Evaporator and condenser section structure for thermosiphon

a technology of condenser section and thermosiphon, which is applied in the direction of refrigerating machines, tubular elements, lighting and heating apparatus, etc., can solve the problems of less efficient counterflow type devices than closed loop systems, and achieve the effects of less efficient, reduced cost and large overall siz

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]Aspects of the invention are not limited in application to the details of construction and the arrangement of components set forth in the following description or illustrated in the drawings. Other embodiments may be employed and aspects of the invention may be practiced or be carried out in various ways. Also, aspects of the invention may be used alone or in any suitable combination with each other. Thus, the phraseology and terminology used herein is for the purpose of description and should not be regarded as limiting.

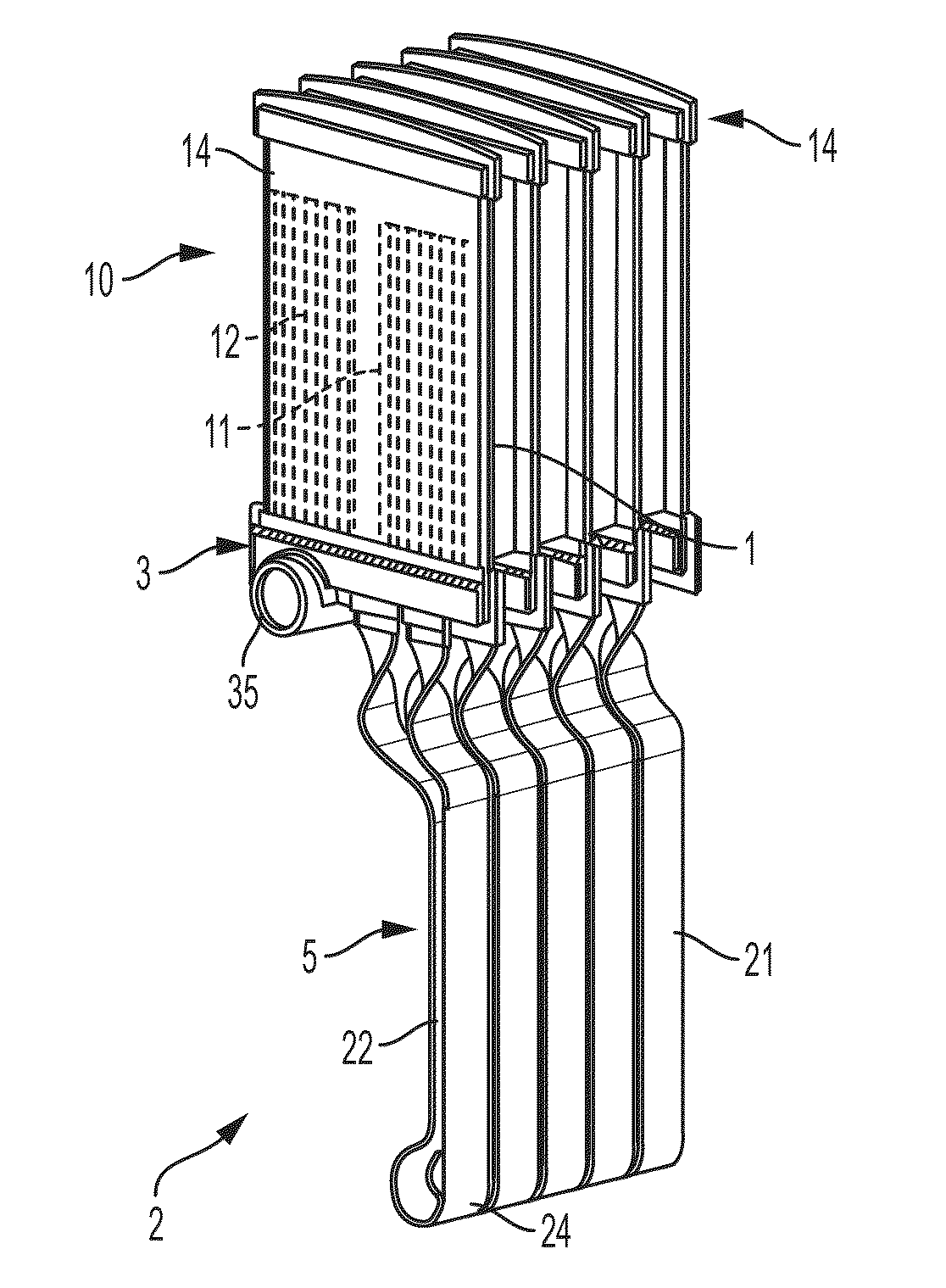

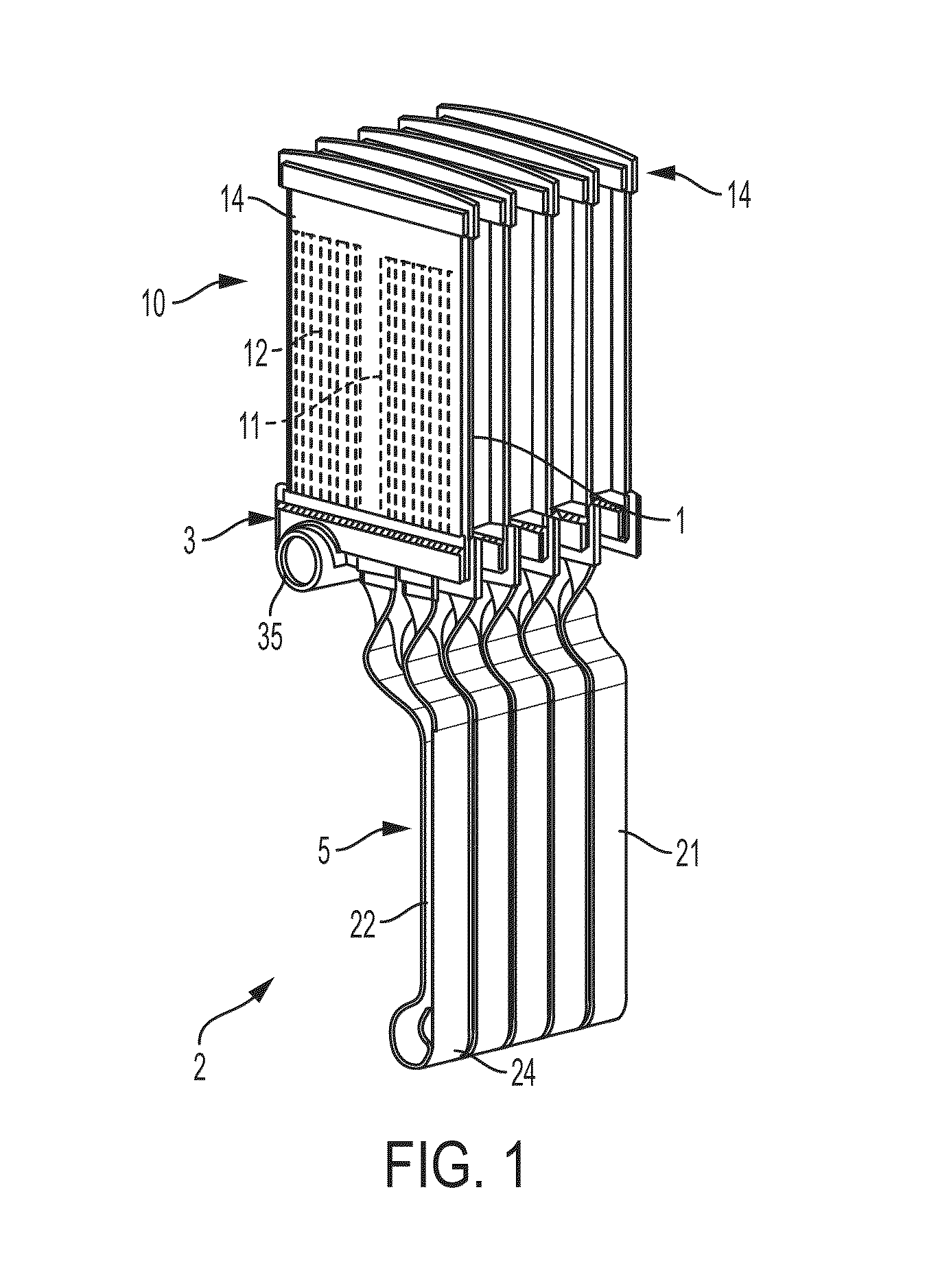

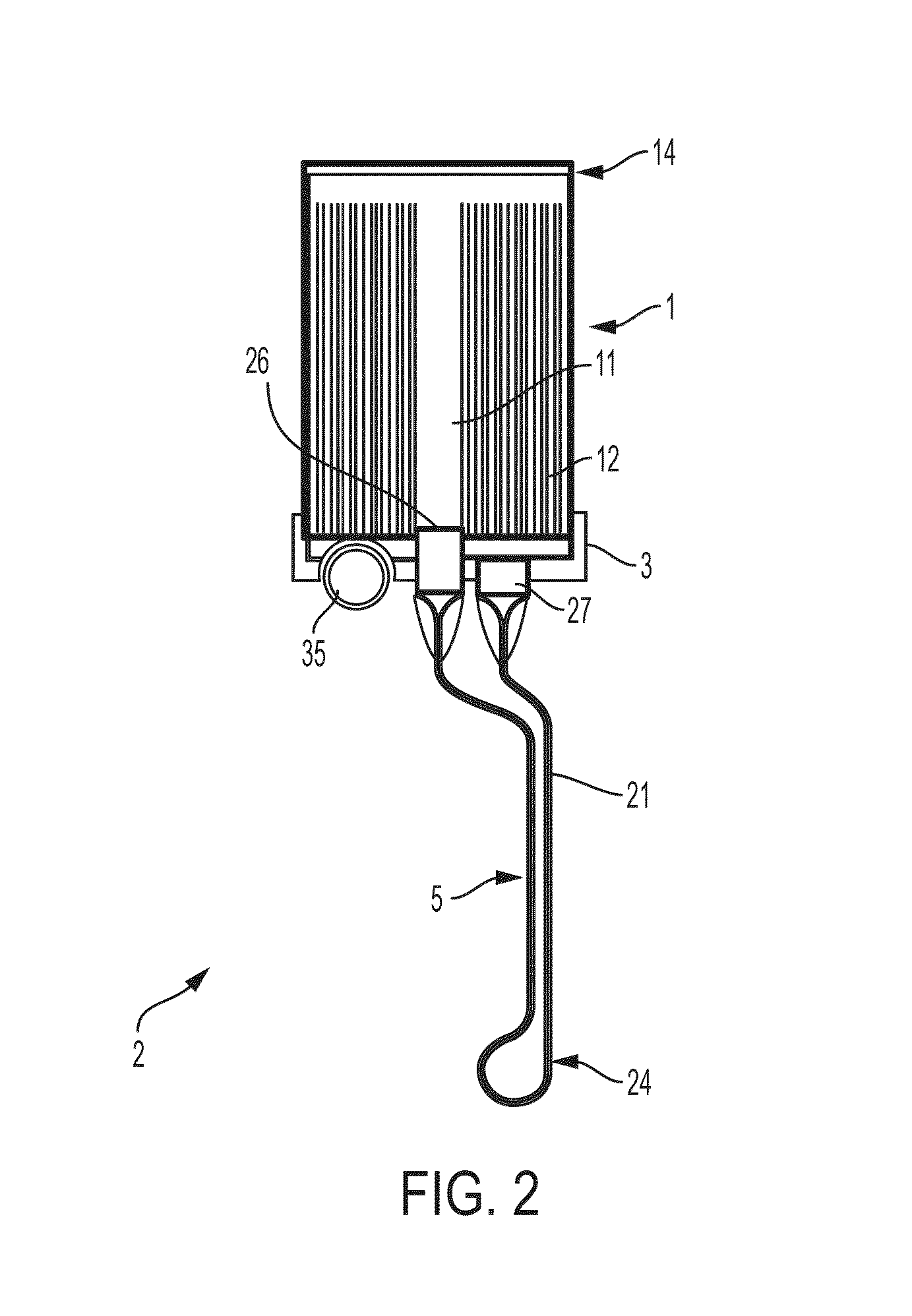

[0035]In accordance with an aspect of the invention, a thermosiphon cooling device includes an evaporator section formed as a flat tube that is bent at a location where the liquid return outlet communicates with the at least one evaporation channel inlet. For example, the evaporator section may include at least one evaporation channel having an inlet and a liquid return path having an outlet that is fluidly coupled to the evaporation channel inlet, where the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com