Patents

Literature

37 results about "Disc repair" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

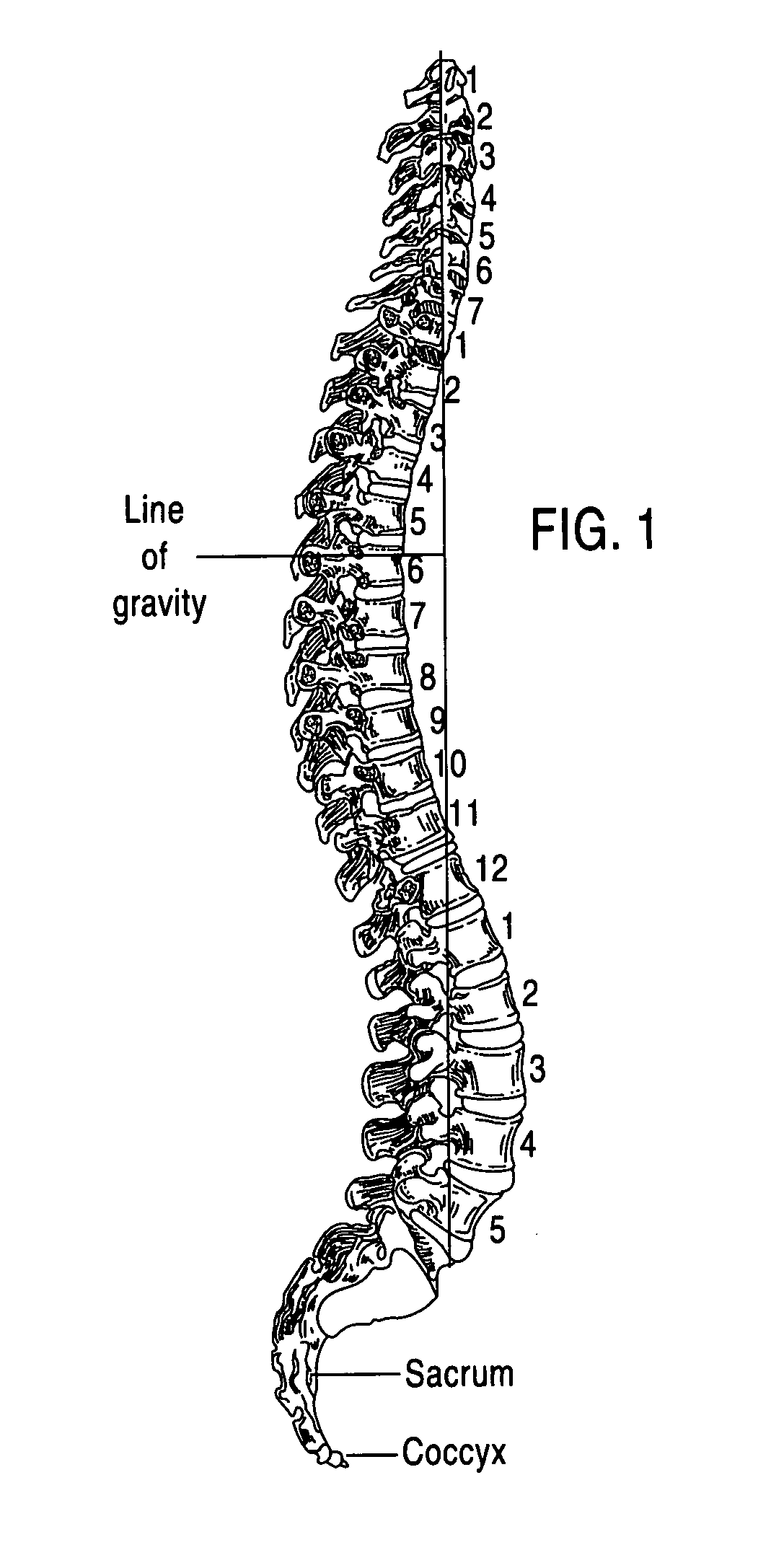

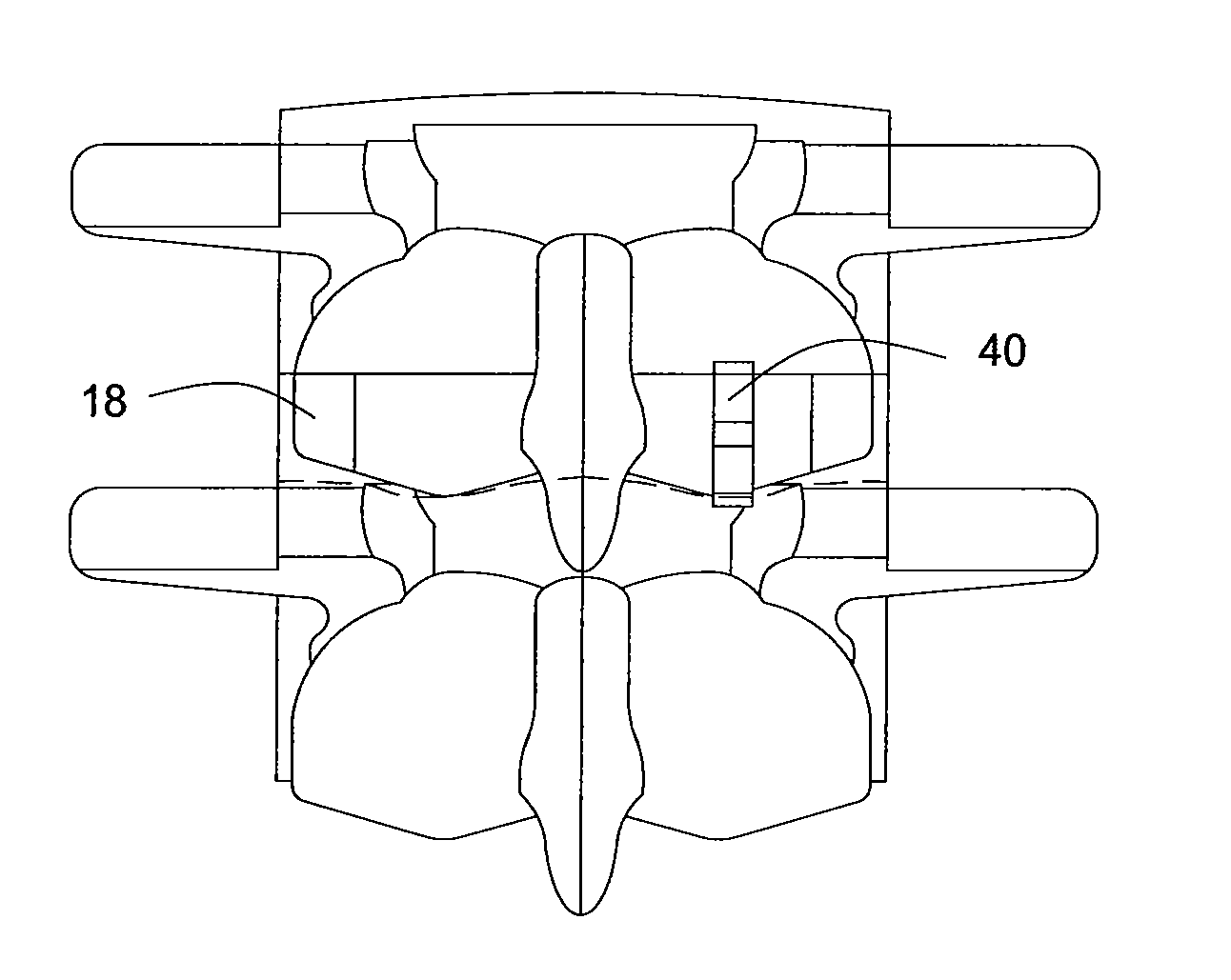

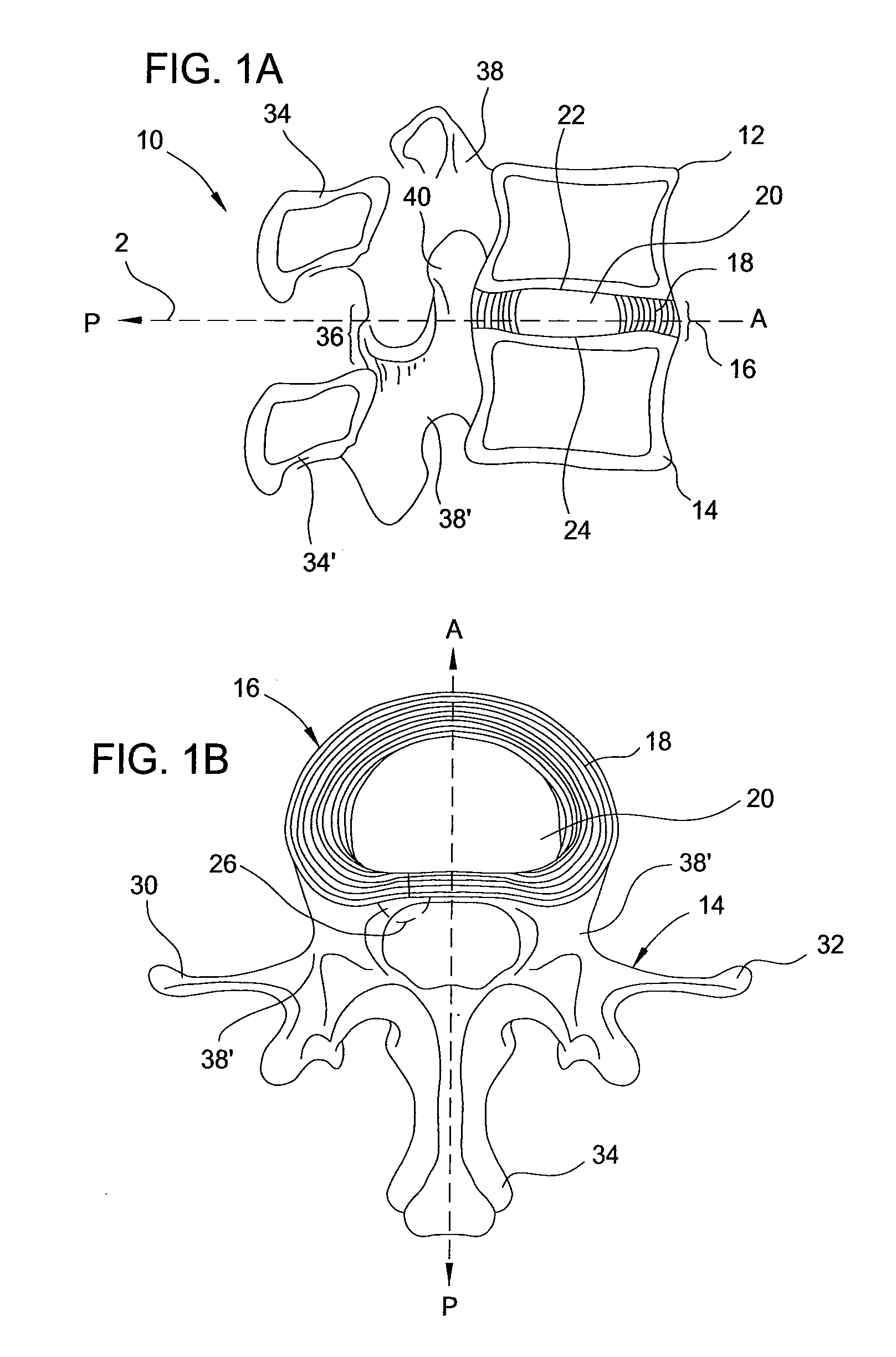

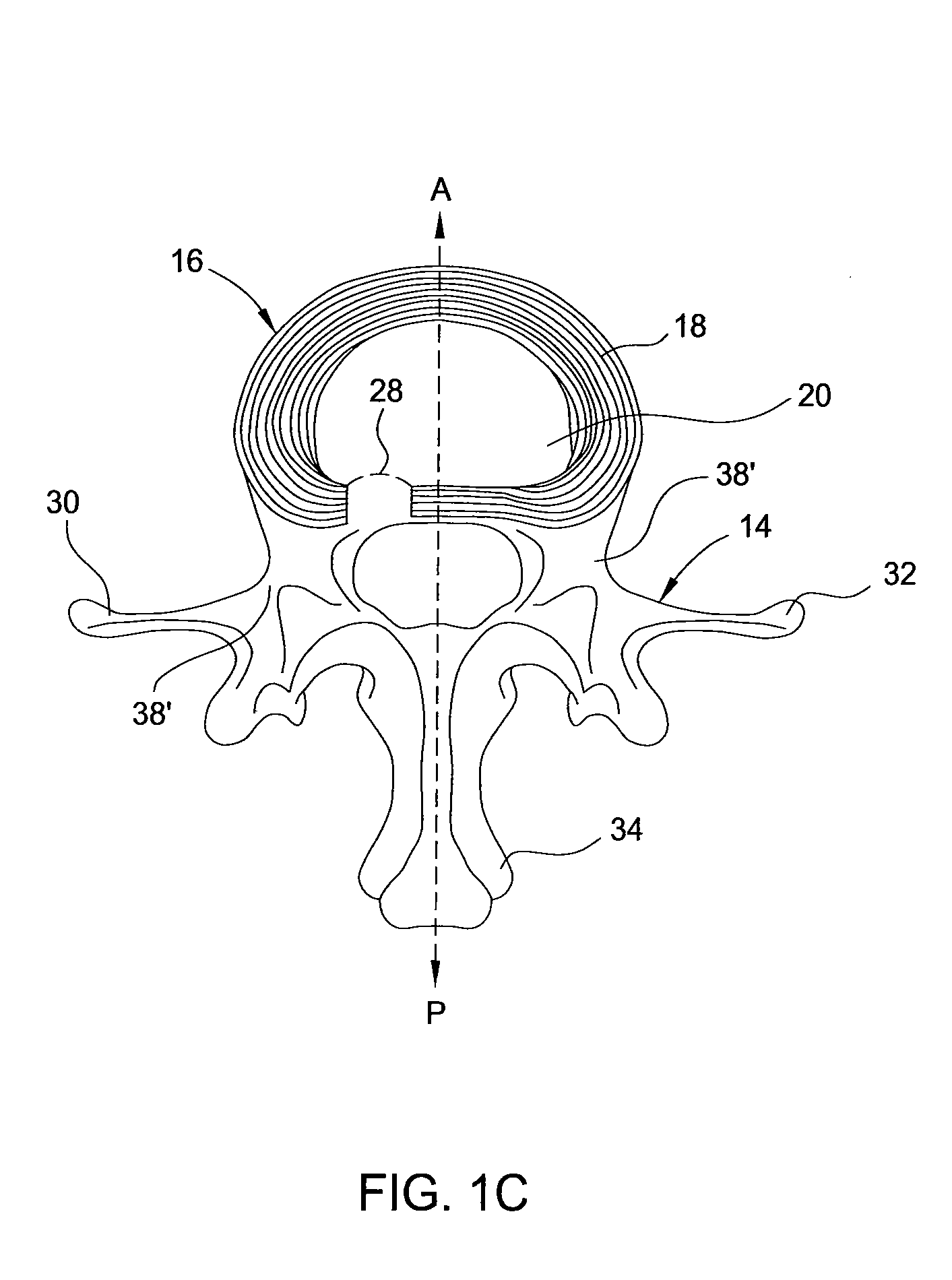

Methods and devices for spinal disc annulus reconstruction and repair

InactiveUS7004970B2Reduce riskImprove integritySuture equipmentsInternal osteosythesisFailure rateDisc repair

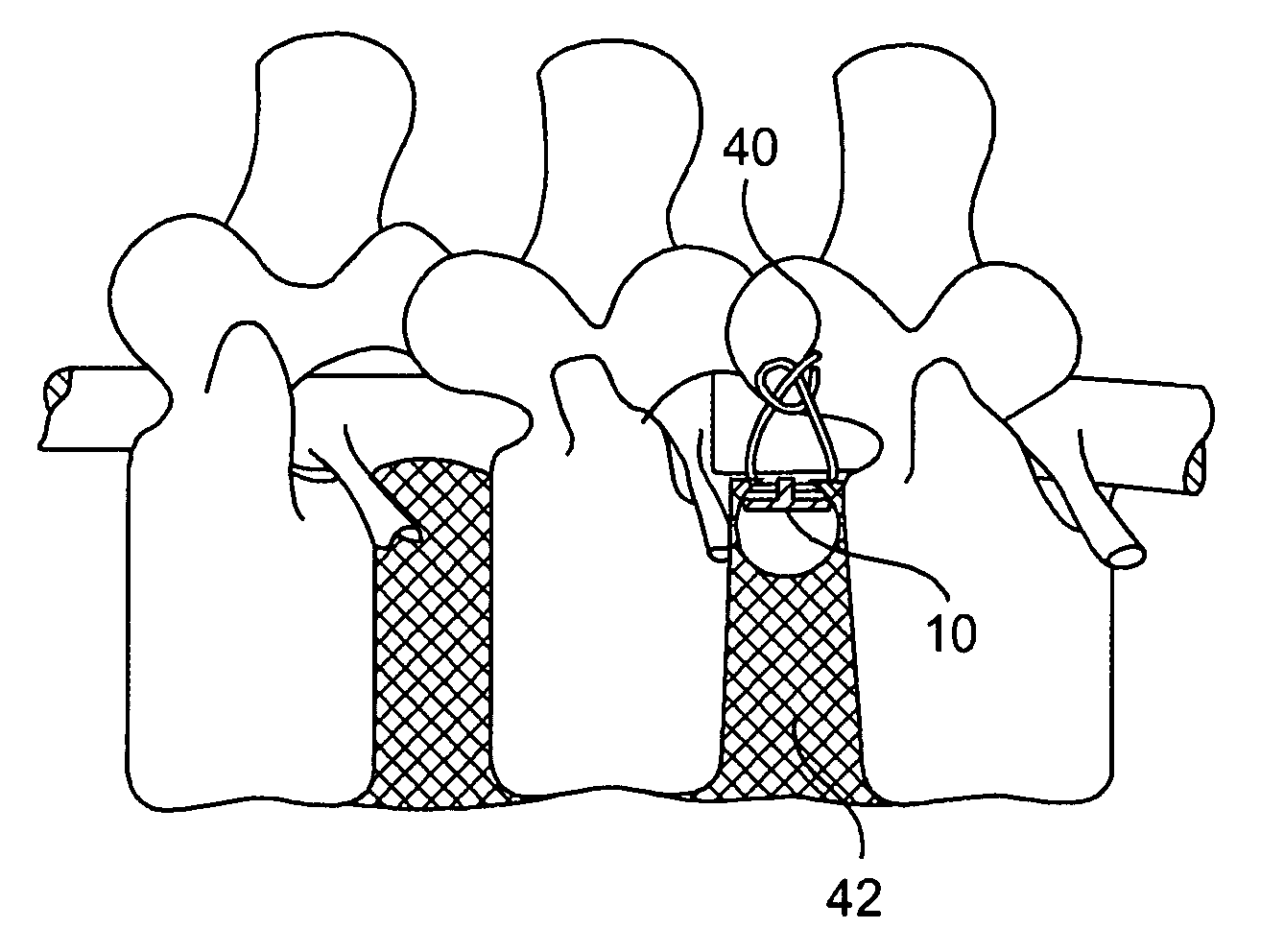

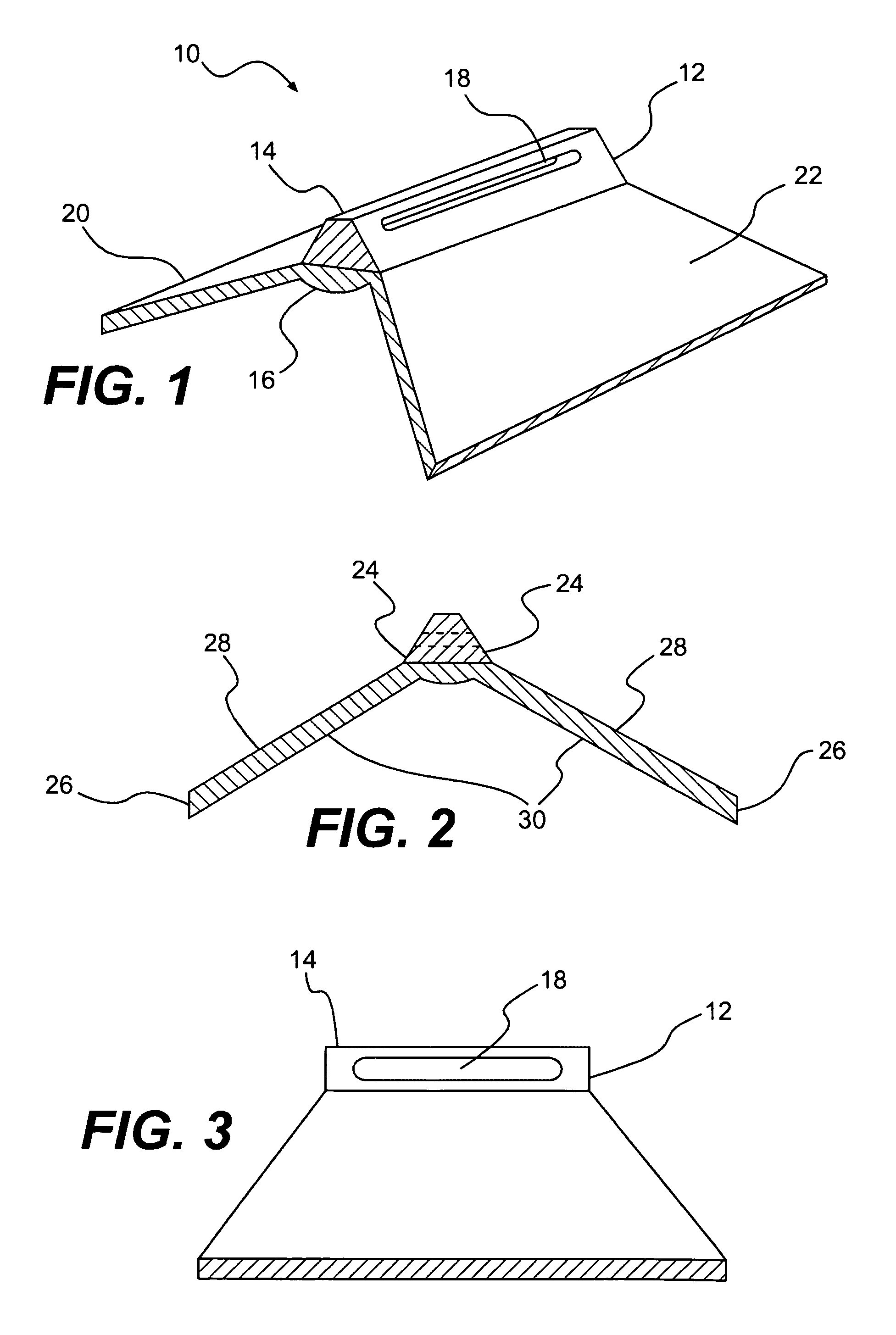

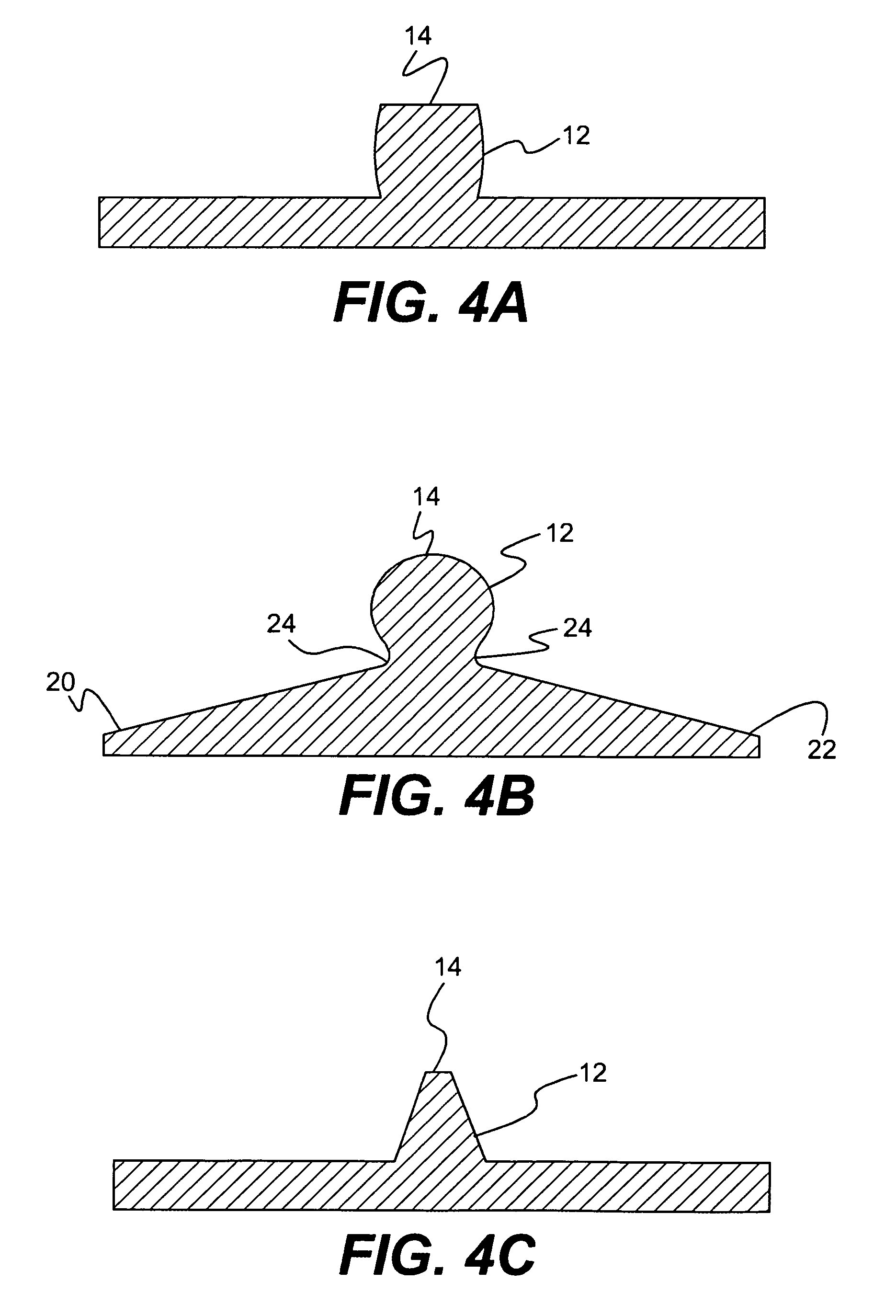

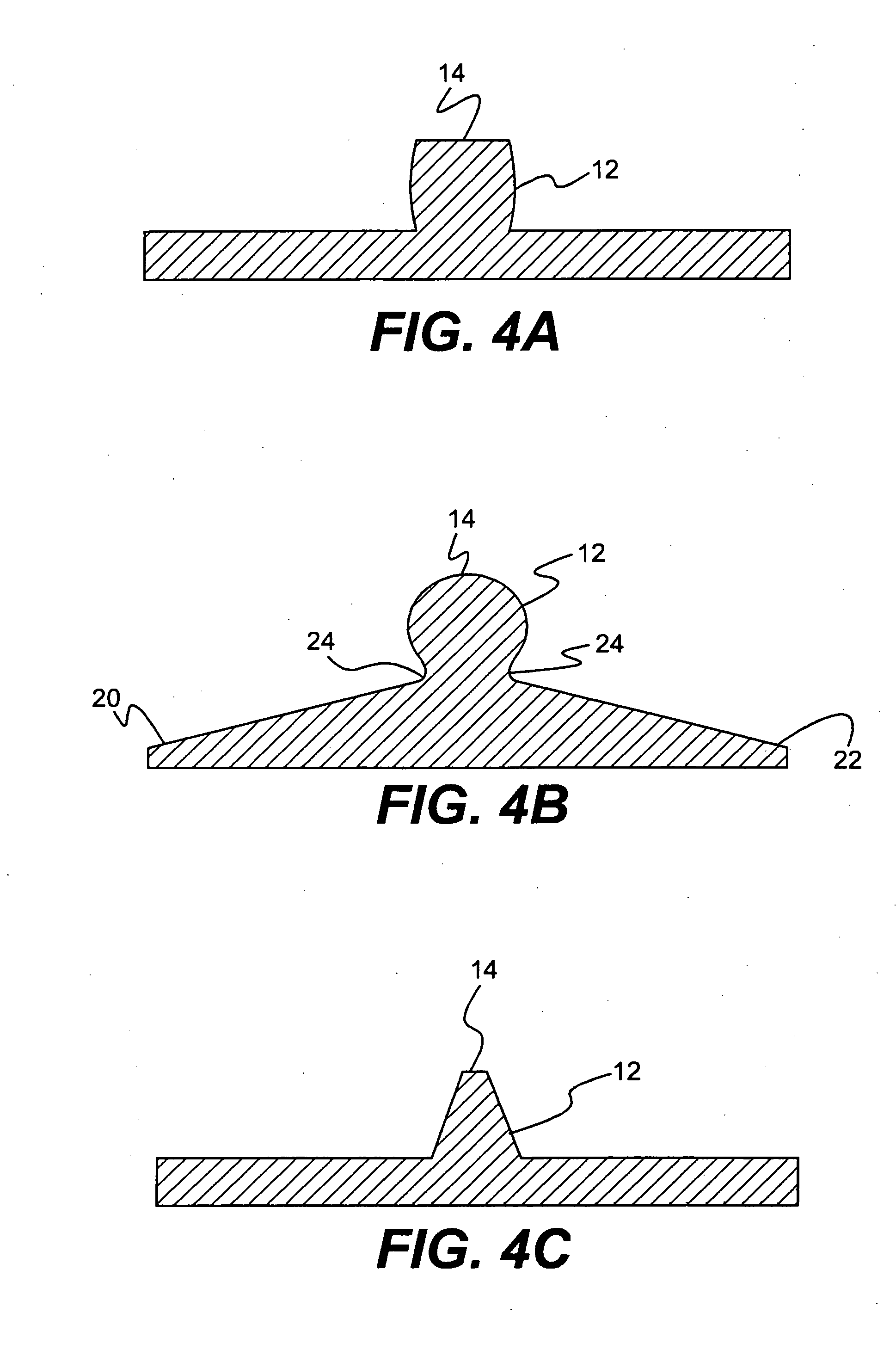

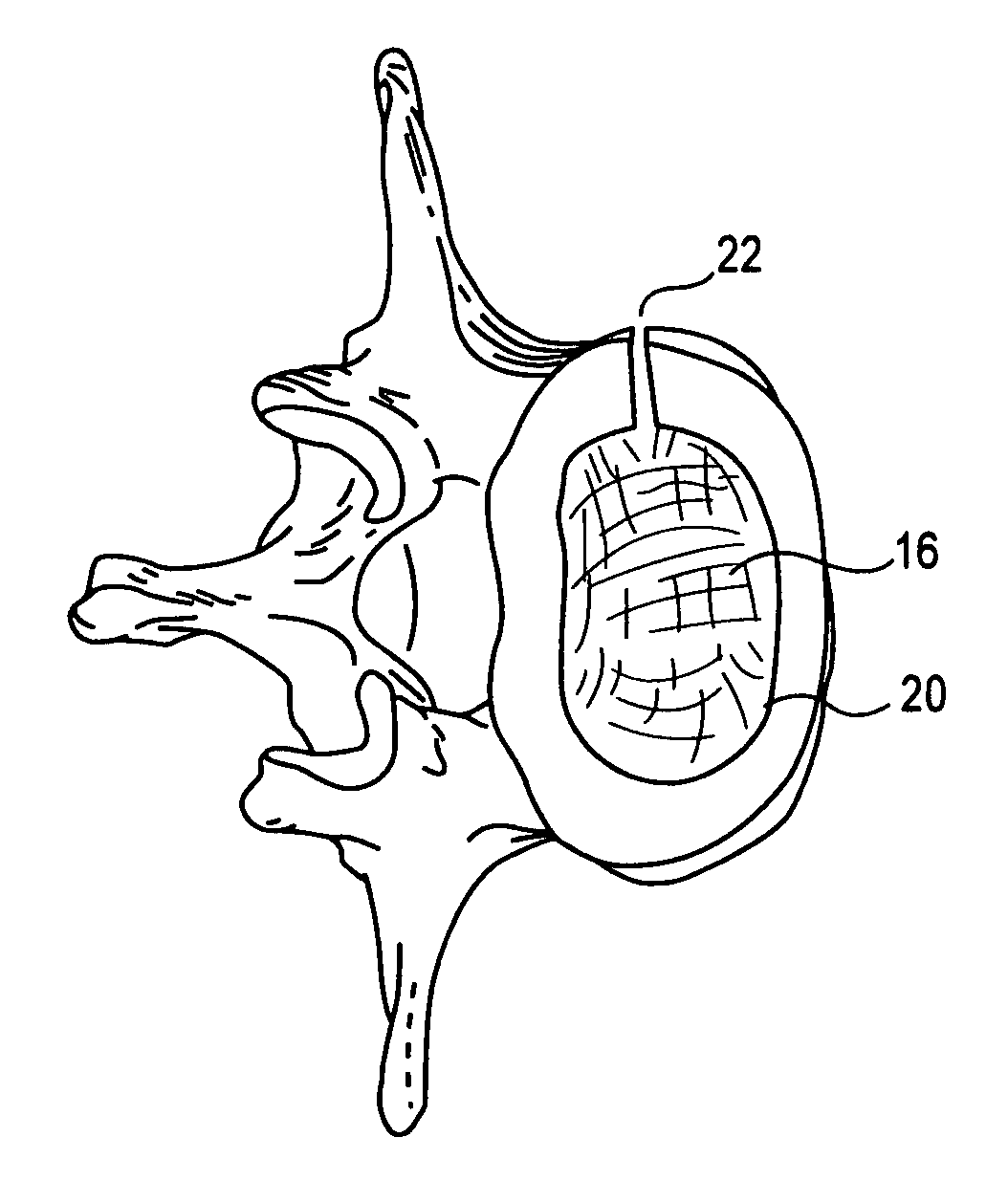

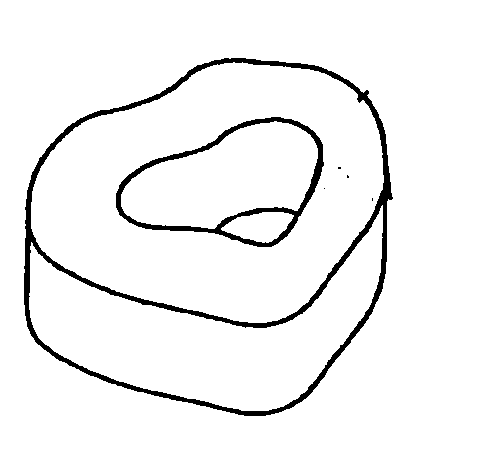

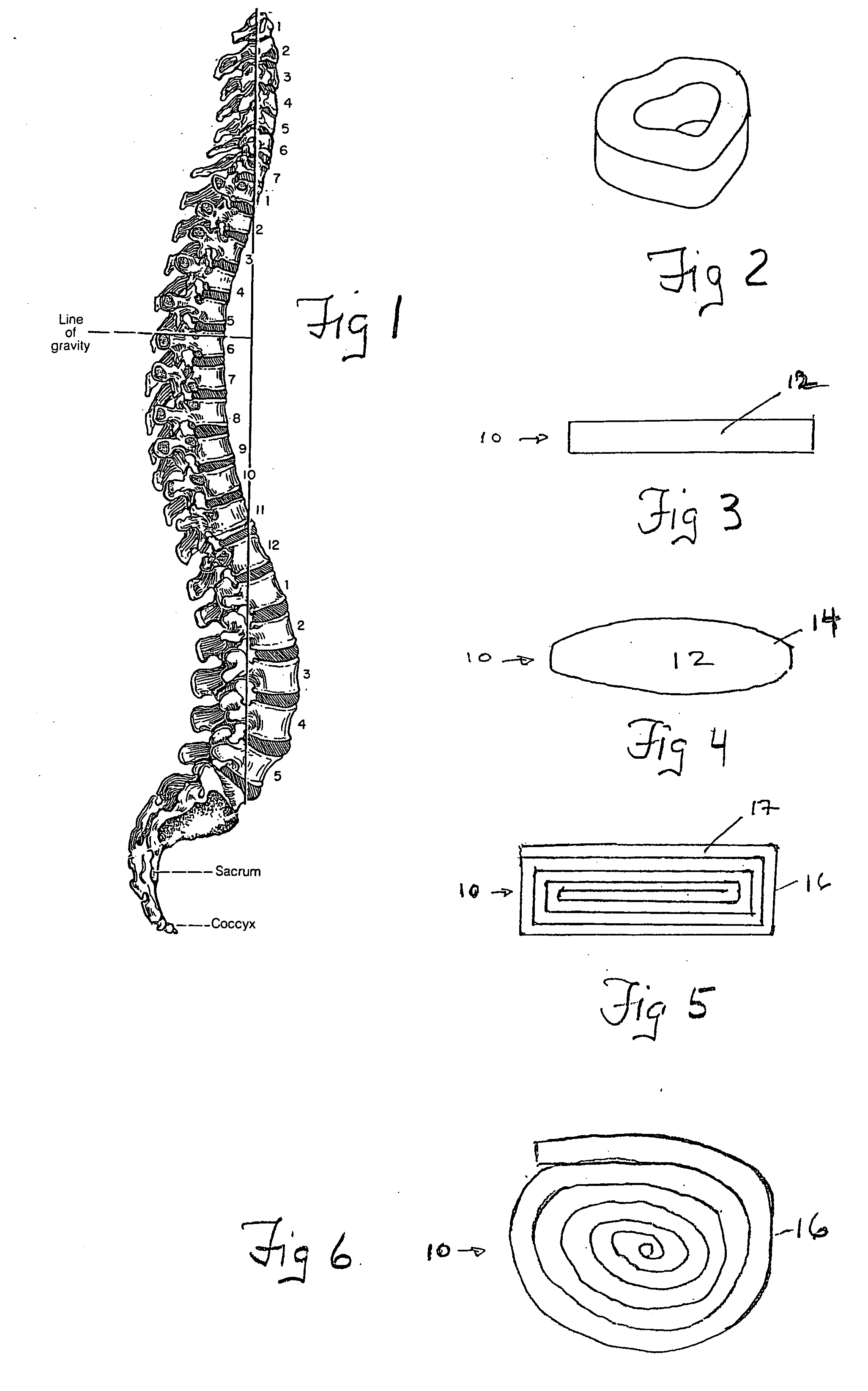

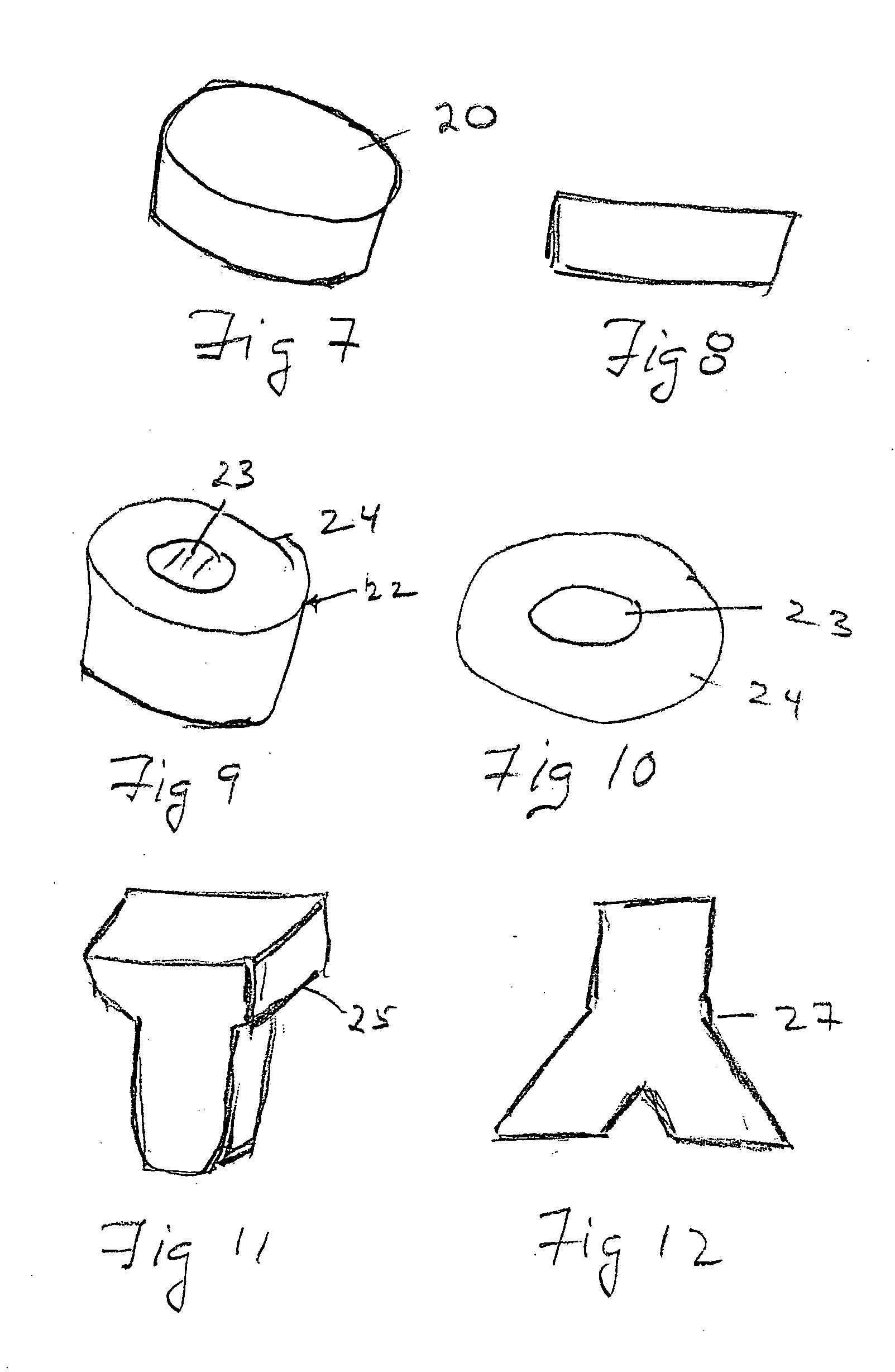

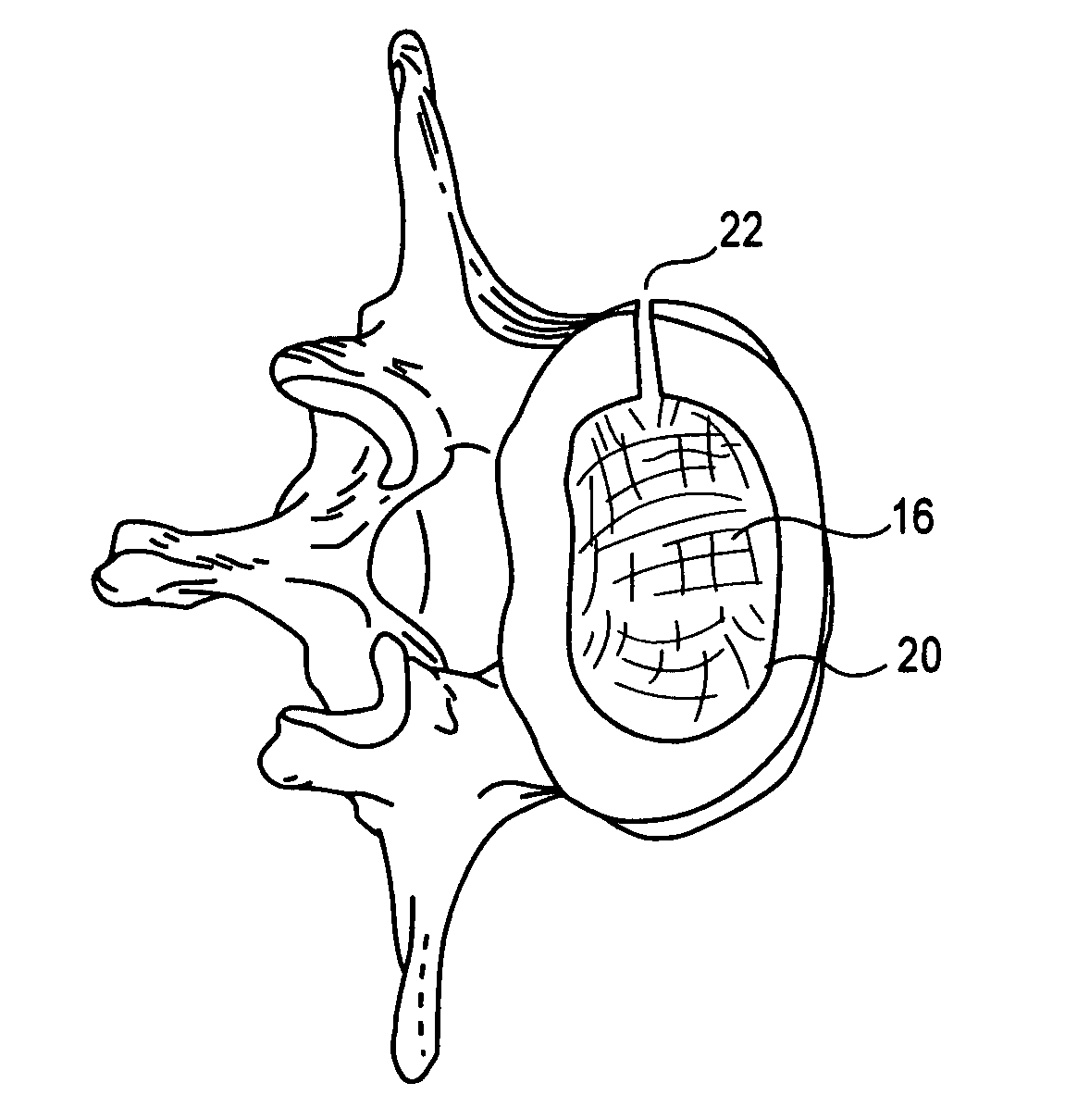

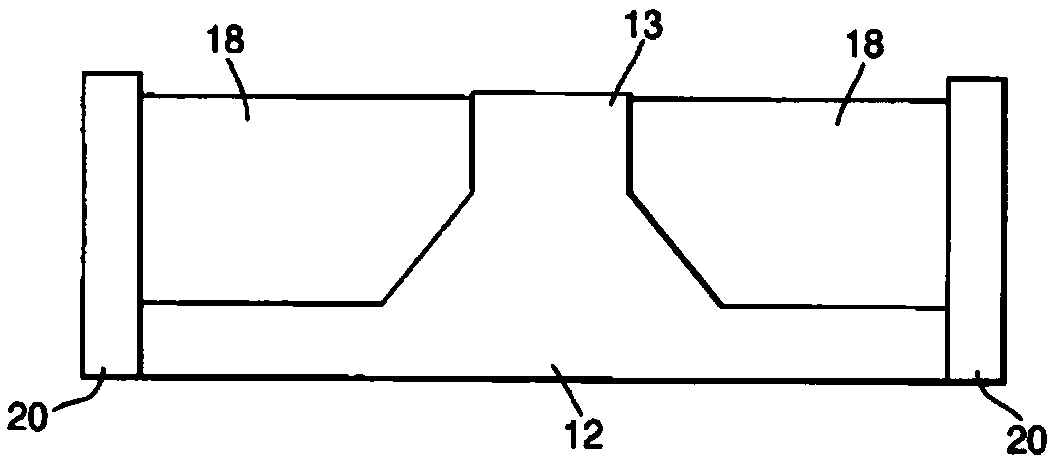

The present invention provides methods and devices for annulus disc repair with and without the use of a patch or stent. The methods and devices are particularly suited to the repair and / or reconstruction of the spinal disc wall (annulus) after surgical invasion or pathologic rupture, with reduced failure rate as compared to conventional surgical procedures.

Owner:KRT INVESTORS

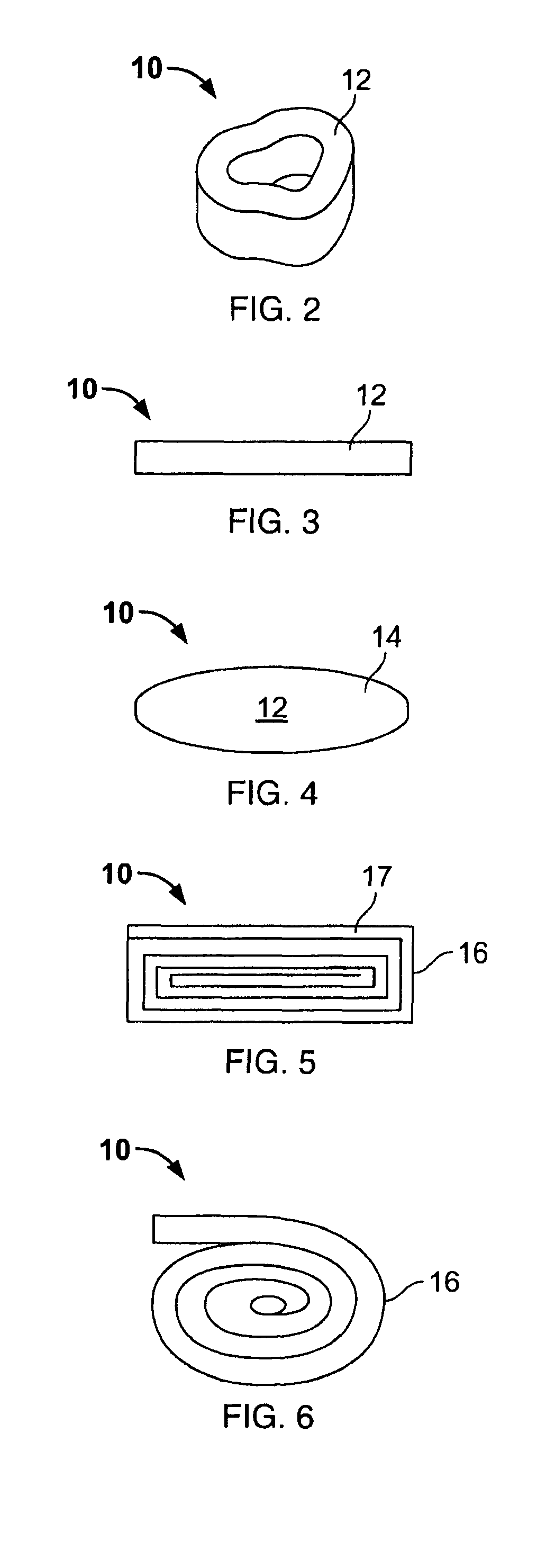

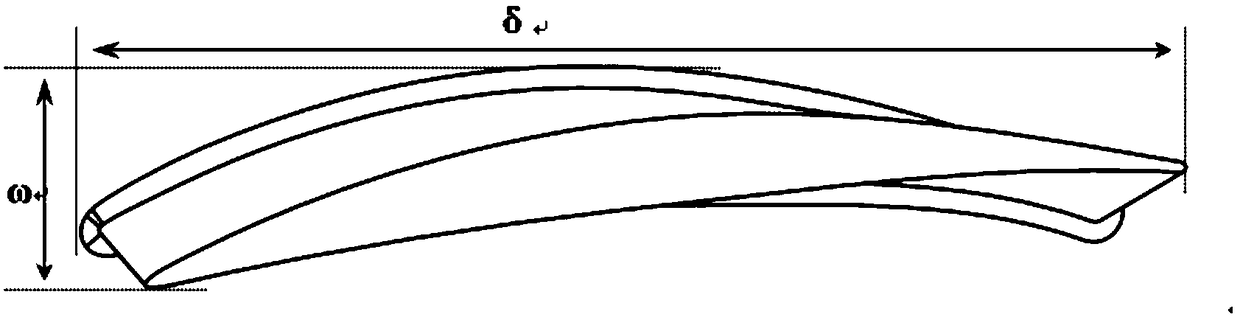

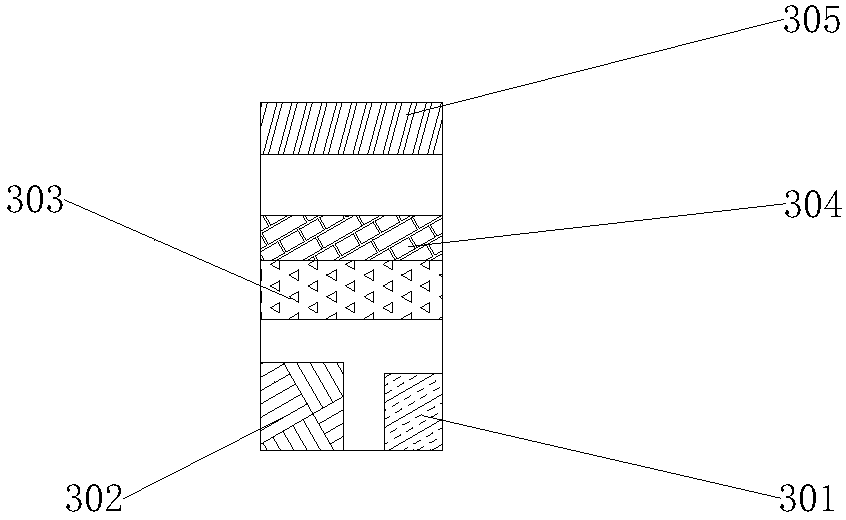

Vertebral disc repair

InactiveUS7879103B2Eliminate osteoinductivitySuture equipmentsBone implantShape-memory alloyBone Cortex

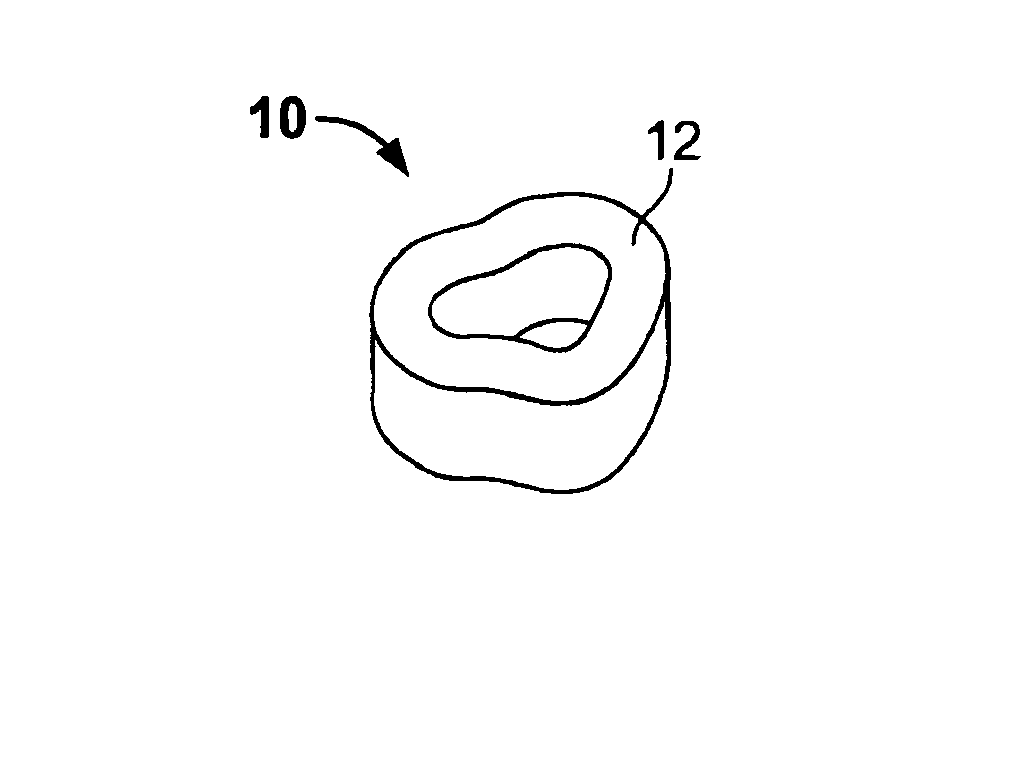

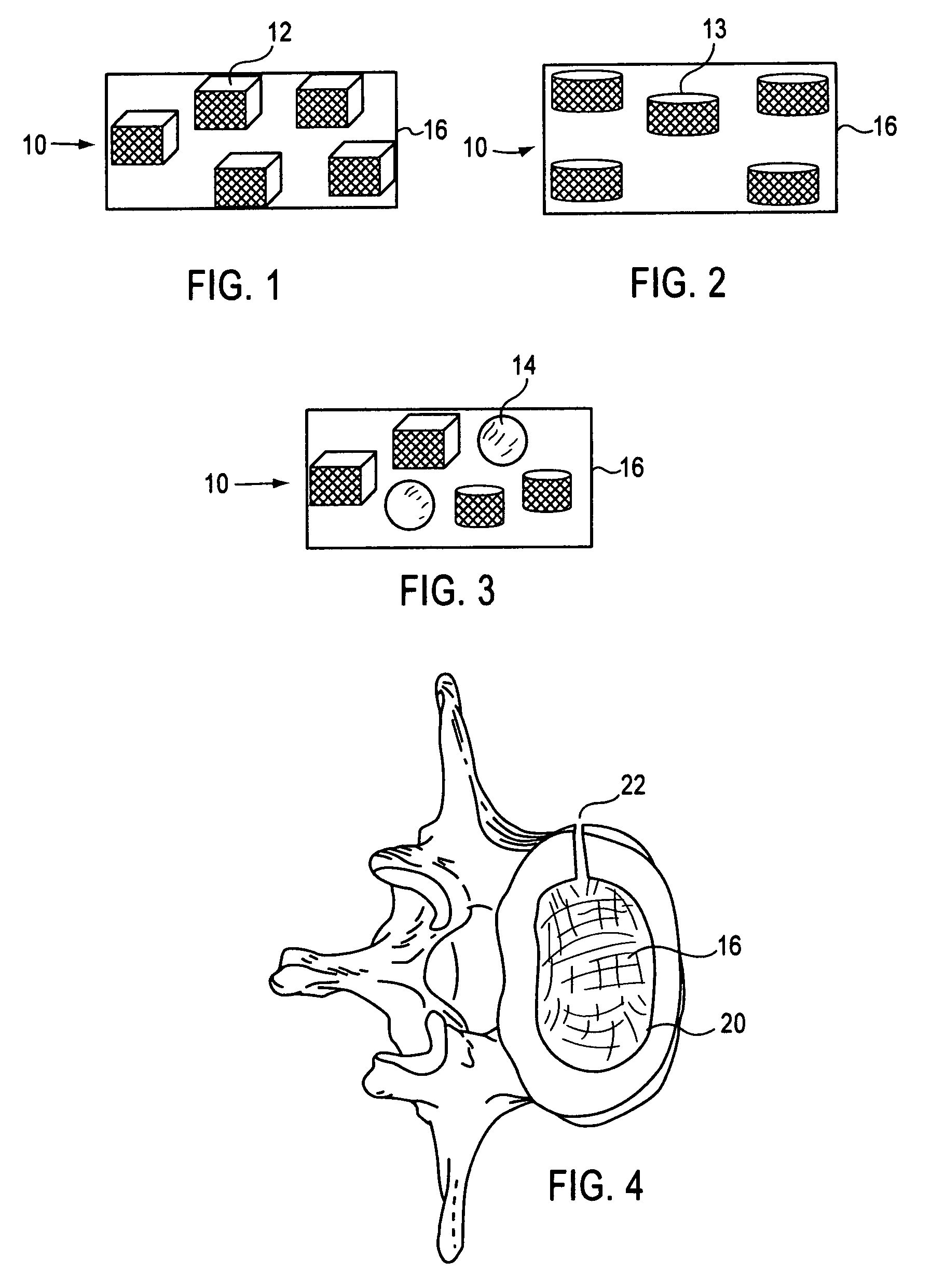

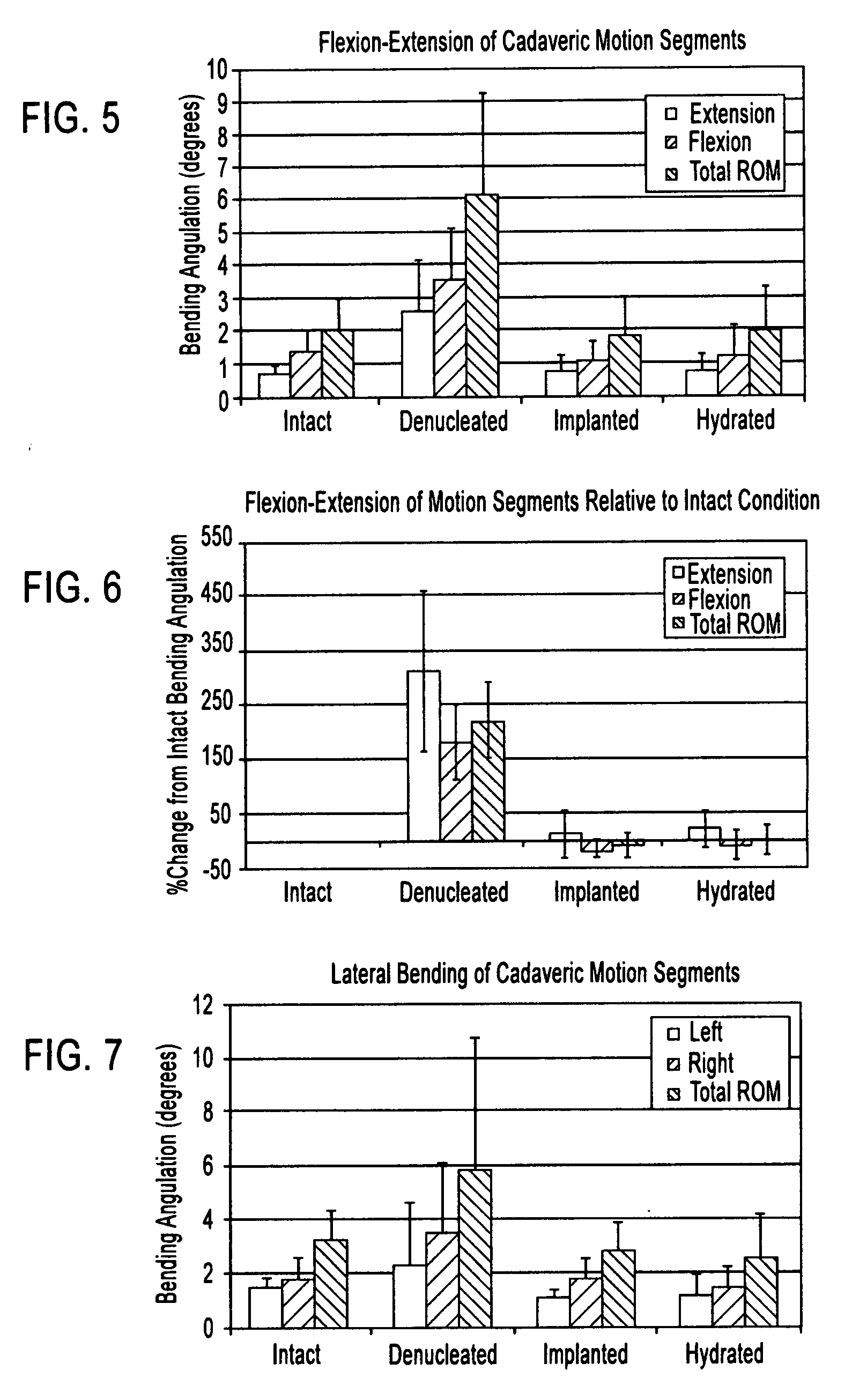

A sterile implant for treatment of a spinal disc defect comprising an allograft cortical bone demineralized to a Type I collagen having a specific shape which is treated to eliminate osteoinductivity. The implant is lyophilized and compressed into smaller first shape which 20 to 80% from its original shape in at least one dimension and hardened. The implant expanding when hydrated into a second shape having the shape memory of the first shape and expanded in dimensional size from the first compressed shape.

Owner:MUSCULOSKELETAL TRANSPLANT FOUND INC

Methods and devices for spinal disc annulus reconstruction and repair

InactiveUS20060129156A1Reduce riskImprove integritySuture equipmentsInternal osteosythesisFailure rateIntervertebral disc

The present invention provides methods and devices for annulus disc repair with and without the use of a patch or stent. The methods and devices are particularly suited to the repair and / or reconstruction of the spinal disc wall (annulus) after surgical invasion or pathologic rupture, with reduced failure rate as compared to conventional surgical procedures.

Owner:KRT INVESTORS

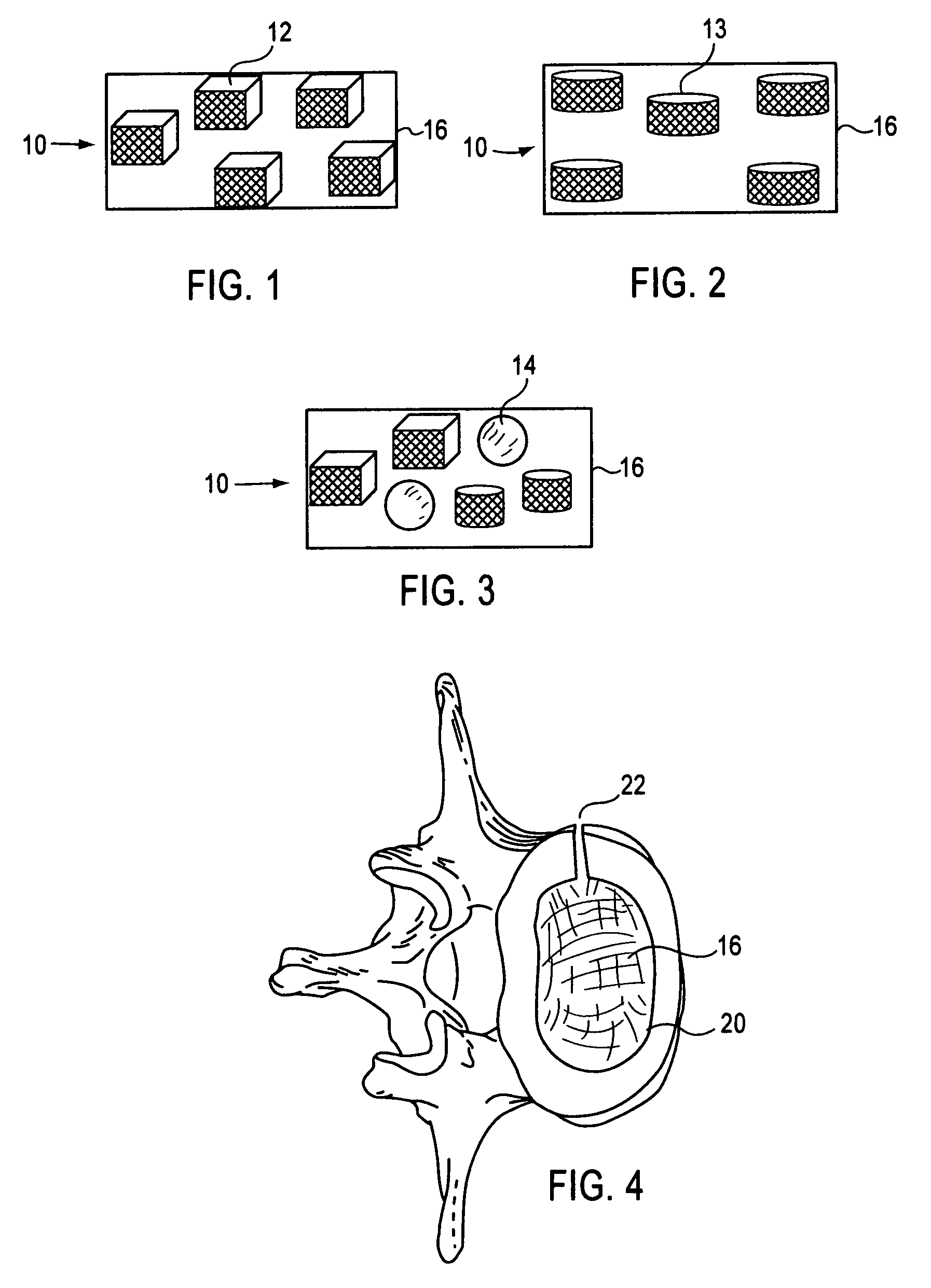

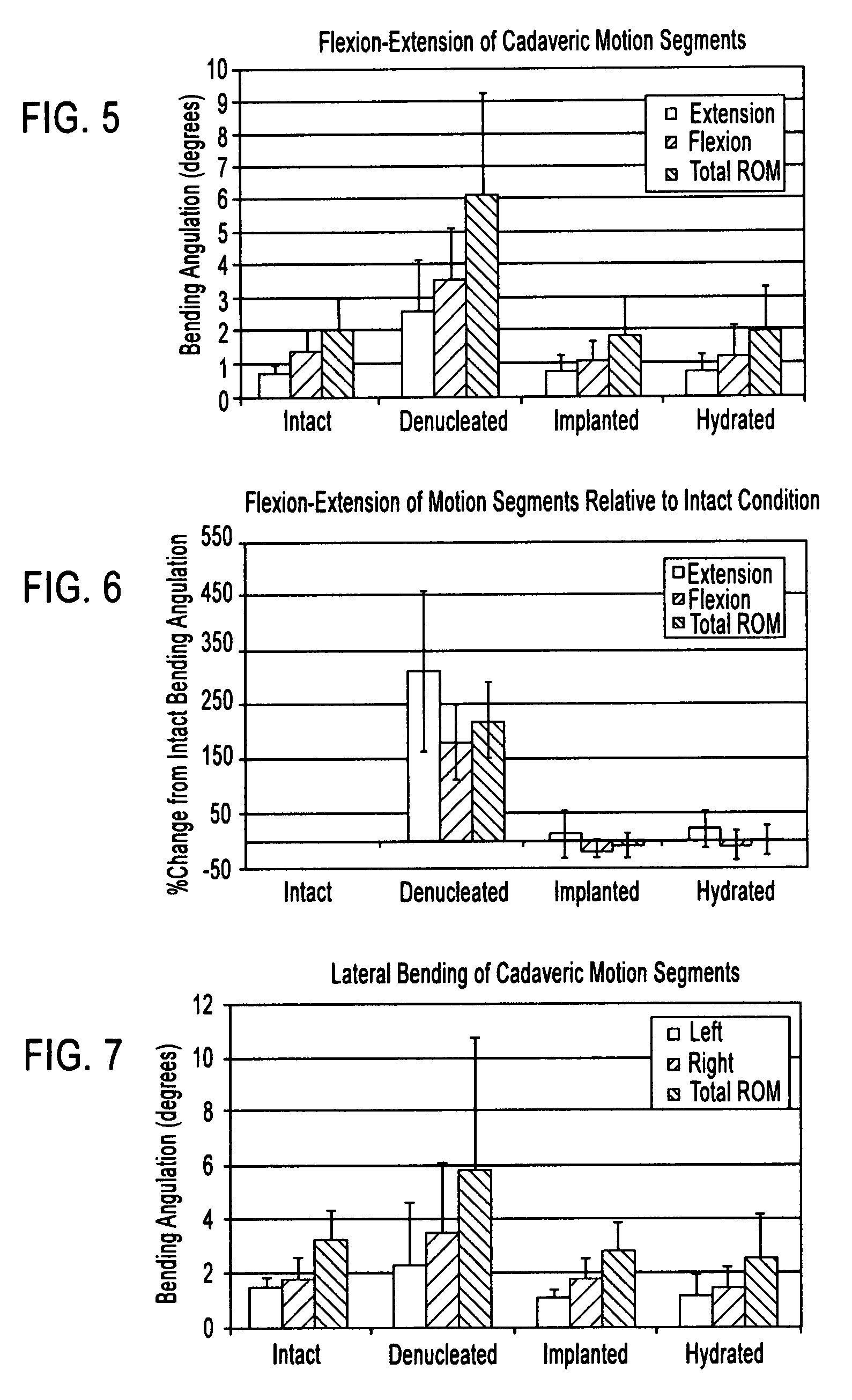

Packed demineralized cancellous tissue forms for disc nucleus augmentation, restoration, or replacement and methods of implantation

A composition for spinal disc repair comprising a plurality of uniformly shaped demineralized cancellous bone pieces ranging in size from about 2.0 mm to about 4.0 mm loaded into a porous mesh container with the cancellous bone pieces being treated so that they are not osteoinductive and are packed in the porous mesh container under compression forces.

Owner:MUSCULOSKELETAL TRANSPLANT FOUND INC +1

Vertebral disc repair

InactiveUS20060235534A1Eliminate osteoinductivitySuture equipmentsBone implantBone CortexCortical bone

A sterile implant for treatment of a spinal disc defect comprising an allograft cortical bone demineralized to a Type I collagen having a specific shape which is treated to eliminate osteoinductivity. The implant is lyophilized and compressed into smaller first shape which 20 to 80% from its original shape in at least one dimension and hardened. The implant expanding when hydrated into a second shape having the shape memory of the first shape and expanded in dimensional size from the first compressed shape.

Owner:MUSCULOSKELETAL TRANSPLANT FOUND INC

Packed demineralized cancellous tissue forms for disc nucleus augmentation, restoration, or replacement and methods of implantation

Owner:MUSCULOSKELETAL TRANSPLANT FOUND INC +1

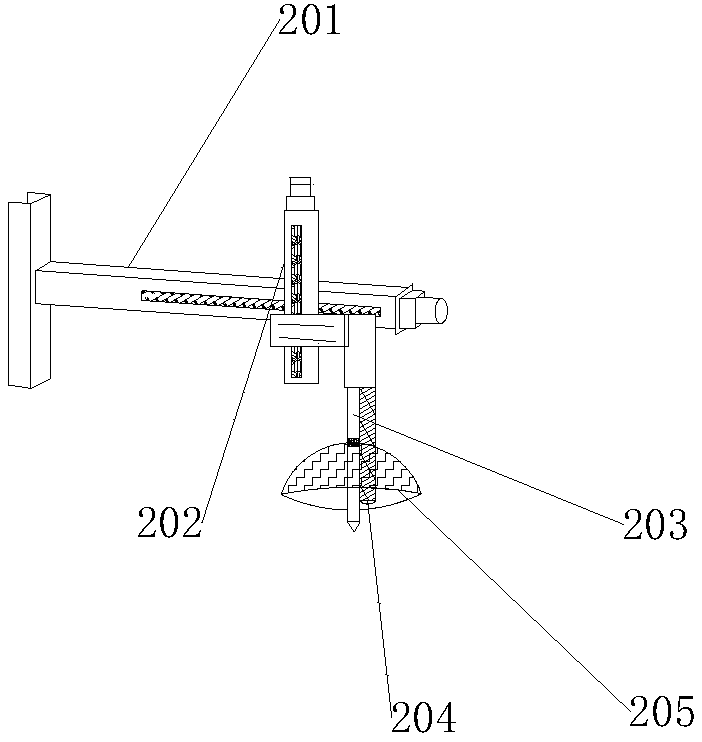

Instrumentation to Facilitate Access into the Intervertebral Disc Space and Introduction of Materials Therein

Methods for facilitating access to the intervertebral disc to deliver materials for disc repair are disclosed. The methods may be used to replace or augment nucleus pulposus as well as to perform interbody fusion procedures. These methods include providing access to the intervertebral disc space by drilling a channel through a vertebral bone, optionally accessing the intervertebral disc space to at least partially remove the disc tissue through the channel in the vertebrae; delivering a disc repairing material to the intervertebral disc space and back-filling the channel in the vertebrae with a channel sealing material. The methods may further comprise distracting the intervertebral height and inserting a restrictor into the channel in the vertebrae. Kits for practicing these methods are also disclosed.

Owner:WARSAW ORTHOPEDIC INC

Methods of treating tissue defects

InactiveUS20070105769A1Promote healingHigh expressionElectrotherapyPeptide/protein ingredientsTissue defectIntervertebral disk

Methods of treating tissue defects, including defects such as bone fractures, vertebrae fusions, and spinal disc repair, using electric or electromagnetic fields and growth factors. In various embodiments, the present invention provides methods for the treatment of a human or other mammal subject in need thereof, by administering electric stimulation and growth factors to stimulate endogeneous stem cells in the subject to facilitate healing. Other embodiments include methods of administering electric stimulation, growth factors, and stem cells to the defect. In various embodiments the amount of growth factor is a subefficacious amount.

Owner:EUROPEAN BIOINFORMATICS INSTITUTE

Devices, systems and methods for treating intervertebral discs

Devices, systems, and methods are provided for treating intervertebral discs. In one embodiment, the systems include instruments for implanting the disc repair devices in a minimally invasive manner. The methods are directed to the minimally invasive implantation of one or more of the disc repair devices to within the intervertebral disc.

Owner:KIM DANIEL H

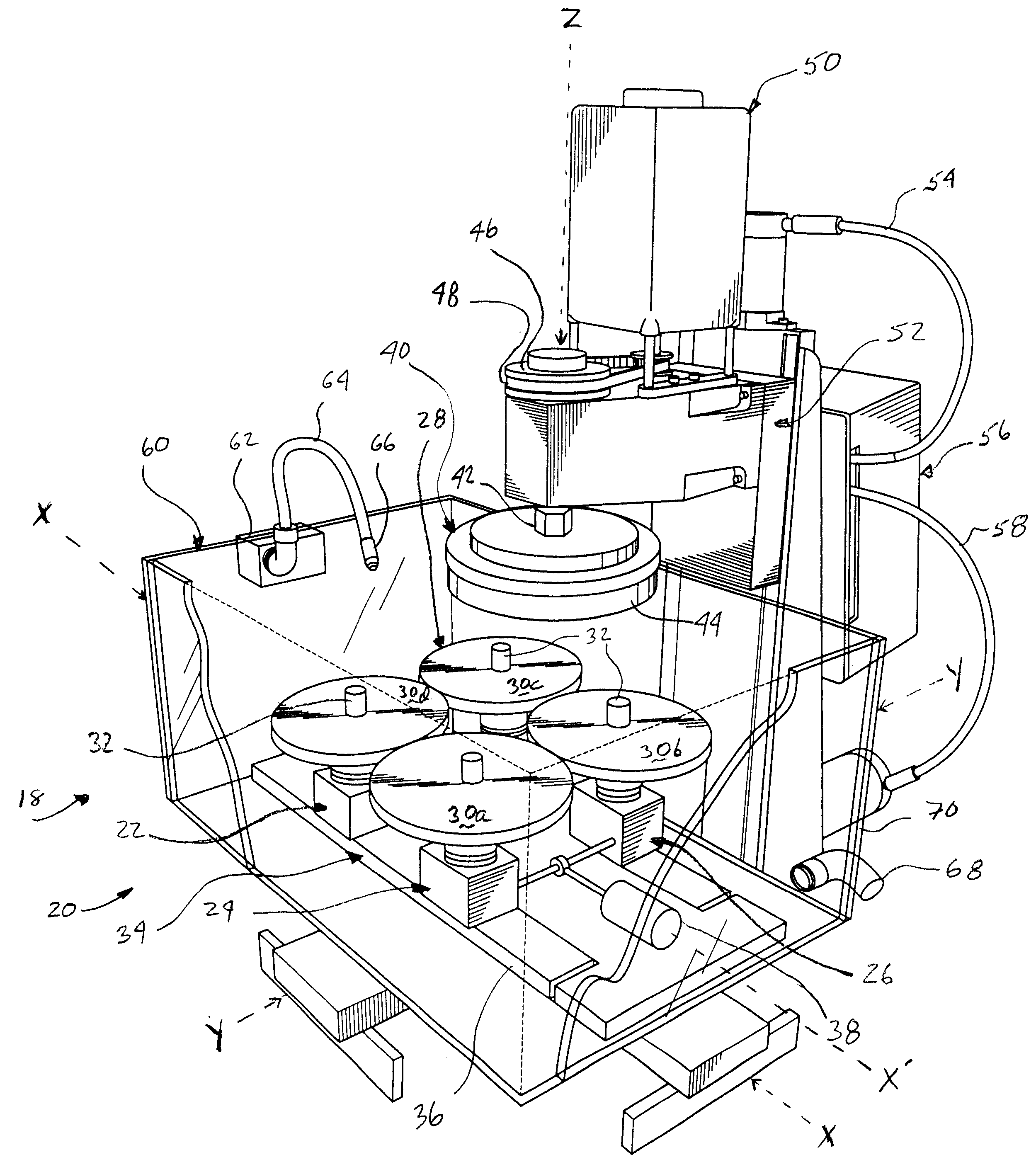

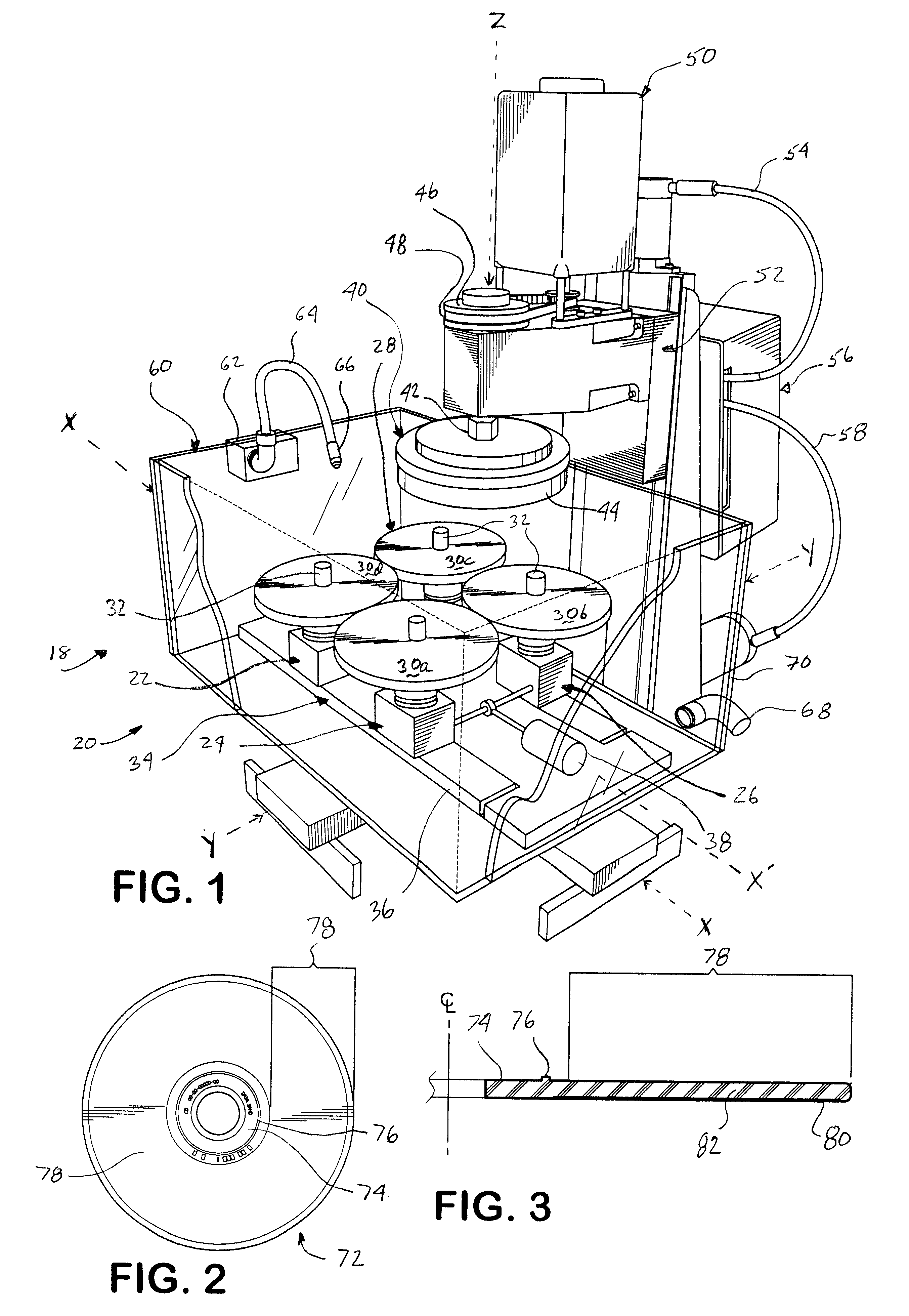

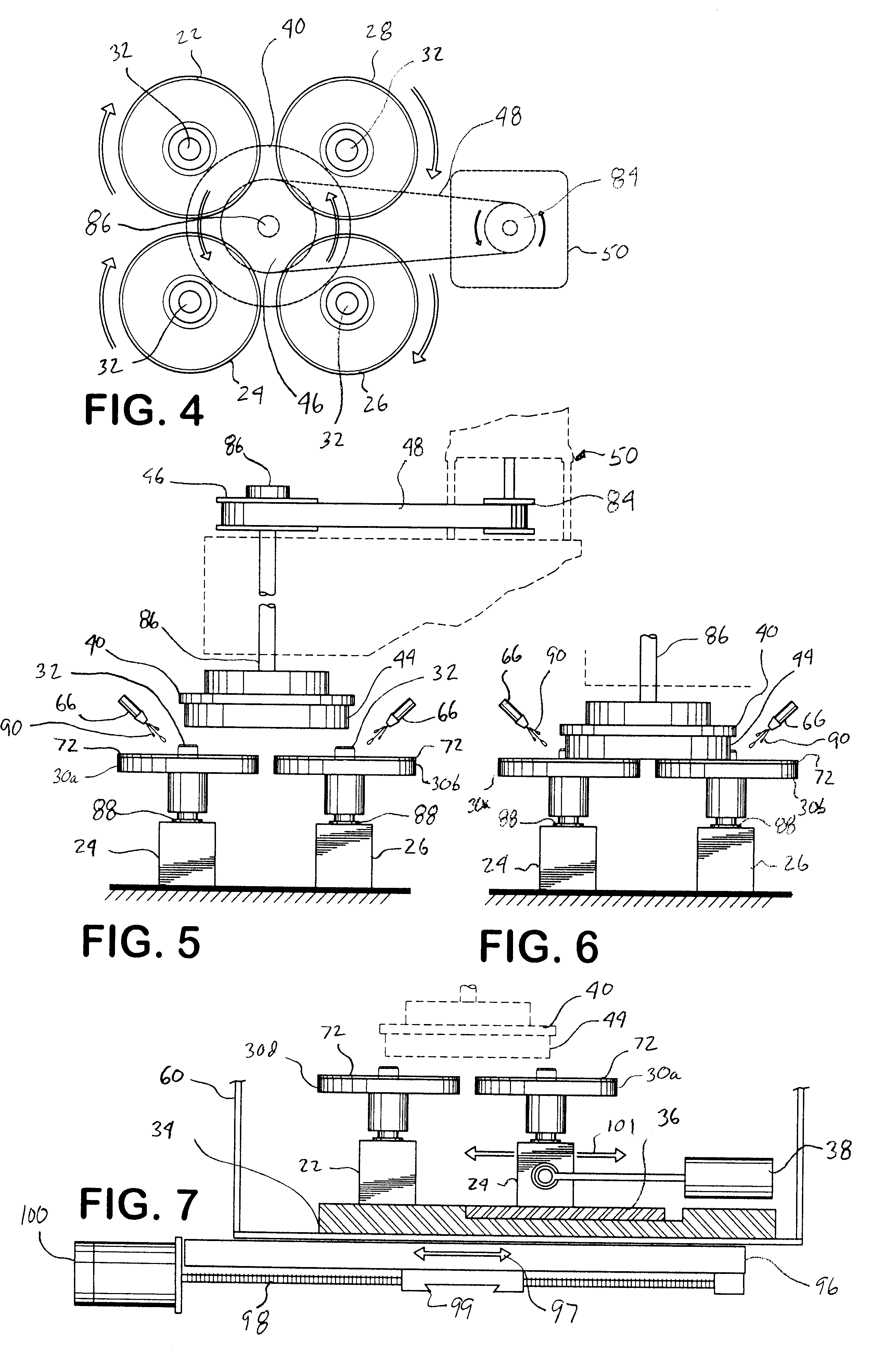

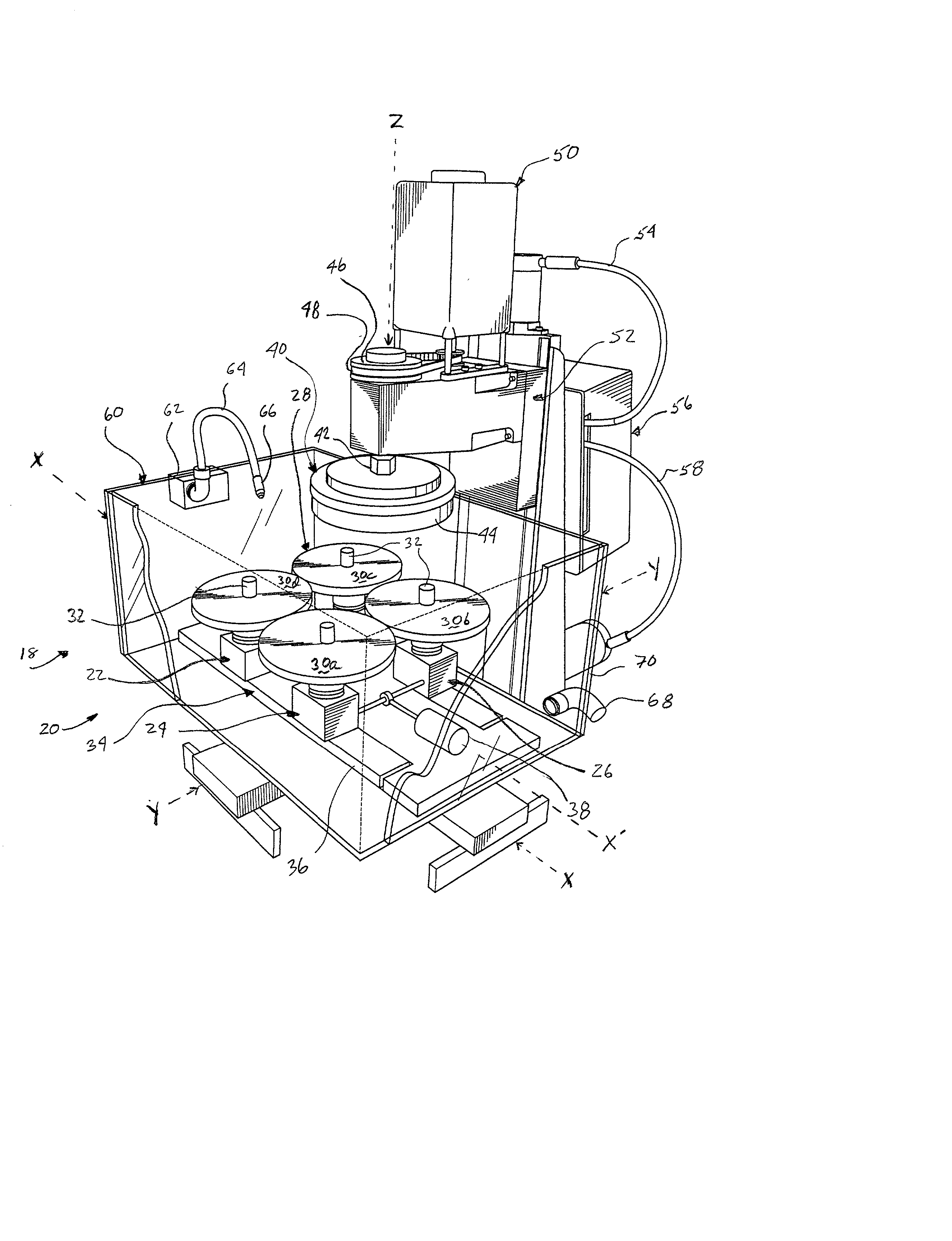

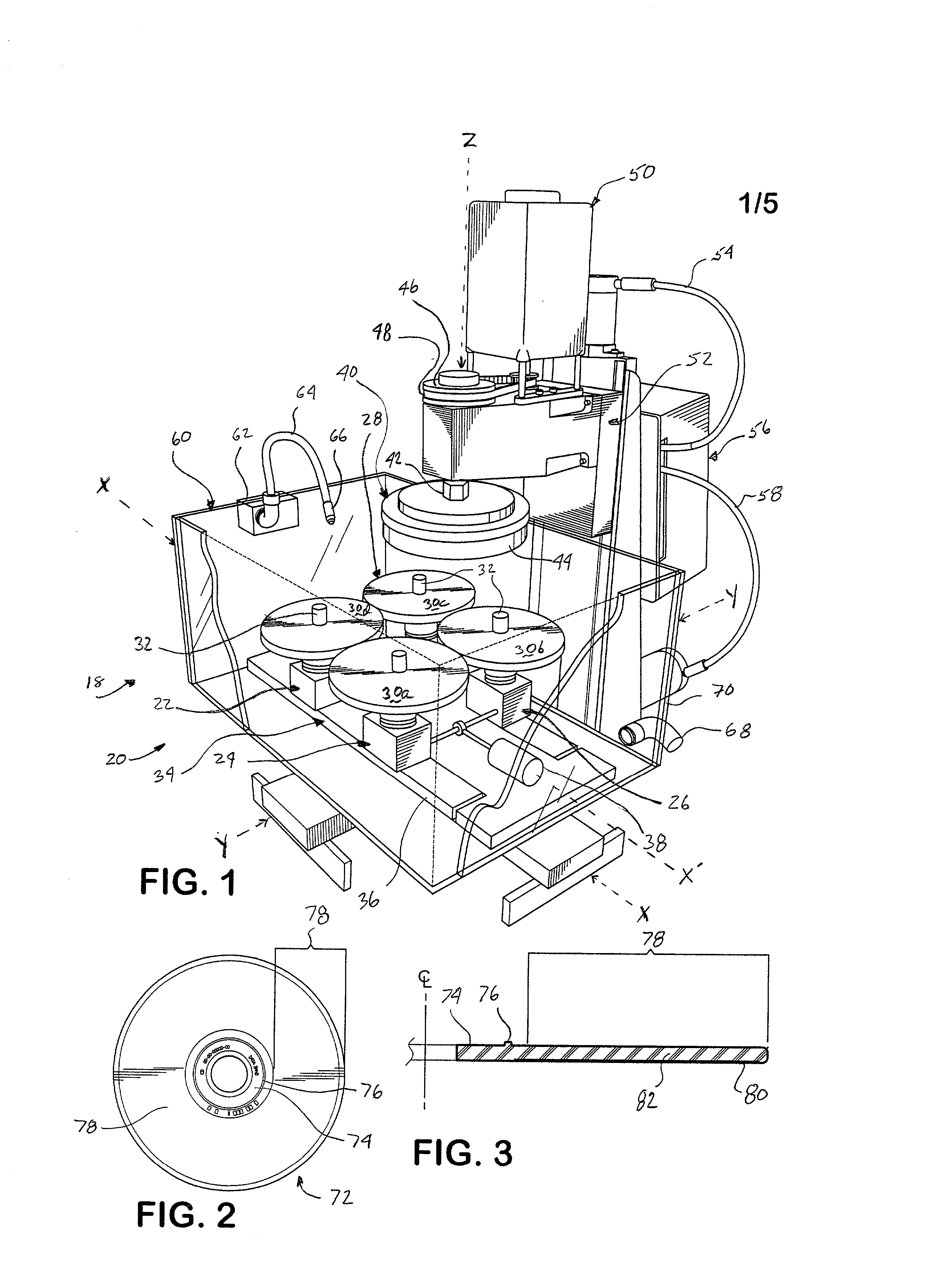

Automatic disc repair system

InactiveUS6726527B2Polishing machinesRevolution surface grinding machinesComputer hardwareOptical distortion

An automatic system for repairing scratches on optically-read discs, (e.g., compact discs often called "CD's" or DVD's). More specifically, an automatic system for refurbishing a plurality of disc surfaces at substantially the same time, such that when refurbished, an optical reader, which uses a laser to read digital information stored on such a disc, can read the digital information on the disc without the optical distortion caused by a scratch.

Owner:AVS SUPPLY

Straight line rolling guiding rail, and guideway slider multiple grinding head combined grinding machine

A combined grinder with multiple grinding heads for grinding the straight rolling track and slide block on the track is composed of a machine body, two vertical columns, a transverse beam installed to said vertical columns, a tool carriage on said transverse beam, 2-4 grinding heads (including vertical and horizontal grinding heads), and an abrasive disc repairing device.

Owner:浙江杭机股份有限公司

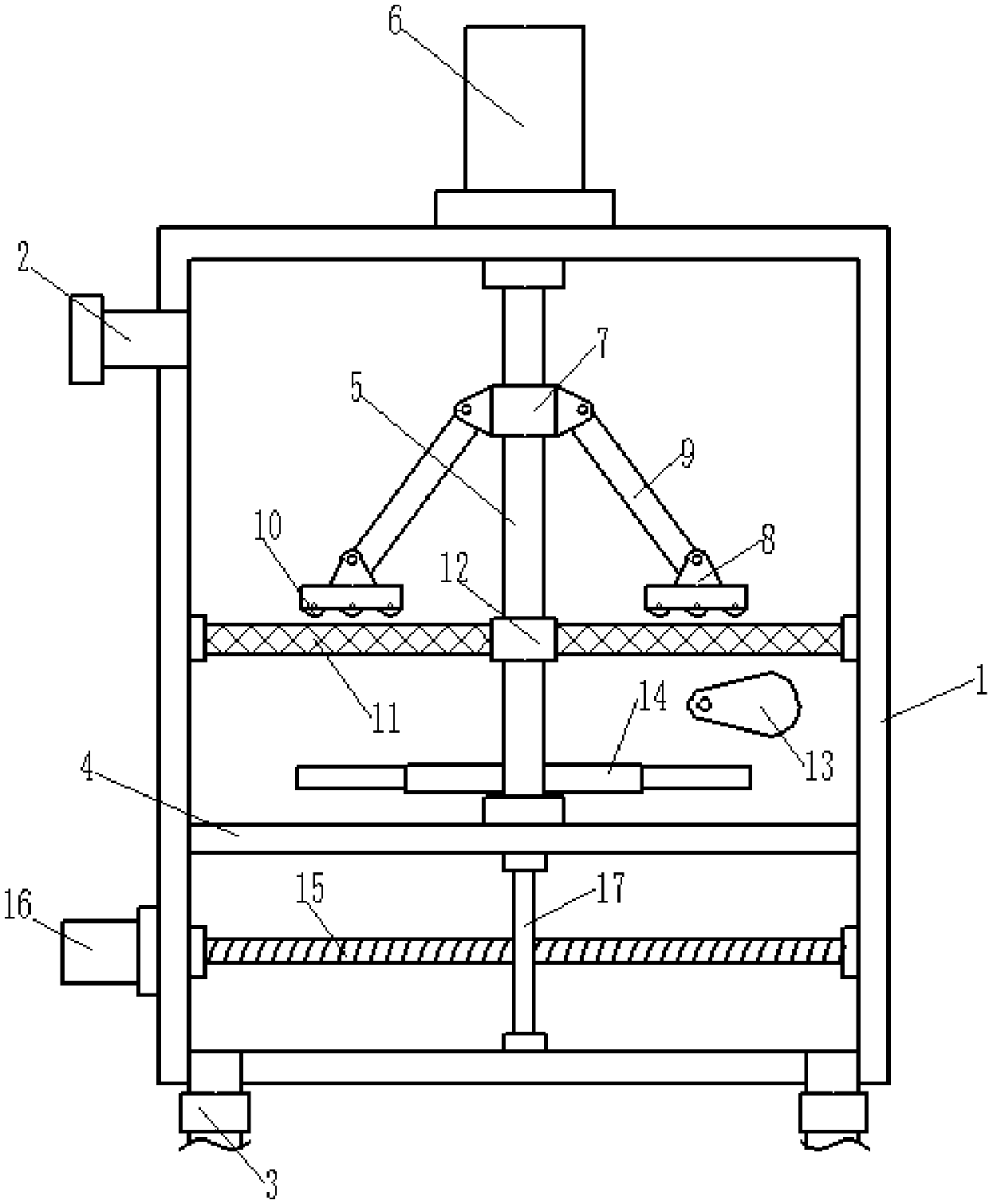

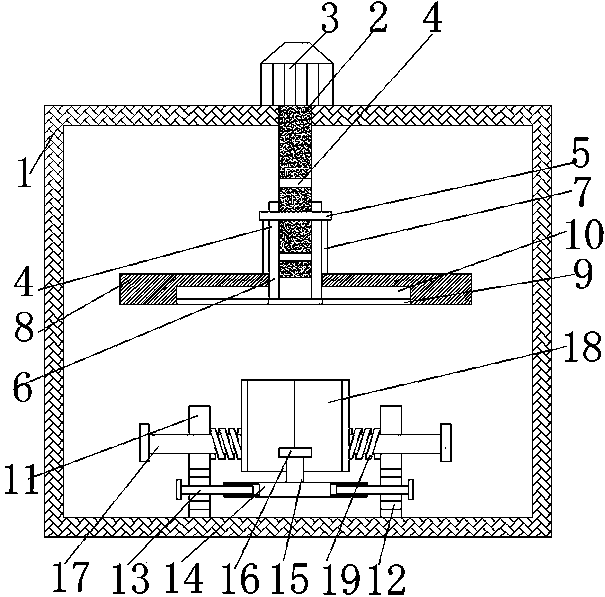

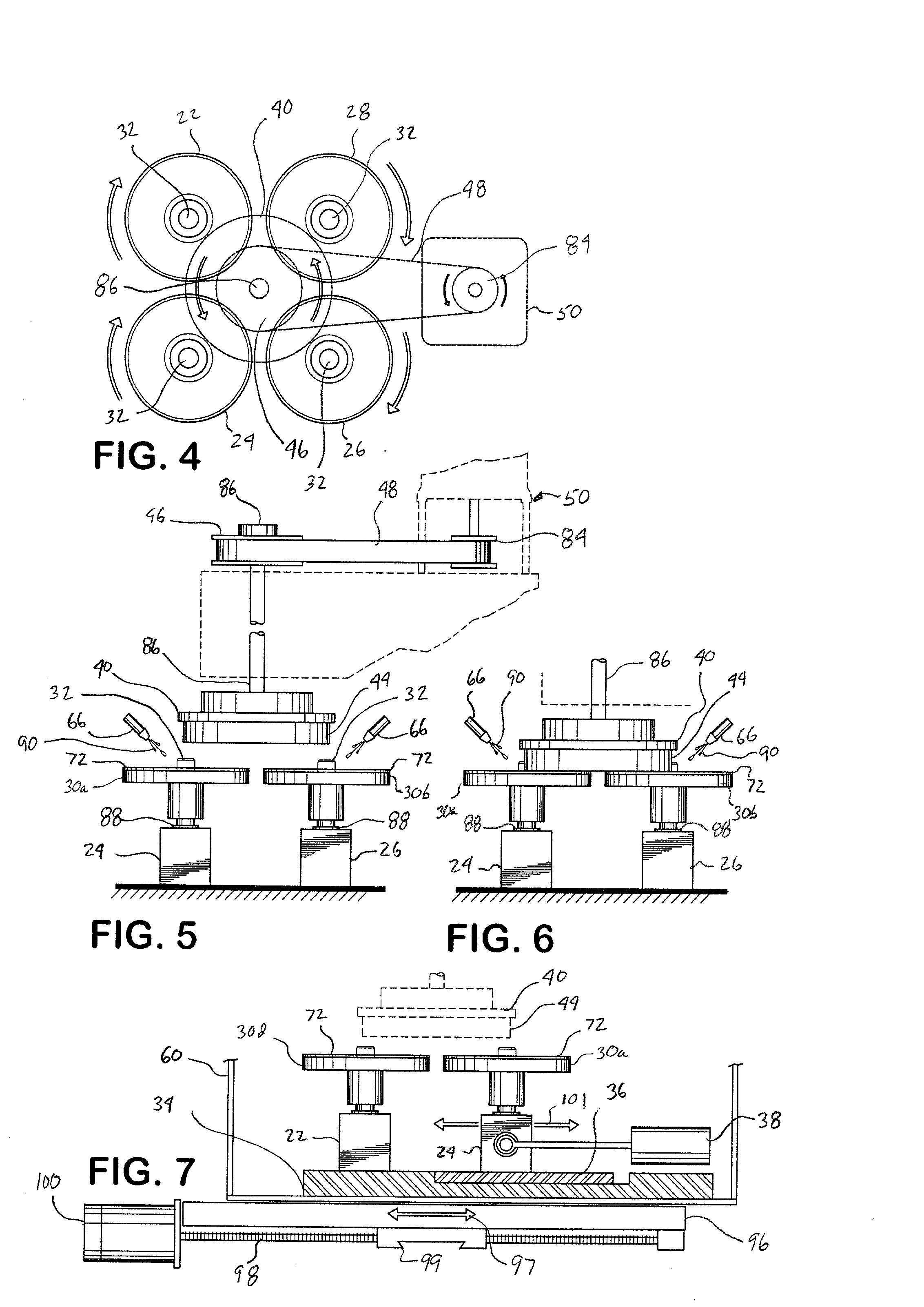

Powder stirring device for grinding disc repair

InactiveCN107890917AImprove stirring efficiencyImprove the mixing effectRotary stirring mixersTransportation and packagingDrive motorPulp and paper industry

The invention discloses a powder stirring device for grinding disc repair. The powder stirring device comprises a stirring barrel; a fixed separation plate is fixedly connected into the stirring barrel; a driving motor is fixedly connected to the top of the stirring barrel; a rotating shaft is arranged in the stirring barrel, and is slidingly connected with a vibration screen plate; the rotating shaft is fixedly connected with a fixed piece; two ends of the fixed piece are hinged with connecting rods; the tail ends of the connecting rods are hinged with rolling devices; the bottoms of the rolling devices are rotationally connected with rolling rollers; the bottom of the rotating shaft is fixedly connected with a stirring rod; a cam is arranged in the stirring barrel; the bottom in the stirring barrel is rotationally connected with a rotation shaft; a discharge motor is fixedly connected to the side wall of the left side of the stirring barrel; and a reciprocating discharge plate sleeves the rotation shaft, and is slidingly connected with the fixed separation plate. The stirring barrel can effectively crush caked powder in the use process to achieve high powder stirring efficiency and excellent powder stirring effect; and the stirred powder is discharged through left-right movement of the reciprocating discharge plate to provide convenience for use by people.

Owner:WUXI WEI KELAI TECH CO LTD

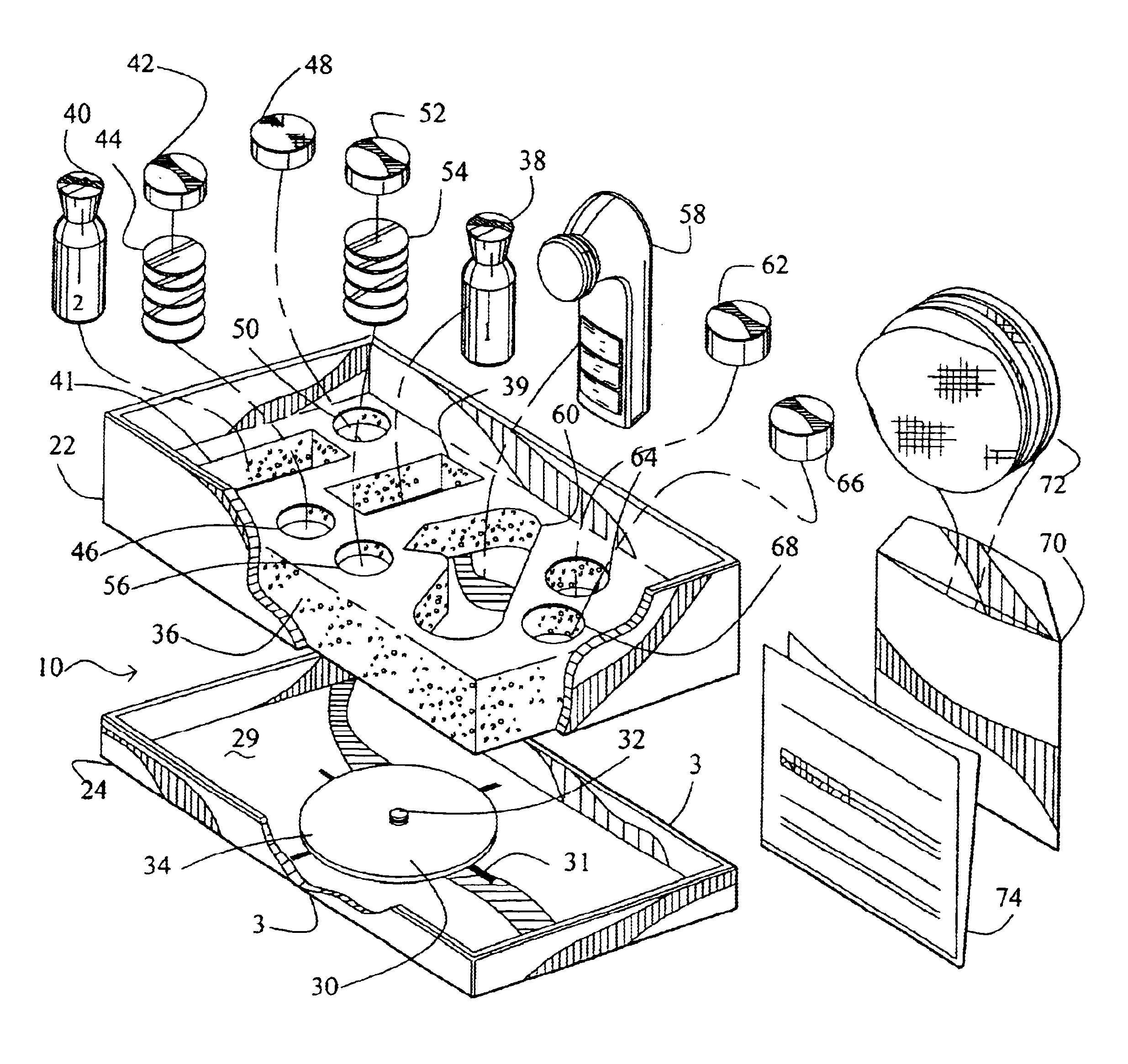

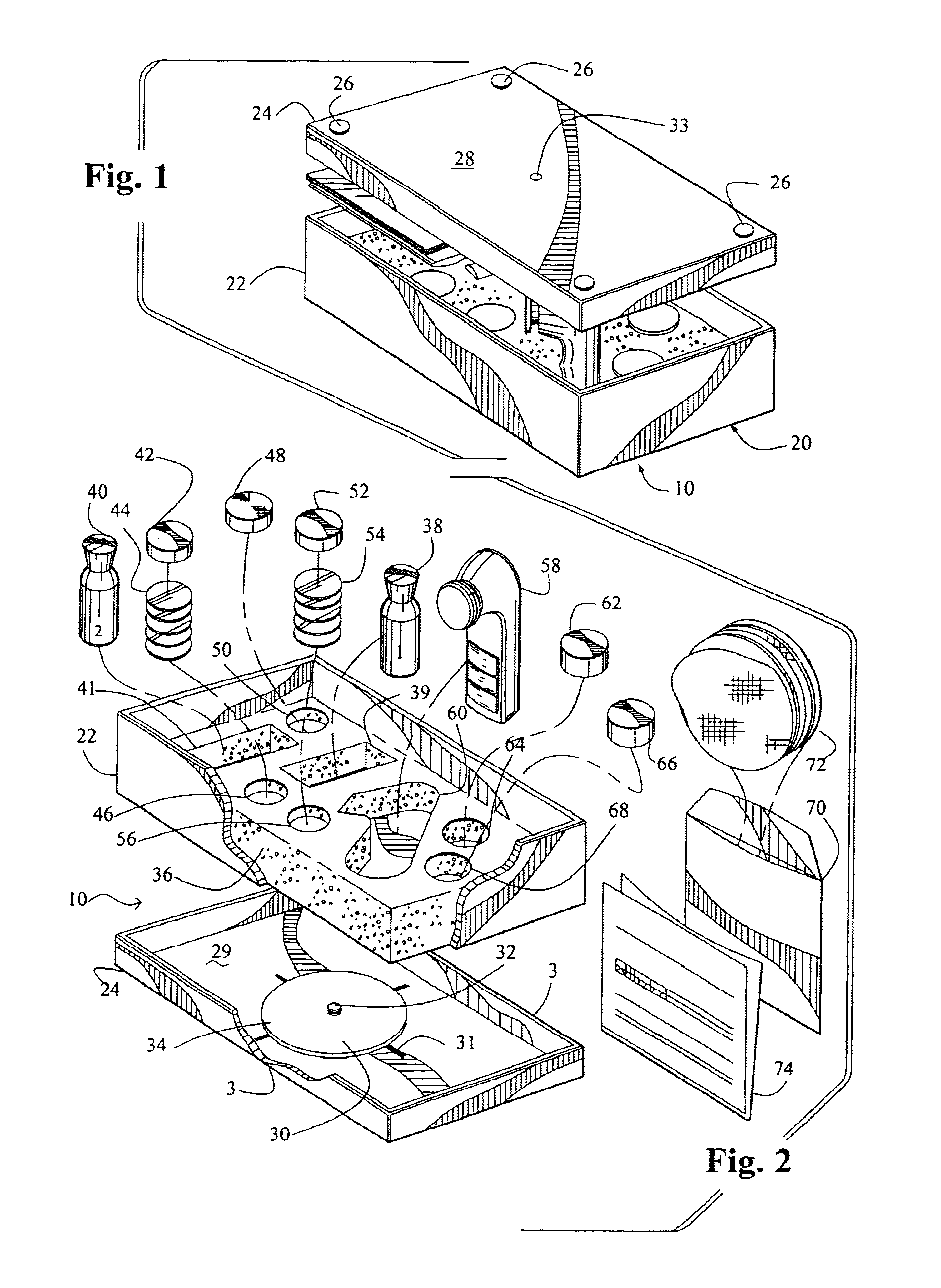

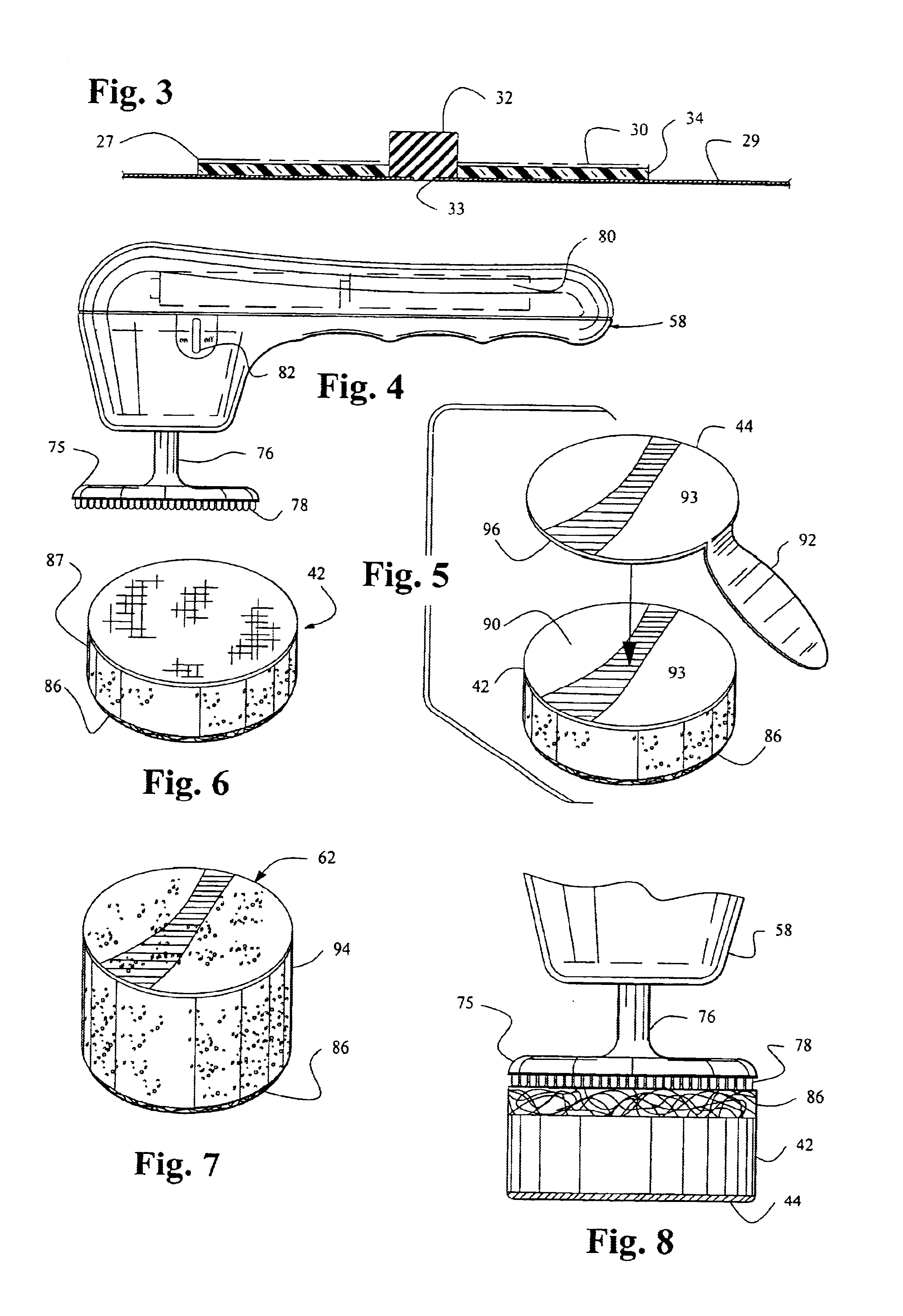

Disc repair system

InactiveUS6638149B2Polishing machinesReconditioning/cleaning record carriersCompact discData information

A disc repair system embodied by a consumer kit, which is provided for the purpose of consumer-repairing of scratches on optically-read discs (e.g., digitally recorded discs, known commonly, as "CD" discs or "DVD" discs, containing audio or video or other formats of data information), such that an optical reader, which uses a laser to read digital information stored on a compact disc, can read the digital information without the optical distortion caused by a scratch. The consumer kit (in a special box package) contains a hand-held rotator which is preferably used in combination with abrading compounds, abrasive discs, and wiping cloths to recondition the disc surface.

Owner:AVS SUPPLY

Grinding device capable of adjusting grinding height

PendingCN107855847AHeight adjustableEasy to operateGrinding work supportsPlane surface grinding machinesSanderArchitectural engineering

The invention discloses a grinding device capable of adjusting the grinding height. The grinding device comprises a fixing frame, the top of the fixing frame is fixedly connected to the bottom of a motor, and the output end of the motor is fixedly connected to the top end of an output shaft; the bottom end of the output shaft penetrates through the top of the fixing frame and extends into the interior of the fixing frame, three through holes are equidistantly formed in the surface of the output shaft, a fixing rod is connected in one through hole in a sleeved mode, and a sleeve is connected tothe bottom end of the output shaft in a sleeving mode. According to the grinding device capable of adjusting the grinding height, the fixing frame, the output shaft, the through holes, the fixing rod, the sleeve, a grinding disc, clamping grooves and a supporting rod are arranged so that when the grinding disc is disassembled, the fixing rod can be pulled out, the sleeve and the grinding disc aretaken down, the grinding disc and the supporting rod are separated, after the grinding disc is repaired or replaced, the sleeve is inserted into the grinding disc, the supporting rod is correspondingly clamped inside the clamping grooves, and after a proper height is selected, the fixing rod is sequentially inserted into the sleeve and the interior of the through hole corresponding to the height.

Owner:郑州博尔德磨料磨具有限公司

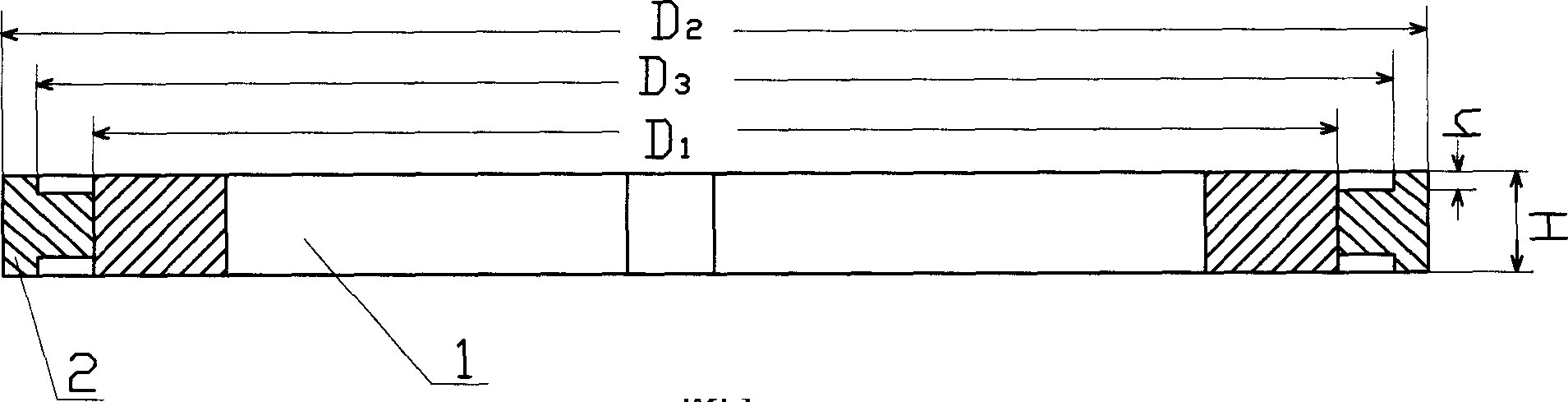

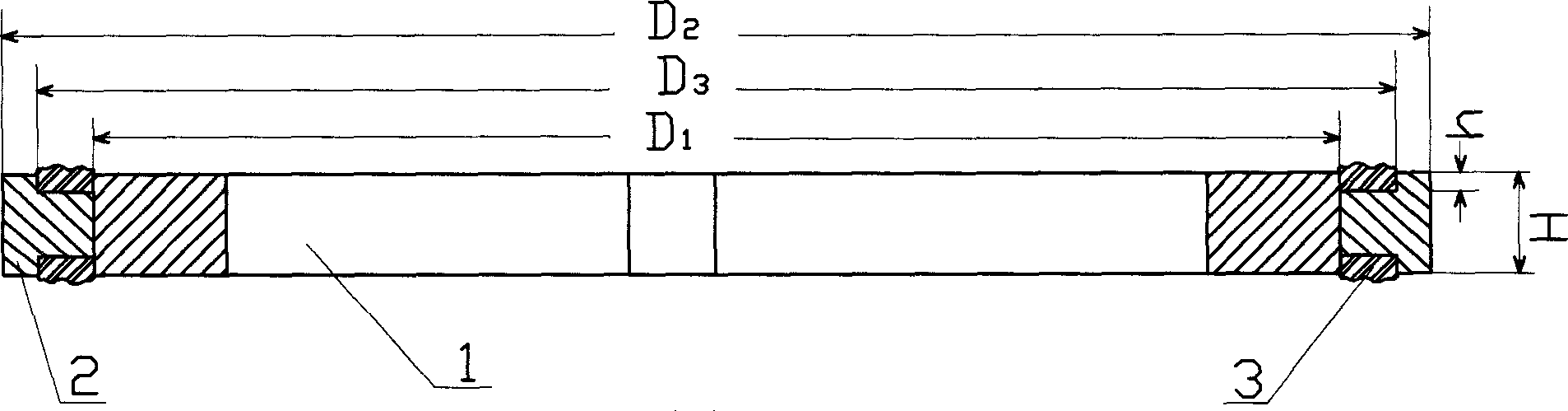

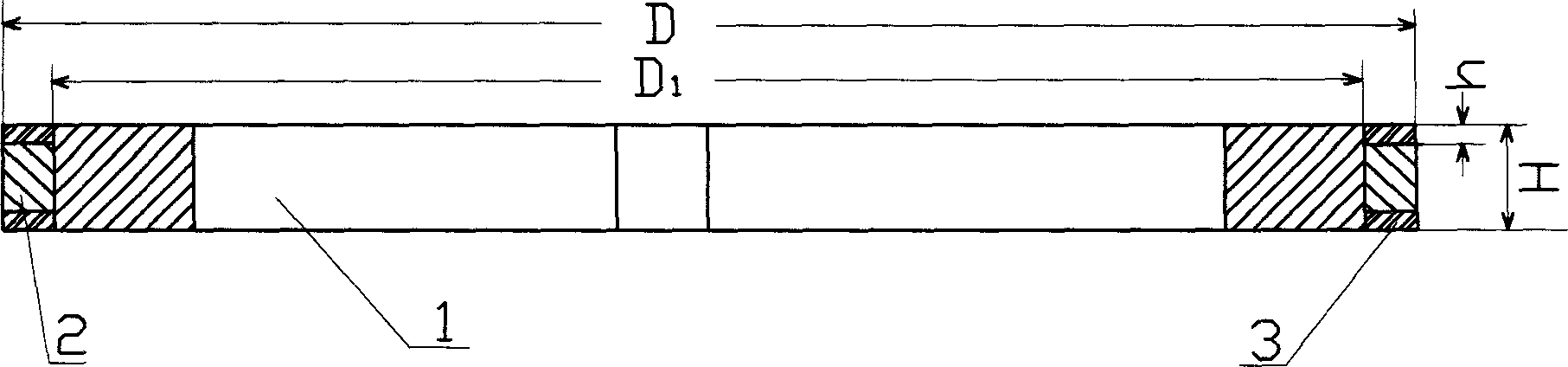

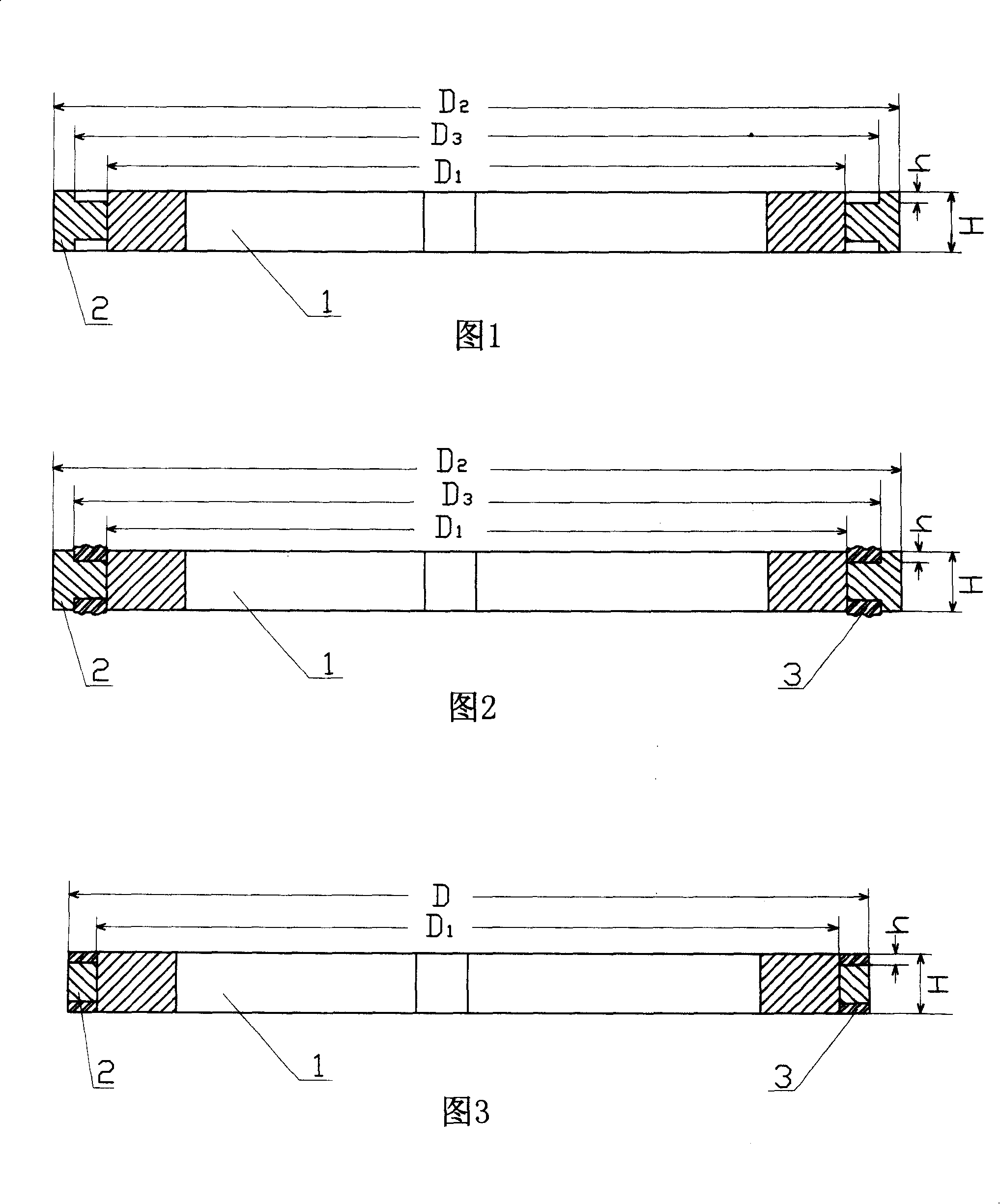

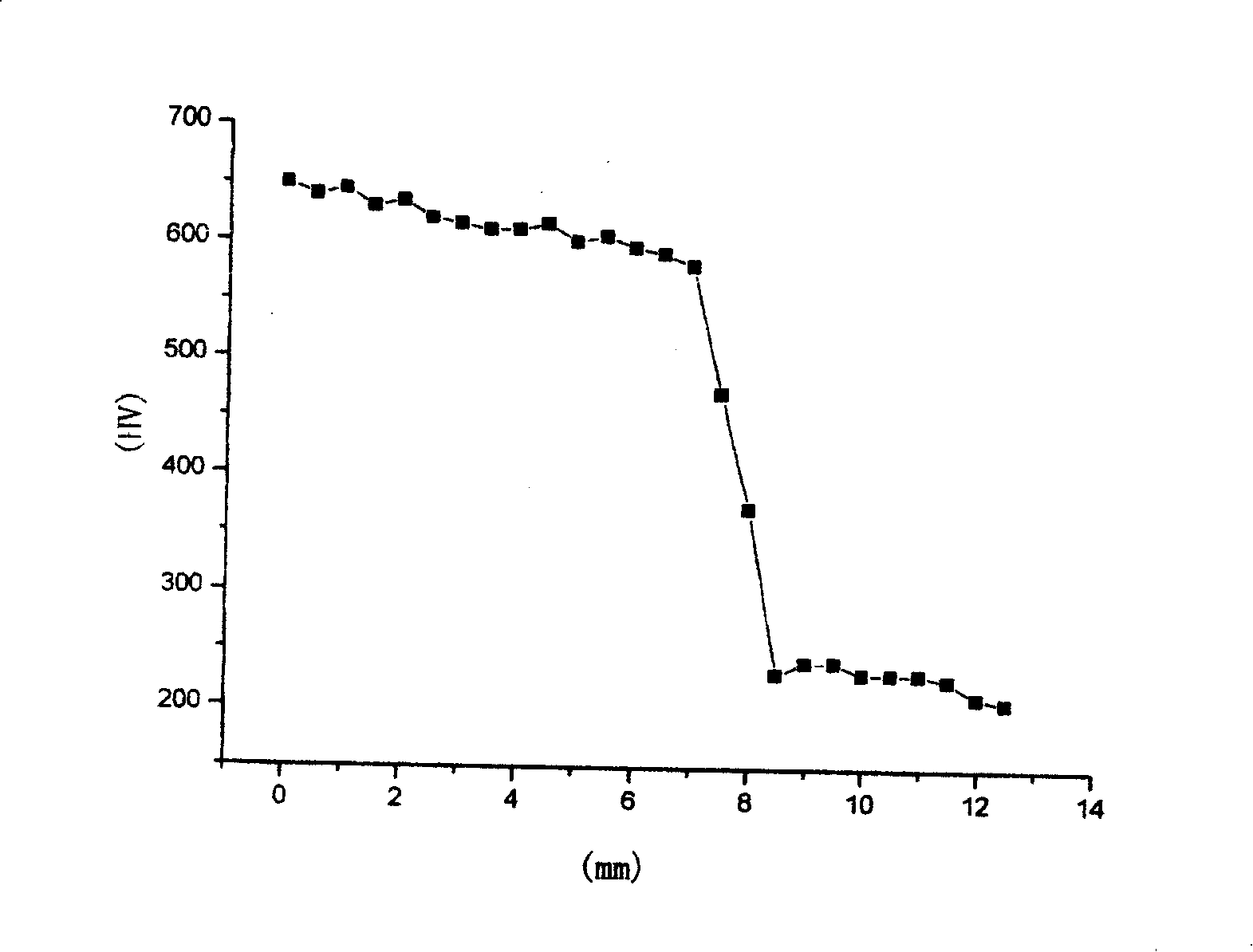

Build-up welding repair process of disc shear blade and repaired disc shear blade thereby

InactiveCN1799762AGuaranteed use strengthHigh hardnessArc welding apparatusShearing machinesCircular discDisc repair

The invention relates to a method for repairing the disc shear blade via built-up welding, comprising following steps: (1) removing abraded edge to process it into disc shear blade base plate with D1 diameter; (2) acid cleaning derusting; (3) using carbon steel to prepare disc repair element whose outer diameter is D2, inner diameter is D1 and the thickness is same with base plate while the D2-D is 12-30 mm and the two surface of inner edge has annular grooves; (4) integrating the repair element and base plate; (5) preheating the welding bar and using the metal comprising W, Mo, V, and Cr to built-up weld welding bar; (6) preheating the integrated disc shear blade; (7) processing several built-up welding to repair the grooves of inner edge; (8) keeping disc shear blade in 450-550Deg. C for 0.8-1.2 hours; being cooled to 10-30Deg. C; keeping it in 480-560Deg. C for 0.8-1.2 hours to be tempered; (9) processing mechanical machining to attain repaired disc shear blade with smooth surface and D outer diameter, while it has better rigidity and abrasion resistance. The inventive shear blade has same machining ability with new blade, while it utilizes waste blade to reduce the producing cost.

Owner:桂林航天工业高等专科学校

Automatic disc repair system

InactiveUS20020187733A1Polishing machinesRevolution surface grinding machinesComputer hardwareCompact disc

An automatic system for repairing scratches on optically-read discs, (e.g., compact discs often called "CD's" or DVD's). More specifically, an automatic system for refurbishing a plurality of disc surfaces at substantially the same time, such that when refurbished, an optical reader, which uses a laser to read digital information stored on such a disc, can read the digital information on the disc without the optical distortion caused by a scratch.

Owner:AVS SUPPLY

Powder extrusion device for grinding disc repair

InactiveCN107812483AImprove stirring efficiencyExpand the mixing rangeRotary stirring mixersTransportation and packagingRotational axisControl system

The invention discloses a powder extrusion device for grinding disc repair. The device comprises a stirring barrel; a driving motor is fixedly connected to the top of the stirring barrel; a rotating shaft is arranged in the stirring barrel; the top of the rotating shaft is connected with a driving motor; the bottom of the rotating shaft is rotationally connected with the inner wall of the stirringbarrel; a supporting frame is fixedly connected with the rotating shaft; stirring rods are respectively hinged to the upper end and the lower end of the supporting frame; threads are uniformly distributed on the rotating shaft; an extruding plate sleeves the rotating shaft; the extruding plate is in threaded connection with the rotating shaft; the extrusion plate is in sliding connection with theinner wall of the stirring barrel; an electromagnetic valve is arranged on the extrusion plate; the electromagnetic valve is electrically connected with an outer side control system; and the bottom of the rotating shaft is fixedly connected with a stirring shaft. The stirring efficiency of powder is greatly improved in the use process of the device; and the stirring rod swings up and down, so that the stirring range of the powder is enlarged, and the mixing degree of the powder is improved. The device moves downwards through the extrusion plate in the using process, the powder is pressed out,so that discharging is facilitated, and convenience is provided for use of people.

Owner:WUXI WEI KELAI TECH CO LTD

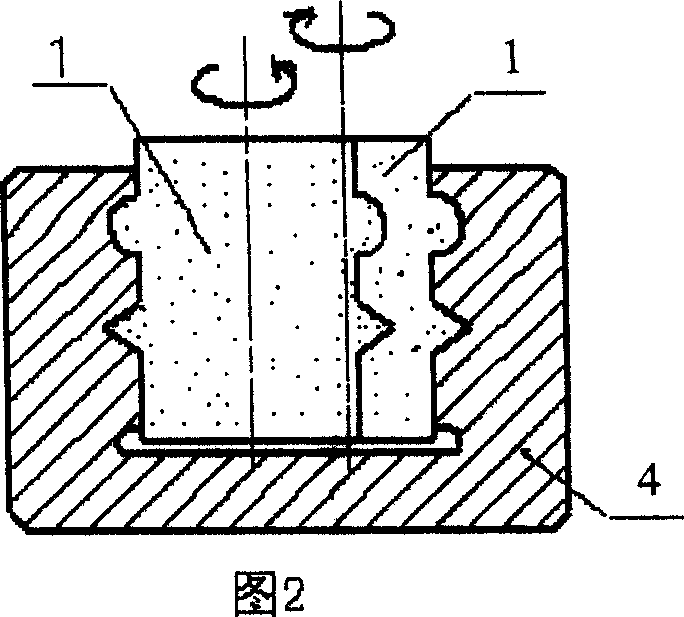

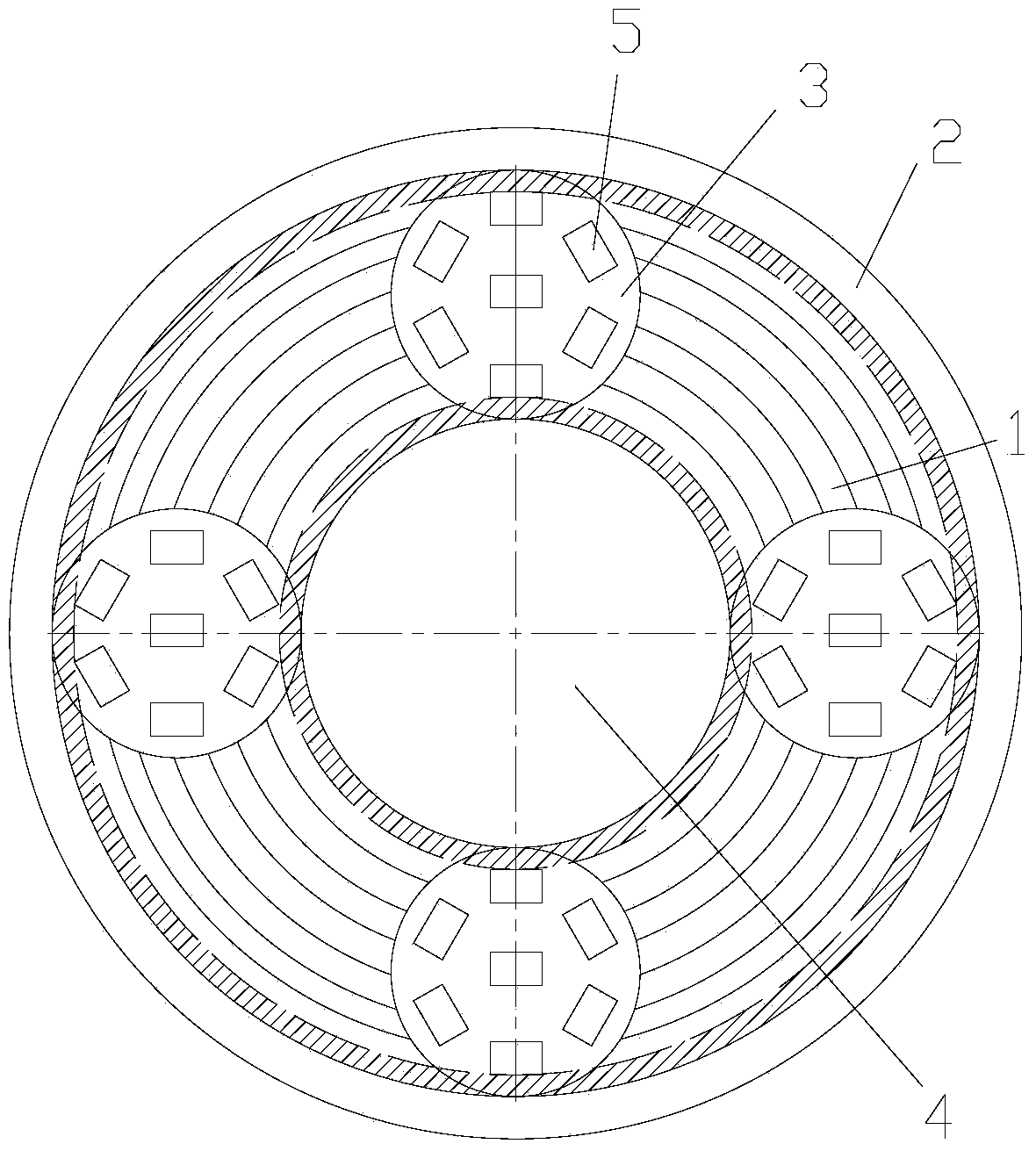

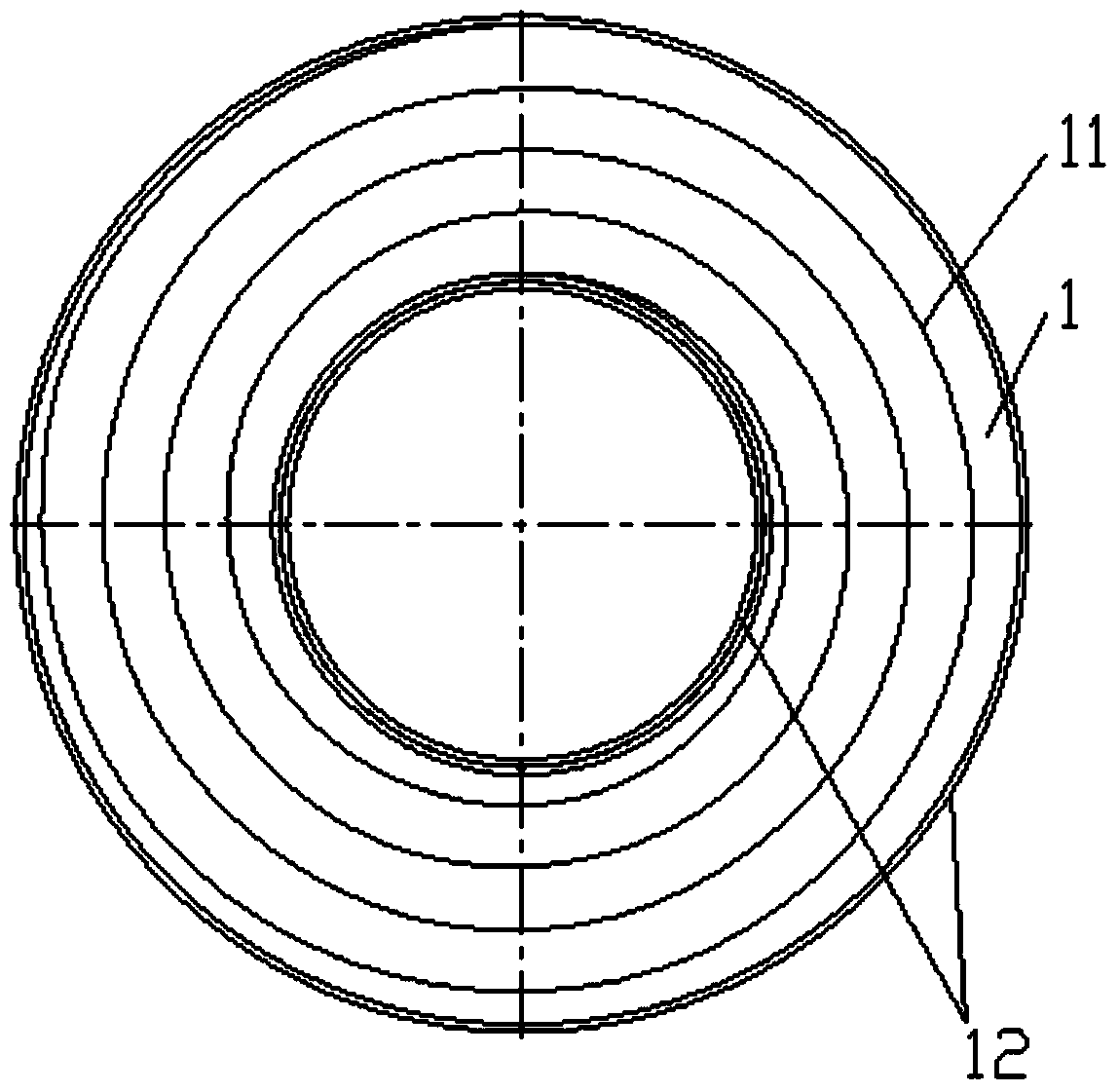

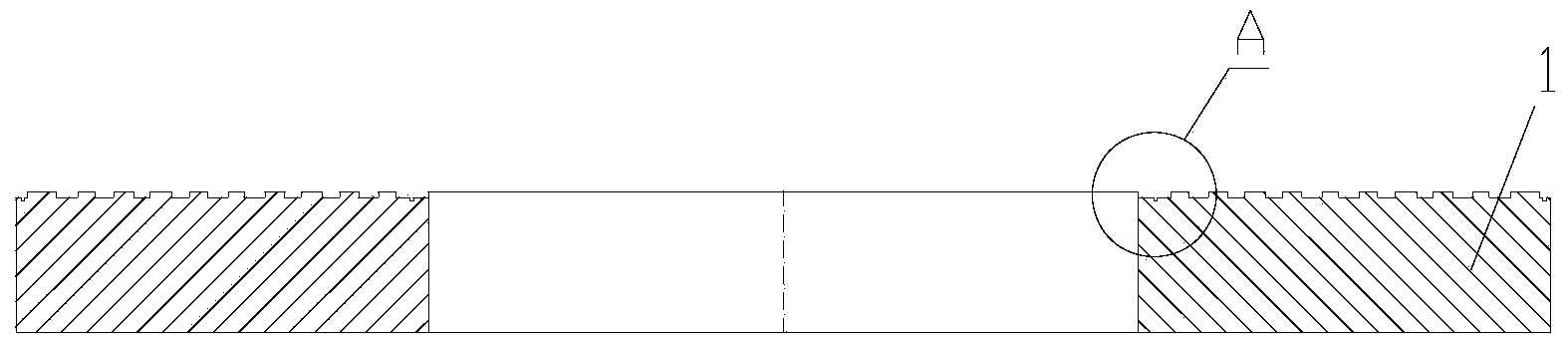

Copper disc for sapphire polishing and disc repair method thereof

ActiveCN104044087AAvoid the defects of uneven wearQuality assuranceAutomatic/semiautomatic turning machinesWorkpiecesDisc repairSapphire

The invention discloses a copper disc for sapphire polishing. Grinding grooves in a spiral or concentric circle shape are formed in an annular surface of the copper disc, and stepped grooves are formed in an annular outer ring and an inner ring of the copper disc. The invention further discloses a disc repair method of the copper disc for sapphire polishing. The disc repair method specifically includes the following steps that firstly, an upper copper disc and a lower disc turning tool or a lower copper disc and an upper disc turning tool are horizontally moved, and the turning tools are aligned to the original positions of the grinding grooves in the corresponding copper discs; secondly, the upper copper disc and the lower copper disc are controlled to rotate at the same rotation speed in the opposite directions, the turning tools are fixed and not moved, the upper copper disc or the lower copper disc is controlled for transverse feed, and corresponding grinding grooves are turned through the turning tools; thirdly, the turning tools are moved away, and the surfaces of the corresponding copper discs are flushed. According to the copper disc, the surfaces of the copper discs can be evenly abraded, and machining quality of sapphire panels is guaranteed. According to the disc repair method, the grinding grooves in the copper discs can be quickly finished, and production efficiency is effectively improved.

Owner:LENS TECH

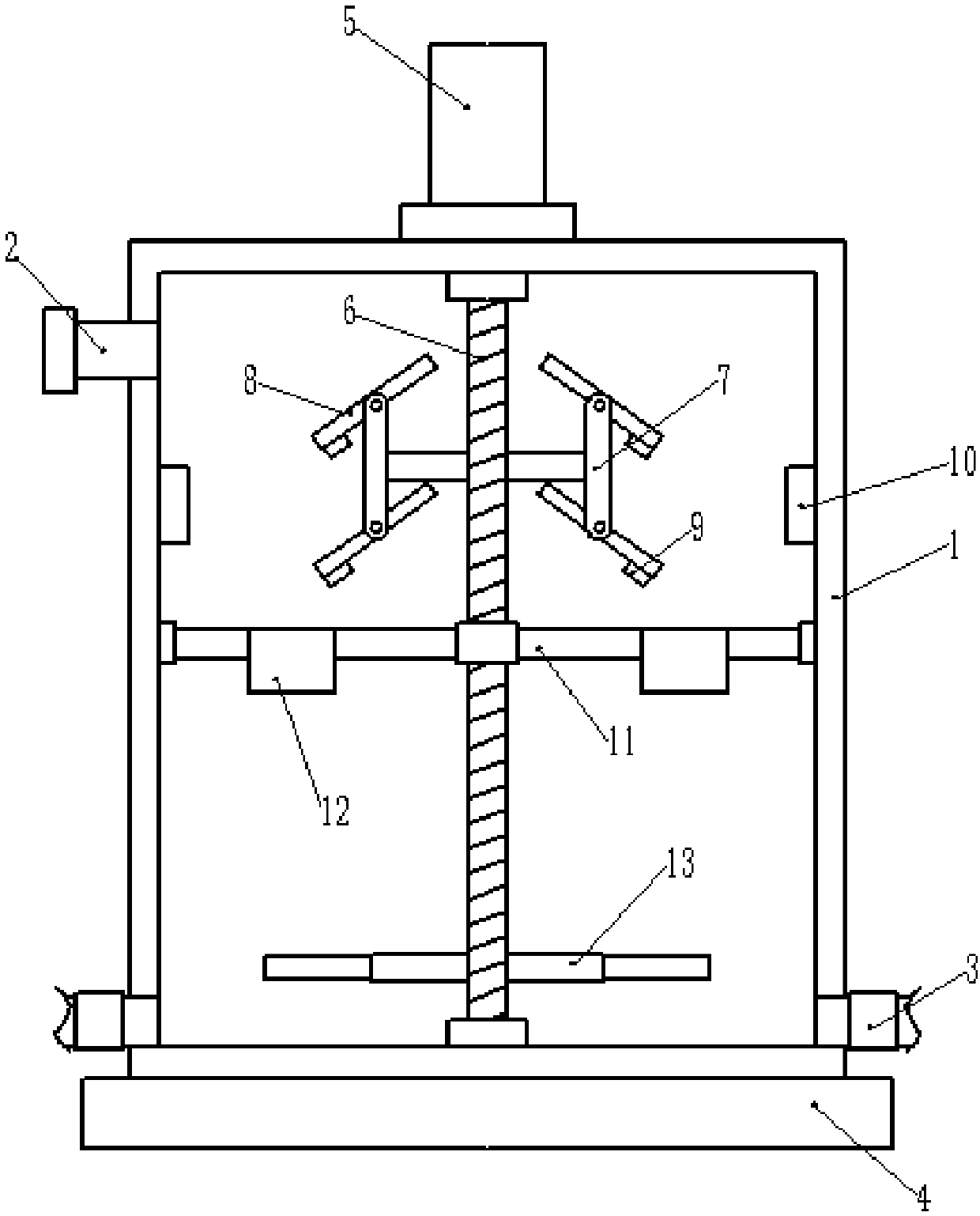

Gantry clutch friction steel disc repairing device and reproducing method thereof

InactiveCN102922391ASmall grinding resistanceRepair uniformGrinding machinesGrinding work supportsMetallurgyMechanical equipment

The invention belongs to the technical field of automobile automatic gearbox reproducing, and particularly relates to a gantry clutch friction steel disc repairing device and a reproducing method thereof. The gantry clutch friction steel disc repairing device reproducing method including the following steps: first, a friction steel disc wheelabrator is used to carry out stress peening on a friction steel disc, second, the gantry clutch steel disc repairing device is used to cope the friction steel disc, grinding wheels with different marks are used to cope the friction steel disc, generally, a coarse grinding wheel is first used for preliminary grinding, and then a fine grinding wheel is used for fine grinding and repairing, and reproducing of the friction steel disc is completed. According to the gantry clutch friction steel disc repairing device and the reproducing method thereof, grinding through mechanical equipment replaces traditional manual grinding, grinding equipment is compact, scientific and reasonable in structure, batch and even repairing of the friction steel disc is achieved, the production efficiency and the reproducing machining accuracy of the friction steel disc are improved, and the success rate of one-time automobile loading of a reproduced automobile gearbox is improved.

Owner:王春梅 +1

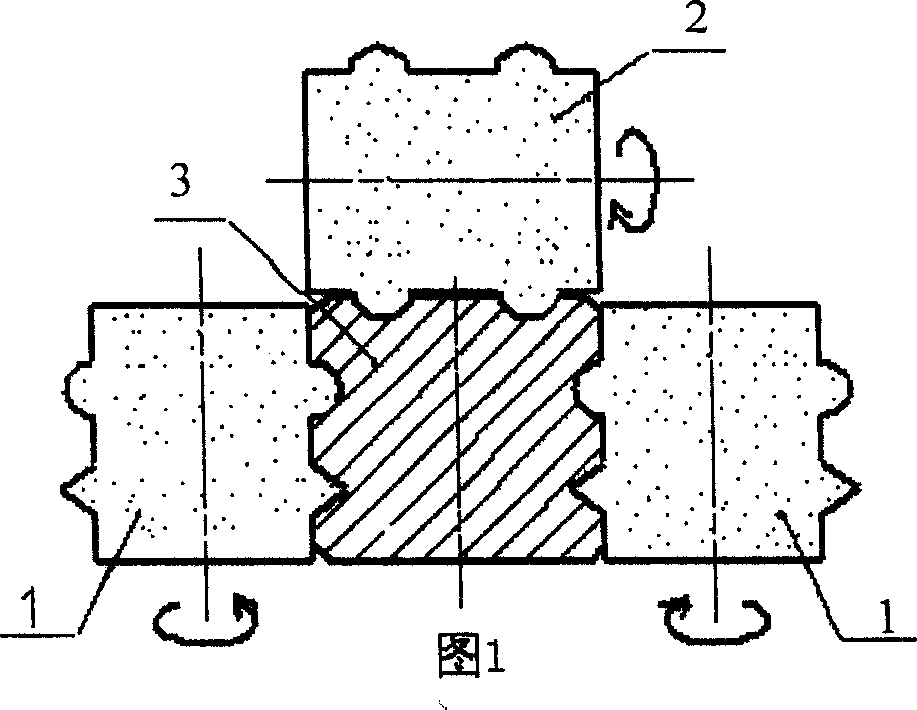

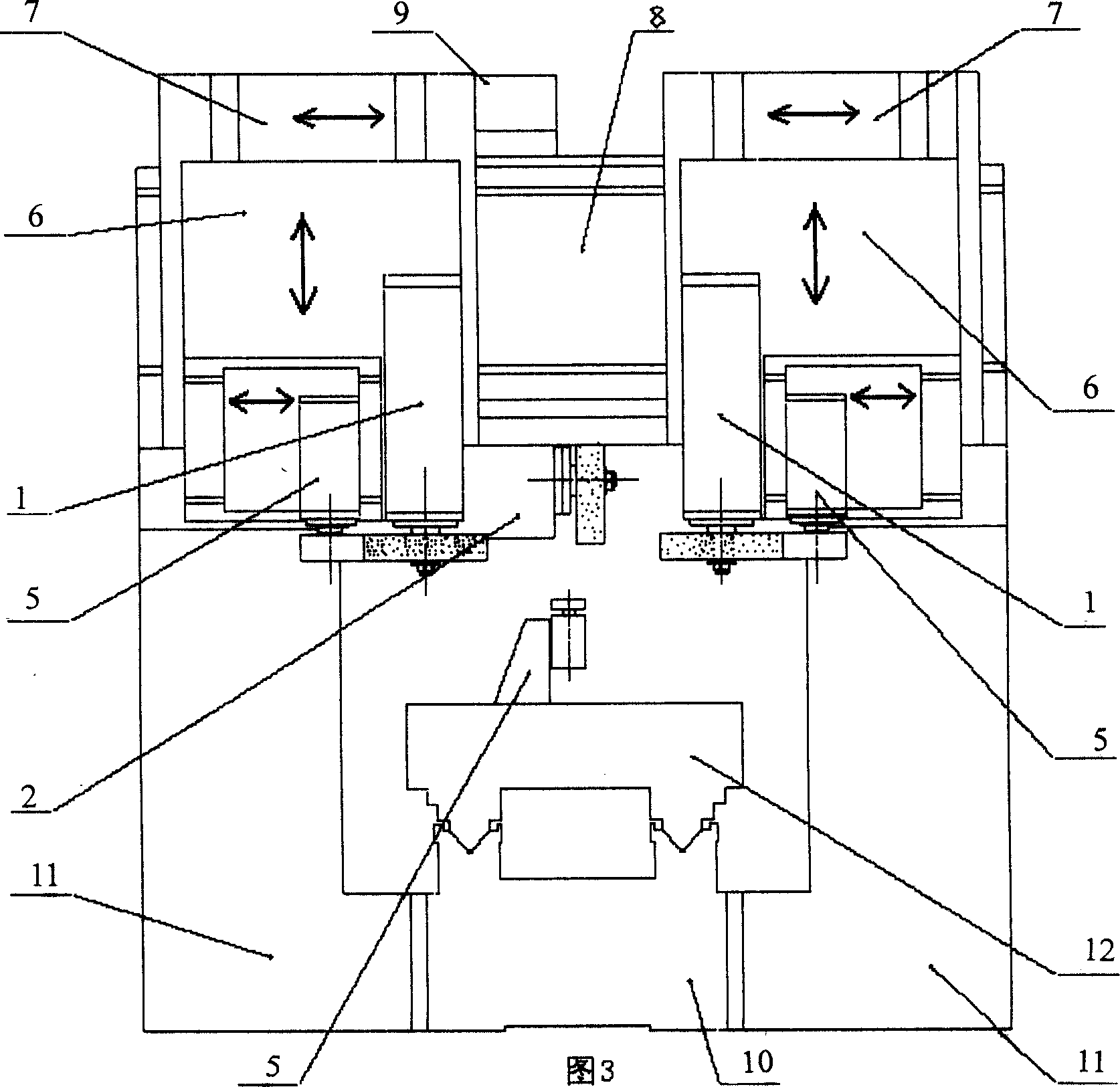

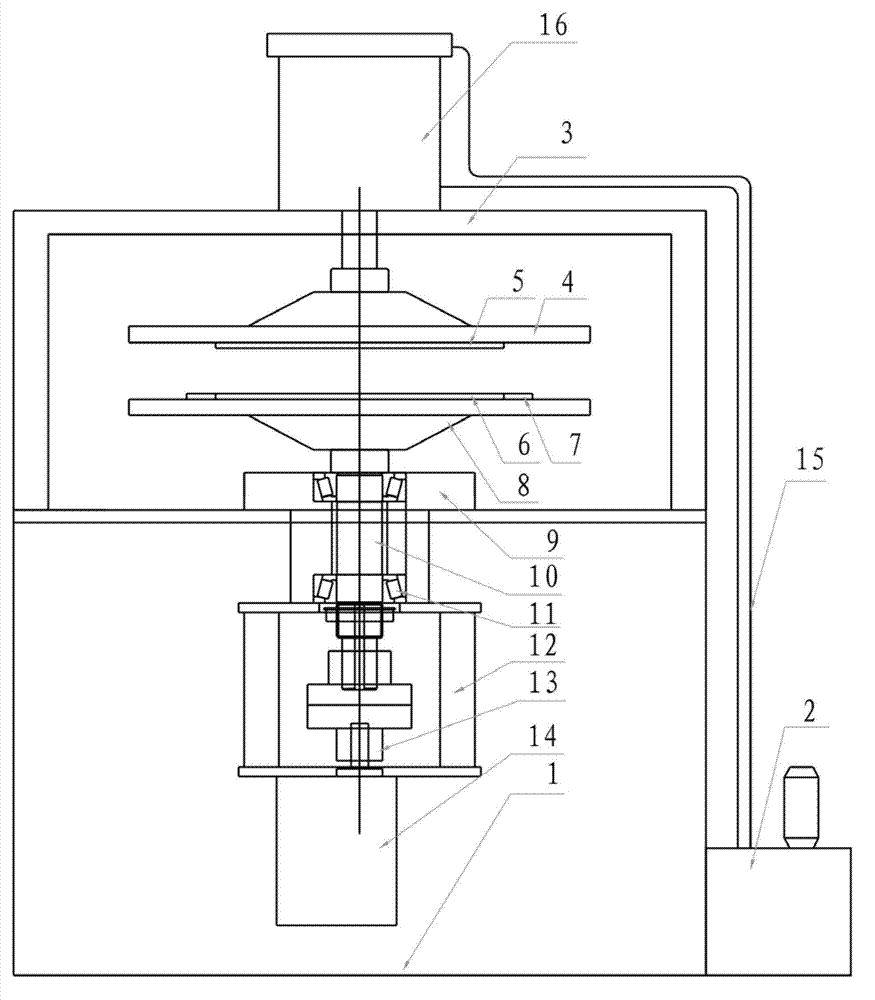

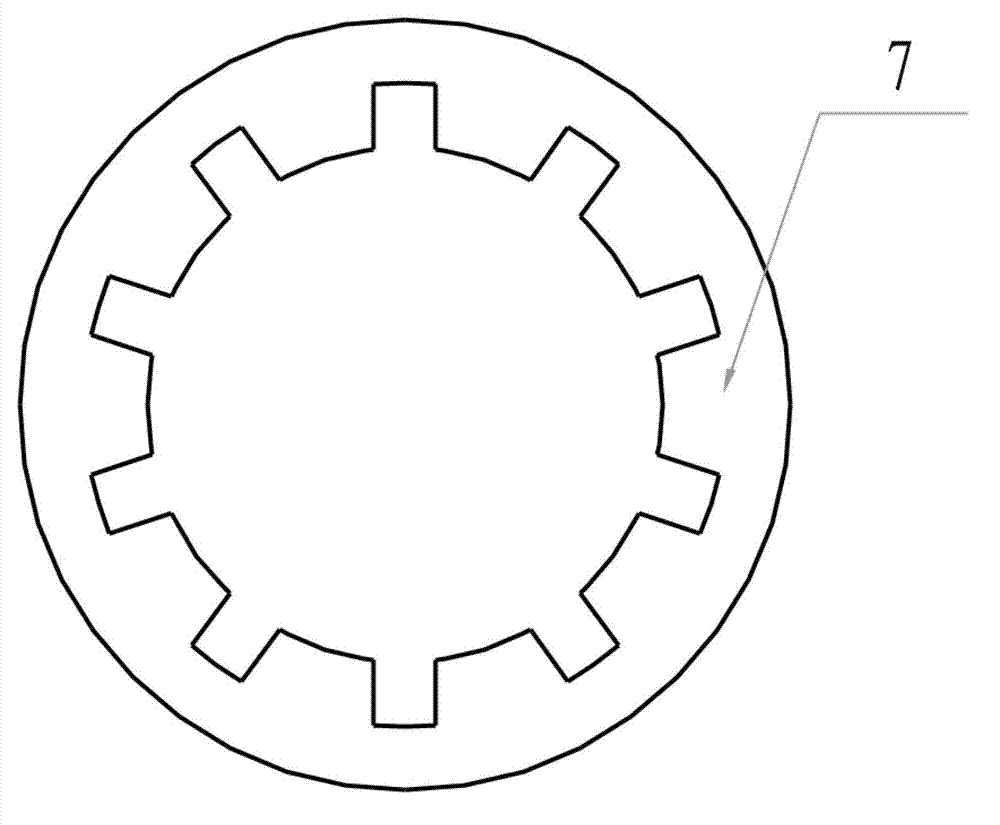

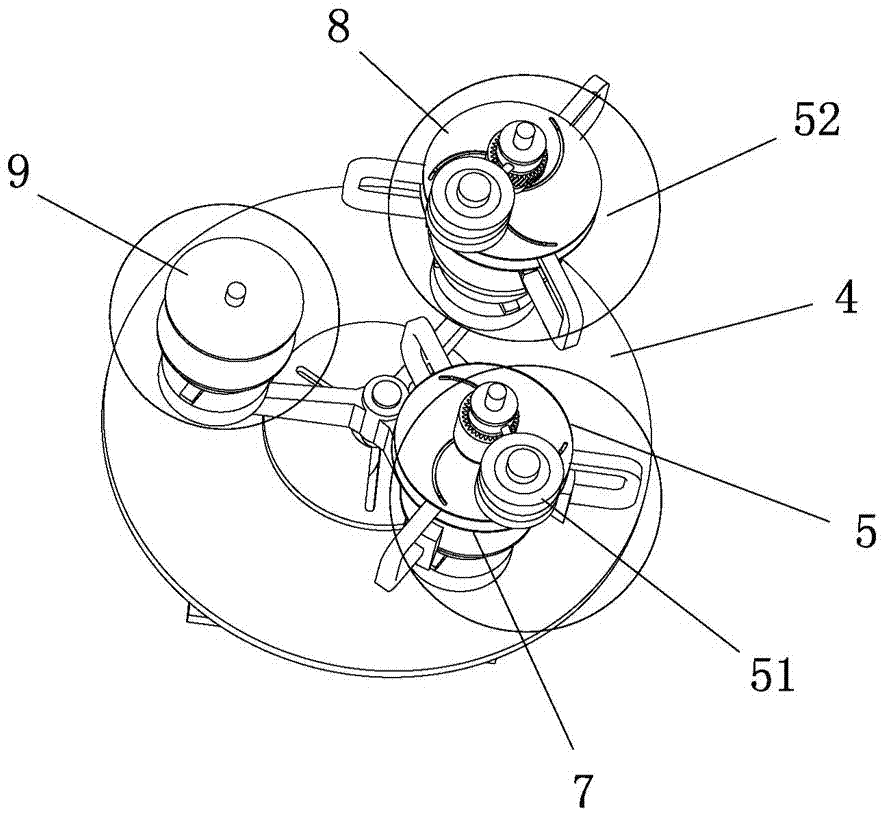

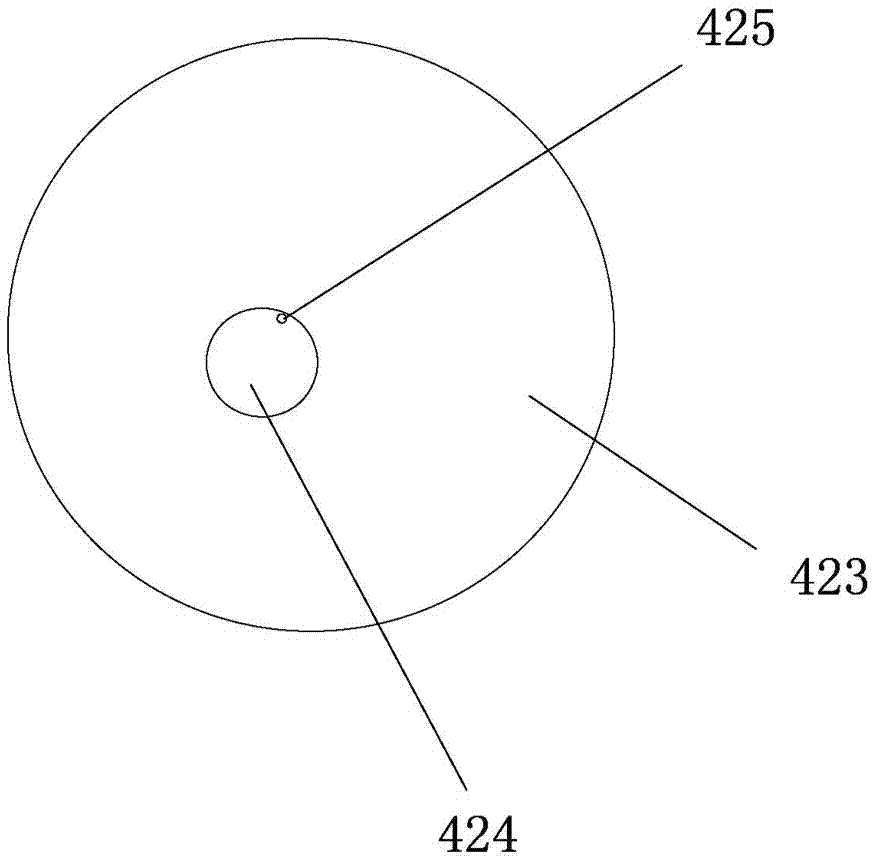

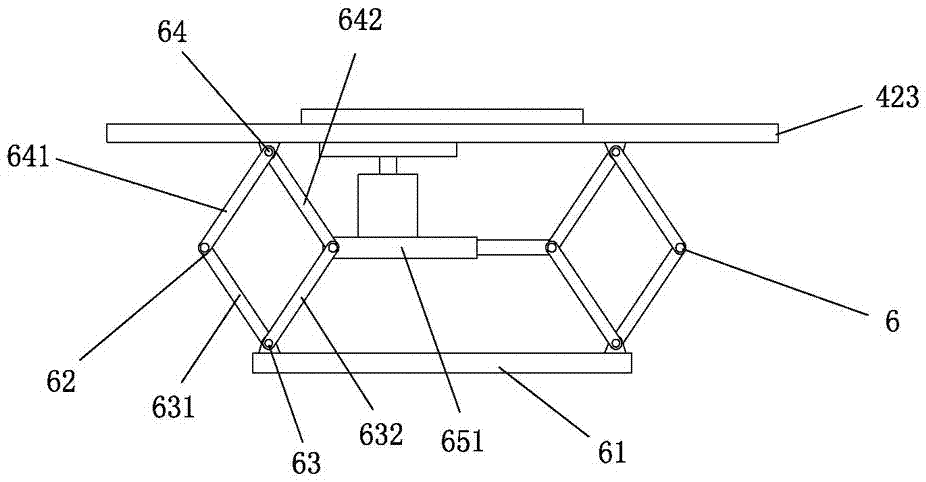

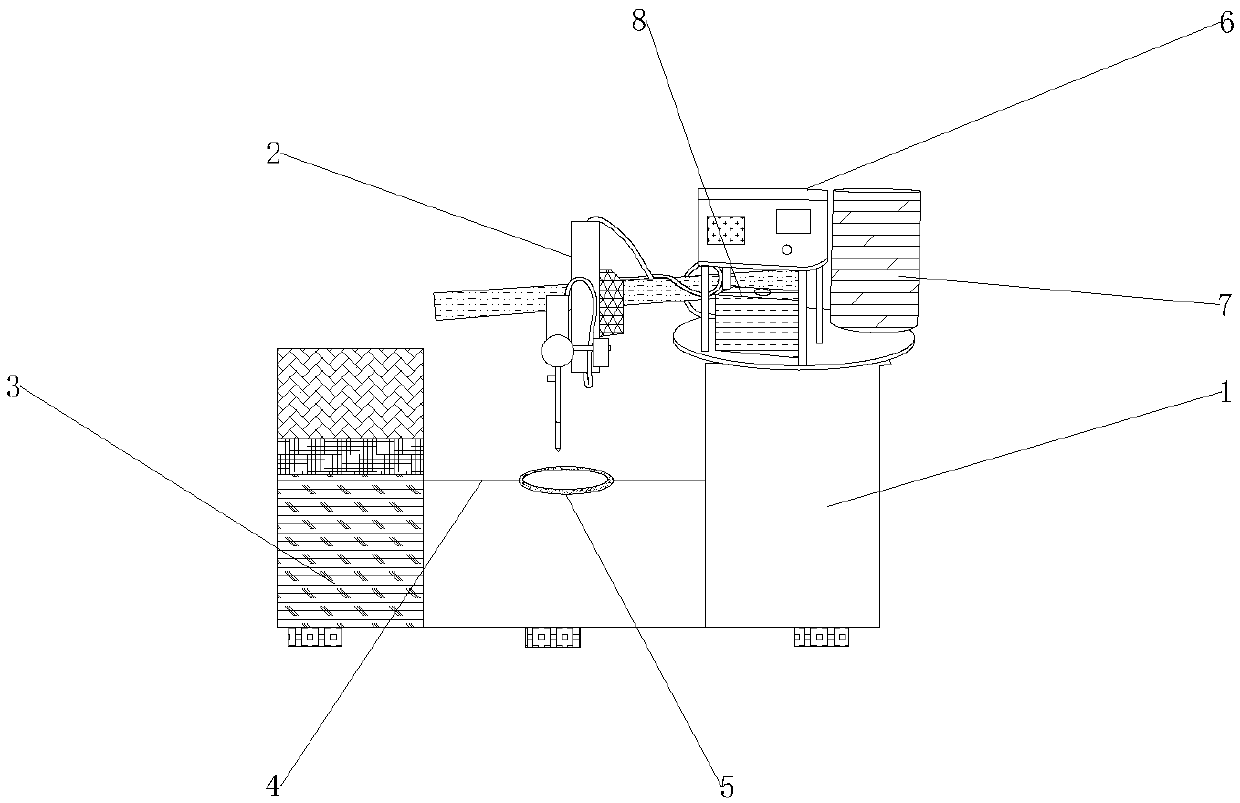

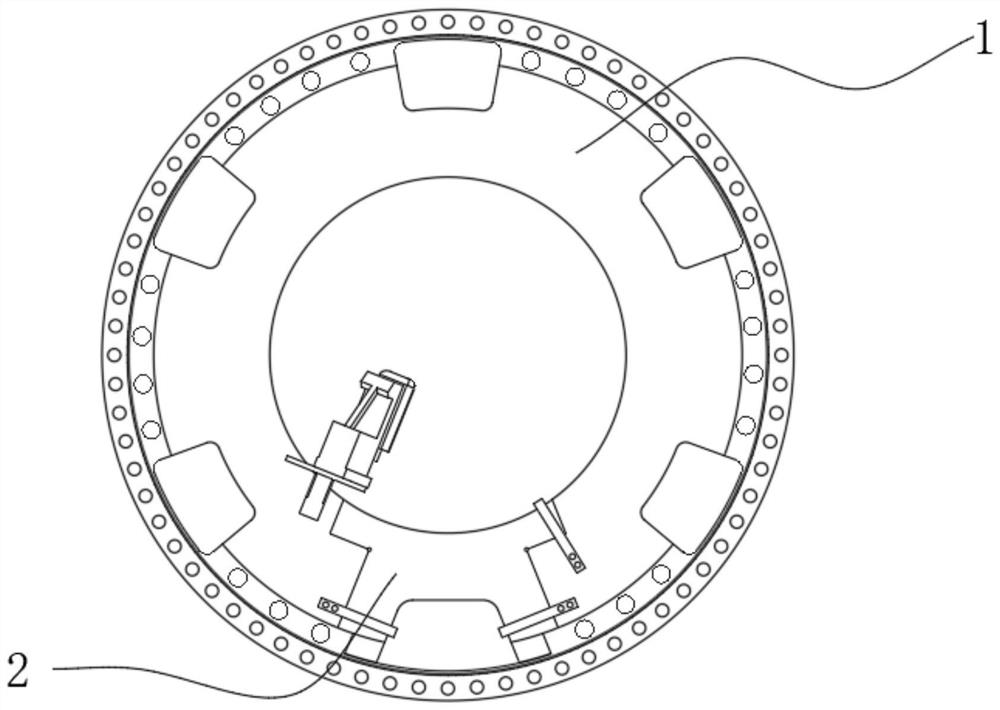

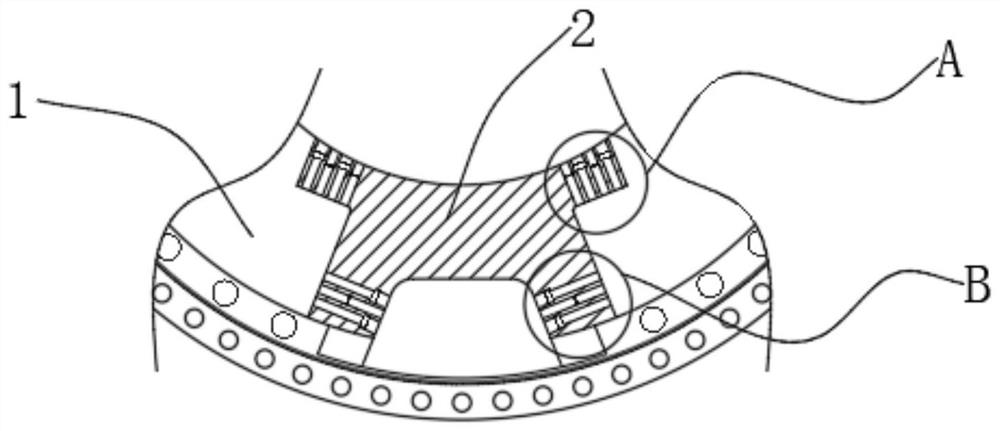

Conical disc repairing assembly system for remanufacturing of automobile continuously variable transmission

The invention relates to the technical field of transmission maintenance and machining, in particular to a conical disc repairing assembly system for the remanufacturing of an automobile continuously variable transmission. The conical disc repairing assembly system comprises a rotation station conversion device and a machining device, wherein the rotation station conversion device is used for driving a conical disc to perform station conversion among three stations; the machining device is used for machining the conical disc and comprises a grinding mechanism mounted at the first station and a polishing mechanism mounted at the second station. When the conical disc repairing assembly system is used, the grinding mechanism grinds the conical disc at the first station, the ground conical disc is moved to the second station through the rotation station conversion device, the polishing mechanism polishes the conical disc, the polished conical disc is moved to the third station through the rotation station conversion device, the third station is an empty station, the machined conical disc is taken out from the third station, and conical discs can be continuously machined in a circulating manner.

Owner:上海新孚美变速箱技术服务有限公司

Materials and methods for augmenting and/or repairing intervertebral discs

A method of expanding and / or repairing an intervertebral disc by applying stem cell material in the disc. Stem cells can be undifferentiated cells, or they can be cells that have differentiated but subsequently dedifferentiated. Stem cells can be induced to express at least one characteristic of human intervertebral disc cells, such as fibroblasts, chondrocytes or dorsal cells, by exposing them to agents and / or environments that induce the desired differentiation. In some embodiments, the stem cell material can be provided along with a collagen-based material, which can be a collagen-rich lattice. Stem cell material can be provided as a stem cell isolate, which can be substantially free of non-stem cell material. Other therapeutic agents can be administered with the stem cell material.

Owner:WARSAW ORTHOPEDIC INC

Blade position fixing method used in integral blade disc repairing process

ActiveCN109333351AEasy to separateAvoid damageGrinding work supportsAviationManufacturing technology

The invention relates to a blade position fixing method used in the integral blade disc repairing process in the technical field of aviation manufacturing. The method comprises the steps that the periphery of a residual blade root of a to-be-repaired blade is covered with a metal film, and the metal film is closely attached to the profile of the residual blade root; metal powder is sprayed to theperiphery of the metal film, a clamping block is formed after the preset thickness is reached through spraying, and accordingly rigidity of the blade root is enhanced; heat treatment is conducted on the clamping block formed after spraying, and accordingly the mutual combination mechanical performance between particles of the metal powder in the clamping block is improved; and the clamping block is assembled to the periphery of the residual blade root, and a clamping clamp is arranged on the outer side of the clamping block for fixing the blade position. The problem that in the linear frictionwelding repairing process, blade clamping position fixing is not reliable, and deformation is likely to be caused is solved, and it is guaranteed that the profile quality of the repaired blade is notinfluenced.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

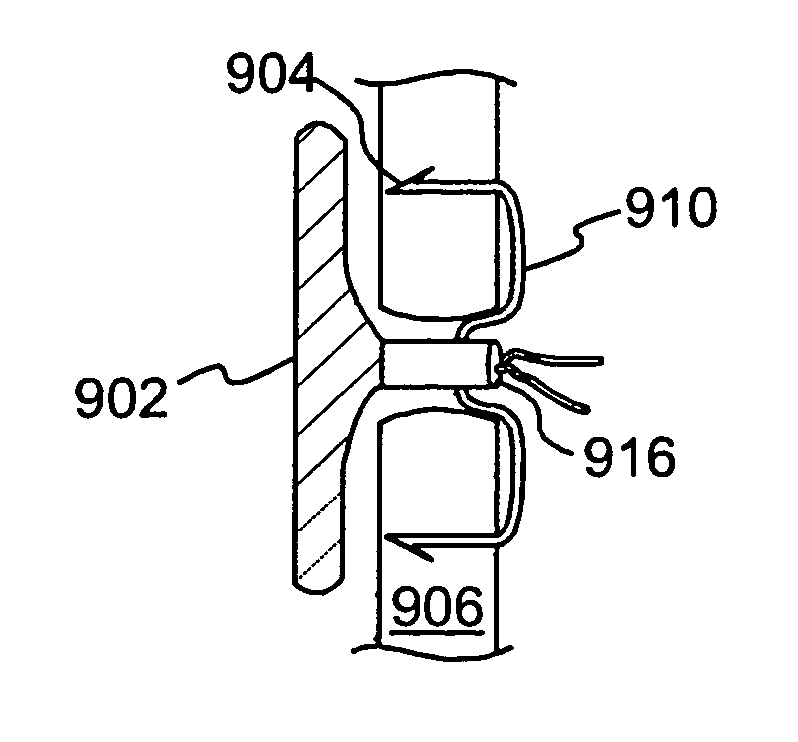

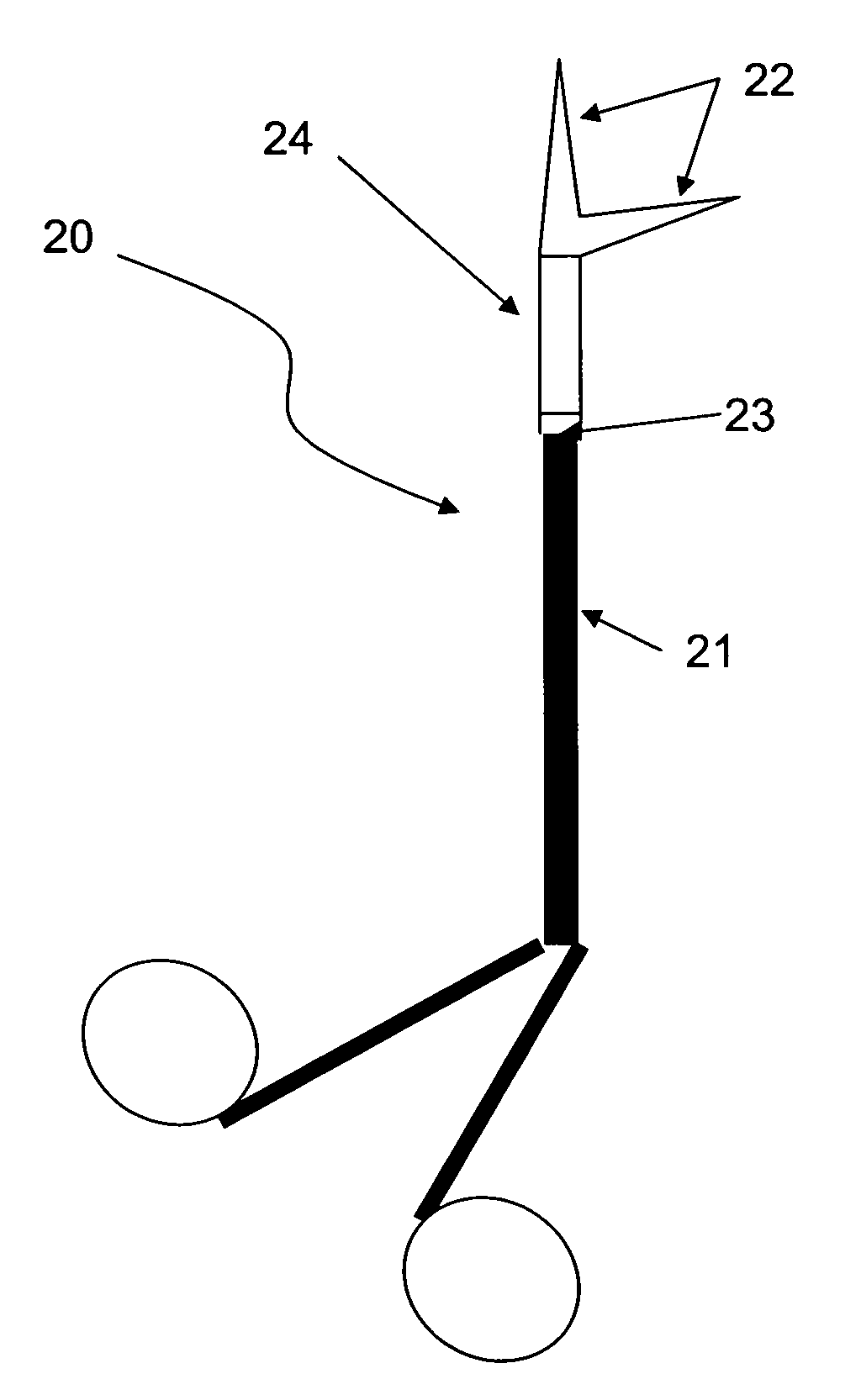

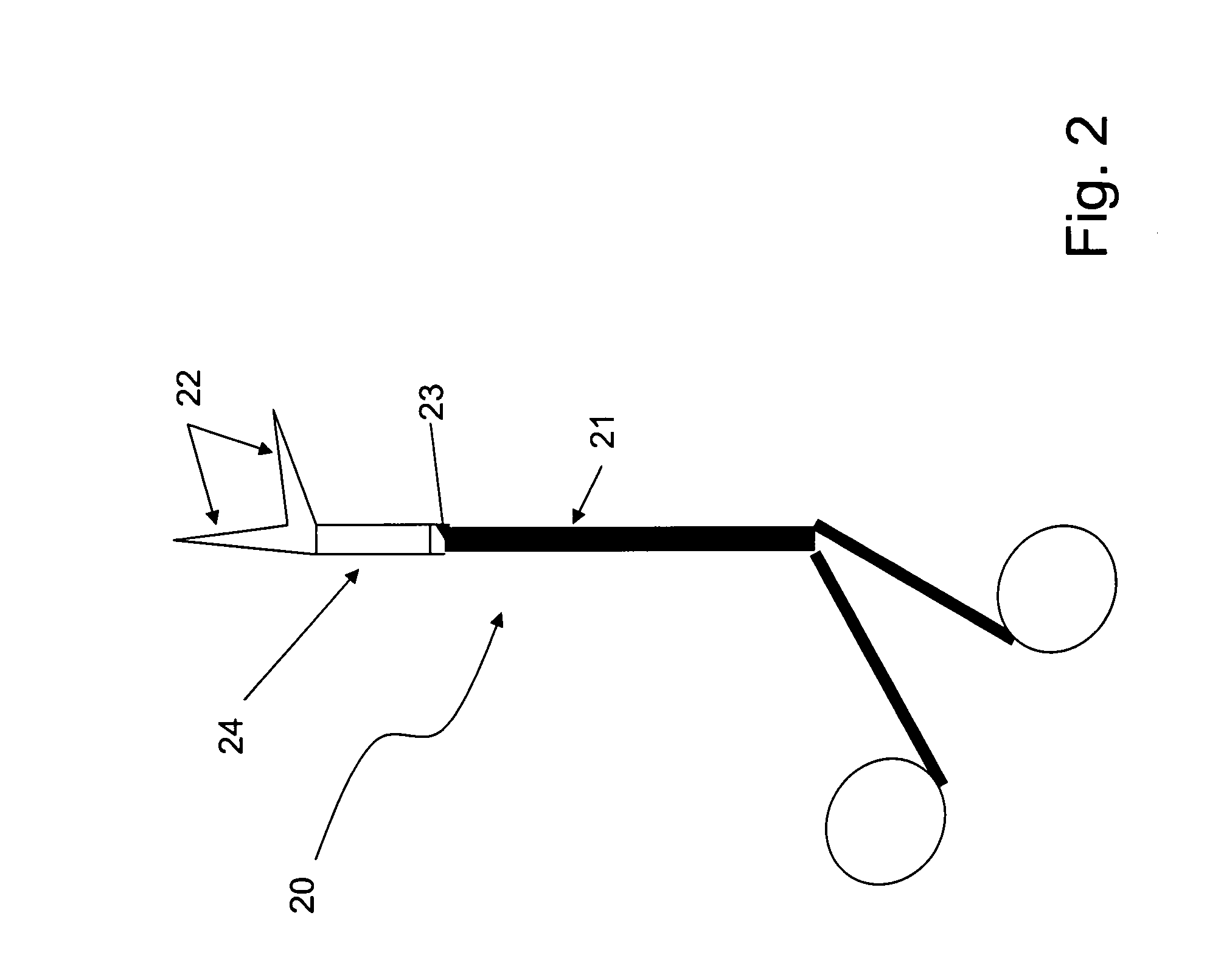

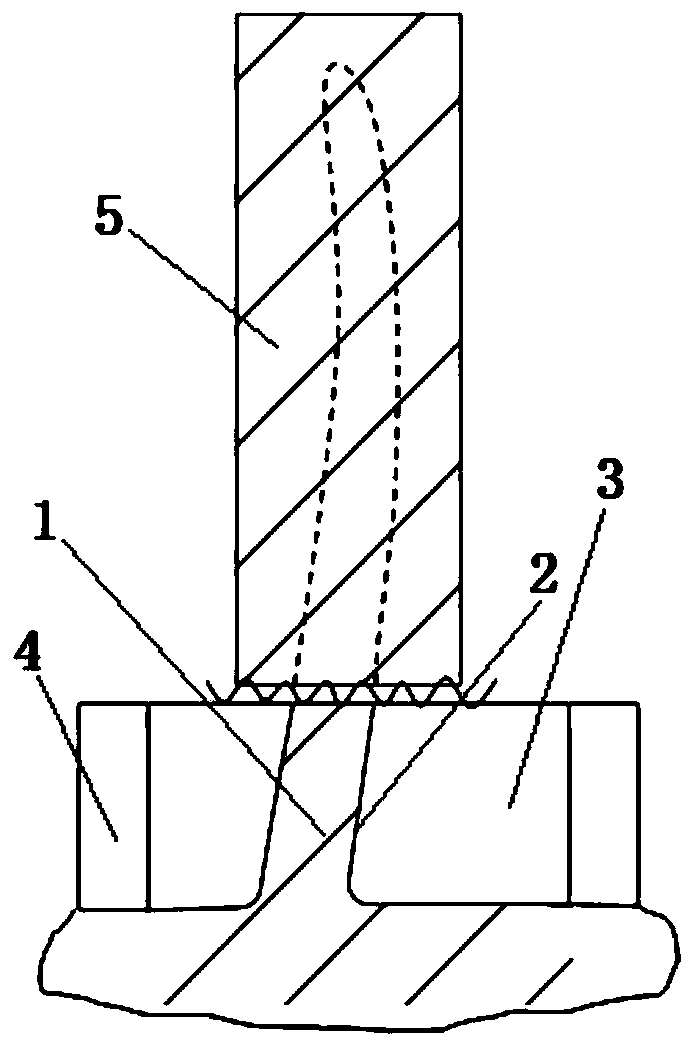

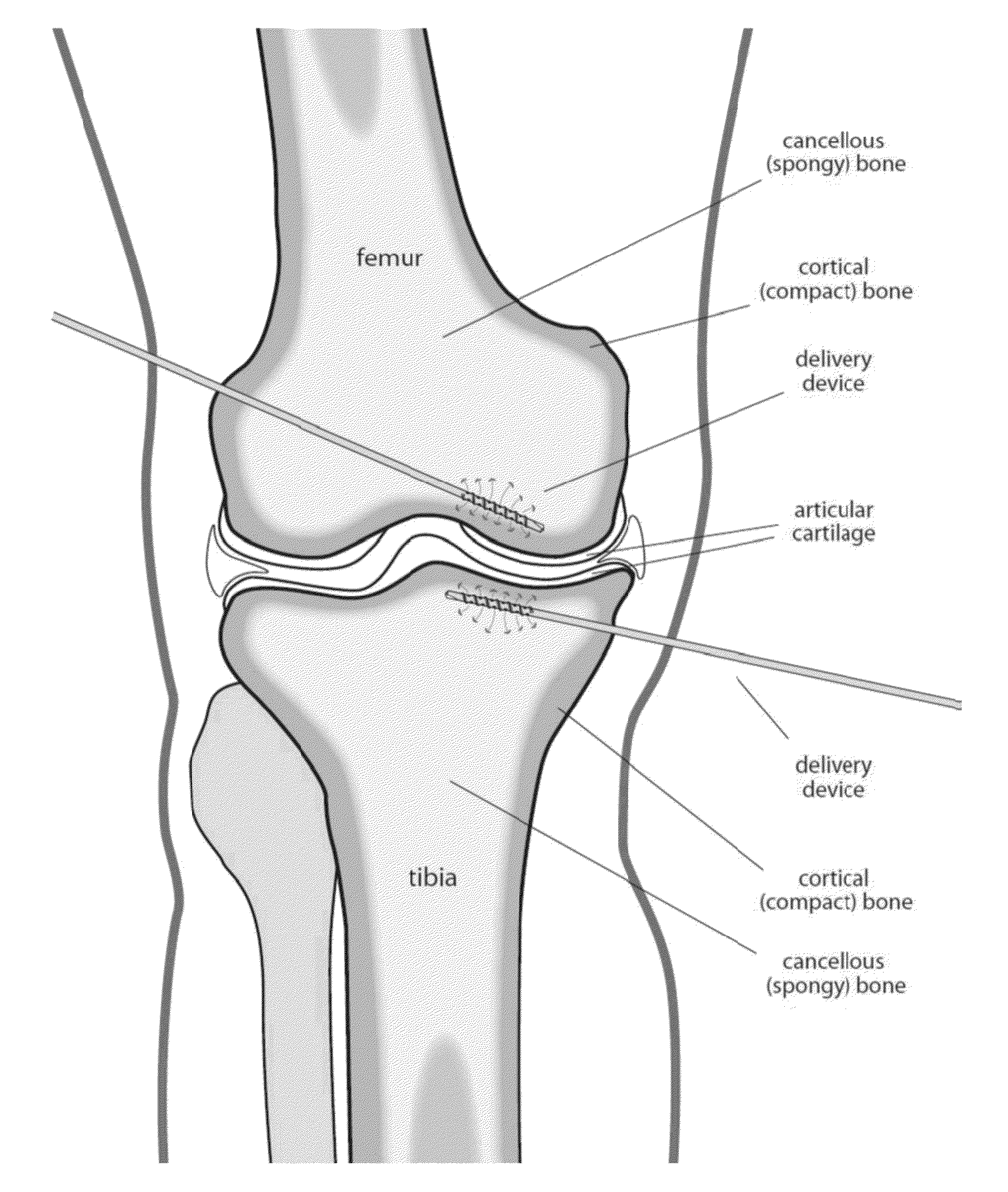

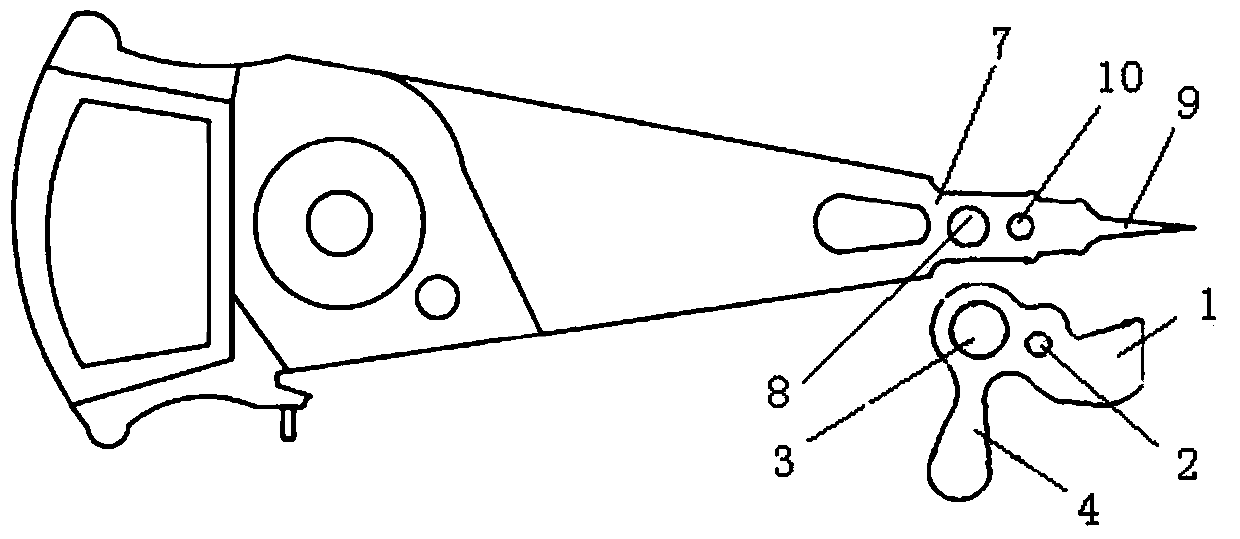

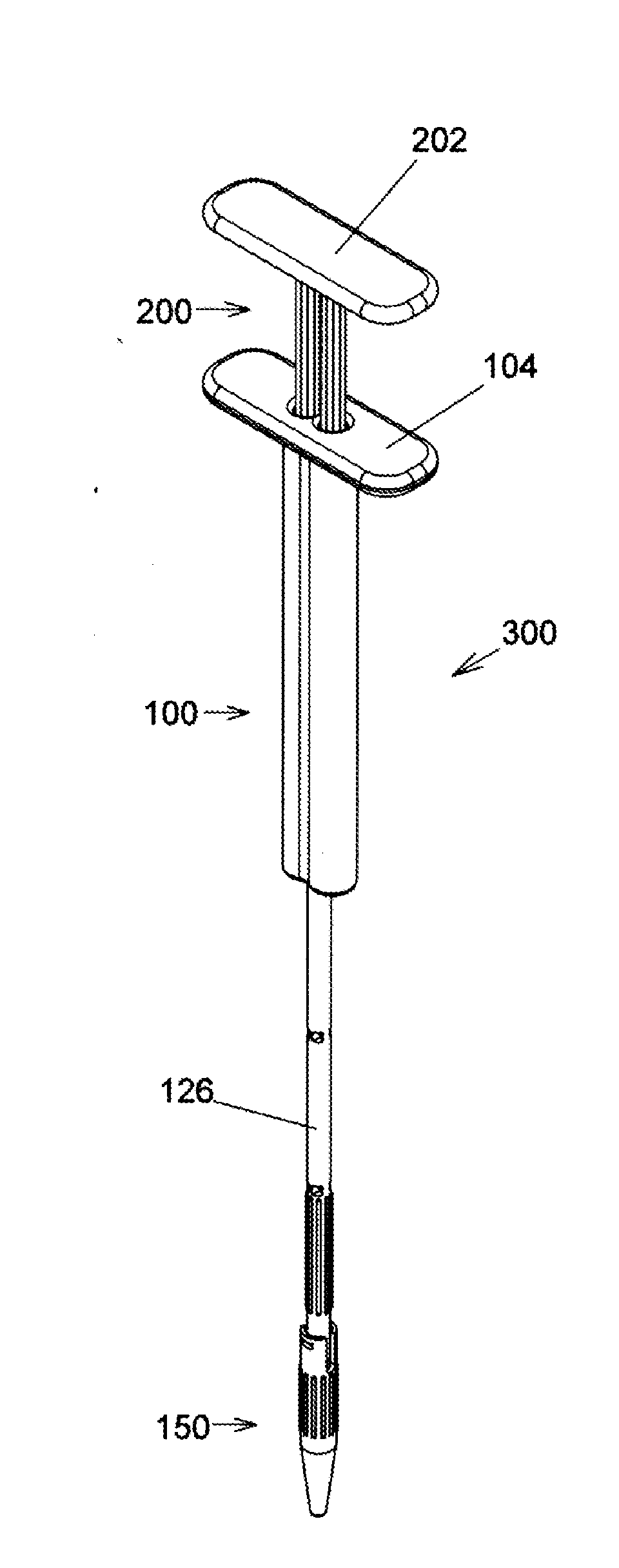

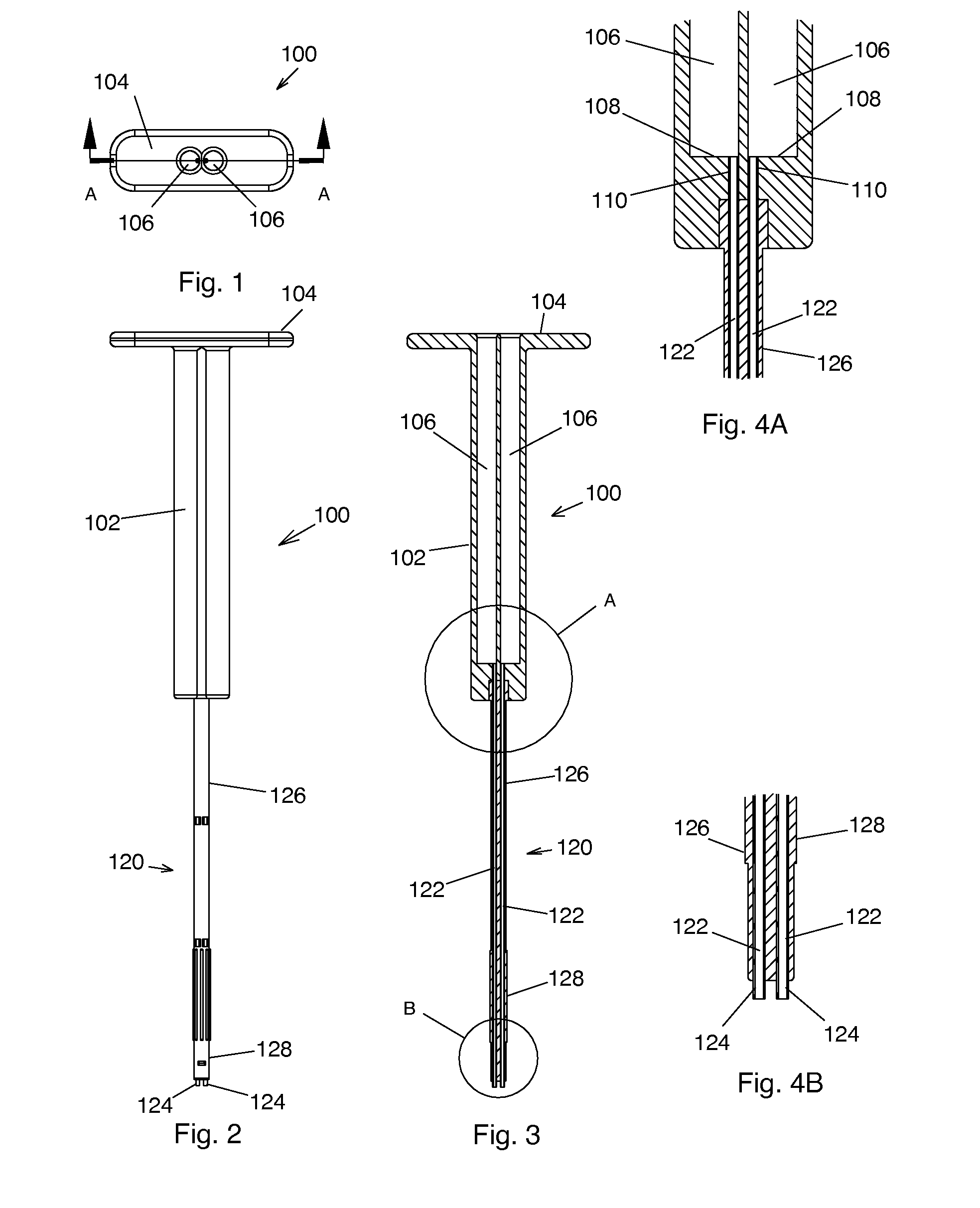

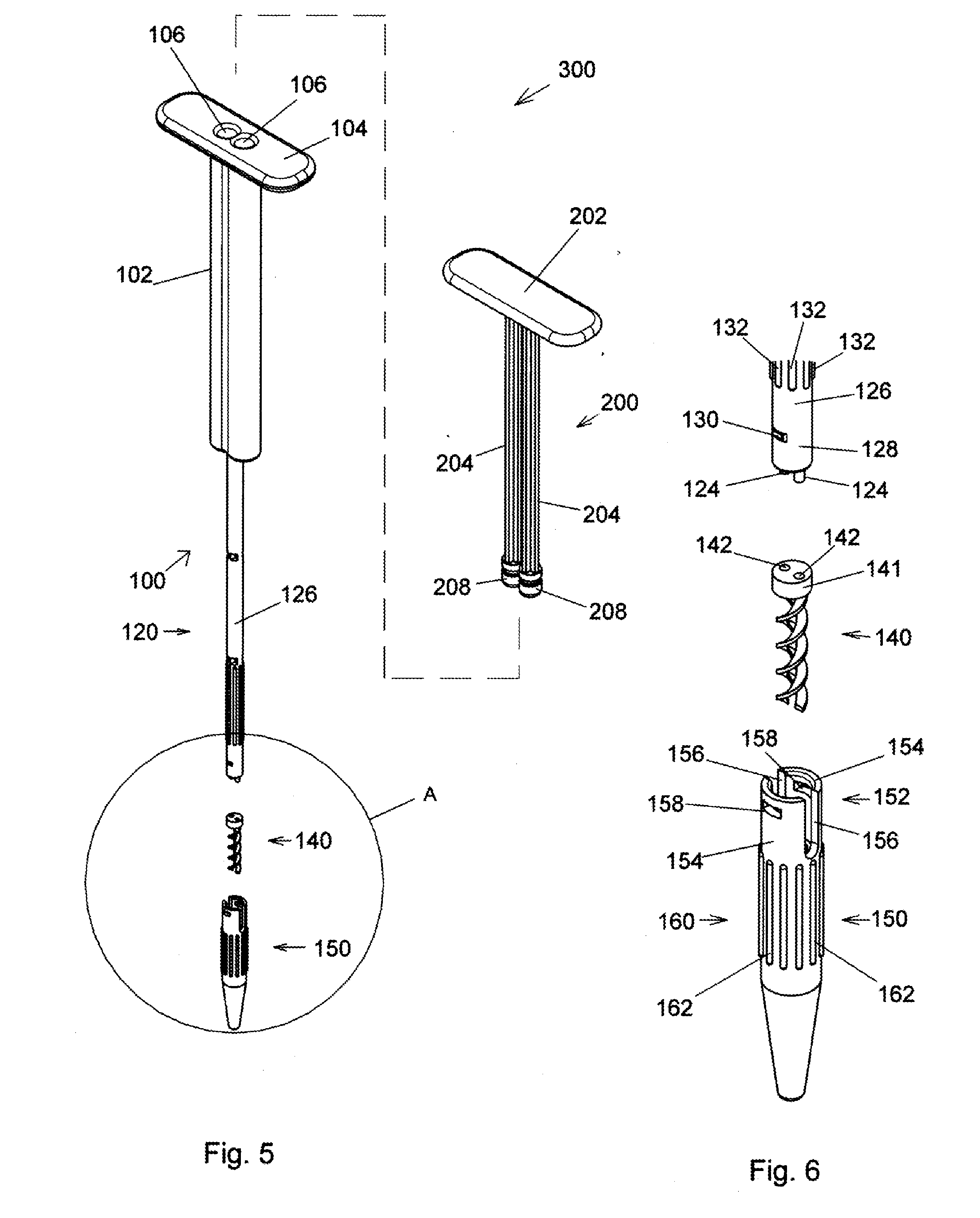

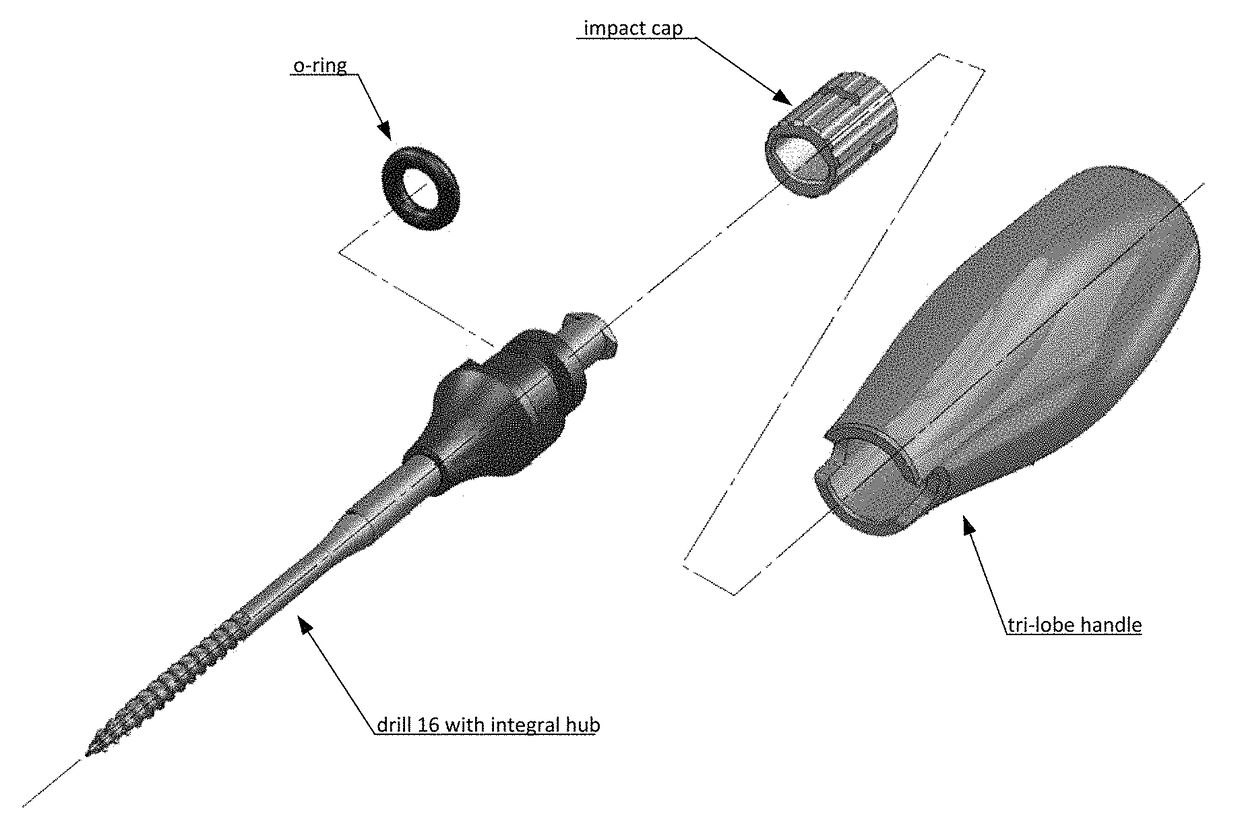

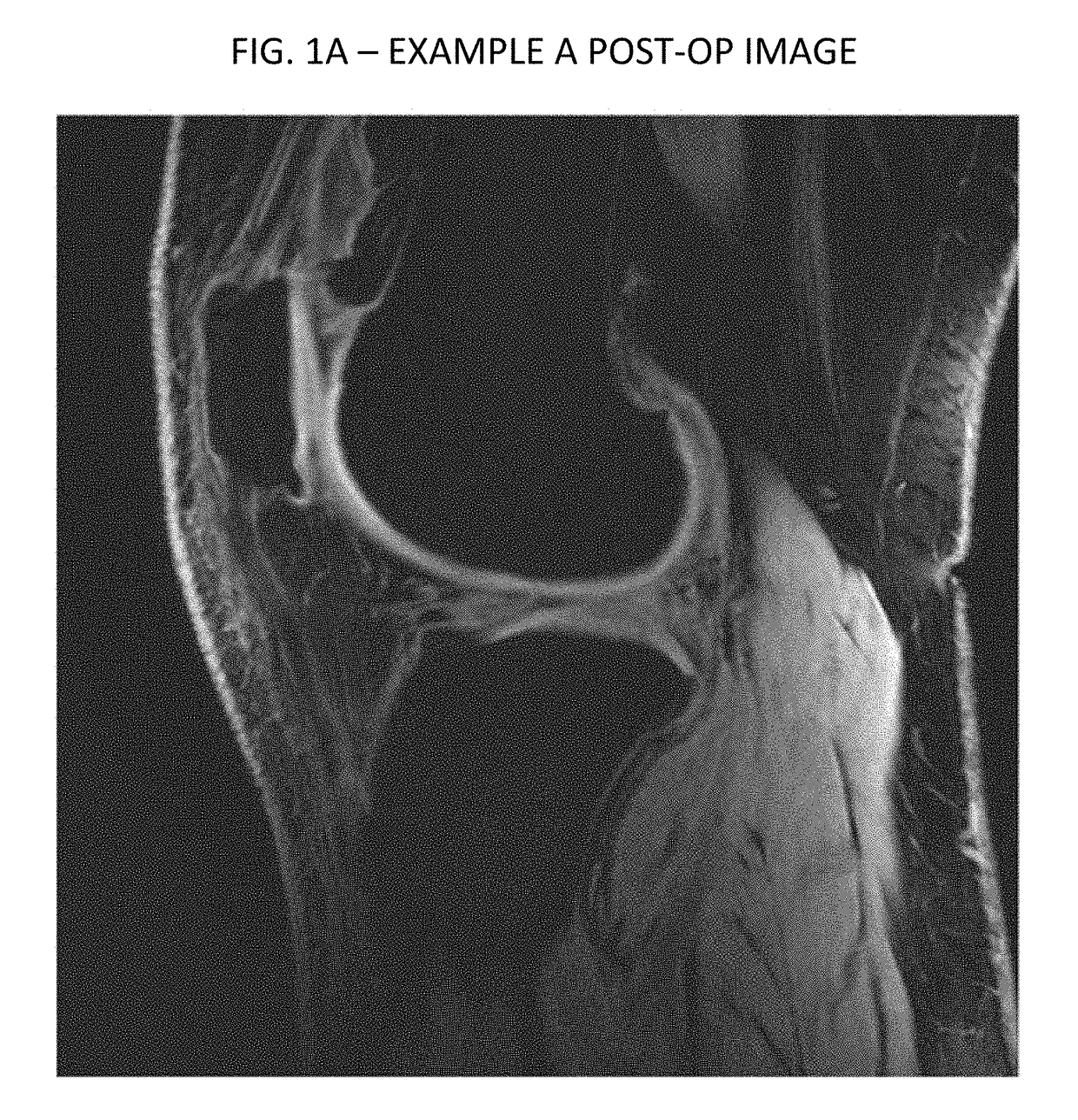

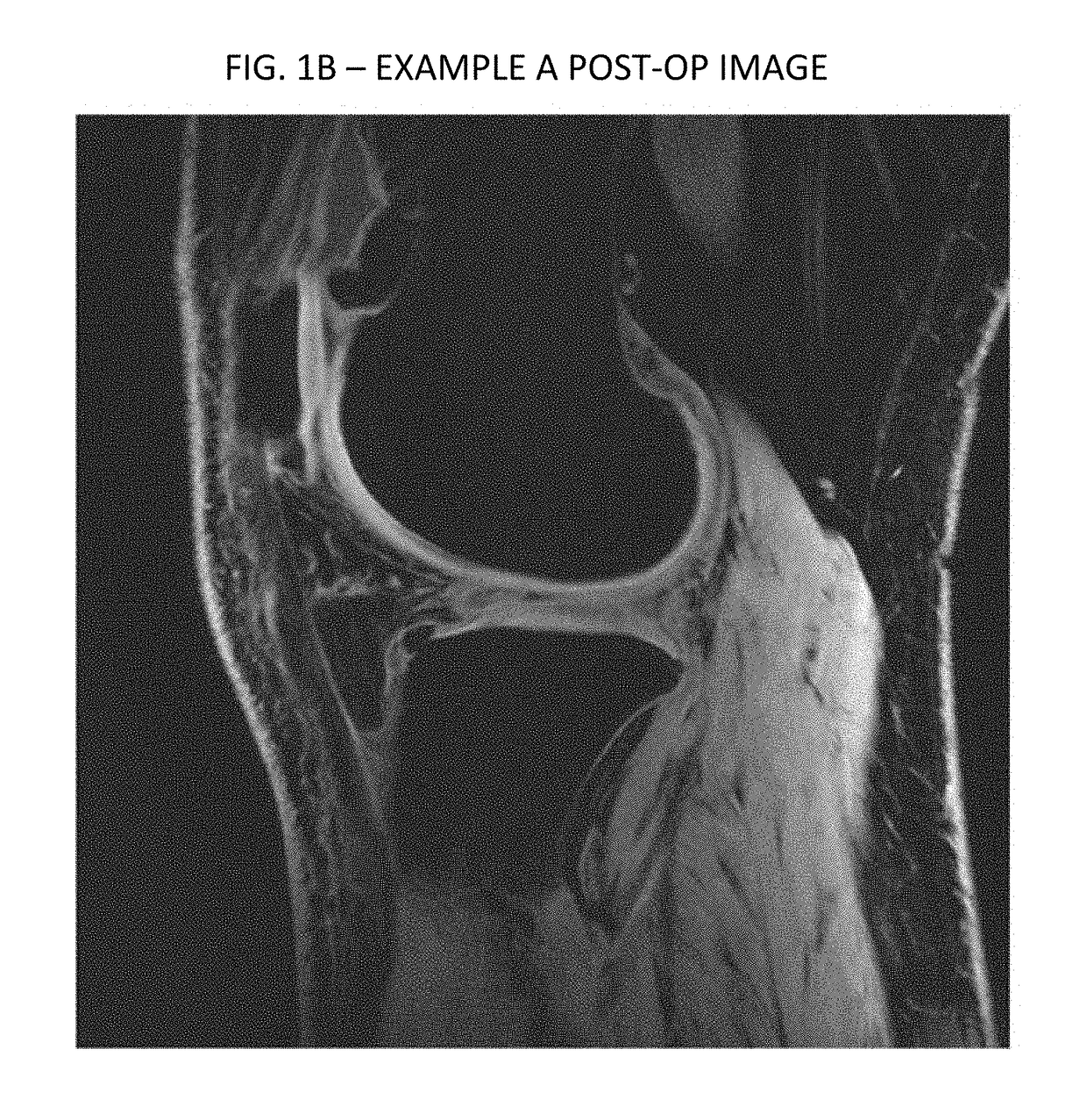

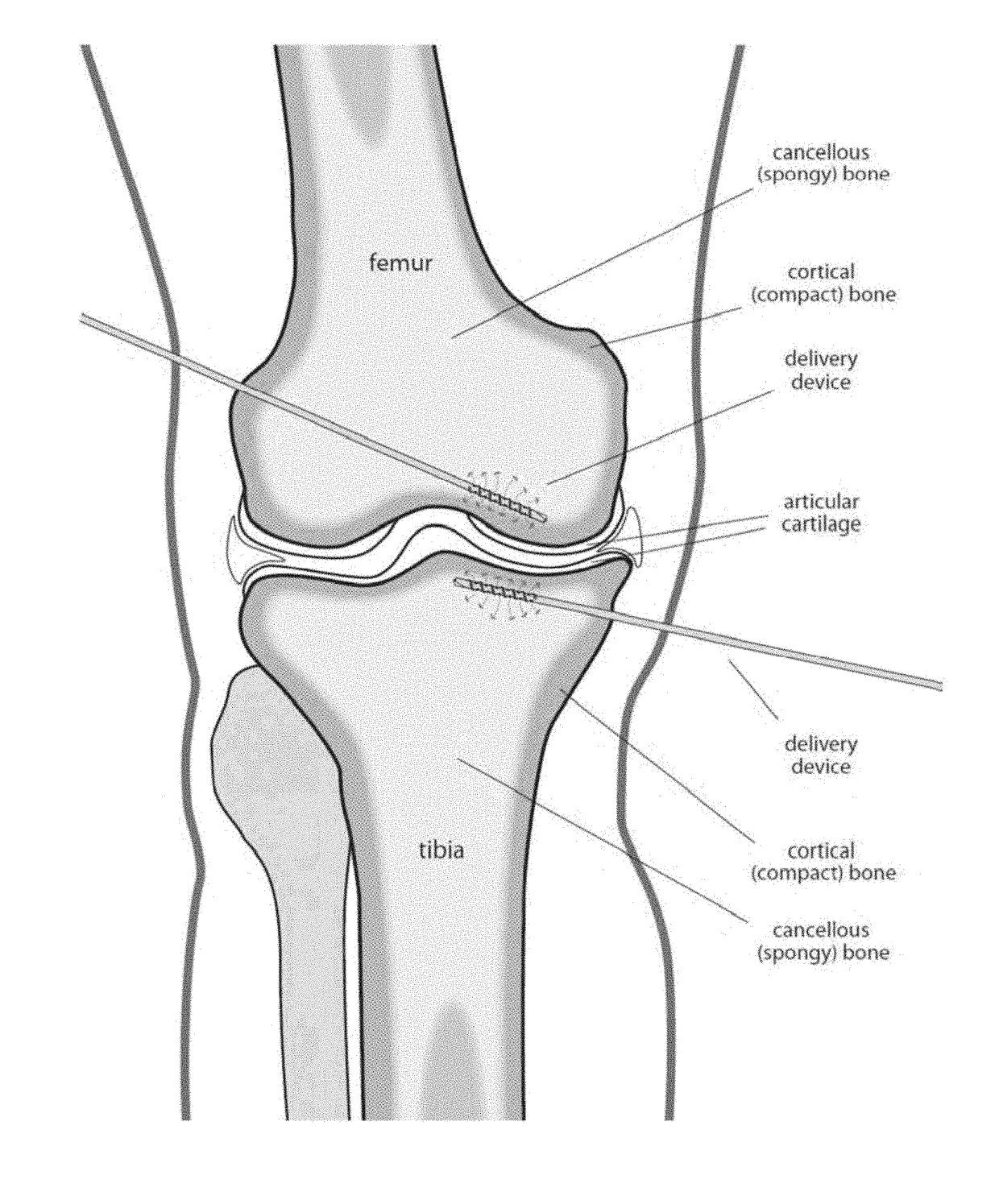

Cartilage repair, preservation and growth by stimulation of bone-chondral interfase and delivery system and methods therefor

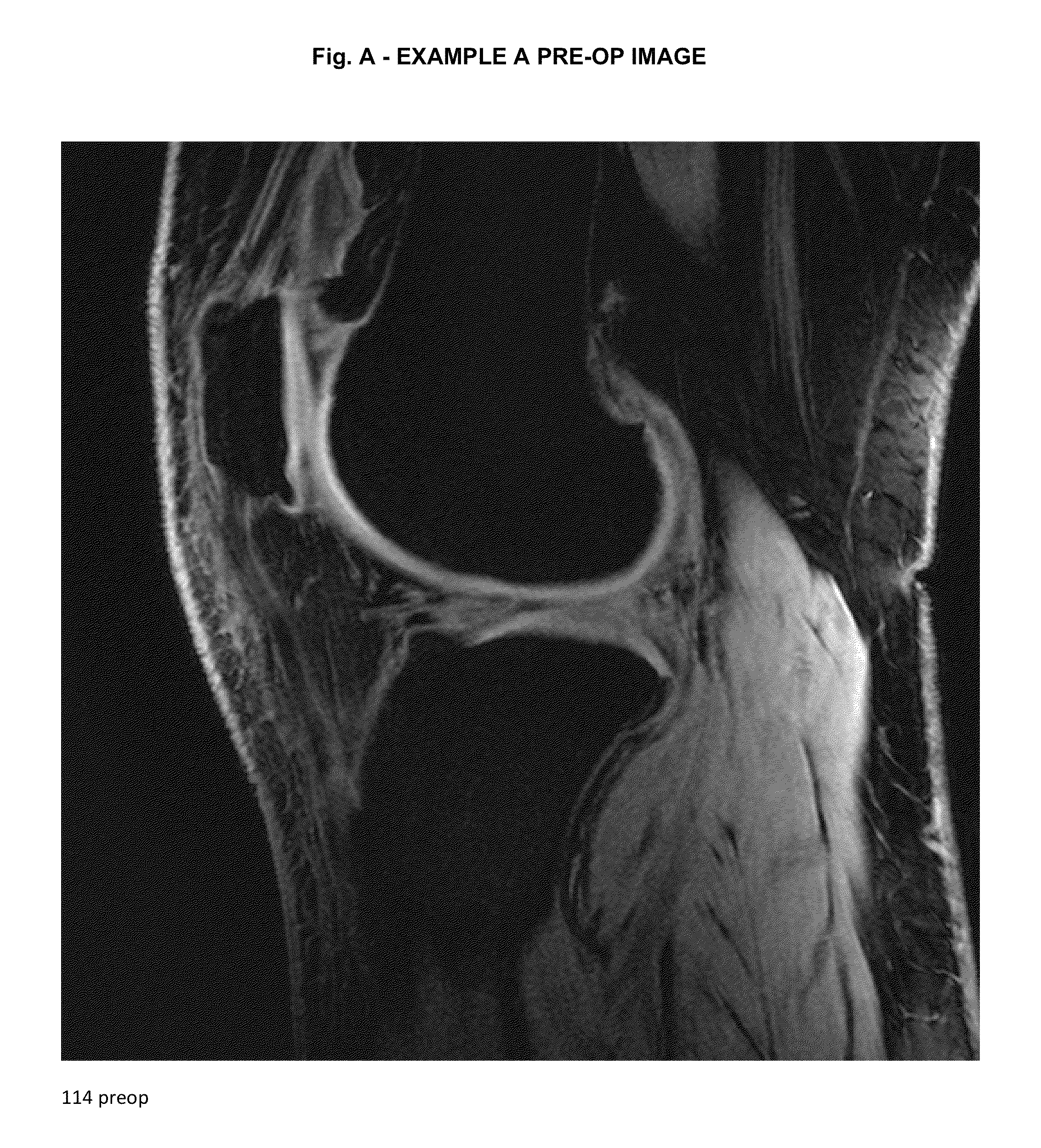

ActiveUS20140088551A1Easy to manufactureLess risk of infectionSurgical needlesMedical devicesCartilage repairDisc repair

Therapeutics and methods of treatment to repair, preserve and grow cartilage are presented. In addition, systems and methods for delivering a therapeutic to a hard to reach anatomical area, such as, for example, the BCI, are presented. A cannulated delivery device provided with a cutting tip, cutting flutes and threads on its distal end is disclosed, as well as therapies for joint and cartilage repair, preservation and generation using it. Alternatively, for disc repair, a “PIARES” device for Percutaneous Intradiscal Annular Repair introduces therapeutics intradiscally. The device may have two-needles; a first cannula / needle with a finger grip, and a longer inner needle to penetrate through the outer needle into the disc, and introduce therapeutics via a syringe. When provided with a septum at the inner needle's proximal end, the PIARES device is a completely closed system; using it minimizes trauma.

Owner:VAD SCI

Hard disc magnetic head separator

InactiveCN103761978AEasy to operateAvoid deformationProtective measures for recording headsStiffness coefficientEngineering

The invention relates to the field of disc repair, in particular to a hard disc magnetic head separator. The hard disc magnetic head separator comprises a separator body, the separator body is of an angle breaking type structure, a grabbing part is arranged on one side of the angle breaking type structure, the grabbing part comprises a facade body, at least three separation bodies which are used for being inserted between elastic clamping pieces on the front portion of a magnetic head arm are arranged on the facade body in parallel, the separation bodies extend in the direction away from the facade body, the thickness of the separation bodies is used for being suitable for a ballistic interval of stiffness coefficients of the elastic clamping pieces, a rotating shaft used for being inserted in a rotating shaft hole is fixedly arranged on the other side of the angle folding type structure, and the rotating shaft and the grabbing part extend in the same direction and are parallel. The hard disc magnetic head separator is easy to operate, and the safety of magnetic head separation is improved.

Owner:韩松峰

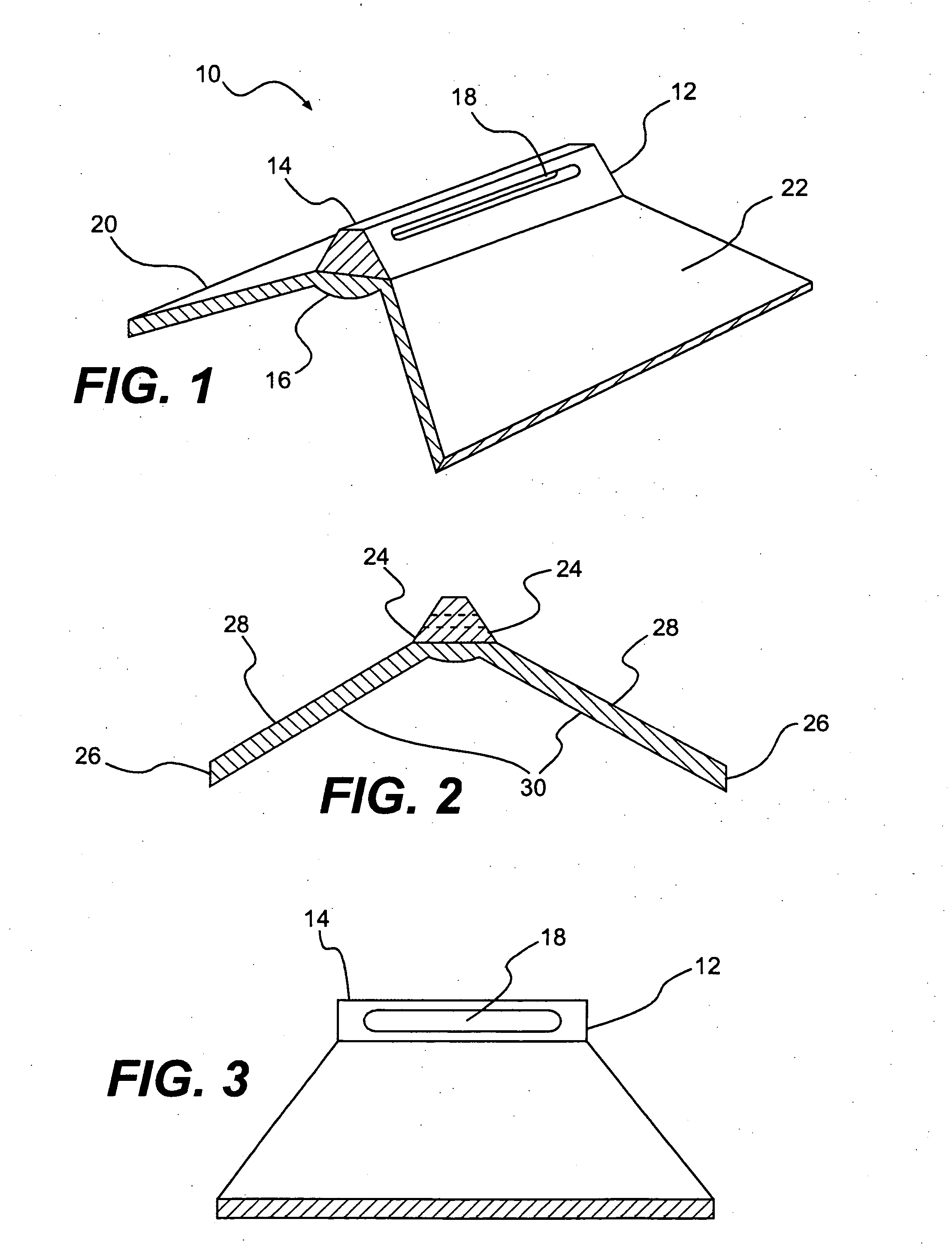

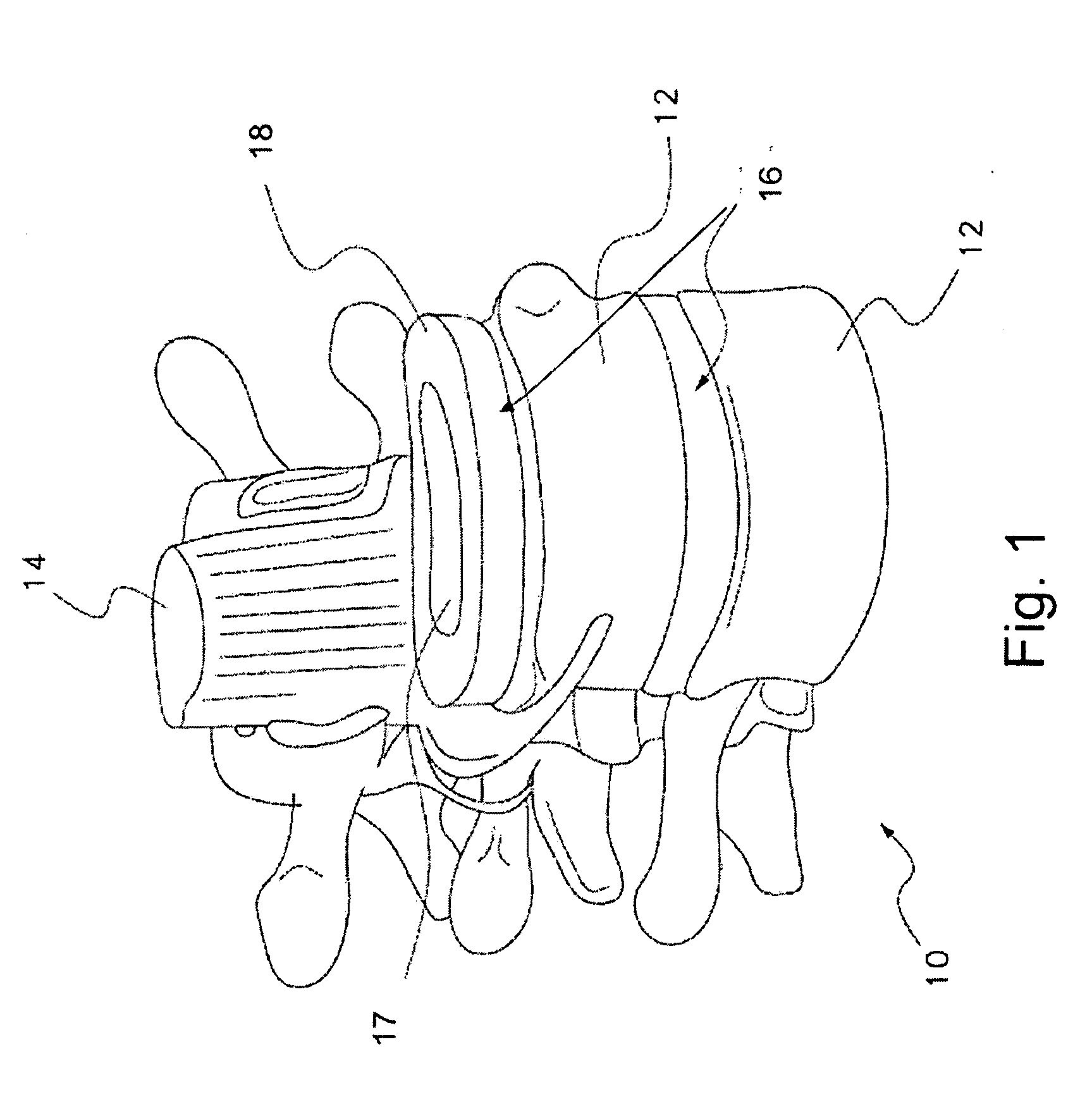

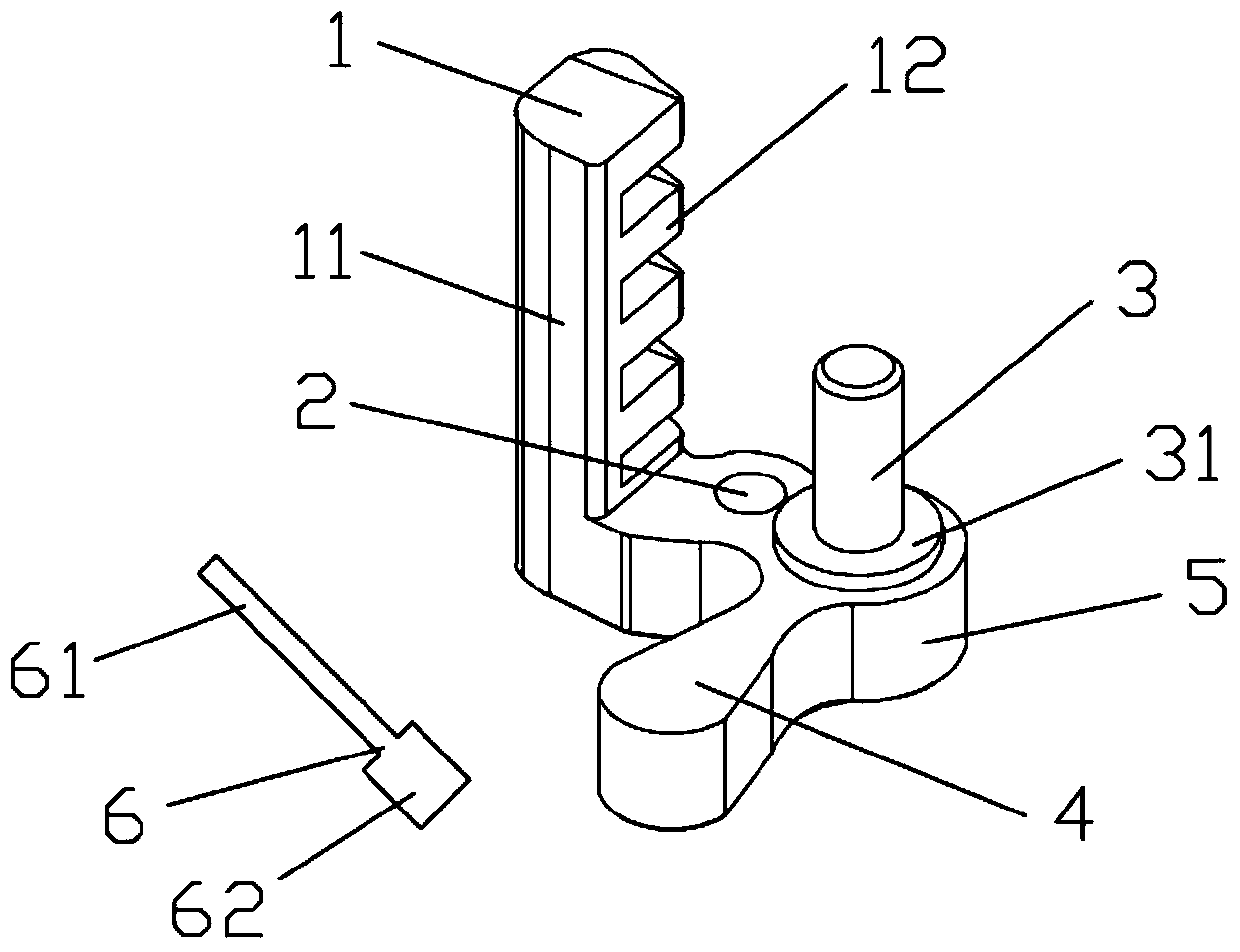

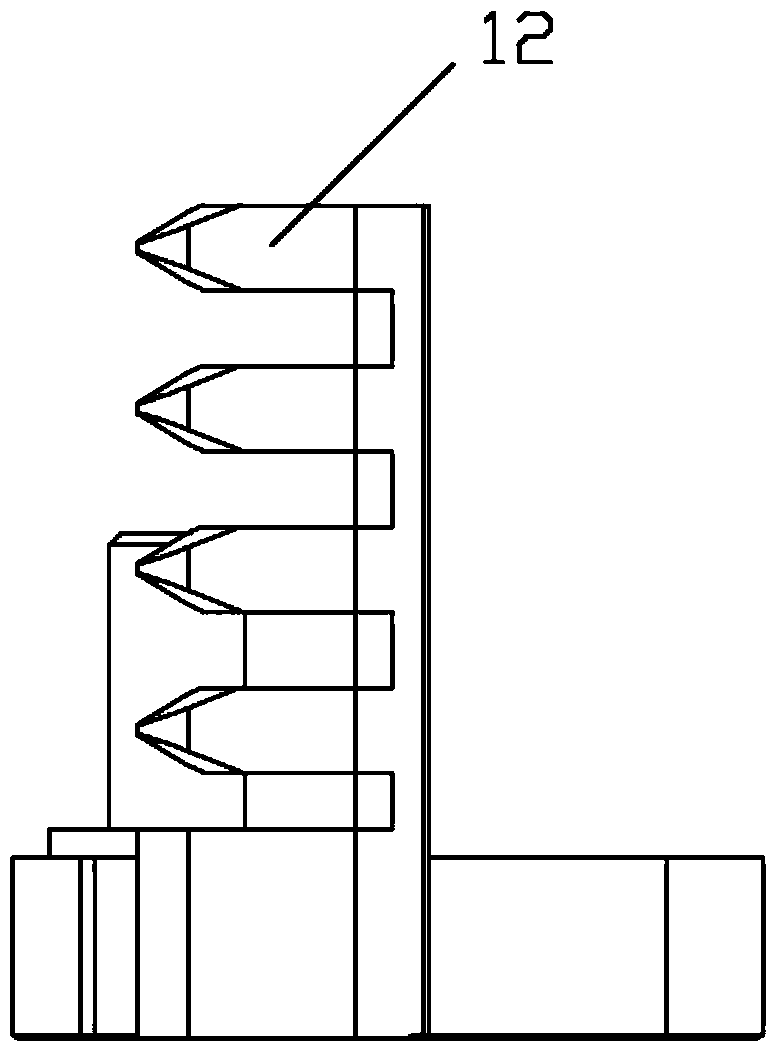

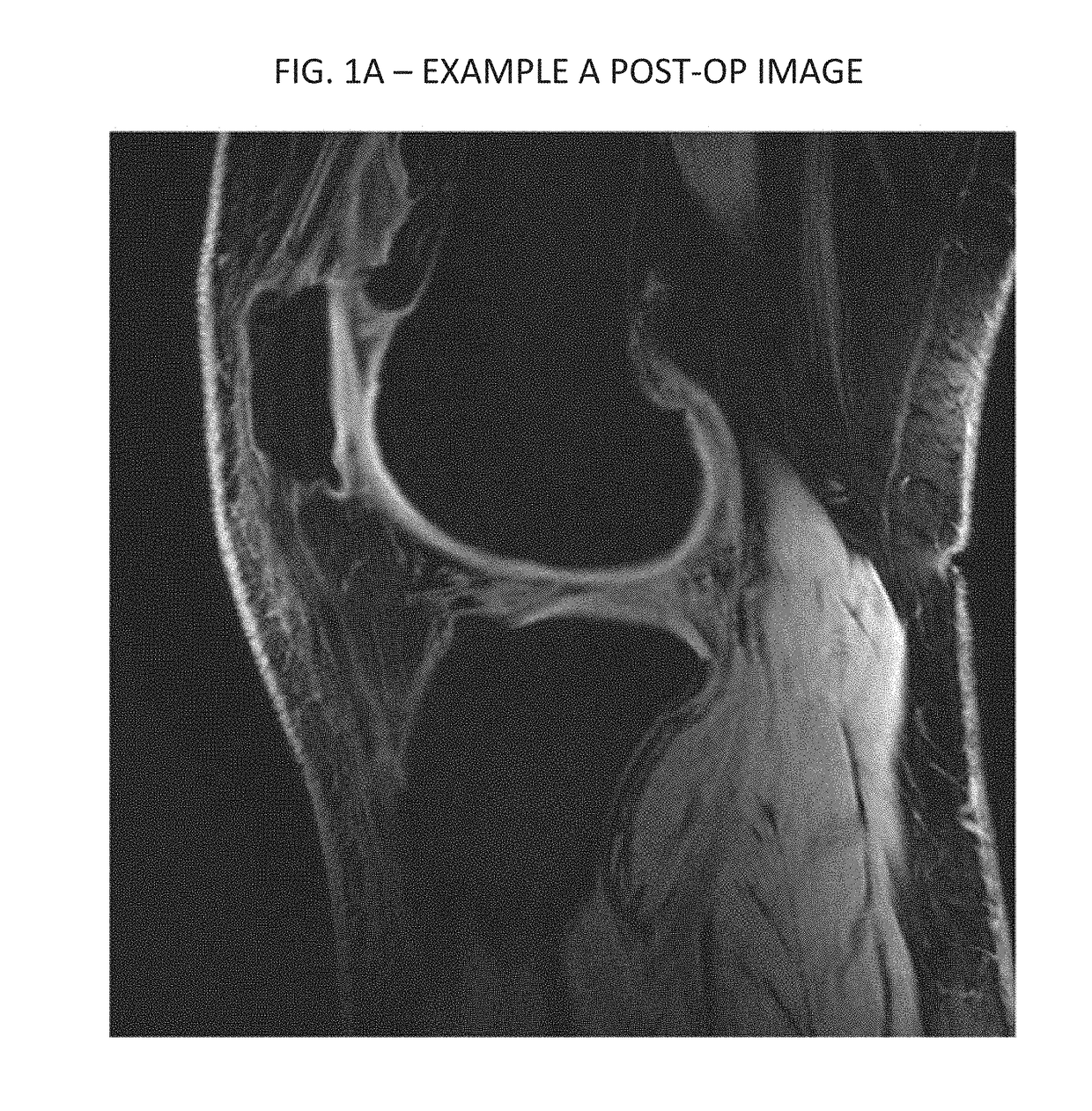

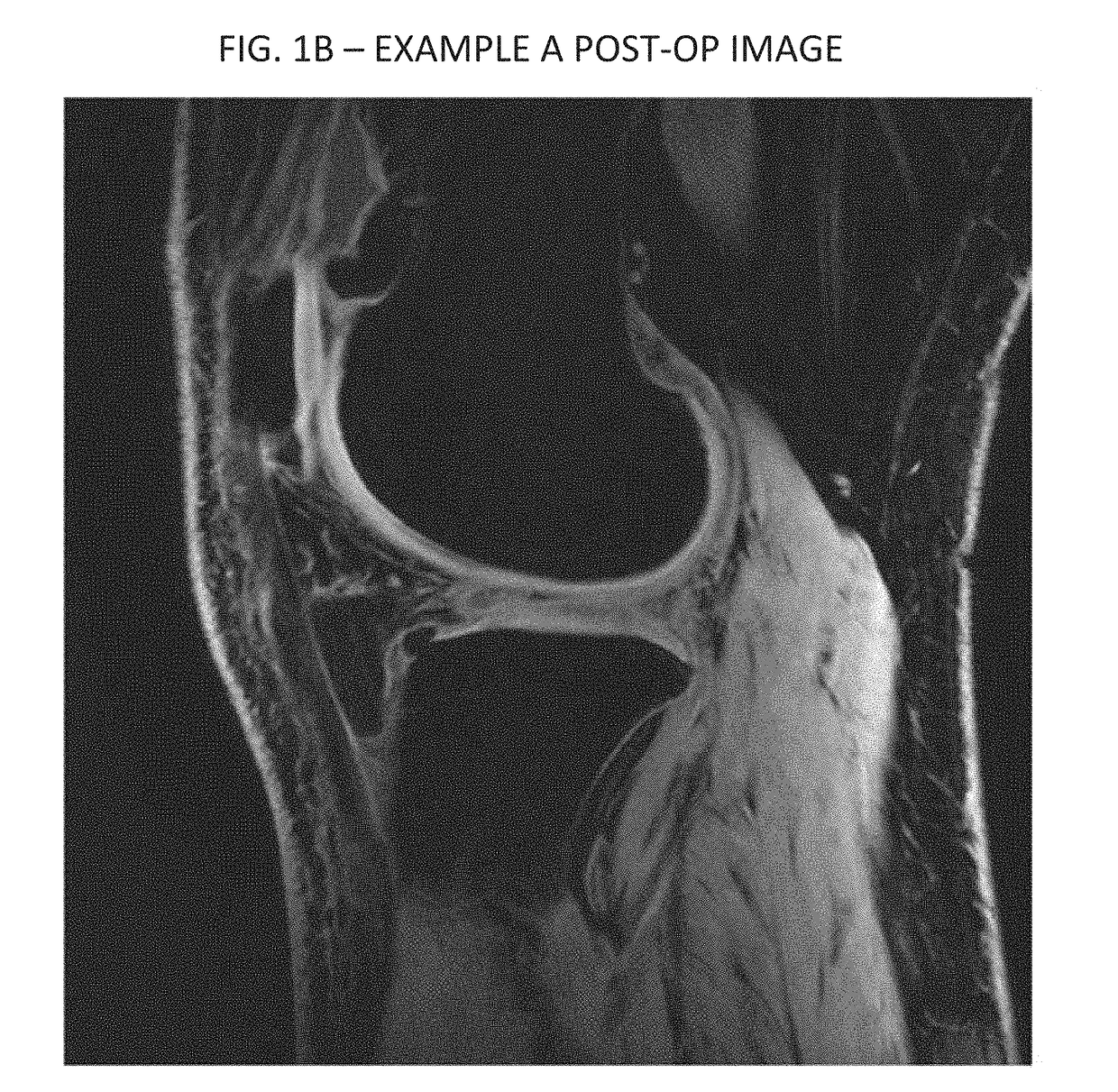

Devices, systems and methods for disc and meniscus repair

InactiveUS20160206300A1Short setting timeLimited accessSurgical adhesivesPharmaceutical delivery mechanismMeniscal repairBioadhesive

Arising from the discovery that a non-immunogenic poly-synthetic bioadhesive based on polyphenolic proteins produced by sandcastle worms (Phragmatopoma californica) may be used to anneal tears of the meniscus and annulus fibroses and repair spinal disc herniations, herein disclosed are suture-less meniscal and disc repair devices, systems and methods that may be implemented least invasively, in fluid filled or dry / semi-dry environments using simple instrumentation and without the need for suturing or the placement of anchors. The present invention is less technically demanding for the practioner and thus expected enhance outcomes and represent a distinct advancement over prior art techniques presently available.

Owner:TENJIN

Welding repair equipment for abrasive disc

InactiveCN107813041AExtended cooldownImprove work efficiencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWater cooling

The invention discloses a grinding disc welding and repairing equipment, which comprises a device main body, welding equipment and a high-frequency welding machine. The welding equipment is arranged on the upper left side of the device main body, the welding equipment is embedded in the device main body, and the left side of the device main body is installed. There are high frequency welding machines. This kind of disc welding repair equipment has a protective cover in the welding torch. The protective cover is made of stainless steel and has the characteristics of pressure resistance and high temperature resistance. During welding, the sparks generated by welding can not splash around and avoid damage to the welding work. There is a high-frequency welding machine on the left side of the welding equipment. The function and use of the high-frequency welding machine are not only for single welding, but also for diathermy, smelting, heat treatment and other processes, so that the grinding disc can be welded and heated for repairing. , There is a water-cooled torch in the welding equipment, which can cool the welded grinding disc, increase the cooling time of the grinding disc, make the grinding disc cool quickly, and improve the work efficiency of the grinding disc welding repair.

Owner:WUXI WEI KELAI TECH CO LTD

Cartilage repair, preservation and growth by stimulation of bone-chondral interphase and delivery system and methods therefor

ActiveUS9827010B2Speed up the repair processEasy to manufactureSurgical needlesMedical devicesMedicineCartilage repair

Therapeutics and methods of treatment to repair, preserve and grow cartilage are presented. In addition, systems and methods for delivering a therapeutic to a hard to reach anatomical area, such as, for example, the BCI, are presented. A cannulated delivery device provided with a cutting tip, cutting flutes and threads on its distal end is disclosed, as well as therapies for joint and cartilage repair, preservation and generation using it. Alternatively, for disc repair, a “PIARES” device for Percutaneous Intradiscal Annular Repair introduces therapeutics intradiscally. The device may have two-needles; a first cannula / needle with a finger grip, and a longer inner needle to penetrate through the outer needle into the disc, and introduce therapeutics via a syringe. When provided with a septum at the inner needle's proximal end, the PIARES device is a completely closed system; using it minimizes trauma.

Owner:VAD SCI

Build-up welding repair process of disc shear blade and repaired disc shear blade thereby

InactiveCN100400219CGuaranteed use strengthHigh hardnessArc welding apparatusShearing machinesCircular discEngineering

Owner:桂林航天工业高等专科学校

Cartilage repair, preservation and growth by stimulation of bone-chondral interface and delivery system and methods therefor

InactiveUS20180317962A1Preserve and grow cartilageEasy to manufactureSurgical needlesMedical devicesFluteIntervertebral disc

Therapeutics and methods of treatment to repair, preserve and grow cartilage are presented. In addition, systems and methods for delivering a therapeutic to a hard to reach anatomical area, such as, for example, the BCI, are presented. A cannulated delivery device provided with a cutting tip, cutting flutes and threads on its distal end can be provided. Using such an exemplary device, various novel therapies for joint and cartilage repair, preservation and generation can be implemented. Alternatively, for disc repair, a delivery device directed to percutaneous intradiscal annular repair, or “PIARES” device can be used to introduce therapeutics intradiscally. The device may have two-needles, with a first cannula / needle, with a finger grip at its distal end, and a longer inner needle to penetrate through the outer needle into the disc, and introduce therapeutics, for example, via a syringe. When provided with a septum at the inner needle's proximal end, the PIARES device is a completely closed system, and its use minimizes trauma.

Owner:VAD SCI

Fan brake disc in-cabin repairing method and structure

The invention relates to the technical field of brake disc repair, and discloses a fan brake disc in-cabin repair method and a fan brake disc in-cabin repair structure, the specific size of a damaged part is obtained by entering a site for scribing and surveying and mapping, and the size of a panel is determined according to the specific size of the damaged part; the panels are designed according to panel size data determined on site, and the shapes, threaded holes, pin holes and grooves of the panels are machined; the brake disc enters the site again, the damaged part of the original damaged brake disc is marked according to the size and appearance of the panel, and cutting, plane machining, groove machining and detection are conducted according to the marked part; a panel, a bolt, a pin and a welding assisting mode are adopted for repairing, namely, a main rigid body framework is constructed by adopting the shearing resistance and the tensile resistance of the pin and the high-strength bolt and local friction force formed by the clamping force of the high-strength bolt, a welding seam strength assisting mode is adopted, Q345 is selected as the panel material, the tensile strength is 490 MPA to 62OMPA, the tensile strength meets or even exceeds the tensile strength of base metal, and the service life of the panel is prolonged. The toughness is far better than that of base metal.

Owner:湖南高创新能源智慧运维有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com