Method for processing oil sand bitumen

a technology of oil sand bitumen and processing method, which is applied in the petroleum industry, liquid hydrocarbon mixture production, and treatment with plural serial stages only, etc., can solve the problems of unreasonable price reduction of diluting agent at a price lower than its original cost, economic unreasonable, and huge working capital, etc., to achieve low equipment cost, reduce the viscosity of bitumen products, and reduce the effect of viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

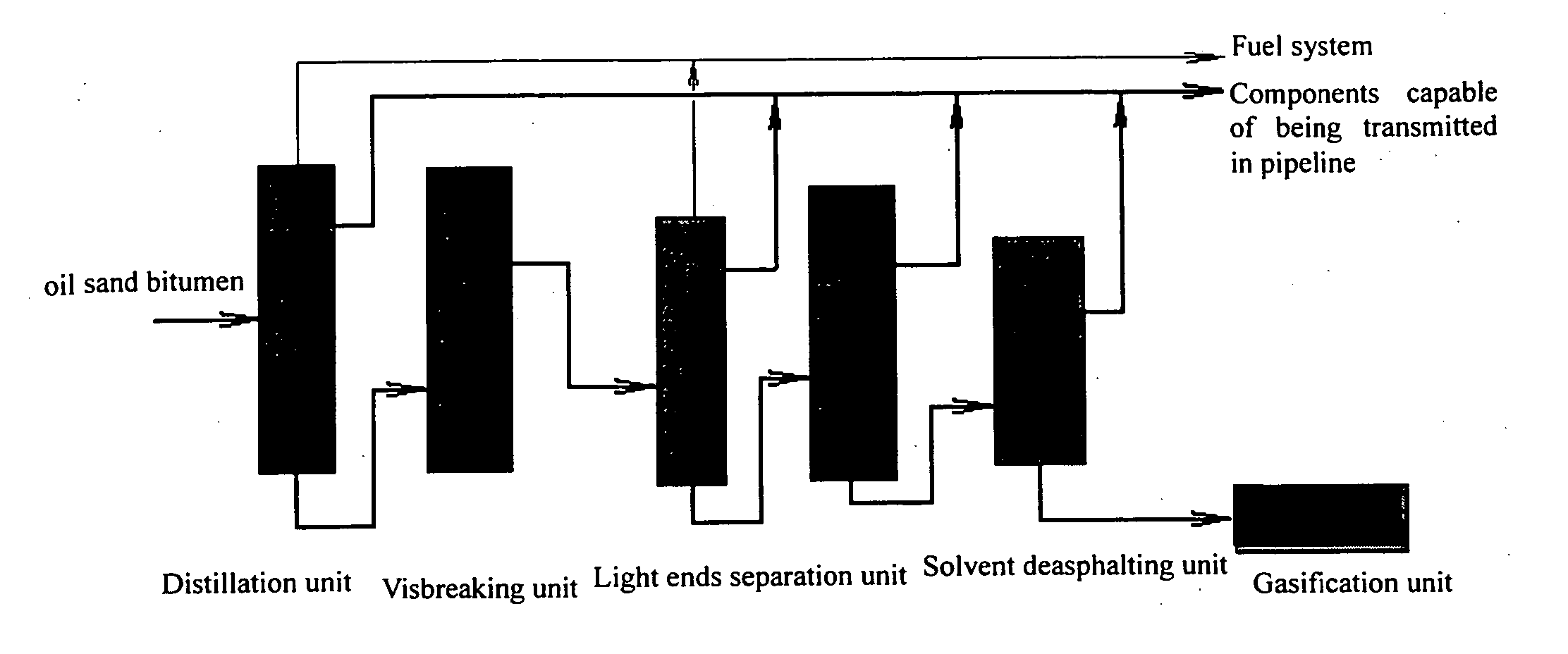

[0037] According to the process shown in FIG. 1, the oil sand bitumen is routed to the distillation unit to directly separate the components boiling below 200° C. as the components capable of being transmitted in pipeline from the oil sand bitumen, with the remaining high-boiling point distillation residue entering the visbreaking unit to be subjected to visbreaking at a temperature of 400° C., a pressure of 0.5 MPa and a residence time of 2 hours. The visbreaking products are routed to the light ends separation unit, where the visbreaking products are separated into the components boiling below 500° C. as the components capable of being transmitted in pipeline and the remaining high-boiling point heavy components used as the feedstock of the solvent deasphalting. Said heavy components is carried out the contact extraction with n-butane solvent in the solvent deasphalting unit under the following conditions: a tower bottom temperature of 140° C., a tower overhead temperature of 160°...

example 2

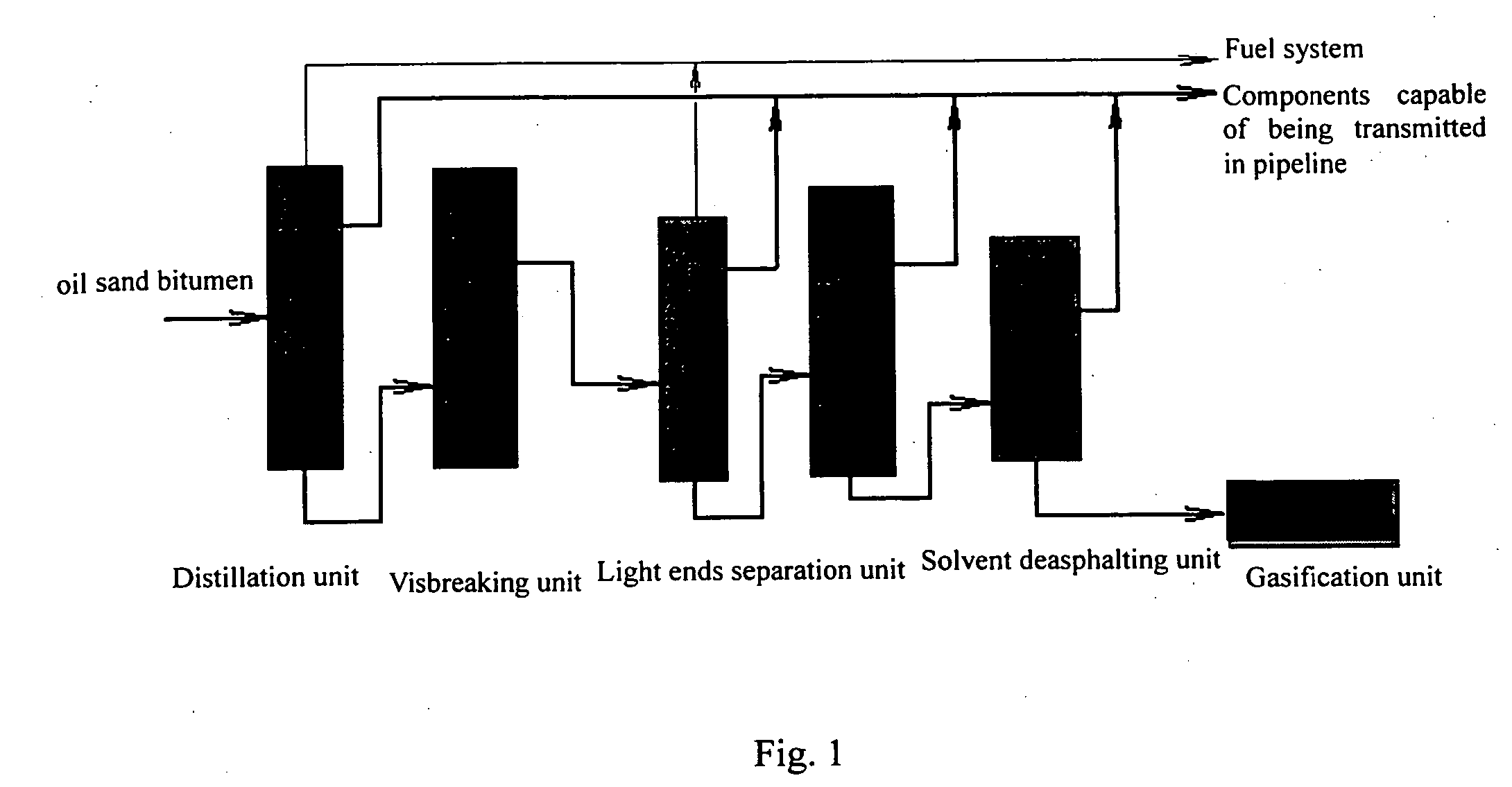

[0038] According to the process shown in FIG. 2, the oil sand bitumen is routed to the atmospheric distillation unit to directly separates the tower overhead components boiling below 200° C. as the components capable of being transmitted in pipeline from the oil sand bitumen, with the AR from the tower bottom being routed to the vacuum distillation unit and being separated into the tower overhead oil boiling between 200-500° C. and the vacuum residuum (VR) boiling above 500° C. Said VR is subjected to contact extraction with the pentane mixed solvent in the solvent extraction unit under the following conditions: a tower bottom temperature of 150° C., a tower overhead temperature of 170° C., a pressure of 5 MPa, and a solvent ratio of 4:1. After the step of solvent deasphalting, a DAO comprising a large amount of solvent and a DOA comprising little or a little of solvent are obtained. The DAO is separated from the tower overhead and is combined after solvent recovery with said vacuum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com