Method for manufacturing nano calcium carbonate from high-concentration carbon dioxide industrial exhaust gases

A nano-calcium carbonate and carbon dioxide technology, applied in the direction of calcium carbonate/strontium/barium, etc., can solve the problems affecting the performance of calcium carbonate products, unfavorable calcium carbonate nucleation and growth, and uneven particle size of calcium carbonate, so as to save carbonization Response time, excellent gloss, low surface energy density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

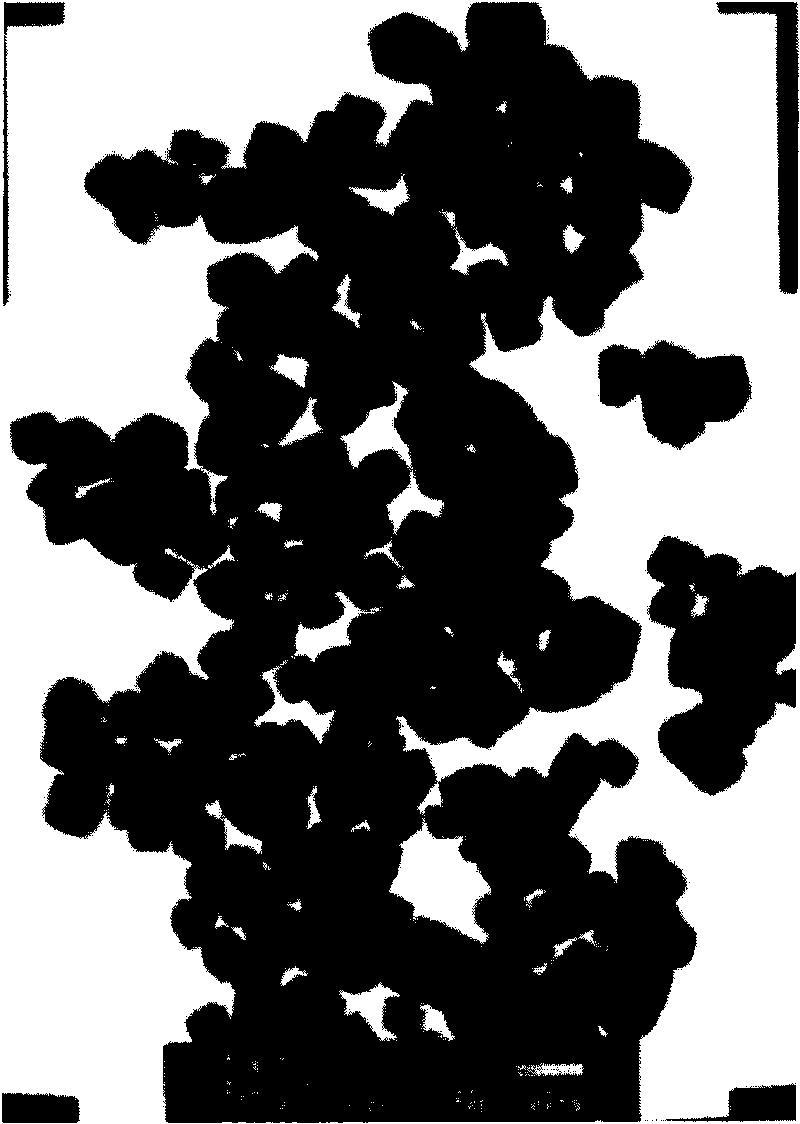

Embodiment 1

[0025] at 60m 3 Add 50m 3 Calcium hydroxide concentration 10% (weight concentration) initial temperature is the lime emulsion of 25 ℃, add 20kg sucrose and 130kg triethanolamine at the same time, after stirring evenly, pass into the industrial gas that the carbon dioxide content is 95% (volume concentration) and start to carry out Carbonization reaction, when the carbonization rate reaches 90%, add 20.5kg magnesium chloride, continue to ventilate until slurry pH is 6.5-7, obtain the nano-calcium carbonate suspension that temperature is 63 ℃, add sodium stearate 250kg in this slurry Concentration of 7% (weight concentration) saponified emulsion, continue to stir for 1.5h for coating activation treatment, then filter the slurry while hot, dry at 100°C, and pulverize to obtain cubic and spherical transparent calcium carbonate. The carbonization reaction time is 110 minutes, and the method specified by the national standard (GB / T 19590-2004) is used for measurement. The main part...

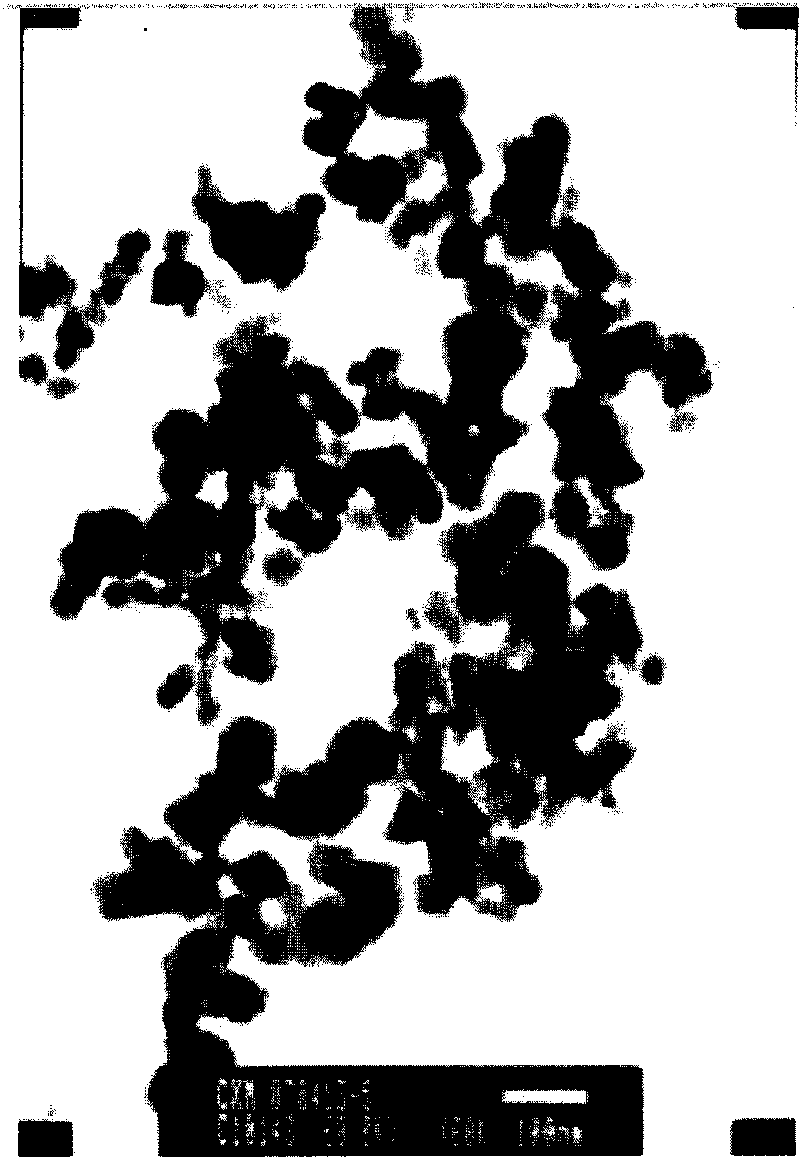

Embodiment 2

[0027] at 60m 3 Add 50m 3 Calcium hydroxide concentration 8.5% (mass concentration) initial temperature is the refined lime emulsion of 30 ℃, add 81kg sucrose simultaneously, after stirring, pass into the industrial gas that carbon dioxide content is 78% (volume concentration) and begin to carry out carbonization reaction, When the carbonization rate reaches 80%, add 8.6kg sodium hexametaphosphate, and continue aeration until the pH of the slurry is 6.5-7 to obtain a nano-calcium carbonate suspension with a temperature of 55°C. Add 125kg of sodium stearate to the slurry. The saponified emulsion with a concentration of 5% (weight concentration) is continuously stirred for 2 hours to carry out coating activation treatment, the slurry is filtered while it is hot, and dried at 100° C. to obtain cubic and spherical nano-active calcium carbonate. The carbonization reaction time is 70 minutes, and the method specified in the national standard (GB / T 19590-2004) is used for measuremen...

Embodiment 3

[0029] at 60m 3 Add 50m 3Calcium hydroxide concentration 13% (mass concentration) initial temperature is the refined lime emulsion of 39 ℃, add 160kg sodium citrate at the same time, after stirring evenly, pass into the industrial gas that carbon dioxide content is 85% (volume concentration) and begin to carry out carbonization Reaction, when the carbonization rate reaches 95%, add 60kg of sodium bicarbonate, and continue to ventilate until the pH of the slurry is 6.5-7 to obtain a nano-calcium carbonate suspension with a temperature of 70°C, and add TC-311 titanic acid to the slurry Lipid coupling agent 85kg concentration is the aqueous solution of 15% (weight concentration), continues to stir 1h and carries out coating activation treatment, slurry is filtered while hot, through 100 ℃ of drying, pulverization promptly obtains cubic nano-active calcium carbonate. The carbonization reaction time is 120 minutes, and it is measured by the method stipulated in the national standa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com