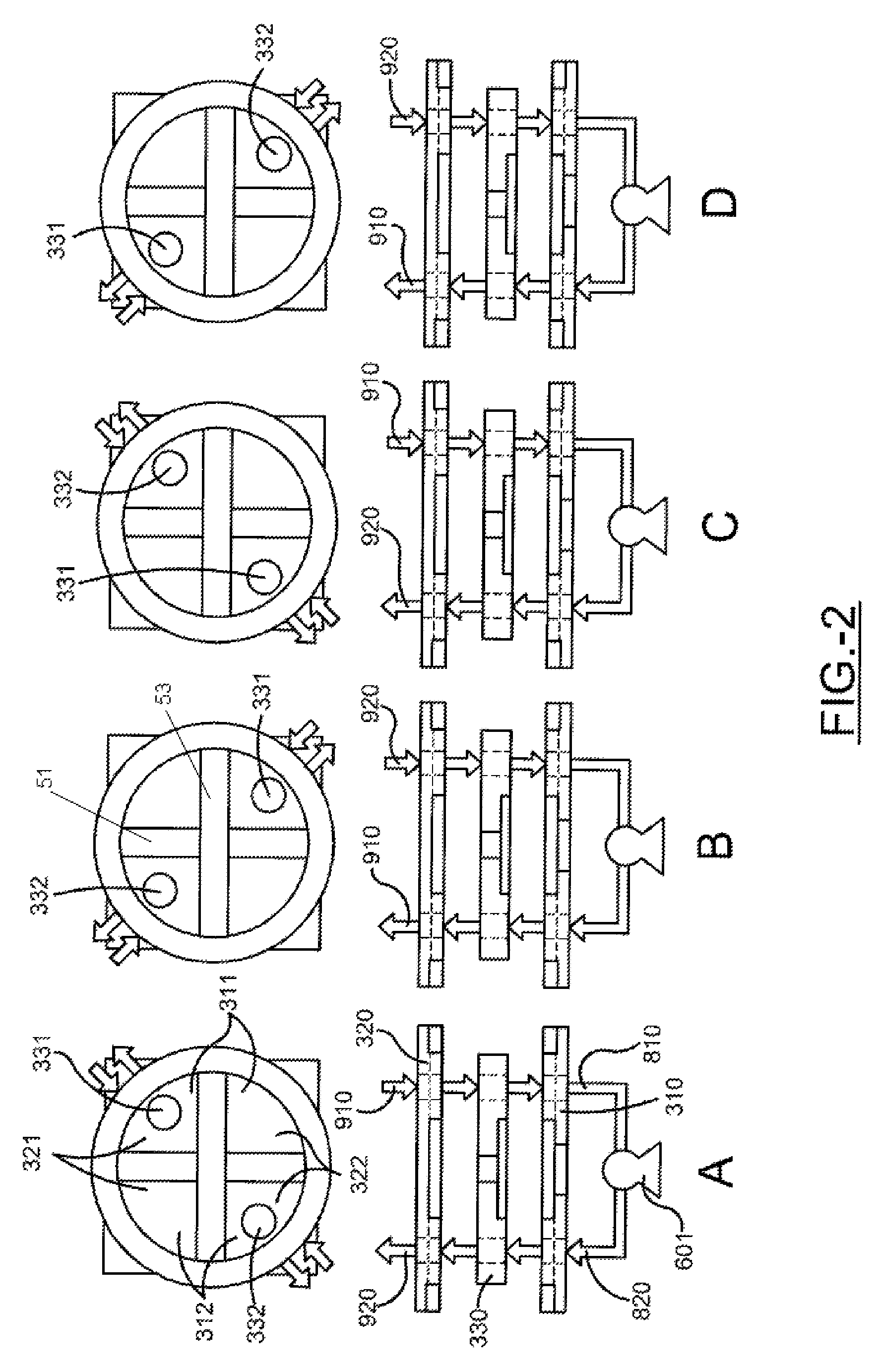

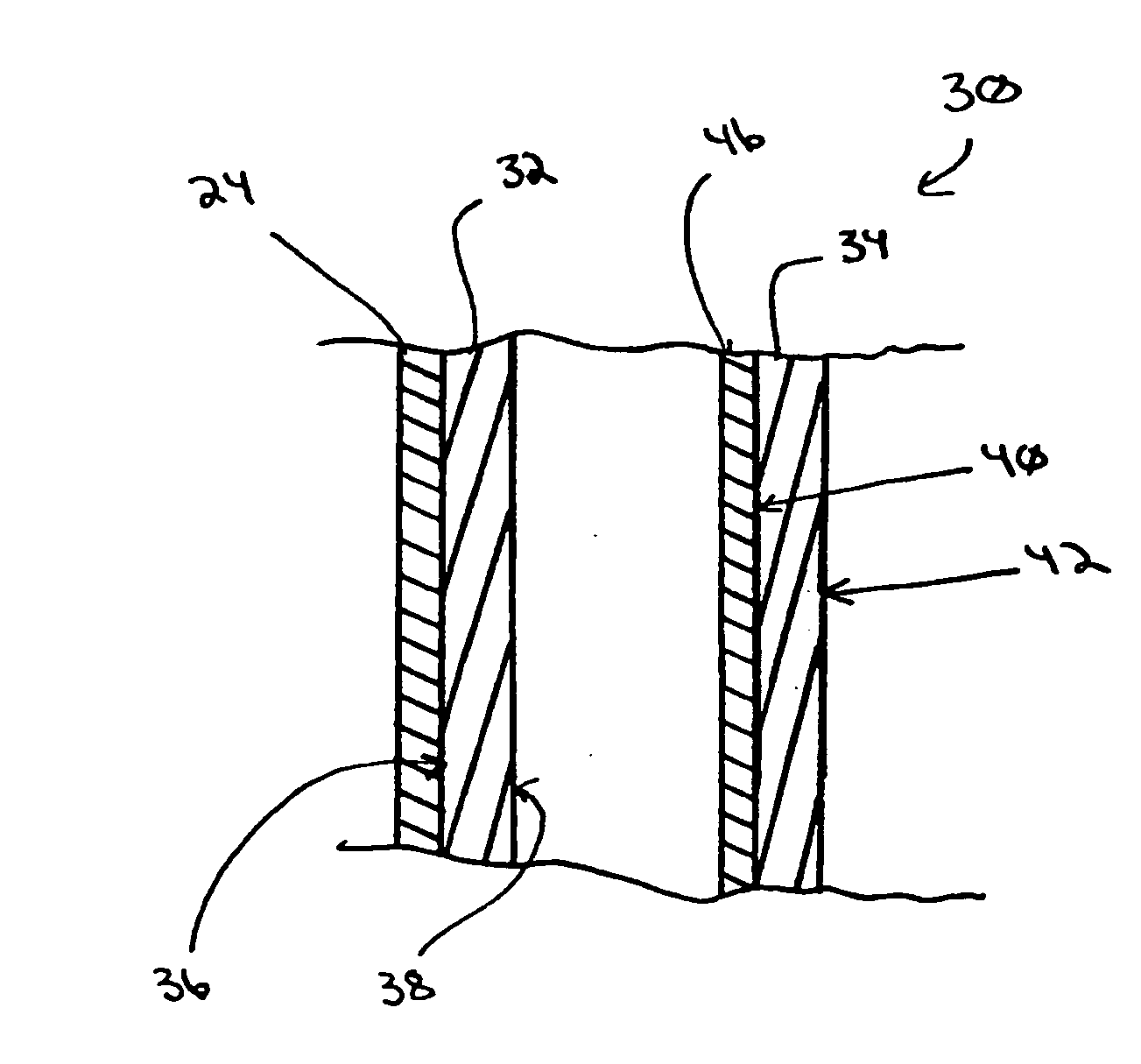

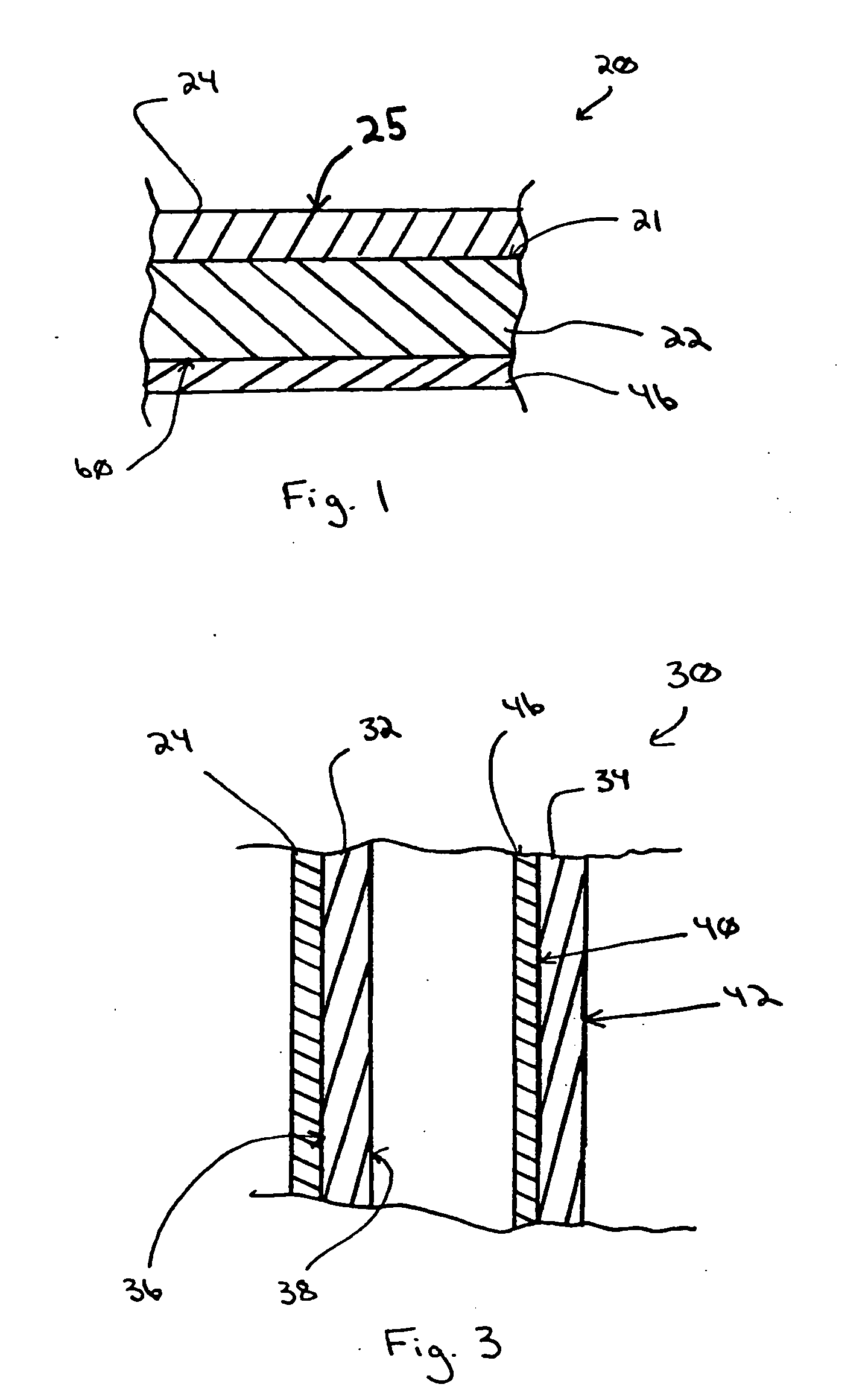

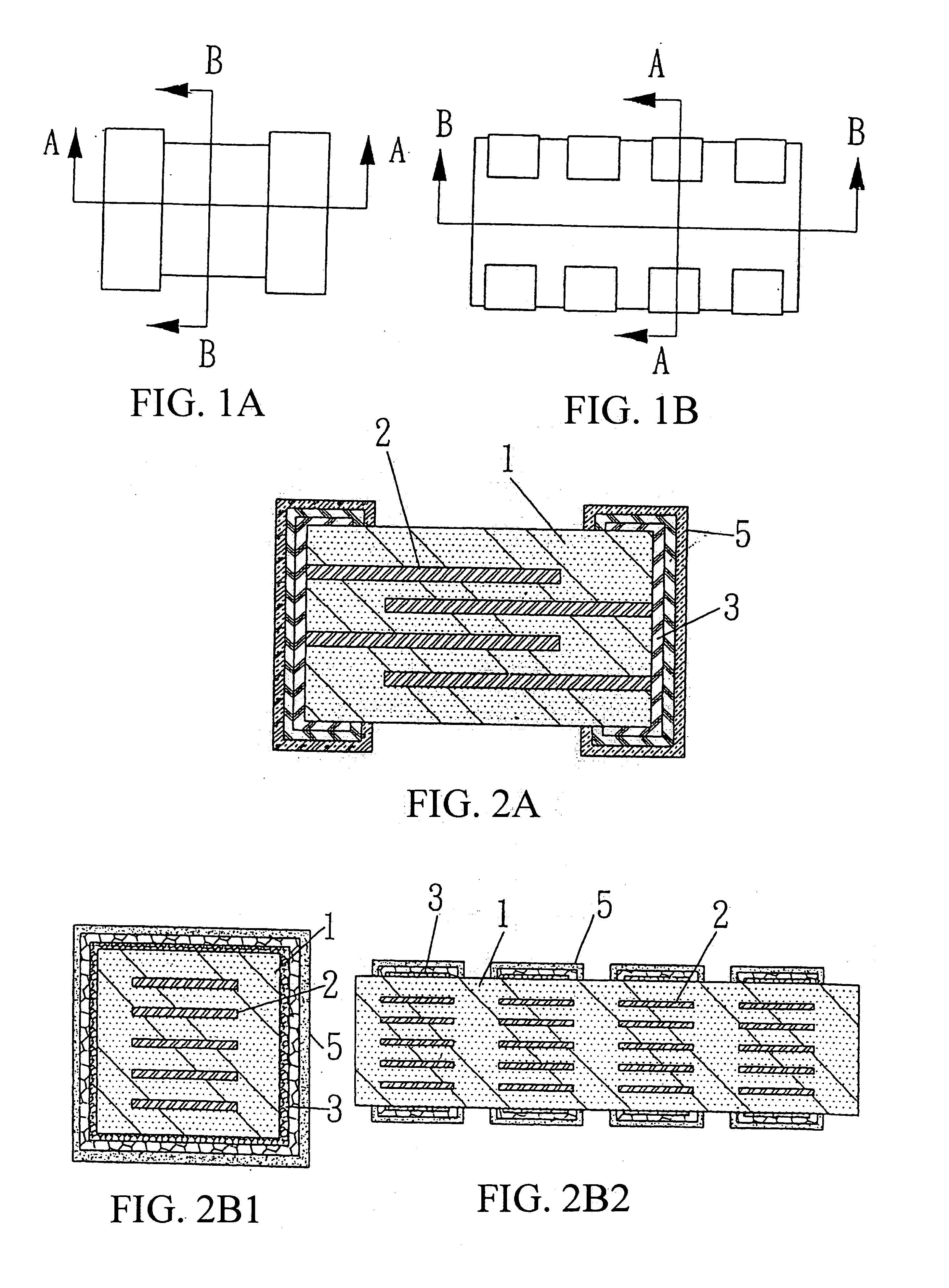

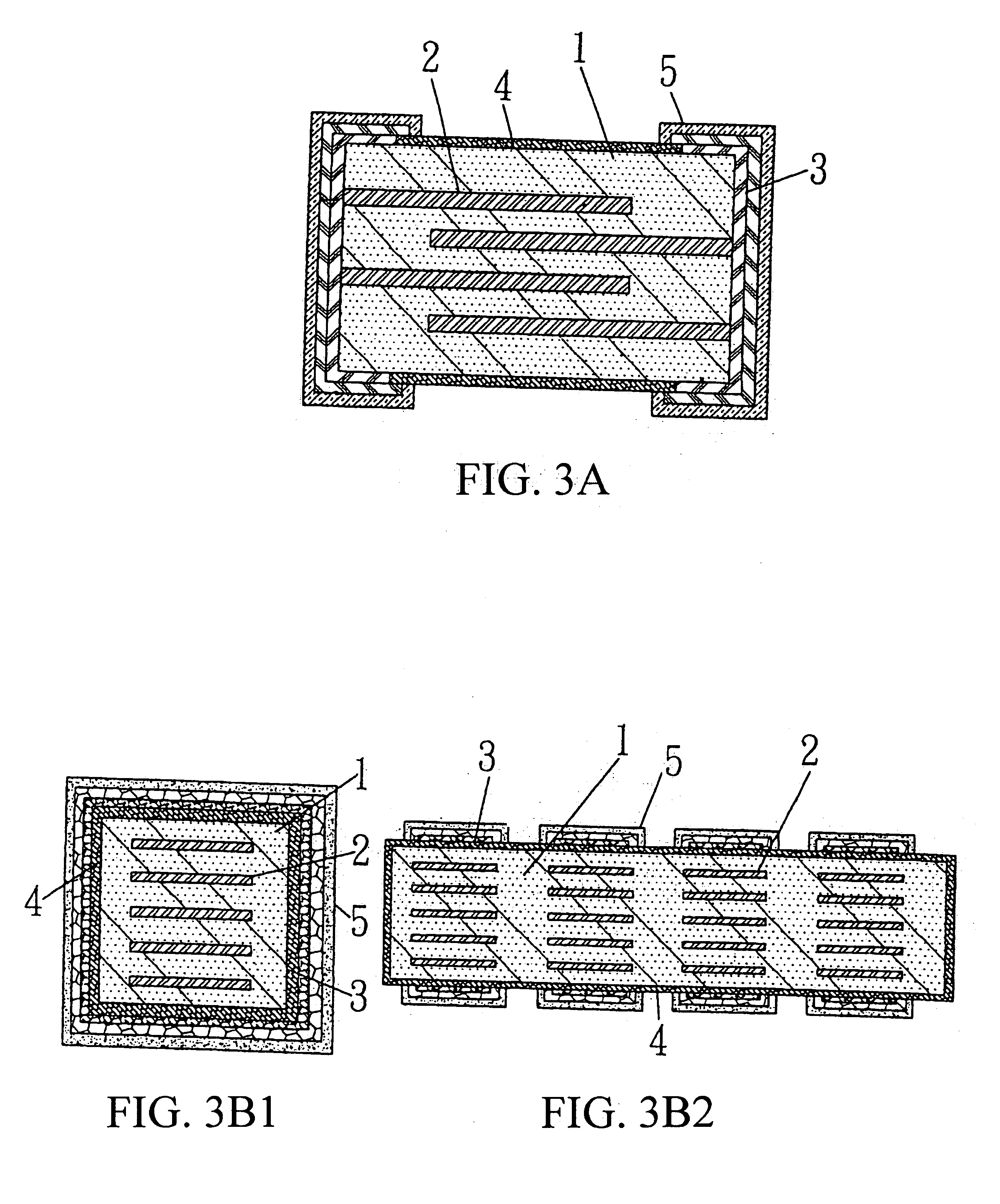

Branched flow filtraction and system

InactiveUS20050029192A1Improve operationImprove performanceMembranesWater/sewage treatment bu osmosis/dialysisReverse osmosisCross-flow filtration

A cross flow filtration apparatus for nanofiltration or reverse osmosis has pressure vessels with a plurality of filter cartridges in each vessel. A feed port is provided at an intermediate position on the side of the vessel, and two permeate flows or branches exit opposite ends of the vessel, and the first branch has a characteristically high “upstream” flux and quality, while the second is of lesser flux and / or quality. The system provides a high degree of moduarity, enhancing flux or yield at a reduced driving pressure or overall pressure drop. Centered or off-center port, and a stop or valve in the permeate stream may apportion flows between the two outlets. Staged systems may employ a first stage bypass to achieve a target quality with increased yield. A flow divider or adaptor permits the cartridges to fit and seal in the vessel and an installation tool or sleeve may facilitate installation or replacement of cartridges having a directional perimeter seal. A tool permits modules to be bi-directional installed in the pressure vessel. Other embodiments involve adapting a conventional vessel designed for end-to-end feed flow utilizing a restrictor, obstruction or valve inside the filter cartridge to bifurcate or otherwise split or apportion the permeate. RO elements may be modified to movably position an obstruction or valve along a string of the elements and vary the take-off to two or more permeate outlets, or to provide pressure relief valves that present different pressure conditions for different elements of a string. A pressure vessel may have an intermediate inlet, with symmetric or asymmetric branching of permeate flow to opposed ends of the vessel, enhancing permeate flux, permeate quality and / or energy efficiency.

Owner:IONICS INC

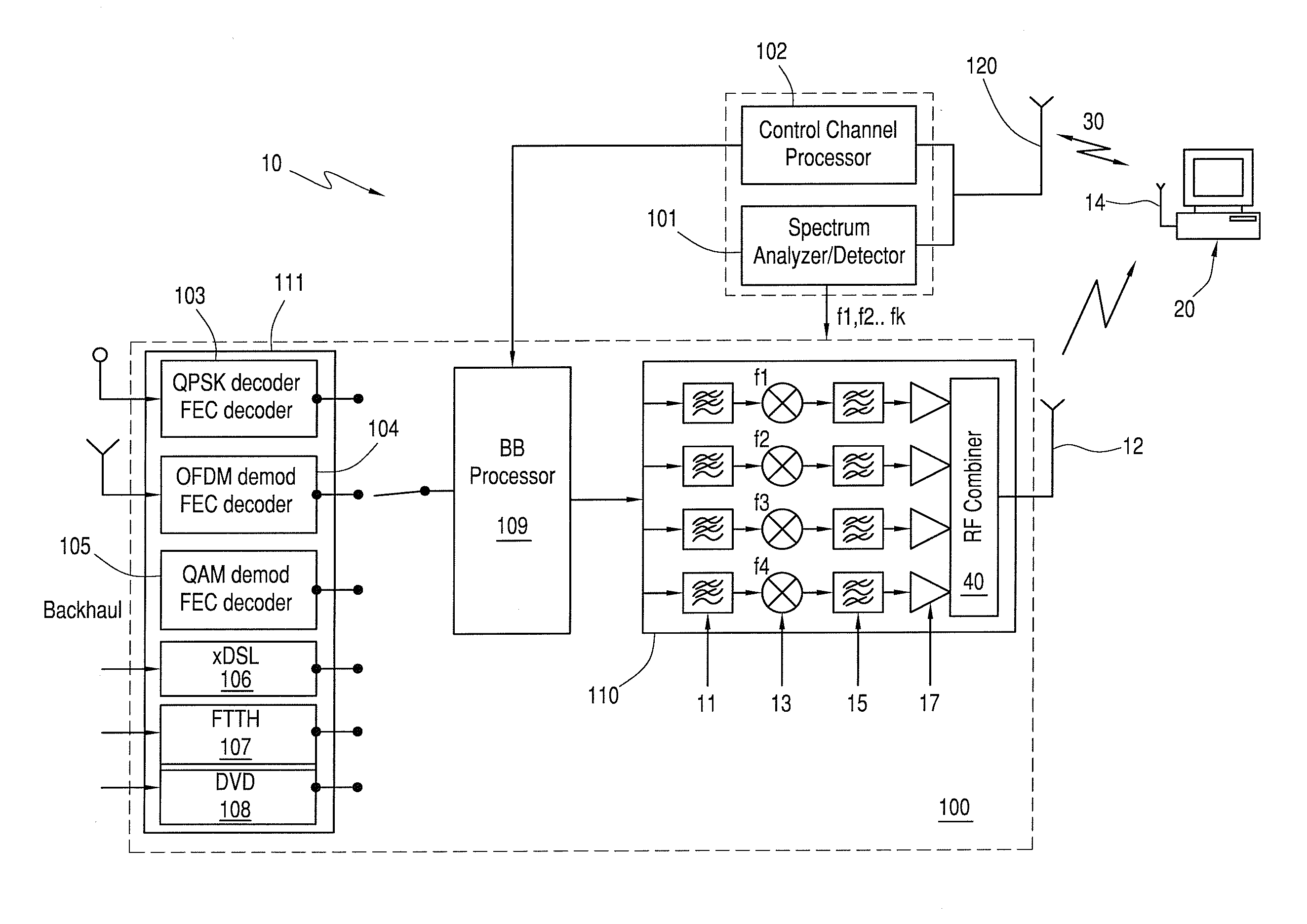

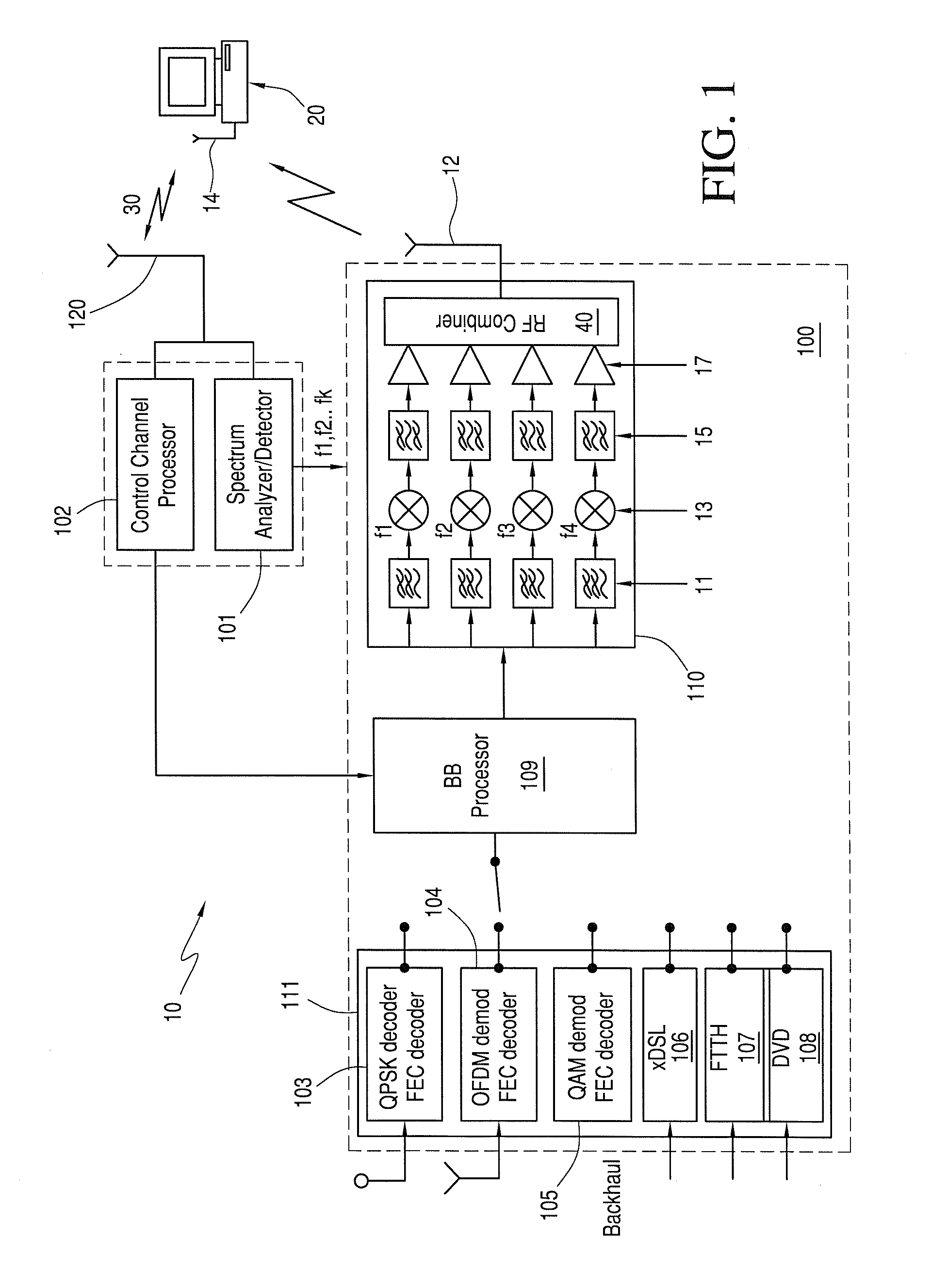

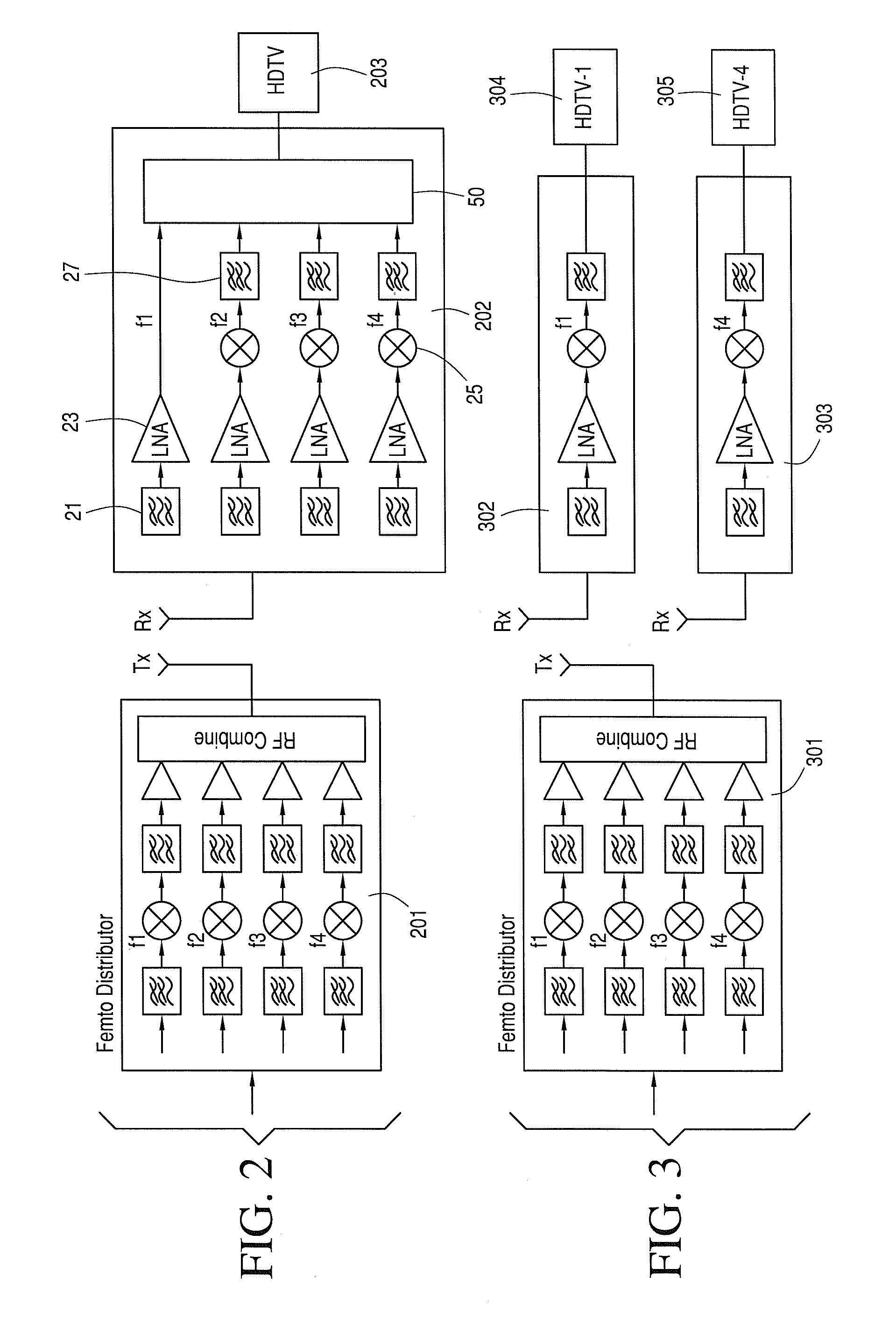

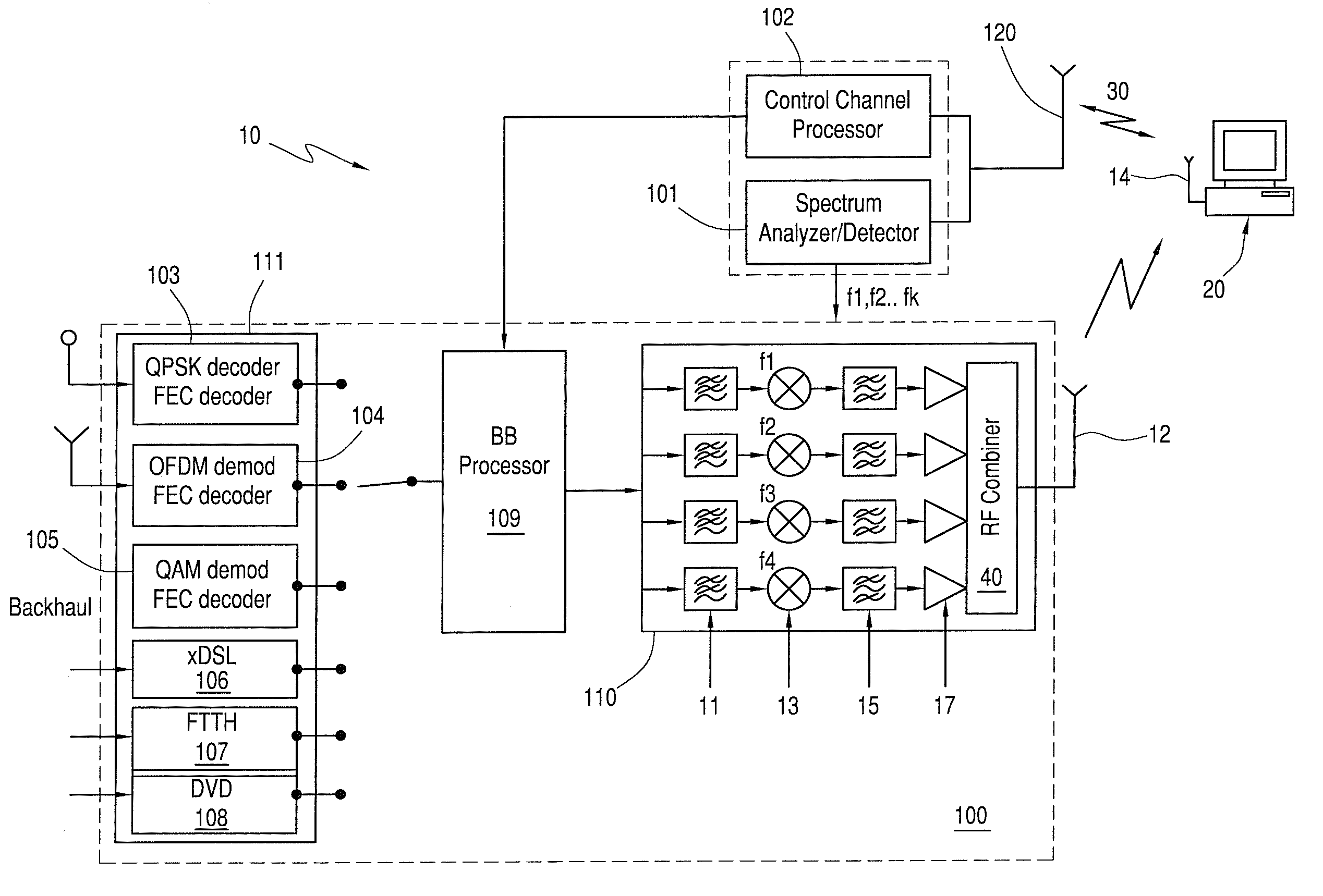

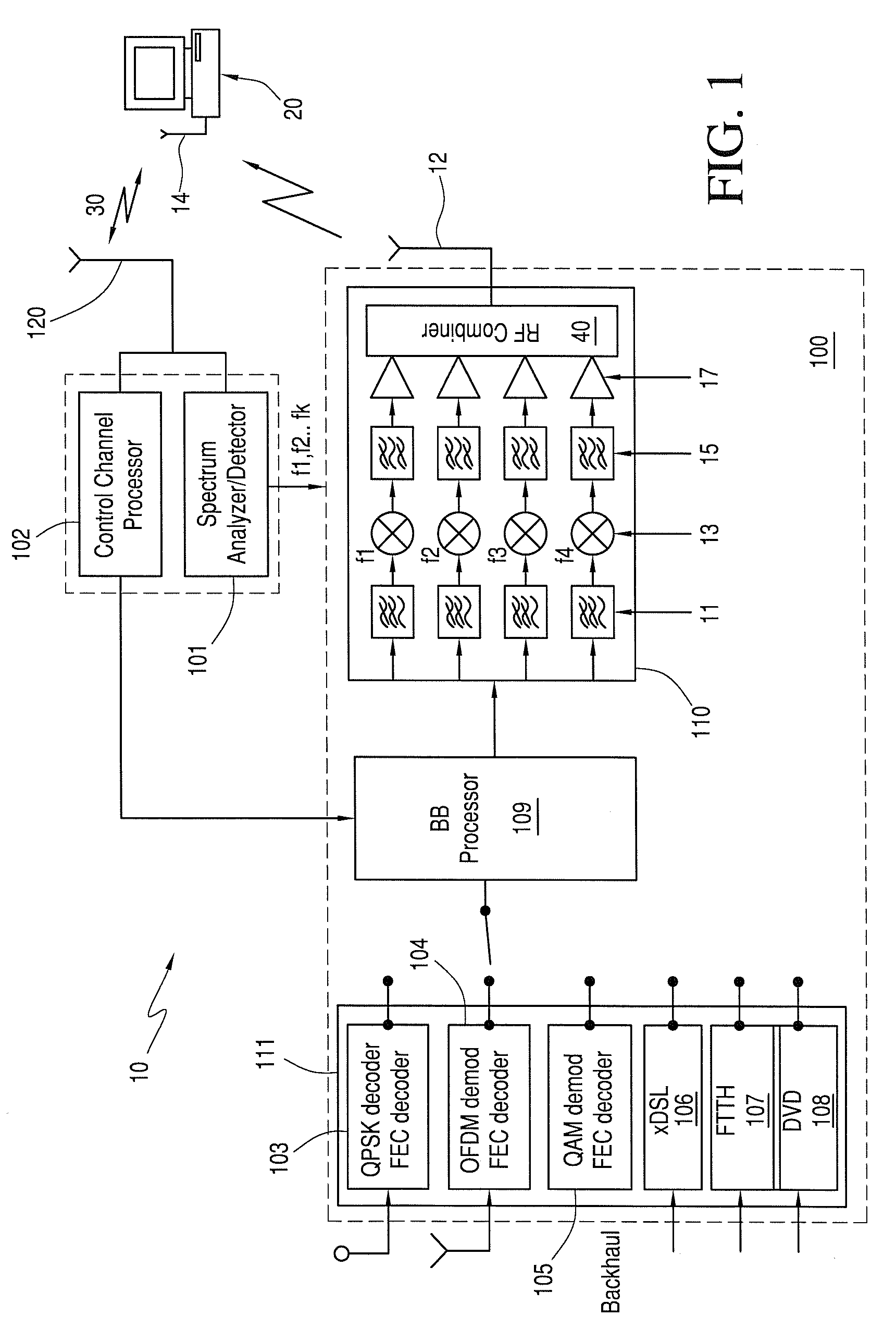

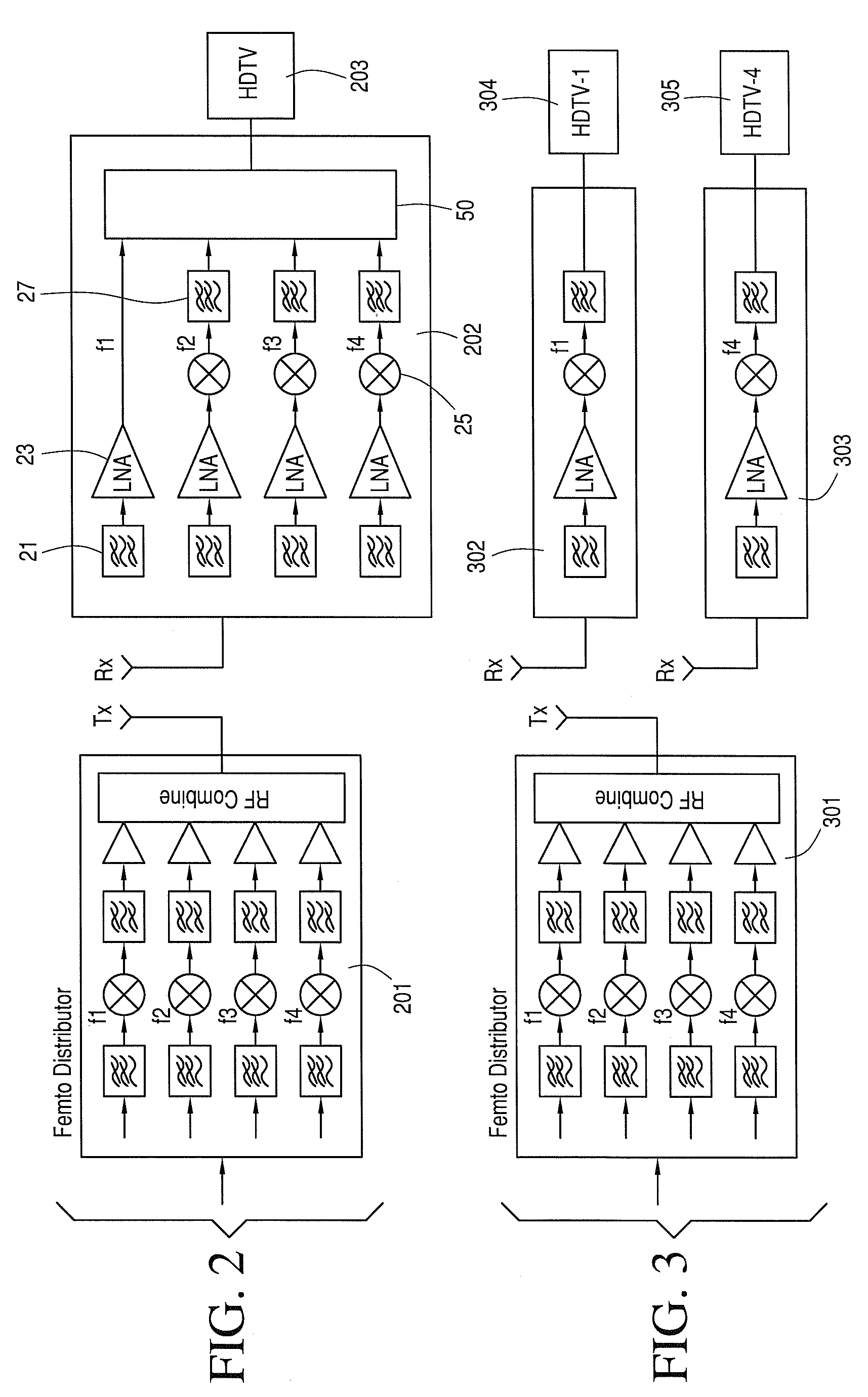

System and apparatus for cascading and redistributing HDTV signals

InactiveUS20120212628A1Change is minimalEffective wireless redistributionResource management arrangementsPlural information simultaneous broadcastFrequency spectrumVIT signals

Redistribution of multimedia signals or the like within a service area is performed by identifying one or more pieces of white space in the VHF / UHF spectrum, selecting a carrier frequency for each piece of white space spectrum, parsing the signal into a like number of components and modulating each component over a carrier frequency. The receiving device performs the reverse operation for reconstructing the signal.

Owner:TAIWAN SEMICON MFG CO LTD

System and apparatus for cascading and redistributing HDTV signals

InactiveUS8155039B2Change is minimalEffective wireless redistributionResource management arrangementsClosed circuit television systemsFrequency spectrumElectrical and Electronics engineering

Redistribution of multimedia signals or the like within a service area is performed by identifying one or more pieces of white space in the VHF / UHF spectrum, selecting a carrier frequency for each piece of white space spectrum, parsing the signal into a like number of components and modulating each component over a carrier frequency. The receiving device performs the reverse operation for reconstructing the signal.

Owner:TAIWAN SEMICON MFG CO LTD

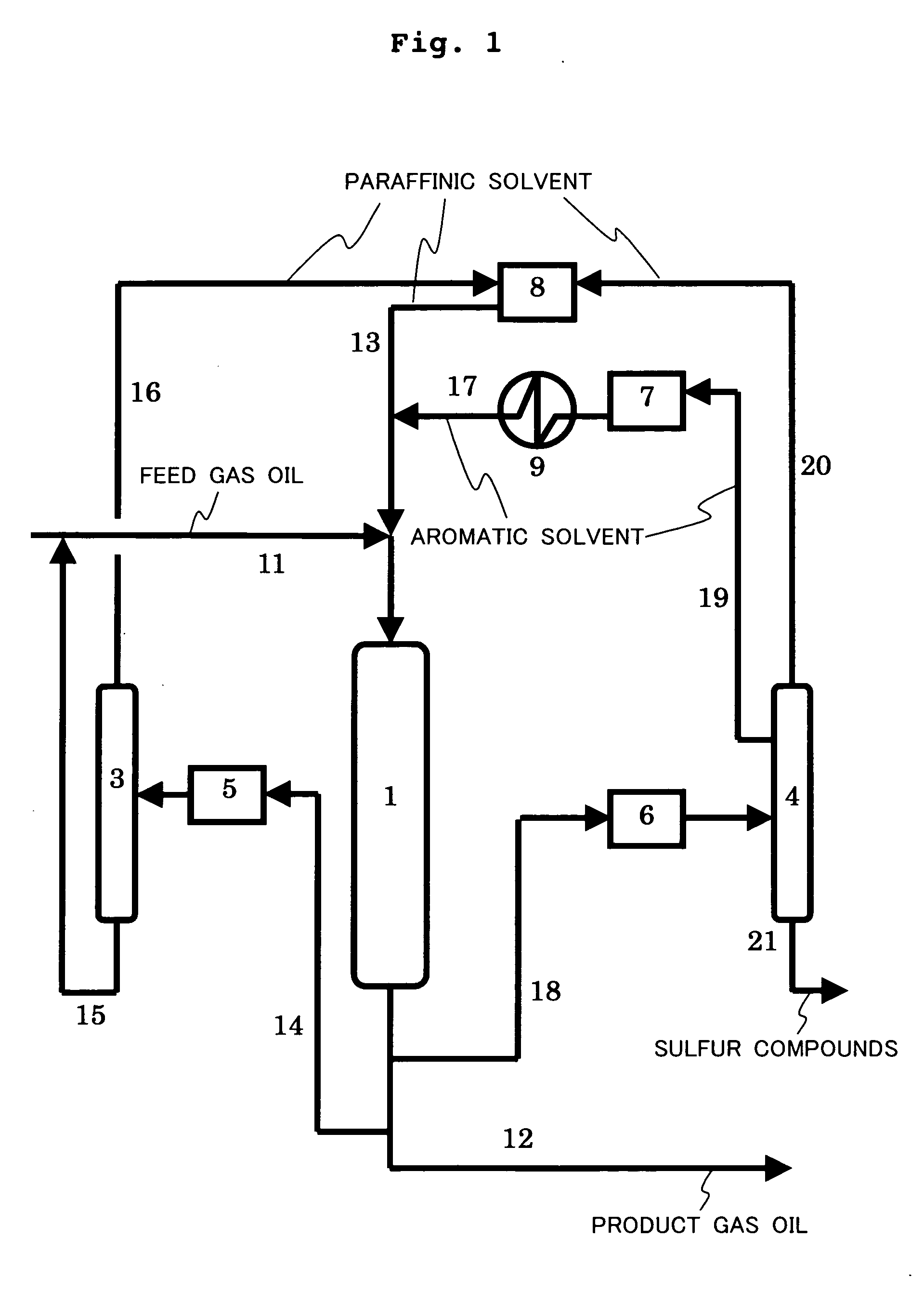

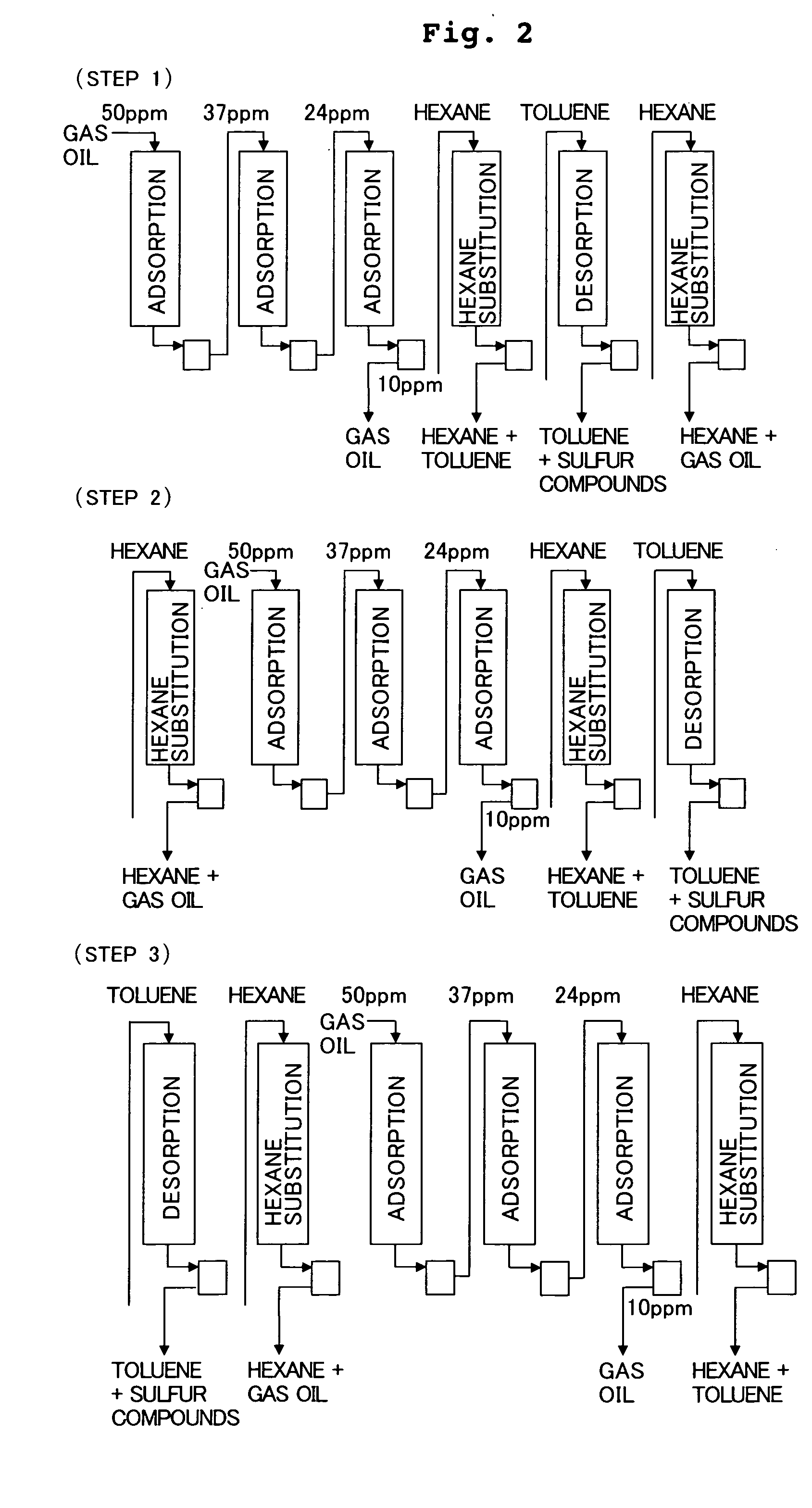

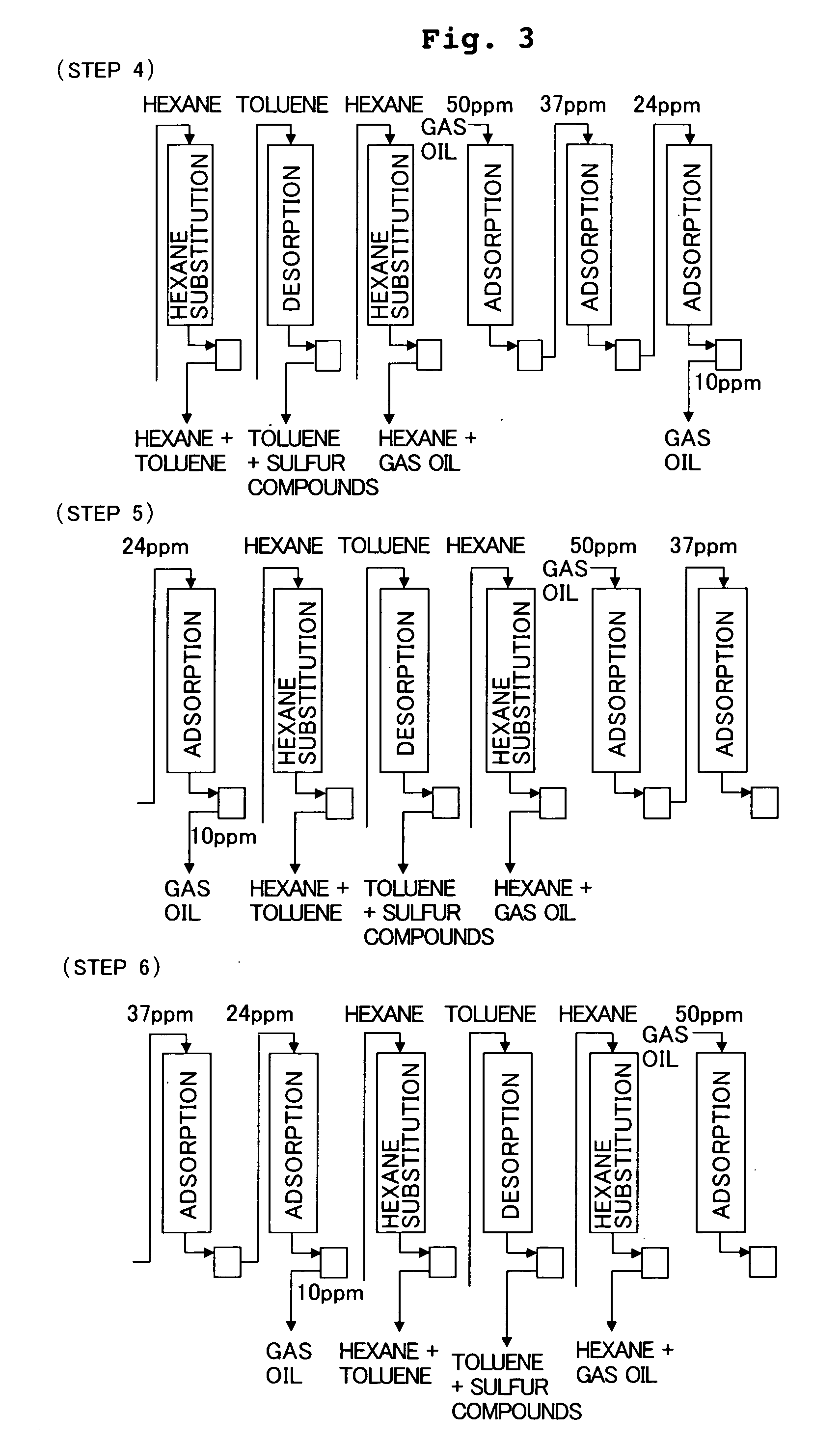

Adsorption desulfurization agent for desulfurizing petroleum fraction and desulfurization method using the same

InactiveUS20050173297A1Reduce equipment costsLow running costOther chemical processesLiquid organic insulatorsDesorptionTower

A desulfurization method for a gas oil which includes a step of removing sulfur compounds contained in a gas oil distillate product by the adsorption with an adsorptive desulfurization agent formed of a fibrous active carbon and provided in an adsorption tower (1), and a desorption regeneration step of washing the used adsorptive desulfurization agent with an aromatic solvent to regenerate the desulfurization agent. The method allows the production of gas oil being satisfactorily freed of sulfur content at relatively low equipment and operation costs over a long period of time, and in the method, difficult-to-remove sulfur compounds, such as 4,6-DMDBT, and polycyclic aromatic compounds having two or more rings are selectively removed.

Owner:JAPAN ENERGY CORP

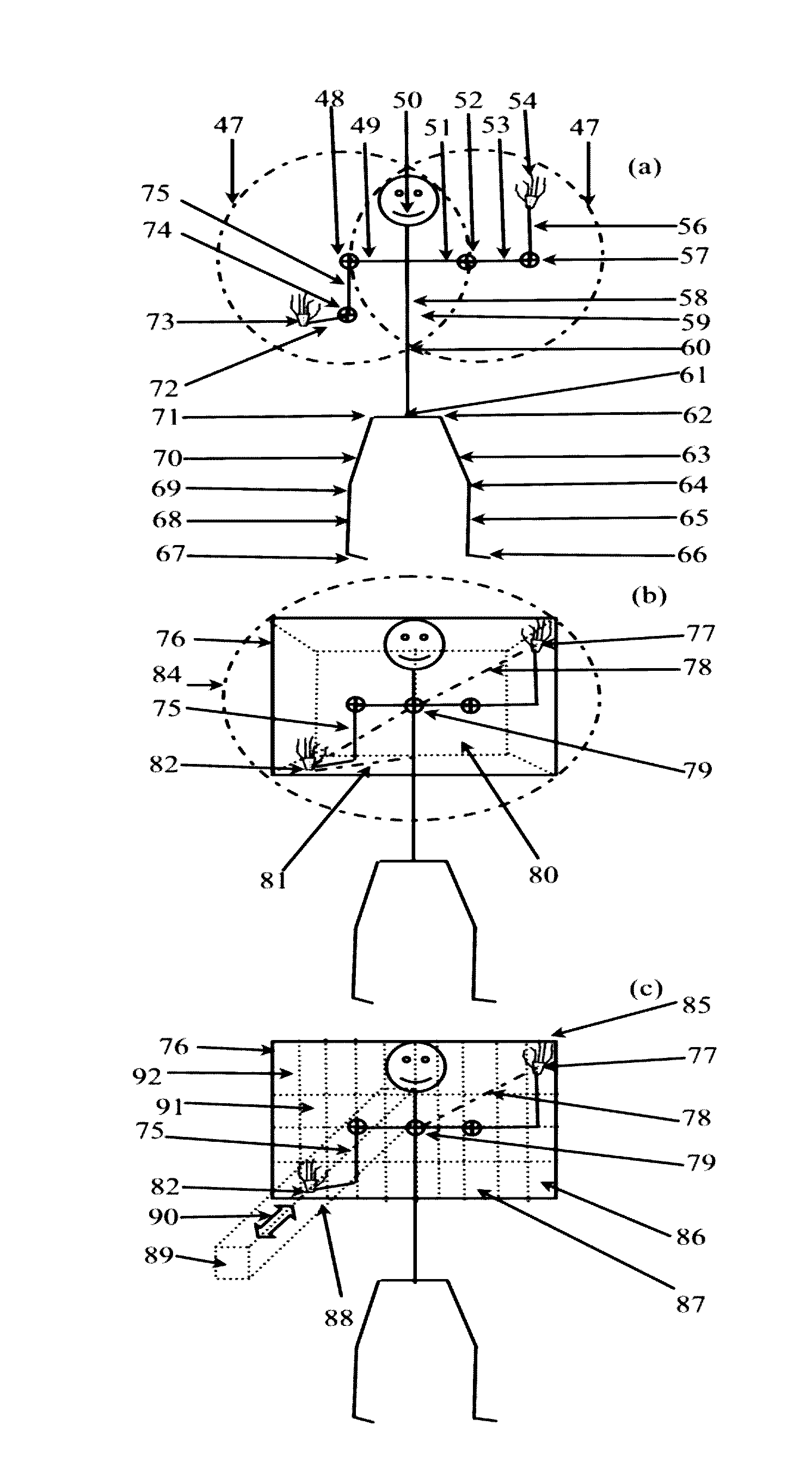

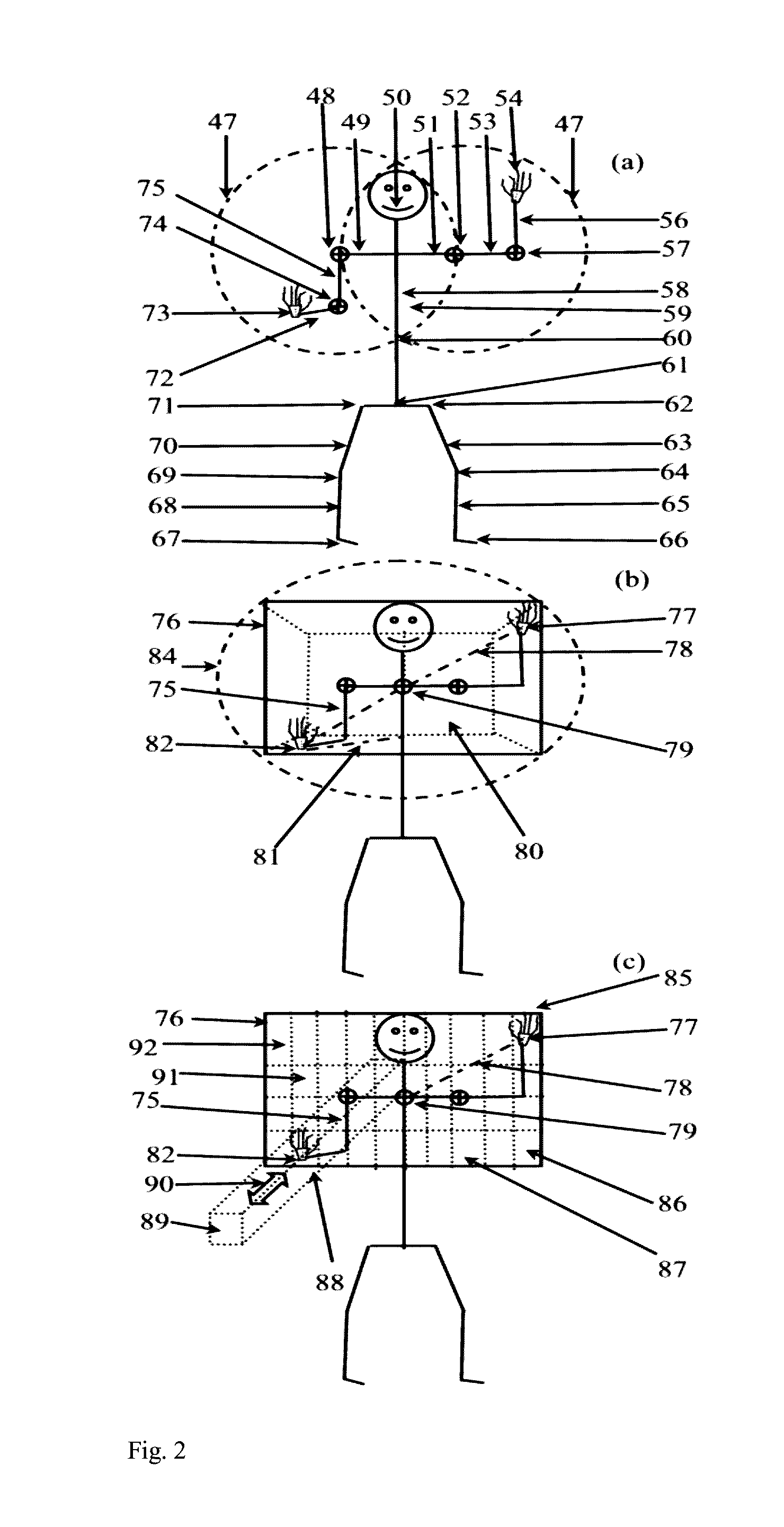

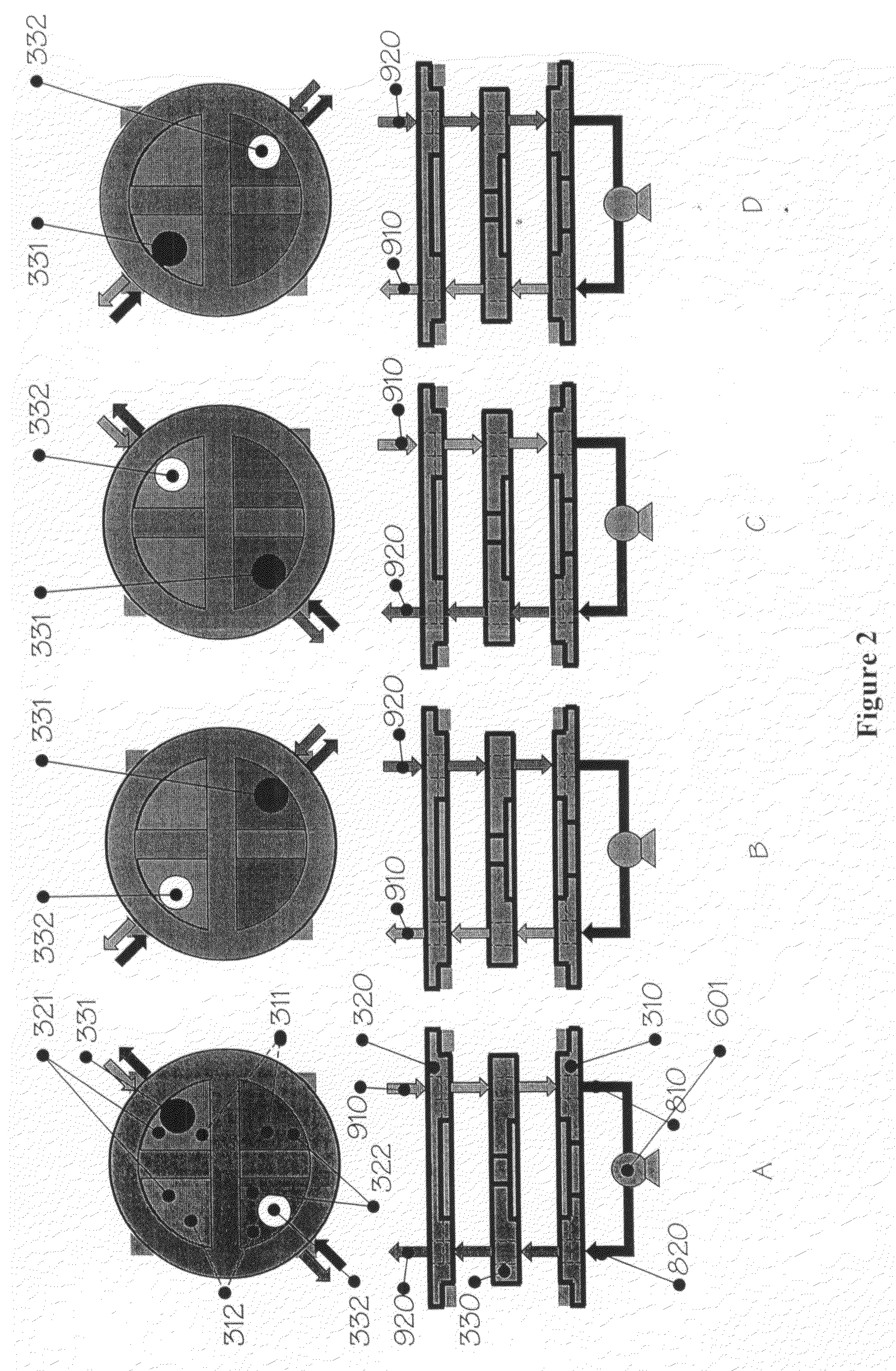

Gesture Interface Robot

ActiveUS20160350589A1Avoid injuryIncrease choiceInput/output for user-computer interactionTelevision system detailsGraphicsRemote control

Gesture Interface Robot auto measure work zone to establish virtual puzzle cell locate in user gesture comfortable area where easy moving hands gesture to push out select virtual keys, prevent injury. Robot drawing virtual keyboard images graphic that display each puzzle cell command, and video vision sensing detect user's hand location that on its virtual keyboard in the workspace zone. Special unique gesture hand sings design for enhances hand control virtual key selections. Push hand z dimension distant divide into 3 select zones. Real-time display highlight selected key graphic image to visual indicate for user to see. Using UIRT cable sending IR signal remote control computer, machine. Instantly generate virtual puzzle cell keyboard or controller that user selected. Introduce new gesture interface method, a Touch Screen Mouse combine with Puzzle Cell virtual keys in sandwich layers gesture zones method for operate computer keys and mouse operations, robot.

Owner:CHIU HSIEN HSIANG

Branched flow filtration and system

InactiveUS7410581B2Improve operationImprove performanceMembranesReverse osmosisCross-flow filtrationReverse osmosis

A cross flow filtration apparatus for nanofiltration or reverse osmosis has pressure vessels with a plurality of filter cartridges in each vessel. A feed port is provided at an intermediate position on the side of the vessel, and two permeate flows or branches exit opposite ends of the vessel, and the first branch has a characteristically high “upstream” flux and quality, while the second is of lesser flux and / or quality. The system provides a high degree of moduarity, enhancing flux or yield at a reduced driving pressure or overall pressure drop. Centered or off-center port, and a stop or valve in the permeate stream may apportion flows between the two outlets. Staged systems may employ a first stage bypass to achieve a target quality with increased yield. A flow divider or adaptor permits the cartridges to fit and seal in the vessel and an installation tool or sleeve may facilitate installation or replacement of cartridges having a directional perimeter seal. A tool permits modules to be bi-directional installed in the pressure vessel. Other embodiments involve adapting a conventional vessel designed for end-to-end feed flow utilizing a restrictor, obstruction or valve inside the filter cartridge to bifurcate or otherwise split or apportion the permeate. RO elements may be modified to movably position an obstruction or valve along a string of the elements and vary the take-off to two or more permeate outlets, or to provide pressure relief valves that present different pressure conditions for different elements of a string. A pressure vessel may have an intermediate inlet, with symmetric or asymmetric branching of permeate flow to opposed ends of the vessel, enhancing permeate flux, permeate quality and / or energy efficiency.

Owner:IONICS INC

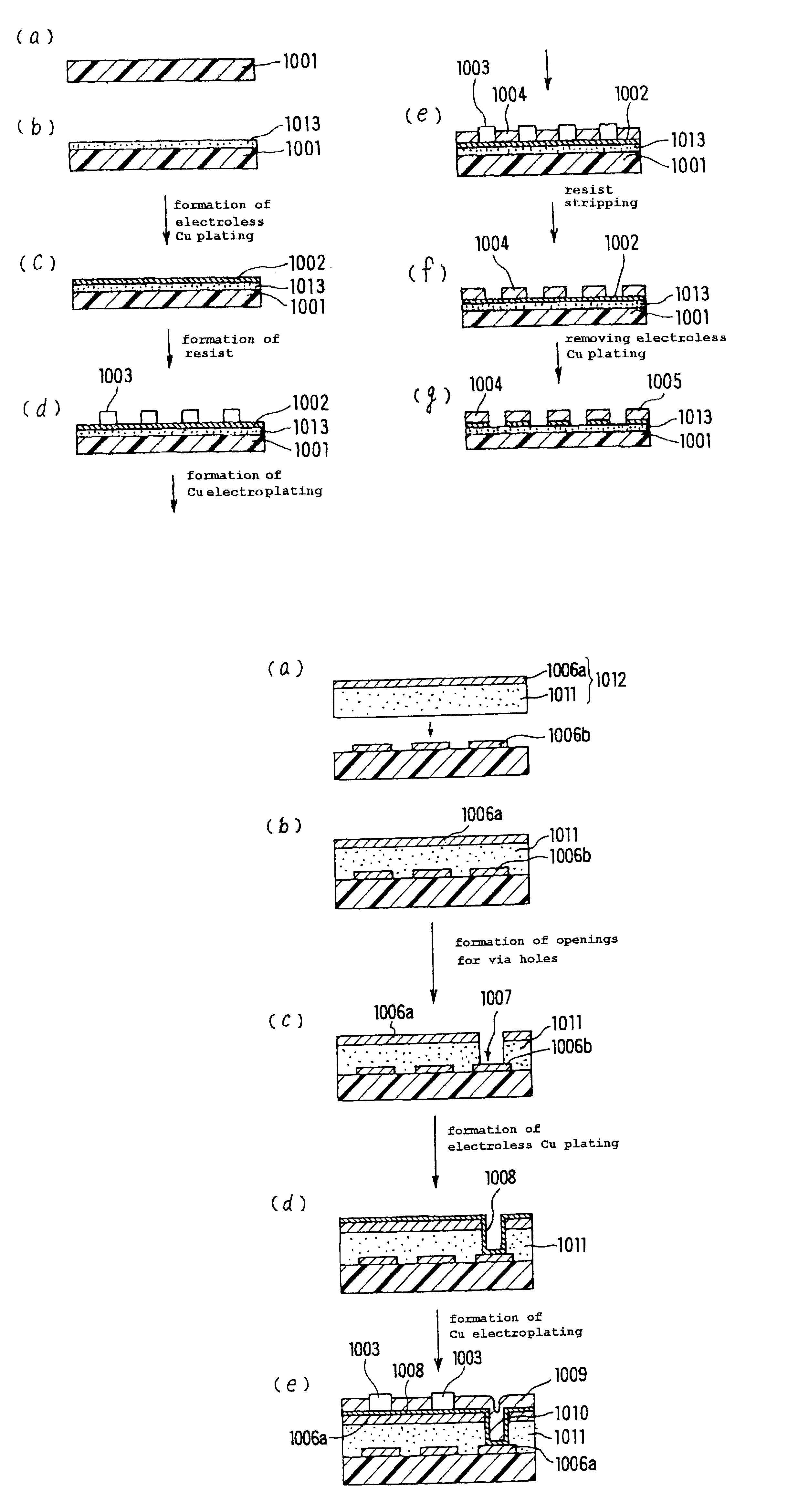

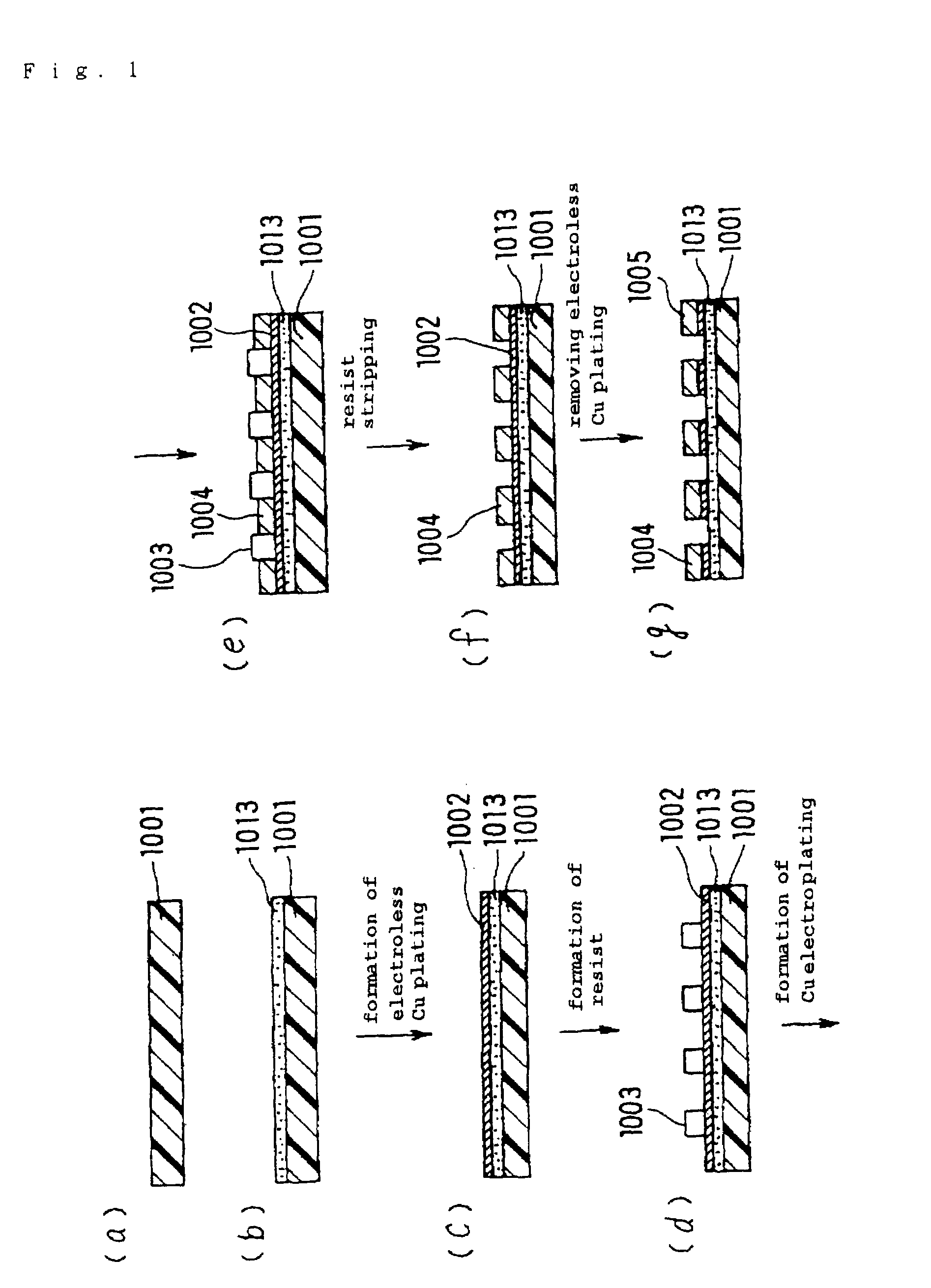

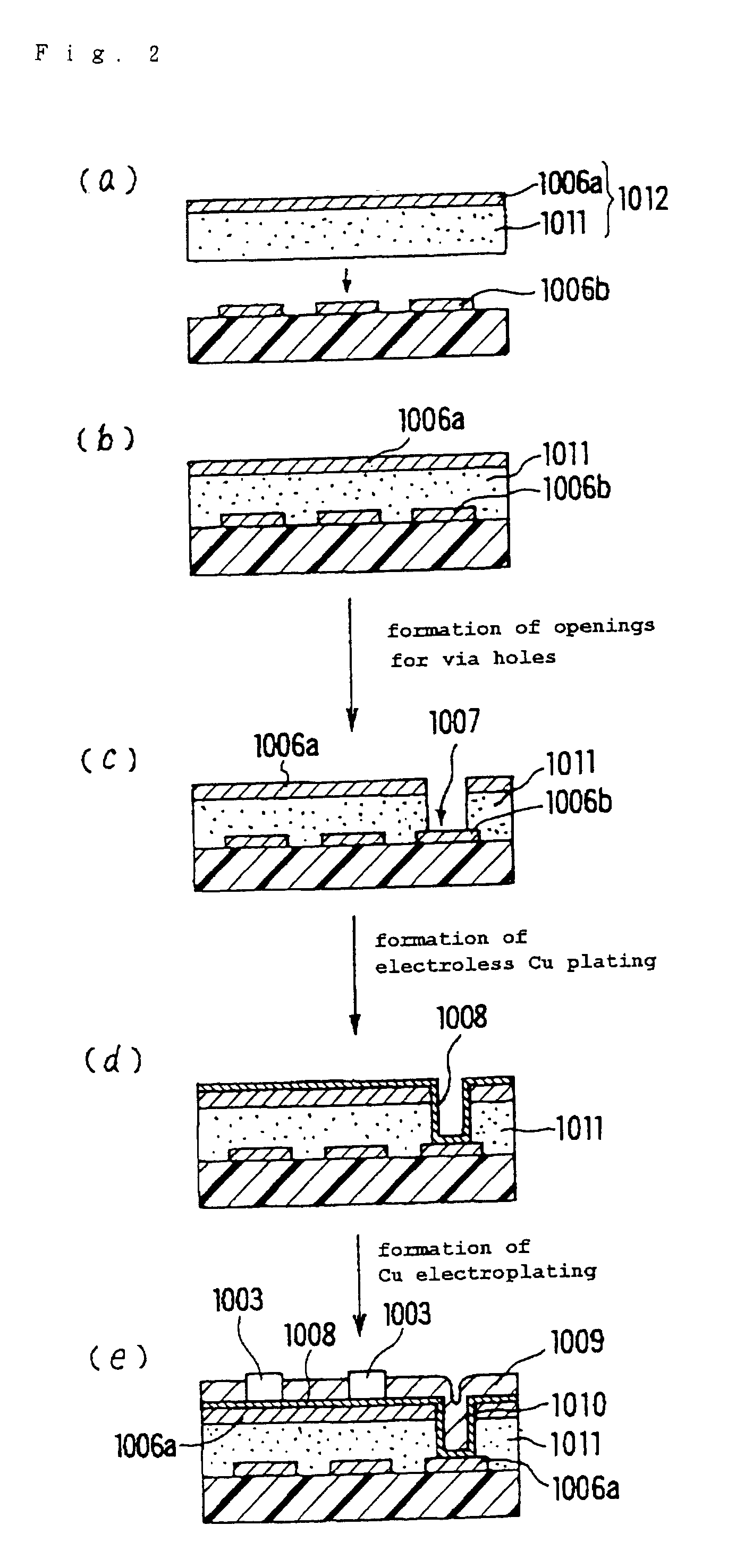

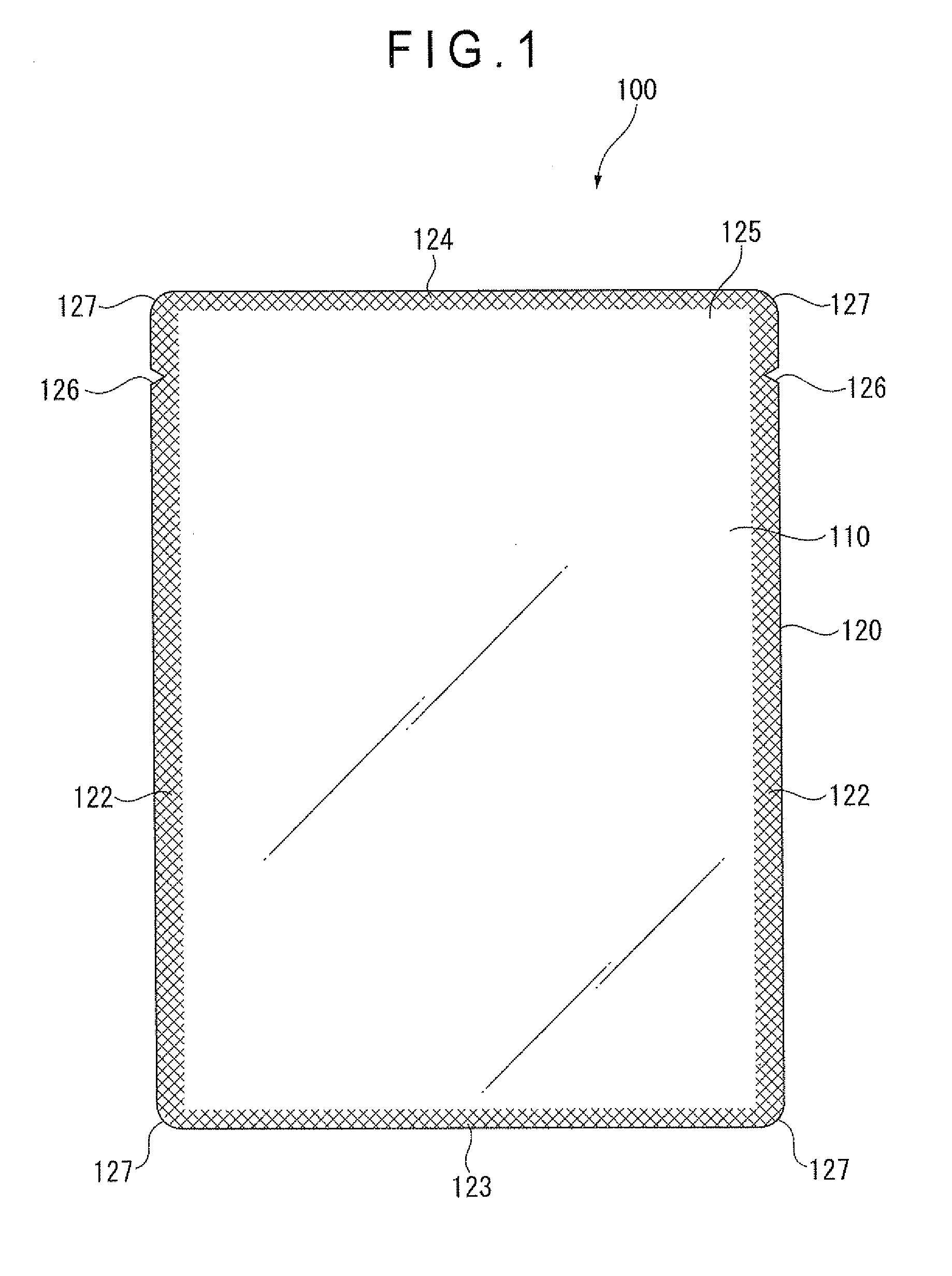

Printed wiring board and its manufacturing method

InactiveUS7230188B1High crystallinityLow equipment costInsulating substrate metal adhesion improvementPrinted circuit aspectsElectrical conductorHigh density

Owner:IBIDEN CO LTD

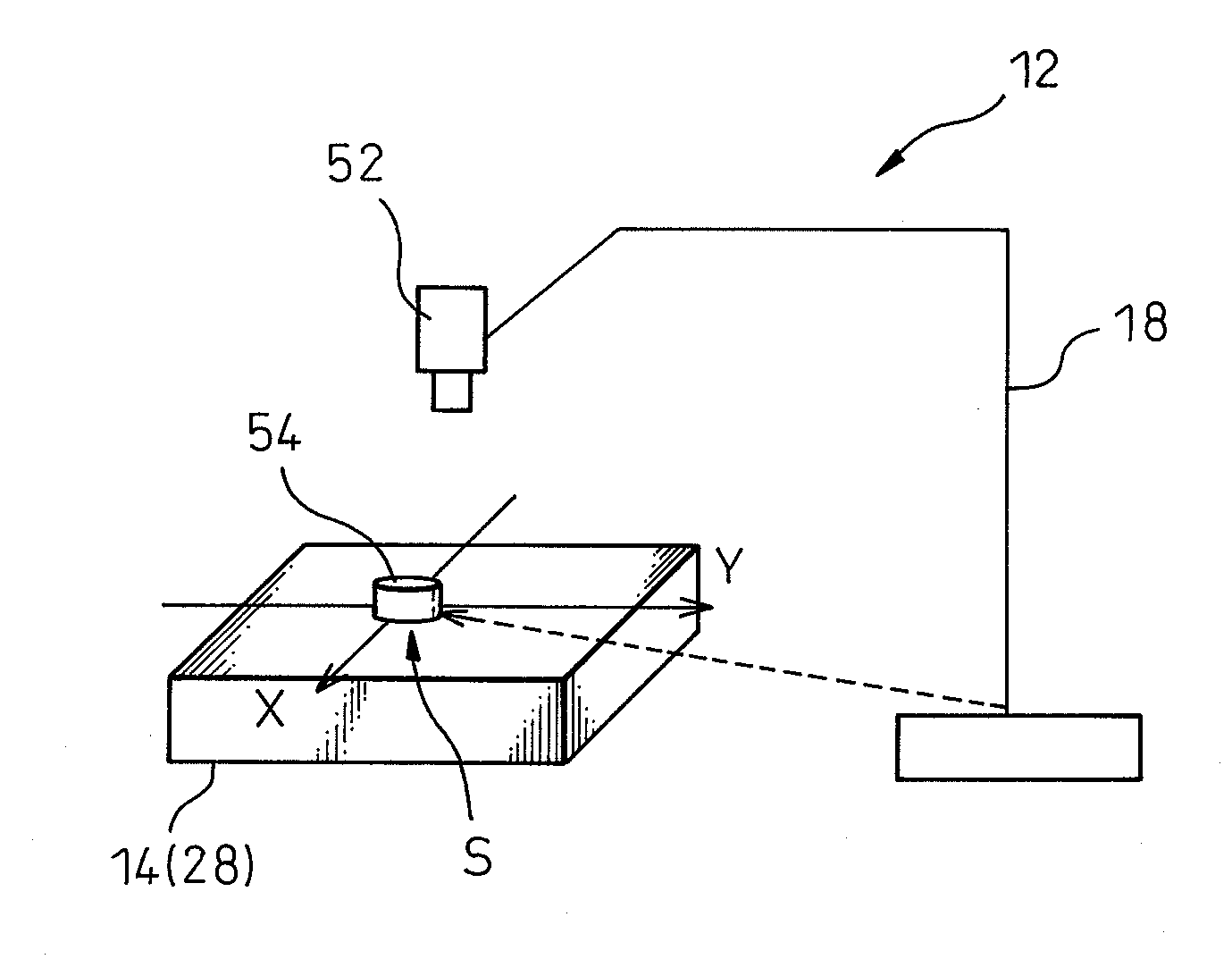

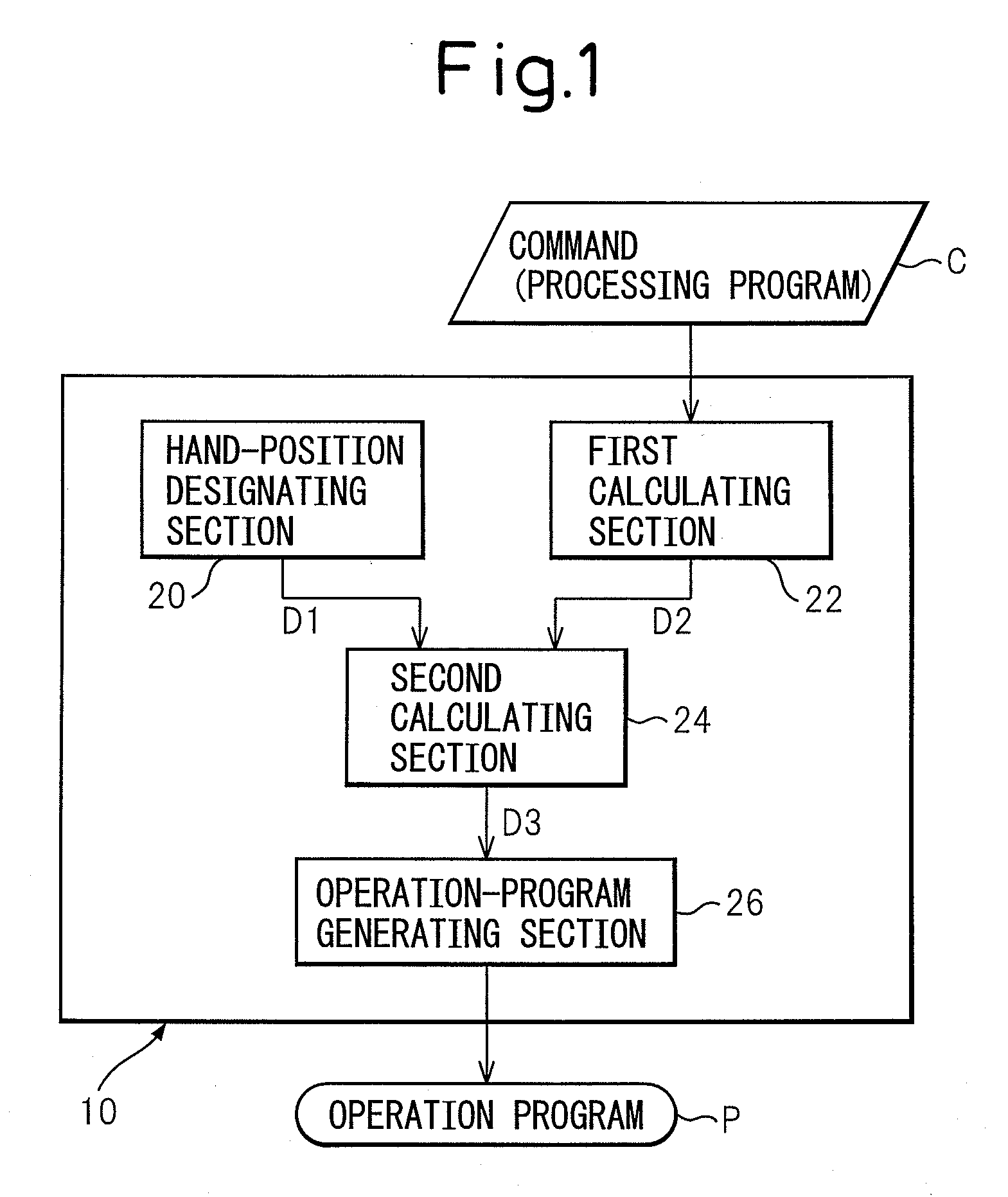

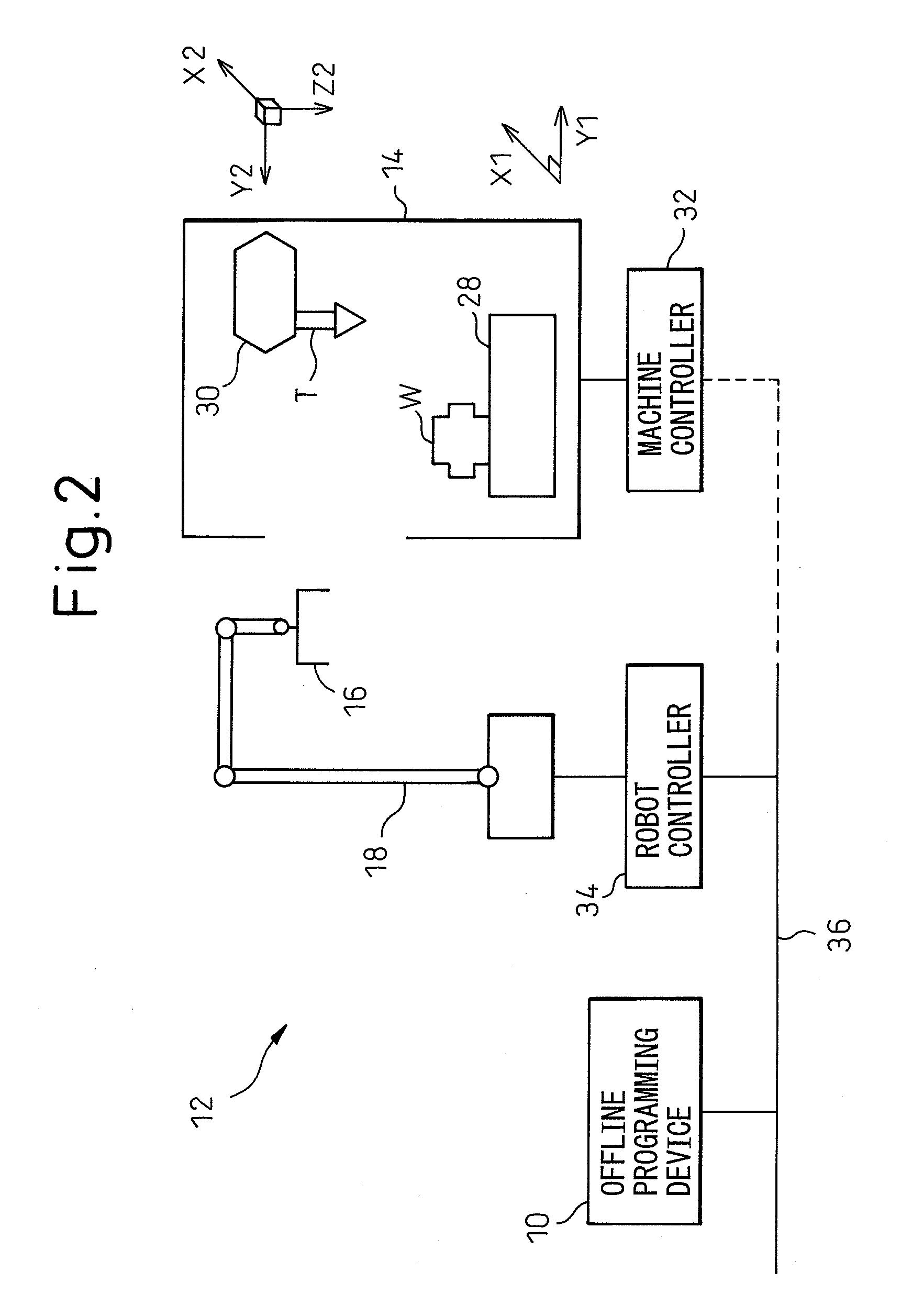

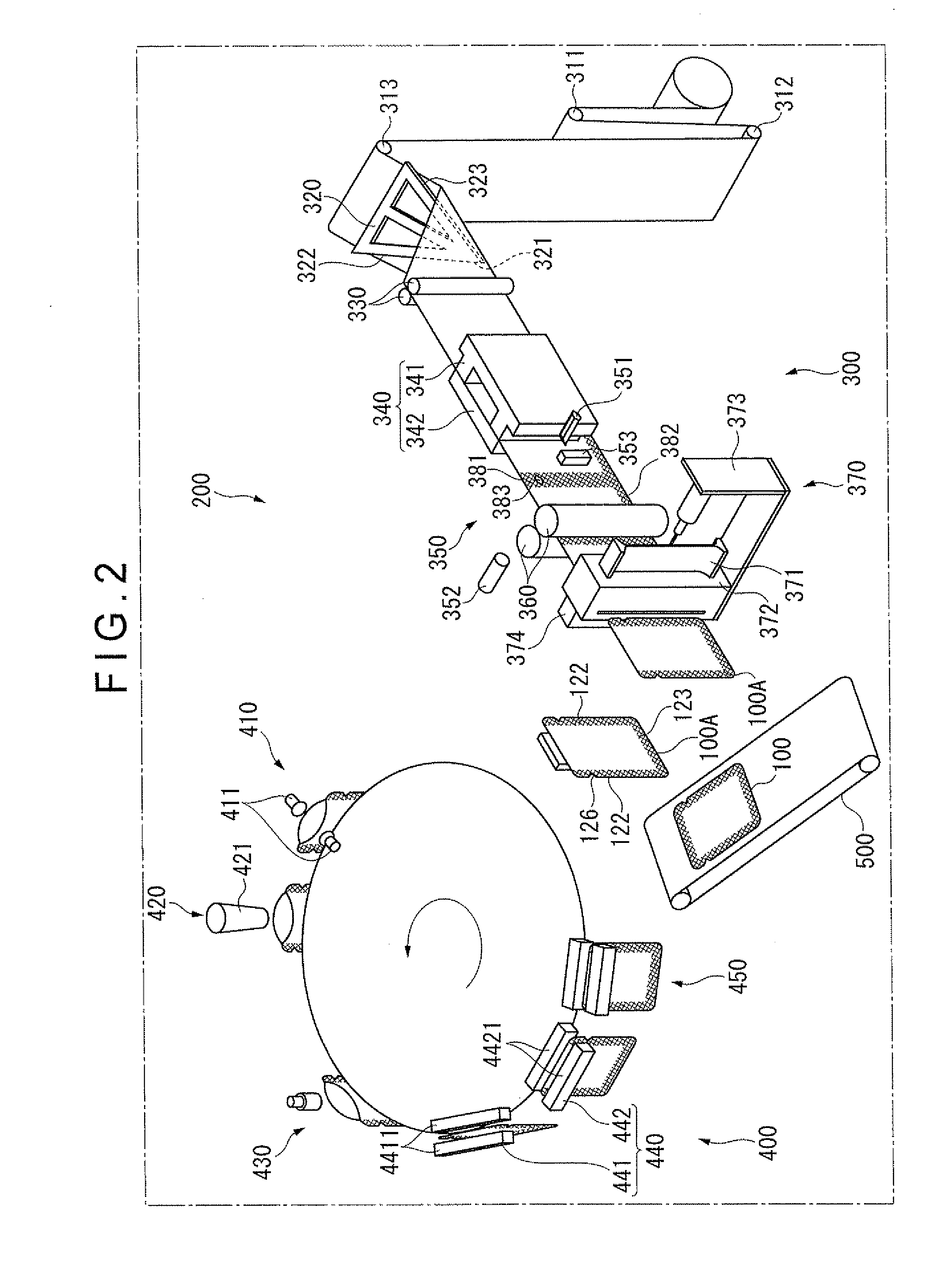

Device, method, program and recording medium for robot offline programming

ActiveUS20080154428A1Easily and accurately operateLow equipment costProgramme-controlled manipulatorComputer controlHand positionMachine tool

An offline programming device for preparing an operation program for making a robot with a hand perform a handling operation for an object with respect to a machine tool. The device includes a hand-position designating section designating a relative positional relationship between the object and the hand when the hand holds the object; a first calculating section determining a position and orientation of the object mounted on the machine tool when the robot performs the handling operation, based on a command specifying a position of the object and included in a workpiece processing program given to the machine tool; a second calculating section determining a position and orientation of the robot acting to hold the object by the hand when the robot performs the handling operation, based on the relative positional relationship between the object and the hand and the position and orientation of the object; and an operation-program generating section generating the operation program by using the position and orientation of the robot.

Owner:FANUC LTD

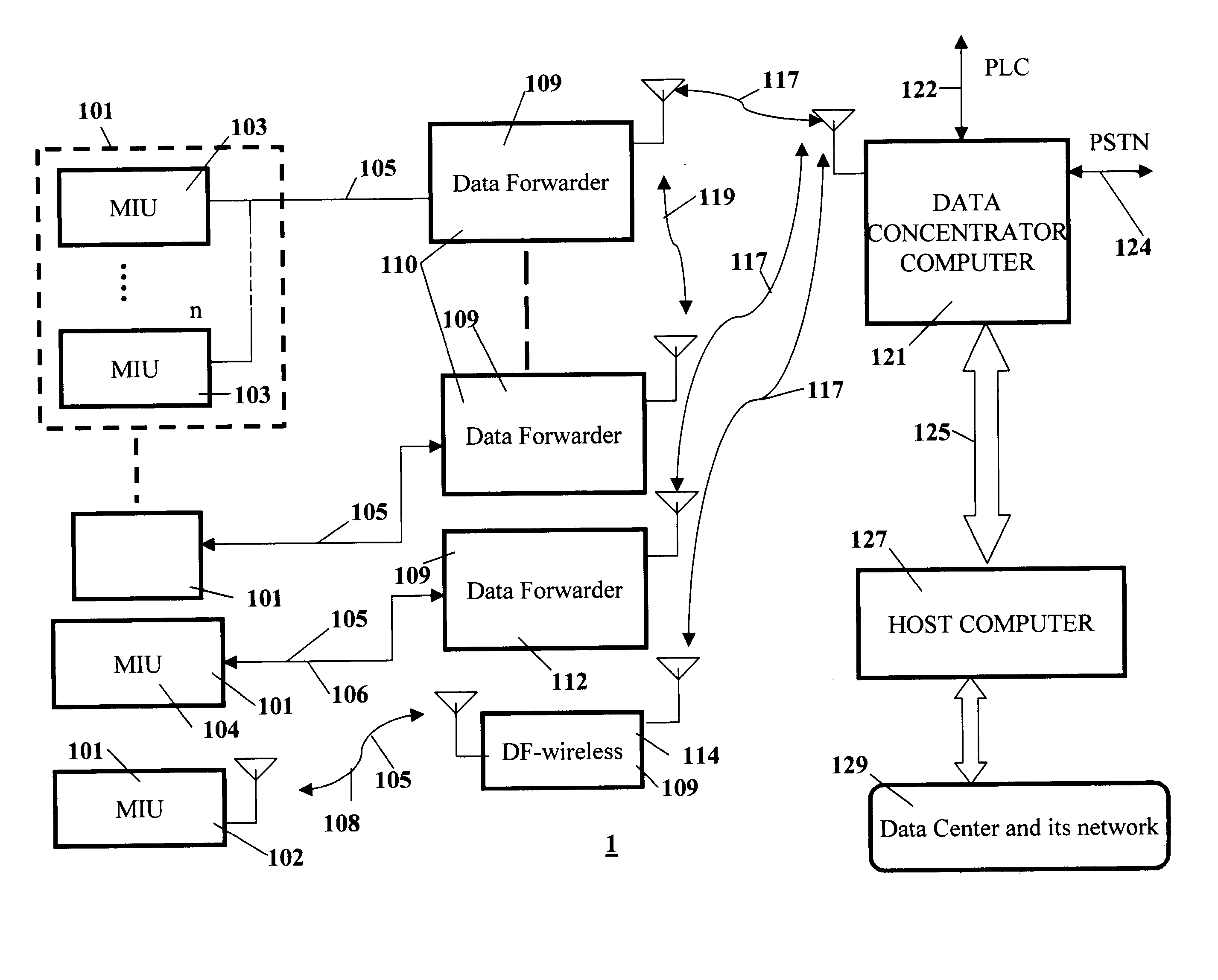

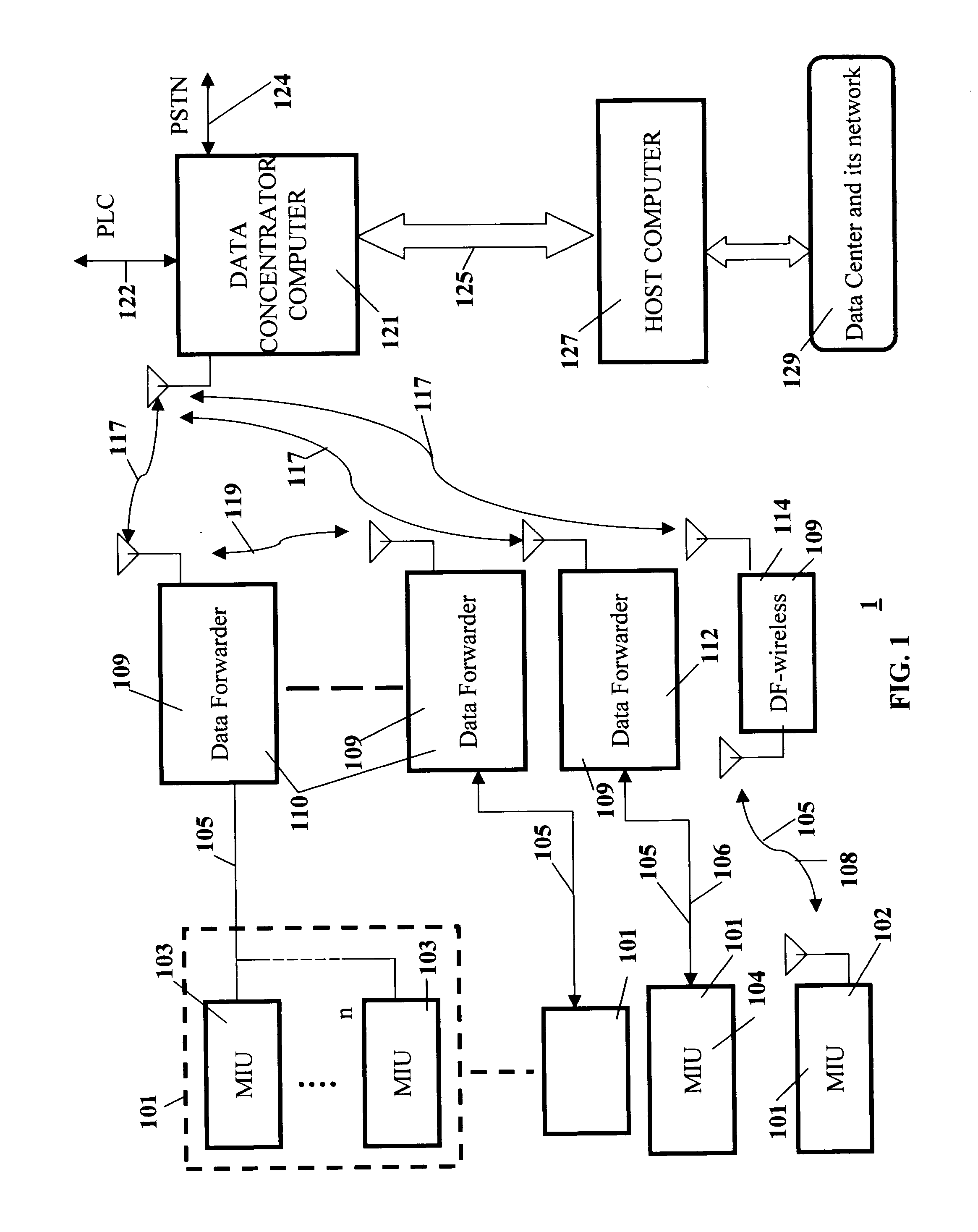

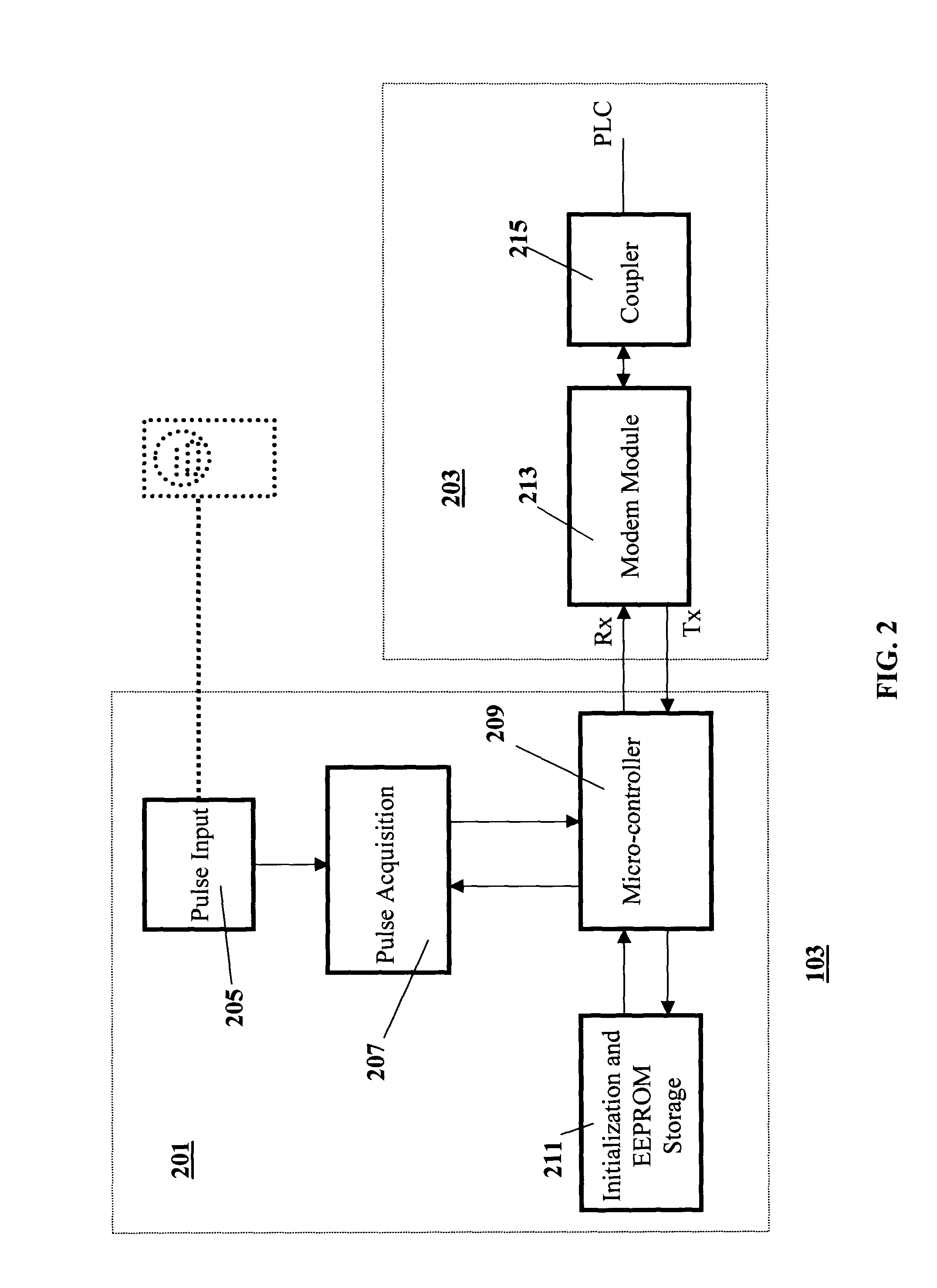

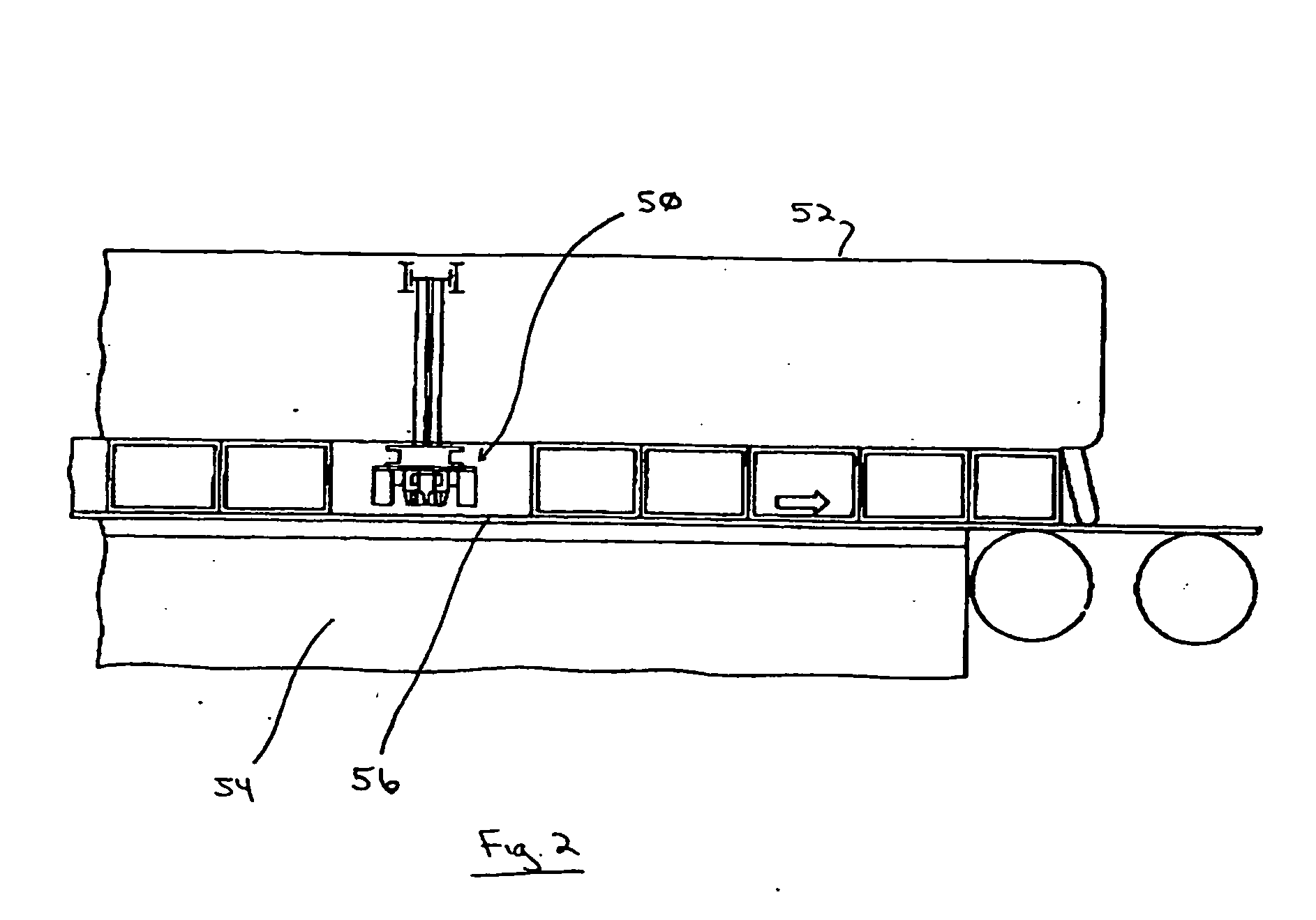

Automated utility metering system

InactiveUS20050033534A1Low costLow equipment costElectric devicesTariff metering apparatusCarrier signalComputer science

An automatic metering system in accordance with the principles of the invention comprises a plurality of groups of geographically related utility meters. Each utility meter comprises an interface unit operable to accumulate usage data and to transmit the usage data over power lines utilizing power line carrier. The system further comprises a plurality of data forwarding apparatus each comprising power line carrier communication apparatus operable to receive usage data from each utility meter in its group of utility meters. Each data forwarding apparatus comprises a first wireless communication module. Each data forwarding apparatus has a geographic relationship to its corresponding group of utility meters. A computer is located geographically apart from the plurality of data forwarding apparatus. The central computer comprises a second wireless communication module and operates cooperatively with each data forwarding apparatus to upload usage data from all of the utility meters via the plurality of data forwarding apparatus.

Owner:POWERONEDATA

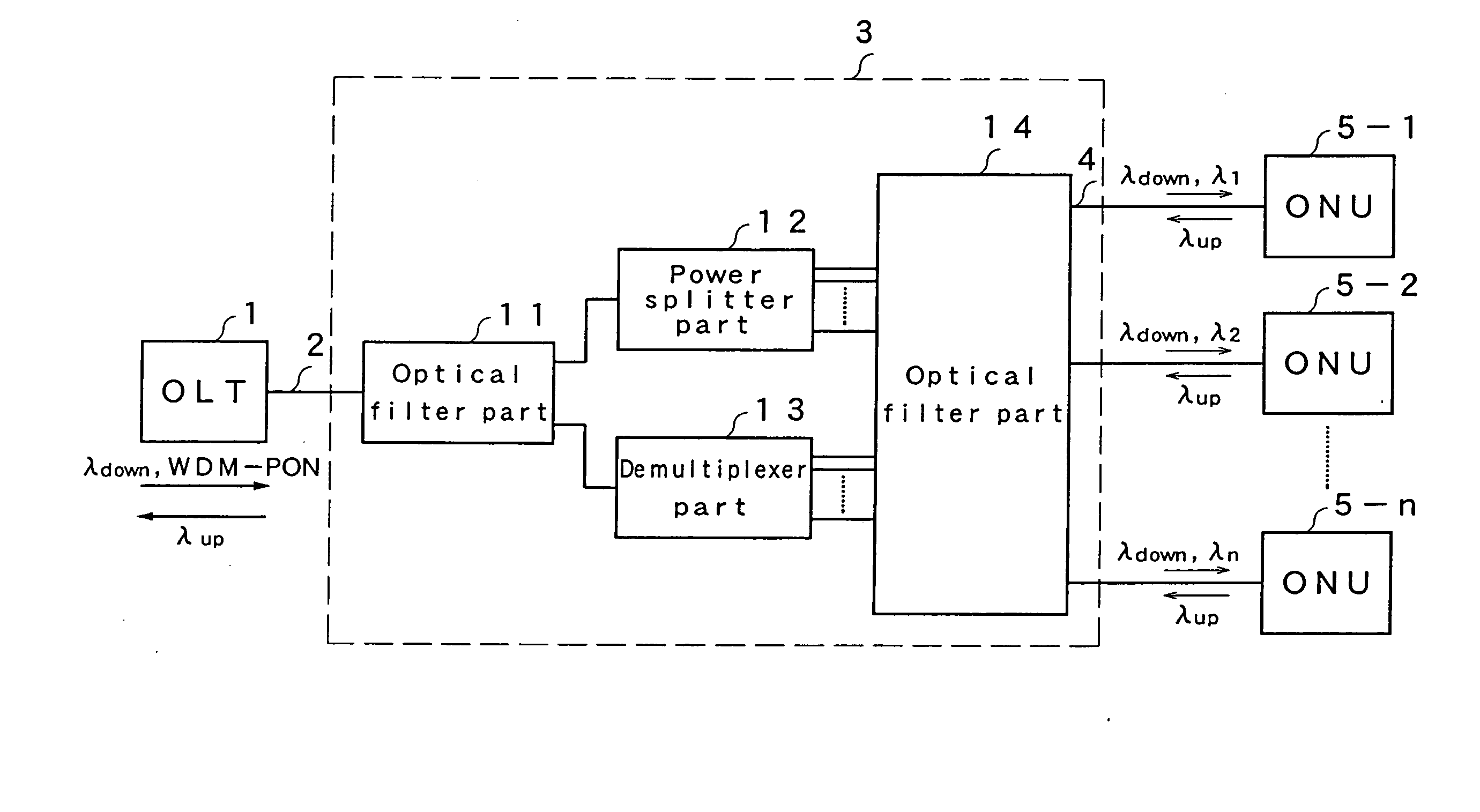

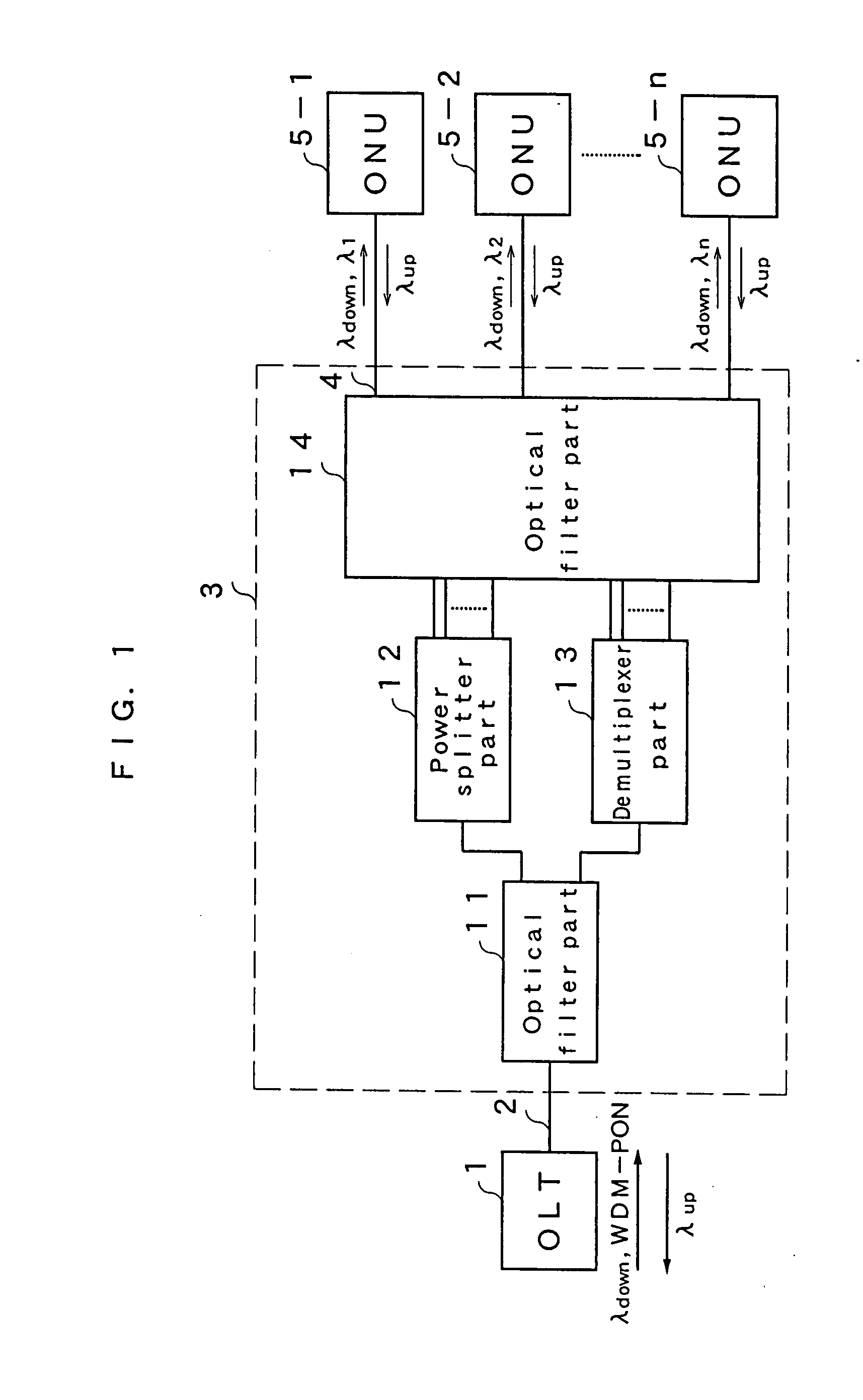

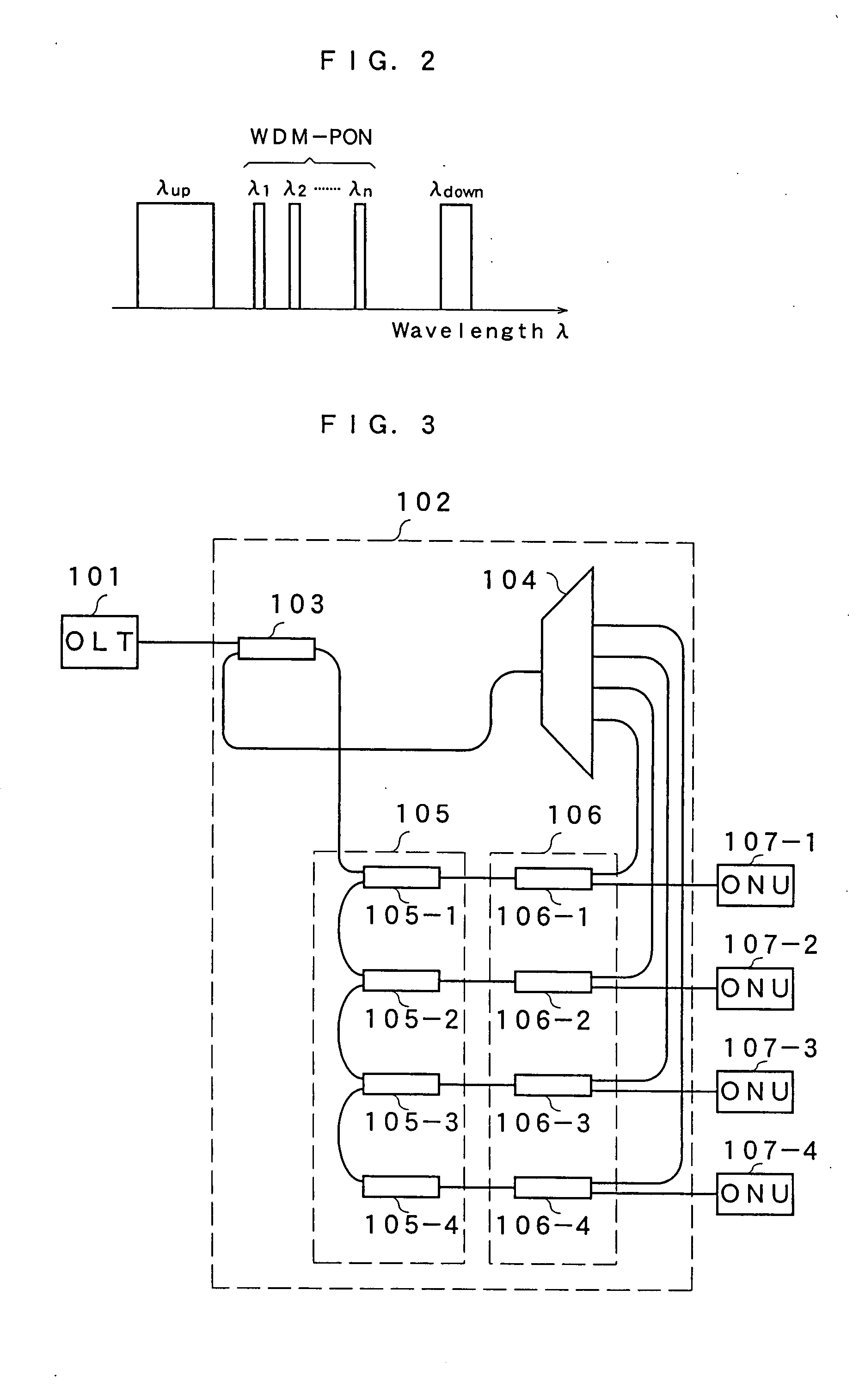

WDM hybrid splitter module

InactiveUS20080031625A1Fast communication speedLow costWavelength-division multiplex systemsOptical light guidesEngineeringLength wave

A downlink signal and WDM-PON signal from an OLT 1 are separated by an optical filter part 11, and a downlink signal is split by a power splitter part 12. A WDM-PON signal is also split in each wavelength by a demultiplexer part 13, and a downlink signal and a WDM-PON signal of either one of the wavelengths are outputted to each ONU, in an optical filter part 14. Moreover, an uplink signal from the ONU is introduced to the power splitter part 12 via the optical filter part 14, and outputted to the OLT 1 via the optical filter part 11. Therefore, it is possible to realize a hybrid splitter module which allows upgrading a downlink signal to a WDM-PON without adding changes to a device on a subscriber side.

Owner:SANTEC

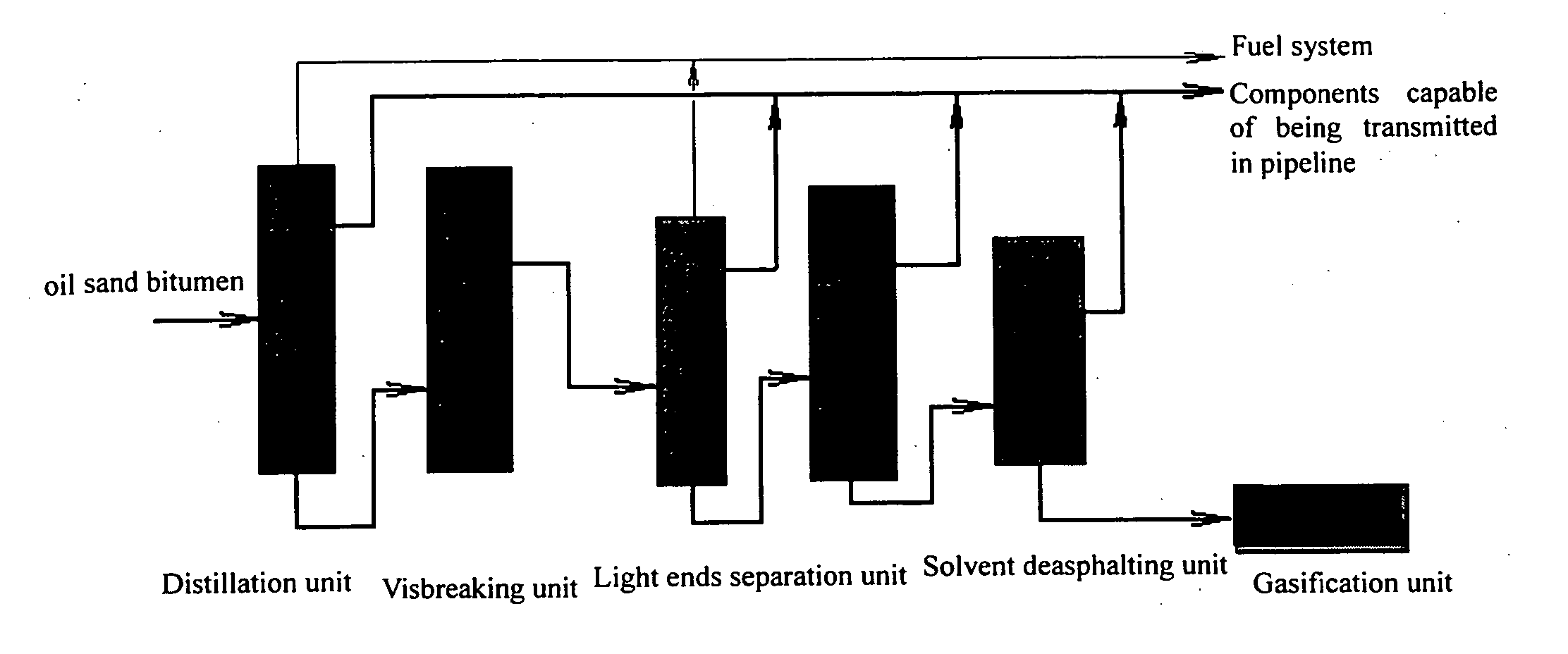

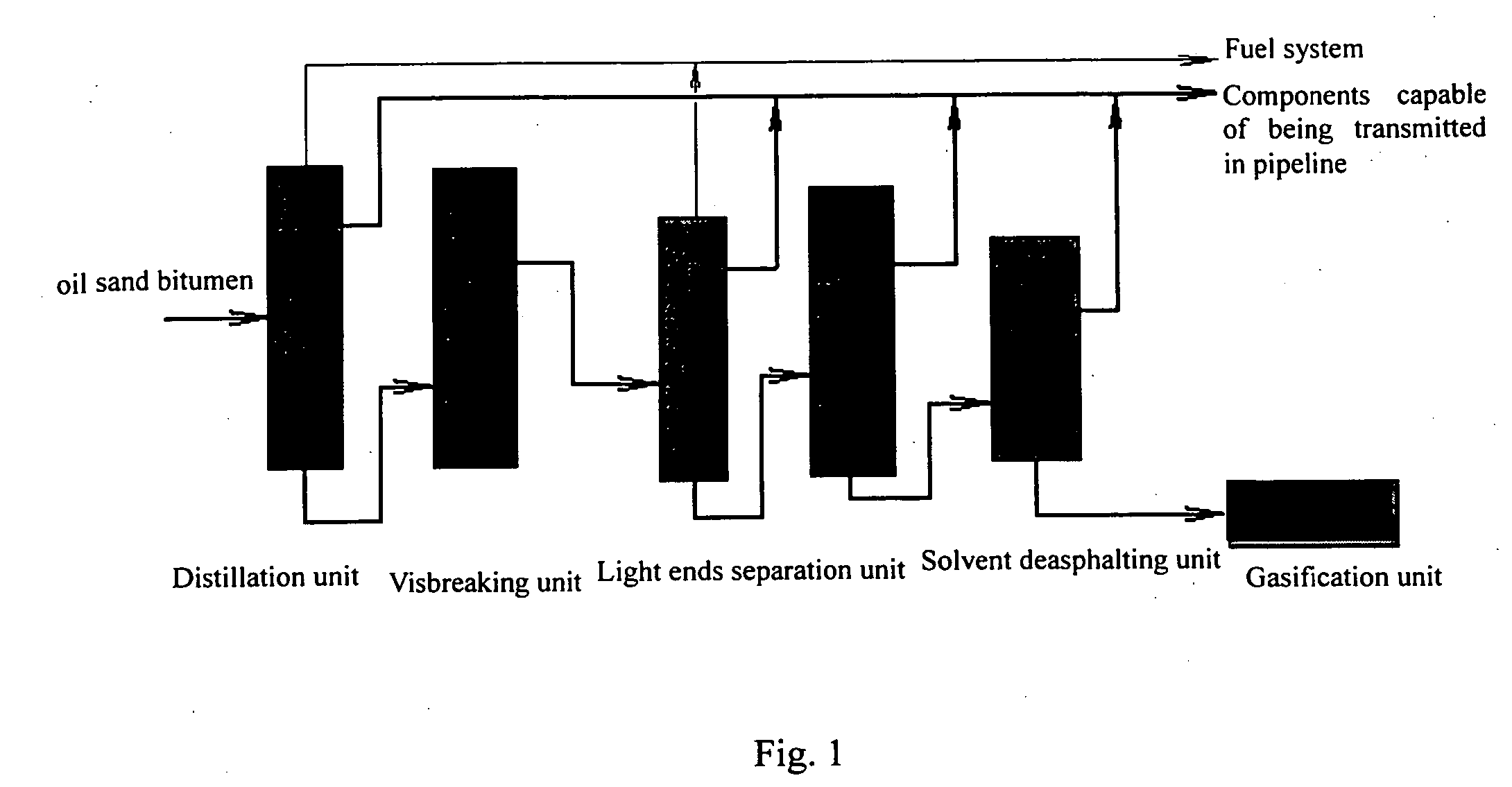

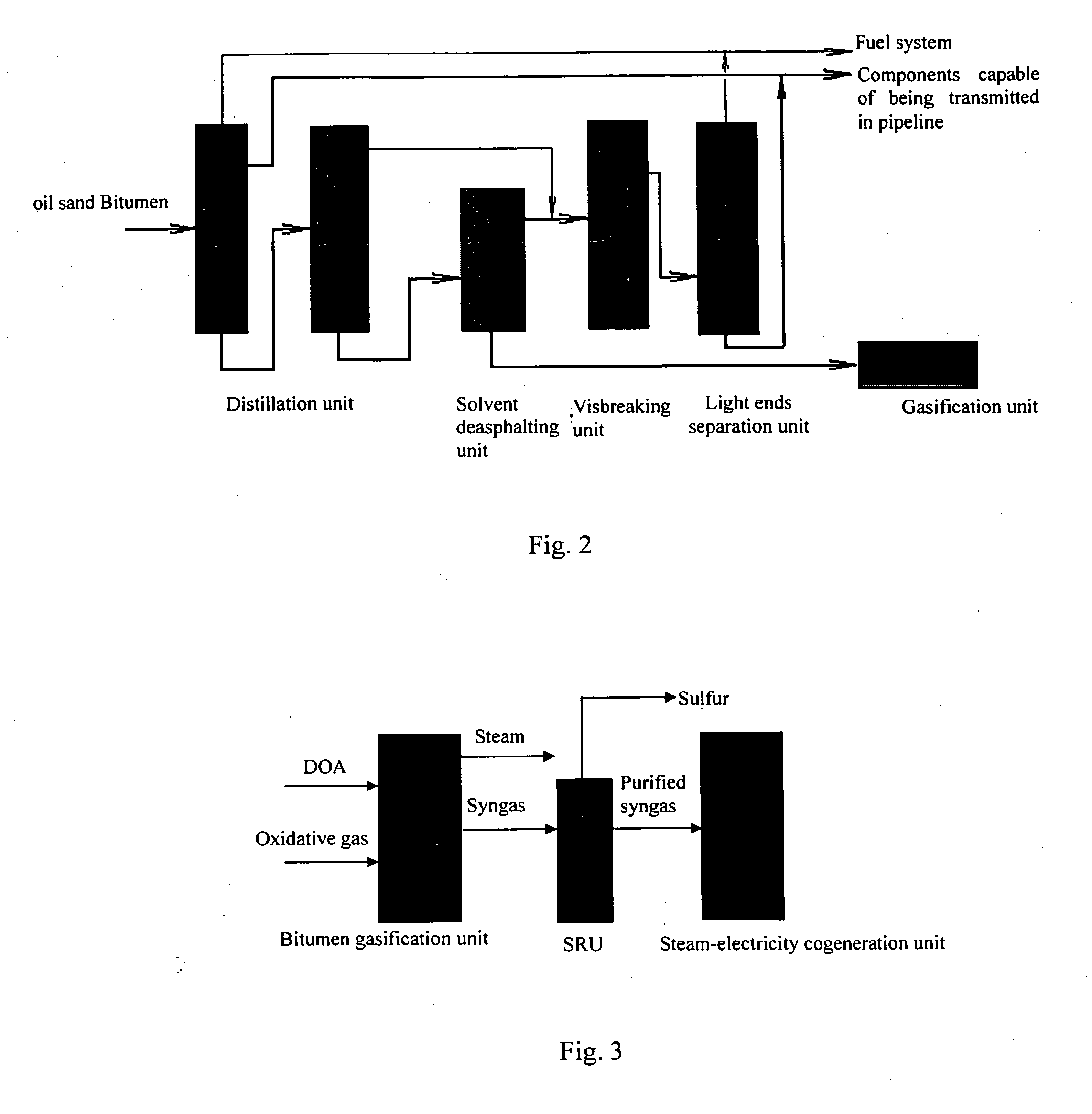

Method for processing oil sand bitumen

InactiveUS20070125686A1Low costLow viscosityTreatment with plural serial stages onlyLiquid hydrocarbon mixture productionEmission standardPollutant emissions

This invention relates to a method for processing oil sand bitumen including solvent deasphalting and visbreaking oil sand bitumen to yield de-oiled asphalt (DOA) and components capable of being transmitted in pipeline. The method for processing oil sand bitumen provided by this invention can effectively transmit oil sand bitumen in pipeline with the advantages of simple operation low equipment cost and significantly reduced operating cost. This method not only can solve the problems arising from enormous working capital required for purchasing diluting agent needed by the traditional unit for processing oil sand bitumen and complications in looking for users, but also can drastically reduce the high investment and high processing cost of such main upgrading avenues as coking and converting heavy oils to light distillates. This invention can enhance the effective products yield and increase the sales income. This method for processing oil sand bitumen can make the recovery of sulfur contained therein by means of the downstream processes easier to significantly reduce the sulfur recovery cost and ensure compliance with the pollutants emission standard.

Owner:CHINA NAT OFFSHORE OIL CORP

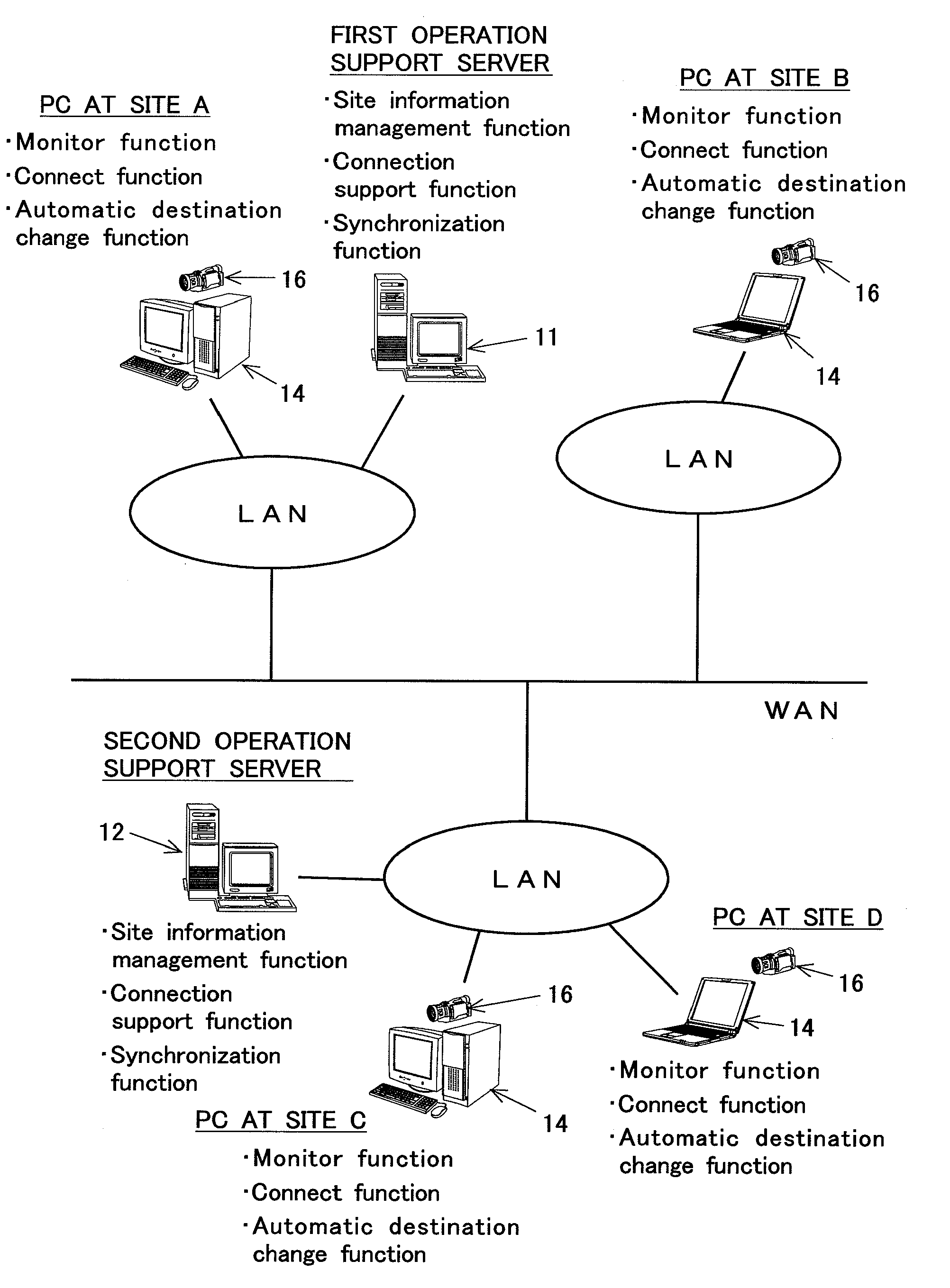

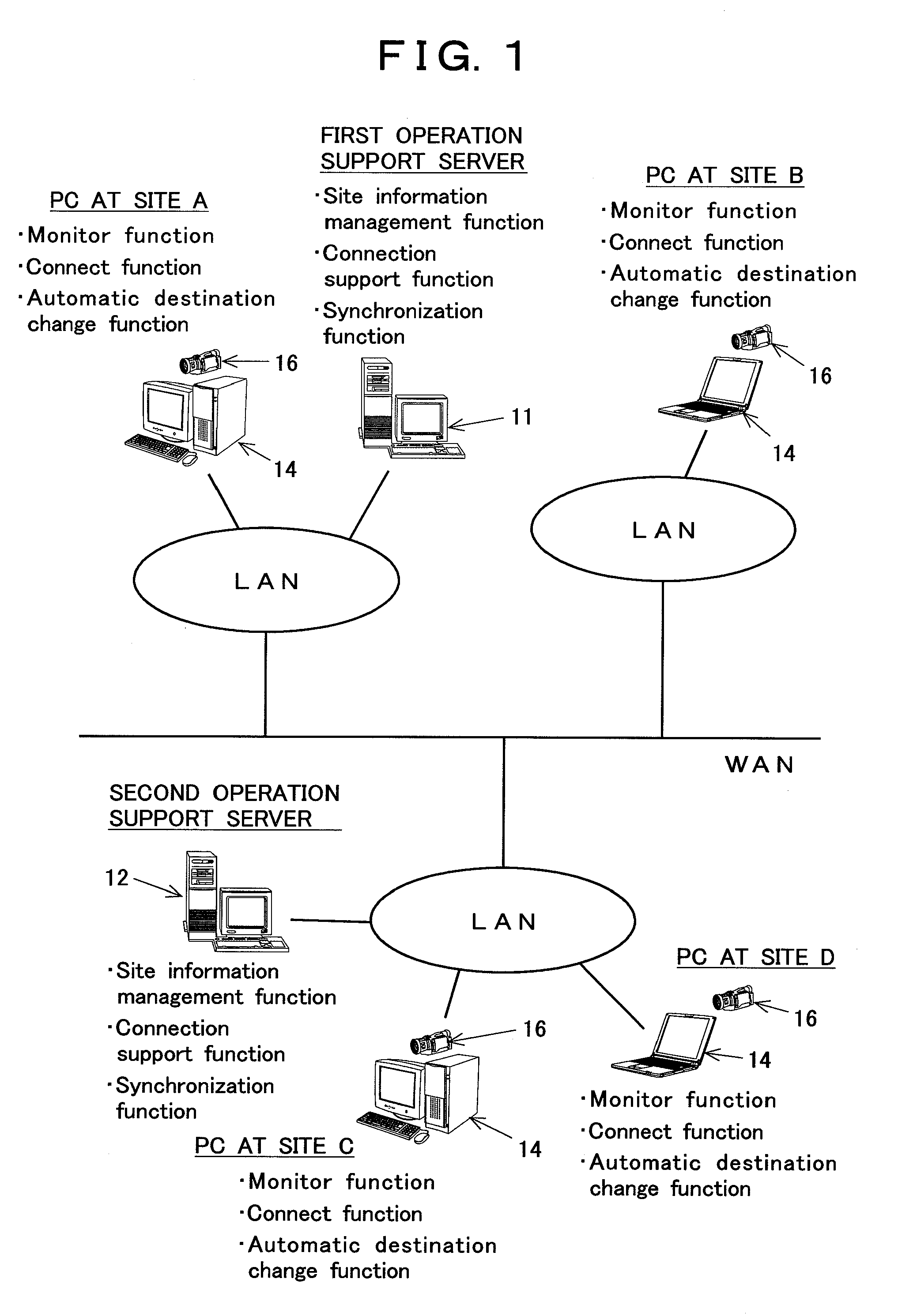

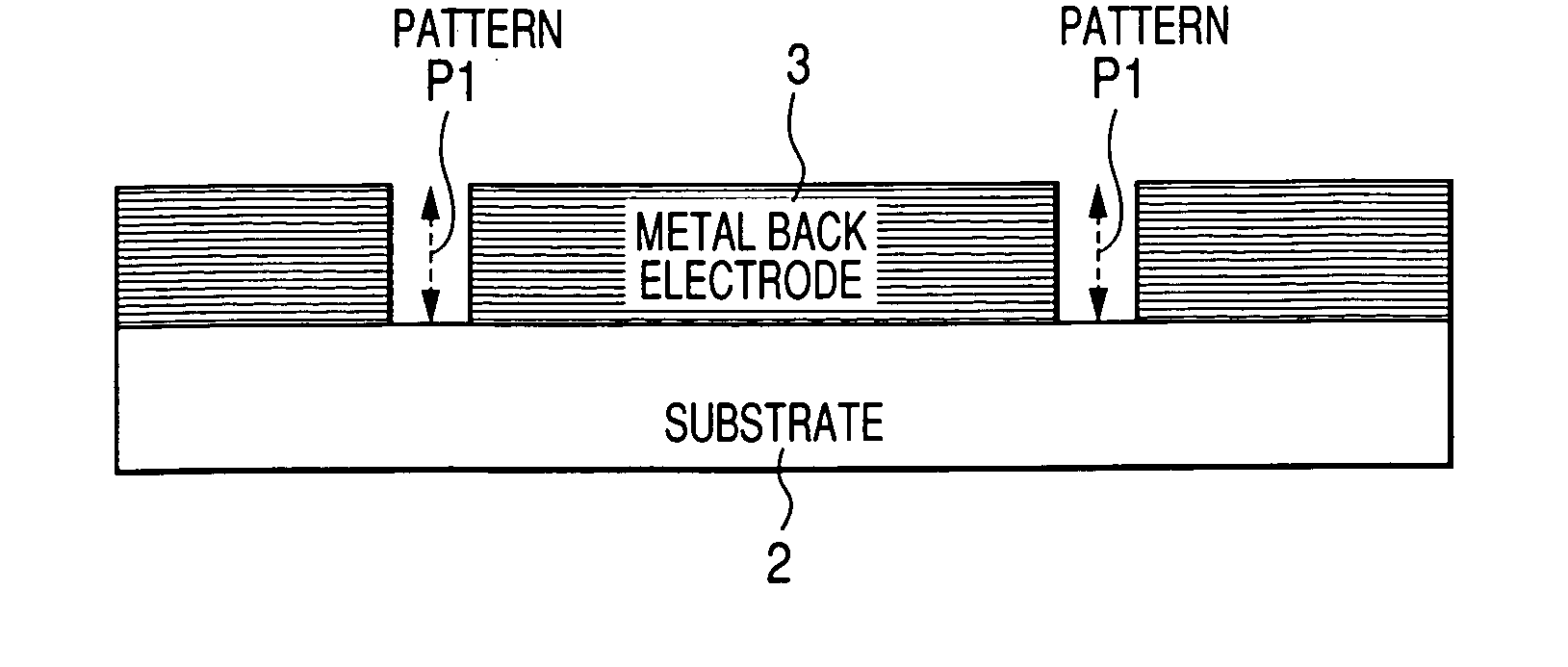

Videoconferencing system using network

InactiveUS20100007713A1Smooth transmissionReadily and quickly opened and closedSpecial service provision for substationMultiplex system selection arrangementsComputer scienceSupport services

Dual (redundant) operation support servers are used to improve the reliability of a video conferencing system and ensure the stability of communication. Switching automatically one operation support server to another enables a video conference to be smoothly continued without interruption. Multiple operation support servers are provided, each including a synchronization function which synchronizes site connection information and live camera information between the operation support servers and prevents an operation support server in a standby state from writing live camera information in a folder for each site. Each site PC 14 includes an automatic server change function which, when an operation support server 11 in service fails, switches connection from the operation support server 11 to an operation support server 12 in a standby state. When the operation support server in service fails, the operation support server in a standby state writes live camera information into a folder for each site and each site PC changes connection from the operation support server that was in service to the operation support server in a standby state.

Owner:JAPAN ATOMIC ENERGY AGENCY INDEPENDANT ADMINISTRATIVE CORP

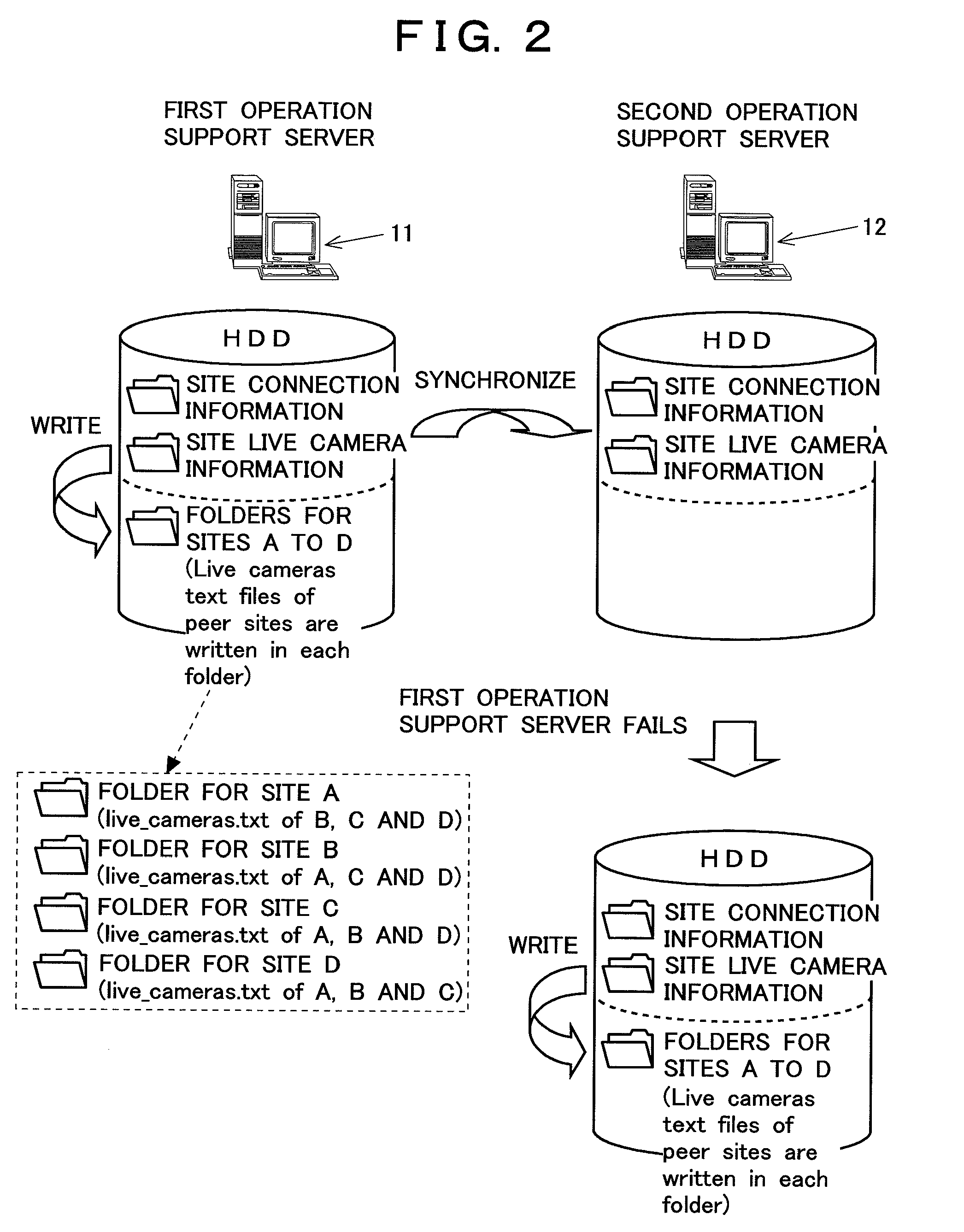

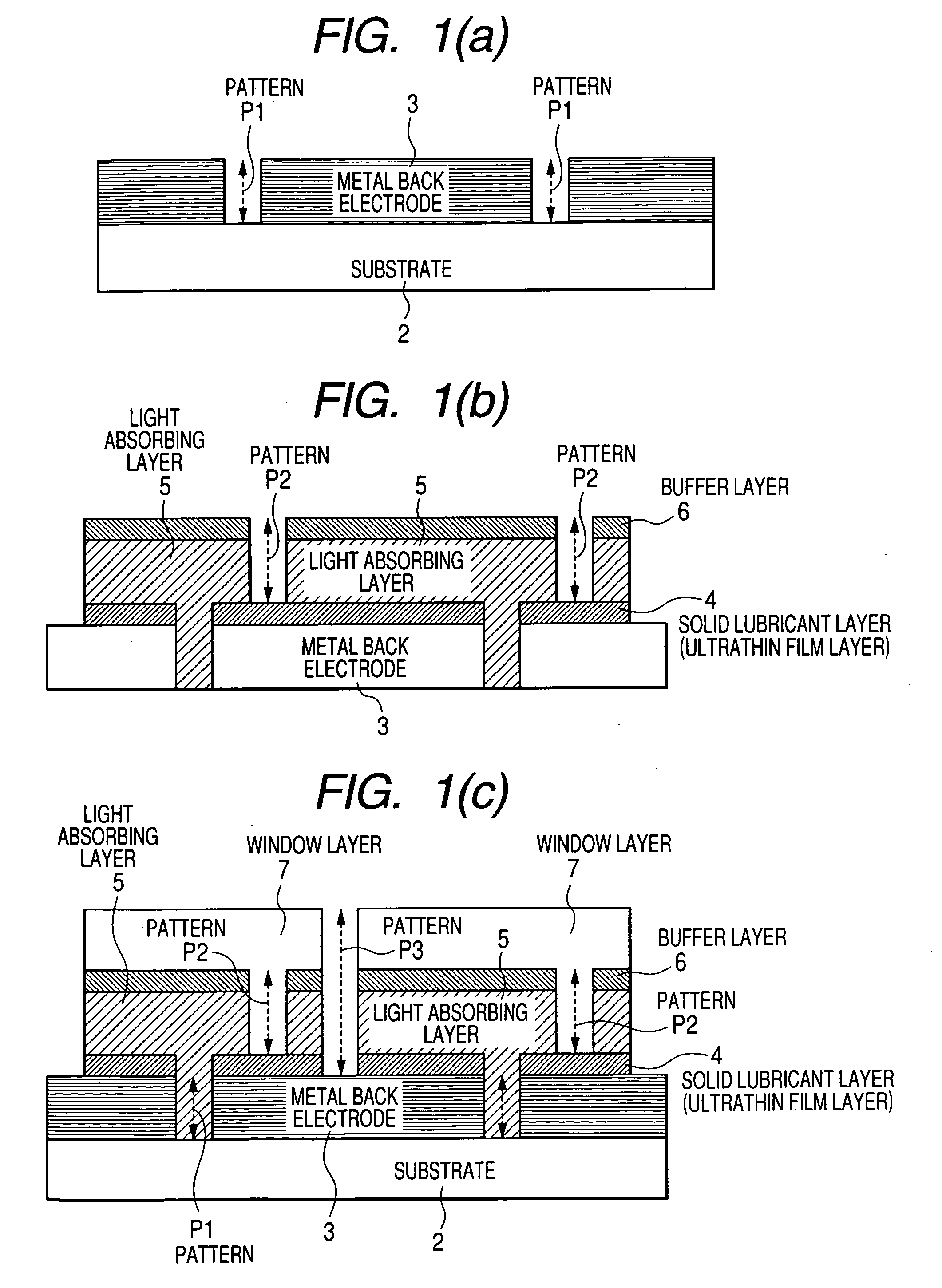

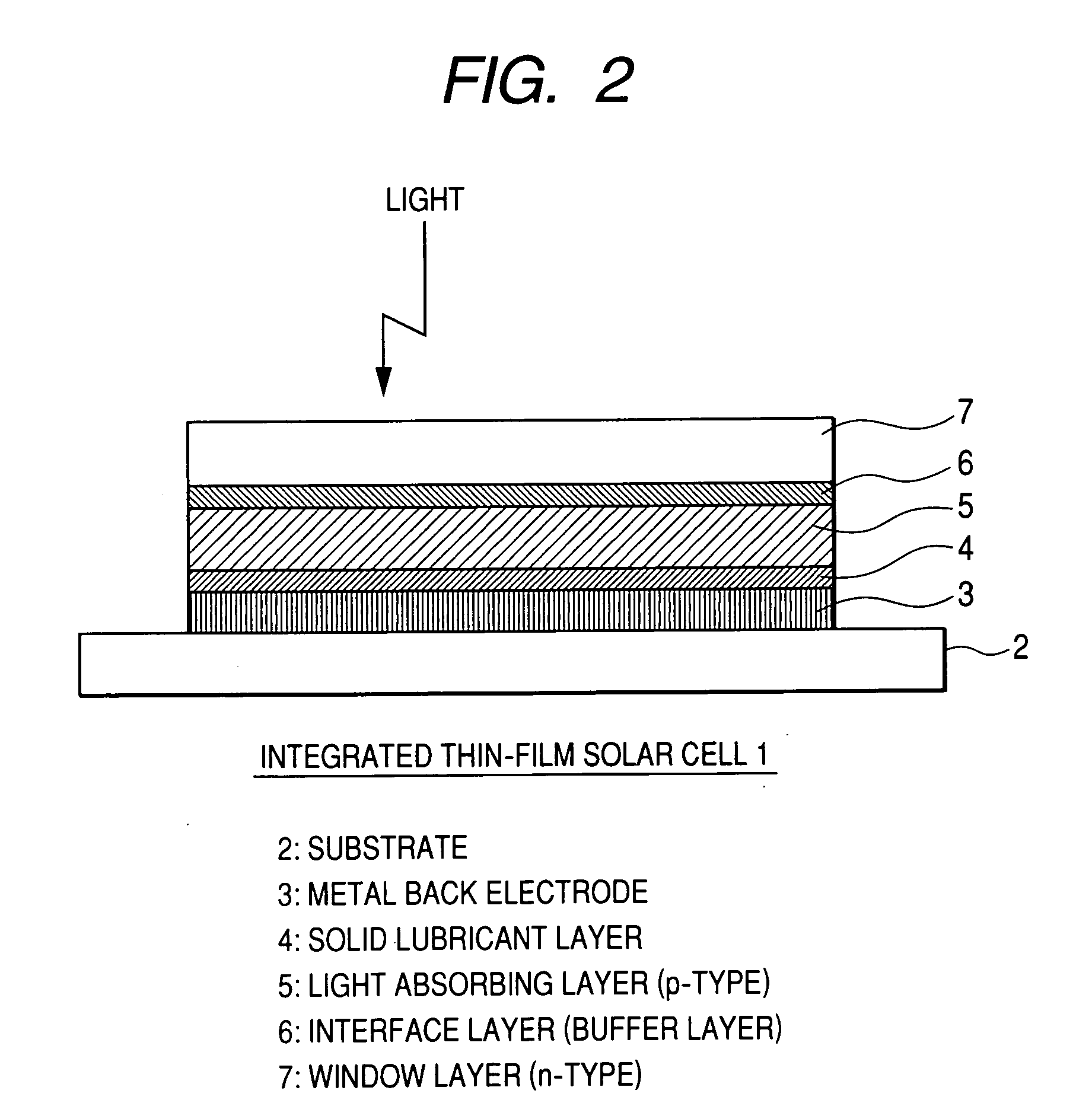

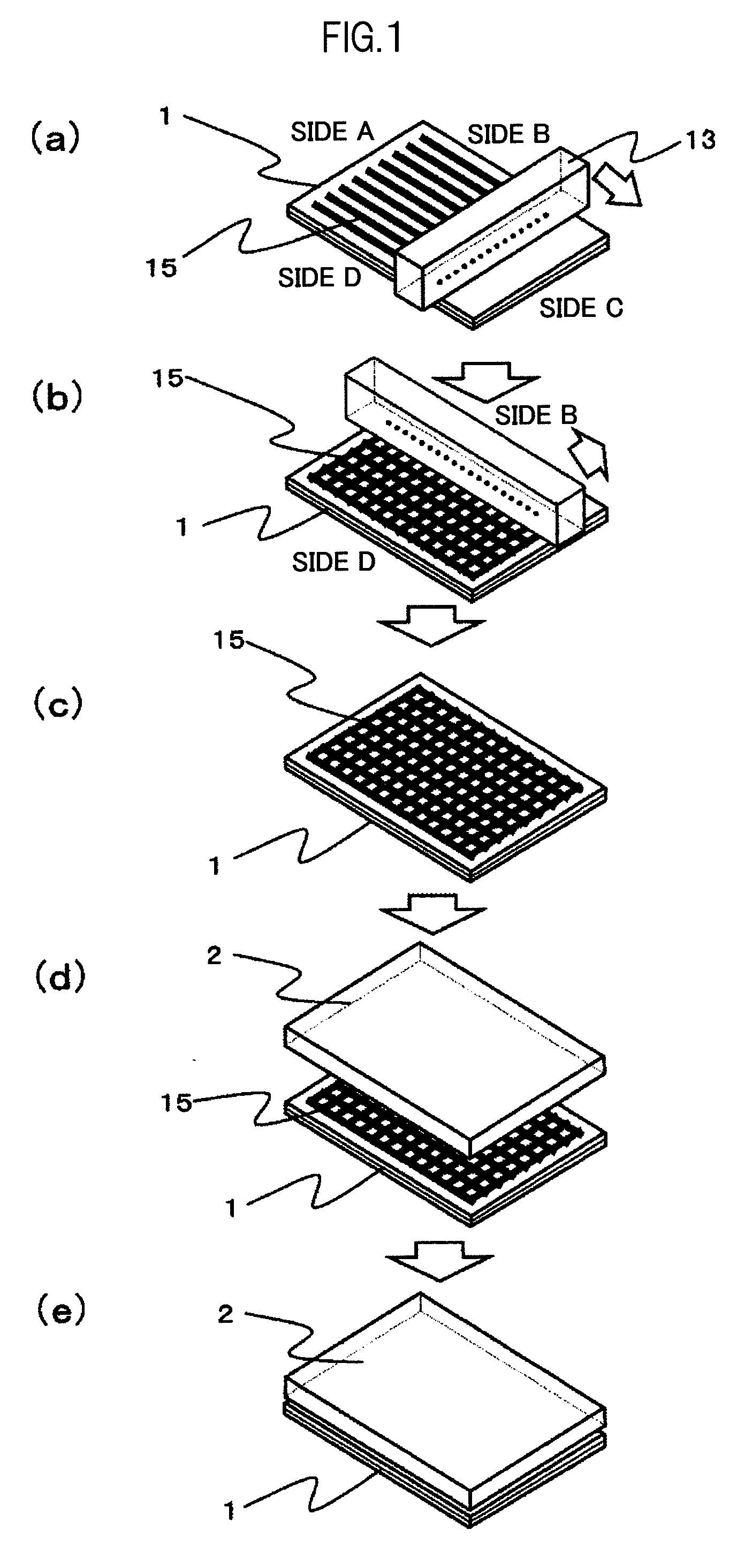

Integrated thin-film solar cell and process for producing the same

InactiveUS20070163646A1Simple processLow production costFinal product manufactureDiodeHigh resistanceEngineering

A problem of the invention is to prevent a substrate from being damaged with a metal stylus upon mechanical patterning. In the invention, a thin film obtained by accumulating in this order a substrate 2, a back surface electrode layer 3, a multi-element compound semiconductor thin film (light absorbing layer) 5, a transparent buffer layer 6 having a high resistance and a transparent and electroconductive window layer 7 is divided into respective unit cells, which are connected plurally in series to obtain a prescribed voltage, and it contains patterning P1 of dividing the back surface electrode layer 3, patterning P2 of dividing the light absorbing layer 5, or the light absorbing layer and the buffer layer 6, and patterning P3 of dividing from the window layer 7 up to the light absorbing layer 5, in which in P2 and P3, an ultrathin film layer 4 formed secondarily through reaction with a chalcogen element on the surface of the back surface electrode layer 3 in the formation step of the light absorbing layer is used as a solid lubricant upon mechanically removing the constitutional thin film layers with a metal stylus to form grooves.

Owner:SHOWA SHELL SEKIYU KK

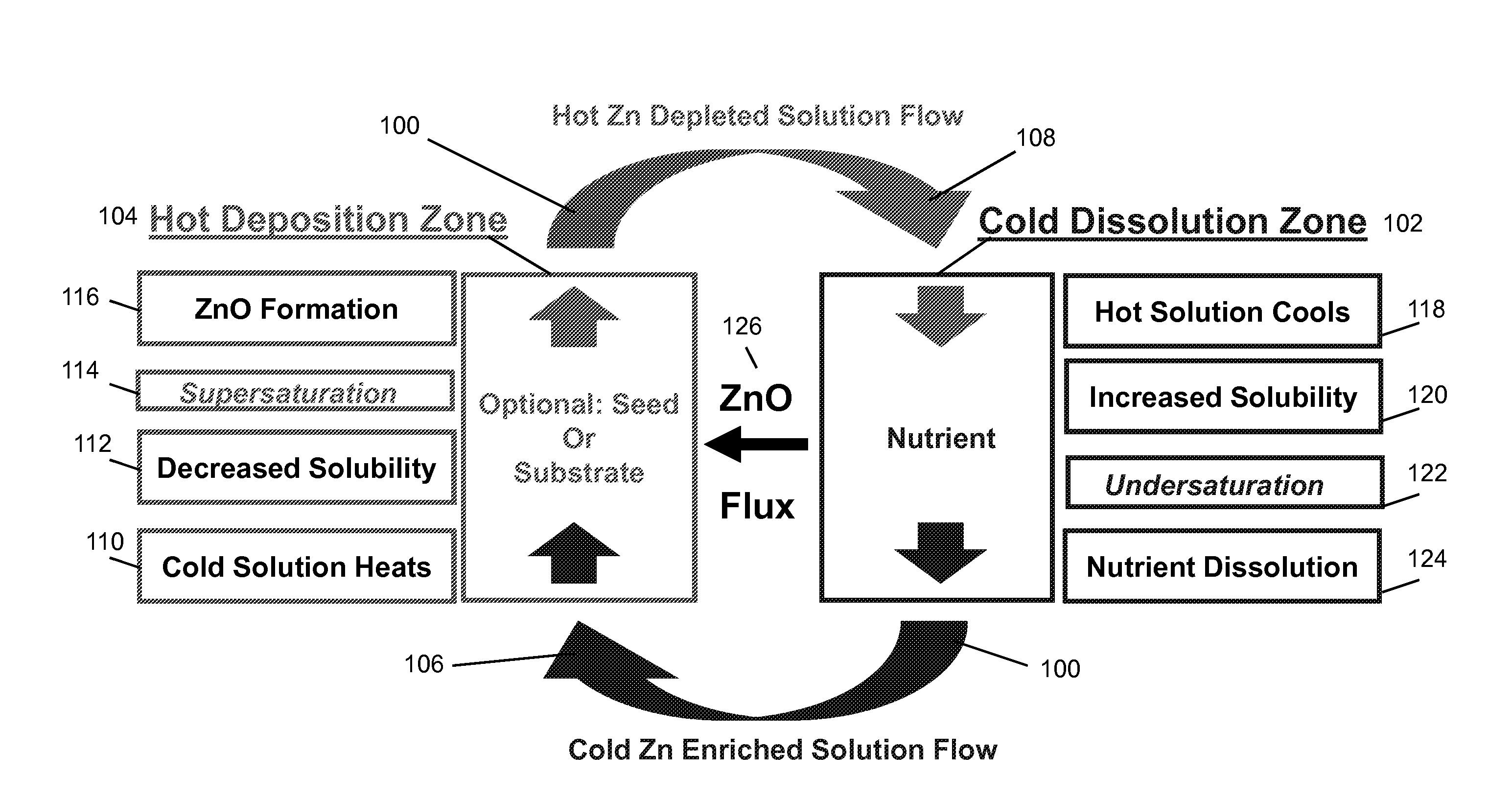

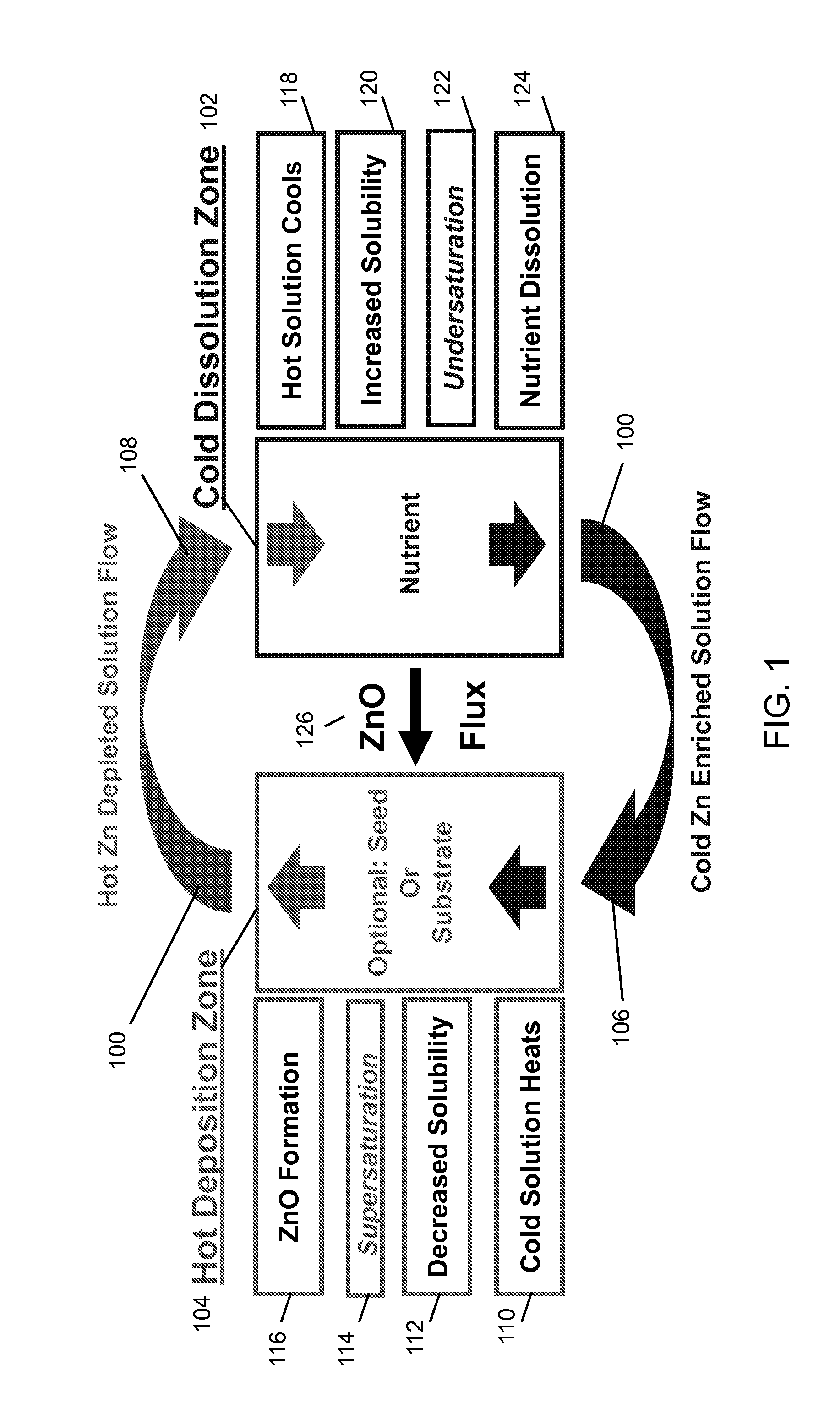

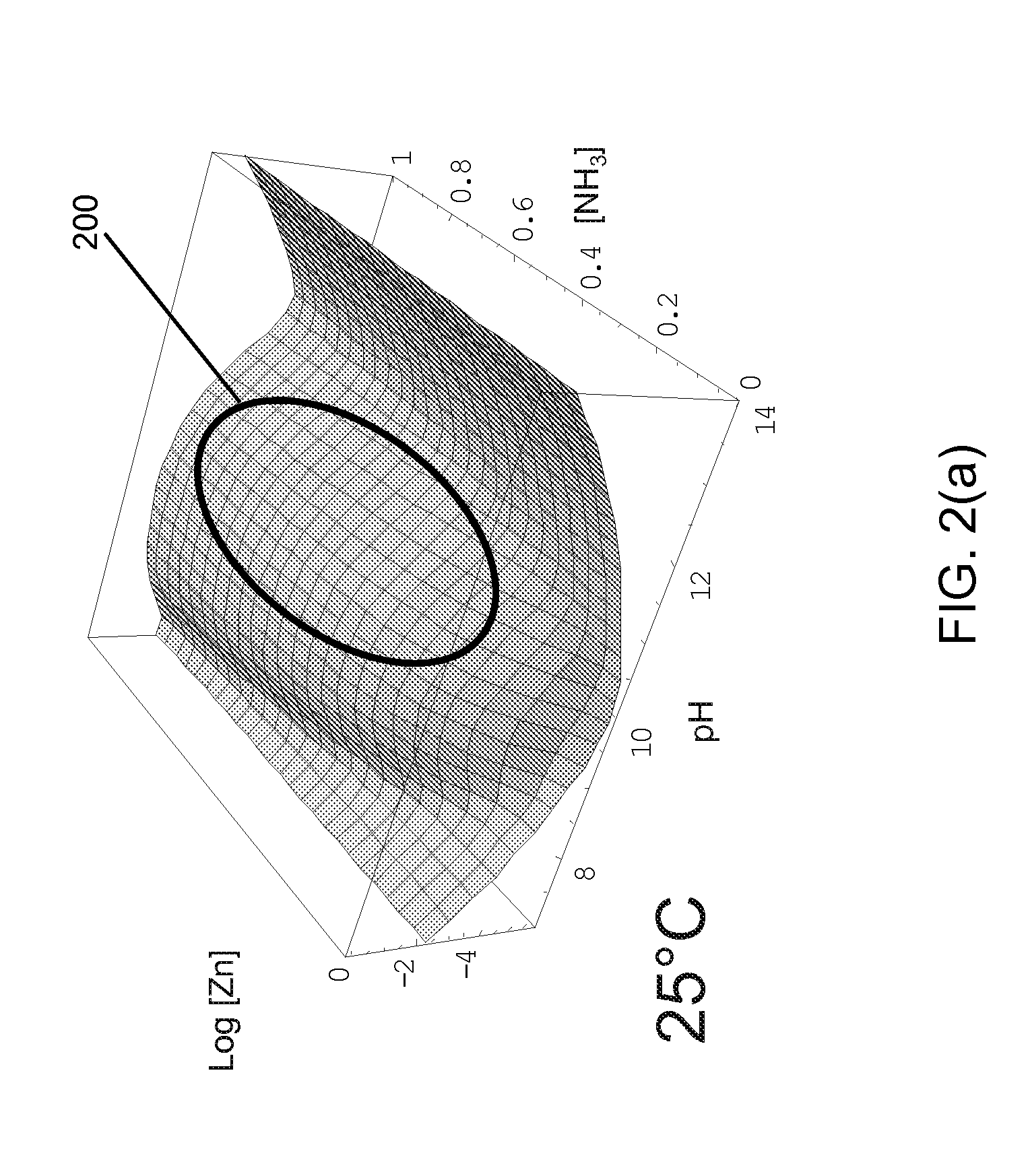

LOW TEMPERATURE CONTINUOUS CIRCULATION REACTOR FOR THE AQUEOUS SYNTHESIS OF ZnO FILMS, NANOSTRUCTURES, AND BULK SINGLE CRYSTALS

ActiveUS20100263586A1Improve compatibilityLowering environmental impact and costFrom normal temperature solutionsLiquid-phase epitaxial-layer growthSource materialSingle crystal

A method for synthesizing ZnO, comprising continuously circulating a growth solution that is saturated with ZnO between a warmer deposition zone, which contains a substrate or seed, and a cooler dissolution zone, which is contains ZnO source material.

Owner:RGT UNIV OF CALIFORNIA

Printed wiring board and its manufacturing method

InactiveUS20070266886A1High crystallinityLow equipment costLiquid surface applicatorsSolid-state devicesResistElectrical conductor

The present invention has for its object to provide a process for manufacturing multilayer printed circuit boards which is capable of simultaneous via hole filling and formation of conductor circuit and via holes of good crystallinity and uniform deposition can be constructed on a substrate and high-density wiring and highly reliable conductor connections can be realized without annealing. The present invention is related to a process for manufacturing multilayer printed circuit boards which comprises disposing an interlayer resin insulating layer on a substrate formed with a conductor circuit, creating openings for formation of via holes in said interlayer resin insulating layer, forming an electroless plated metal layer on said interlayer resin insulating layer, disposing a resist thereon, performing electroplating, stripping the resist off and etching the electroless plated metal layer to provide a conductor circuit and via holes, wherein the electroplating is performed intermittently using said electroless plated metal layer as cathode and a plating metal as anode at a constant voltage between said anode and said cathode.

Owner:IBIDEN CO LTD

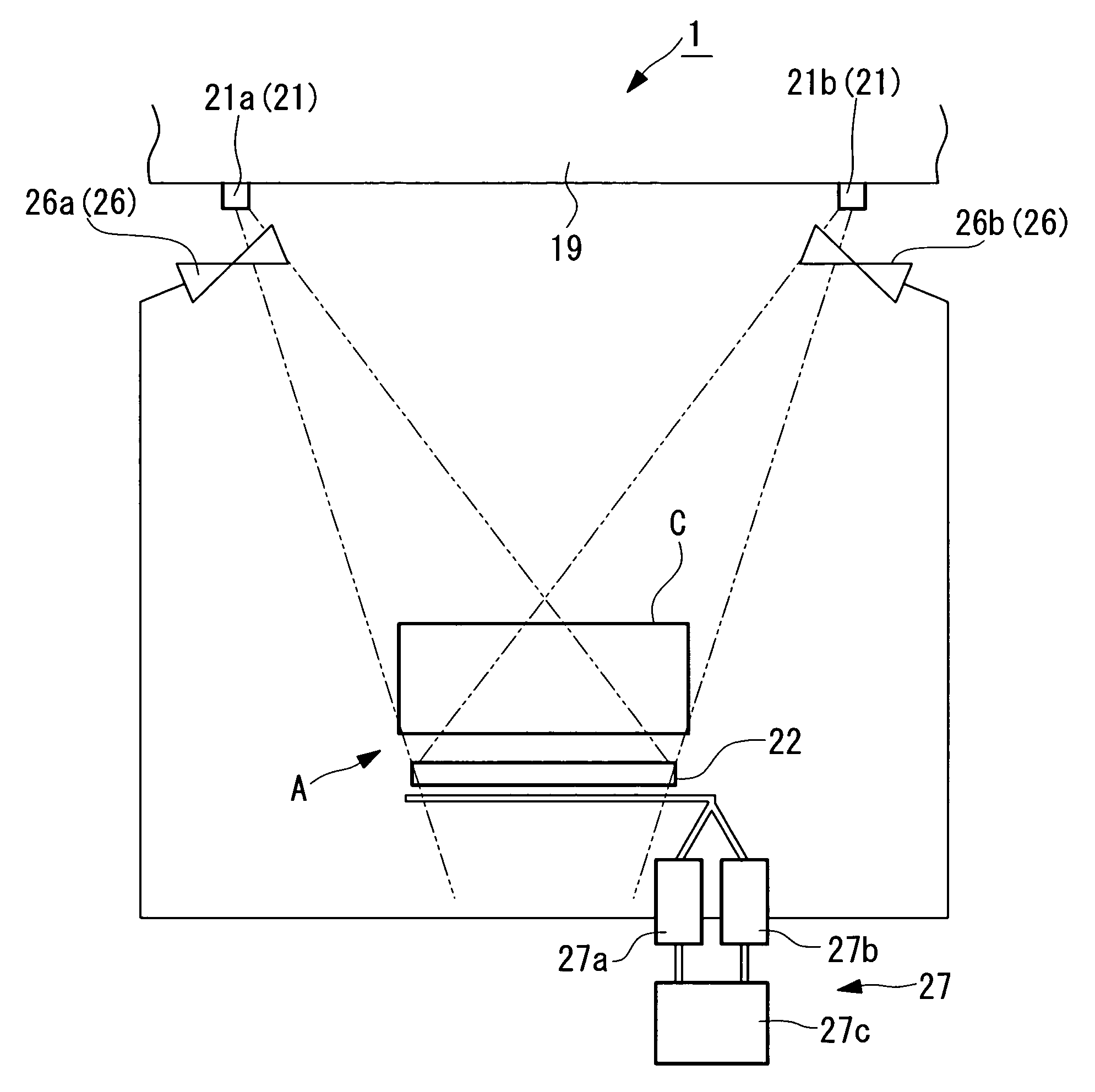

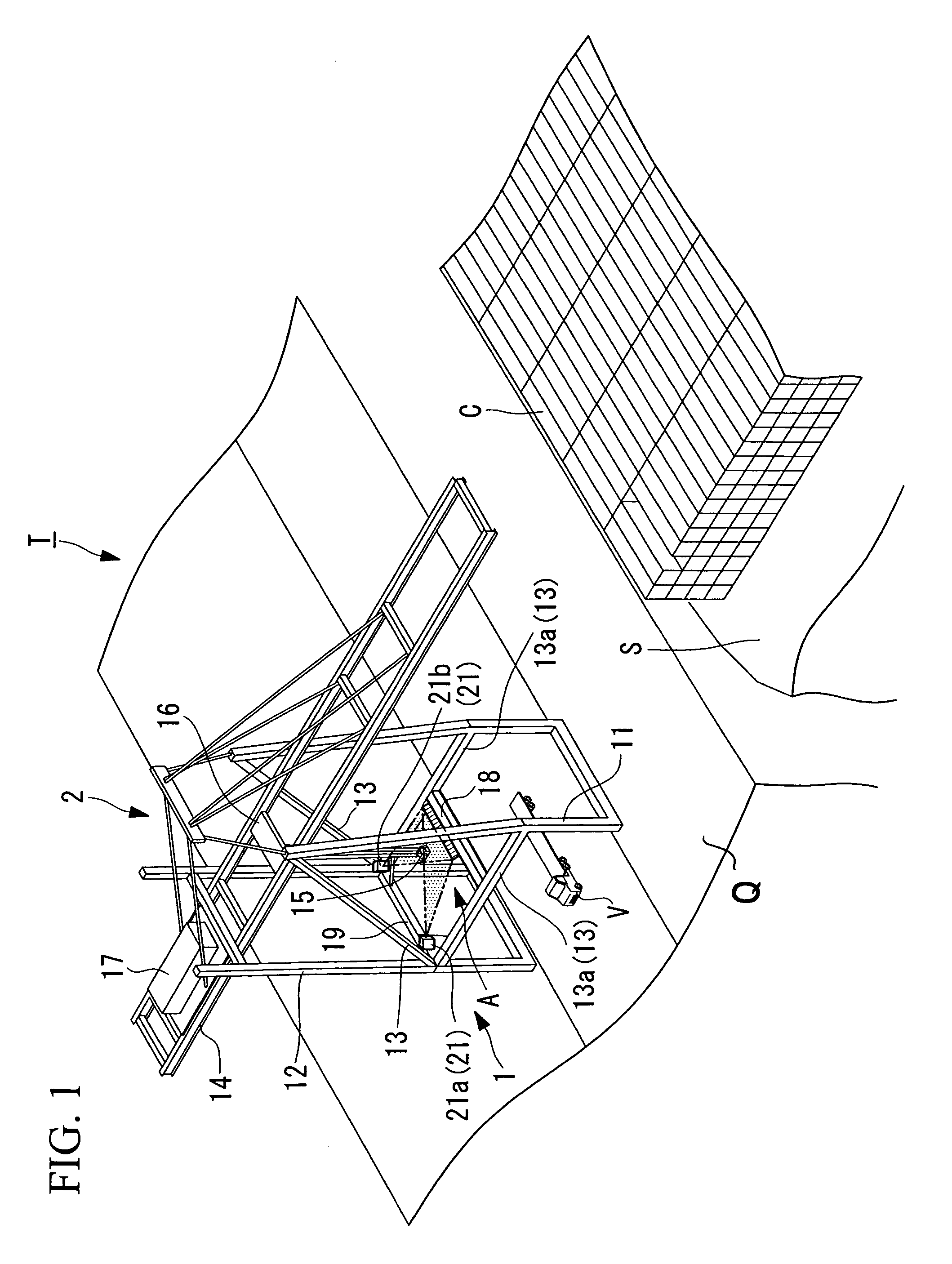

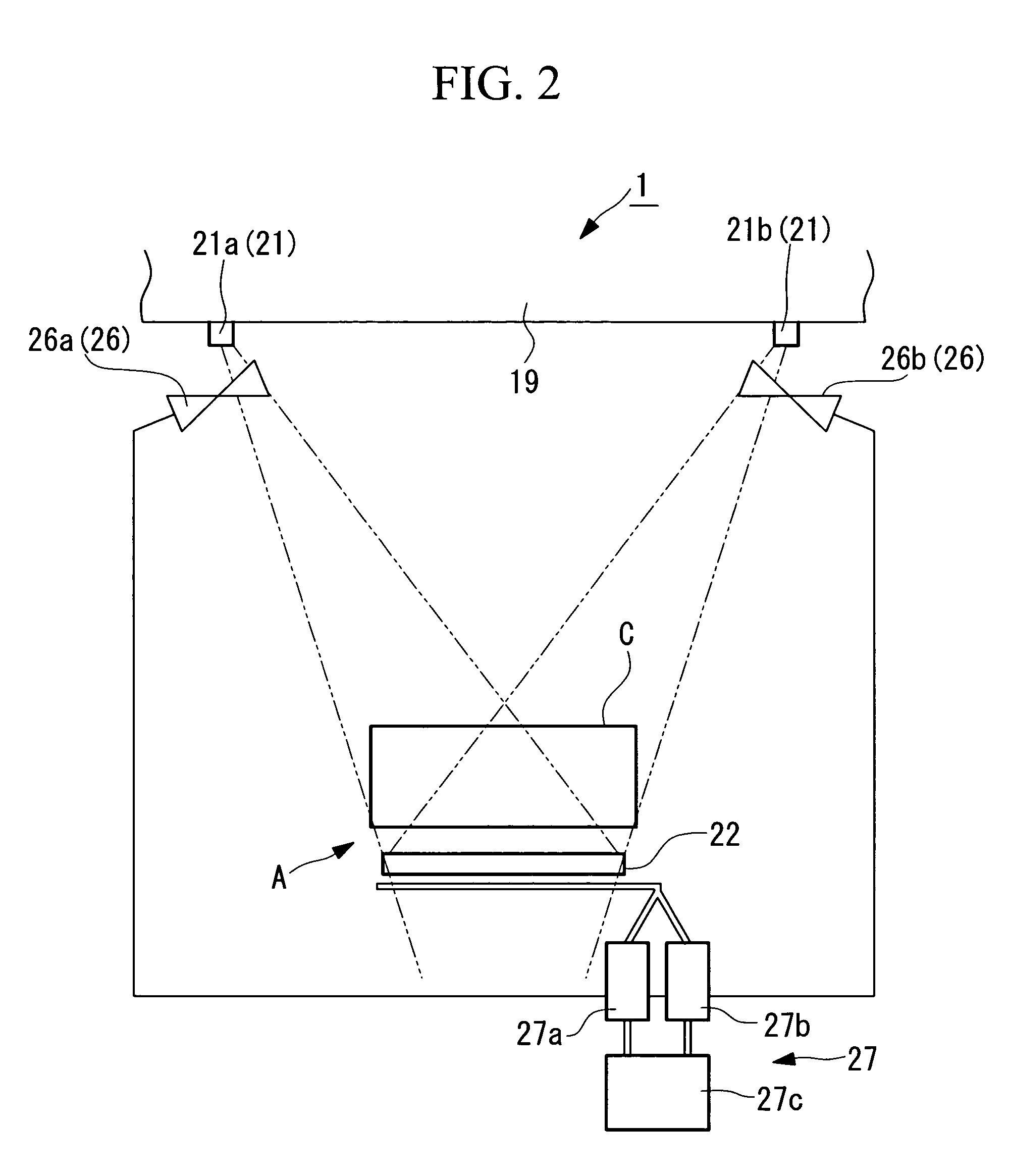

Nondestructive inspection device and crane equipped with nondestructive inspection device

InactiveUS7420174B2Low equipment costMaterial analysis by optical meansMachines/enginesNon destructiveIdentification device

An object is to provide a nondestructive inspection device of a low equipment cost, and a crane equipped with the nondestructive inspection device. The nondestructive inspection device is provided for a quay crane, on a transporting route of the container. The nondestructive inspection device irradiates radiation from radiation sources to a container which has entered into an inspection area, and detects radiation that has transmitted through the container using the same detector, and nondestructively inspects the entire inside of the container based on information of intensity of the radiation and information of detection position of the radiation. The nondestructive inspection device is provided with; a modulation device which assigns different modulations to each radiation emitted from each of the radiation sources, and an identification device that distinguishes the modulation assigned to the radiation incident on the detector based on the output of the detector, and identifies which one of the radiation sources this radiation has been emitted from.

Owner:MITSUBISHI HEAVY IND LTD

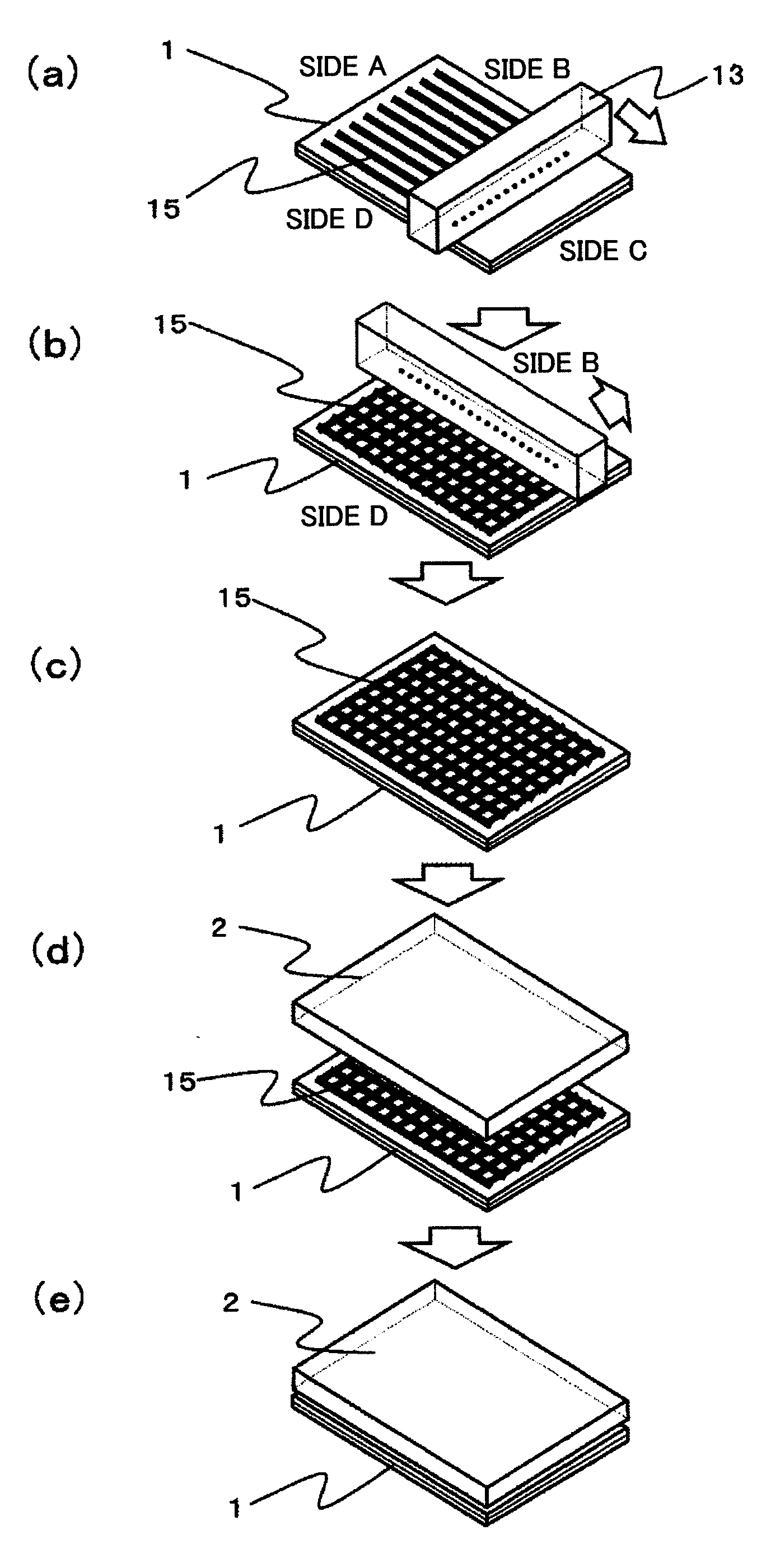

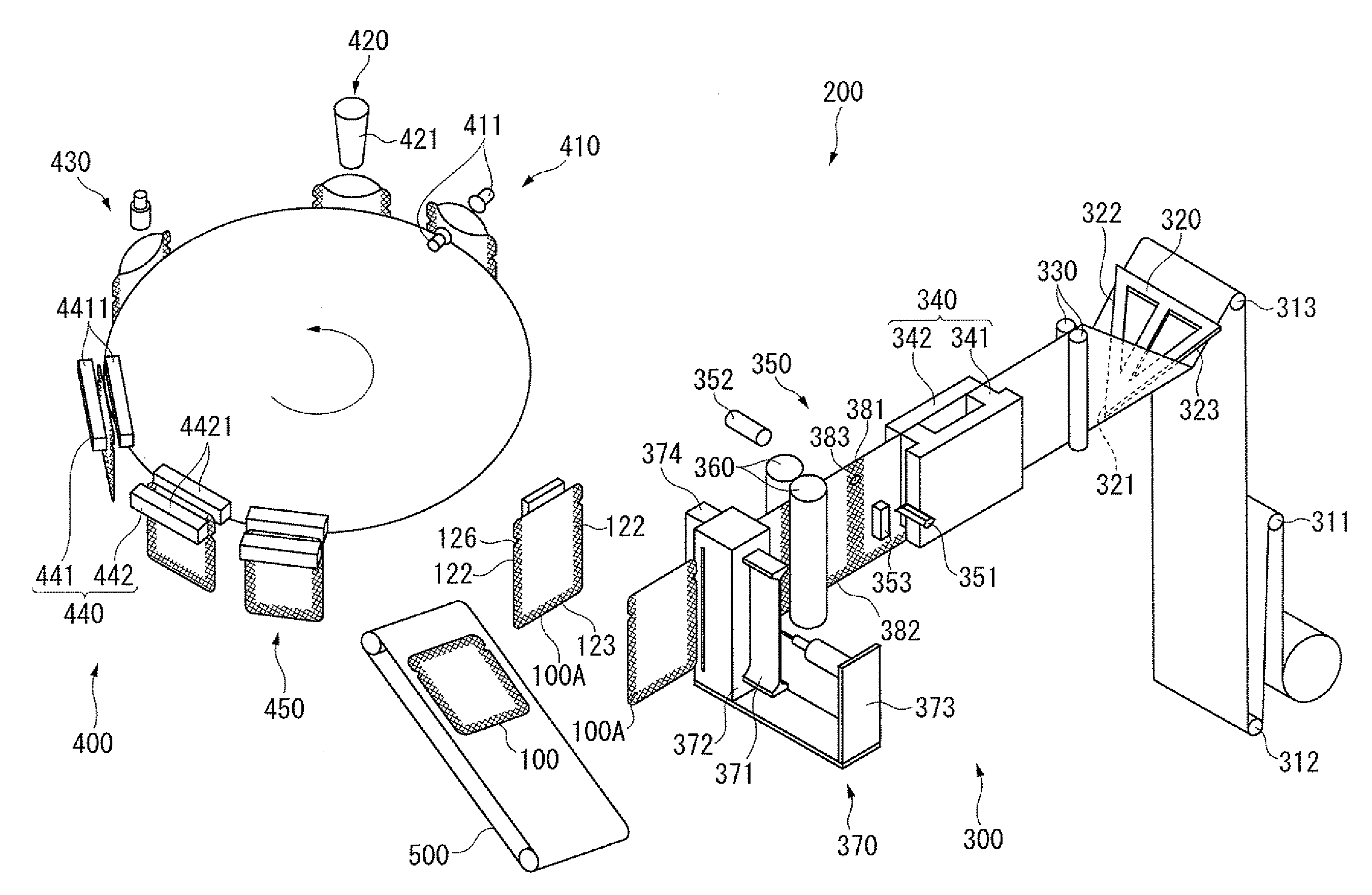

Method of manufacturing a display

ActiveUS20090218034A1Keep for a long timeEquipment cost necessaryLaminationLamination apparatusDisplay deviceEngineering

In a method of manufacturing a display having a display panel, a transparent protective plate, which is placed in front of the display panel, and a layer formed of a transparent organic medium, which is placed between the display panel and the protective plate, a liquid organic medium is applied to, or a sheet-like organic medium is formed on, a surface of one of the display panel and the protective plate, the display panel and the protective plate are bonded together in a reduced pressure atmosphere, and thereafter the liquid organic medium is cured.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

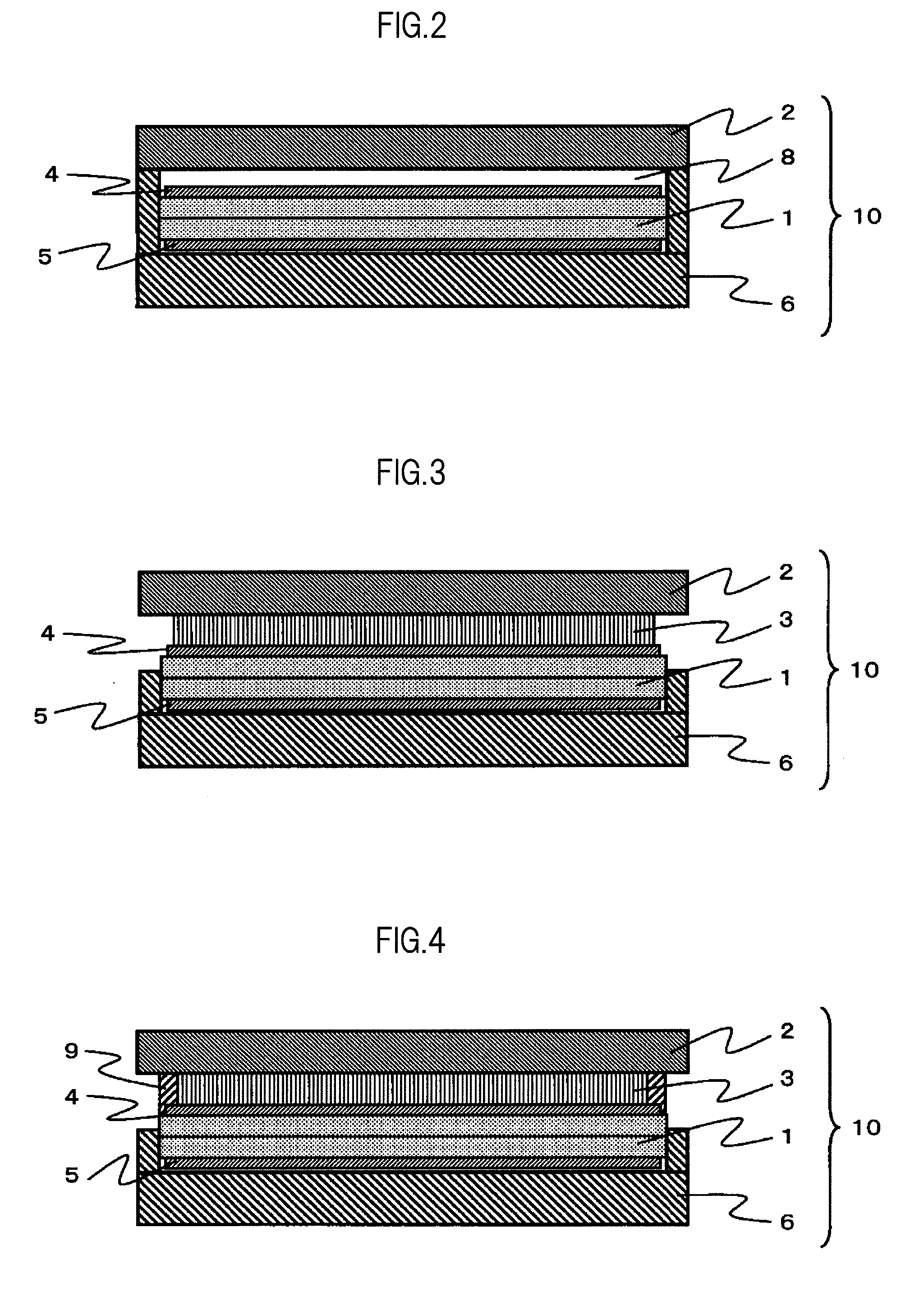

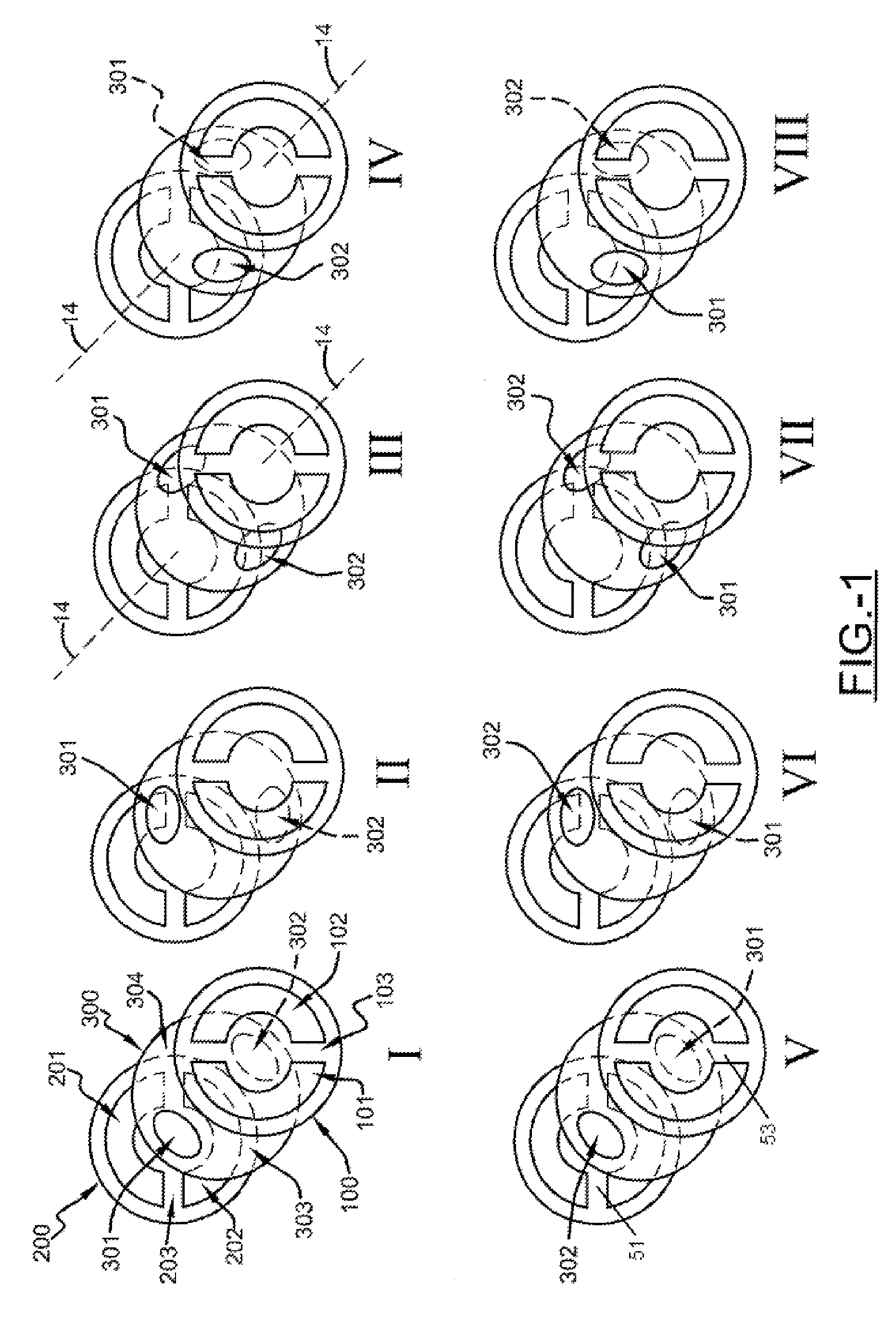

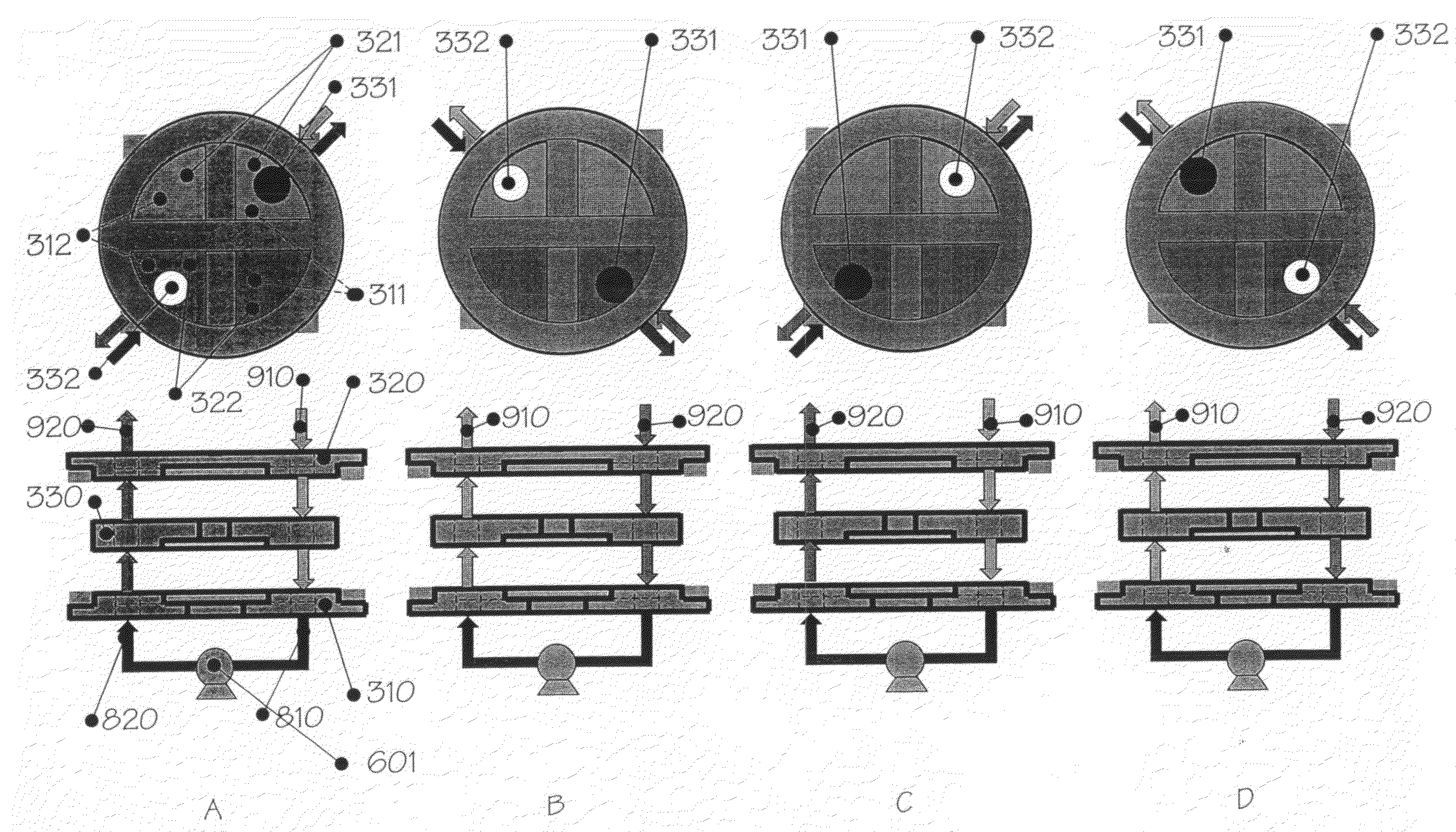

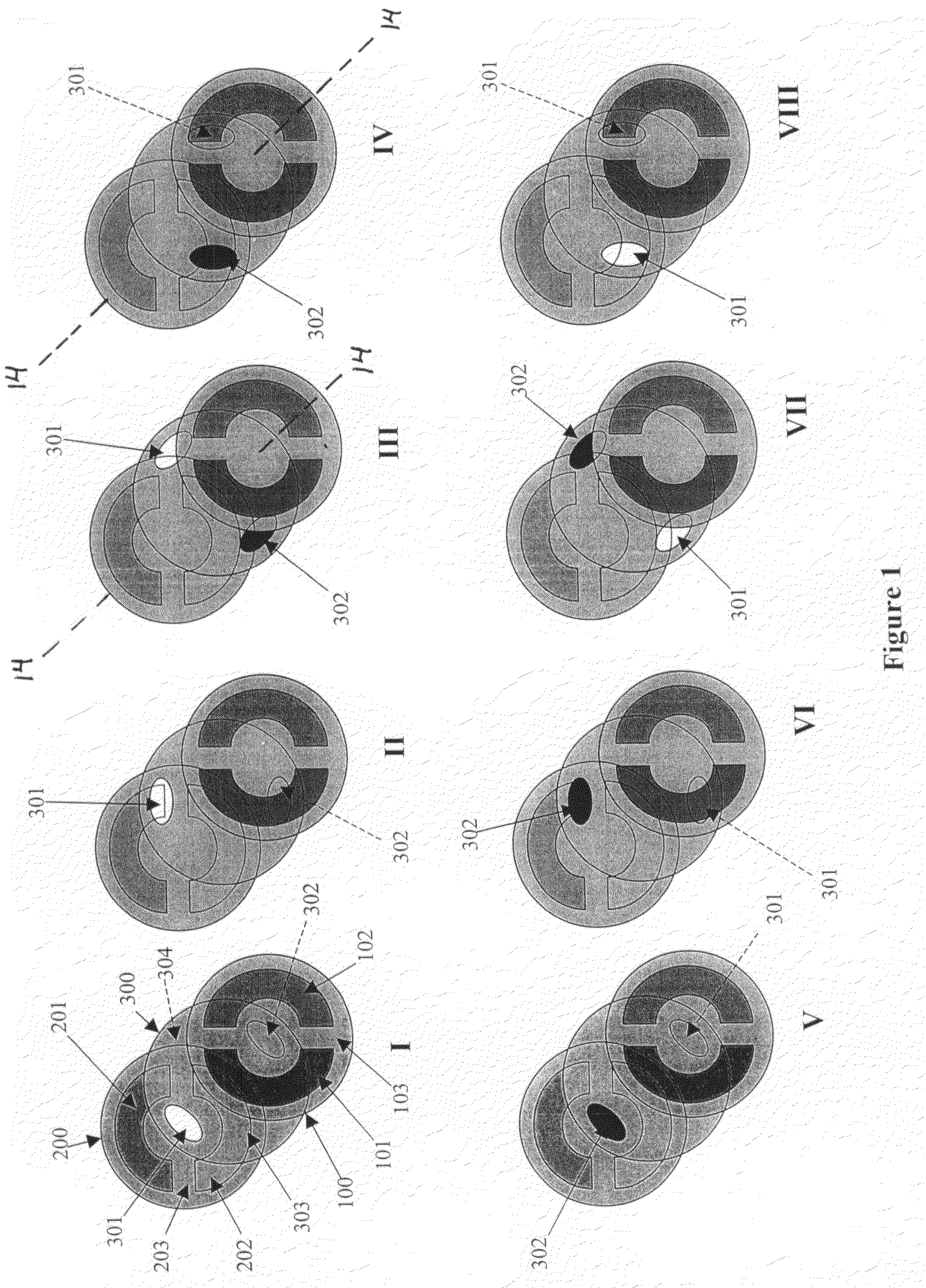

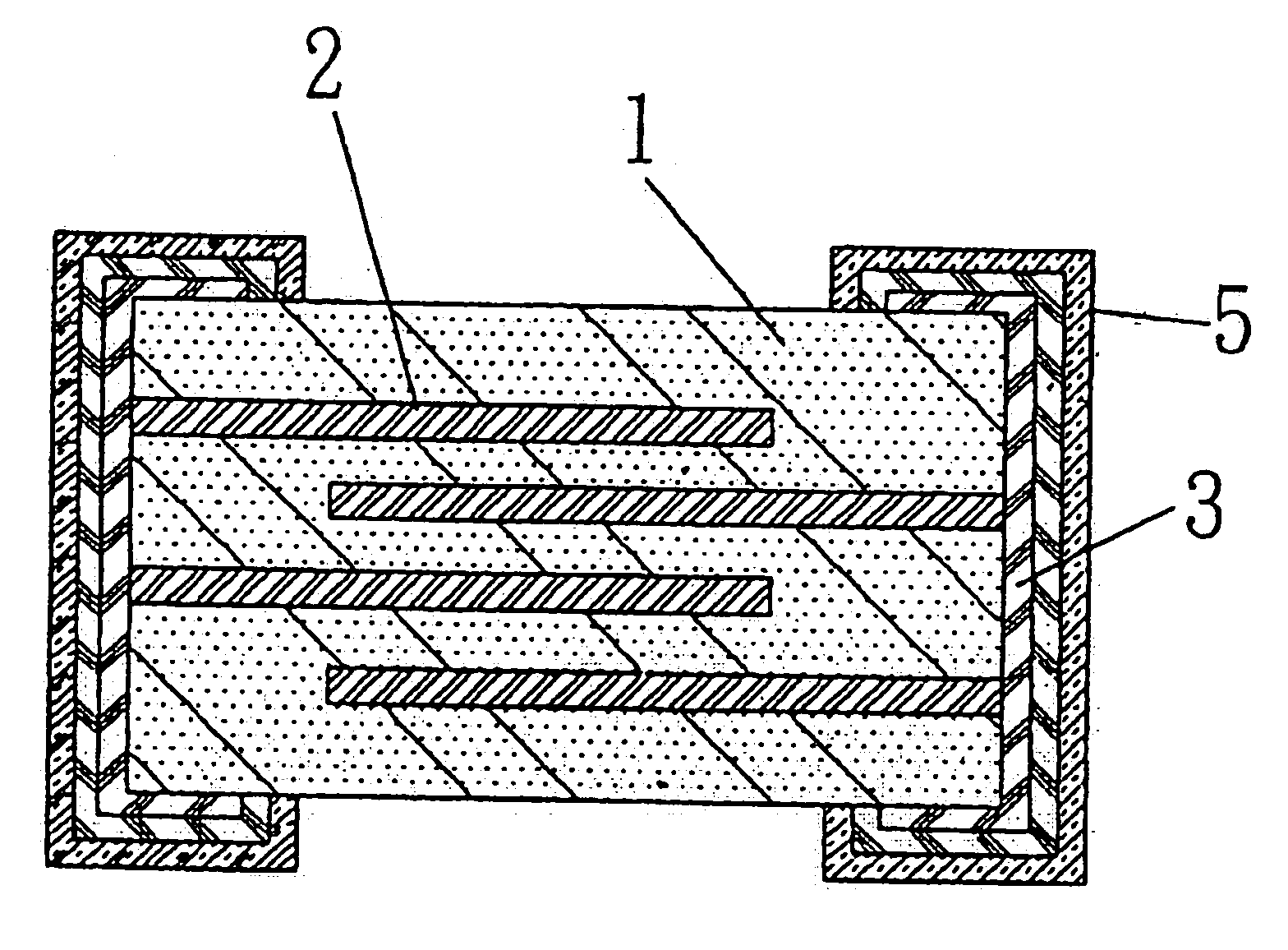

Rotary valve assembly

InactiveUS8210205B2Reduce Design ComplexityImprove system efficiencyPlug valvesIsotope separationProcess systemsRotary valve

A rotary valve assembly for use in a process provides fluid communication and enables variable conduit interconnection and flow passage. Process cycle time is variable by means of rotational speed of through one or more apertures of a third valve member and respective alignment with one or more apertures of a first valve member and one or more apertures of a second valve member. Process step time is variable by means of adjustable position and variable alignment of aperture(s) of the first valve member and the second valve member. The rotary valve assembly provides for gradual transition and flow passage between process steps, flow metering, mixing, reversal, or any combination thereof. Process systems including the rotary valve include an adsorption process, humidity control process, heat pump process and / or water purification process among others.

Owner:MICHAELS GREGORY A

Device for cutting packing bag, device for producing packing bag and method for producing packing bag

InactiveUS20100210439A1Low costLow equipment costEnvelopes/bags making machineryMechanical working/deformationEngineeringMechanical engineering

A cutter includes a male blade, a female blade, an advancement and retraction controller and a suction device. The male blade includes: a linear cutting portion linearly shaped with a predetermined thickness in a center part; a rounded cutting portion where a radius having a substantially arc shape in planar view is continuously formed from the linear cutting portion; and an end provided adjacent to the rounded cutting portion. The female blade has a fitting portion that is a hole conforming to the profile of the male blade in planar view and to which the male blade is fitted. On a lateral side of the female blade, an elongated hole for inserting a base film from one lateral side to the other lateral side is formed as an insertion portion.

Owner:IDEMITSU UNITECH CO LTD

Visible-light-responsive photoactive coating, coated article, and method of making same

InactiveUS20060263610A1Less costlyMore efficientVacuum evaporation coatingSputtering coatingRheniumNiobium

A method is provided for forming a photoactive coating having a photoabsorption band in the visible region of the electromagnetic spectrum. The method includes depositing a precursor composition over at least a portion of a float glass ribbon in a molten metal bath by a CVD coating device. The precursor composition includes a titania precursor material and at least one other precursor material selected from chromium (Cr), vanadium (V), manganese (Mn), copper (Cu), iron (Fe), magnesium (Mg), scandium (Sc), yttrium (Y), niobium (Nb), molybdenum (Mo), ruthenium (Ru), tungsten (W), silver (Ag), lead (Pb), nickel (Ni), rhenium (Re), and mixtures thereof.

Owner:PPG IND OHIO INC

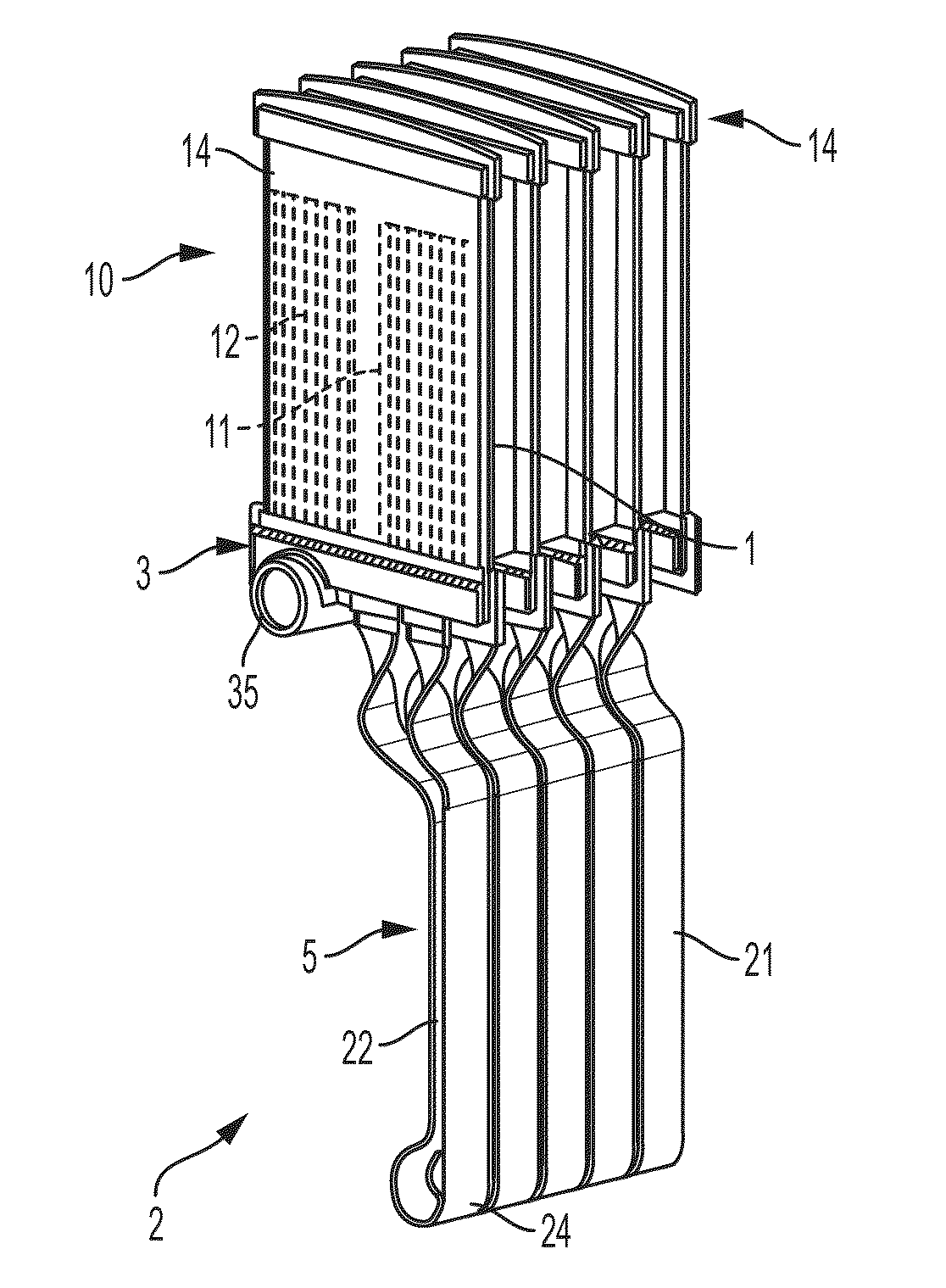

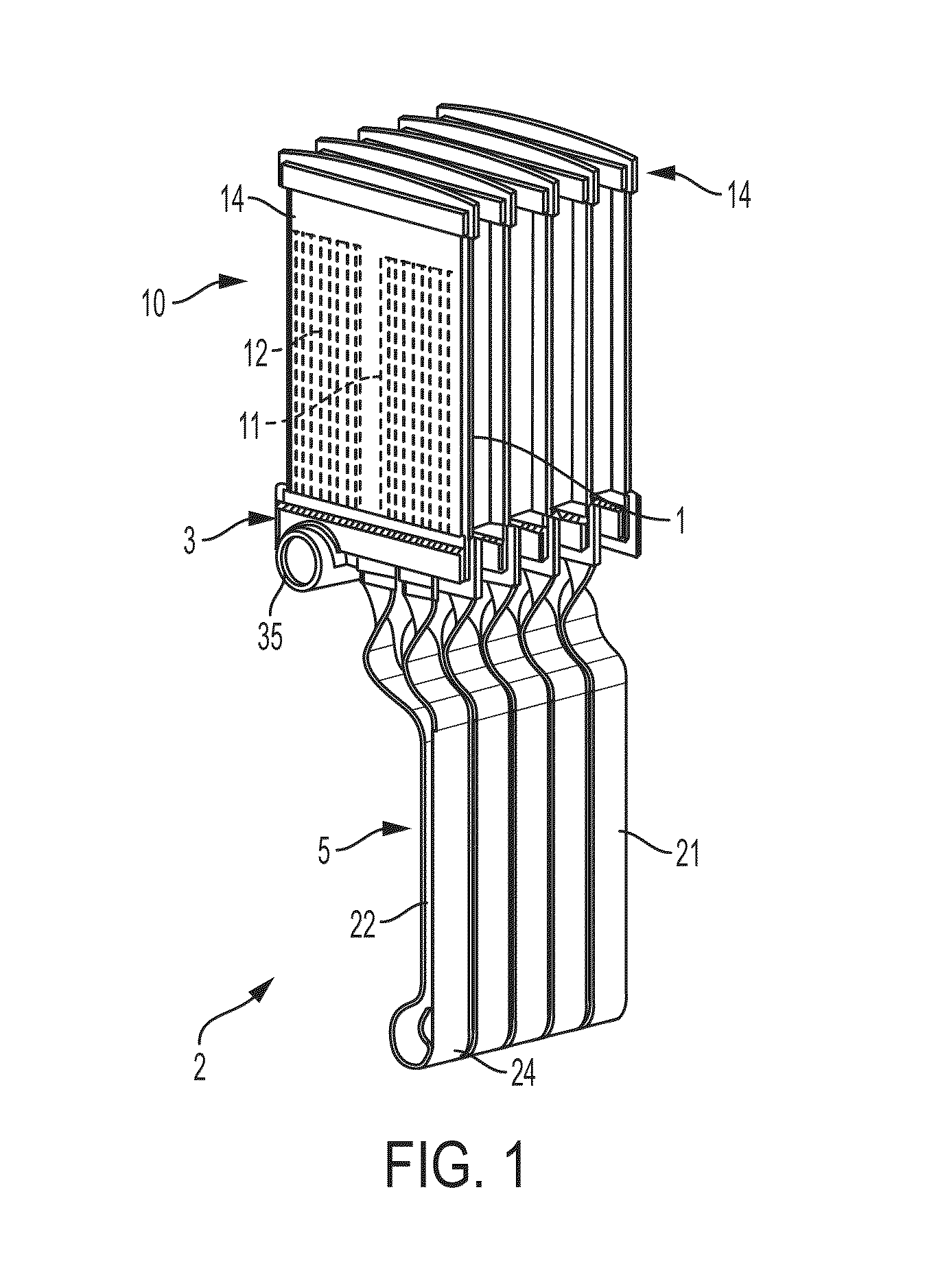

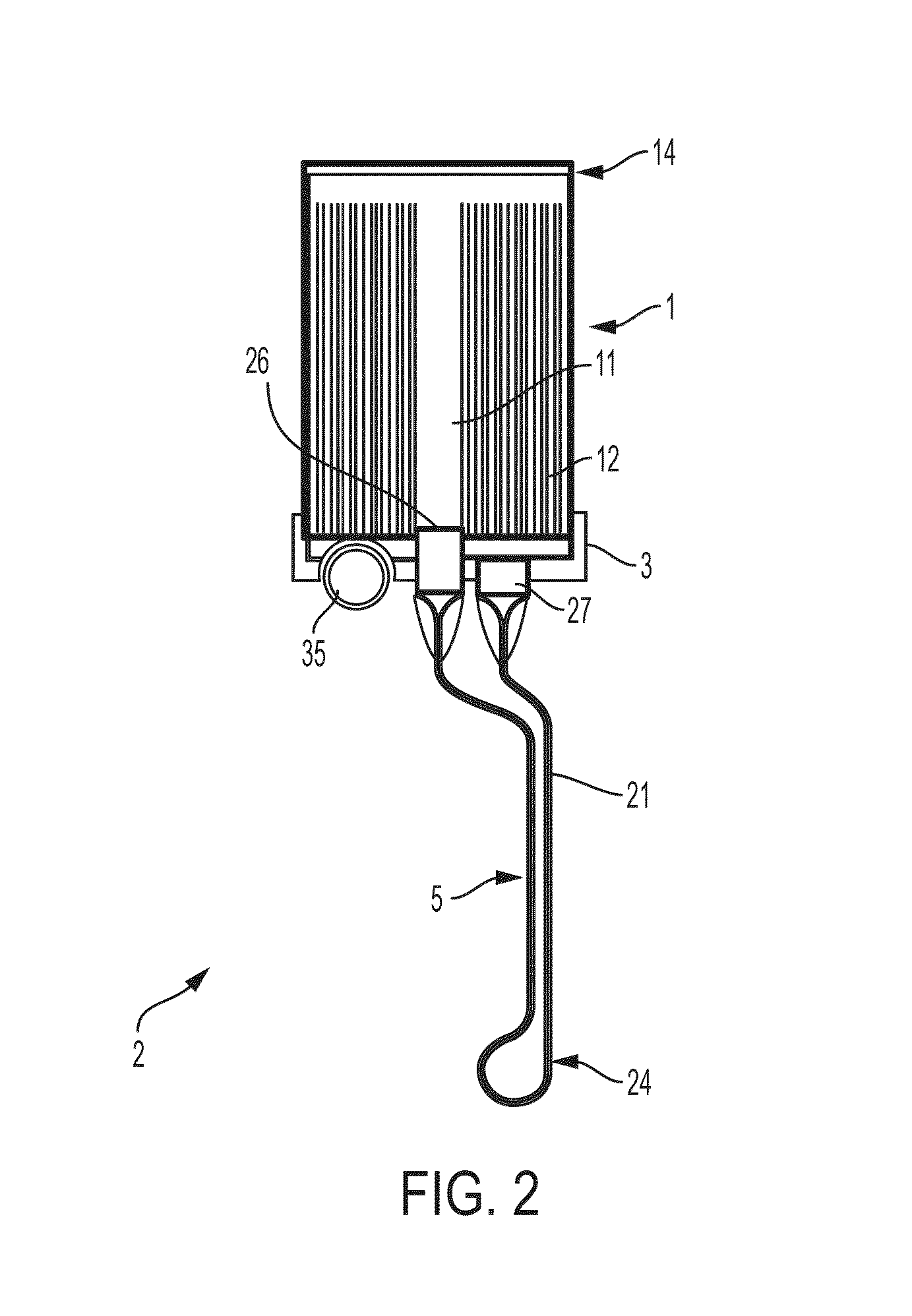

Evaporator and condenser section structure for thermosiphon

InactiveUS20160061532A1Low costSmall sizeEvaporators/condensersIndirect heat exchangersEvaporationClosed loop

A thermosiphon device includes a closed loop evaporator section having one or more evaporation channels that are fed by a liquid return path, and a condenser section with one or more condensing channels. The condenser section may include a vapor supply path that is adjacent one or more condensing channels, e.g., located between two sets of condensing channels. Evaporator and / or condenser sections may be made from a single, flat bent tube, which may be bent about an axis parallel to the plane of the flat tube to form a turnaround and / or twisted about an axis along a length of the tube at the tube ends. A single tube may form both evaporator and condenser sections of a thermosiphon device, and an axially extending wall inside the tube in the evaporator section may separate an evaporator section from a liquid return section.

Owner:AAVID THERMALLOY LLV

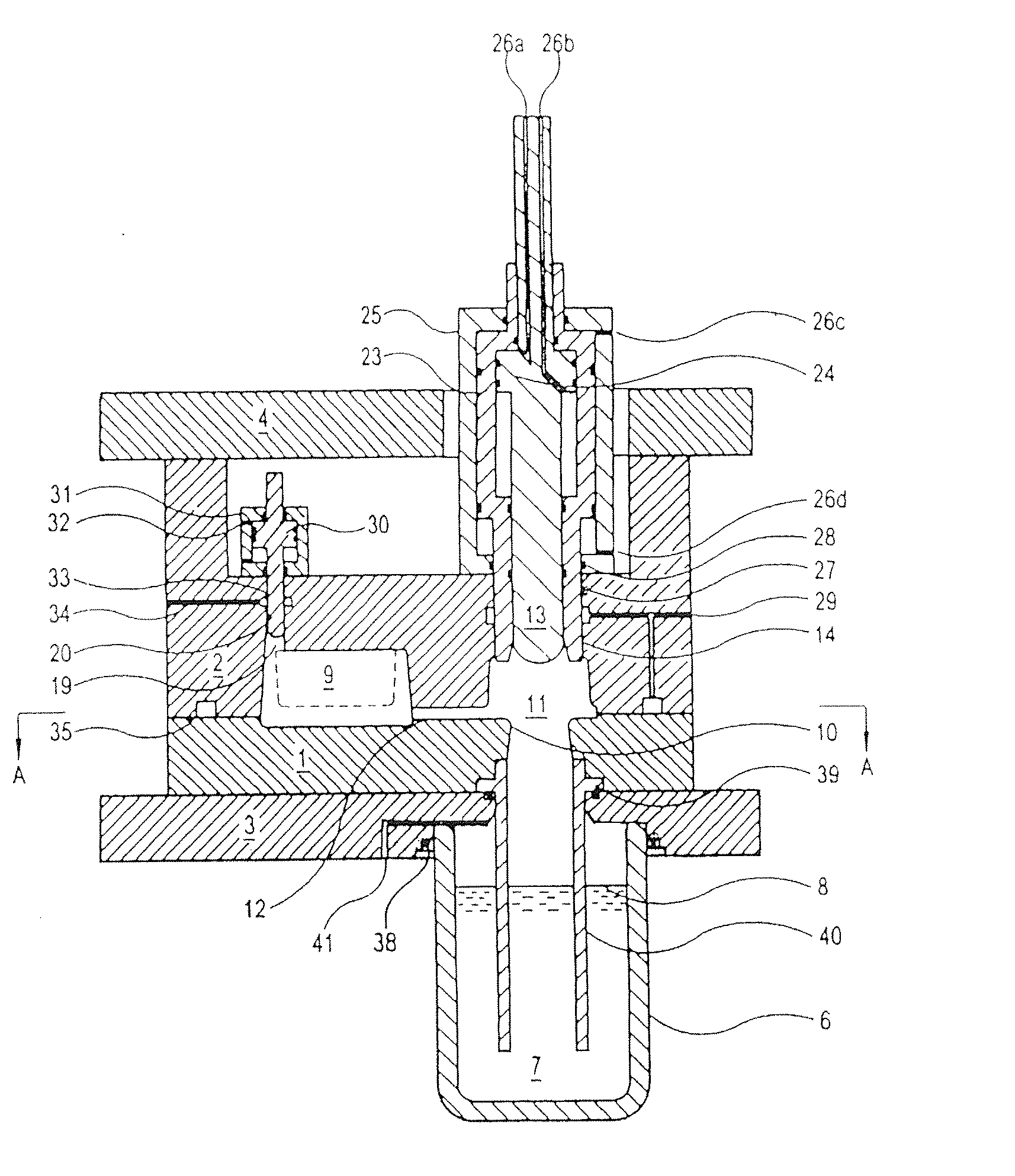

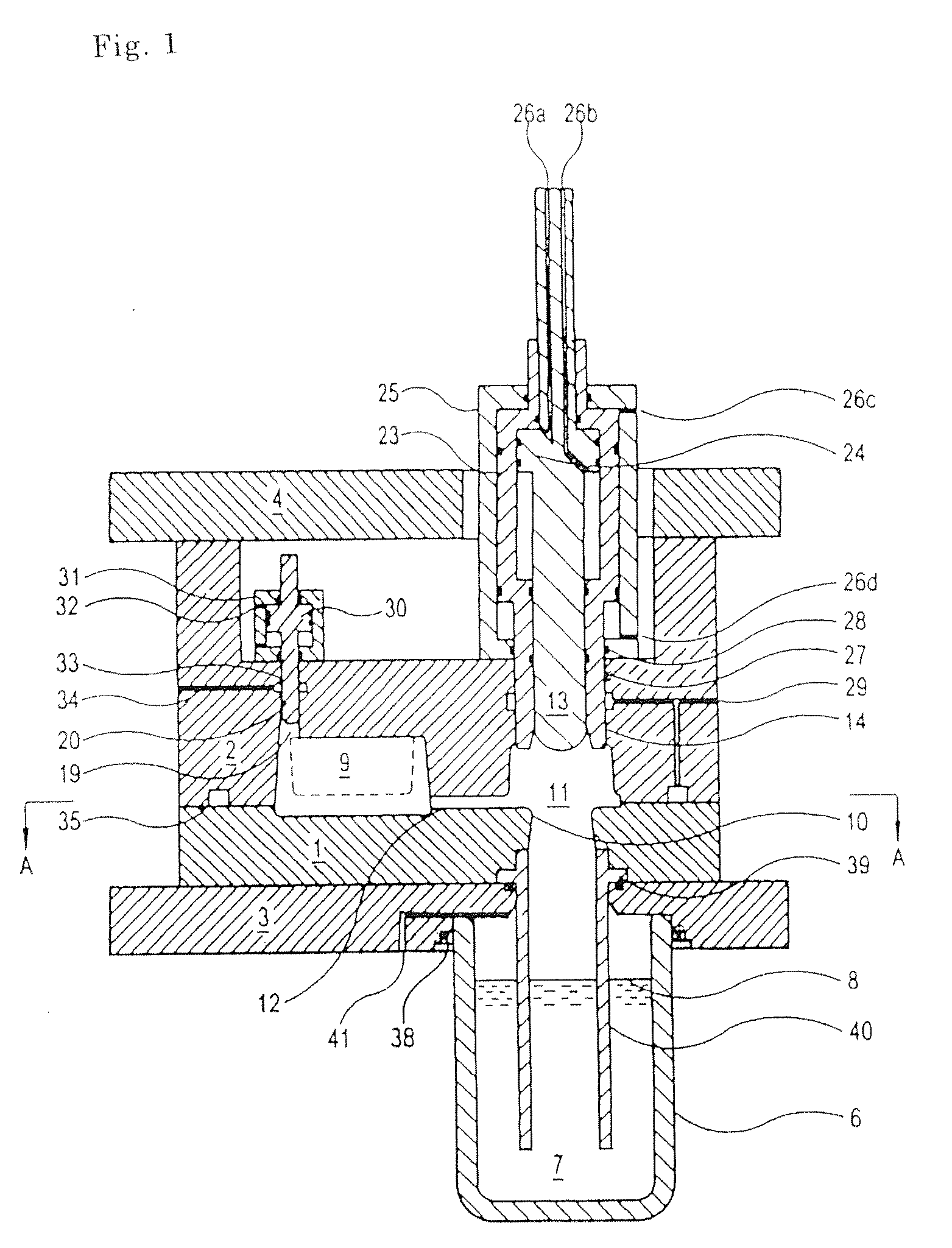

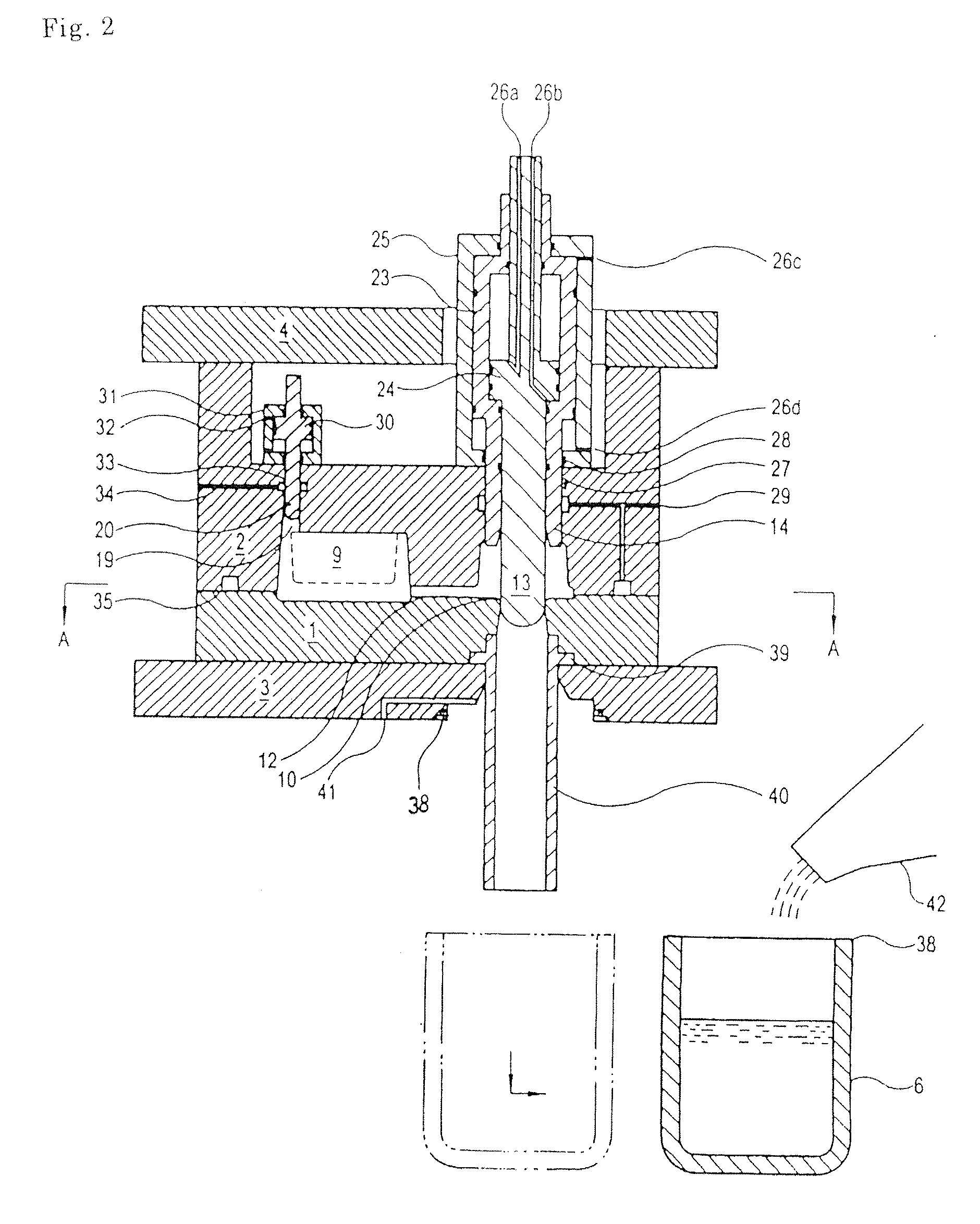

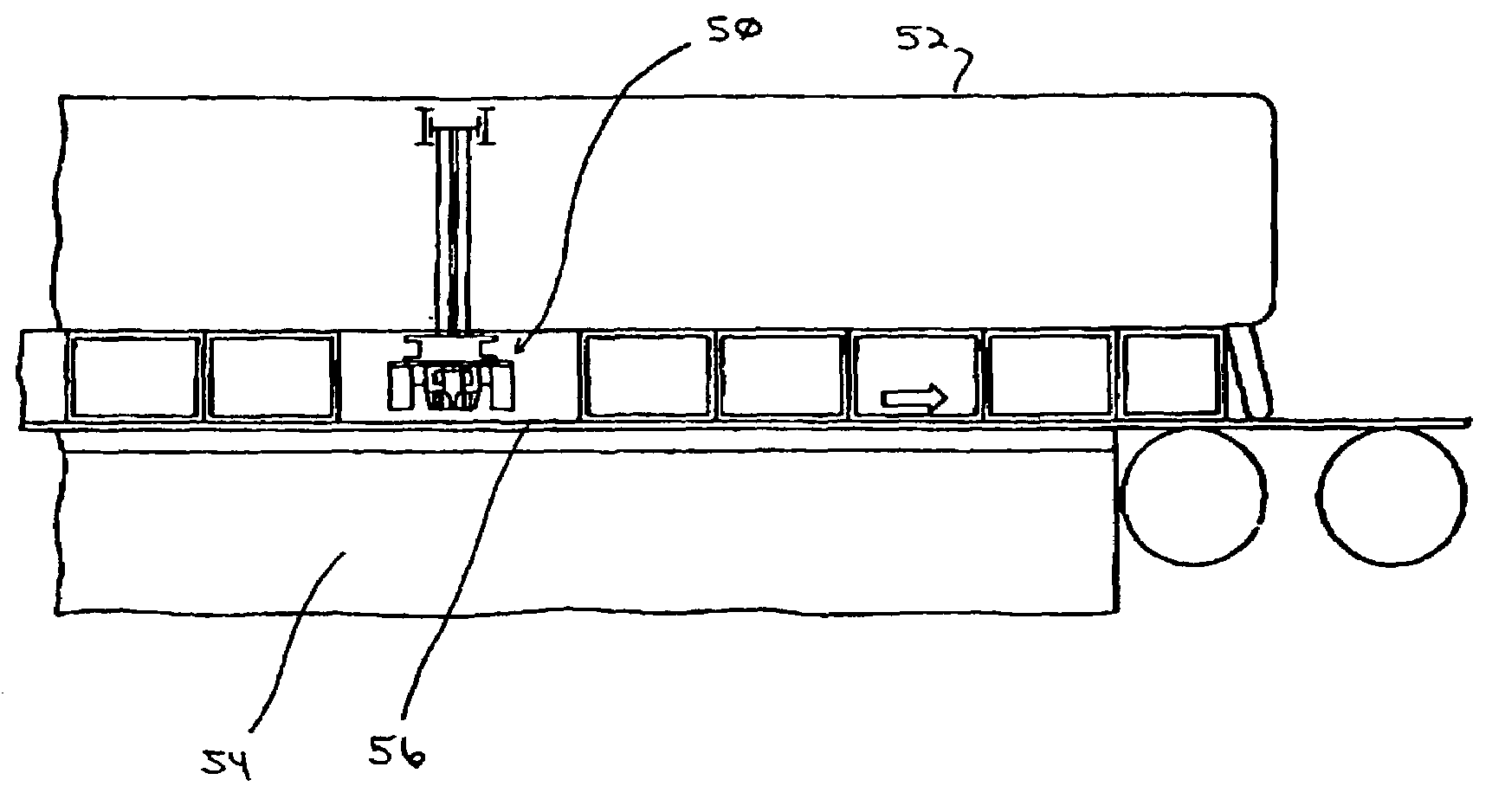

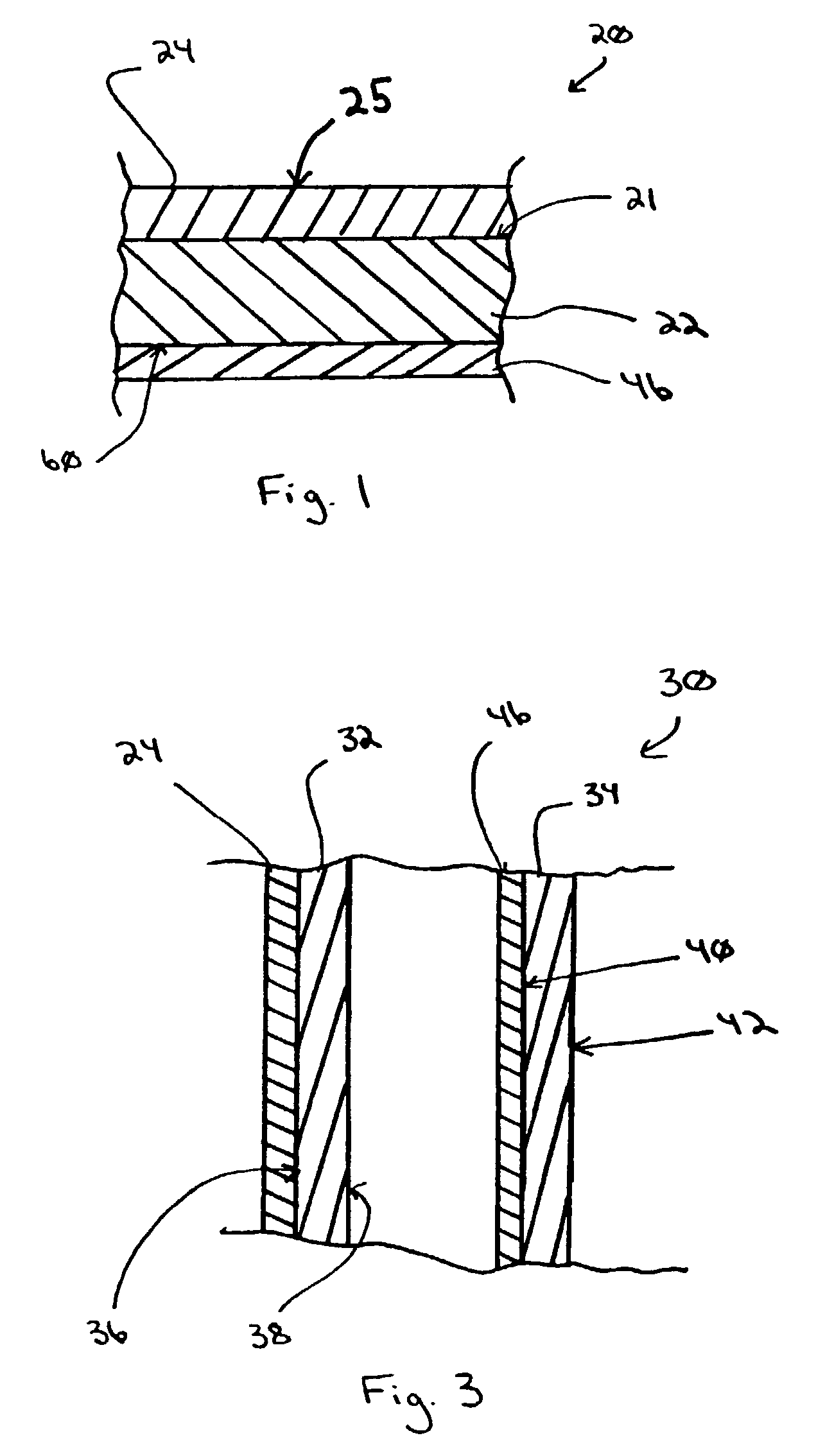

Vertical Casting Apparatus and Vertical Casting Method

The present invention is to provide a vertical casting apparatus capable of easily manufacturing castings without causing shrinkage cavities and entrainment of gas, by filling a molten metal into a mold cavity at a high speed and by effectively pressurizing the molten metal in the closed cavity, which has high work efficiency, ease of maintenance, and a low cost of equipment, and a vertical casting method using the vertical casting apparatus. The vertical casting apparatus is provided with an apparatus body comprising a fixed mold 1 on the lower side and a movable mold 2 on the upper side, a closing means 13 for closing a molten metal in-flow gate 10 formed in the fixed mold 1, and a pressurizing means 20 for pressurizing the molten metal in the closed mold cavity, and a casting means for supplying and filling the molten metal into the mold cavity from the underside. The casting means has a gas-pressurized molten metal pouring ladle 6 attachable to and detachable from the apparatus body.

Owner:KOSEI ALUMINUM

Visible-light-responsive photoactive coating, coated article, and method of making same

InactiveUS7096692B2Eliminate leastReduce leastVacuum evaporation coatingSputtering coatingRheniumNiobium

A method is provided for forming a photoactive coating having a photoabsorption band in the visible region of the electromagnetic spectrum. The method includes depositing a precursor composition over at least a portion of a float glass ribbon in a molten metal bath by a CVD coating device. The precursor composition includes a titania precursor material and at least one other precursor material selected from chromium (Cr), vanadium (V), manganese (Mn), copper (Cu), iron (Fe), magnesium (Mg), scandium (Sc), yttrium (Y), niobium (Nb), molybdenum (Mo), ruthenium (Ru), tungsten (W), silver (Ag), lead (Pb), nickel (Ni), rhenium (Re), and mixtures thereof.

Owner:PPG IND OHIO INC

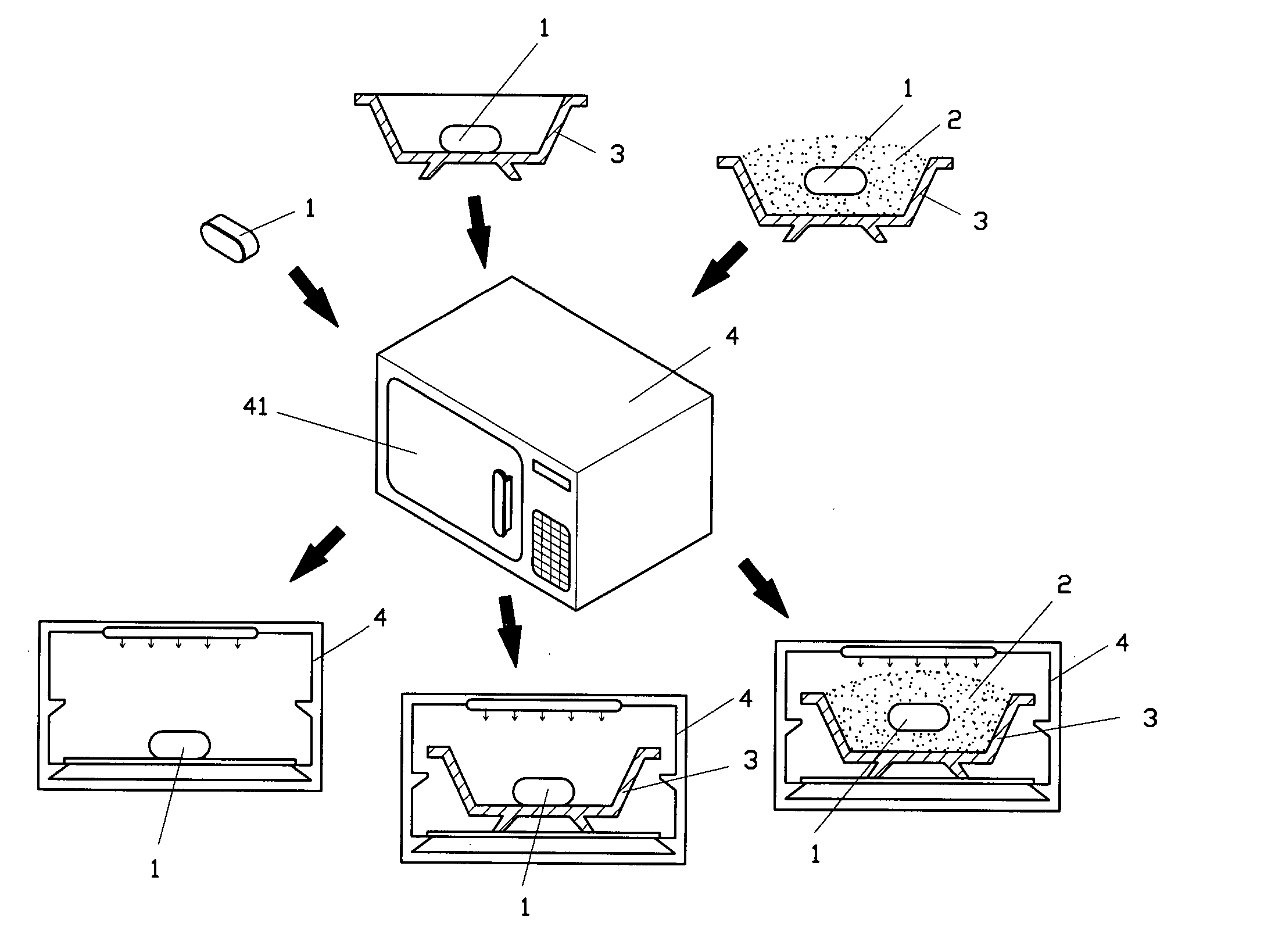

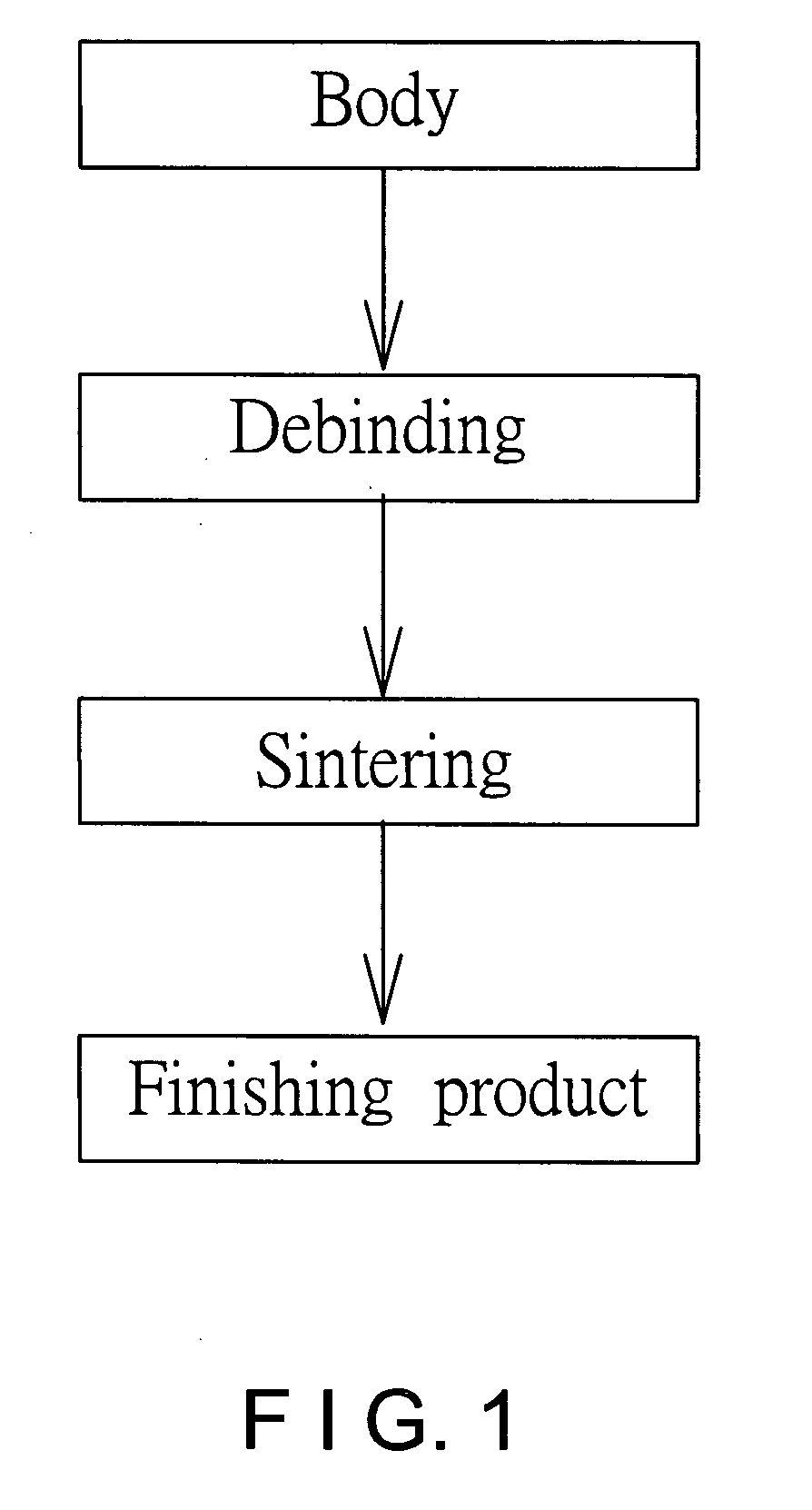

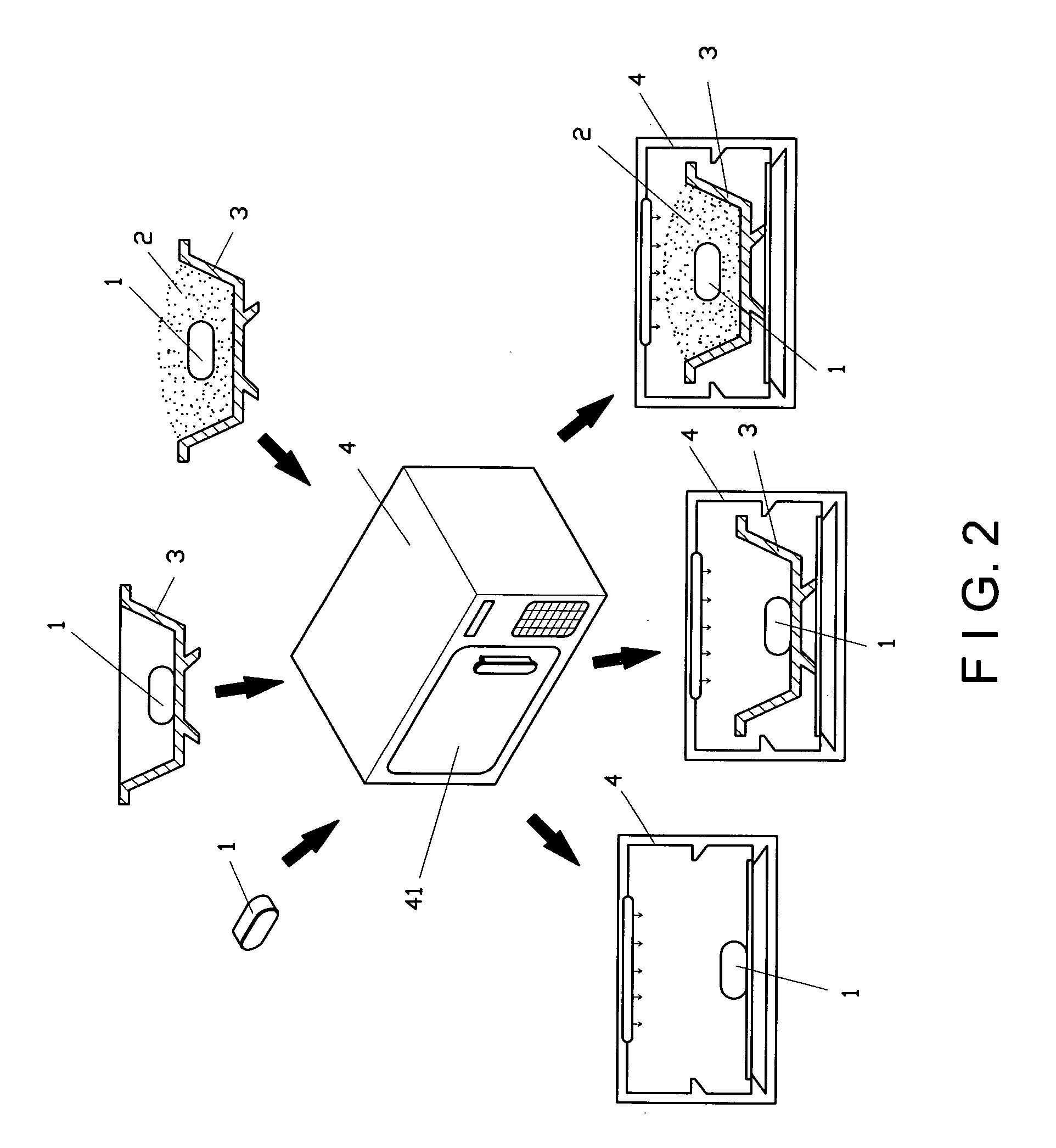

Manufacturing process using microwave for thermal debinding

A manufacturing process using microwave for thermal debinding according to the invention is mainly applied in manufacturing process of powder metallurgy. Wherein, metal powder is mixed polymer materials such as adhesives, fillings or lubricants, and a body is formed by means of molding, forging, extrusion, injection or scraping. The body to be debinded is placed in a microwave environment in an exposed manner or covered with powder, and power and work time of microwave are set for rapidly heating and debinding the body. The manufacturing process according to the invention is capable of accelerating manufacturing procedure, economizing production cost, reducing defects, quickly drying and rapidly removing polymer materials.

Owner:FAR EAST COLLEGE

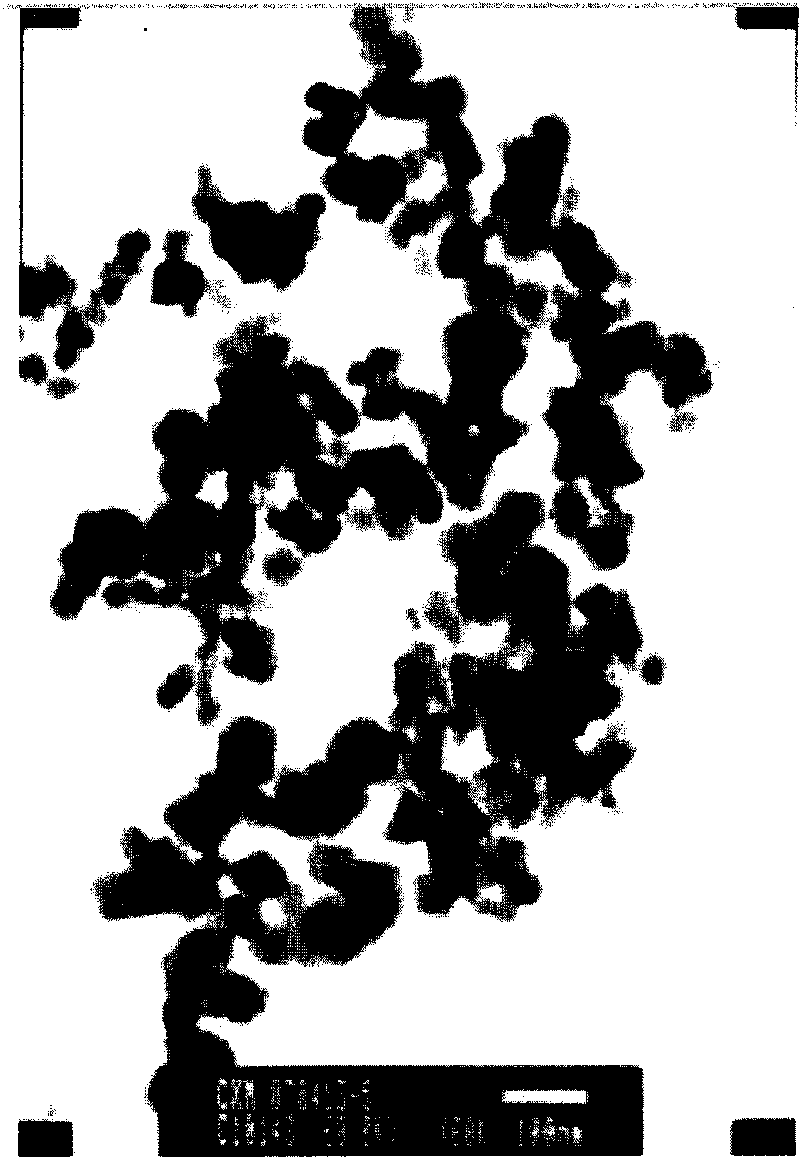

Method for manufacturing nano calcium carbonate from high-concentration carbon dioxide industrial exhaust gases

InactiveCN101723429AIncrease satietyIncrease concentrationCalcium/strontium/barium carbonatesHigh concentrationCalcium hydroxide

The invention provides a method for manufacturing a nano-grade calcium carbonate from high-concentration carbon dioxide industrial exhaust gases, which comprises the following steps: (1) adding a crystal nucleus forming accelerator into a suspension of a calcium hydroxide; (2), introducing a gas containing 50 to 100 volume percent of a carbon dioxide, adding a dispersant when a carbonization rate is over 80 percent, and continuously introducing the gas for 10 to 20min when the pH value of the suspension is reduced to between 6.5 and 7.0, wherein the final temperature of a reaction slurry liquid is 45 to 70 DEG C; and (3) adding the aqueous solution of a cladding agent into the suspension of the calcium hydroxide, wherein a cladding and activating time is 1 to 2h, and then collecting the nano-grade activated calcium carbonate from the reaction product. The method of the invention greatly reduces the equipment and operation costs, quickens the carbonization reaction, saves the time of the carbonization reaction and energy, reduces the energy consumption, increases the oversaturated concentration of the calcium carbonate, and finally generates narrowly distributed nano-grade calcium carbonate particles the grain size of which is uniform.

Owner:SHANGHAI HUAMING HI TECH GRP

Rotary valve assembly

InactiveUS20070246678A1Easy to adjustEasy to adaptPlug valvesIsotope separationProcess systemsRotation velocity

A rotary valve assembly for use in a process provides fluid communication and enables variable conduit interconnection and flow passage. Process cycle time is variable by means of rotational speed of through one or more apertures of a third valve member and respective alignment with one or more apertures of a first valve member and one or more apertures of a second valve member. Process step time is variable by means of adjustable position and variable alignment of aperture(s) of the first valve member and the second valve member. The rotary valve assembly provides for gradual transition and flow passage between process steps, flow metering, mixing, reversal, or any combination thereof. Process systems including the rotary valve include an adsorption process, humidity control process, heat pump process and / or water purification process among others.

Owner:MICHAELS GREGORY A

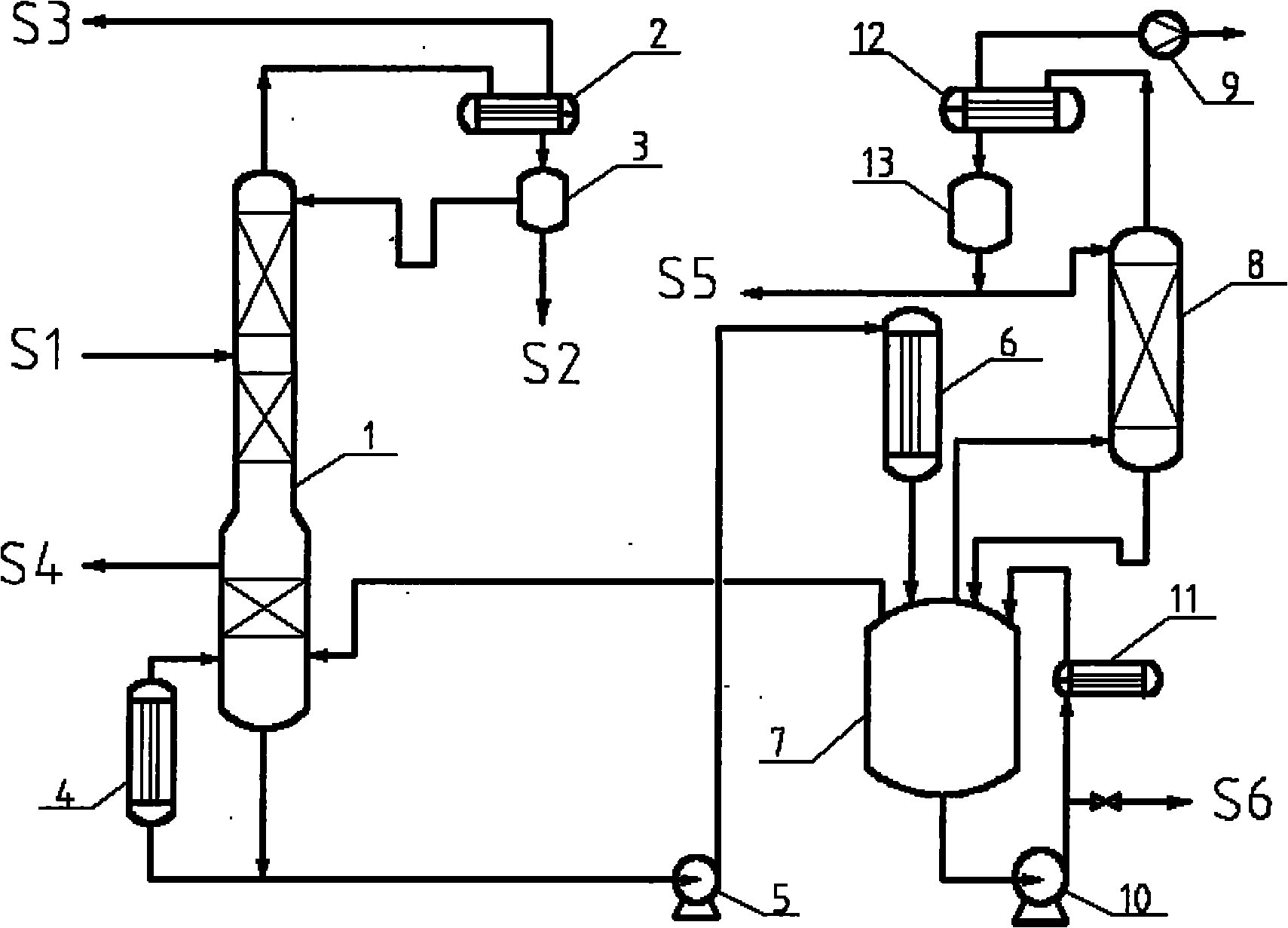

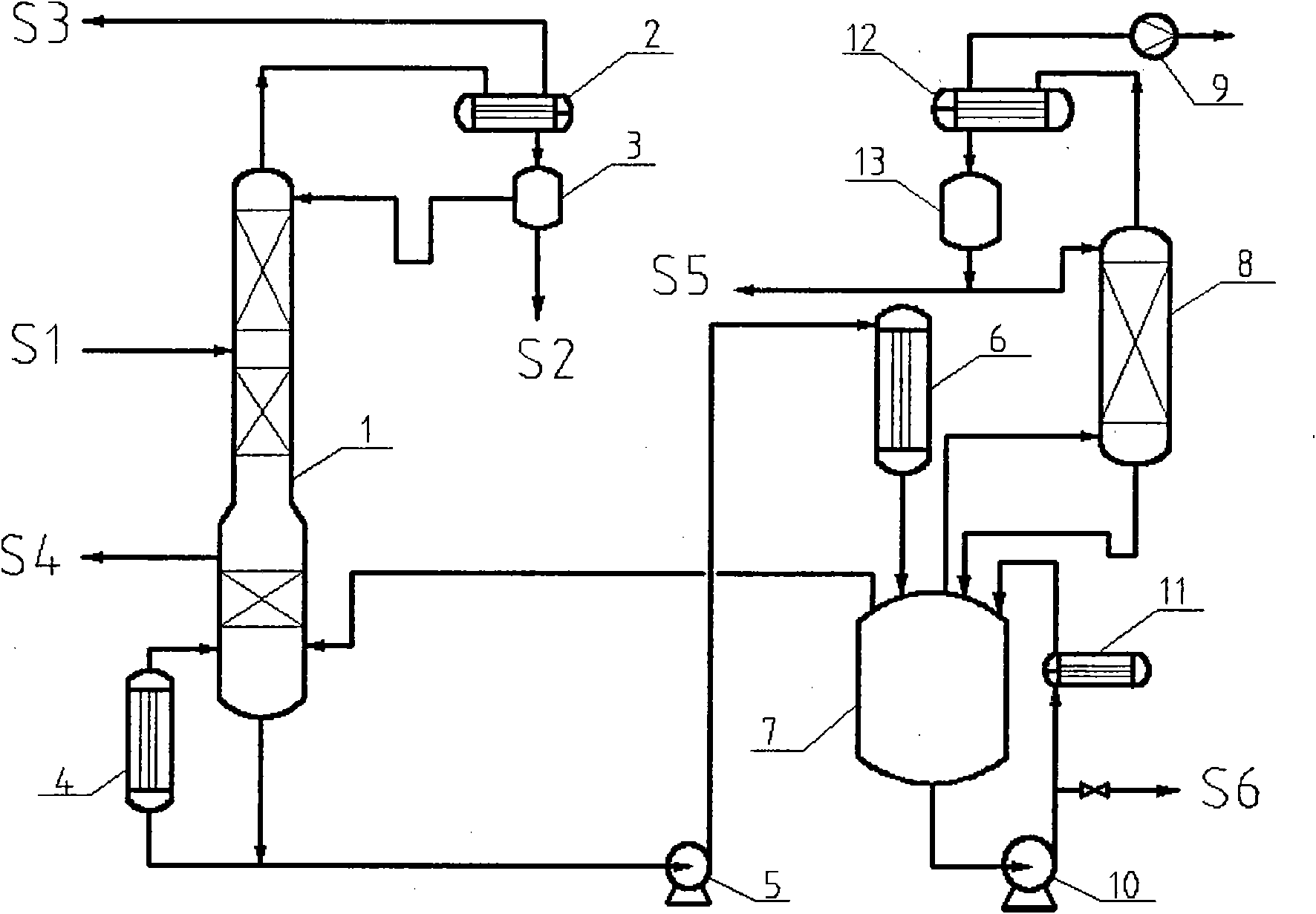

Refining and reclaiming technology of tail gas absorption solvent in production of toluene diisocyanate

InactiveCN101870666AContinuous and stable feedingContinuous and stable dischargeDispersed particle separationDistillation purification/separationToluene diisocyanateGas phase

The invention relates to a refining and reclaiming technology of a tail gas absorption solvent in the production of toluene diisocyanate (TDI). The solvent containing little phosgene, toluene diisocyanate and di-Et-1,3-benzenedicarboxylate (DEIP) performs two-stage refinement in an atmospheric refining tower and a vacuum refining tower, and a falling-film evaporator and a storage tank are arranged between the two towers. The overhead non-condensable gas phase of the atmospheric refining tower is returned to a phosgene absorption tower to recycle phosgene, the refined solvent is drawn from theside of the atmospheric refining tower, the temperature of the tower bottom is controlled to be 3-8 DEG C higher than the boiling point of the solvent, the discharged material of the tower bottom enters the falling-film evaporator, the evaporating temperature is 20-30 DEG C higher than the boiling point of the solvent, the unevaporated material enters the storage tank for storage, the material inthe storage tank performs batch vacuum rectification under the absolute pressure of 0.1-0.25bar, and the unevaporated residual material enters the residue evaporator of a TDI device to recycle TDI and DEIP. By using the solvent refining technology provided by the invention, the useful components in the solvent can be completely recycled, and the technology has the advantages of simple and stable operation and lower cost and energy consumption.

Owner:QINGDAO UNIV OF SCI & TECH +1

Ceramic glaze coating structure of a chip element and method of forming the same

InactiveUS20060234022A1Increase in costEnhance concentrationFixed capacitor dielectricStacked capacitorsCeramic glazeHigh impedance

A ceramic glaze-coating structure of a chip element and a method of forming the same are provided. In the ceramic glaze-coating structure, a high-density, smooth, and high-impedance ceramic glaze is coated on the body of an element. As for the terminal electrode part, the unique firing characteristics between the material of the terminal electrode (e.g., conductive compositions) and the ceramic glaze are utilized, such that the ceramic glaze layer between the surface of the terminal electrode or the terminal electrode and the ceramic body is absorbed and then removed by sintering; thus, the ceramic glaze coating structure of a chip element with only the element body being coated is formed.

Owner:INPAQ TECH

Cascade switch for network traffic aggregation

InactiveUS20070053385A1Low possible equipment costLow equipment costEnergy efficient ICTTime-division multiplexData streamInternet traffic

A method and apparatus for aggregating network traffic using “cascade” of individual nodes, where each node connected to, and configured to monitor, two or more nodes below it. Each node has two or more inputs. These inputs are connected to a CPU having a memory buffer to temporarily store the network data streams from the inputs, and an outlet port capable of transferring network data streams from the memory buffer and the CPU to an output network. The CPU is thus connected to the inputs, the memory buffer and the outlet port, and serves to transfer network data streams from the inputs to the memory buffer, and to simultaneously transmit the network data streams from the memory buffer to the outlet port. Nodes that gather network data streams directly from the network have two or more network controllers, each of which are connected to the network to receive network data streams from the network, and also connected to the node inputs to transfer data to the CPU and the memory buffer.

Owner:BATTELLE MEMORIAL INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com