Processing device for ultrasonic grinding on sapphire lenses

A processing device, sapphire technology, applied in the direction of grinding drive device, metal processing equipment, grinding machine parts, etc., can solve the problems of no alternative processing technology, many resources, shortage of sapphire resources, etc., to shorten auxiliary processing. Time, ensure the processing quality, the installation is accurate, convenient and fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

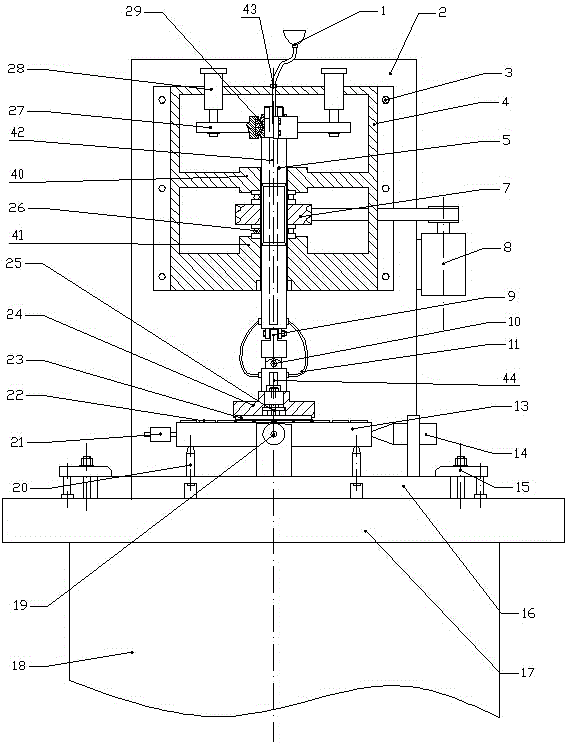

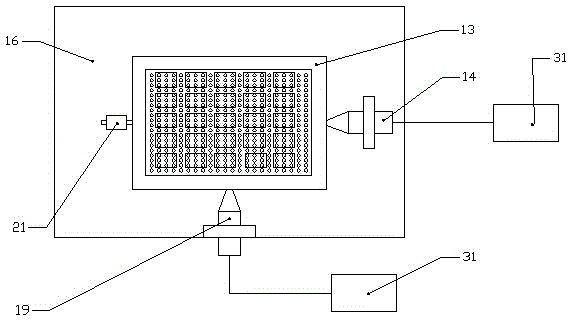

[0026] like figure 1 and figure 2 As shown, the processing device for ultrasonically lapping sapphire lenses of the present invention includes a support 18 and an ultrasonic vibration loading system. The support 18 is provided with a workbench 17 and a machine bed 2, and the machine bed 2 is provided with a The grinding head driving system and the grinding fluid supply system above, the workbench 17 is equipped with a lens fixing system, and the support 18 is provided with an auxiliary tool for controlling the horizontal movement of the workbench 17 along the X and Y directions and the Z-direction lifting movement. exercise system.

[0027] The grinding head driving system includes an adjustable-speed motor 8, a spindle box 4, a cylinder 28, a spline shaft 5, an X-direction hinge mechanism 9, a Y-direction hinge mechanism 10, an abrasive tool mounting plate 24 and a grinding head 23, and the speed can be adjusted. The motor 8 is arranged on the side of the machine bed 2, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com