Ultra-large light-transmission-type decorative board

A decorative panel, super large technology, applied in the direction of building components, layered products, walls, etc., can solve the problems that it is difficult to meet the mechanical properties, heat insulation, sound insulation and surface decoration comprehensive technical requirements of light-transmitting panels, and reach the weight The effect of lightness, weight reduction, and overall rigidity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

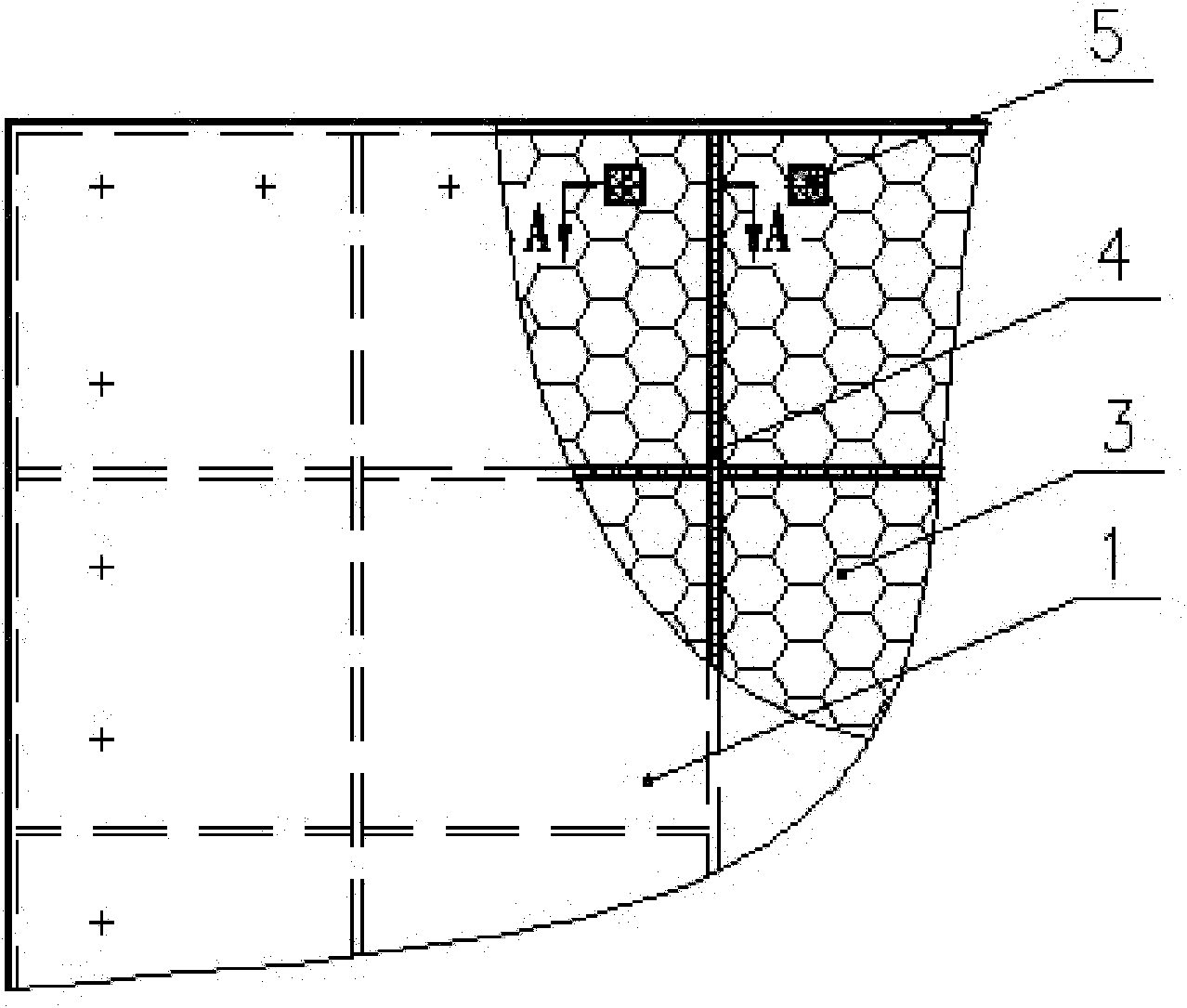

[0042] Specific embodiment 1 of the present invention will be further described below in conjunction with the accompanying drawings: Take a kind of super-large light-transmitting decorative panel for welcome landscape as an example, the overall dimension of this landscape is: 6 * 2.2 * 21m (length * width × height), a total of 6 floors, the outside of the landscape adopts the cantilevered dry hanging method, and the light-transmitting decorative board is used as the overall enclosure of the main structure, and the color of the outer surface is Chinese red. At night, the LED electric light source installed inside can be lit, and the whole body of the landscape can be illuminated through the decorative panel, so that the overall characteristics can be displayed day and night, so as to achieve its welcoming effect.

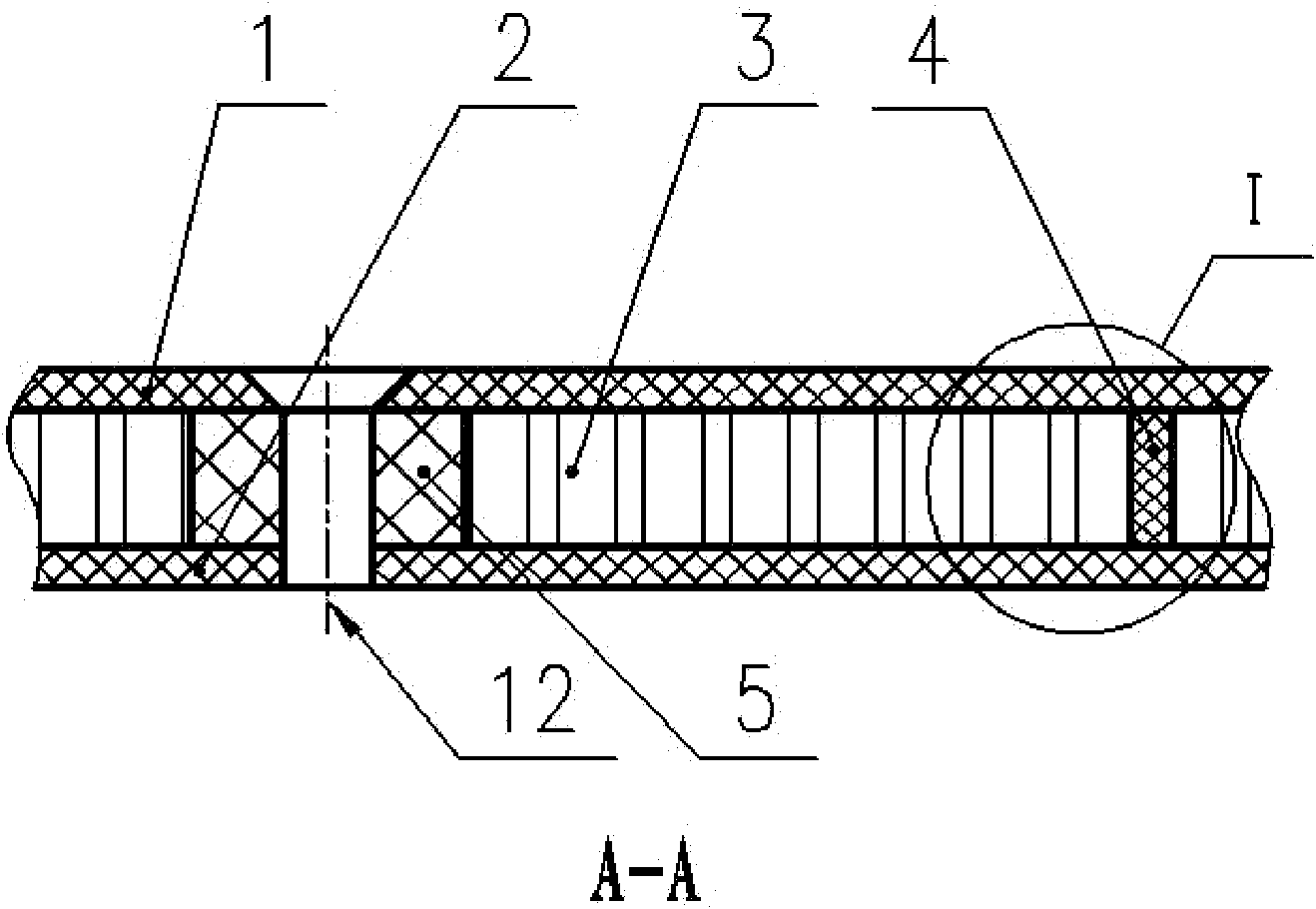

[0043] According to the design requirements and actual functions, the front facade is designed as one decorative board per floor: the area of the single board is 21...

Embodiment 2

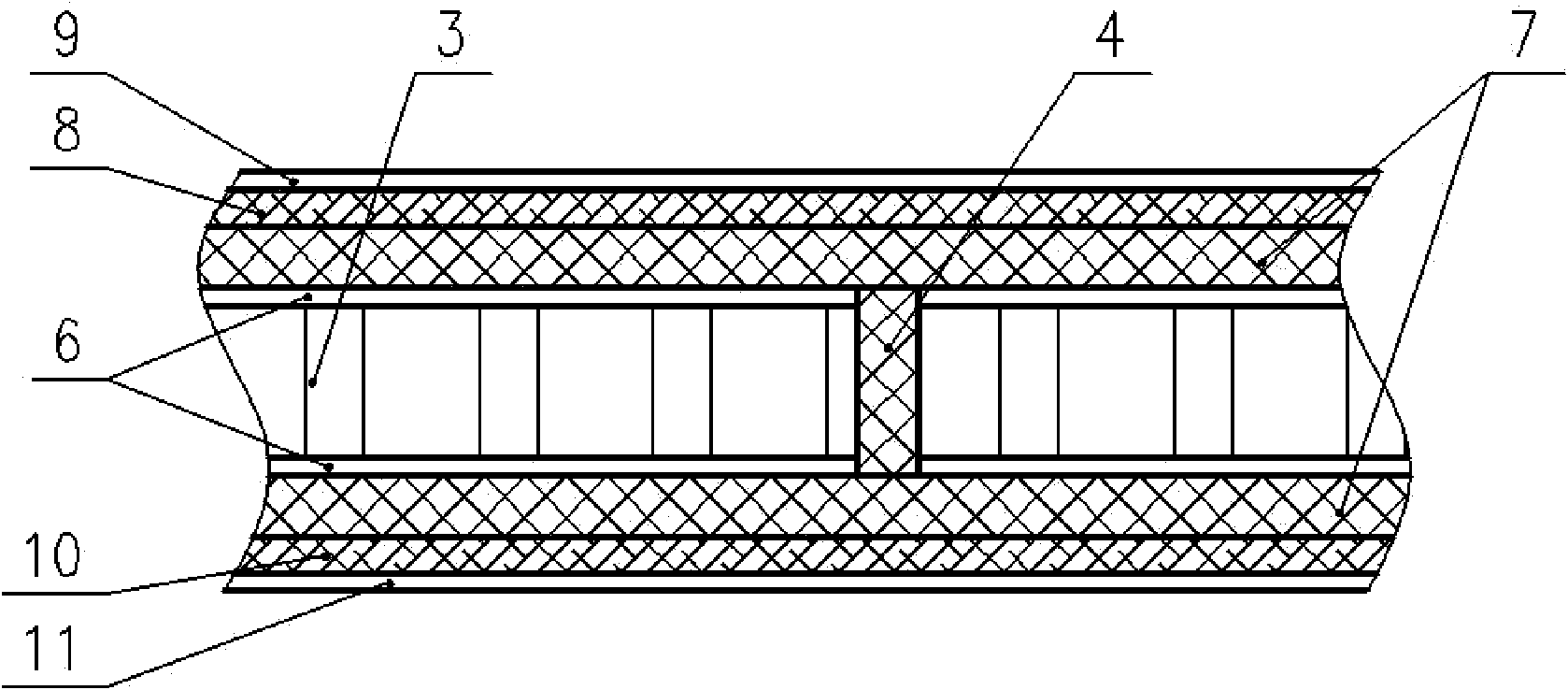

[0064] Such as Figure 5 As shown, this is a decorative panel that does not require surface treatment on the inner surface, and adopts a one-time molding method. The specification of this embodiment is: 6×9m, area 54m 2 , 120mm thick, the outer surface is light fruit green, requiring light transmission at night (5 ~ 10Lux / m 2 ), there is no special requirement for the inner surface. According to user requirements, the layup design is: 15+90+15, that is: (inner and outer) FRP structure layer 7 thickness 15mm; core material adopts FRP honeycomb board, thickness 90mm, single block area 2.25m 2 (1.5×1.5m); the thickness of the rib is 10mm, and the suture belt of 90mm wide non-alkali glass fiber chopped strand mat is used; the installation holes are arranged equidistantly along the four sides, and the distance between the installation holes is ≤600mm. To ensure safety, in the center of the board (two pairs Corner line intersection point) is provided with a connection hole, the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Plate thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com