Fan brake disc in-cabin repairing method and structure

A repair method and brake disc technology, applied in the direction of climate sustainability, sustainable building, renewable energy integration, etc., can solve problems such as poor weldability, low strength, and complicated welding process, and achieve the effect of excellent toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

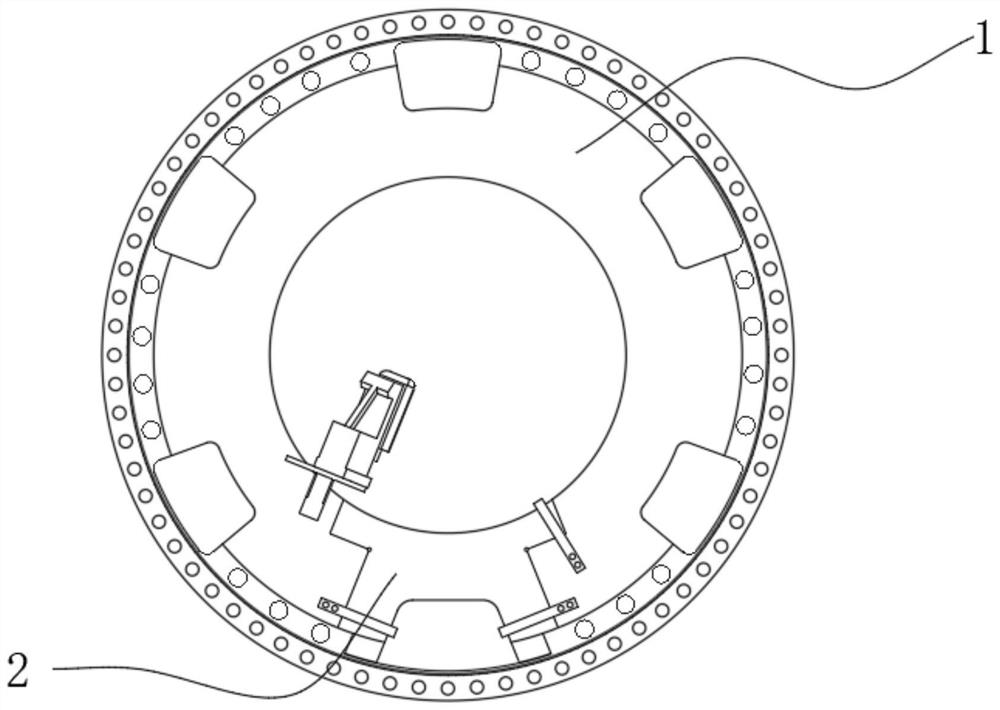

[0037] A method for repairing a fan brake disc cabin, comprising the following steps:

[0038] S1: Enter the site to carry out marking and mapping, get the specific size of the damaged part, and determine the size of the panel according to the specific size of the damaged part;

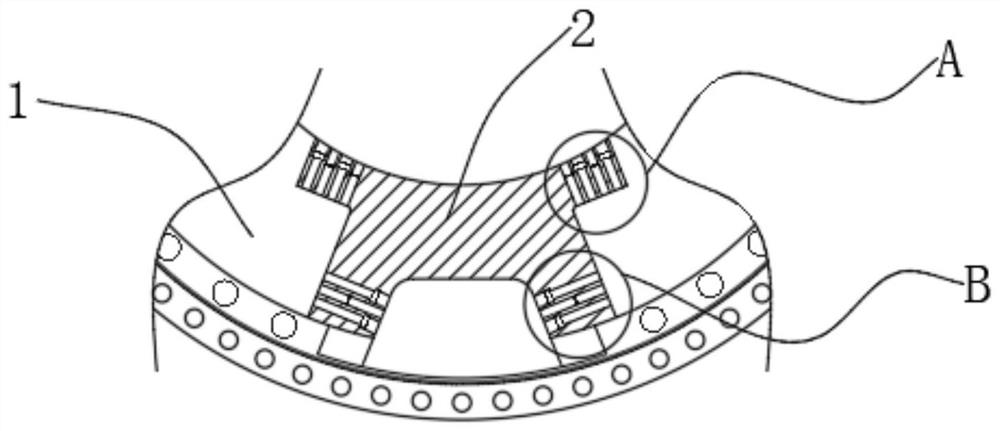

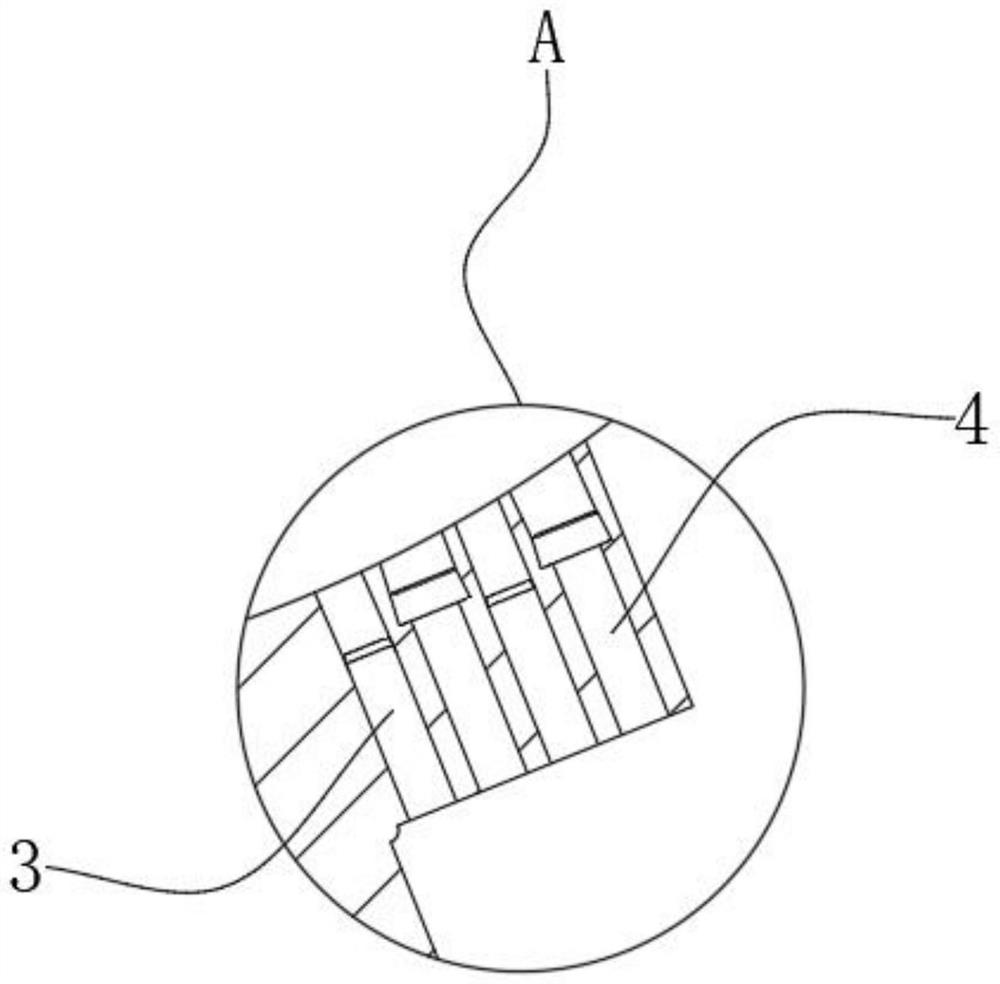

[0039] S2: Design the panel according to the panel size data determined on site, and process the shape, threaded hole, pin hole and groove of the panel;

[0040] S3: Enter the site again, draw a line on the damaged part of the original damaged brake disc according to the size and shape of the panel, and perform cutting, plane processing, bevel processing and inspection according to the drawn part to ensure the panel and the brake disc. The flatness and verticality of the base metal butt joint, and ensure that the mating state is transition fit after the panel is inserted into the base material of the brake disc;

[0041] S4: Use a fixture to fix and position the panel and the base material of the bra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com