Copper disc for sapphire polishing and disc repair method thereof

A technology of sapphire and copper discs, which is applied in the direction of cutting tools for lathes, turning equipment, drilling/drilling equipment, etc., can solve the problems of long working hours, affecting the production efficiency of production enterprises, and high labor intensity, so as to improve Production efficiency, avoiding fast intermediate wear, and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

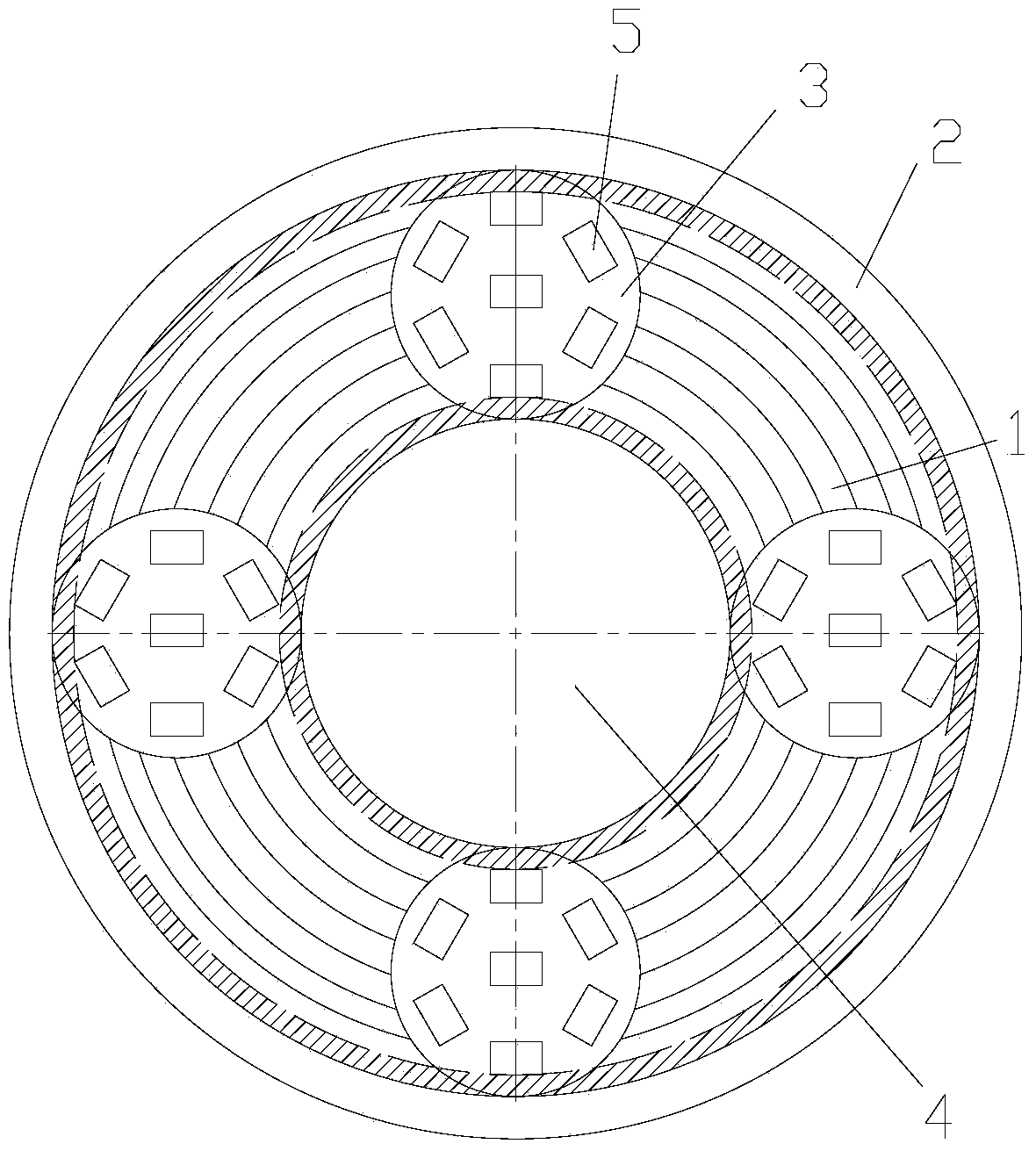

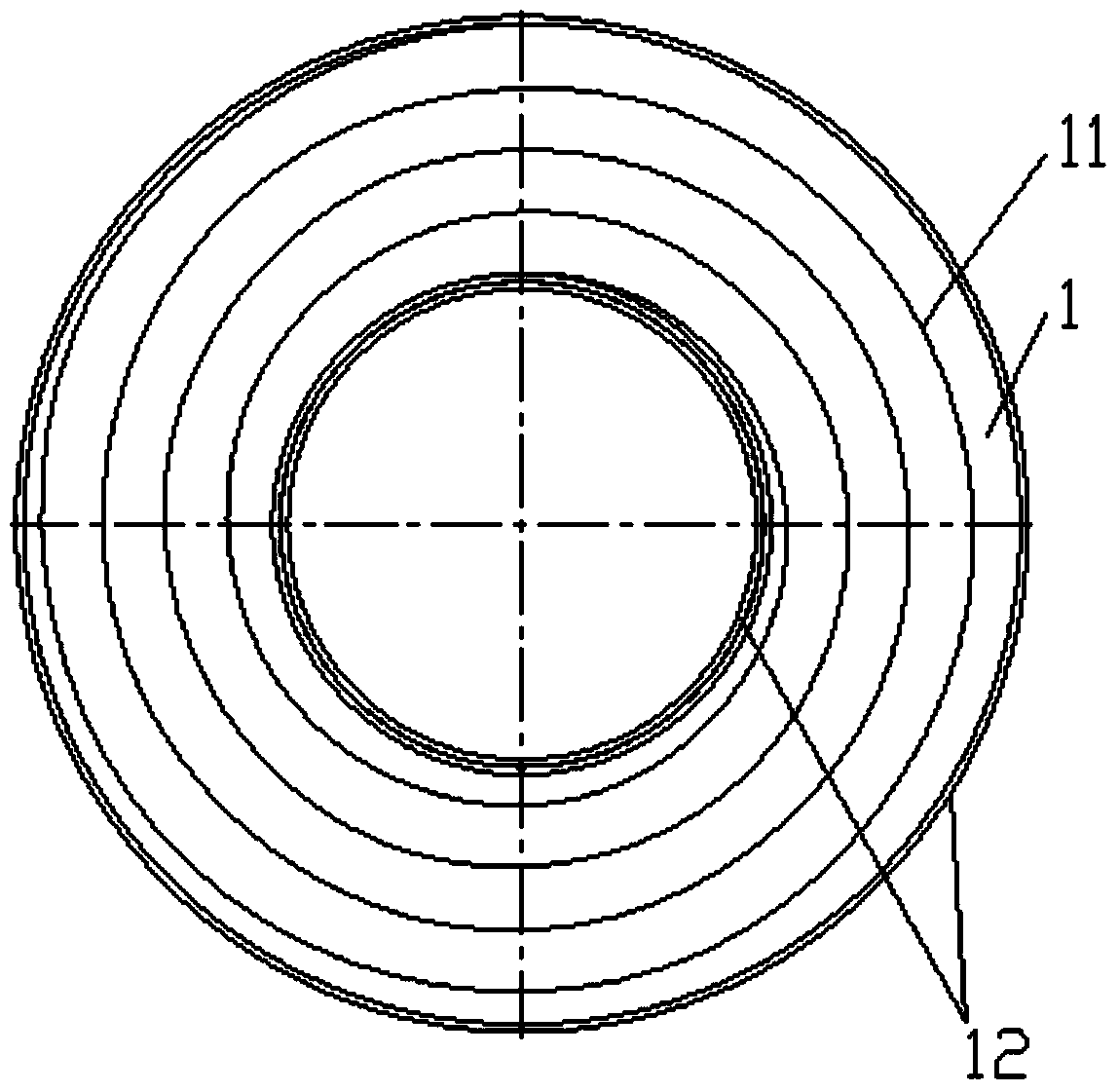

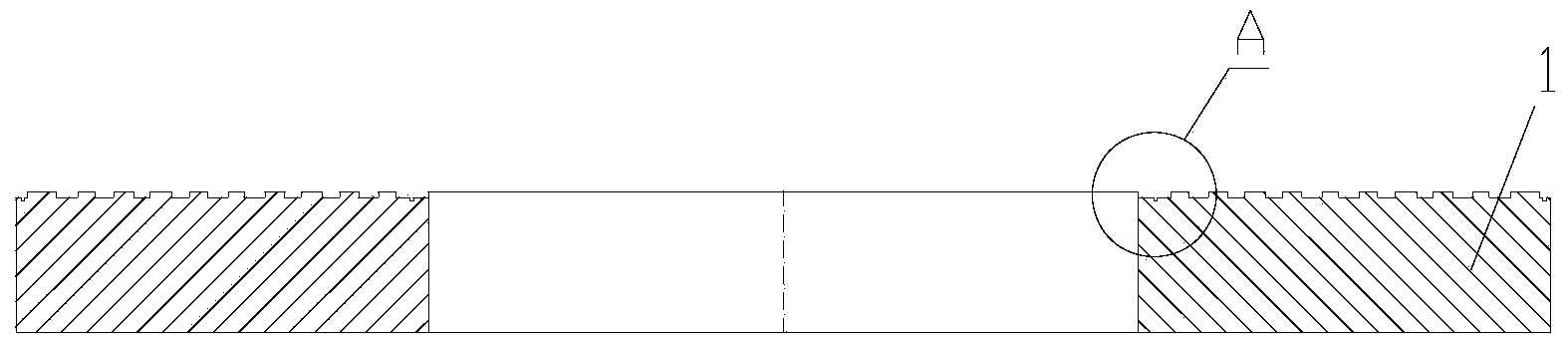

[0027] see Figure 2 to Figure 4 , The annular surface of the copper disc 1 in the figure is provided with a spiral grinding groove 11, and a stepped groove 12 is provided along the annular outer ring and the inner ring of the copper disc 1. In addition, the grinding groove 11 can also be arranged in the form of concentric circles, and both can be processed by turning. Wherein the depth of the grinding groove 11 is: 0.25-0.35mm, and the spacing of the grinding groove is: 1.2-1.4mm (attached figure 2 The spiral shape is highlighted in the middle, which is only a schematic diagram and does not represent a specific size requirement).

[0028] specific combination figure 1 For the positional relationship of the middle star wheel, the width of the step groove 12 should not be less than the minimum distance from the edge of the star wheel cavity placed on the copper plate 1 to the outer edge of the copper plate, so as to ensure that all the grinding groove areas on the copper pla...

Embodiment 2

[0031] Copper dish 1 among the embodiment 1 is applied in Figure 5 The shown double-sided copper disc polishing machine includes an upper copper disc 1' and a lower copper disc 1 that rotate in opposite directions. The upper copper disc 1' is set on the lower copper disc 1 through a lifting arm 8, and the upper copper disc 1' On the boom 8 on one side, a lower turning tool 7 facing downward is fixed, and on the opposite side of the lower copper plate 1, an upper turning tool 9 is fixed; specifically, the lower copper plate 1 and the upper turning tool 9 A mounting seat is arranged on the transverse guide rail 6 on the double-sided copper disc polishing machine, and the lower copper disc 1 and the upper disc turning tool 9 are moved and fed along the transverse guide rail 6 through motor drive, wherein the upper disc turning tool 9 and the lower disc turning tool 9 Turning knife 7 is arranged laterally along the guide rail direction, and the distance from lower turning knife 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com