Manufacturing process using microwave for thermal debinding

a manufacturing process and microwave technology, applied in the direction of coatings, etc., can solve the problems of increasing processing costs, increasing time and energy for pre-heating and heat maintenance, and consuming considerable amounts of energy, so as to accelerate production procedures, reduce production costs, and rapid drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

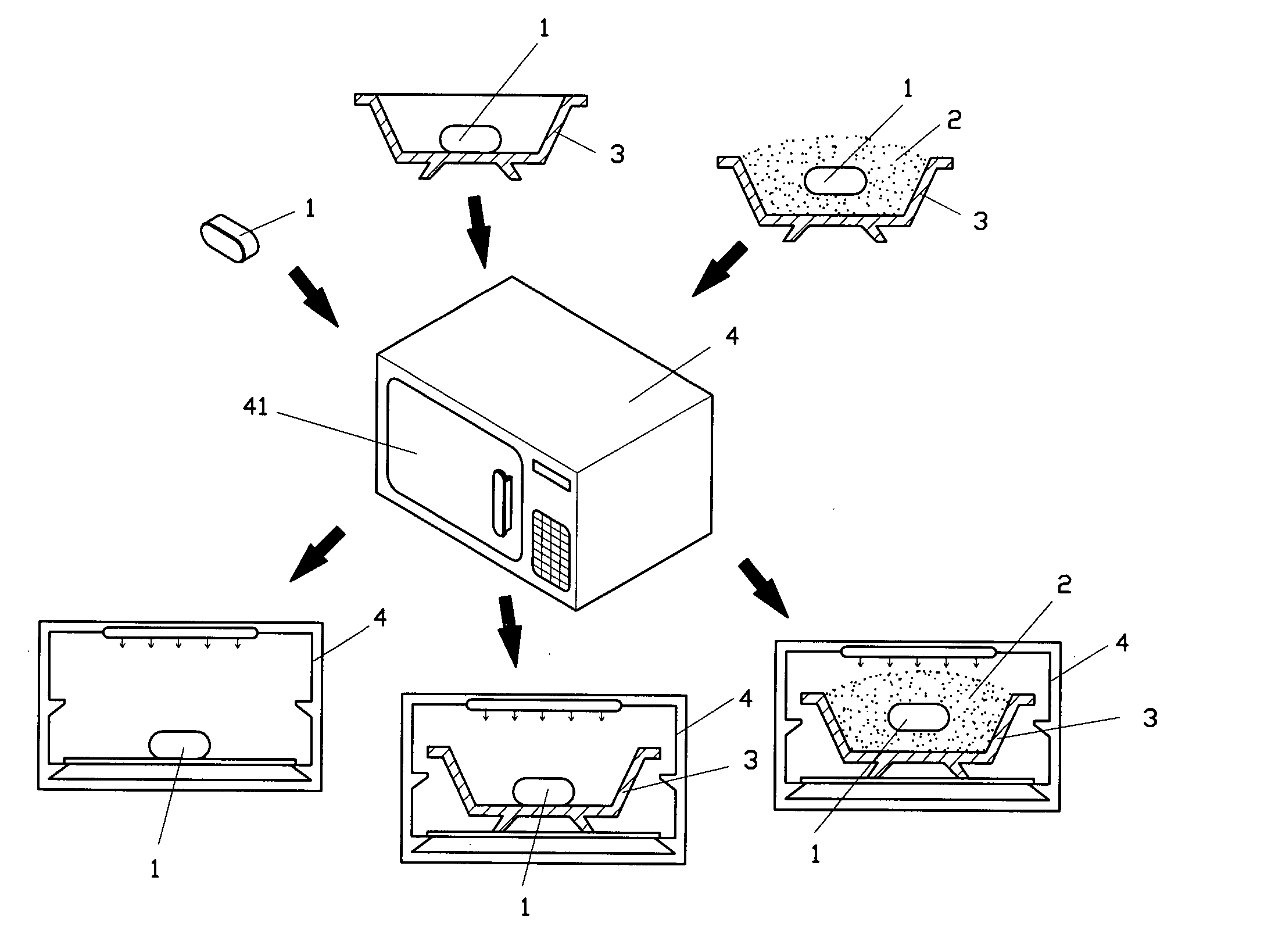

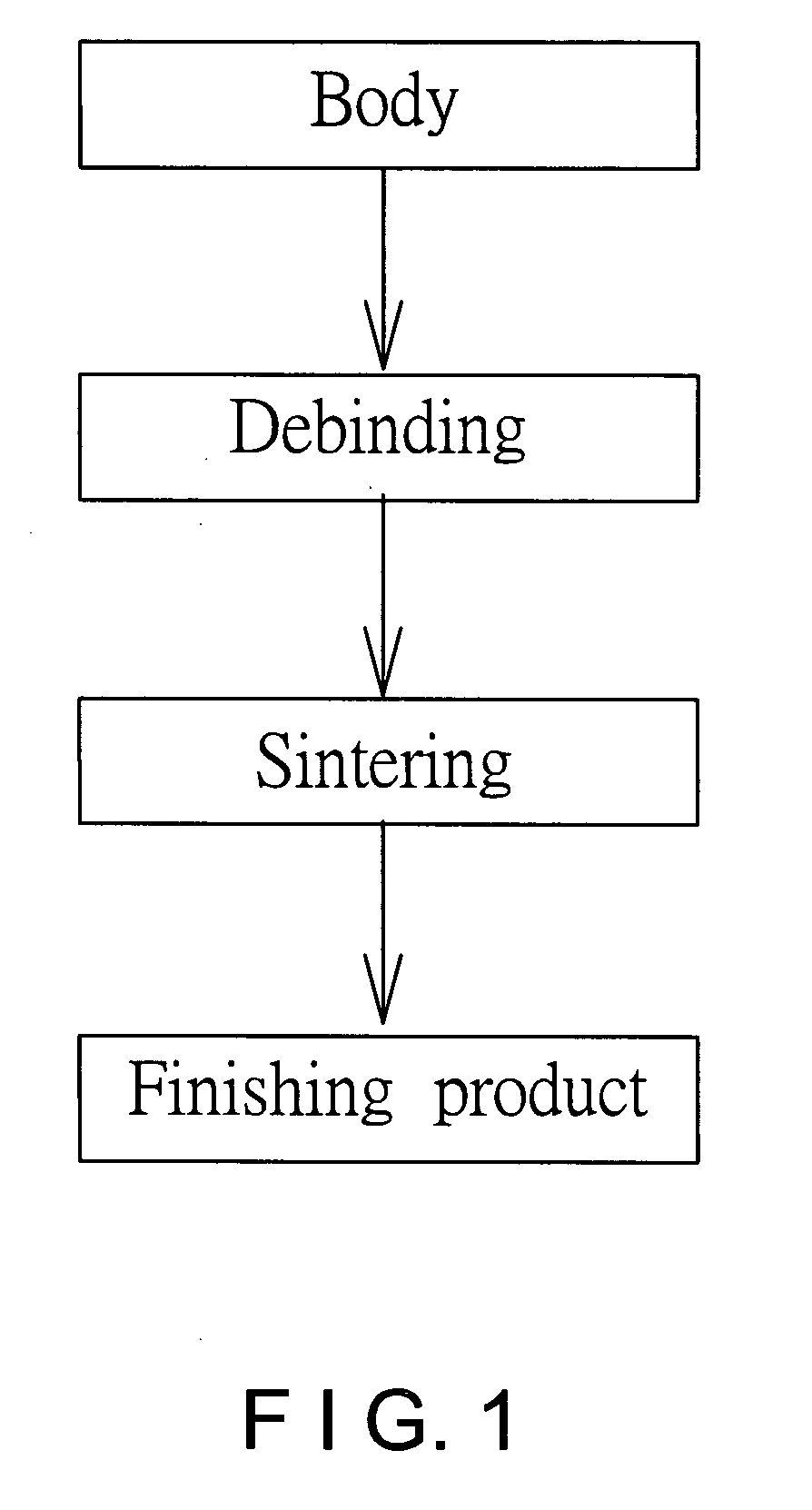

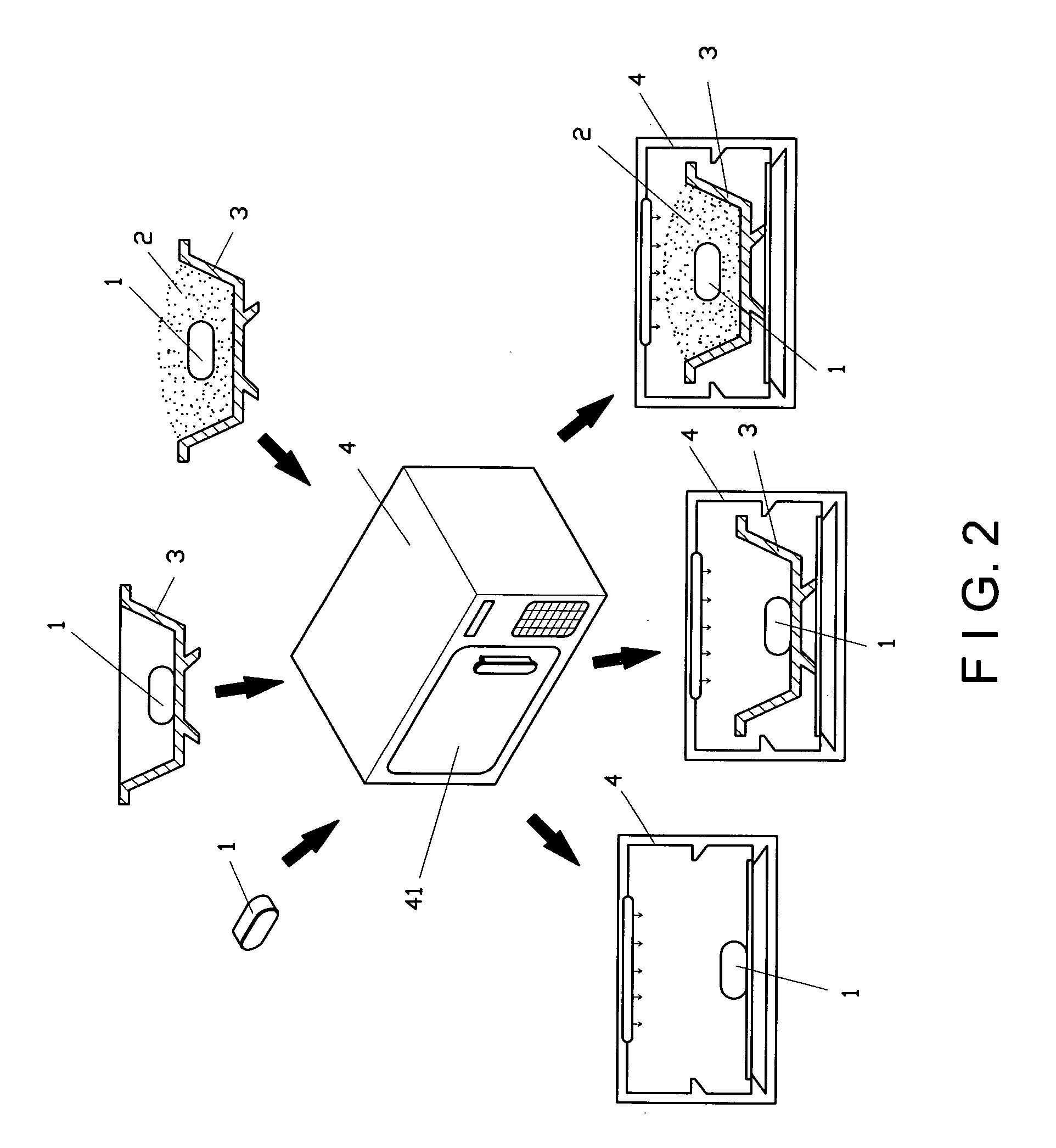

[0028] To better understand the manufacturing process and functions of the present invention, descriptions shall be given with the accompanying drawings below.

[0029] Referring to FIG. 1, procedures of powder metallurgy are: a. forming a body, b. debinding, c. sintering, and d. finishing product. The invention is a manufacturing process using microwave for thermal debinding. When being applied in powder metallurgy, the invention comprises the steps of: [0030] a. forming a body: powder of iron, nickel and copper is mixed with a weight ratio of 90:6:4, and the mixture is then blended with a mixture of low density polyethylene (LDPE), ethylene vinyl acetate (EVA), paraffin wax (PW) and stearic acid (SA) with a weight ratio of 12:12:61:15 at a temperature range between 120 to 160° C. for forming a body 1; wherein the aforesaid metal may be pure metals or alloys of iron (Fe), titanium (Ti), copper (Cu), magnesium (Mg), nickel (Ni), chromium (Cr) and manganese (Mn); [0031] b. debinding: t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

| reaction time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com