Patents

Literature

41 results about "Diathermy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Diathermy is electrically induced heat or the use of high-frequency electromagnetic currents as a form of physical therapy and in surgical procedures. The earliest observations on the reactions of high-frequency electromagnetic currents upon the human organism were made by Jacques Arsene d'Arsonval. The field was pioneered in 1907 by German physician Karl Franz Nagelschmidt, who coined the term diathermy from the Greek words dia and θέρμη therma, literally meaning "heating through" (adj., diather´mal, diather´mic).

Methods and apparatus for utilizing radio frequency spectrum simultaneously and concurrently in the presence of co-channel and/or adjacent channel television signals by adjusting transmitter power or receiver sensitivity

InactiveUS7013145B1Reduce distractionsReduce the required powerTelevision system detailsBroadcast-related systemsUltra-widebandFrequency spectrum

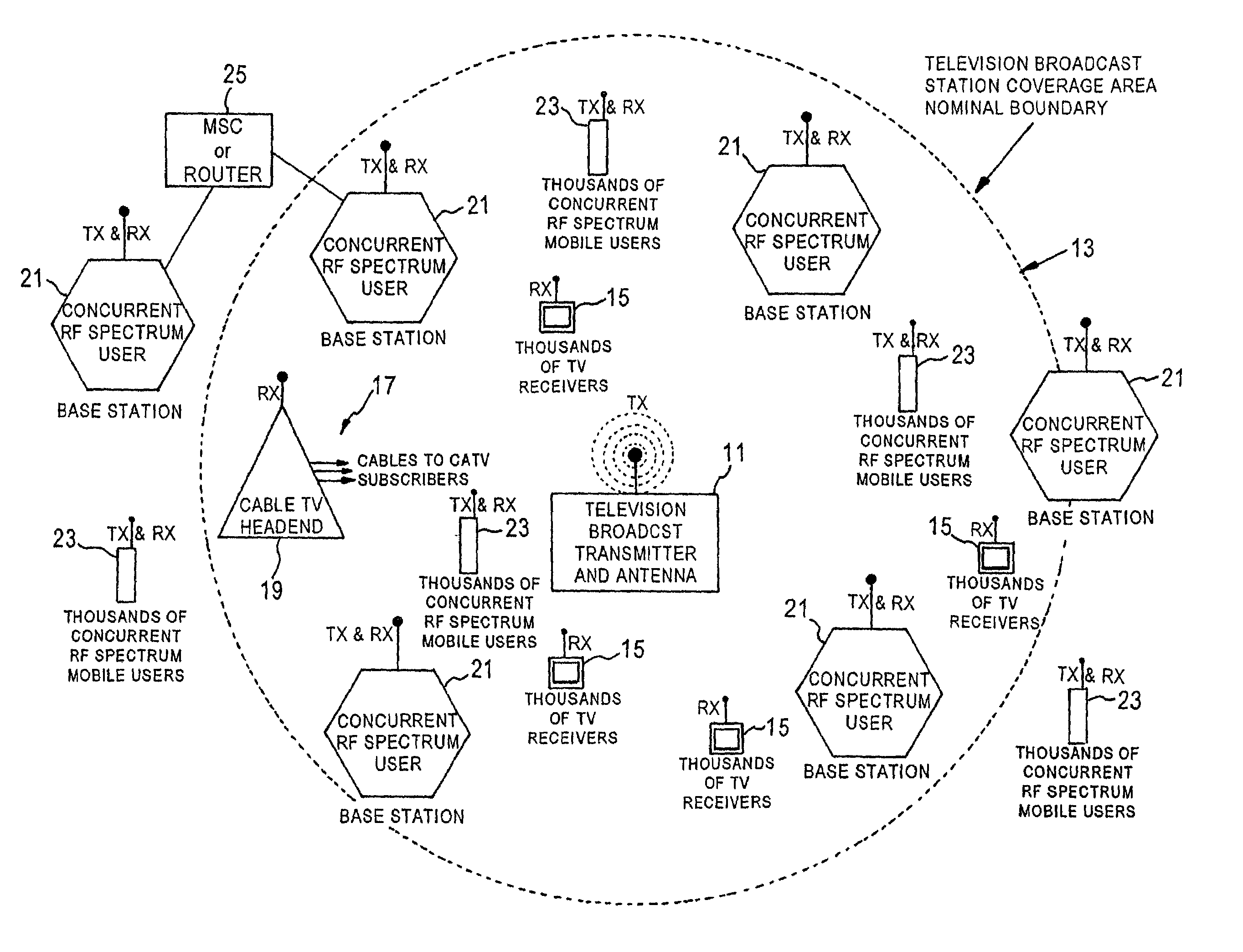

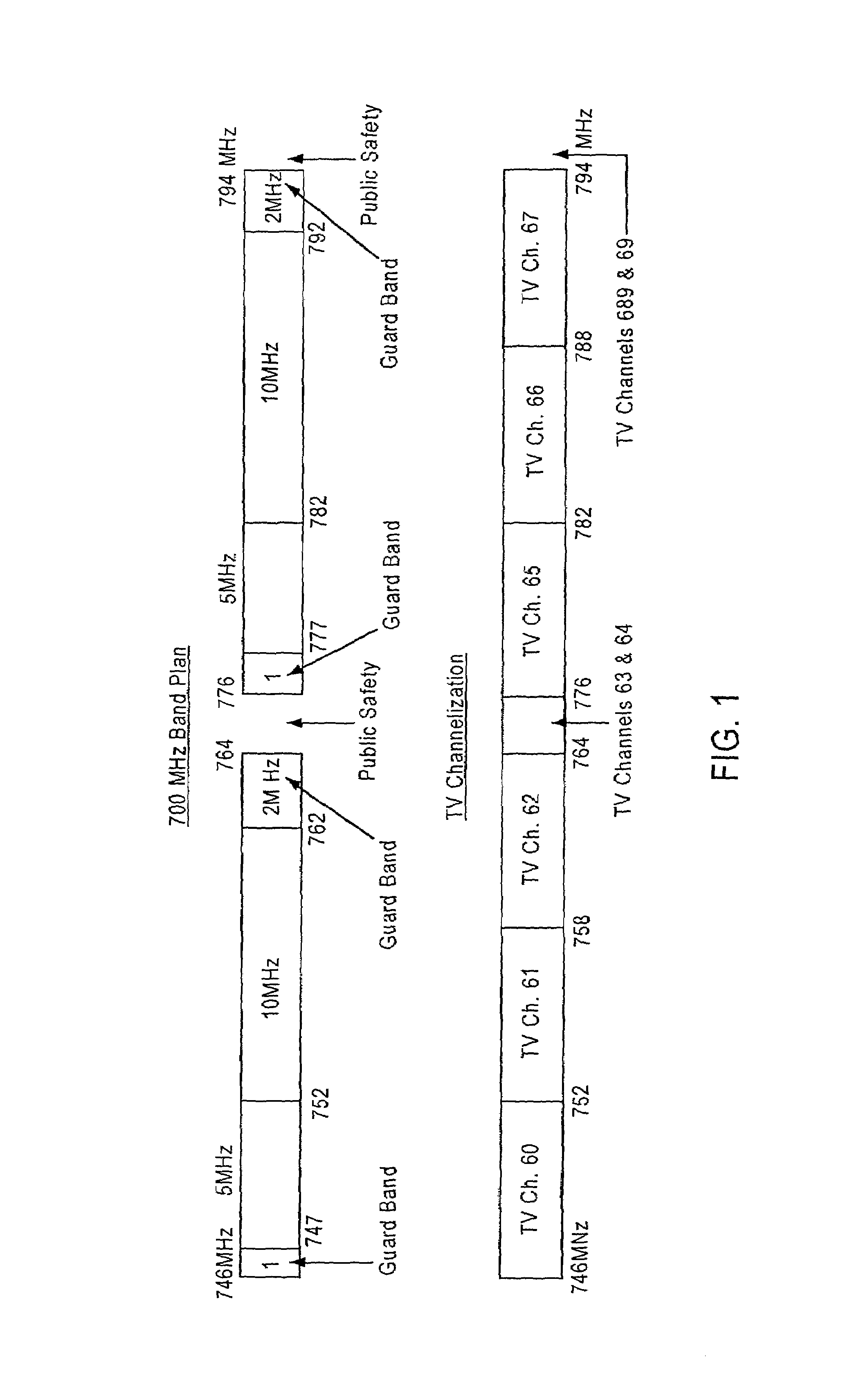

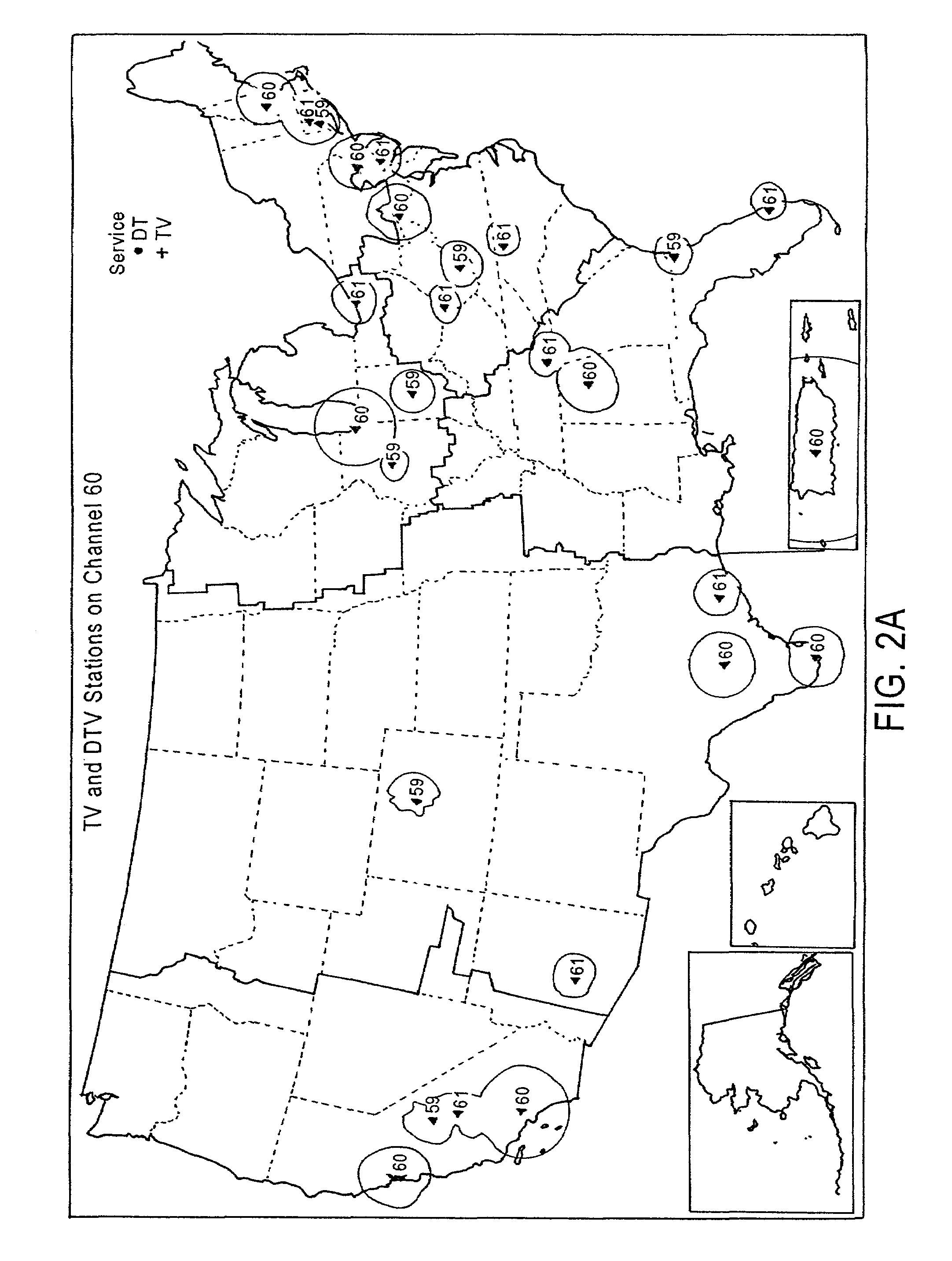

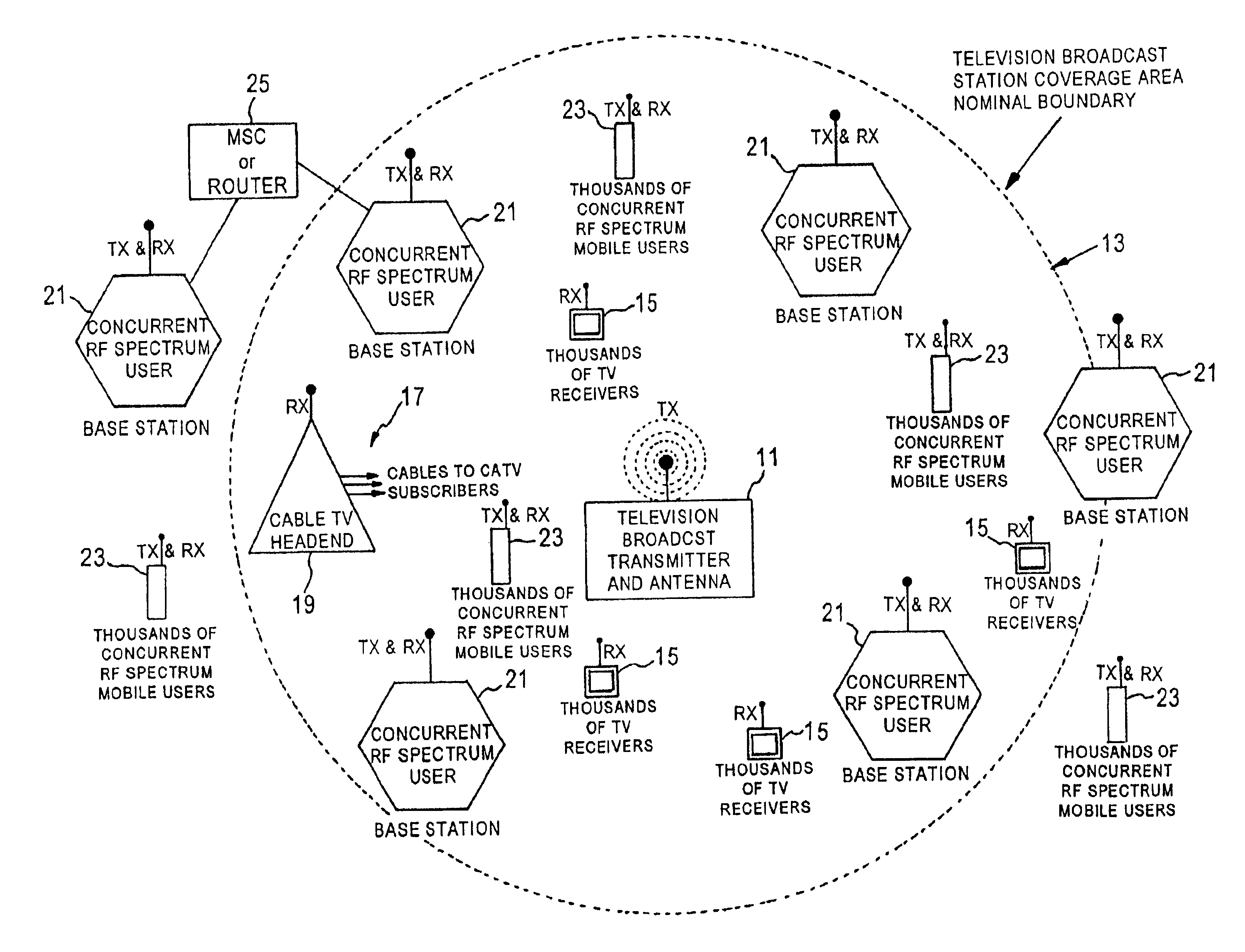

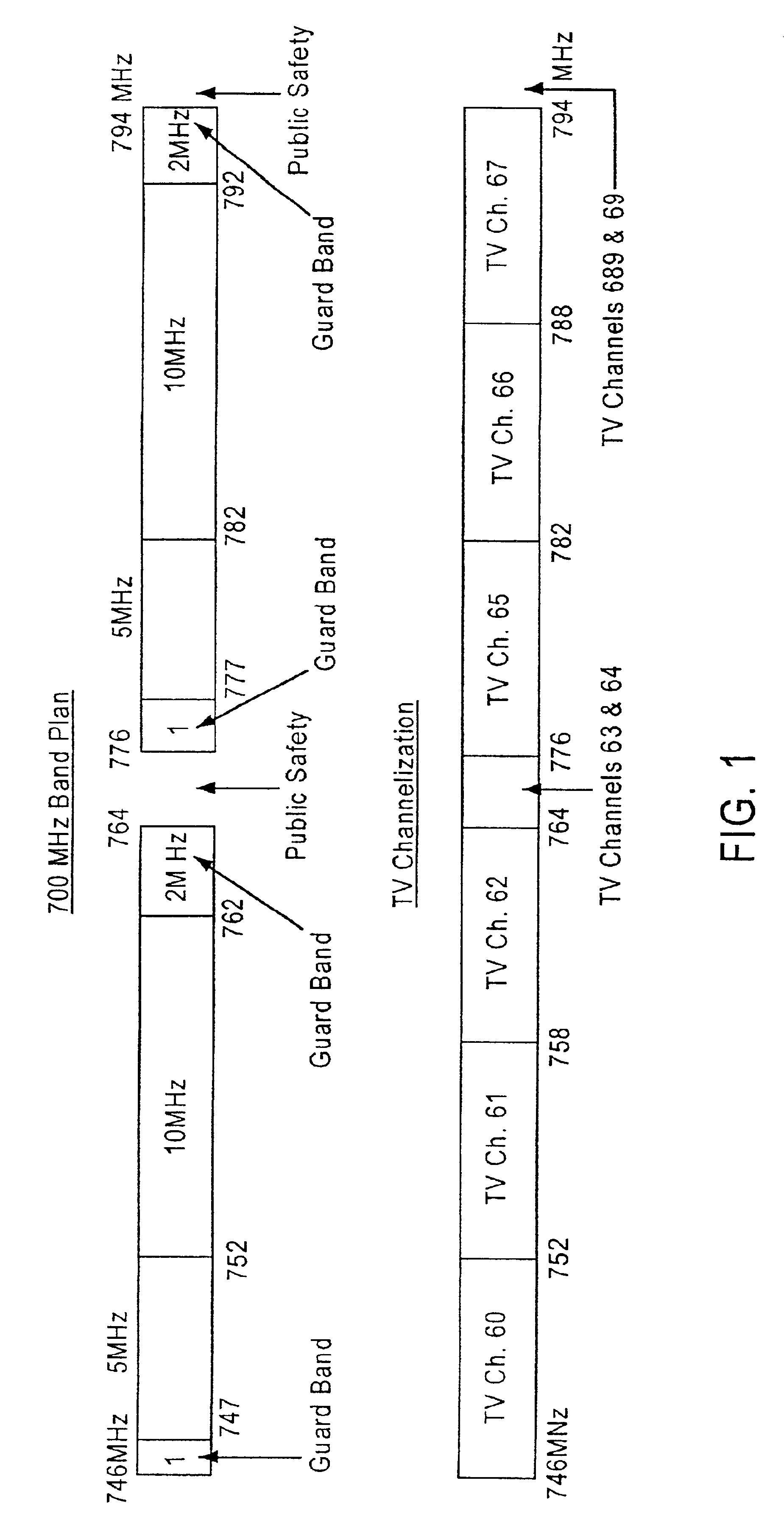

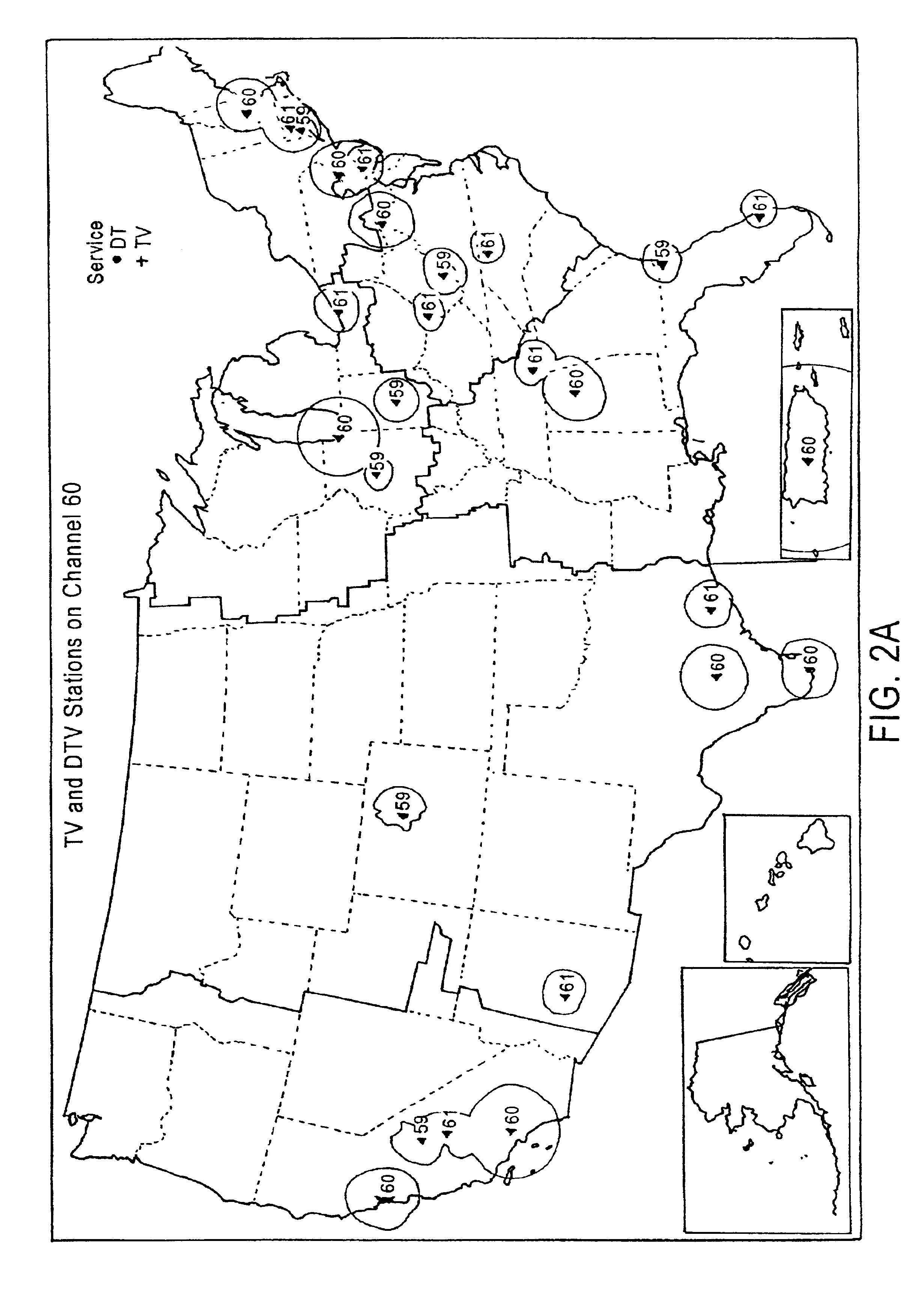

To address the scarcity of radio frequency (RF) spectrum, the disclosed systems offer unique ways to mitigate interference between television broadcasters (including their direct audience and viewers served via cable television) and other concurrent users of the RF spectrum, e.g. for one-way or two-way wireless communication. A preferred embodiment makes use of the “framing” characteristics of the “letterbox” video display format. RF emissions of the simultaneous RF spectrum user are keyed “on” only or substantially only during the time intervals when the blanking intervals and / or letterbox-border video lines are being scanned on the display, i.e. when the potentially affected (interfered with) television display is in the letterbox-frame-scanning portions of each video field. The concurrent uses may support services for voice (including telephony, music etc.), data (including Internet, intranet, etc.); image or control; fixed, portable, mobile or nomadic; narrowband, broadband or ultra-wideband; radiodetermination, diathermy, etc. Additionally, the concurrent user's emitted power and receiver sensitivity is continuously adjusted according to the broadcast television signal.

Owner:CELLCO PARTNERSHIP INC

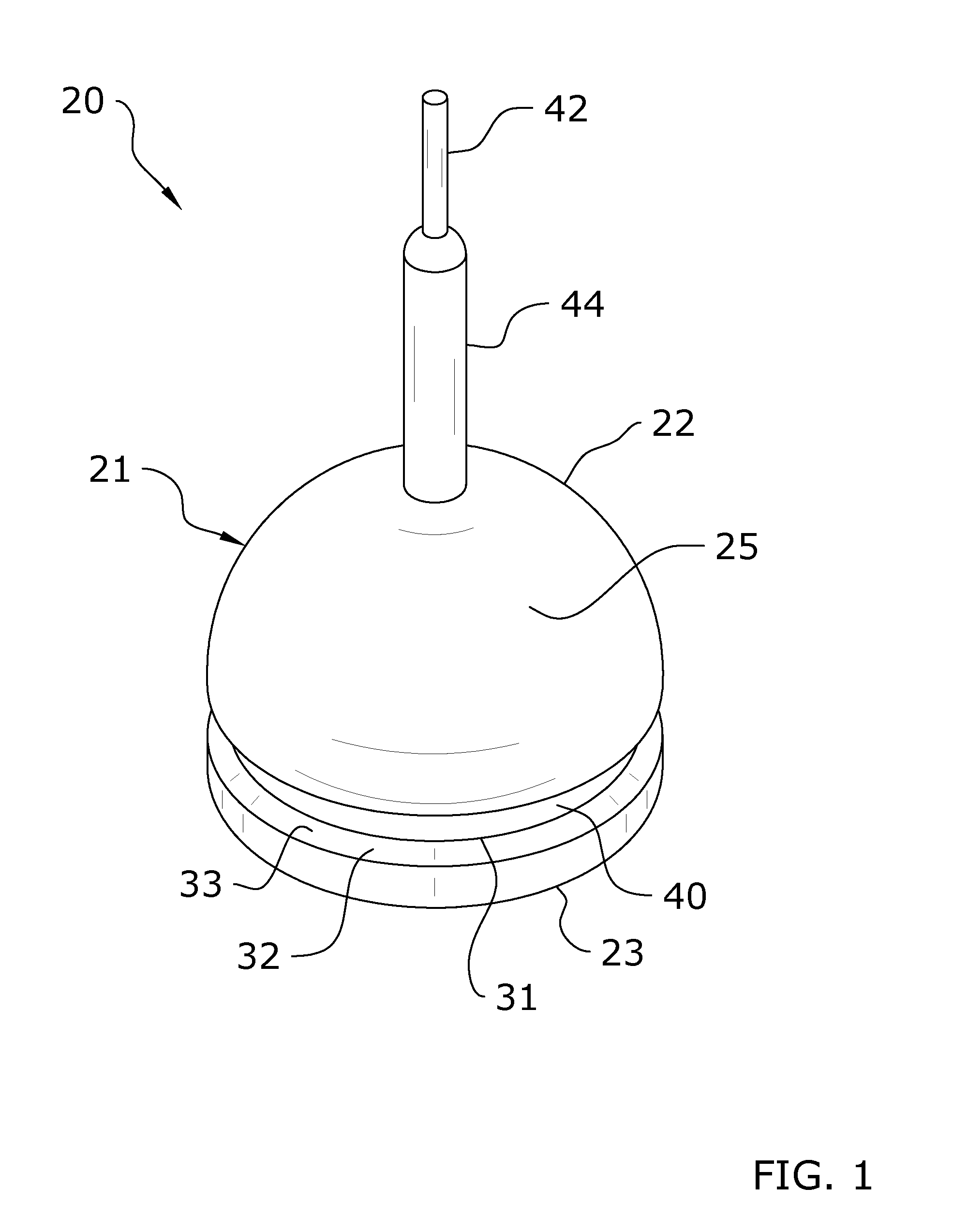

Esthetic device

InactiveUS20130238061A1Smooth connectionUltrasound therapyElectrotherapyCosmetic appearanceBiomedical engineering

means for performing tissue diathermy. The combination of techniques provides a synergistic improvement of the cosmetic appearance of the skin.

Owner:VENUS CONCEPT

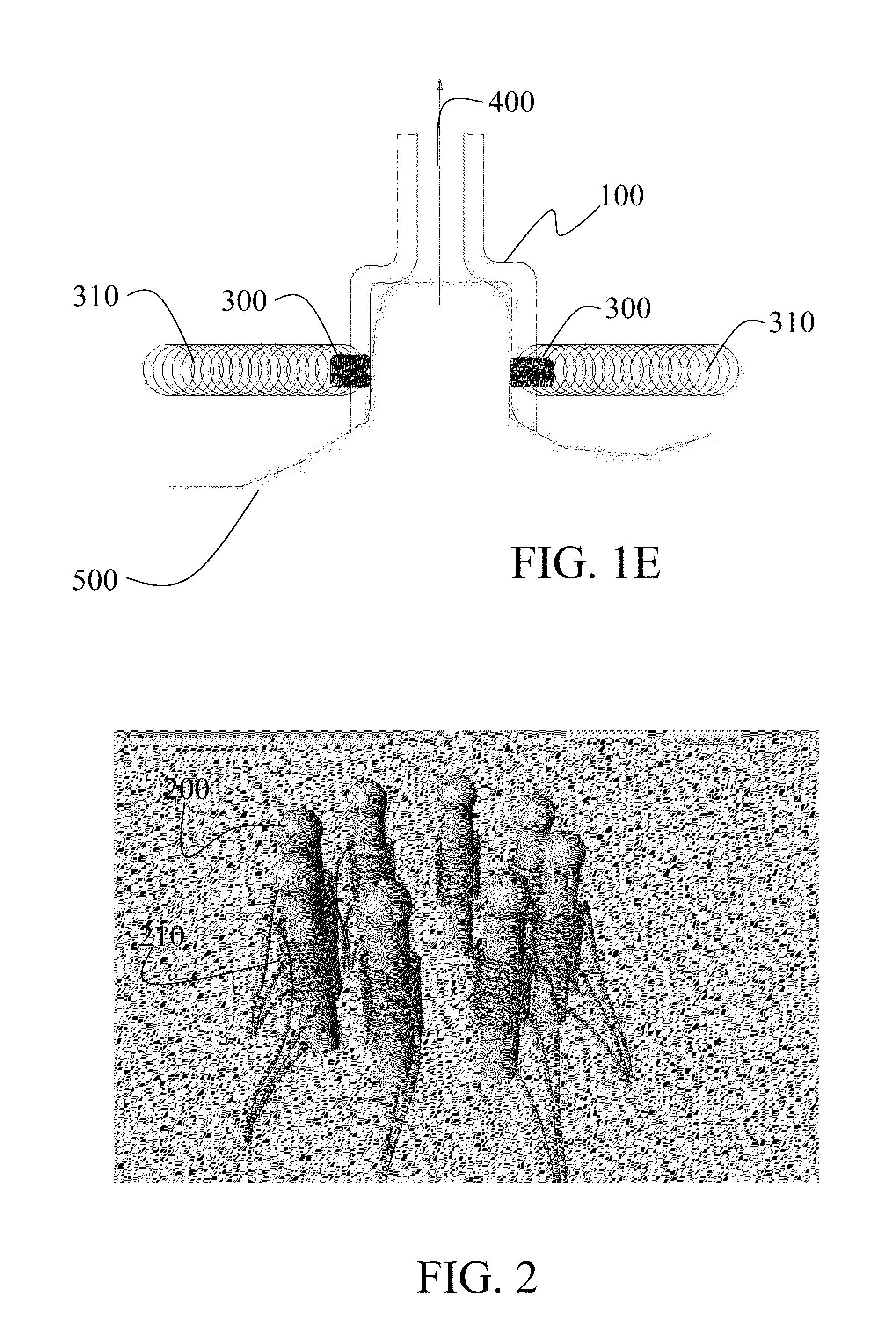

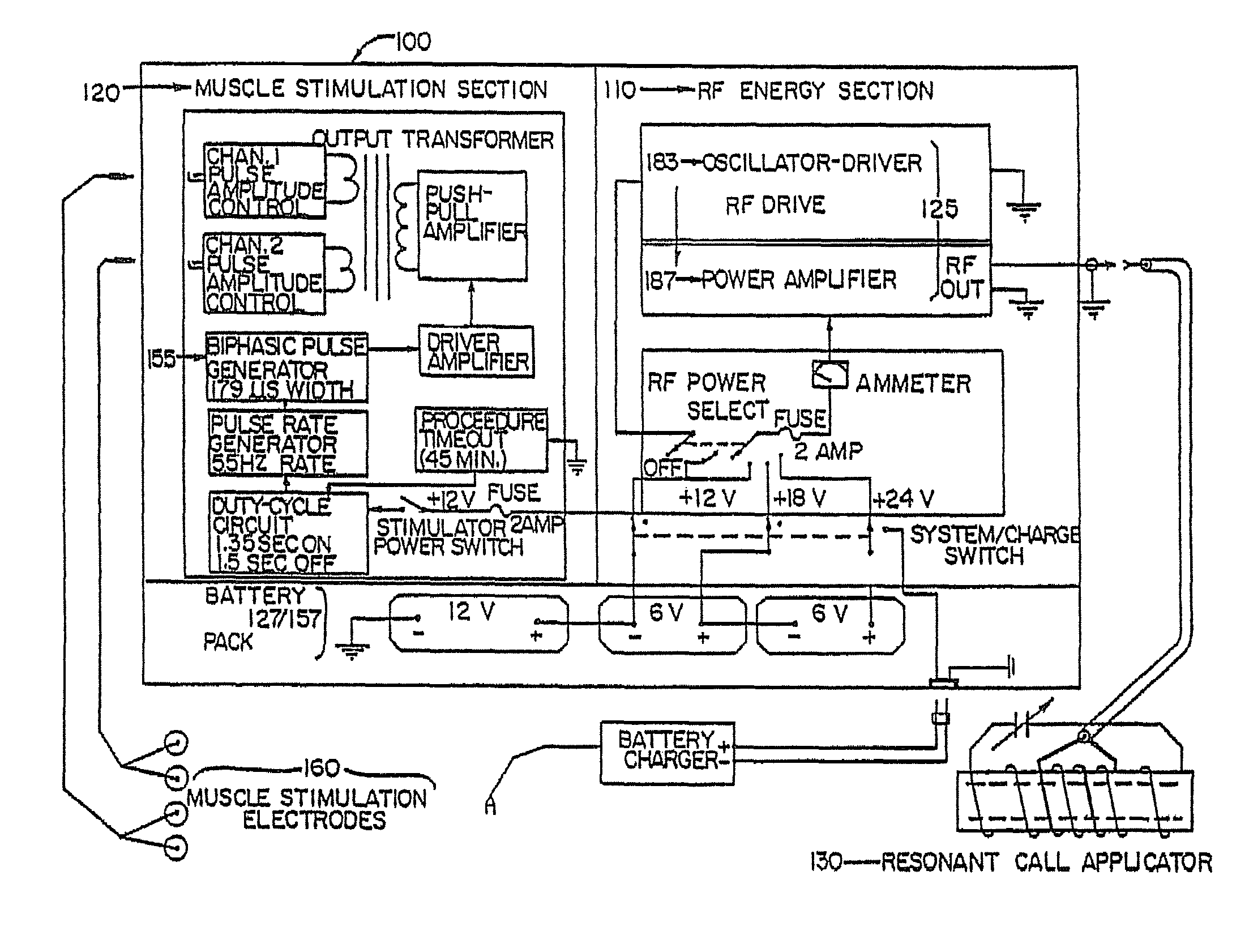

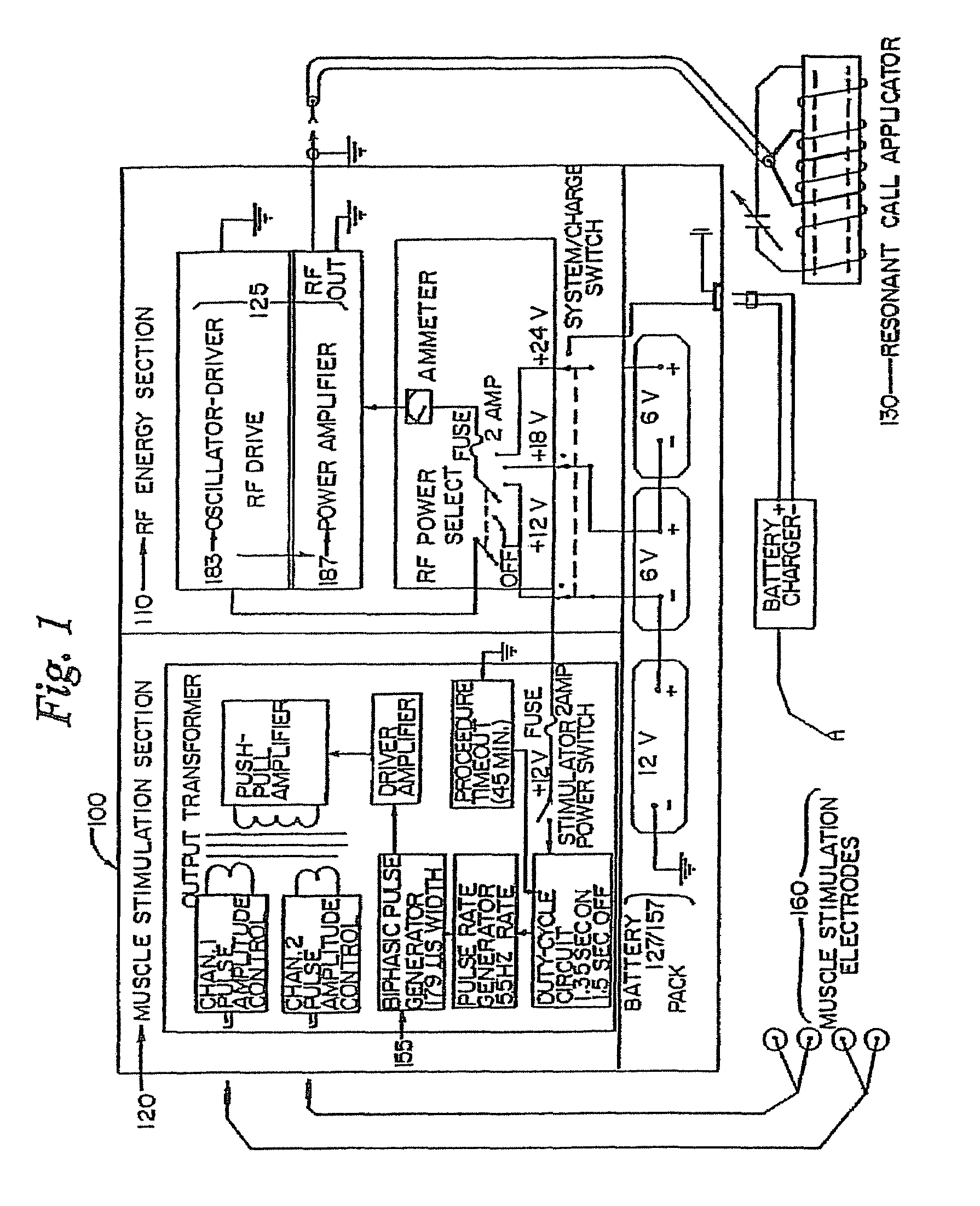

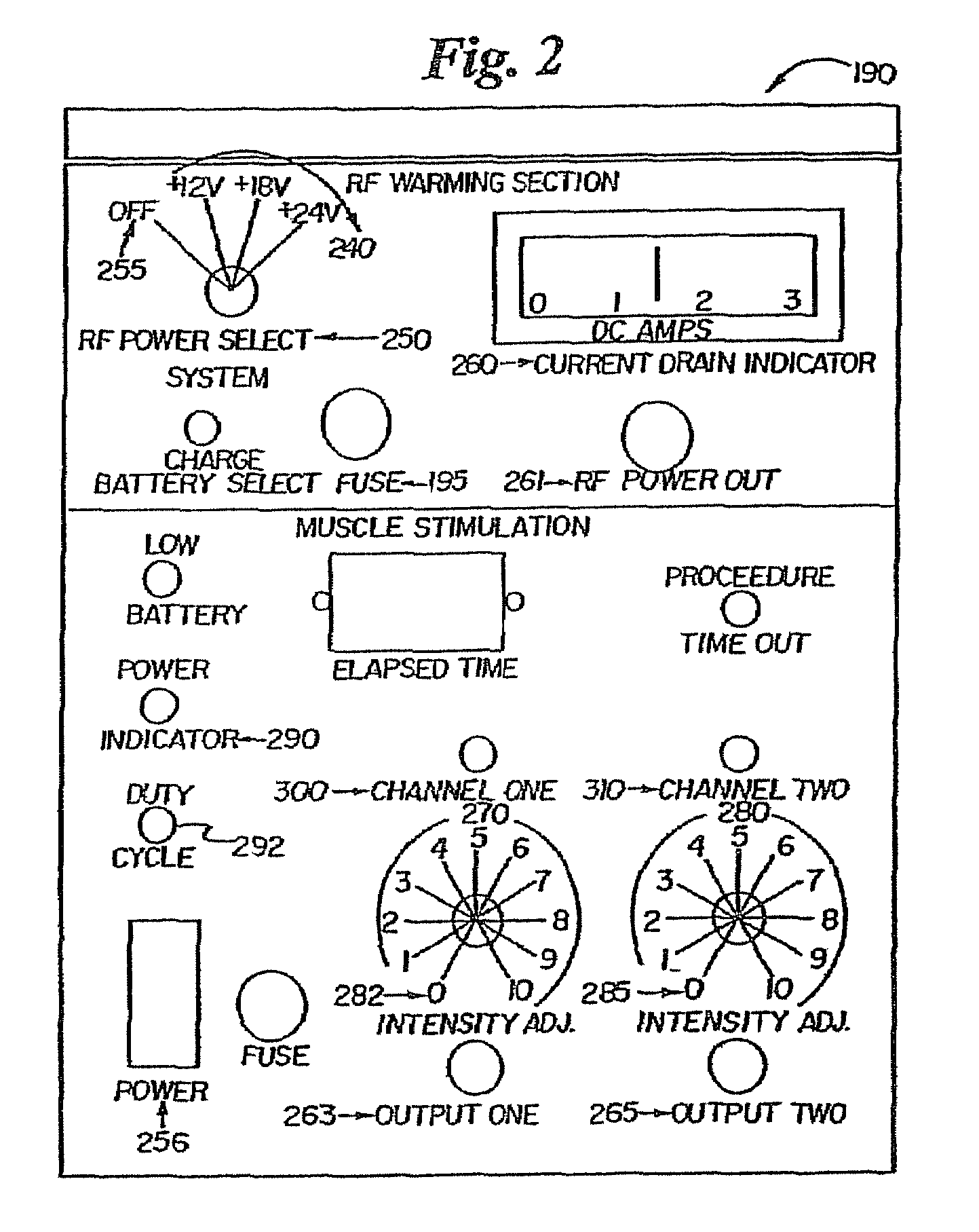

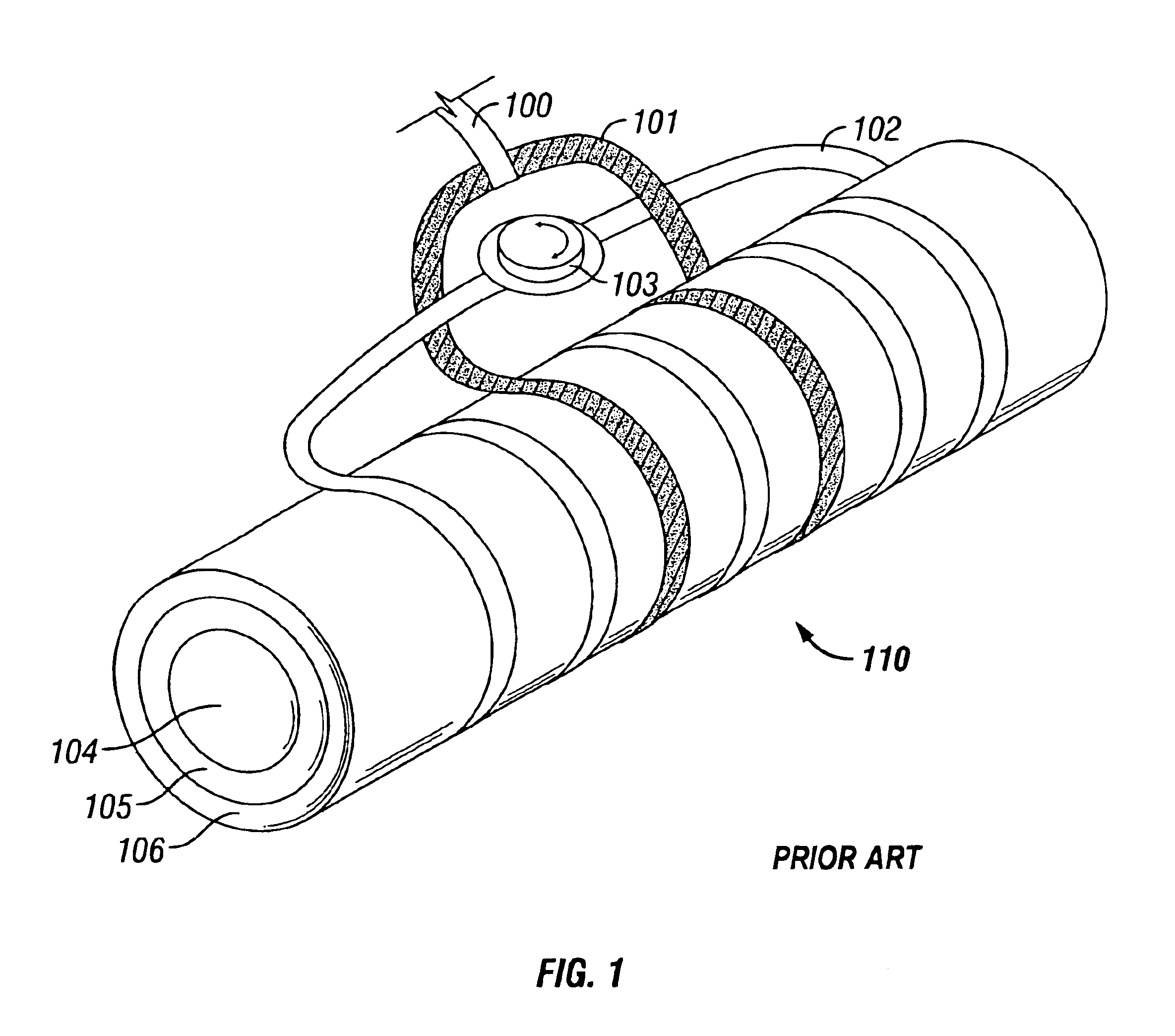

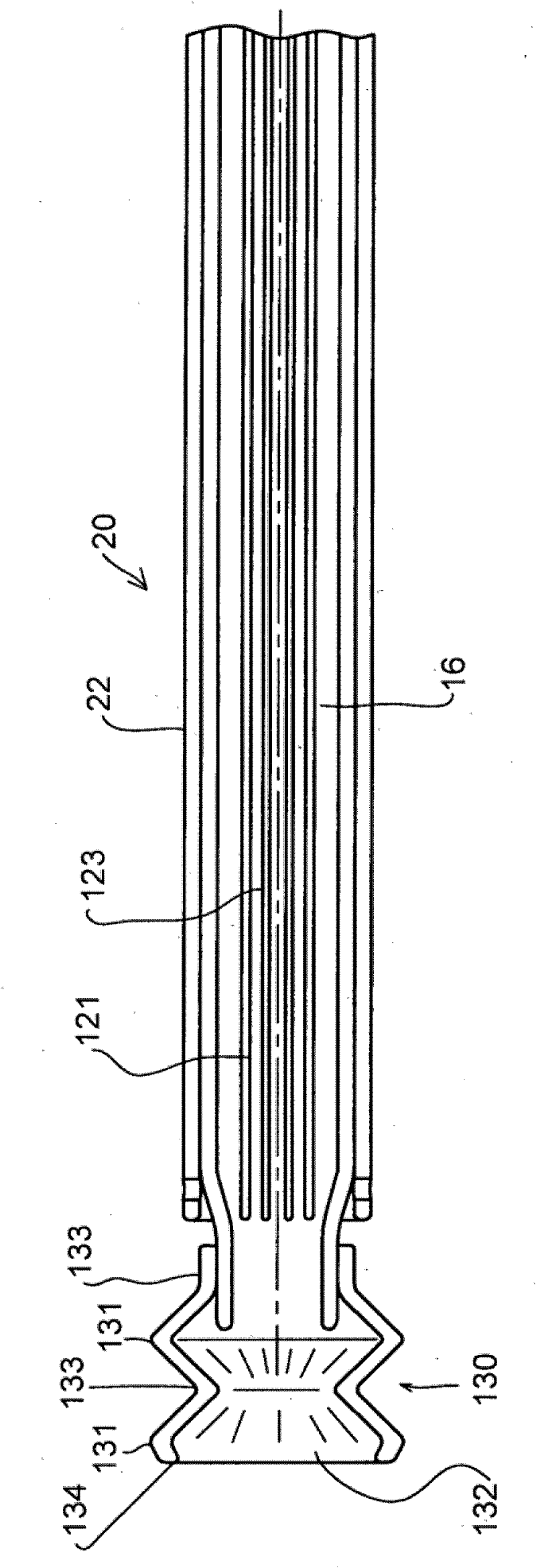

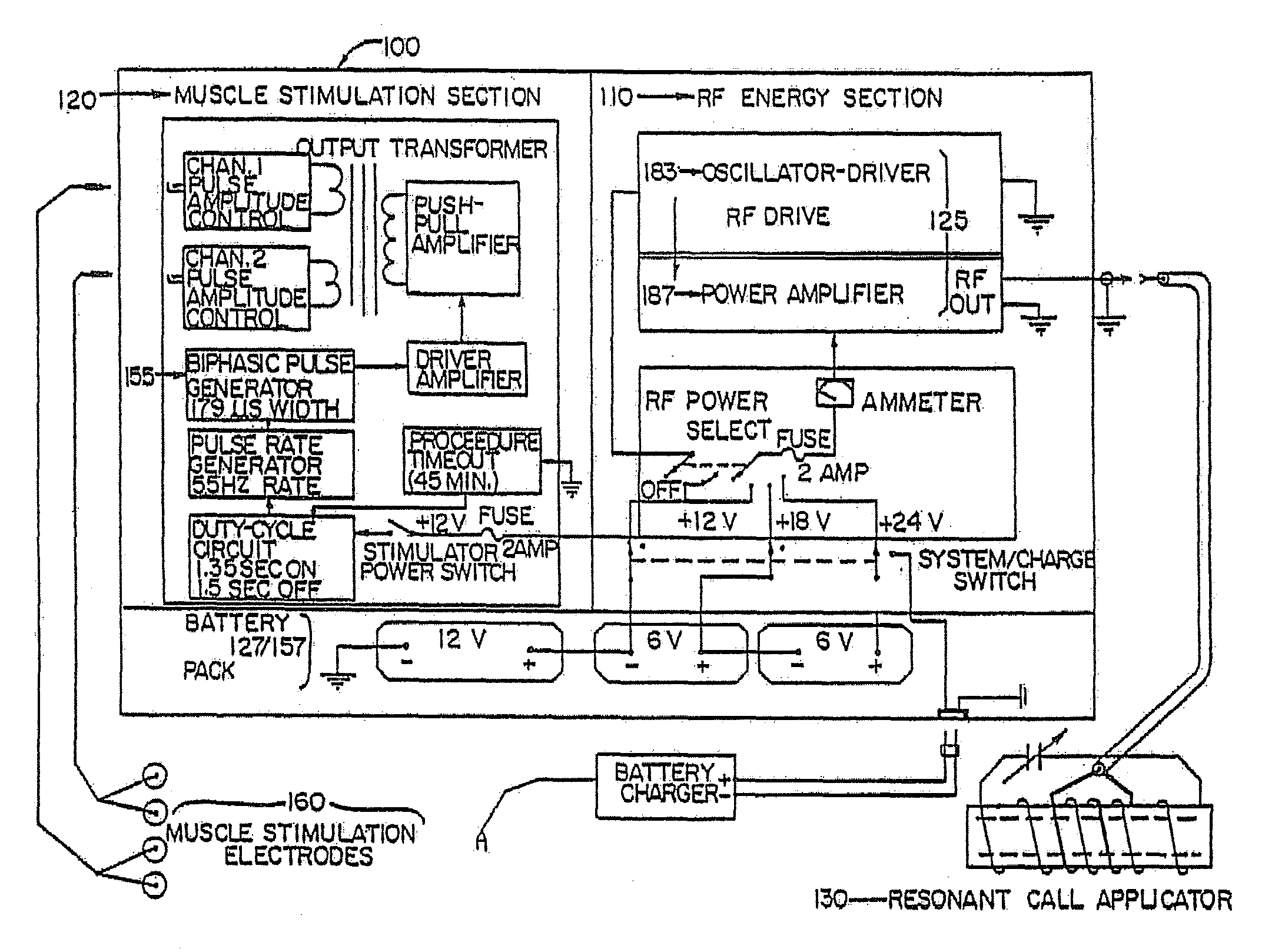

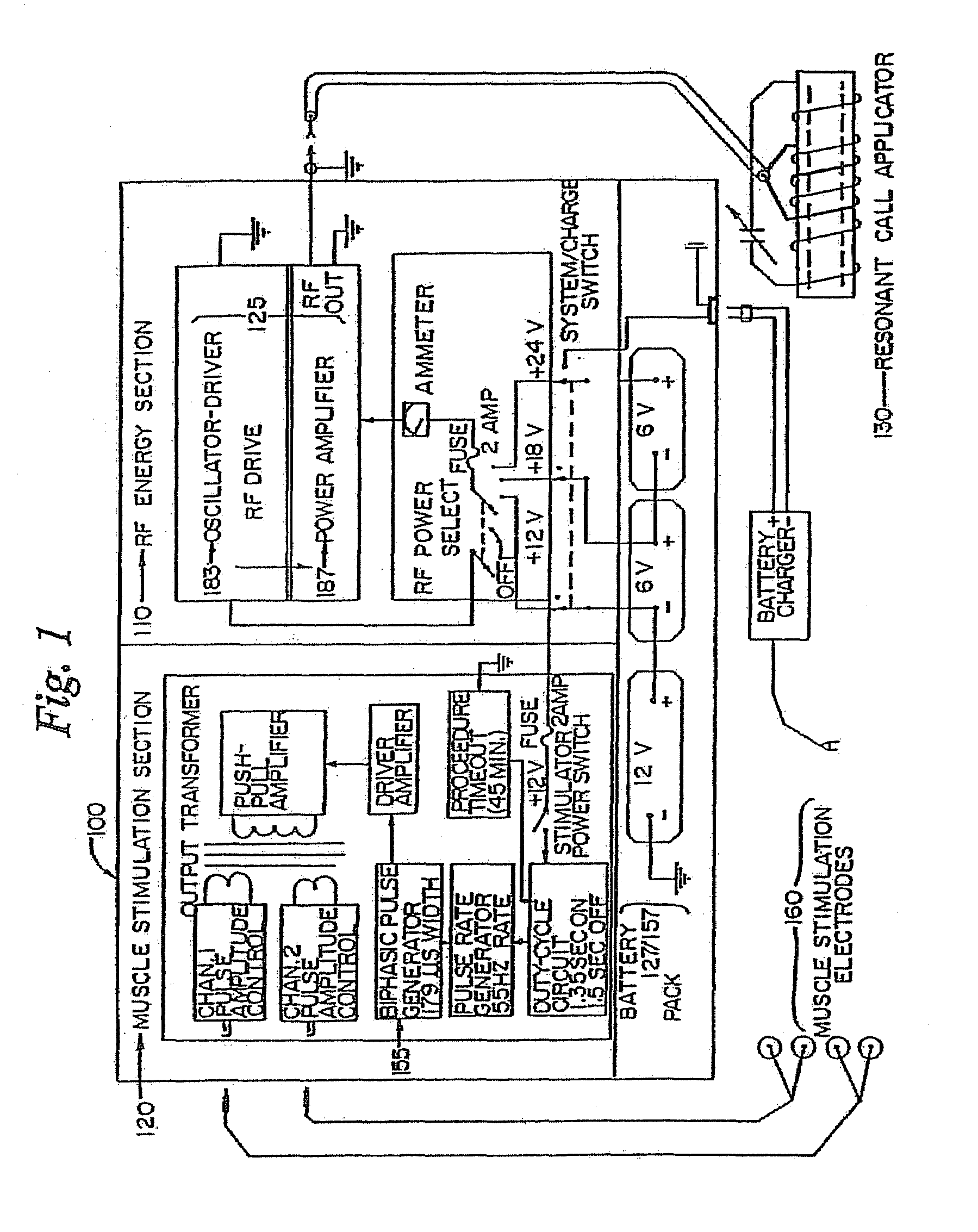

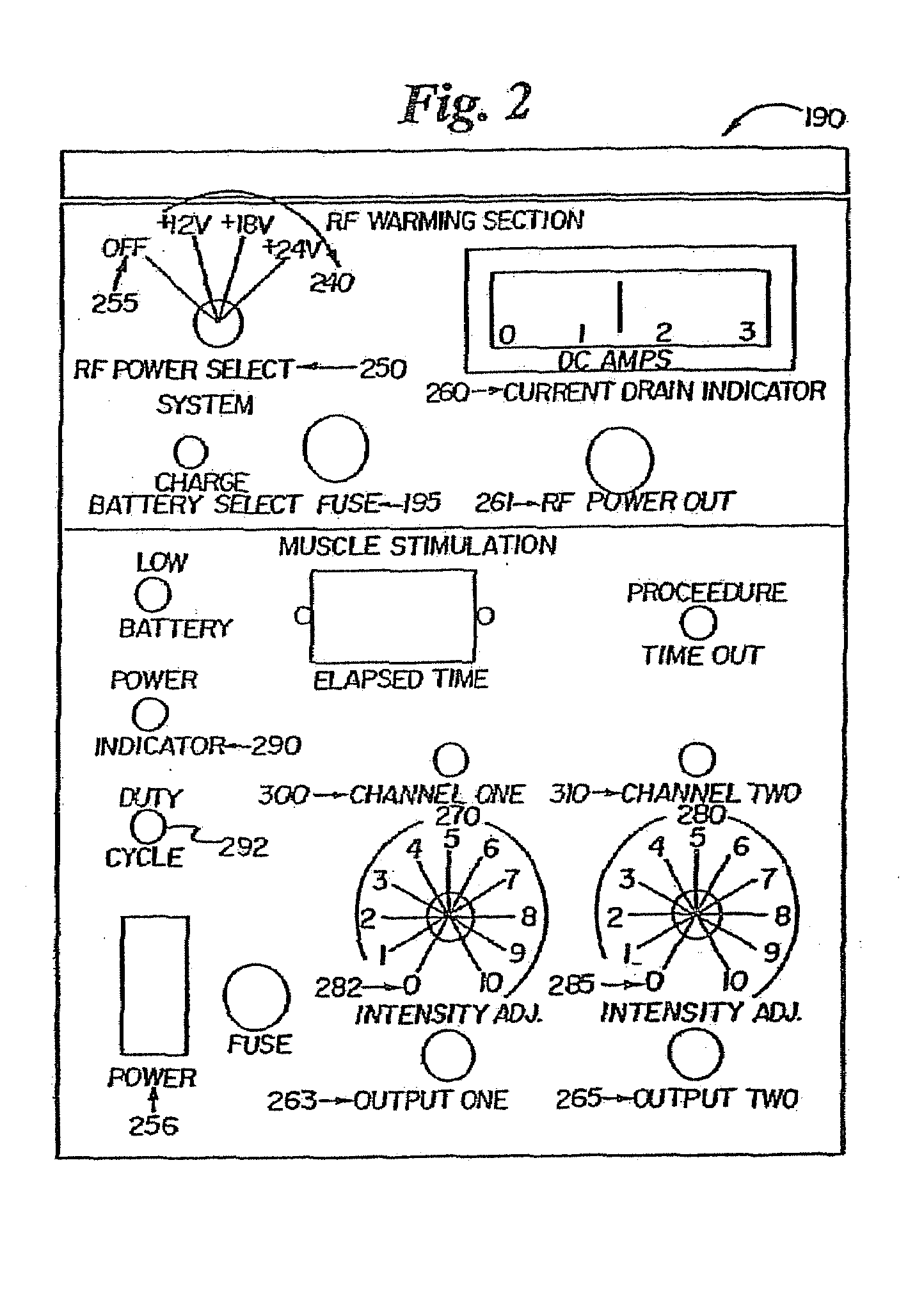

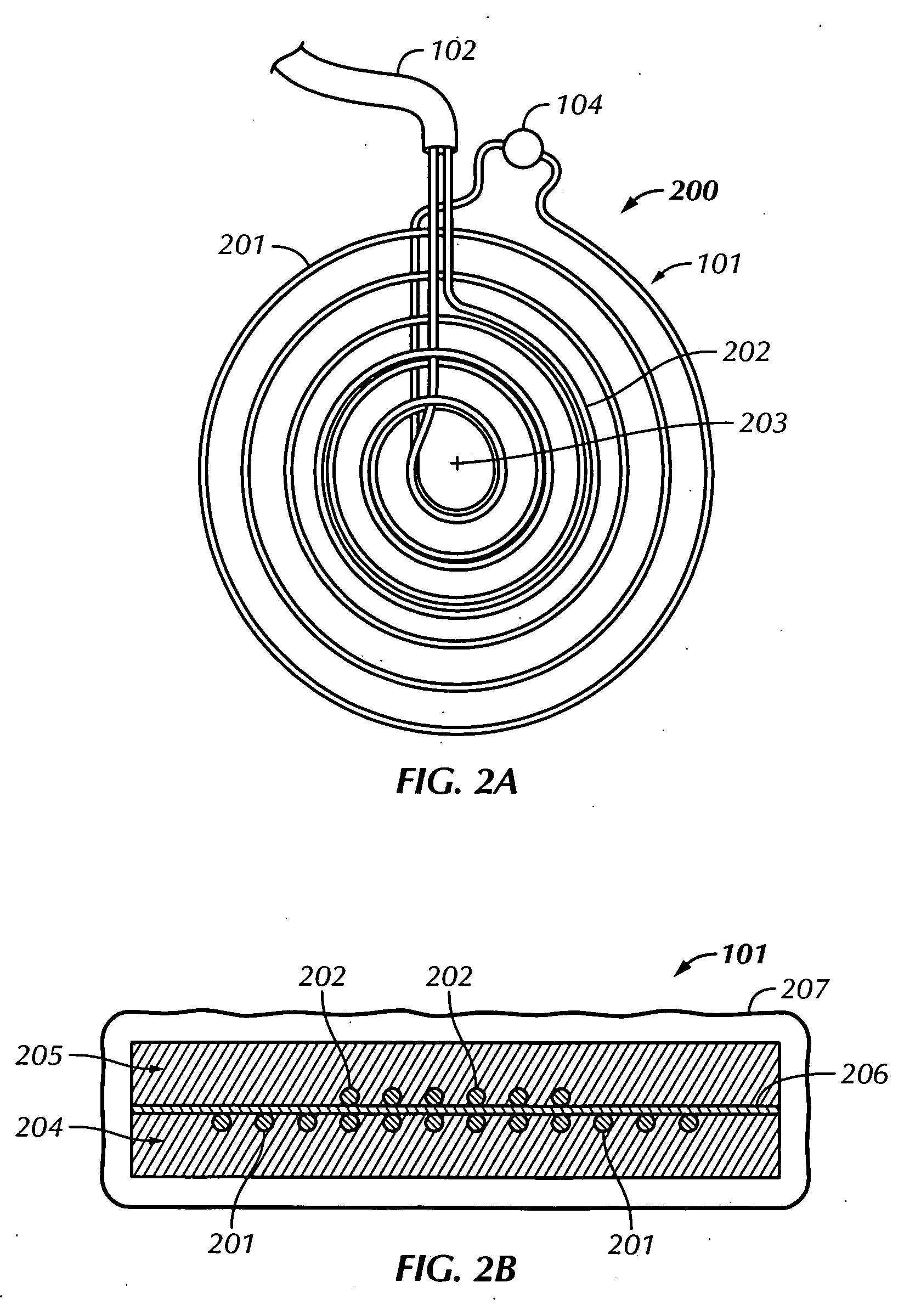

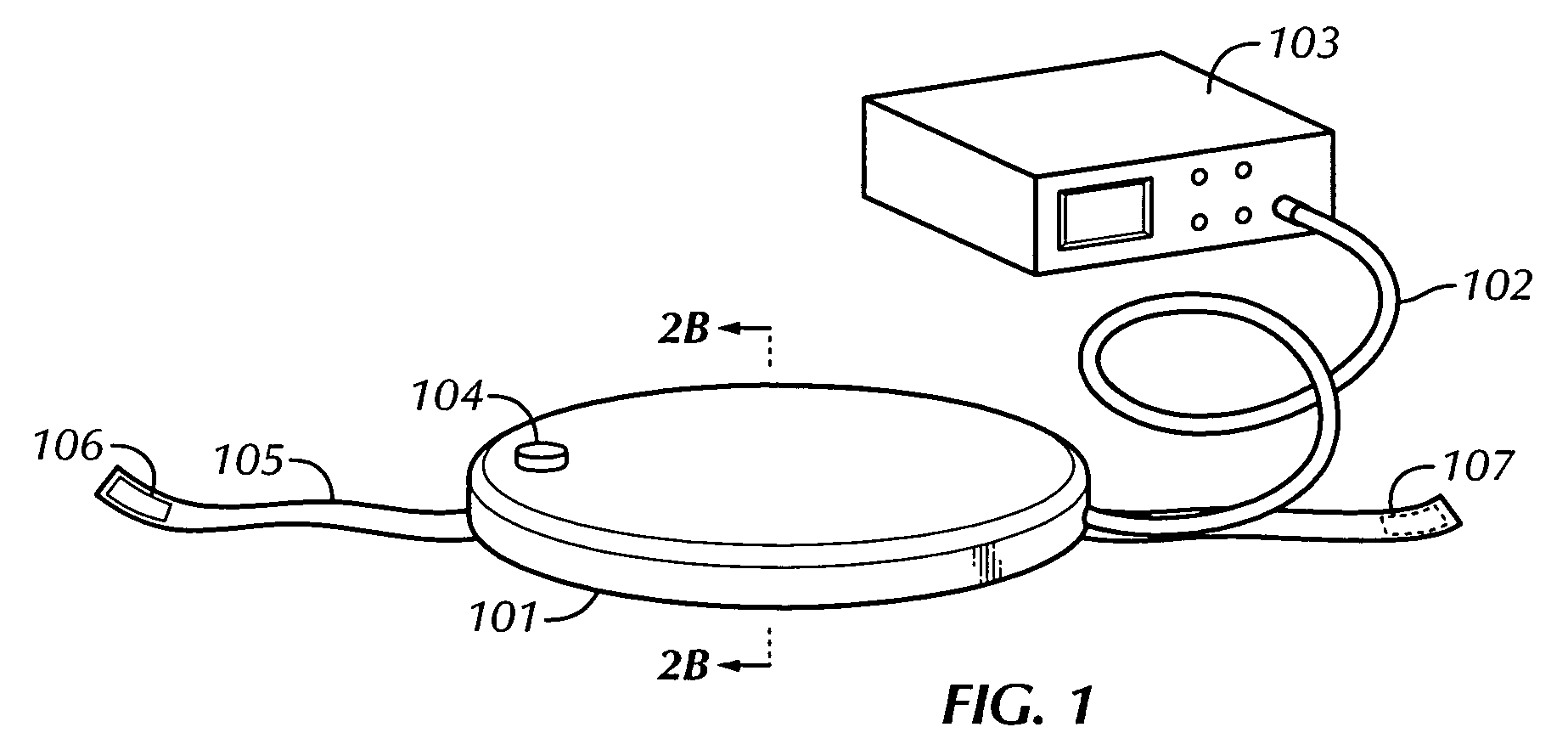

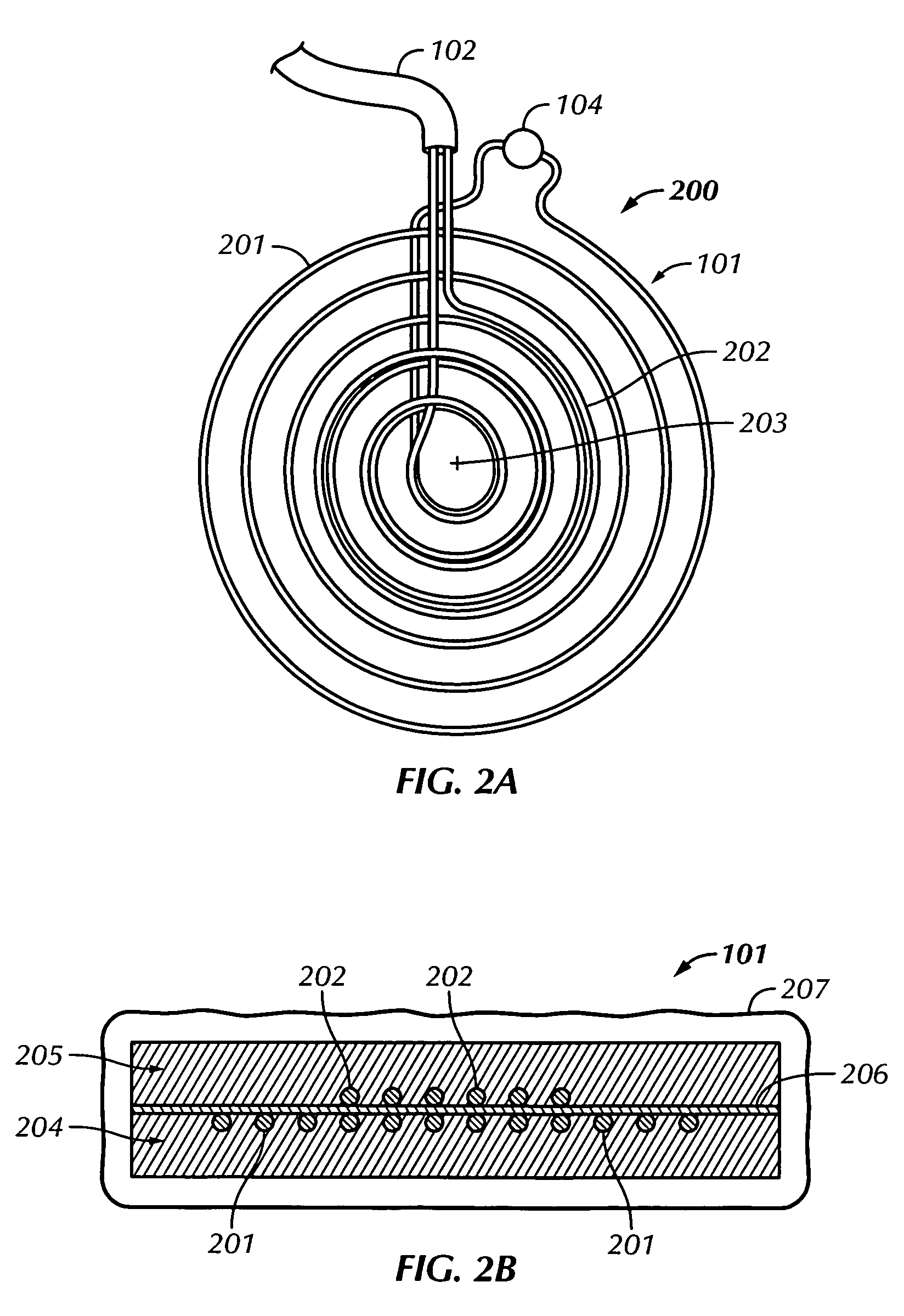

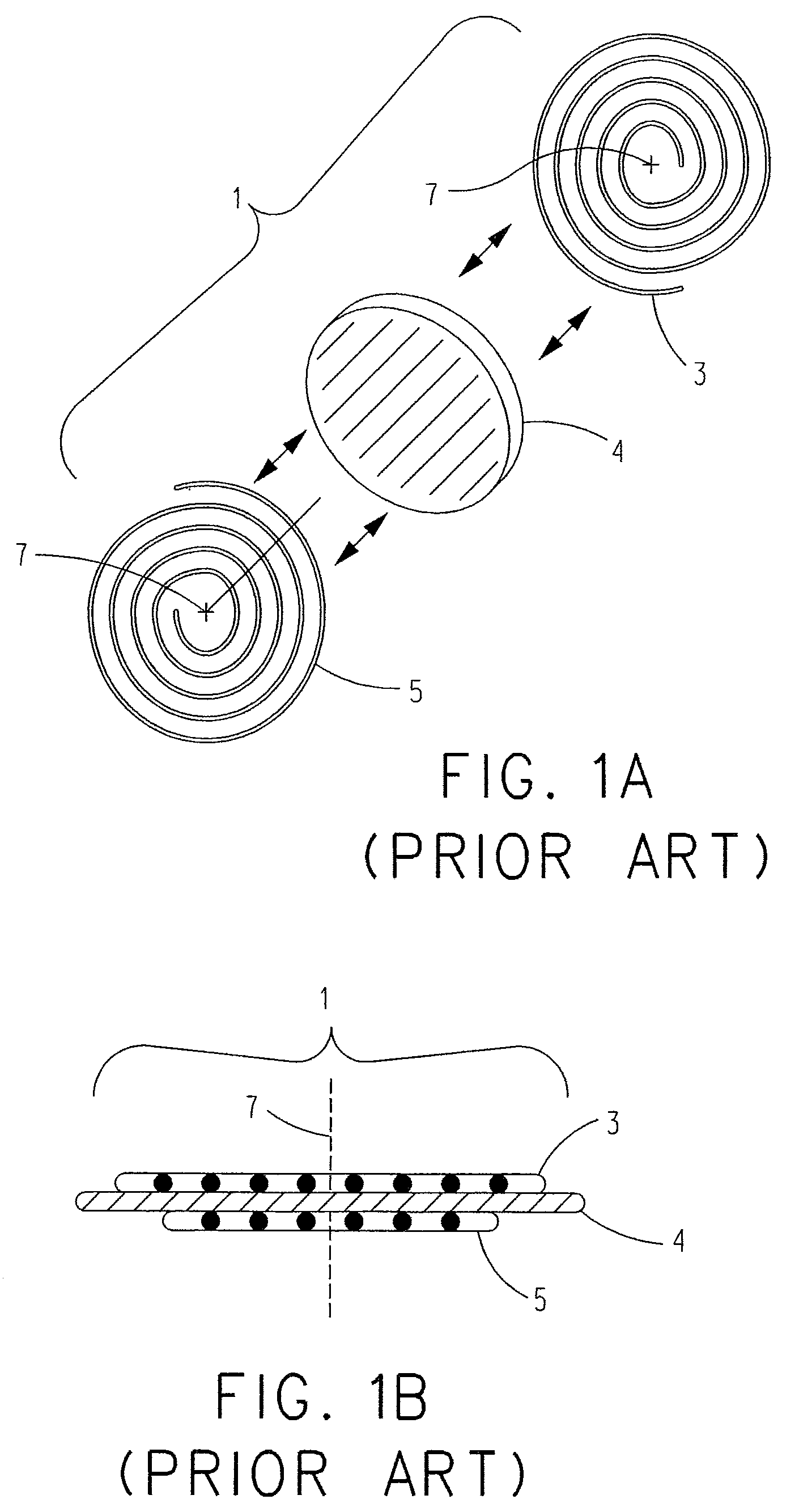

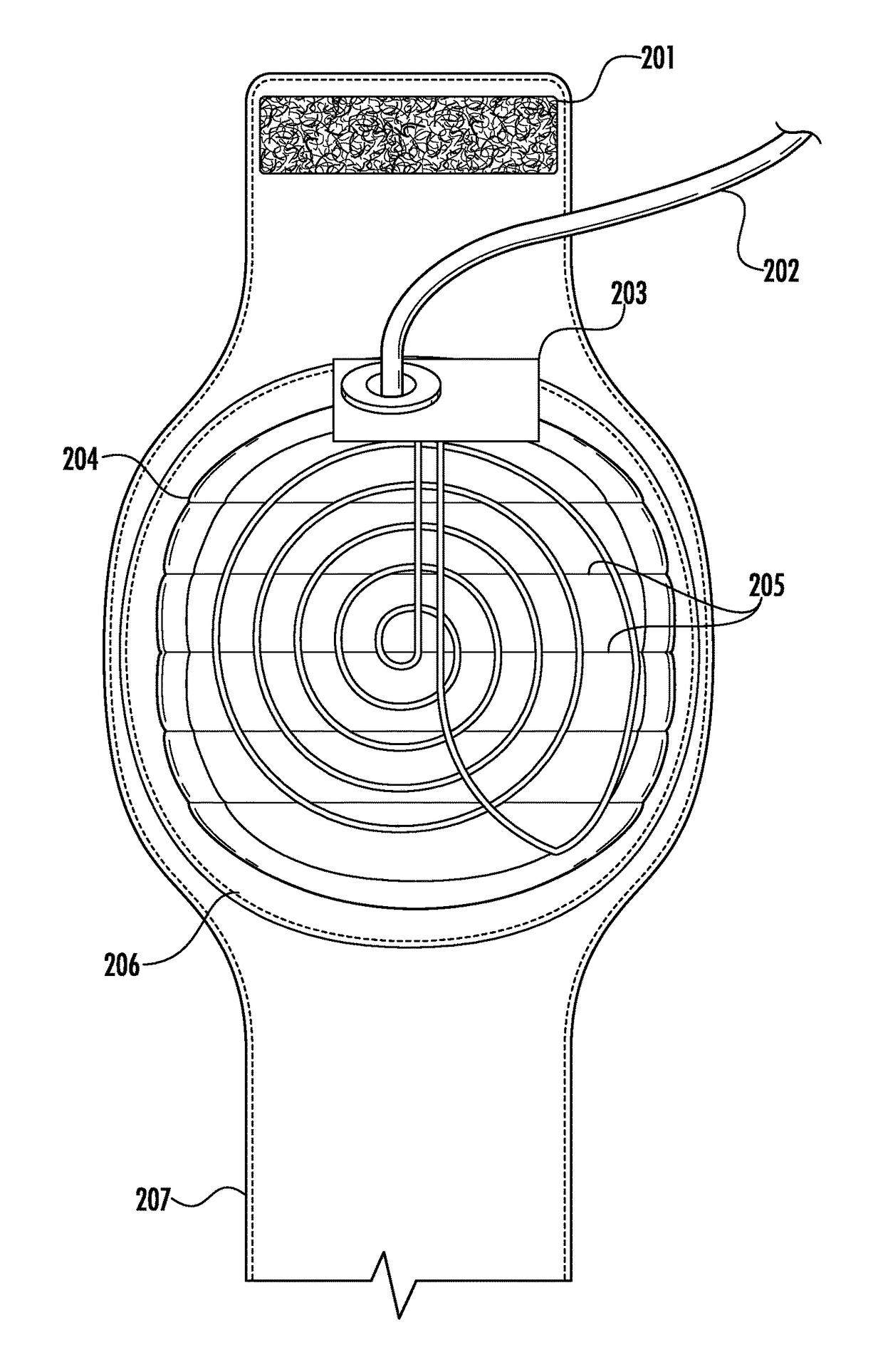

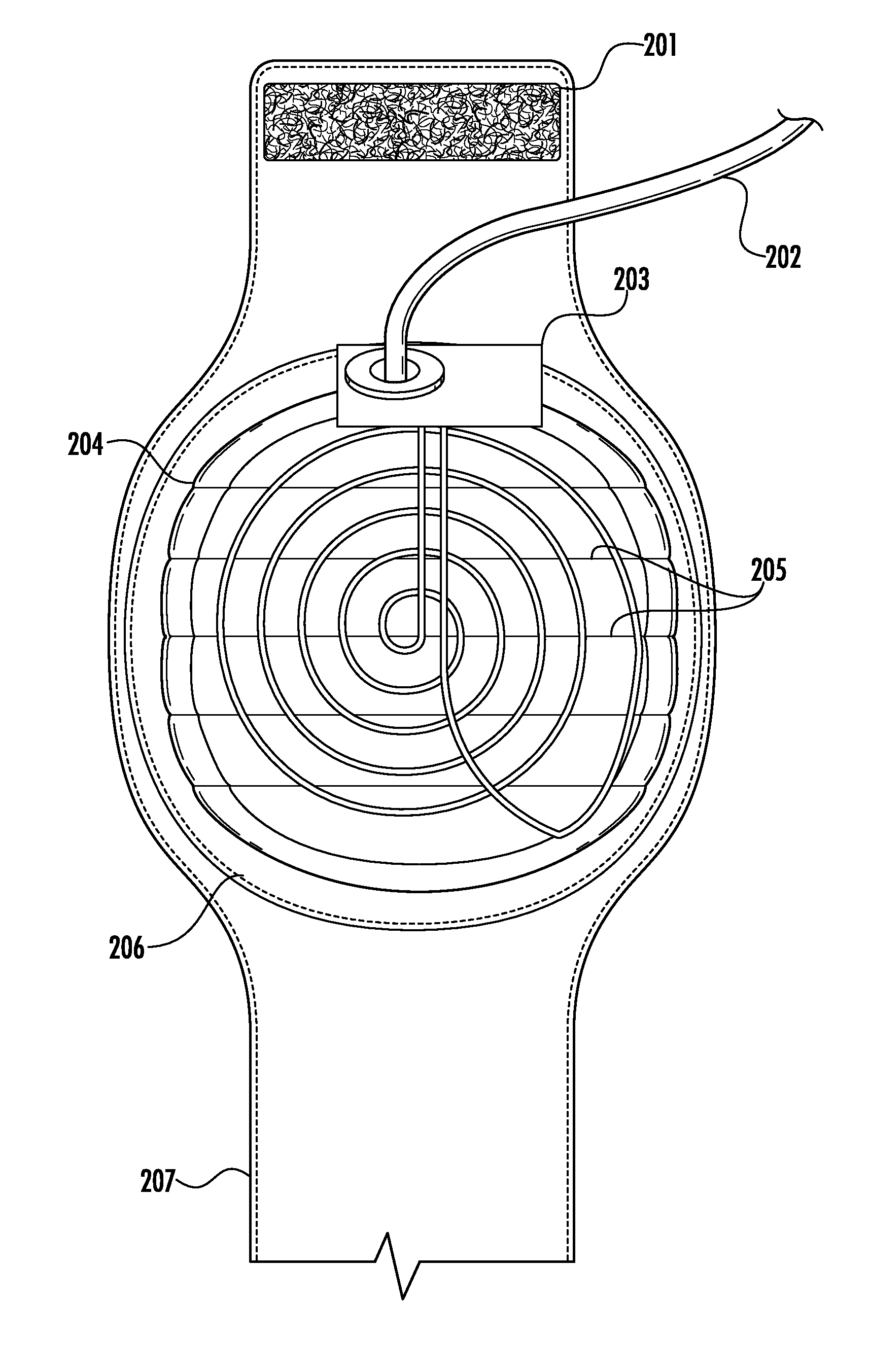

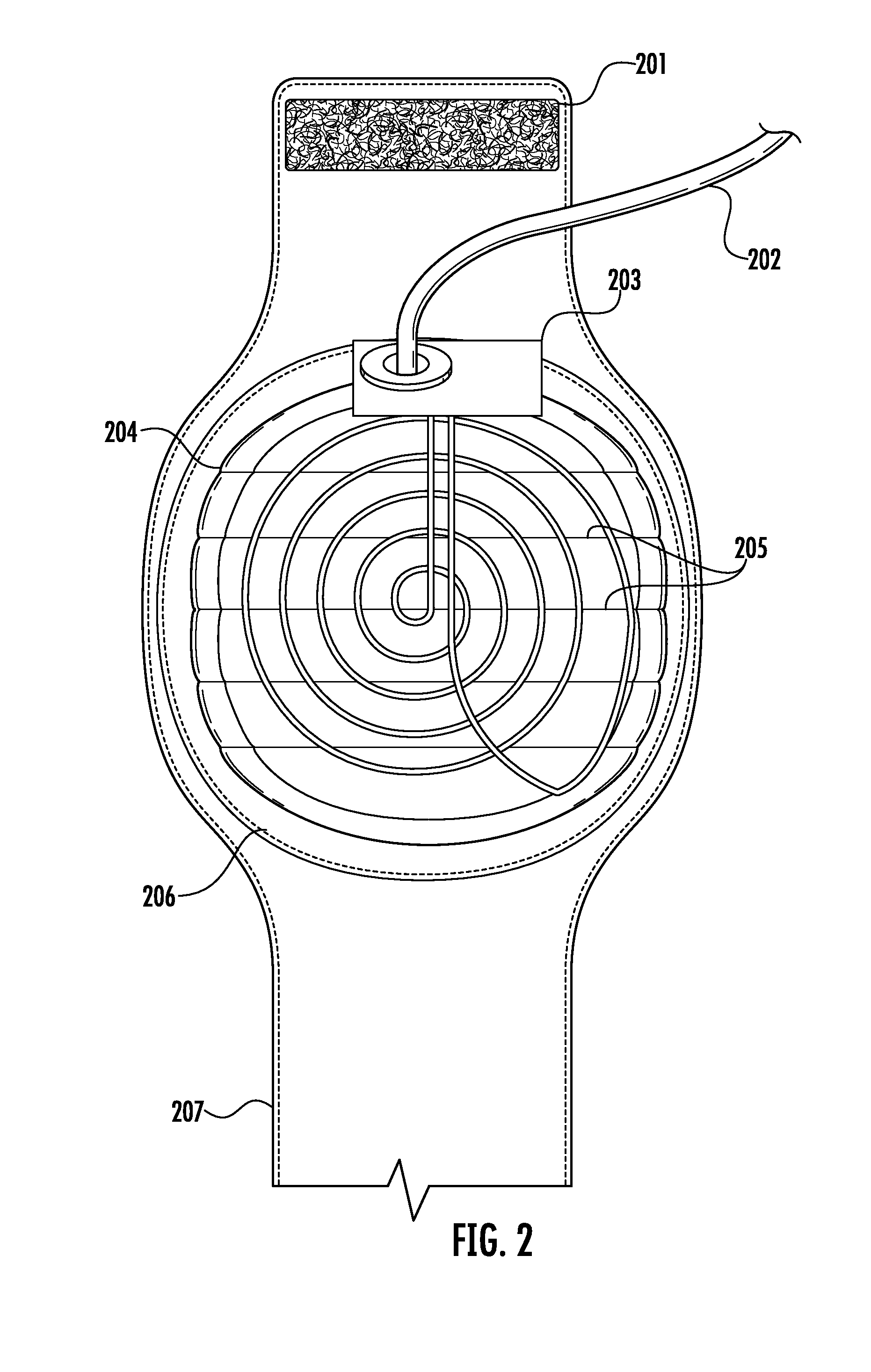

RF diathermy and faradic muscle stimulation treatment

InactiveUS7953500B2Easy to changeUniform and symmetrical distributionElectrotherapyRadiation therapyEngineeringMuscle Stimulation

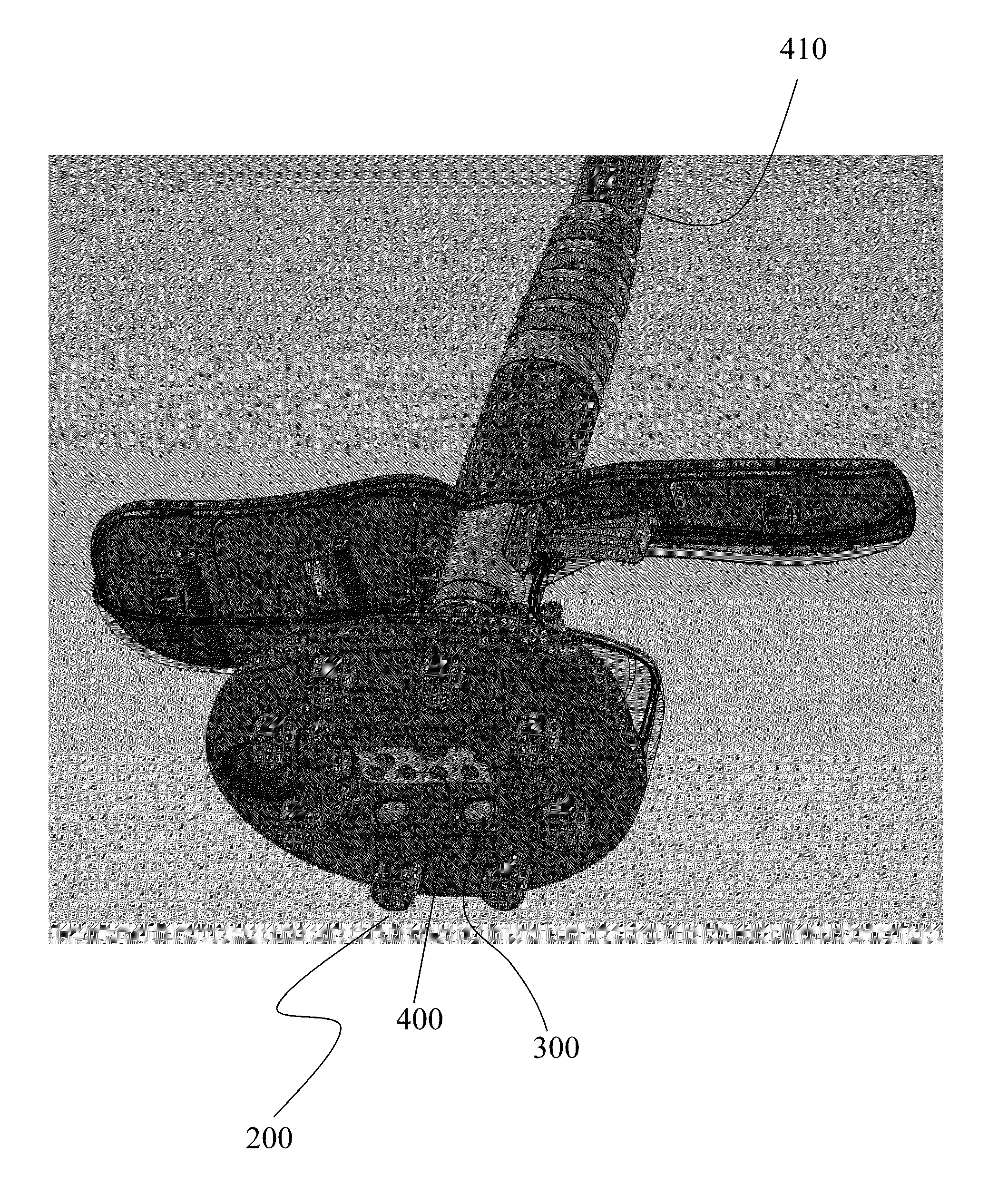

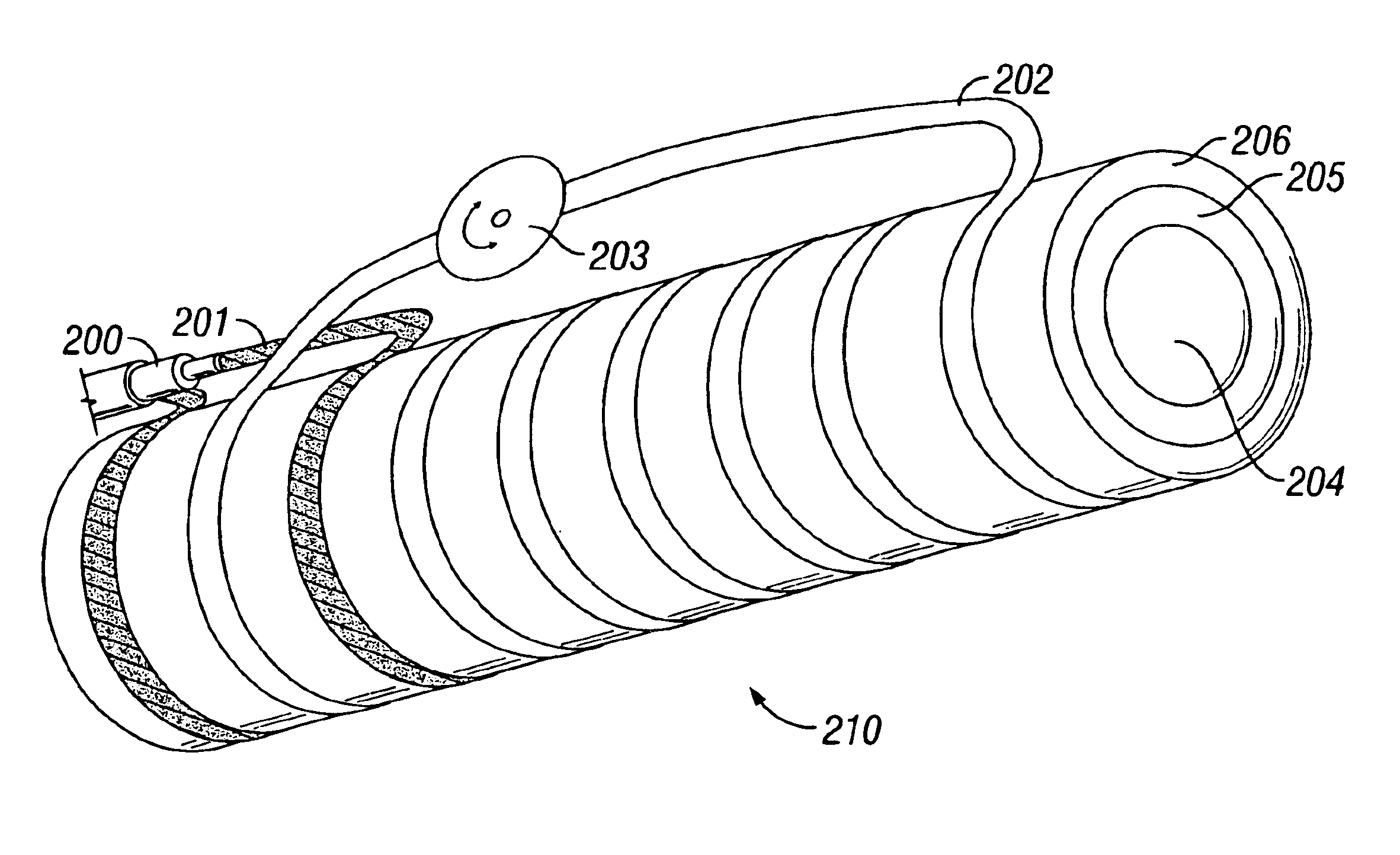

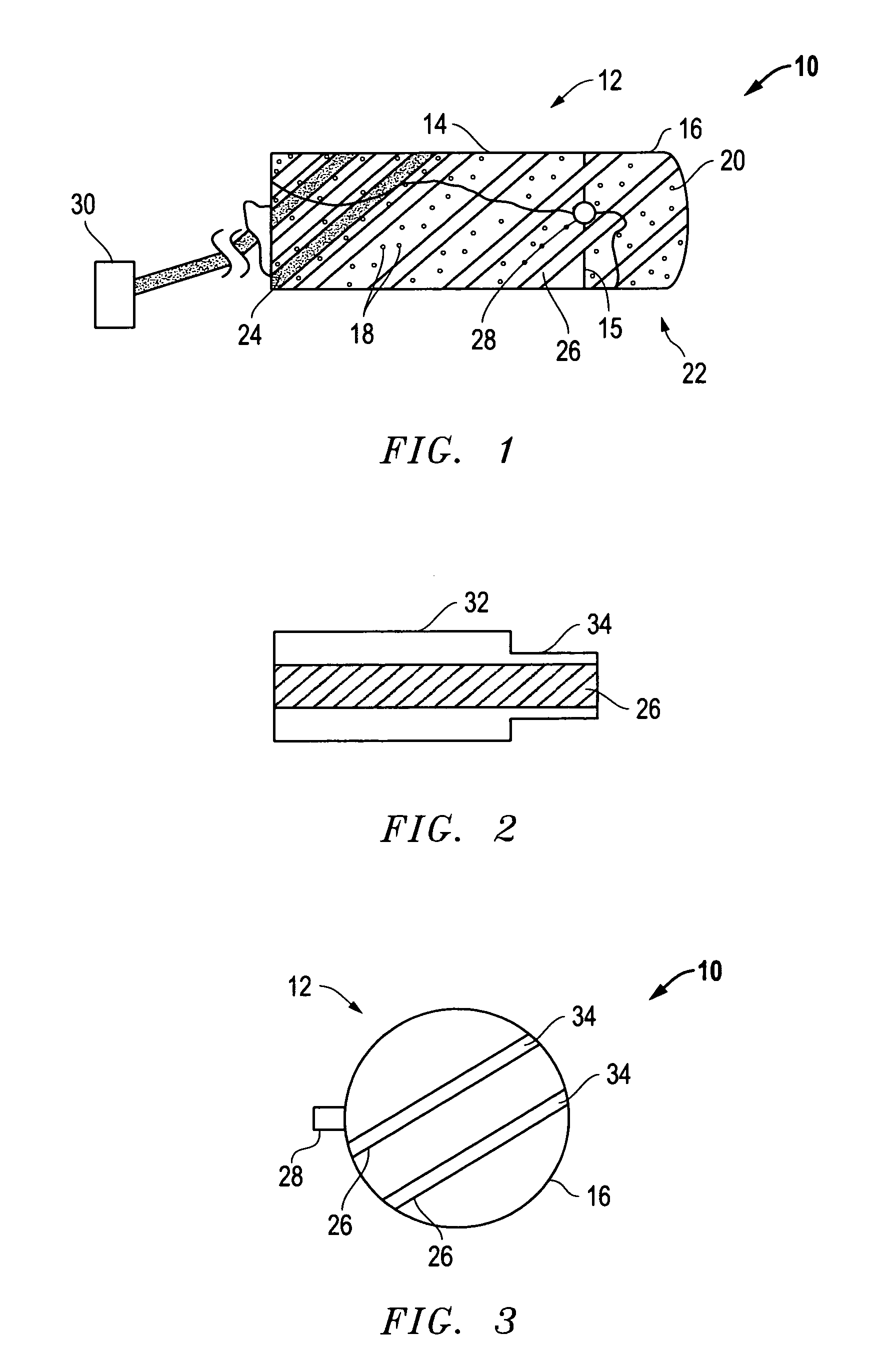

An RF diathermy coil assembly, including a generally elastically deformable patient conforming garment and a conductive coil secured to the garment. The conductive coil having a woven wire construction such that the coil can deform as the garment elastically deforms. The RF diathermy coil assembly can be used for wound healing in conjunction with muscle stimulation.

Owner:HK MEDICAL TECH +1

Delivery and extraction devices

Owner:HICKINGBOTHAM DYSON +1

Methods and apparatus for utilizing radio frequency spectrum simultaneously and concurrently in the presence of co-channel and/or adjacent channel television signals

InactiveUS6909879B1Interference minimizationClose proximityTelevision system detailsBroadcast transmission systemsUltra-widebandFrequency spectrum

To address the scarcity of radio frequency (RF) spectrum, the disclosed systems offer unique ways to mitigate interference between television broadcasters (including their direct audience and viewers served via cable television) and other concurrent users of the RF spectrum, e.g. for one-way or two-way wireless communication. A preferred embodiment makes use of the “framing” characteristics of the “letterbox” video display format. RF emissions of the simultaneous RF spectrum user are keyed “on” only or substantially only during the time intervals when the blanking intervals and / or letterbox-border video lines are being scanned on the display, i.e. when the potentially affected (interfered with) television display is in the letterbox-frame-scanning portions of each video field. The concurrent uses may support services for voice (including telephony, music etc.), data (including Internet, intranet, etc.); image or control; fixed, portable, mobile or nomadic; narrowband, broadband or ultra-wideband; radiodetermination, diathermy, etc.

Owner:CELLCO PARTNERSHIP INC

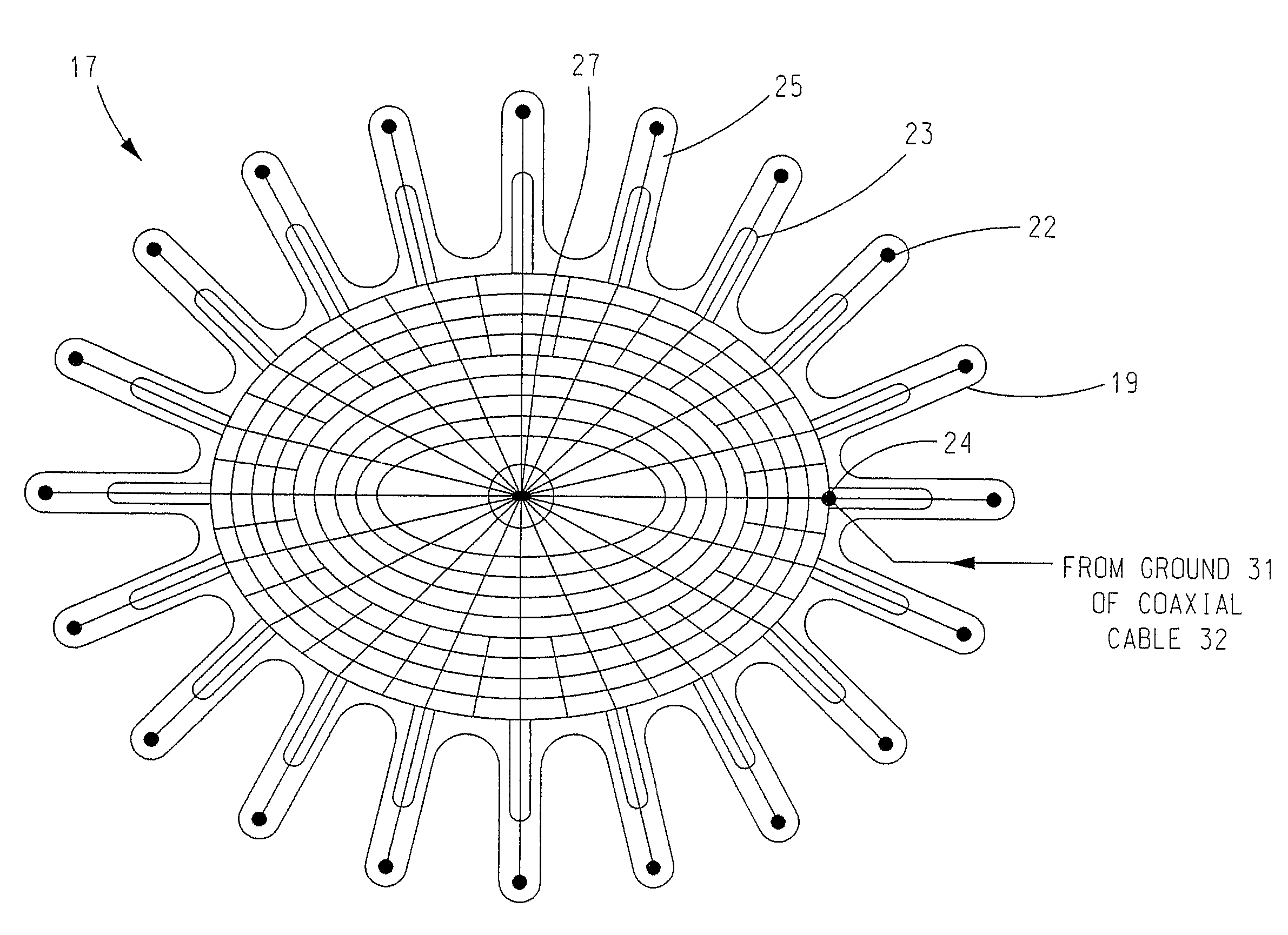

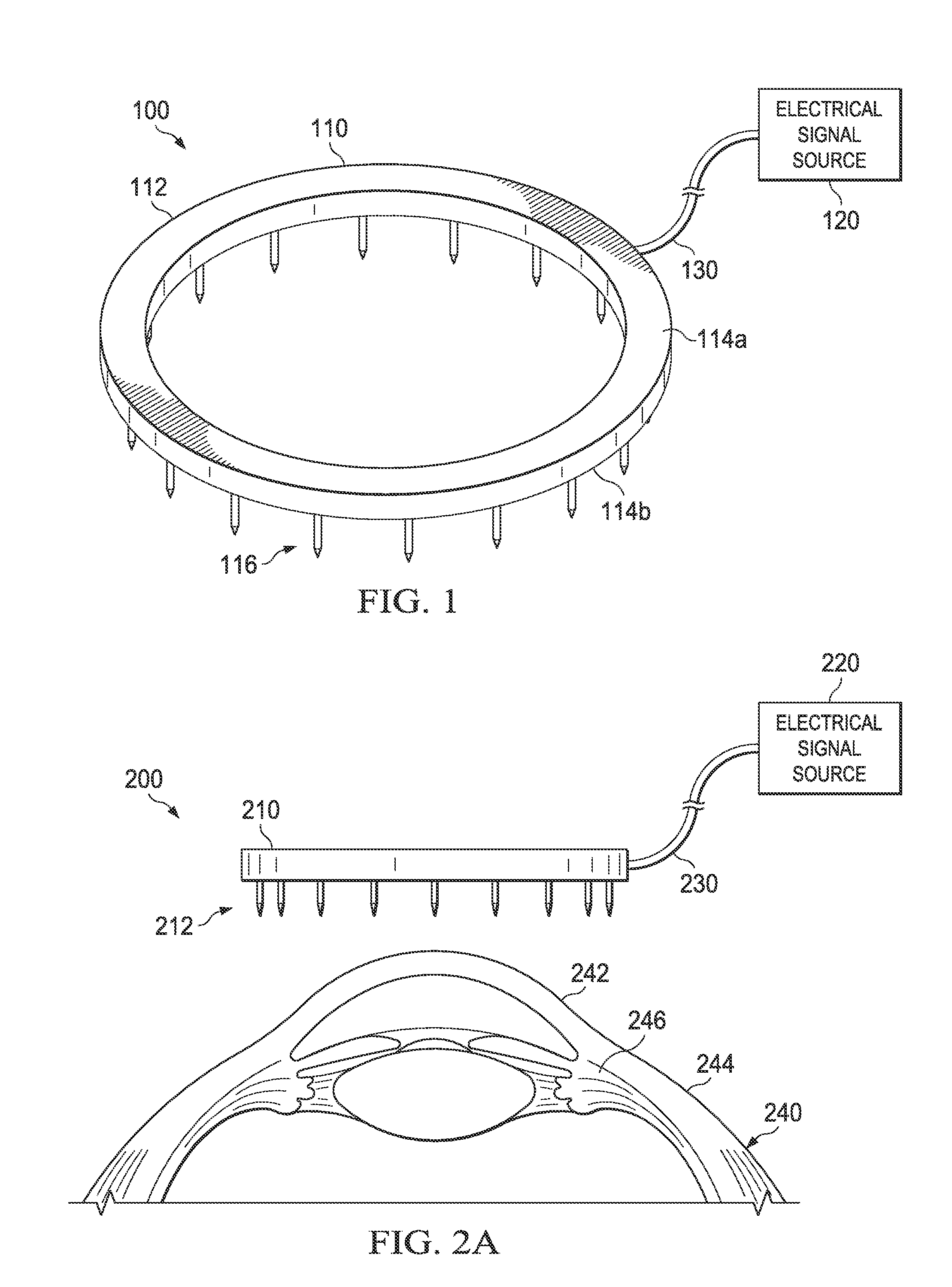

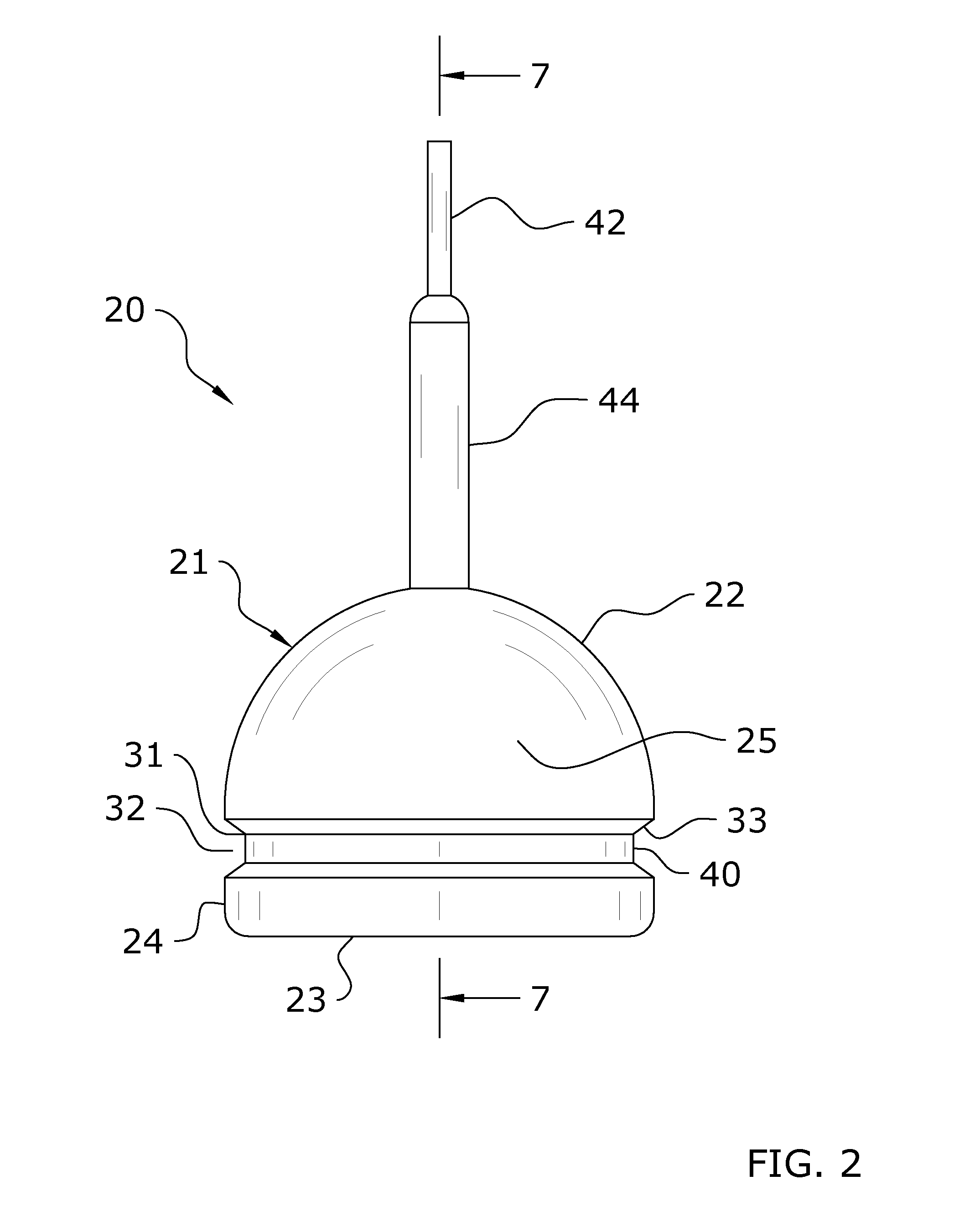

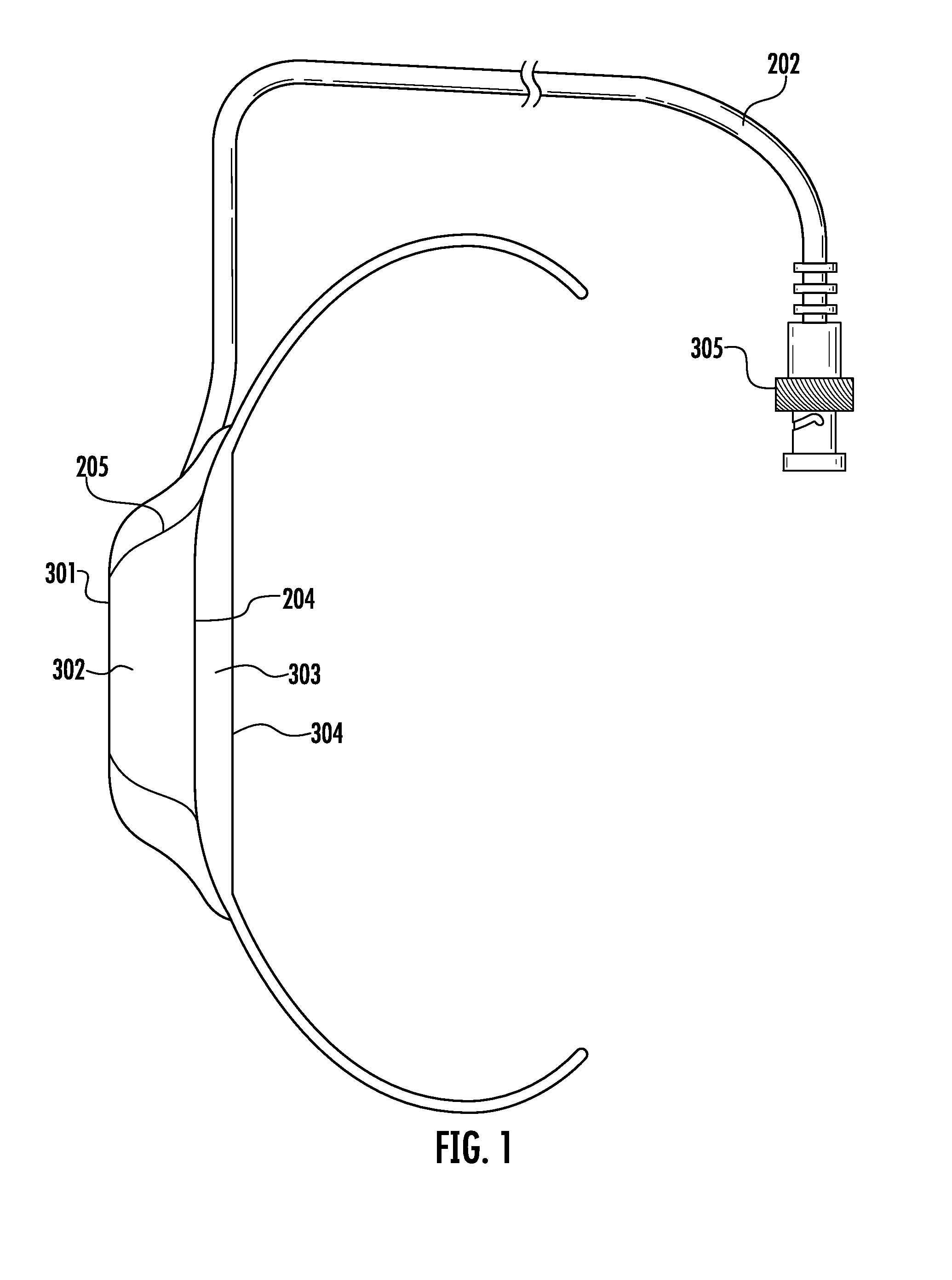

Apparatus for RF diathermy treatment

InactiveUS6853865B2Improving Impedance MatchingElectrotherapyMagnetotherapy using coils/electromagnetsImpedance matchingConductor Coil

Systems for RF diathermy treatment are described. An apparatus includes an RF diathermy coil assembly, comprising: an elastically deformable garment; and a conductive coil assembly secured to the garment, including: a primary winding; and a secondary winding coupled to the primary winding, the primary winding and the secondary winding being configured to optimize an impedance match between the conductive coil and an RF power source connected to the conductive coil.

Owner:VIATHERM THERAPEUTICS LLC

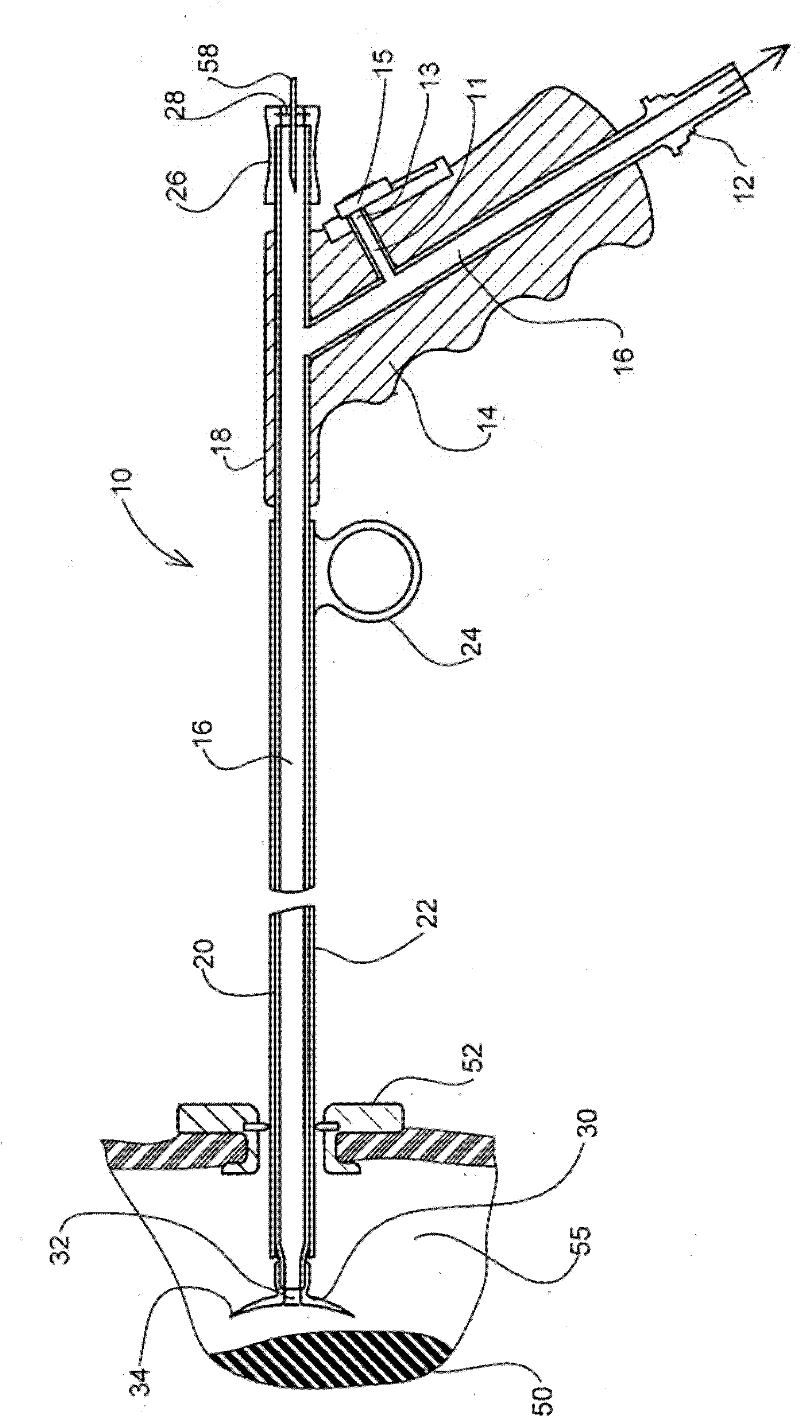

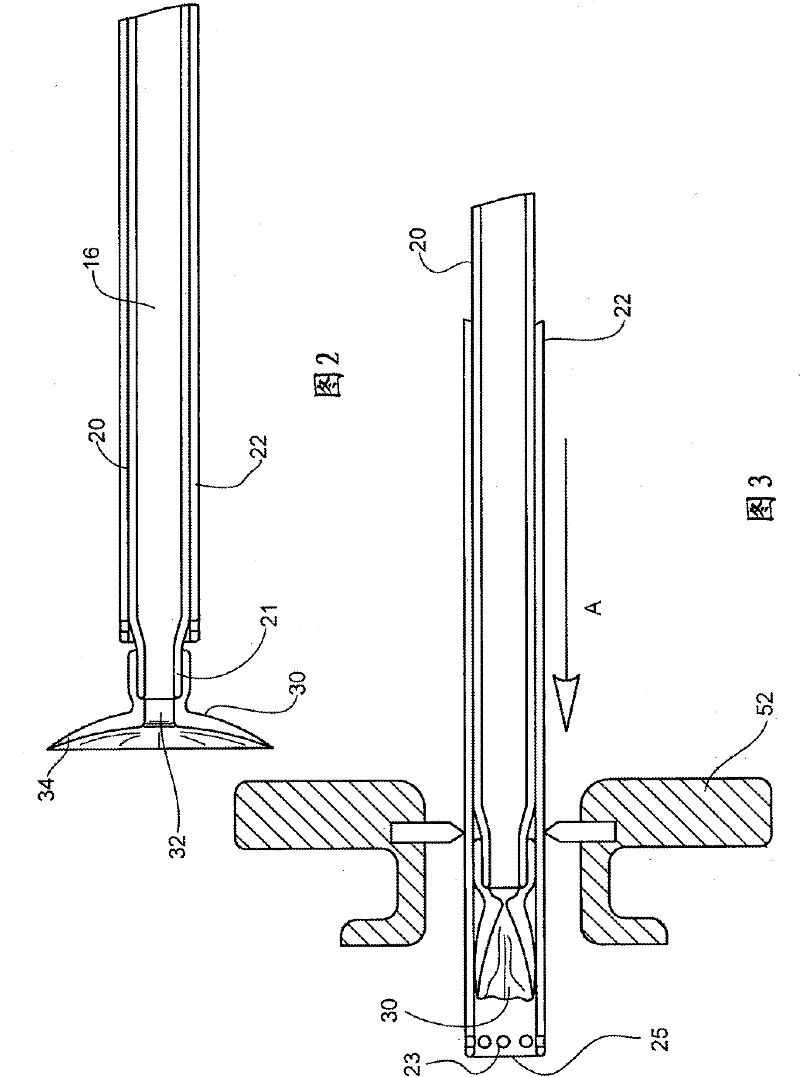

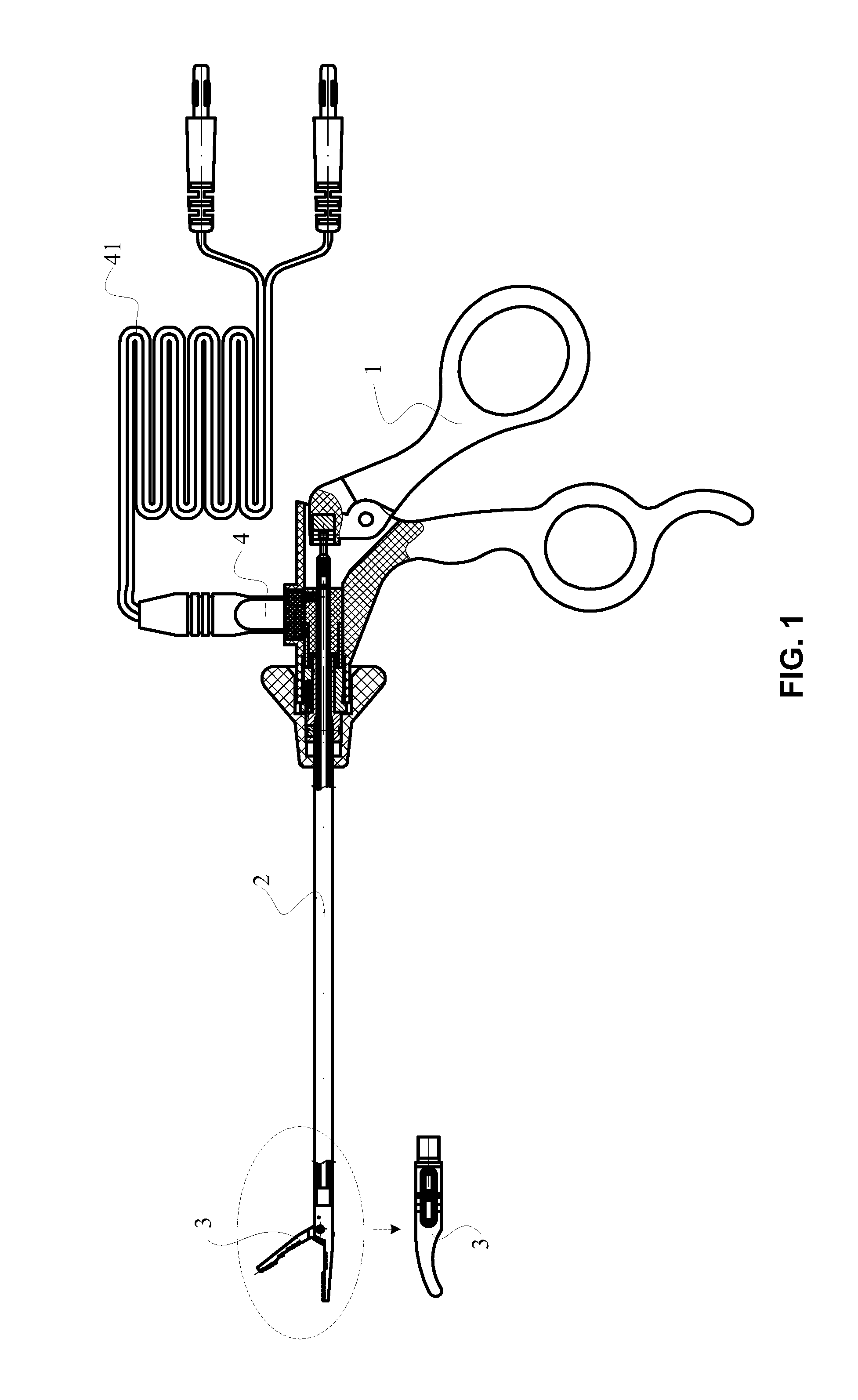

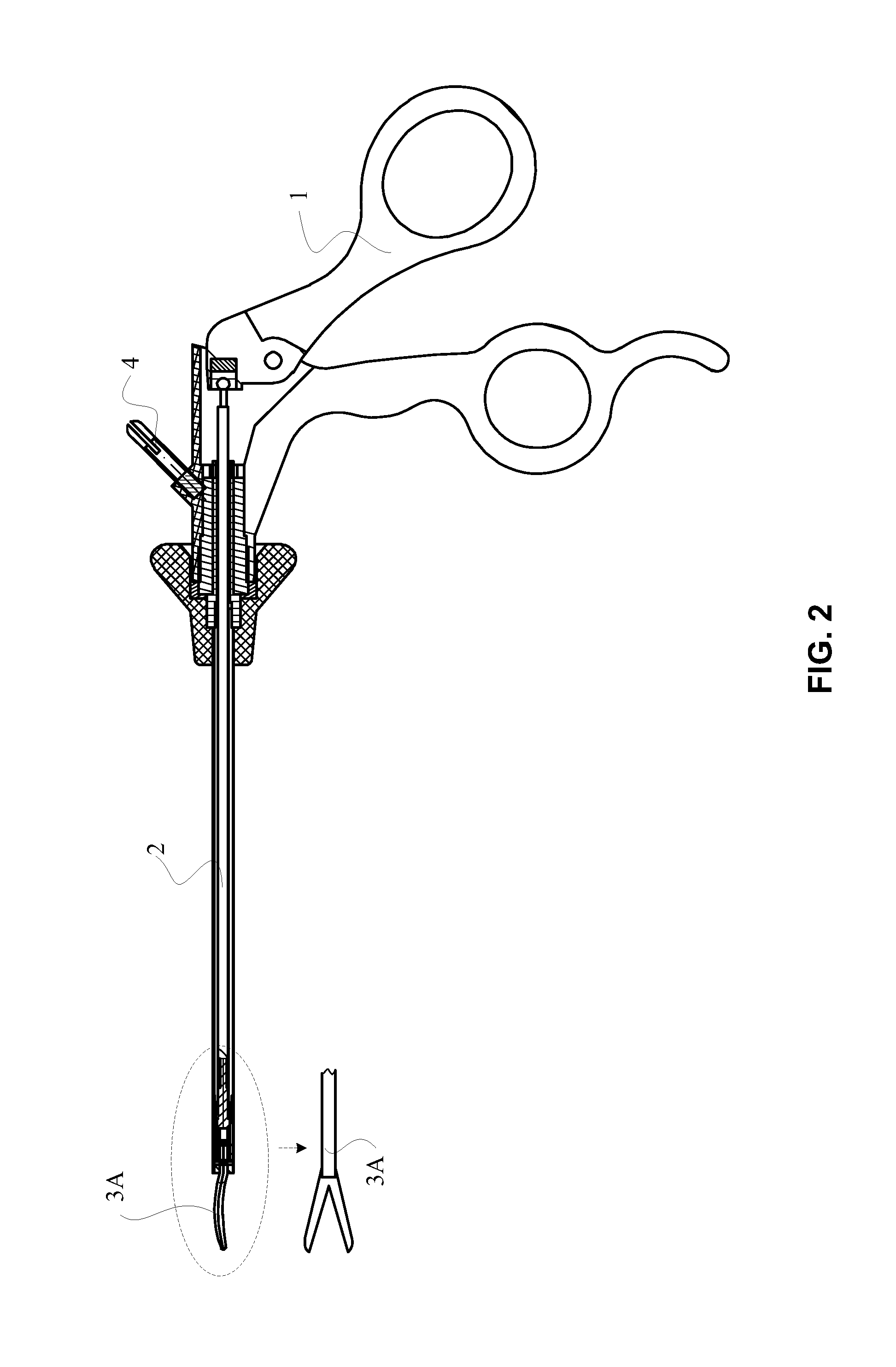

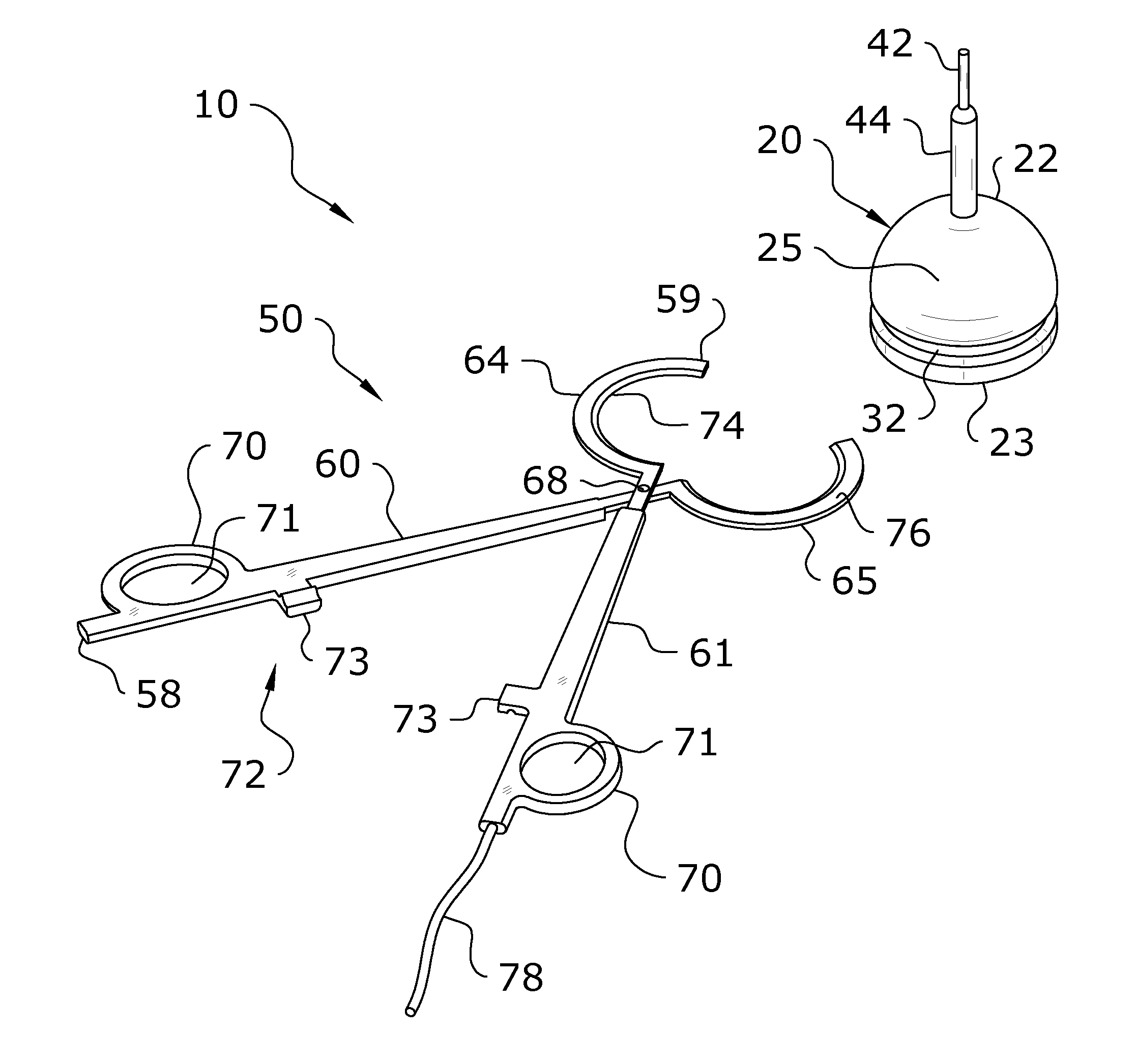

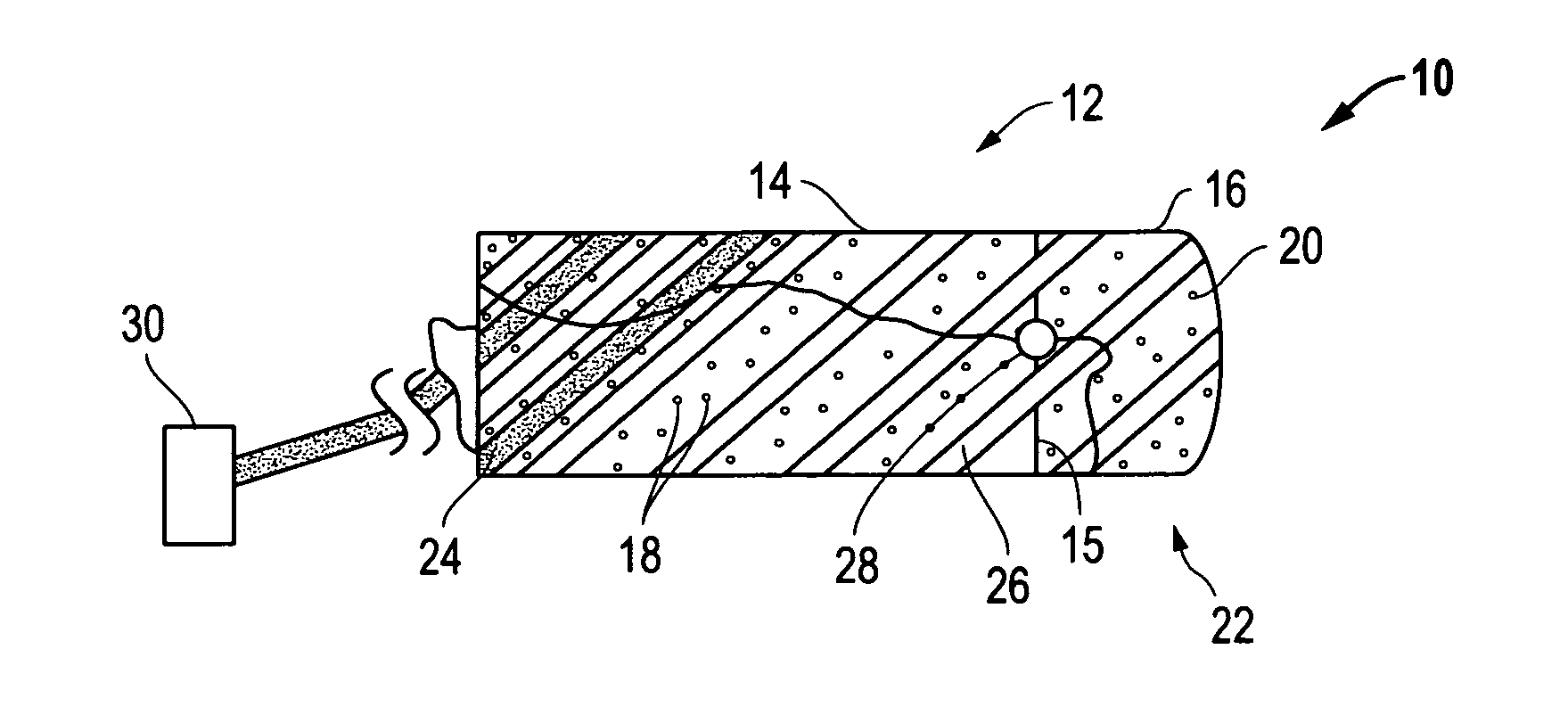

Surgical manipulator

Surgical Manipulator A surgical manipulator (10) is disclosed which employs a suction cup (30) to hold body parts (50) whilst the manipulator is moved to manipulate the body part (50). Suction at the cup (30) is provided by means of a central passage (16) running through an extension (20) and through a handle part (14) to a vacuum connector (12). The suction at the cup (30) can be adjusted by a slider (15) which adjustably opens the passage (16) to atmosphere. Needles (58) and the like can be introduced into the passage (16) and thereby into the body part (50). For laparoscopic surgery the manipulator can be introduced into a laparoscopic port (52) by collapsing the suction cup (30) within an introducer sleeve (22 Fig 3). The introducer sleeve (22) can act as a suction device when the cup (30) is collapsed within it. The needle (58) can be replaced by a diathermy electrode (60 Fig 6) and irrigation is possible using an additional supply tube (121 Figure 4).

Owner:ASALUS MEDICAL INSTR

Circumcision Instrument

ActiveUS20150313624A1Surgical instruments for heatingSurgical instruments using microwavesForeskinEngineering

A circumcision instrument used to perform a circumcision procedure. The circumcision instrument generally includes a housing having a chamber configured to receive a glans penis and an outer surface configured to be enveloped by a prepuce. An annular groove is disposed in the outer surface. A conductive ring is located at the bottom of the annular groove. A clamp has a pair of jaws that are moveable from an open position to a closed position surrounding the prepuce. In the closed position the jaws are disposed at least partially within the annular groove. A conductive inner cutting edge is located on the jaws. The clamp and the housing are connectable to a source of diathermy energy such that diathermy energy can flow between the inner cutting edge and the conductive ring, thereby cutting the prepuce.

Owner:ALTOKHAIS TARIQ IBRAHIM

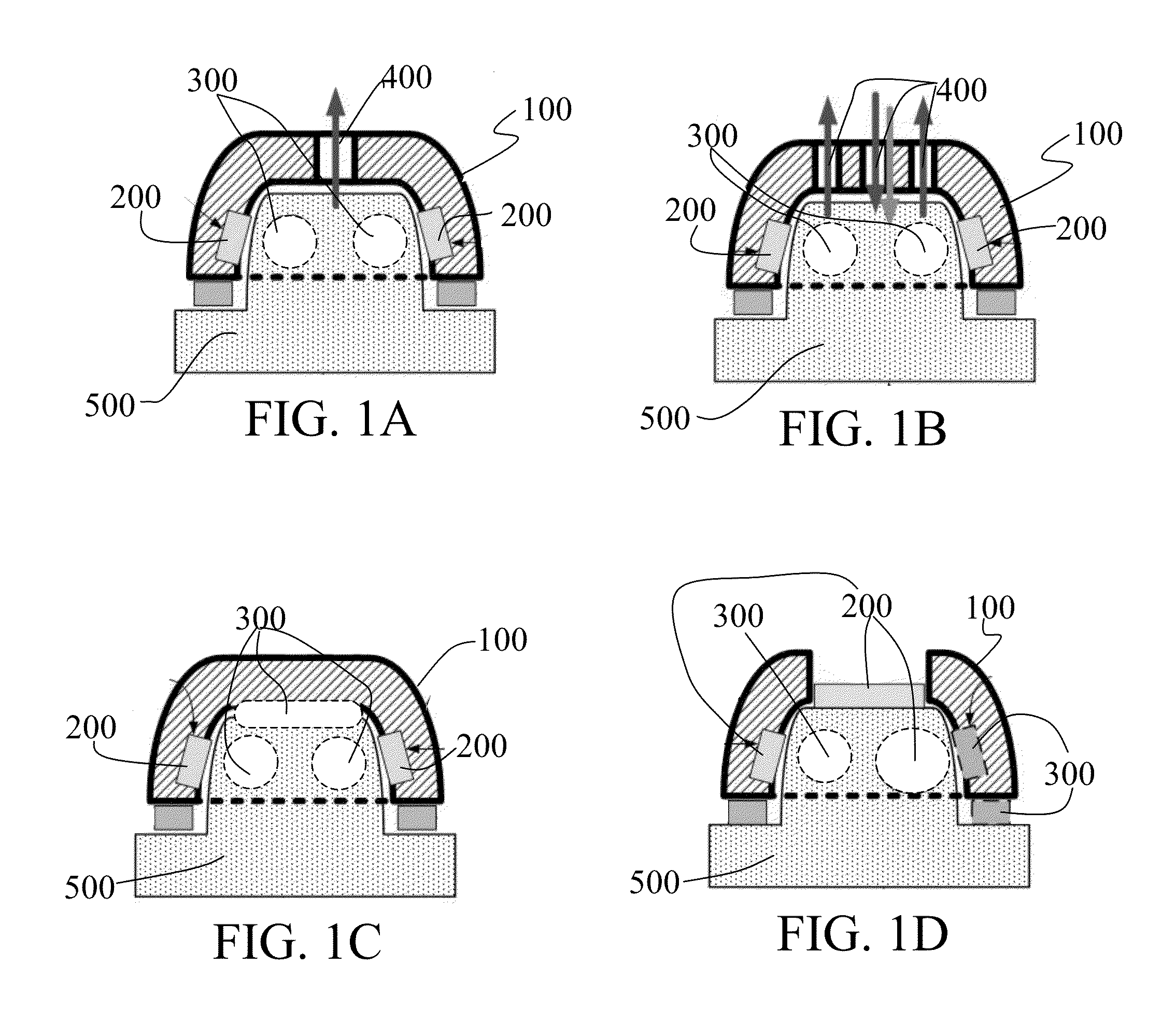

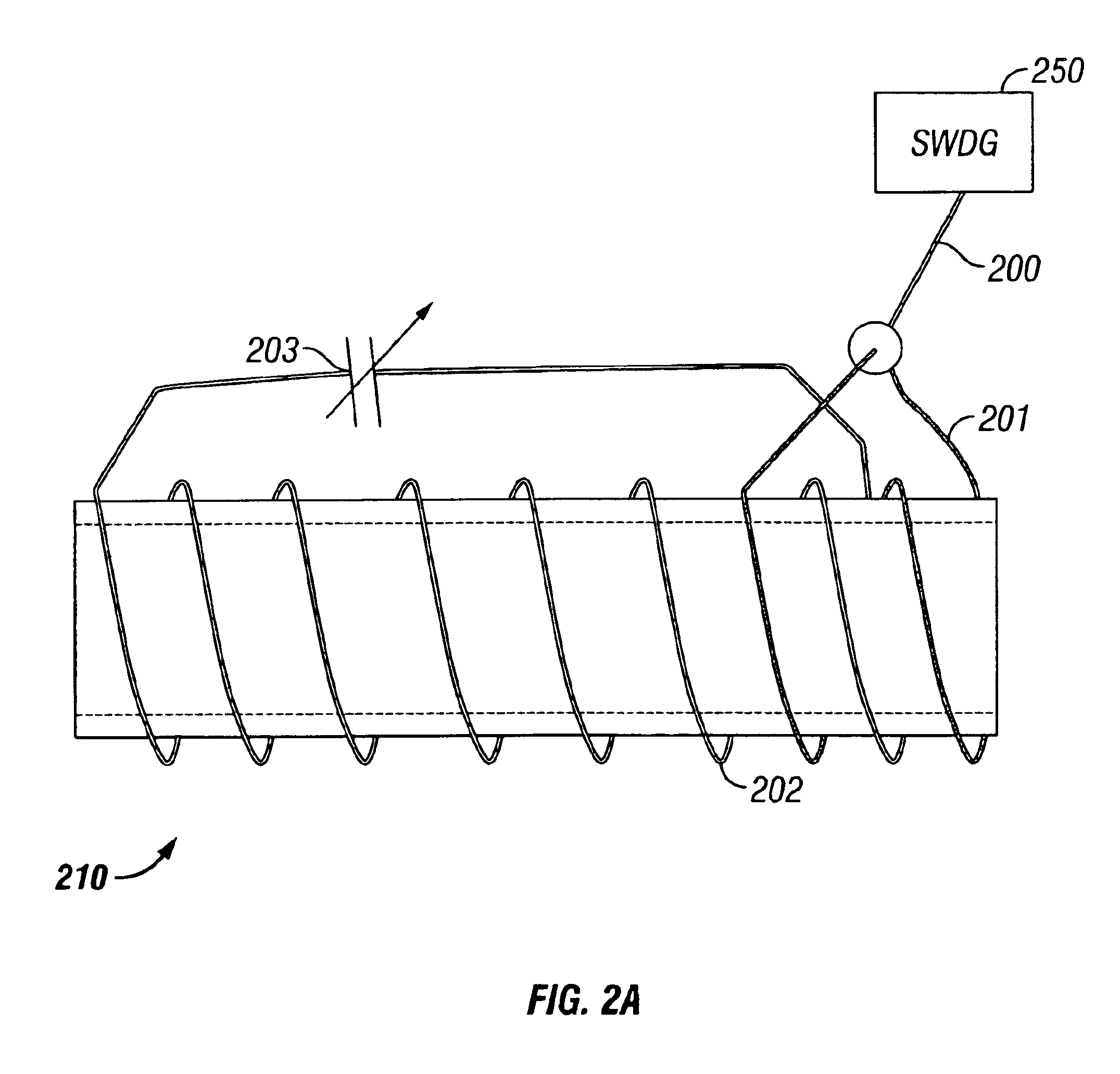

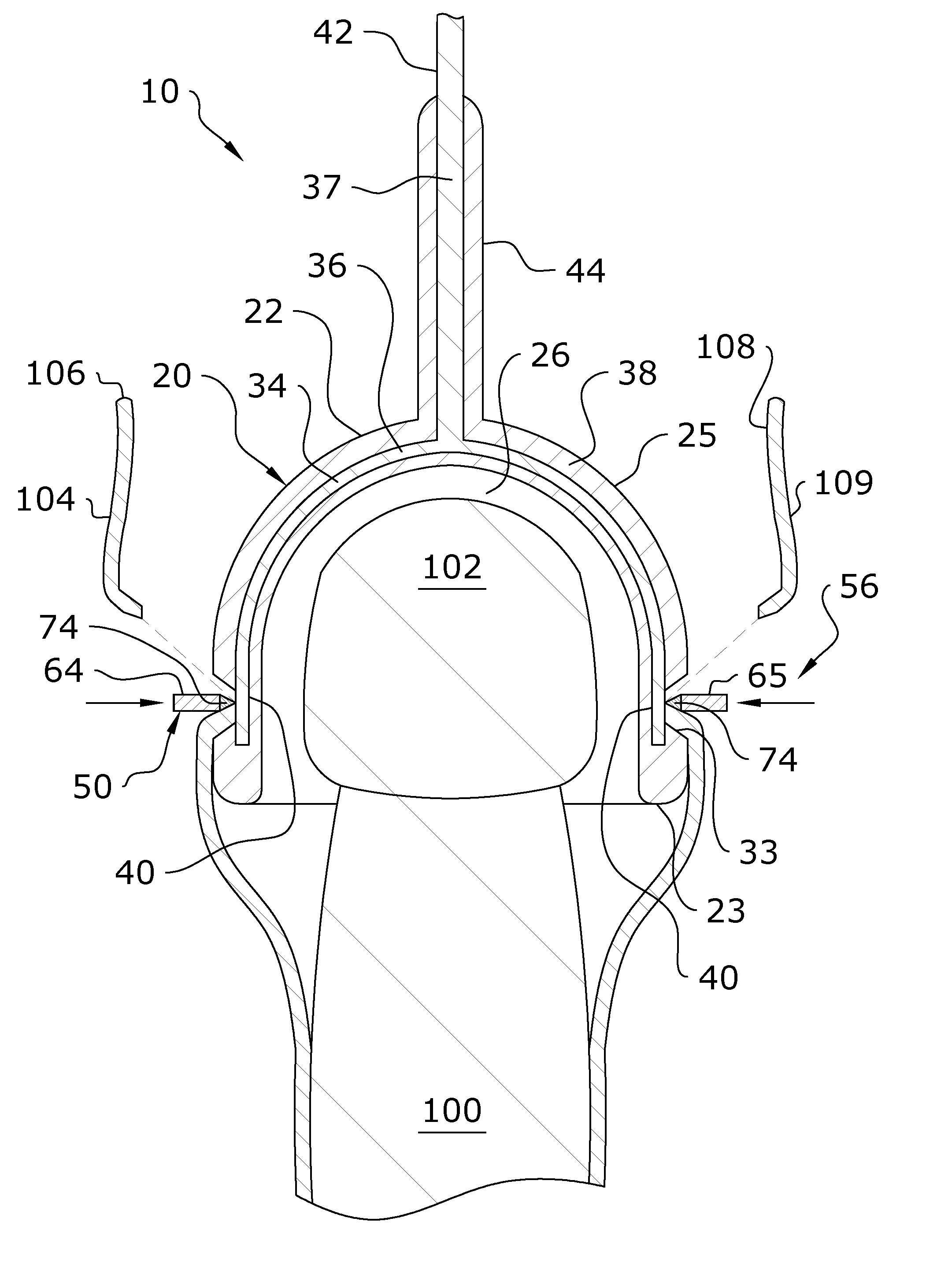

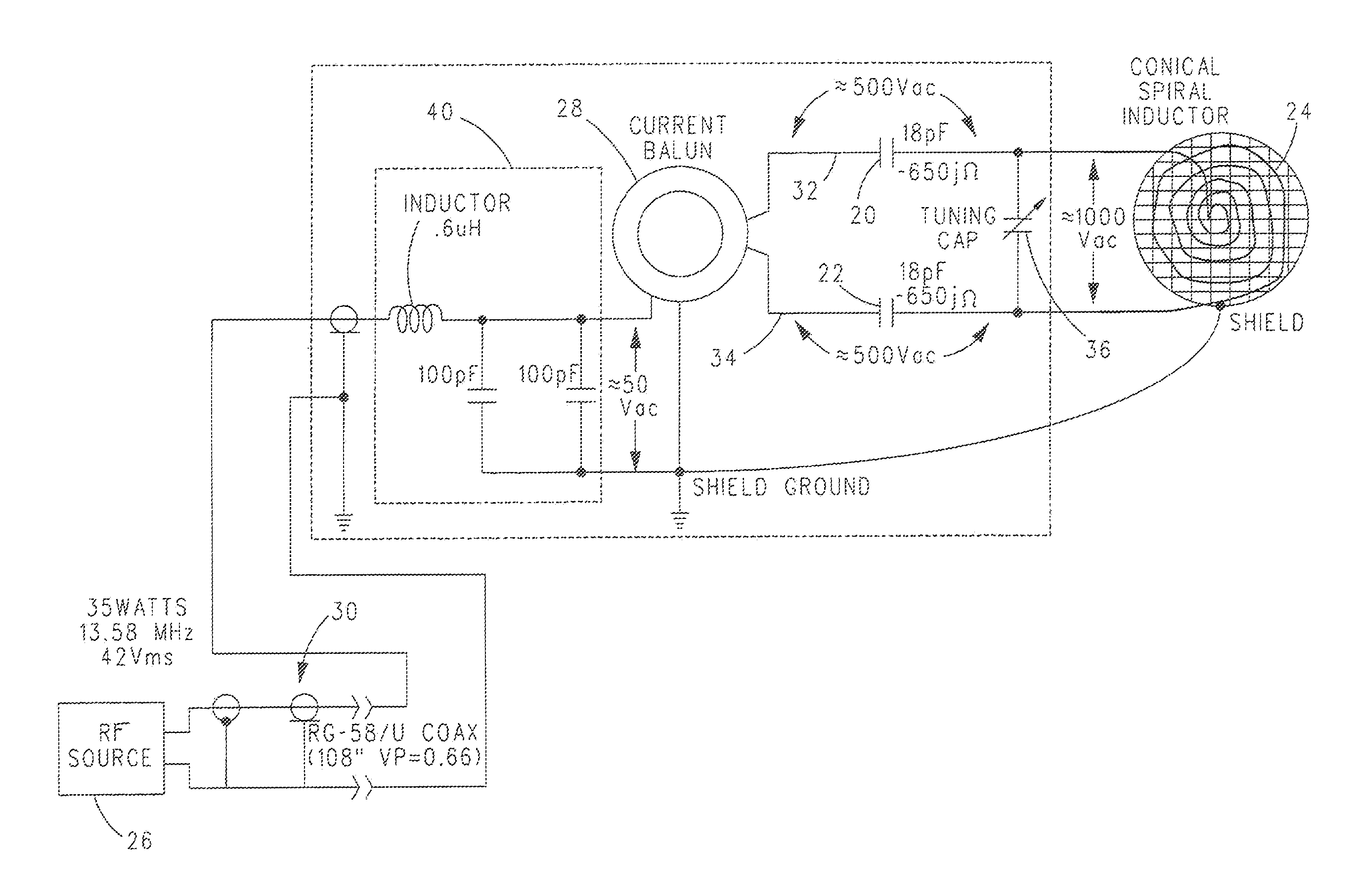

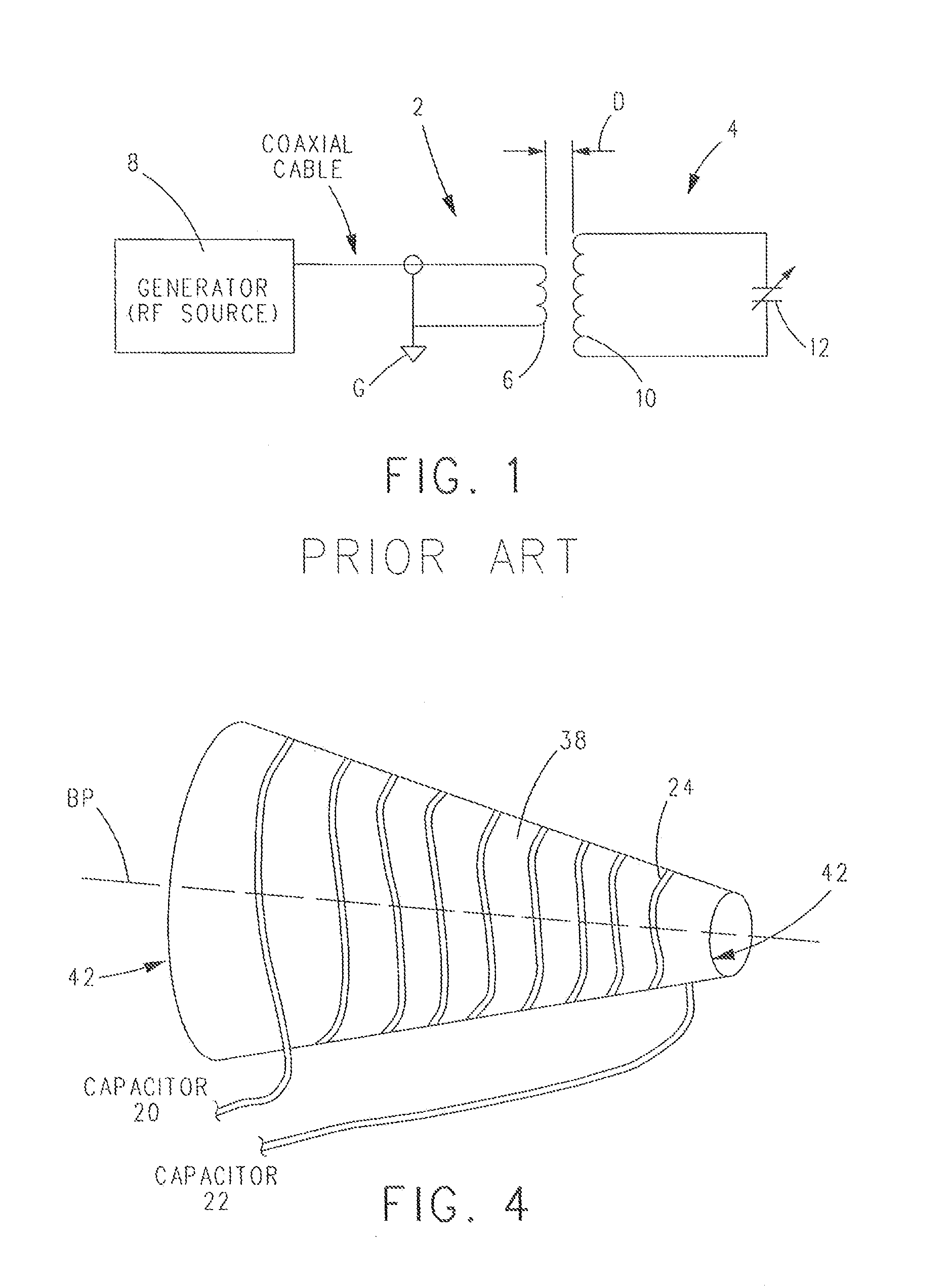

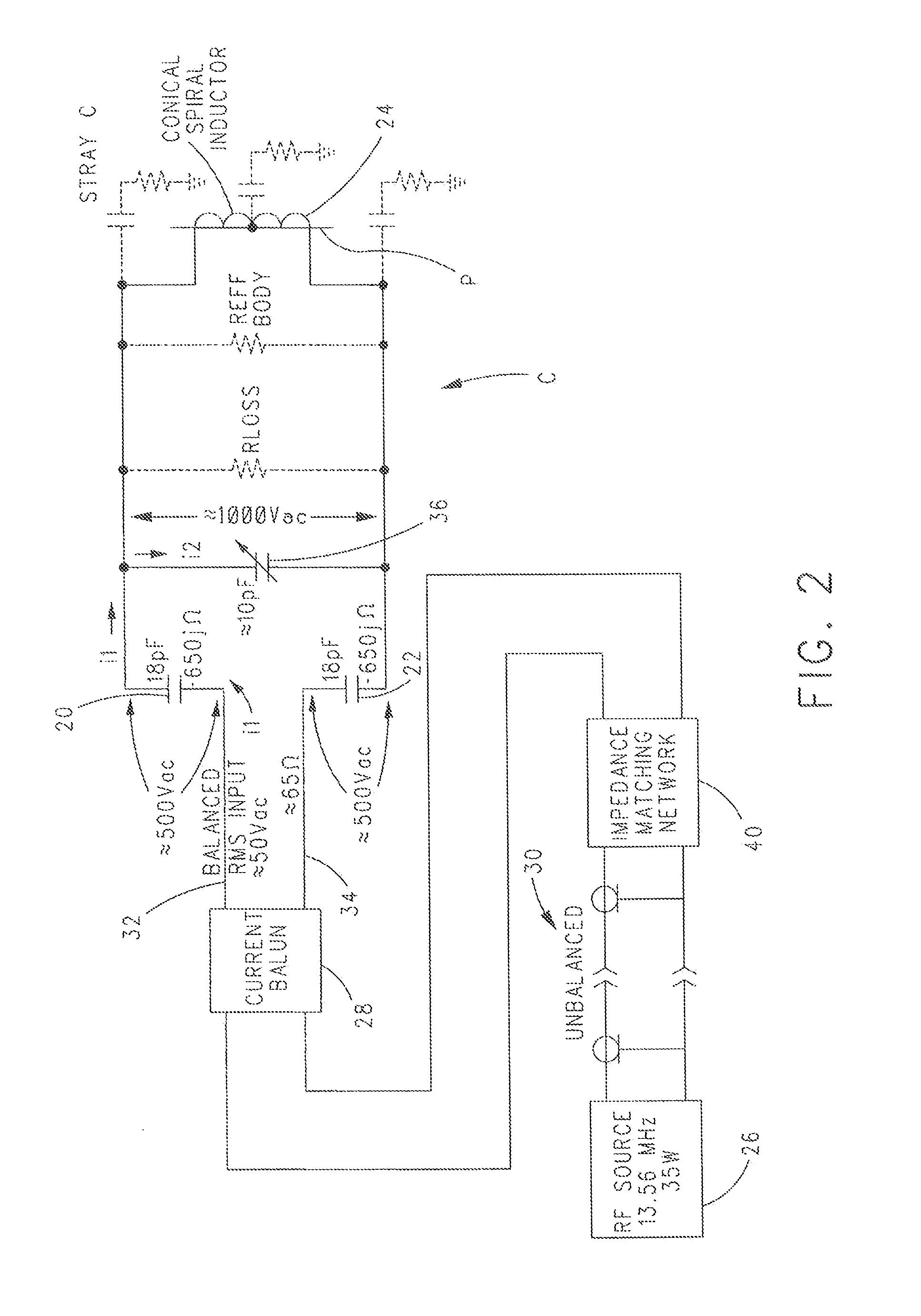

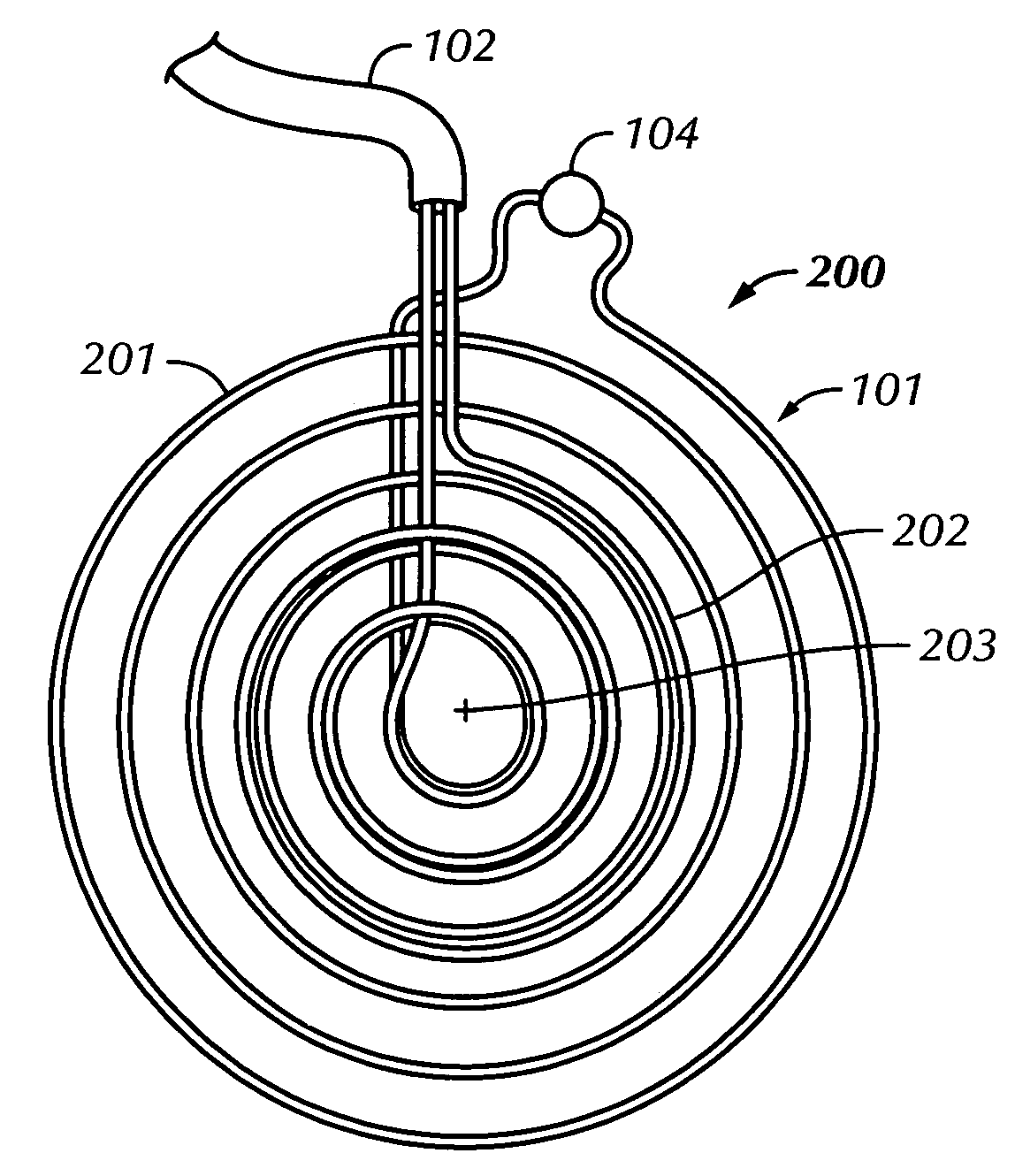

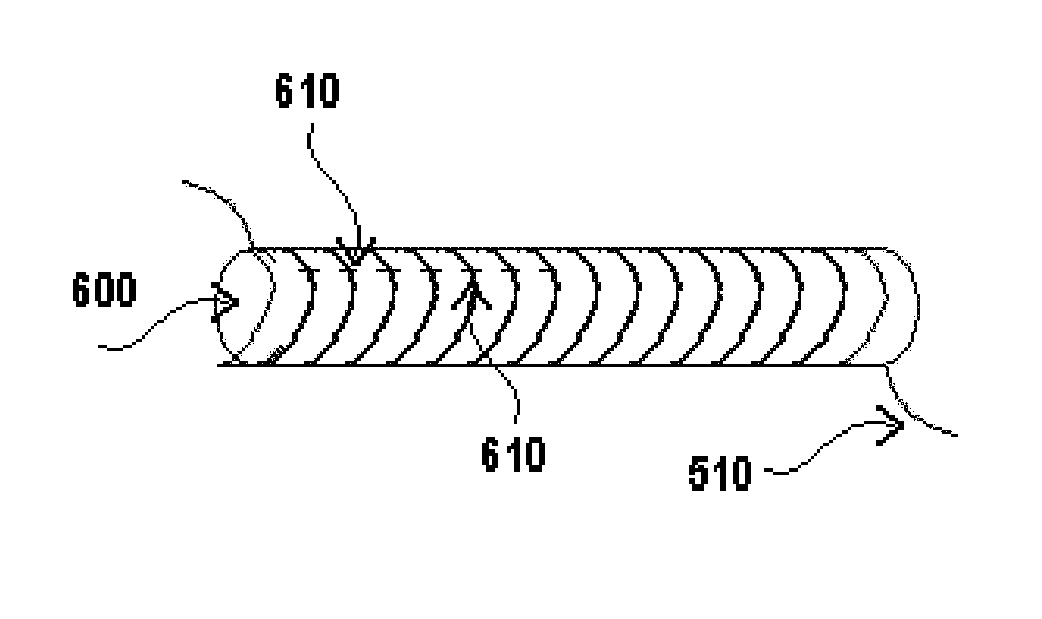

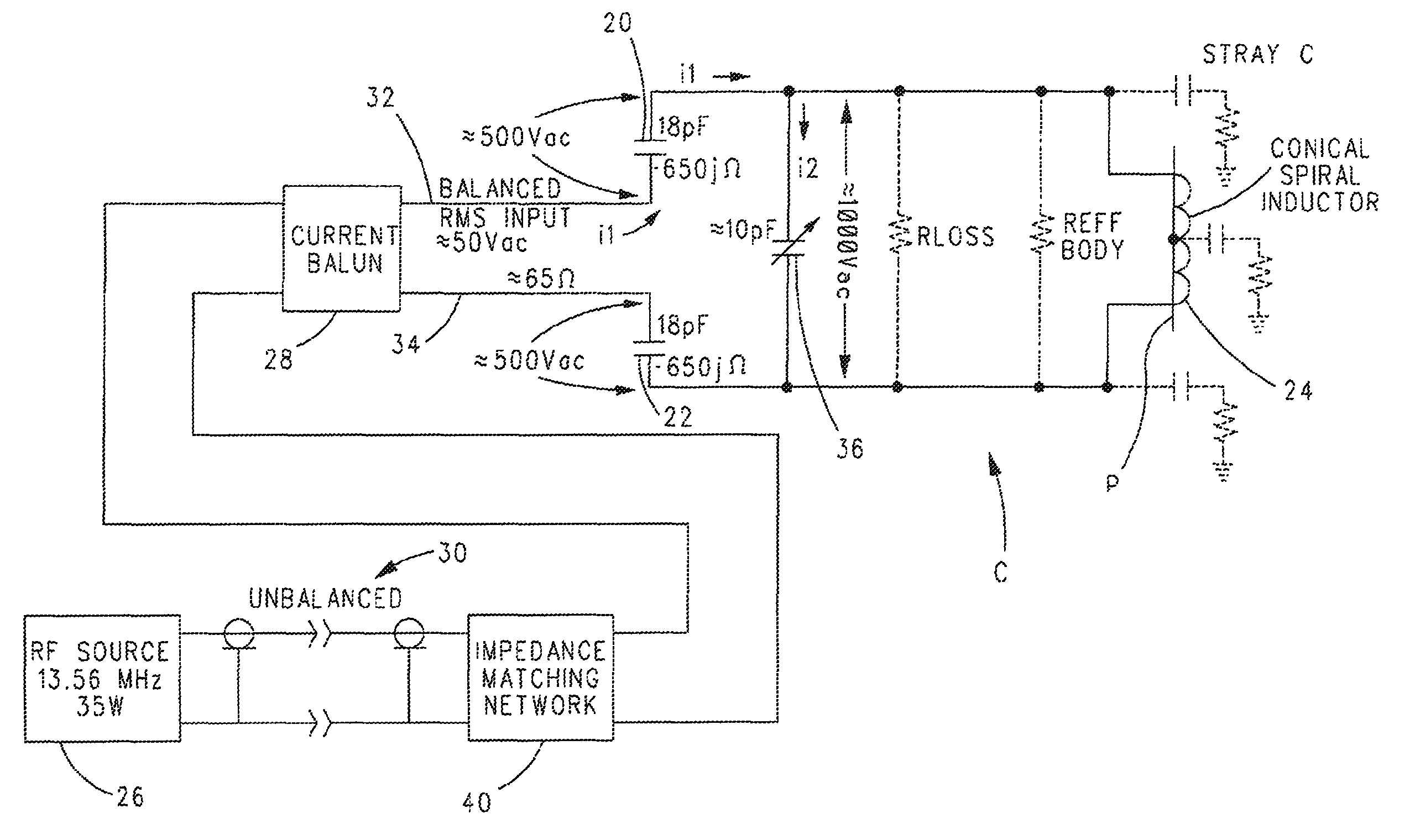

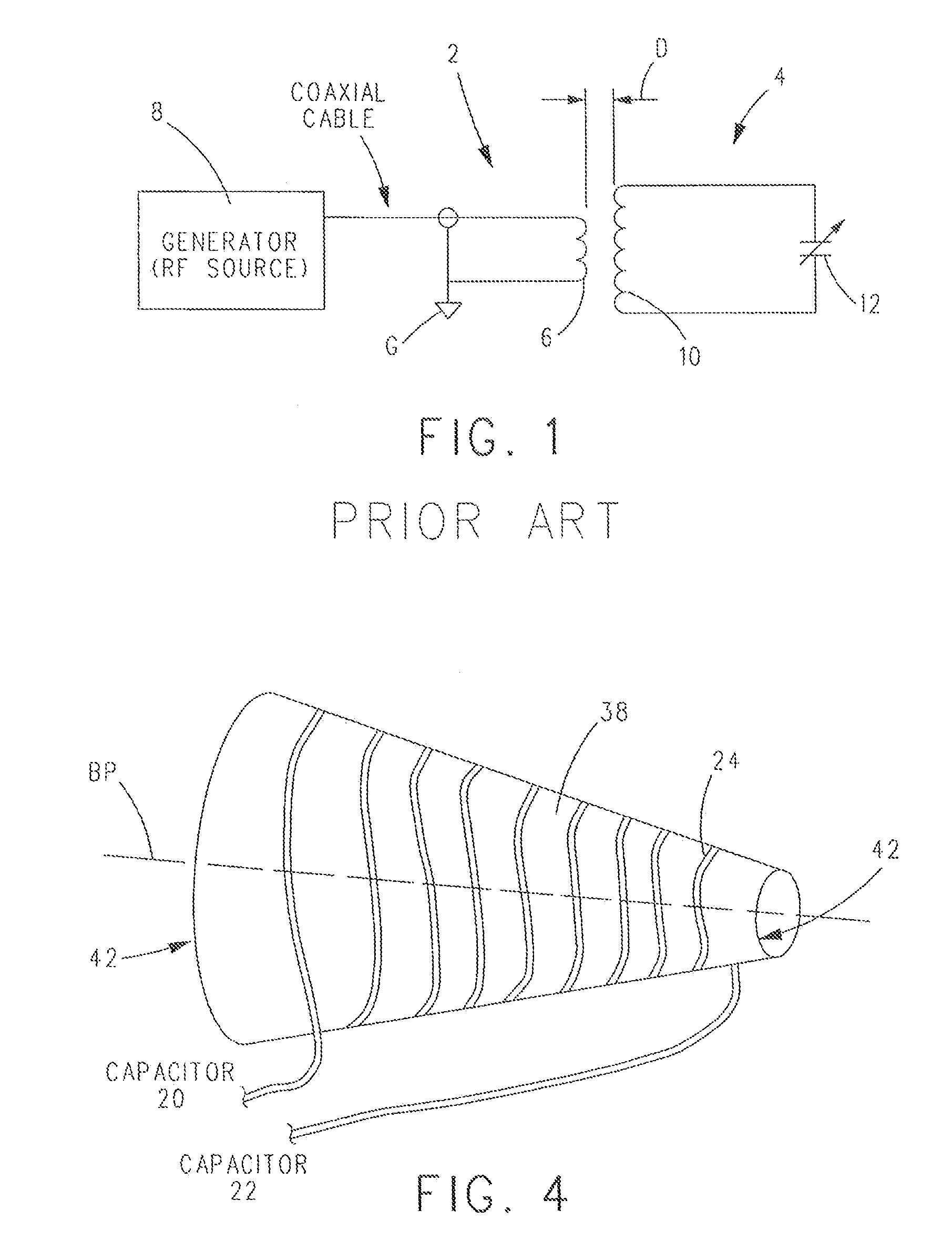

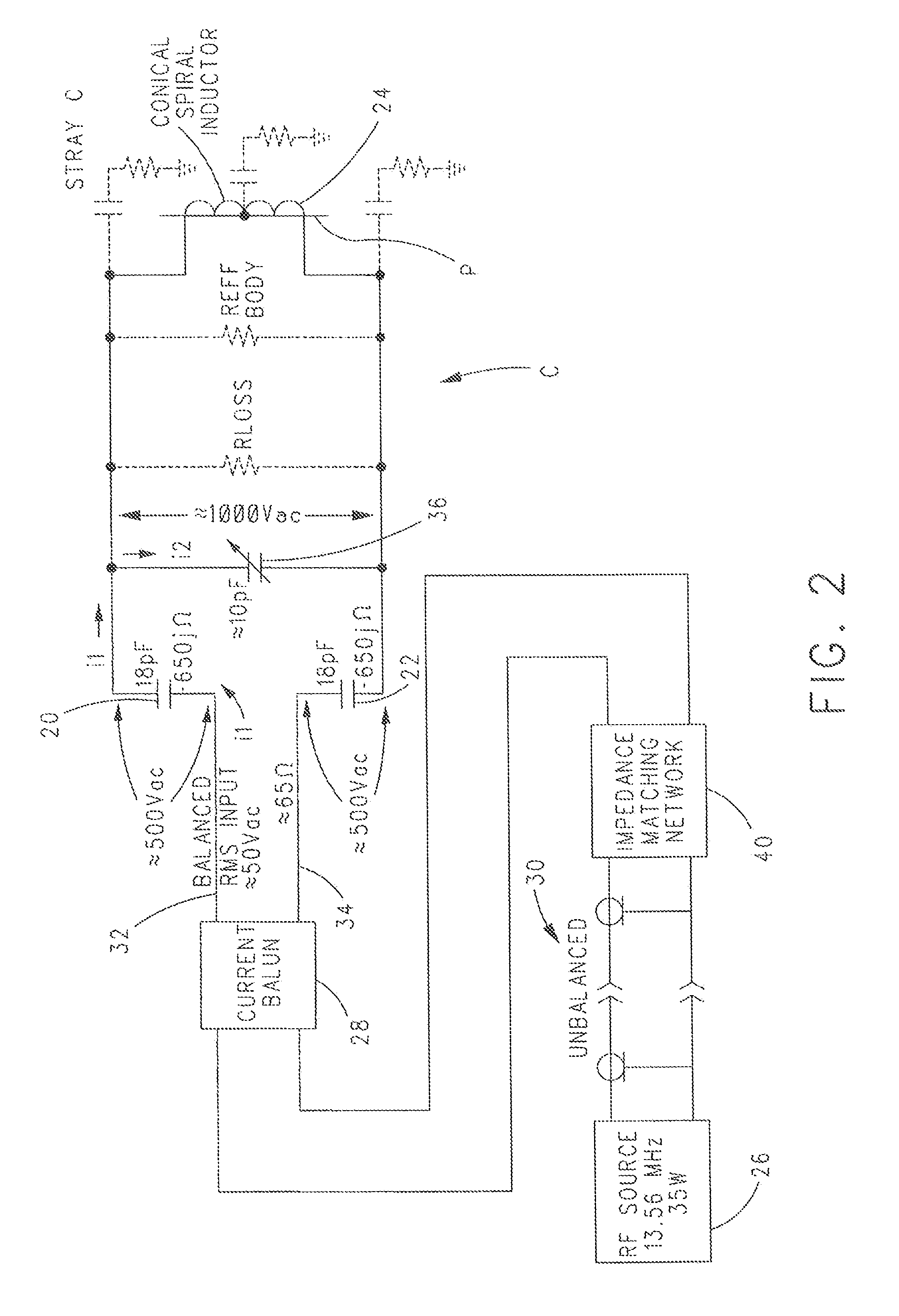

Coupling Method for Resonant Diathermy and Other Bio-Tissue Heating Applicators

ActiveUS20120265277A1Eliminating inductive couplingEfficiently boosting the common-mode rejection ratio (CMRR)Magnetotherapy using coils/electromagnetsSurgical instrument detailsCapacitanceTissue heating

A diathermy apparatus includes a cylindrical coil (24) defining an opening (42), a pair of capacitors of substantially similar capacitance (20 and 22), each capacitor connected to one end of the coil, an RF signal source (26), and a balun (28) connected between the RF signal source (26) and the pair of capacitors (20 and 22). The balun (28) is operative for converting an unbalanced signal received from the RF signal source (26) into a balanced signal supplied to coil (24) via the pair of capacitors (20 and 22). Desirably, the cylindrical coil is a conical cylindrical (or cone-shaped) spiral coil.

Owner:VIATHERM THERAPEUTICS LLC

RF Diathermy and Faradic Muscle Stimulation Treatment

InactiveUS20080215115A1Easy to changeUniform and symmetrical distributionElectrotherapyArtificial respirationWound healingEngineering

An RF diathermy coil assembly, including a generally elastically deformable patient conforming garment and a conductive coil secured to the garment. The conductive coil having a woven wire construction such that the coil can deform as the garment elastically deforms. The RF diathermy coil assembly can be used for wound healing in conjunction with muscle stimulation.

Owner:HK MEDICAL TECH +1

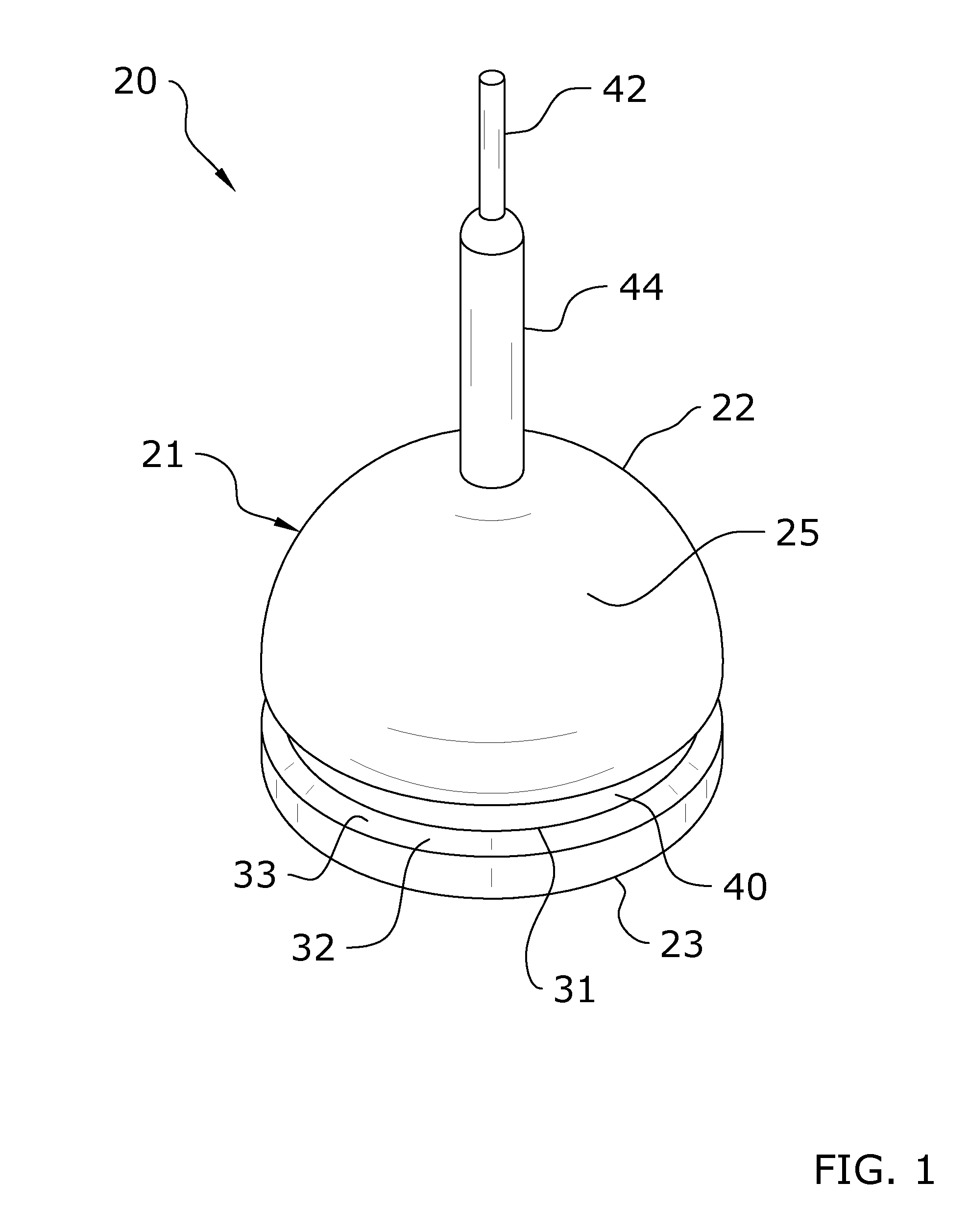

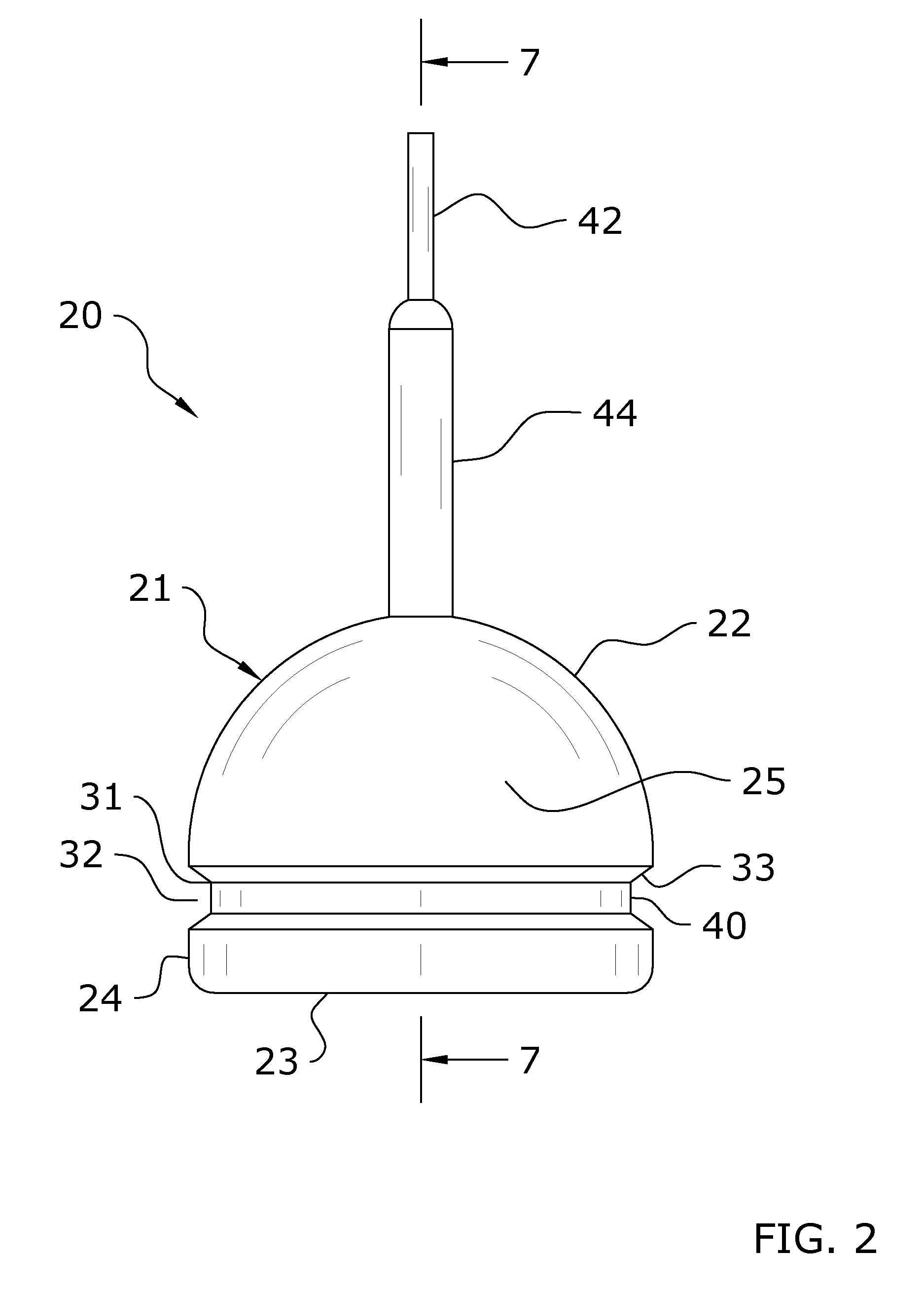

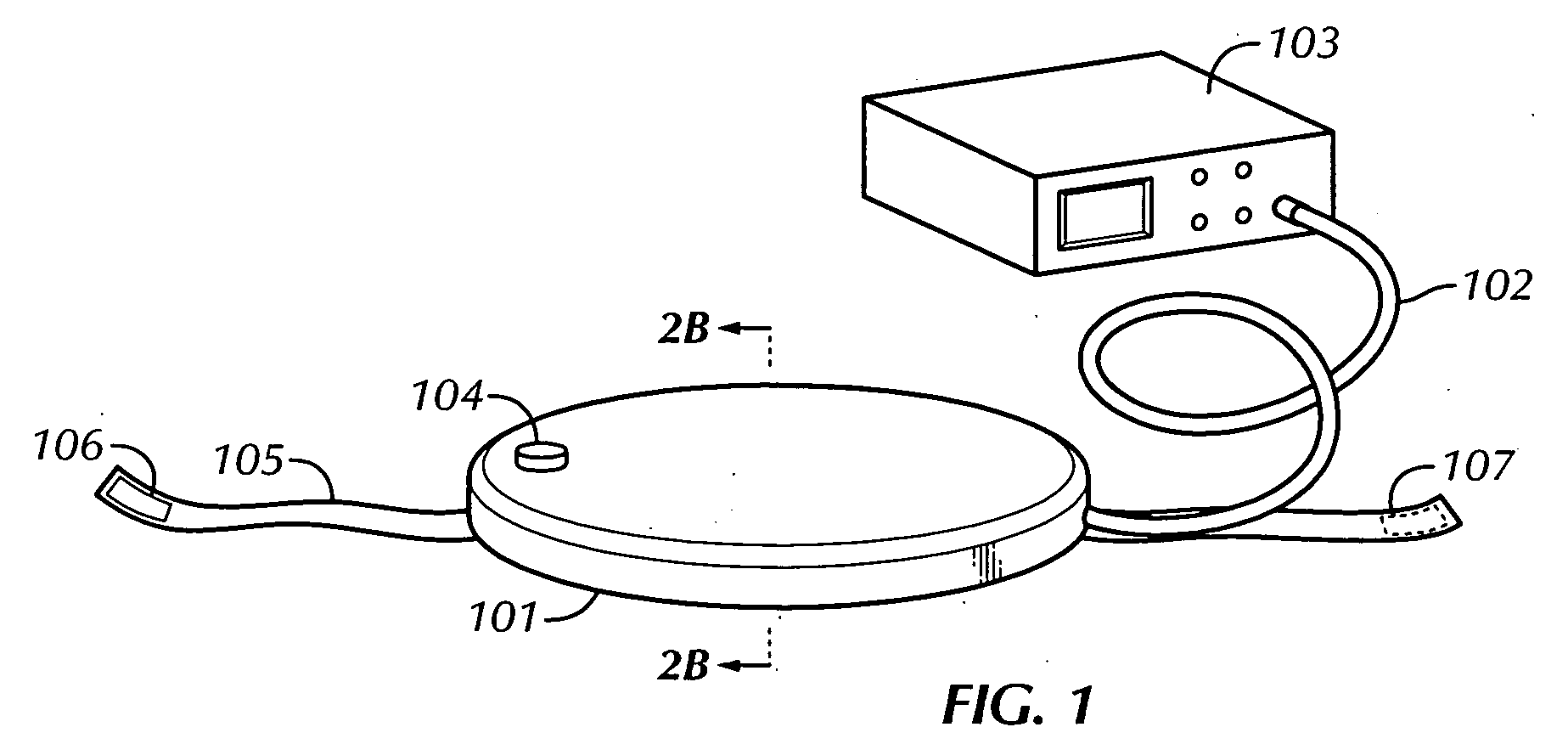

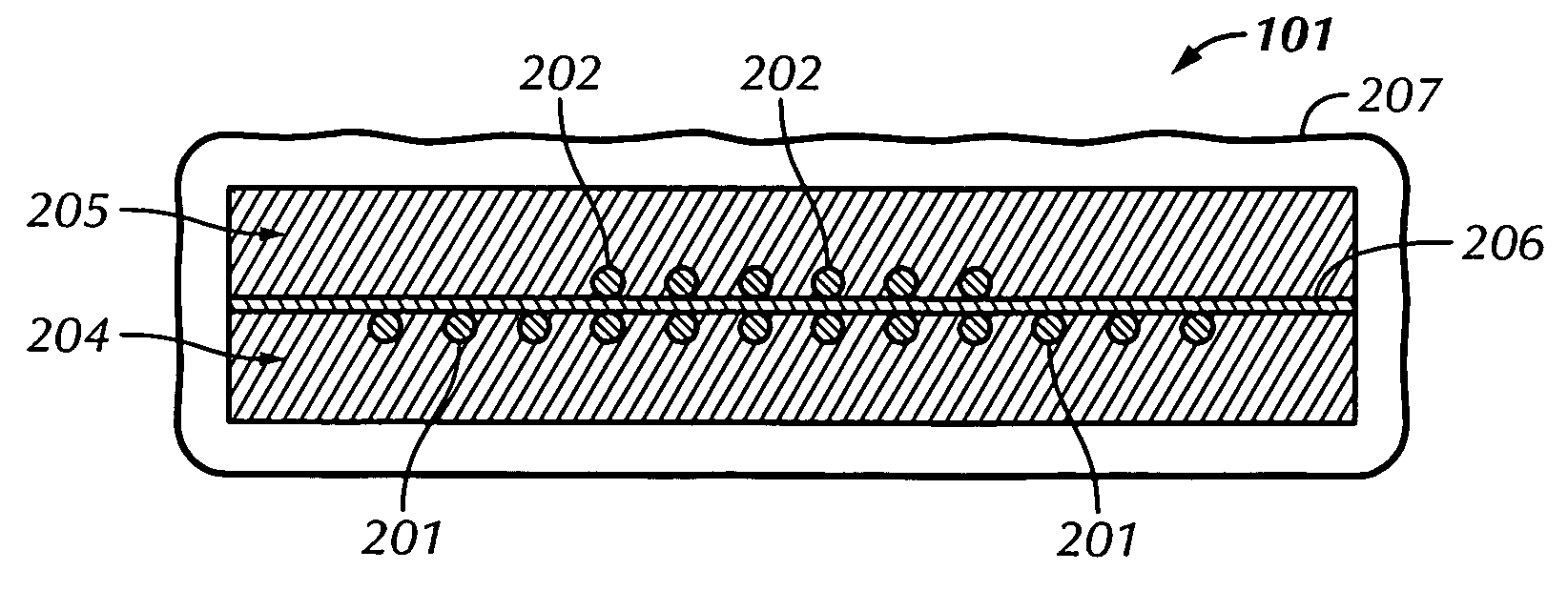

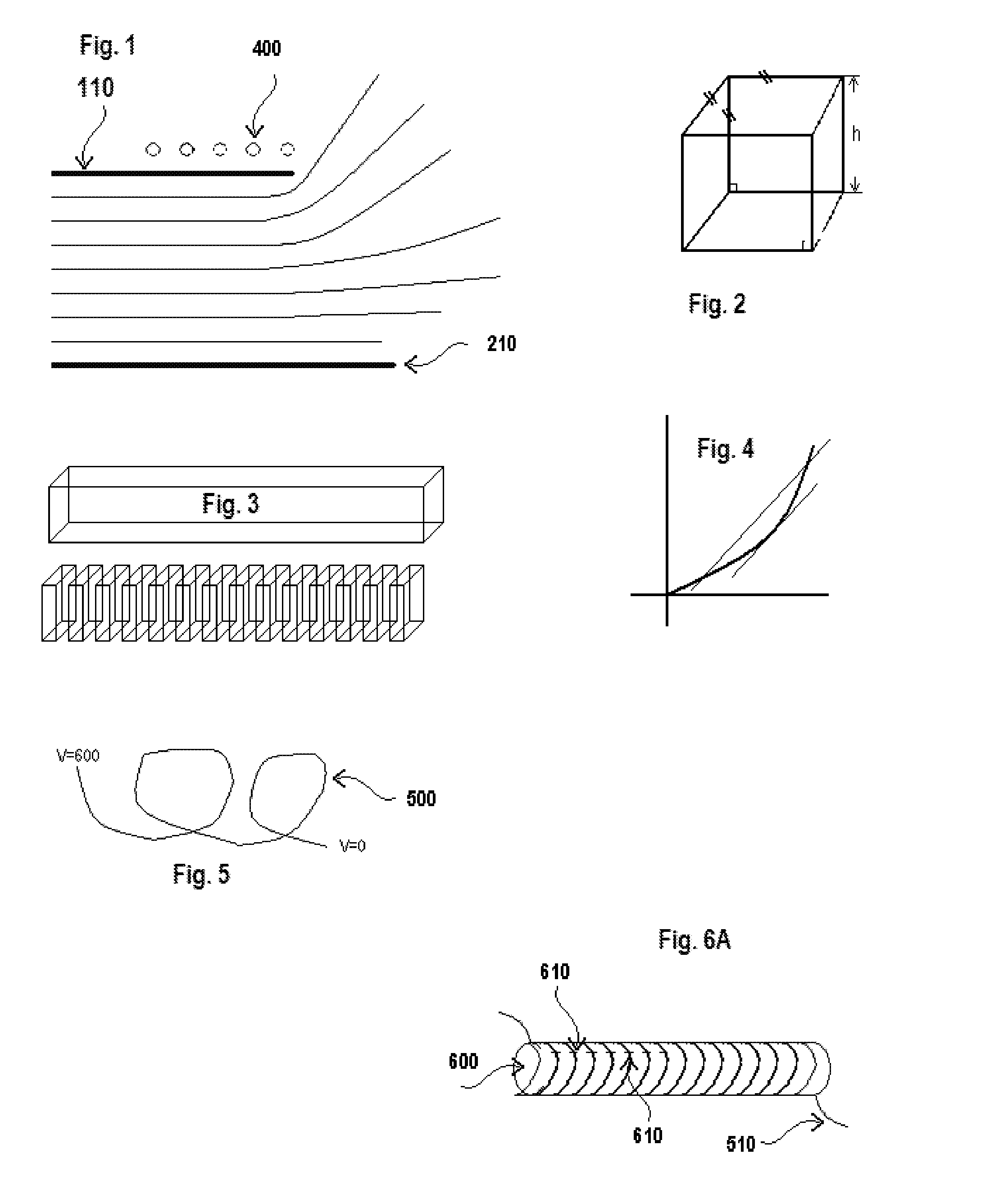

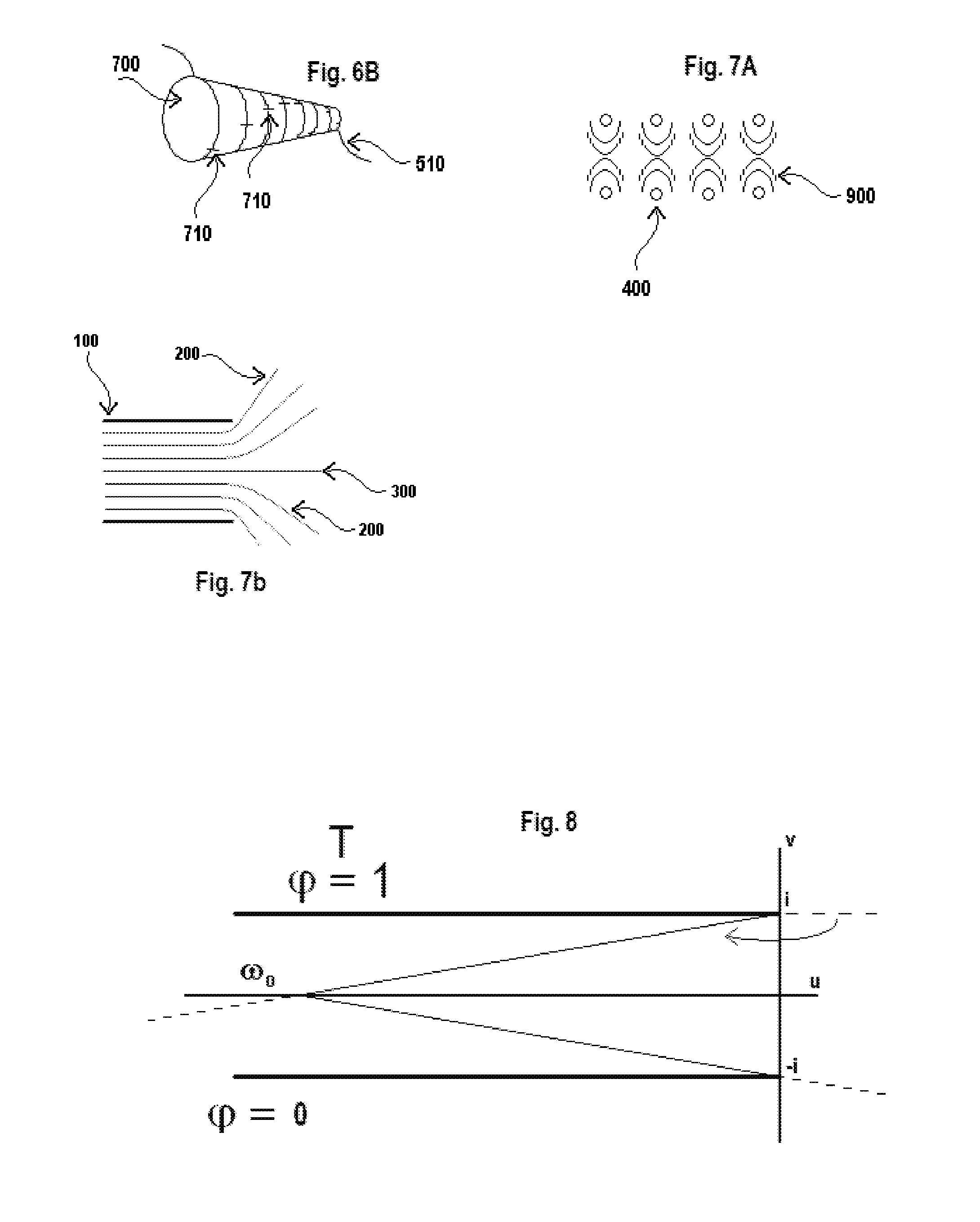

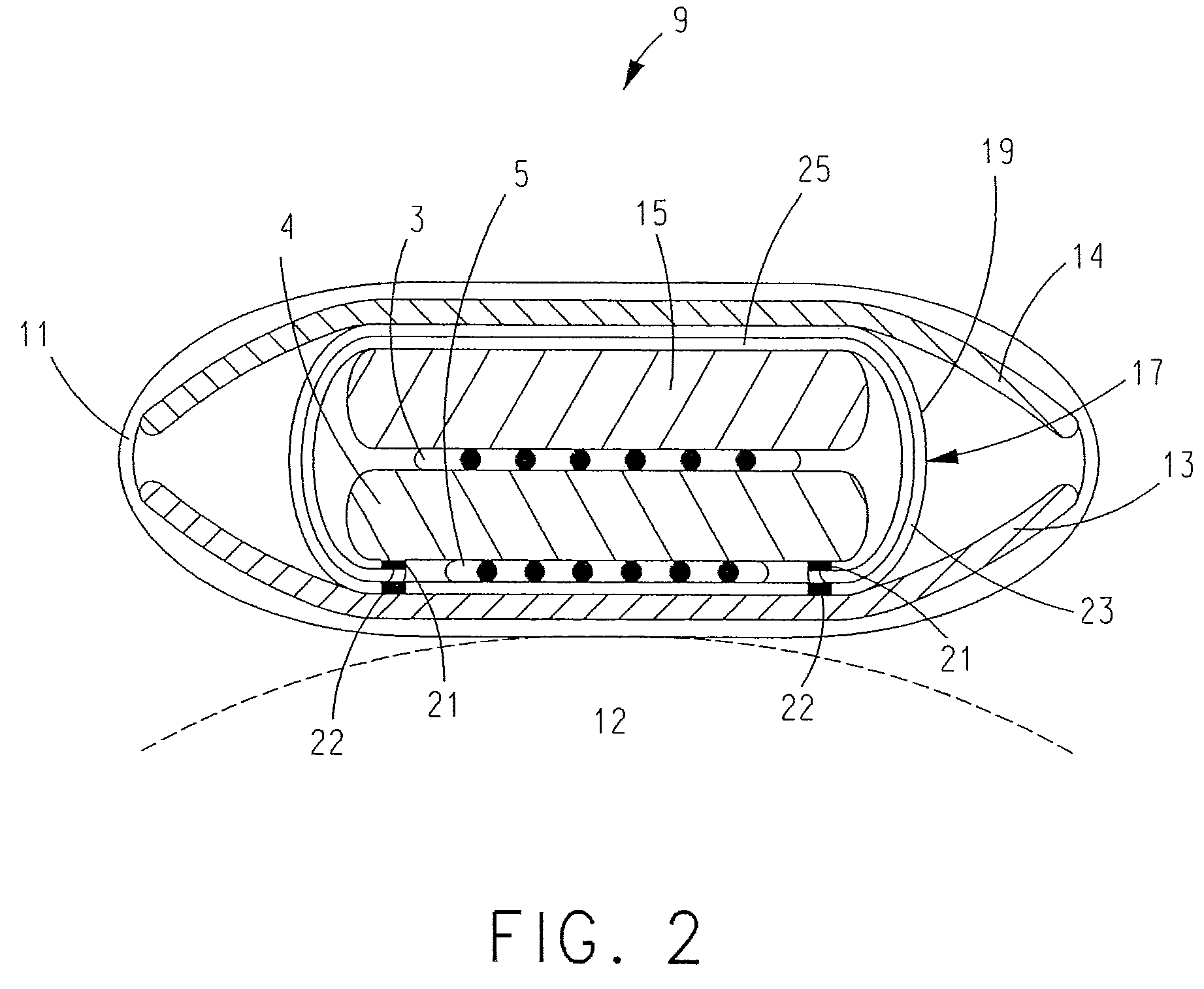

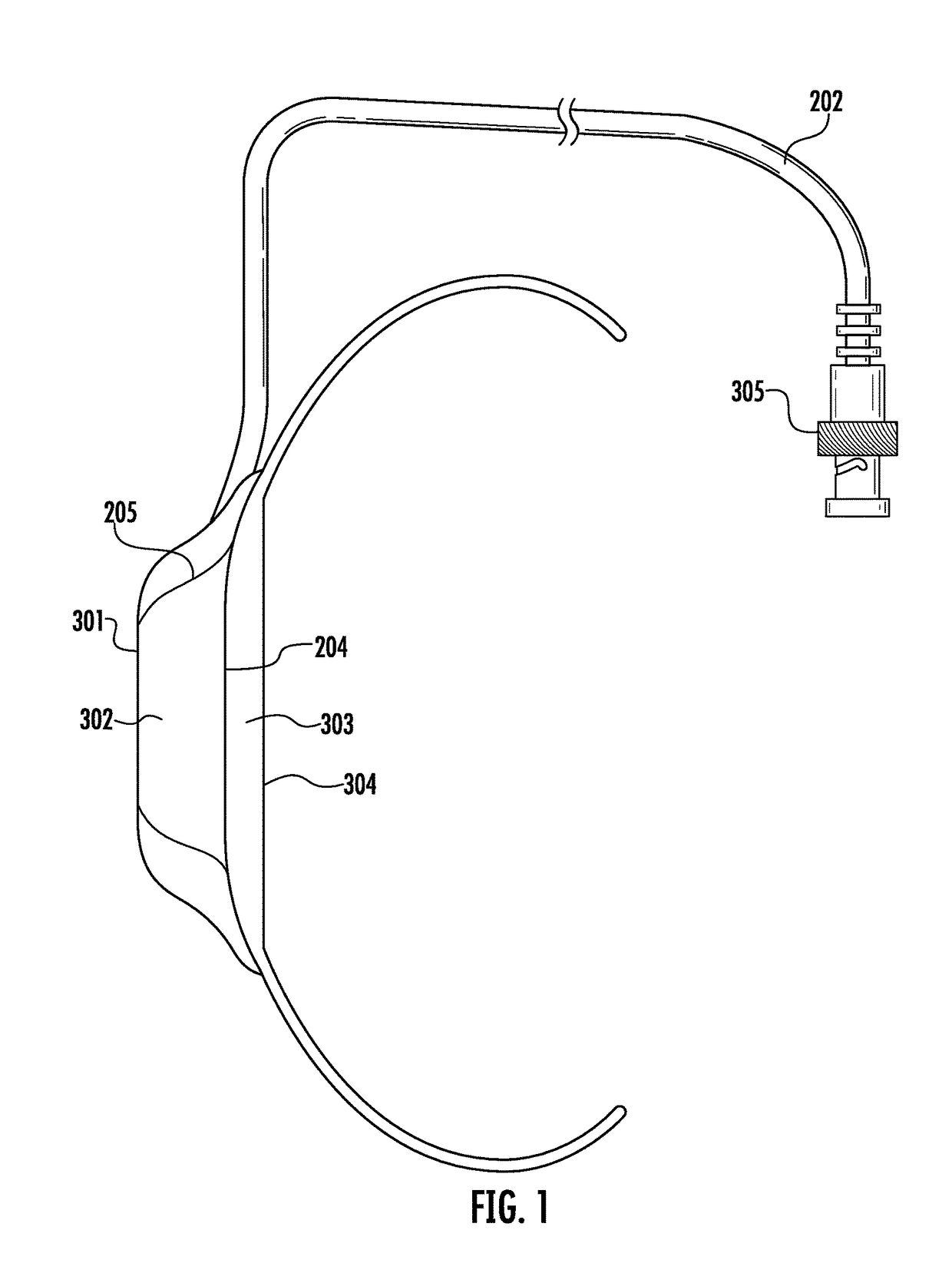

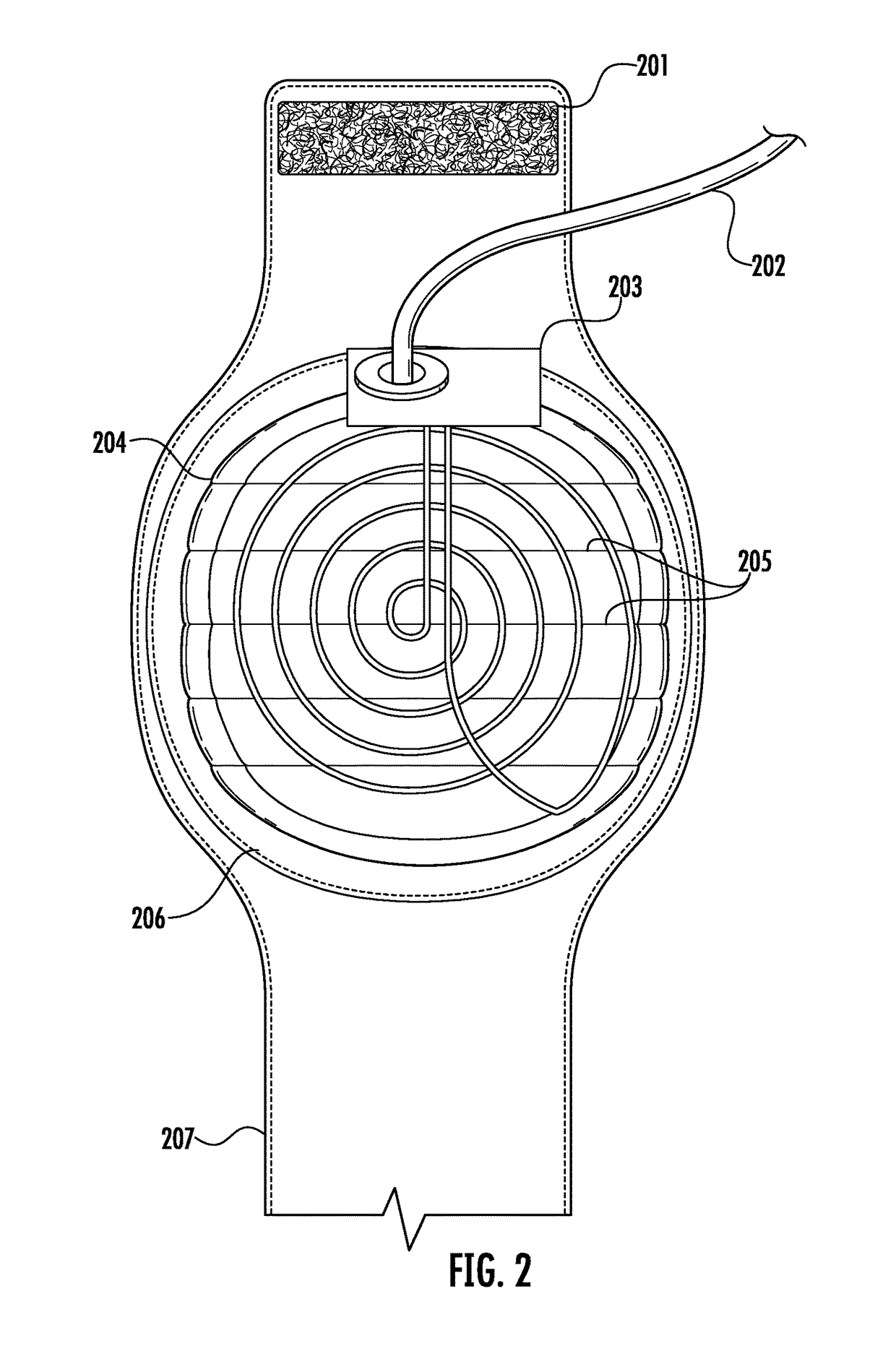

Radio frequency diathermy application system and device

ActiveUS20060119462A1Minimize impactUse minimizedElectrotherapyTherapeutic coolingEngineeringConductor Coil

A radio frequency diathermy application device, including a flexible pad and a flexible coil structure coupled to and supported by the pad The flexible coil structure has a flexible spiral-like primary winding and a flexible spiral-like secondary winding coupled to the primary winding, the primary and secondary windings each substantially lying in separate substantially parallel planes when the pad is in an unflexed state.

Owner:VIATHERM THERAPEUTICS LLC

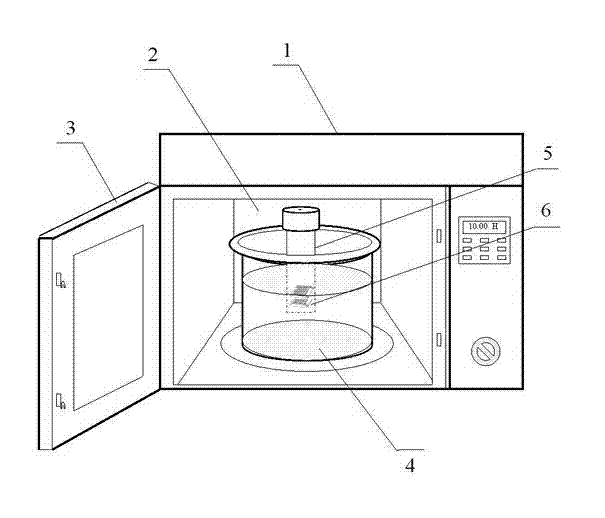

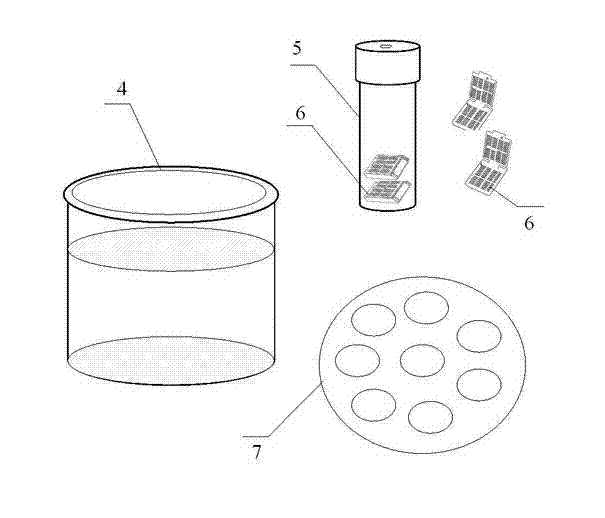

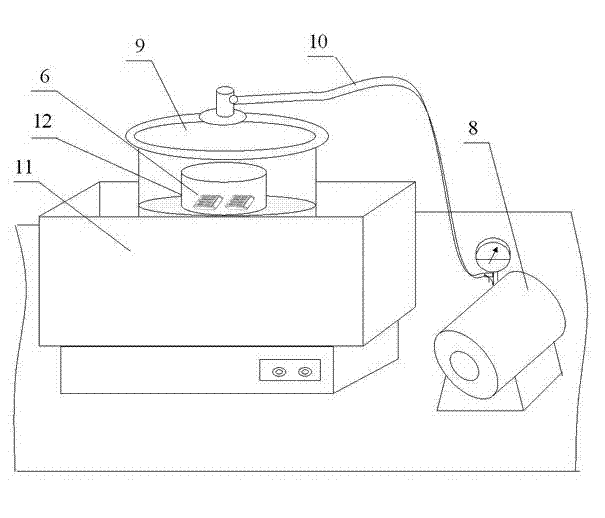

Method for fast flaking paraffin by microwave radiation water bath diathermy and device

InactiveCN102768145AAvoid spillingPrevent evaporationPreparing sample for investigationParaffin waxMedicine

The invention provides a method for fast flaking paraffin for a biological tissue sample and a device. A microwave radiation water bath diathermy is applied to help reagents which are weak in absorbing energy and paraffin be fast heated. The device for fast flaking paraffin is characterized by comprising a microwave radiation water bath diathermy part having the function of fast processing a tissue sample, and a vacuum negative pressure waxing part having the function of fast waxing the tissue sample. The procedure of flaking paraffin comprises the steps of fast tissue fixing, fast tissue dehydration and transparent handling once or twice and fast waxing. The reagents special for flaking paraffin comprises a fast fixing solution, a fast dehydration transparent reagent and a fast decalcification solution. The method and the device have the flexibility of processing tissue samples individually or in batch and the capability of processing different tissue samples simultaneously, and are stable and reliable in the flaking quality, and applied to the fast paraffin flaking and pathologic diagnosis for biological tissue samples for the pathology and inspection in the hospital, scientific research institutes and other organizations.

Owner:CHANGSHA COMBINE MEDICAL TECH

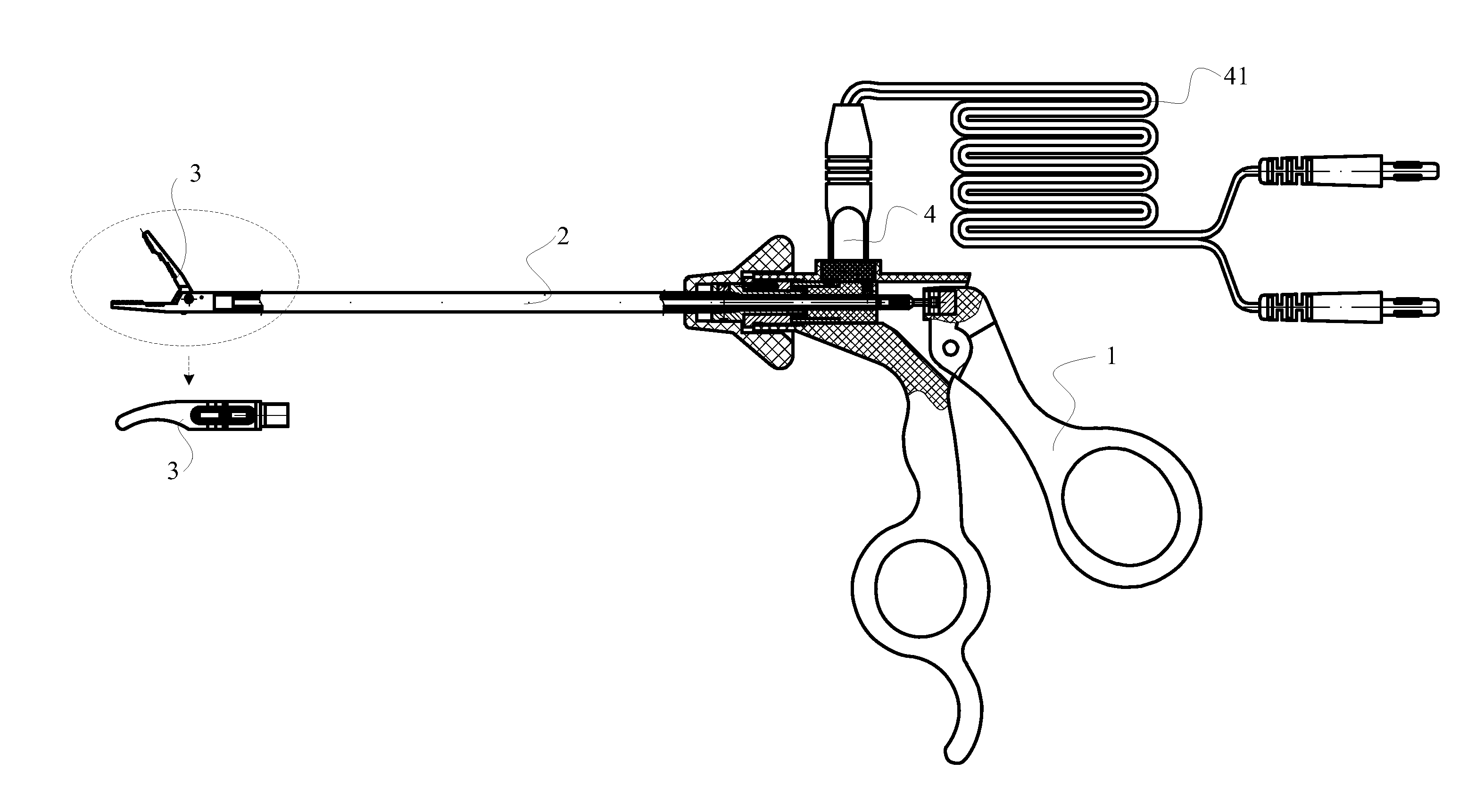

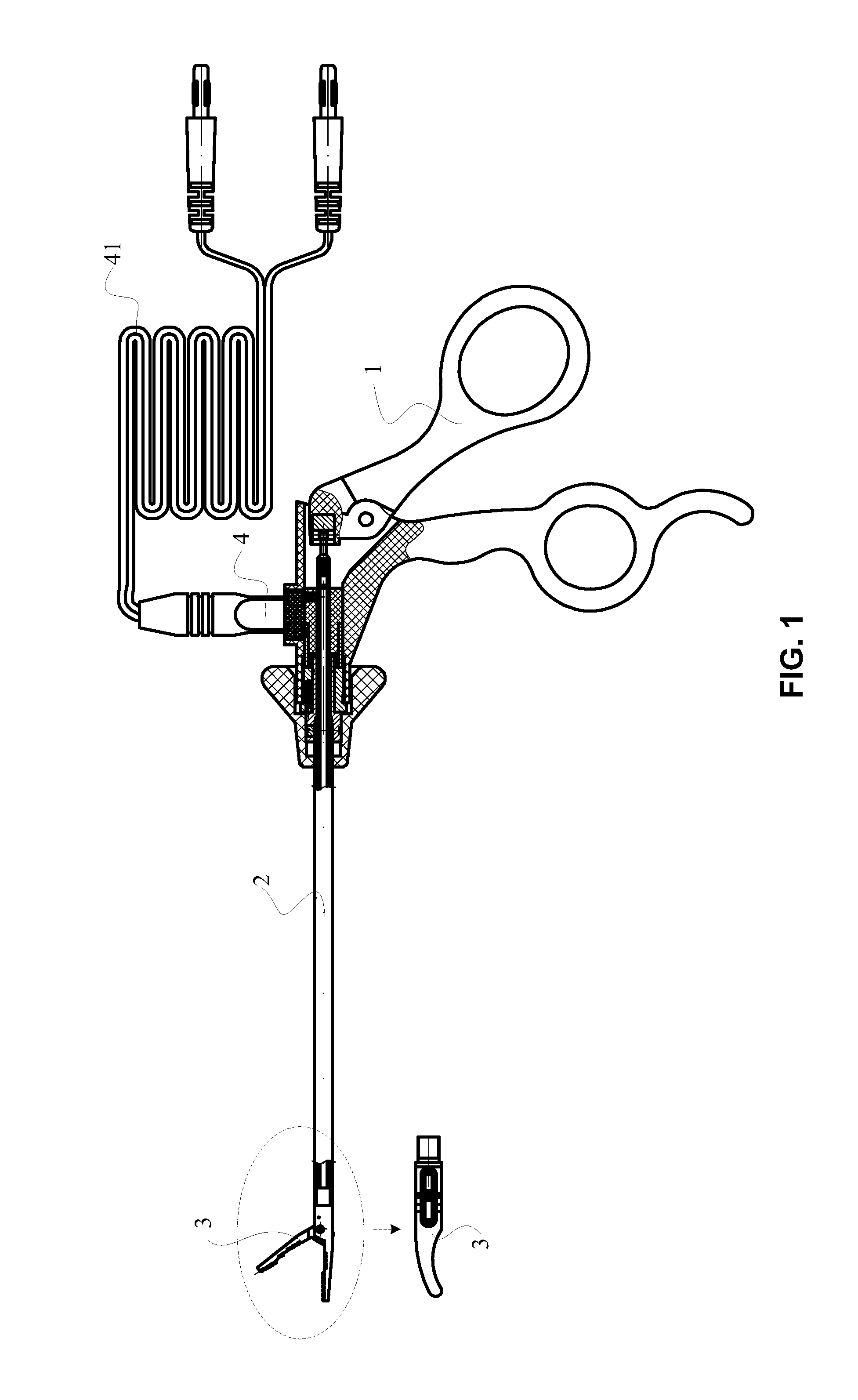

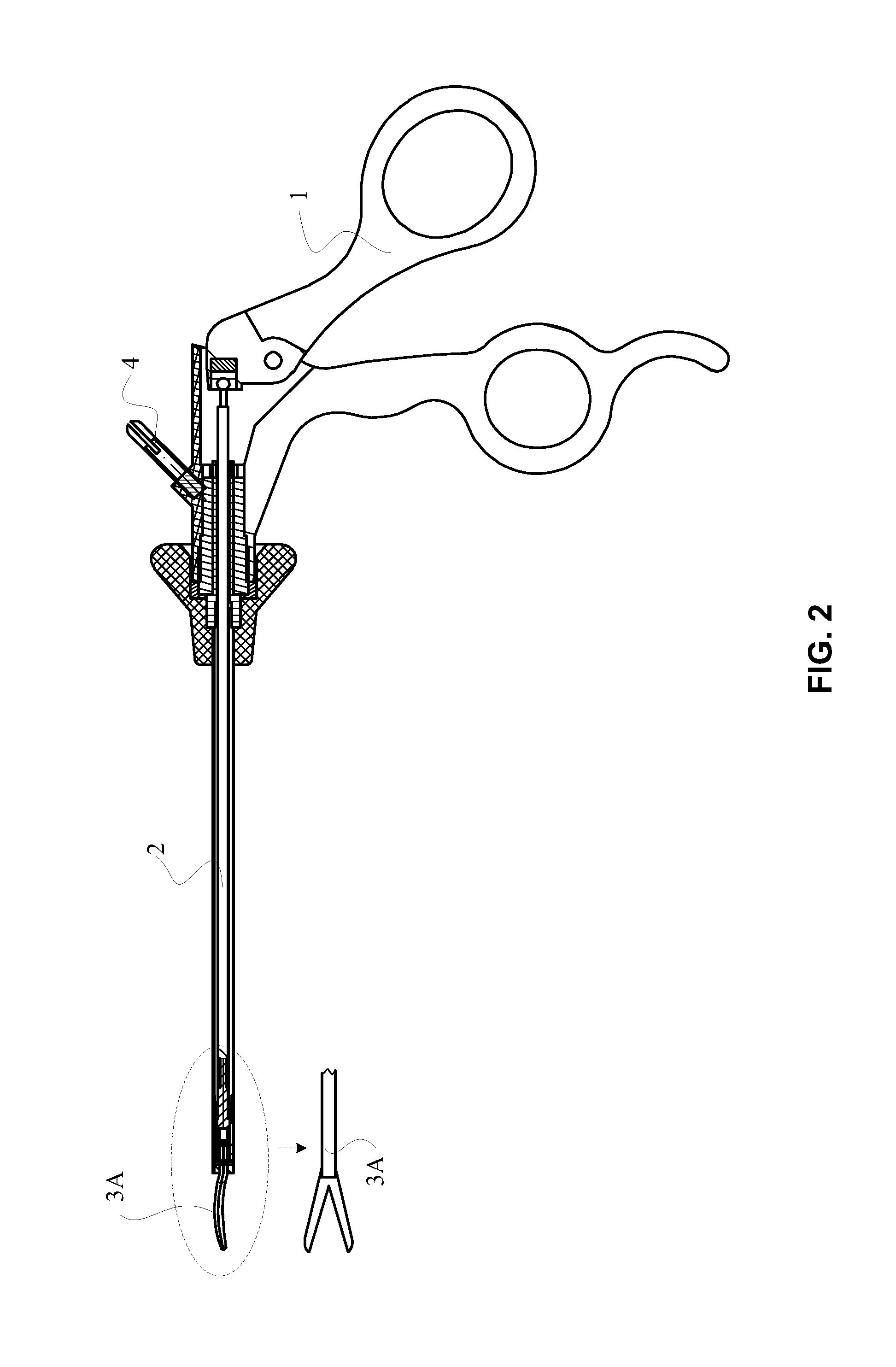

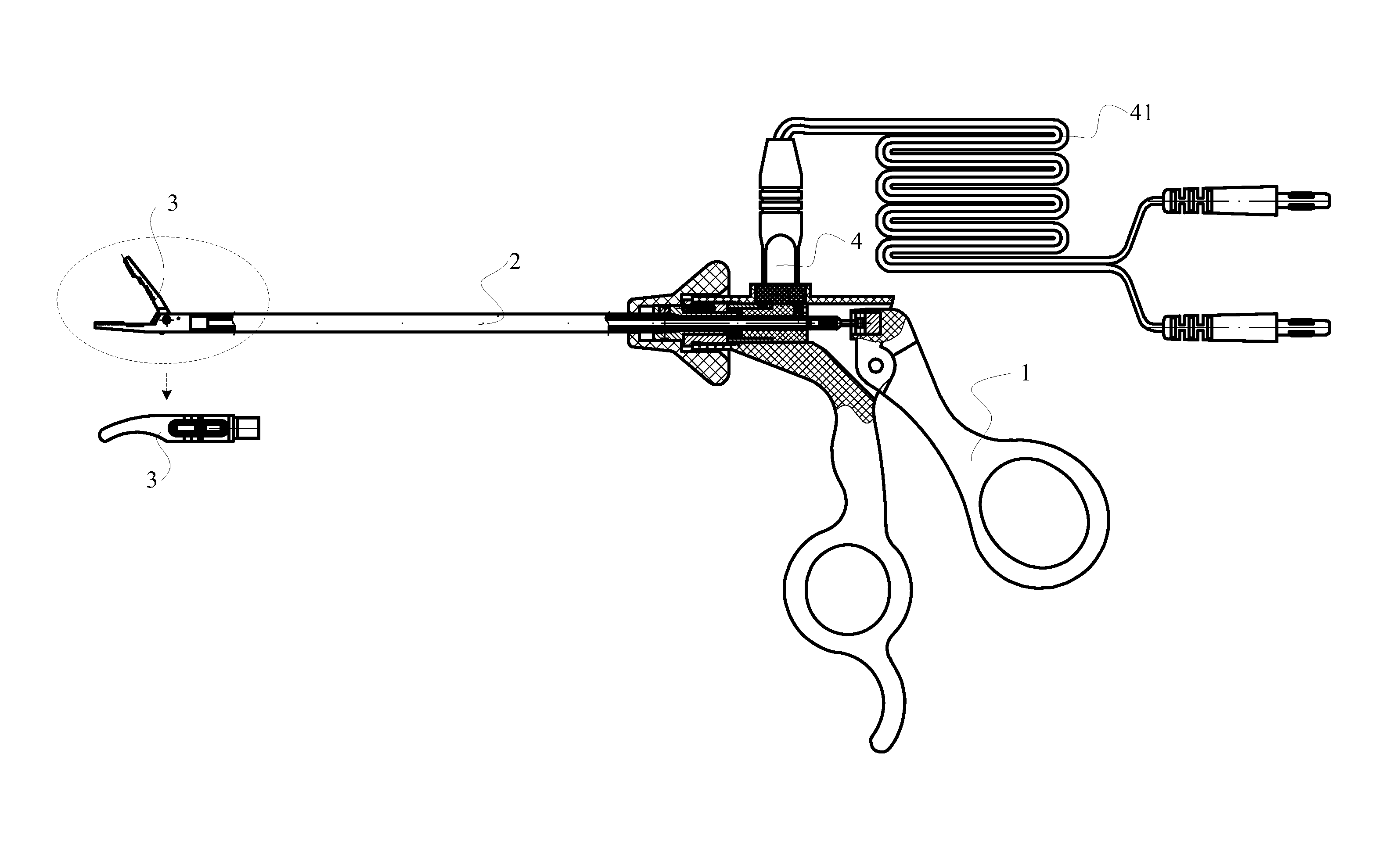

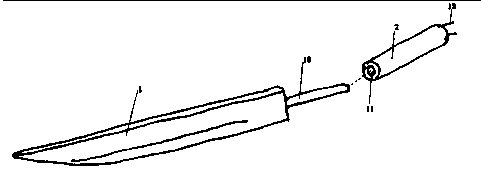

Anti-Sticking Electrosurgical Instrument

InactiveUS20140018801A1Preventing expanding woundProlong surgery timeSurgical instruments for heatingCoatingsElectricityBiomedical engineering

Owner:ADVANCED MEDICAL DESIGN

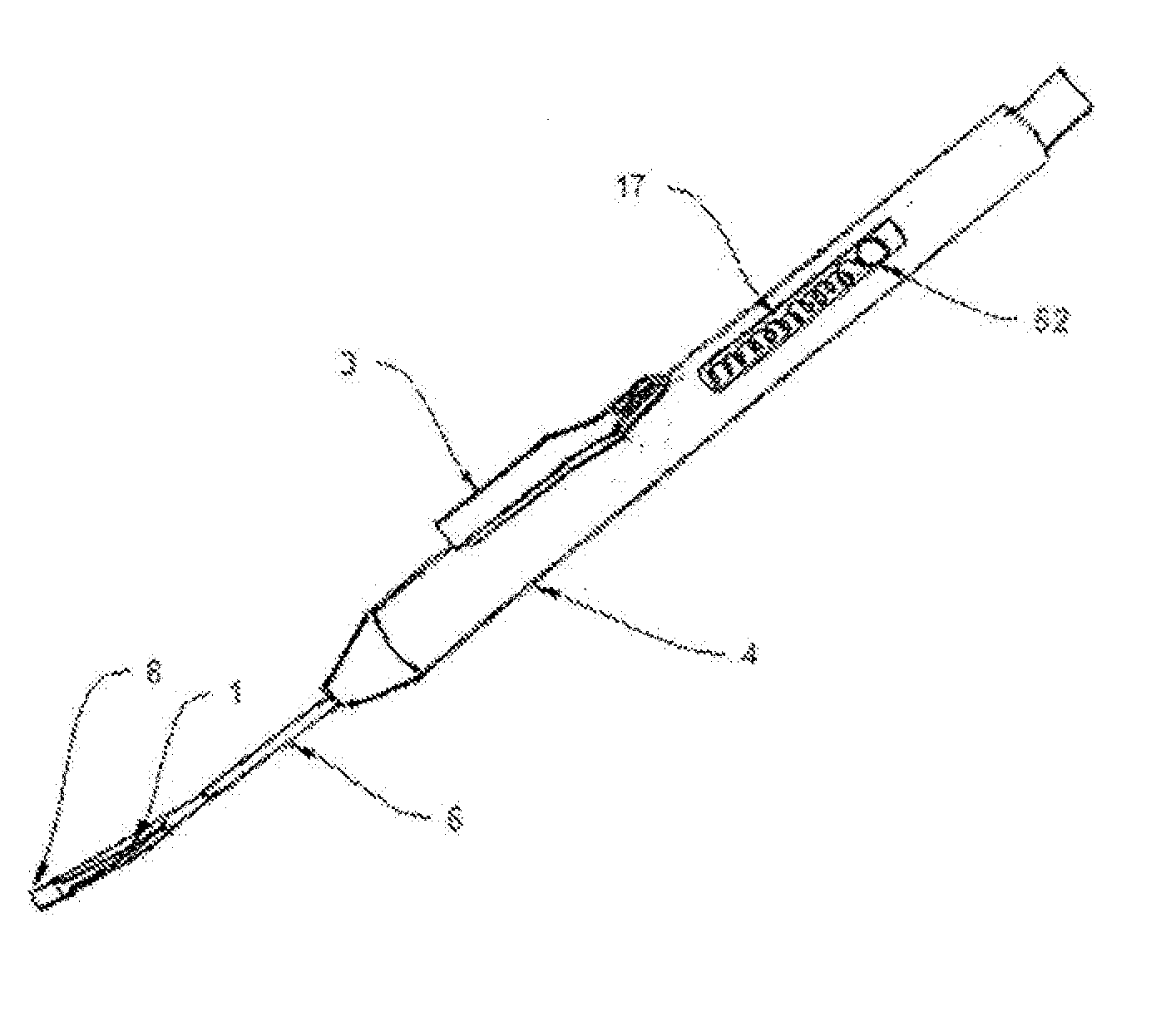

Anti-sticking electrosurgical instrument

InactiveUS8956354B2Enlarging woundProlong surgery timeSurgical instruments for heatingCoatingsElectricityBiomedical engineering

The present invention relates to a non-stick coated electrosurgical diathermy instrumentation, comprising: a handle portion; an isolation tube, connected to the handle portion by one end thereof; an instrument portion, connected to another end of the isolation tube, wherein an anti-sticking layer is formed on the surface of the instrument portion; and an electrode, connected to the handle portion and an external conductive member. In the present invention, the instrument portion is able to generate heat when the conductive member conducts electricity to the instrument portion.

Owner:ADVANCED MEDICAL DESIGN

Radio frequency diathermy application system and device

ActiveUS7979139B2Prevent gross misshaping of the deviceUse minimizedElectrotherapyTherapeutic coolingEngineeringConductor Coil

A radio frequency diathermy application device, including a flexible pad and a flexible coil structure coupled to and supported by the pad The flexible coil structure has a flexible spiral-like primary winding and a flexible spiral-like secondary winding coupled to the primary winding, the primary and secondary windings each substantially lying in separate substantially parallel planes when the pad is in an unflexed state.

Owner:VIATHERM THERAPEUTICS LLC

Pain-relieving paste suitable for various rheumatisms, gouts and traumatic injuries

InactiveCN106692904ALow priceSimple ingredientsHydroxy compound active ingredientsAntipyreticPoulticeRheumatism

The invention relates to pain-relieving paste suitable for various rheumatisms, gouts and traumatic injuries. The pain-relieving paste is characterized by being prepared from bulk pharmaceuticals according to weight parts in a specified range. A preparation method of the paste provided by the invention comprises the following steps: decocting raw materials except a paste substrate and borneol with water in an amount which is 6 to 8 times the total quantity of the raw materials by adopting a conventional method, sieving, airing and smashing decoction dregs with a No. 5 sieve, grinding the decoction dregs into powder, and drying; filtering decocted liquid to obtain filtrate, combining the filtrate and distilled medicinal liquor, concentrating the mixture into pasty thick liquid which is 1.33 in specific weight at the temperature of 80 DEG C, uniformly mixing powder prepared from decoction dregs left after filtering of the thick liquid and the medicinal liquor, the ground borneol and the paste substrate, and uniformly spreading on a cut cloth block. A use method of the pain-relieving paste comprises the following steps: cleaning an affected part; applying a patch of 25g to the affected part every time for 1 to 2 days, wherein diathermy can be taken as an assistant measure. Compared with the prior art, the pain-relieving paste has the advantages of suitability for various rheumatisms, gouts and traumatic injuries, quick response and convenience in use.

Owner:新疆益广康源生物科技有限公司

Diathermy Applicator Garment

ActiveUS20140018889A1Reduction local surface burningImprove uniformityElectrotherapyMagnetotherapy using coils/electromagnetsCapacitive effectBiomedical engineering

A therapeutic diathermy applicator is proposed which minimizes the common problem of burning of skin patient. The heat distribution arising as a result of unwanted capacitive effects is modeled as a manifestation of ‘conservative’ energy. A specific spatial characteristic of RF stimulation is determined and incorporated into the design of the applicator in order to achieve these goals.

Owner:VIATHERM THERAPEUTICS LLC

Shielded diathermy applicator with automatic tuning and low incidental radiation

Owner:VIATHERM THERAPEUTICS LLC

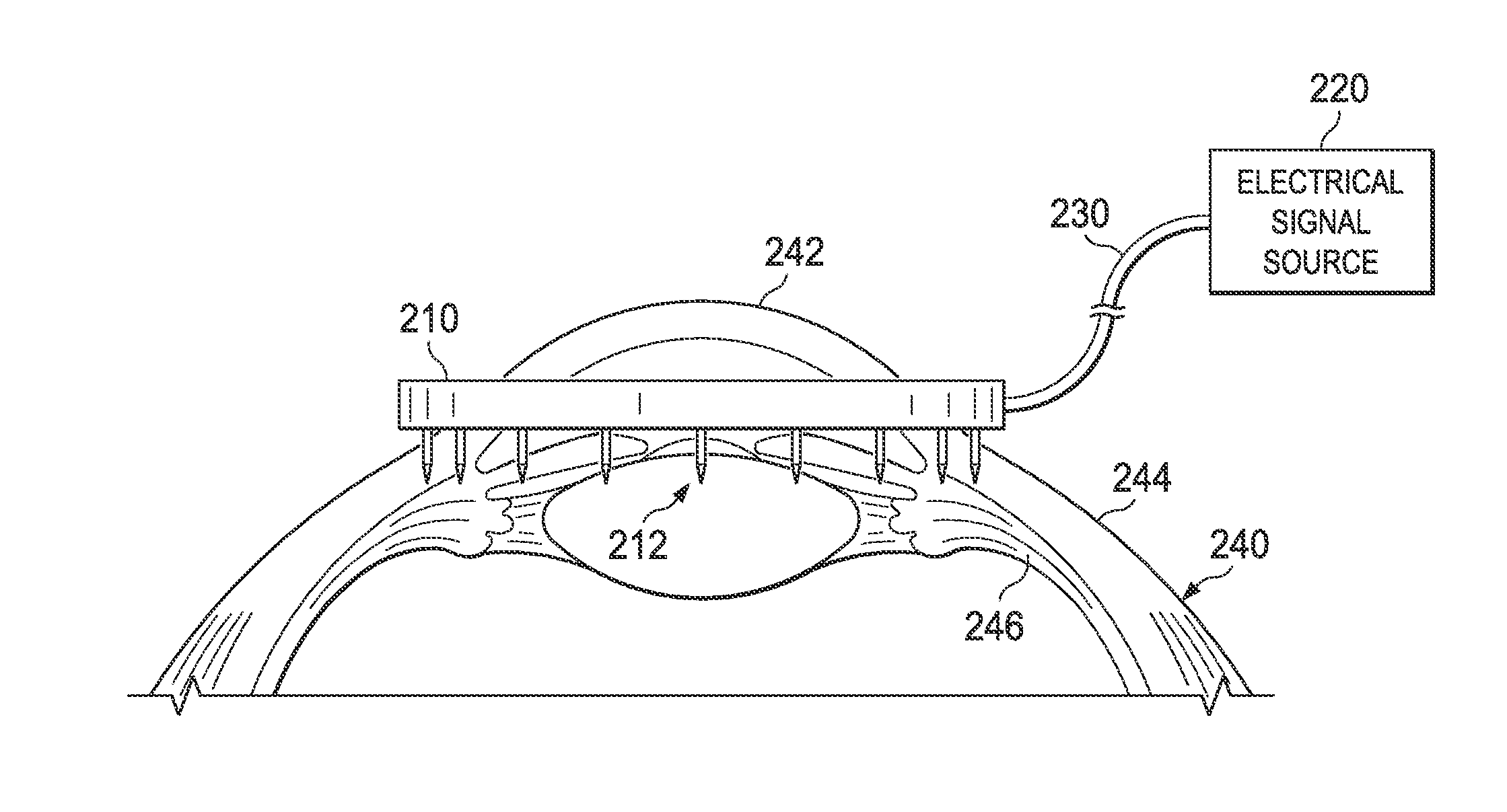

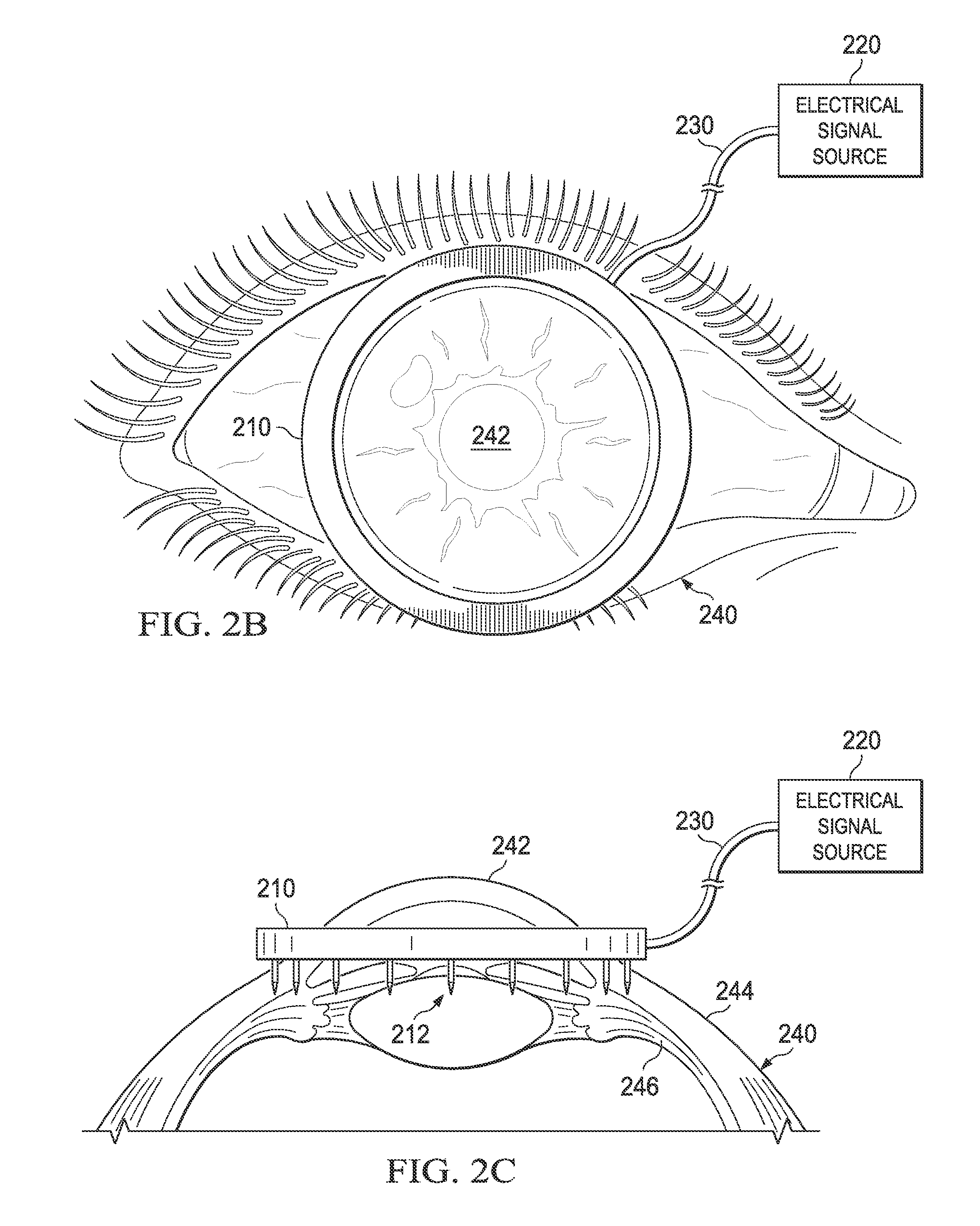

System and procedure for enhancing ocular drainage

InactiveUS20140163542A1Low flow resistanceLower eye pressureEye surgerySurgical instruments for heatingTrabecular meshworkOptometry

Various systems, apparatuses, and processes may be used for enhancing ocular drainage. In particular implementations, a system for ocular drainage may include an ocular interface that includes a base and a number of diathermy needles. The diathermy needles may extend from the base a distance sufficient to penetrate a sclera of an eye and provide radio frequency energy to a trabecular meshwork.

Owner:ALCON RES LTD

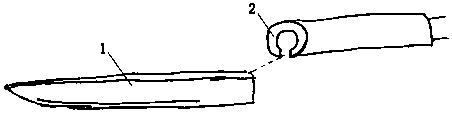

External heated electric diathermy knife

InactiveCN107669333ALess traumaticReduce usageIncision instrumentsSurgical instruments for heatingSurgical operationEngineering

The invention belongs to the technical field of medical instruments, and relates to a medical surgical scalpel, in particular to an external heating type electric heating scalpel, which includes a blade body, on which a heating block for heating the blade body is externally connected, and a wire Leading out from the rear end of the heating block, the rear part of the blade body has stoppers perpendicular to the surface of the blade body and extending symmetrically to both sides; the heating block is connected to the blade body through the card slot opened on it, When the heating block is connected to the blade body, the position of the front end surface of the blade body corresponding to the locking groove abuts against the rear end surface of the stopper. The use of the scalpel can reduce the degree of surgical trauma, reduce bleeding, and effectively shorten the operation time.

Owner:CHANGZHOU EUPHORY MEDICAL CO LTD

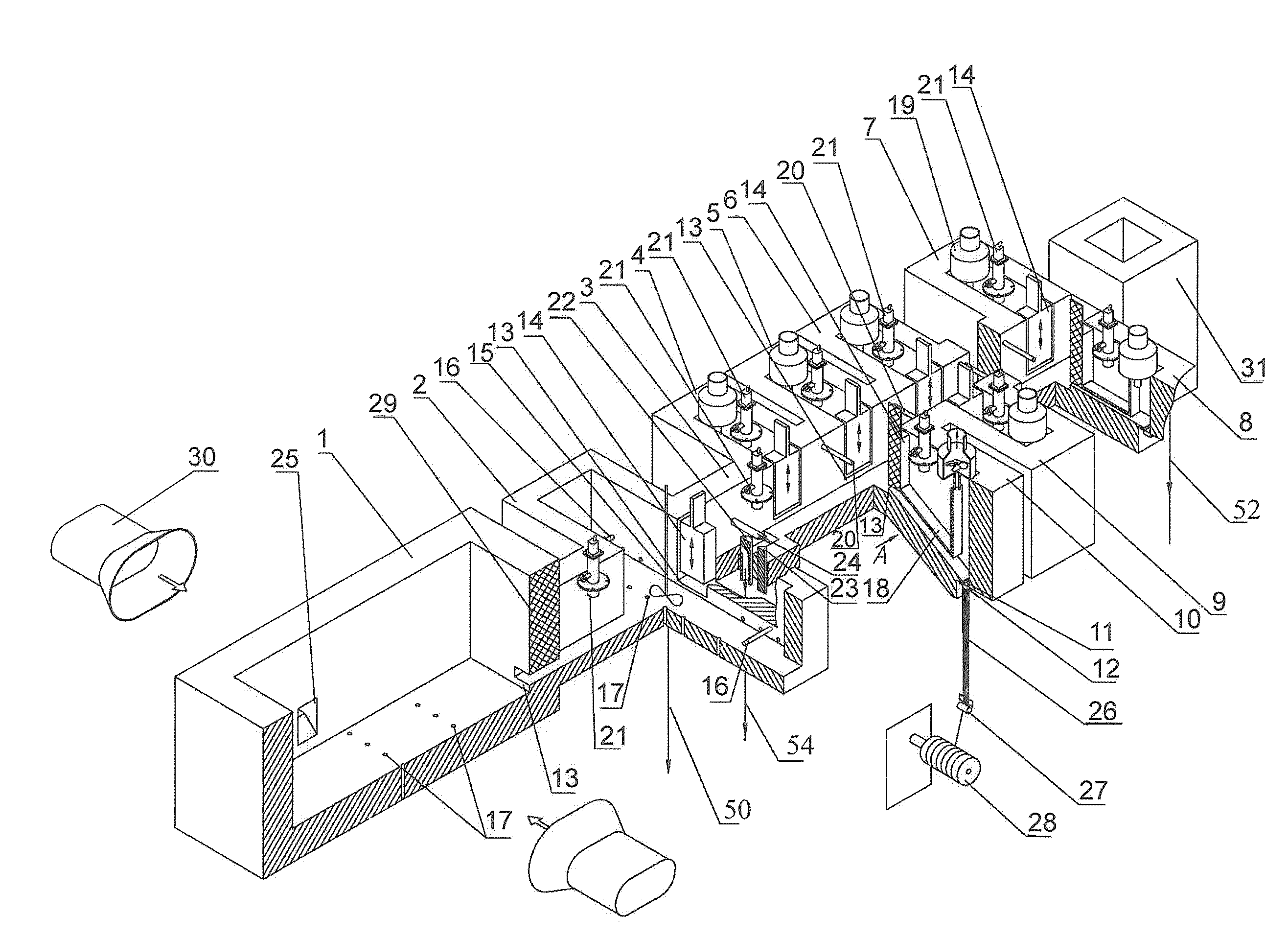

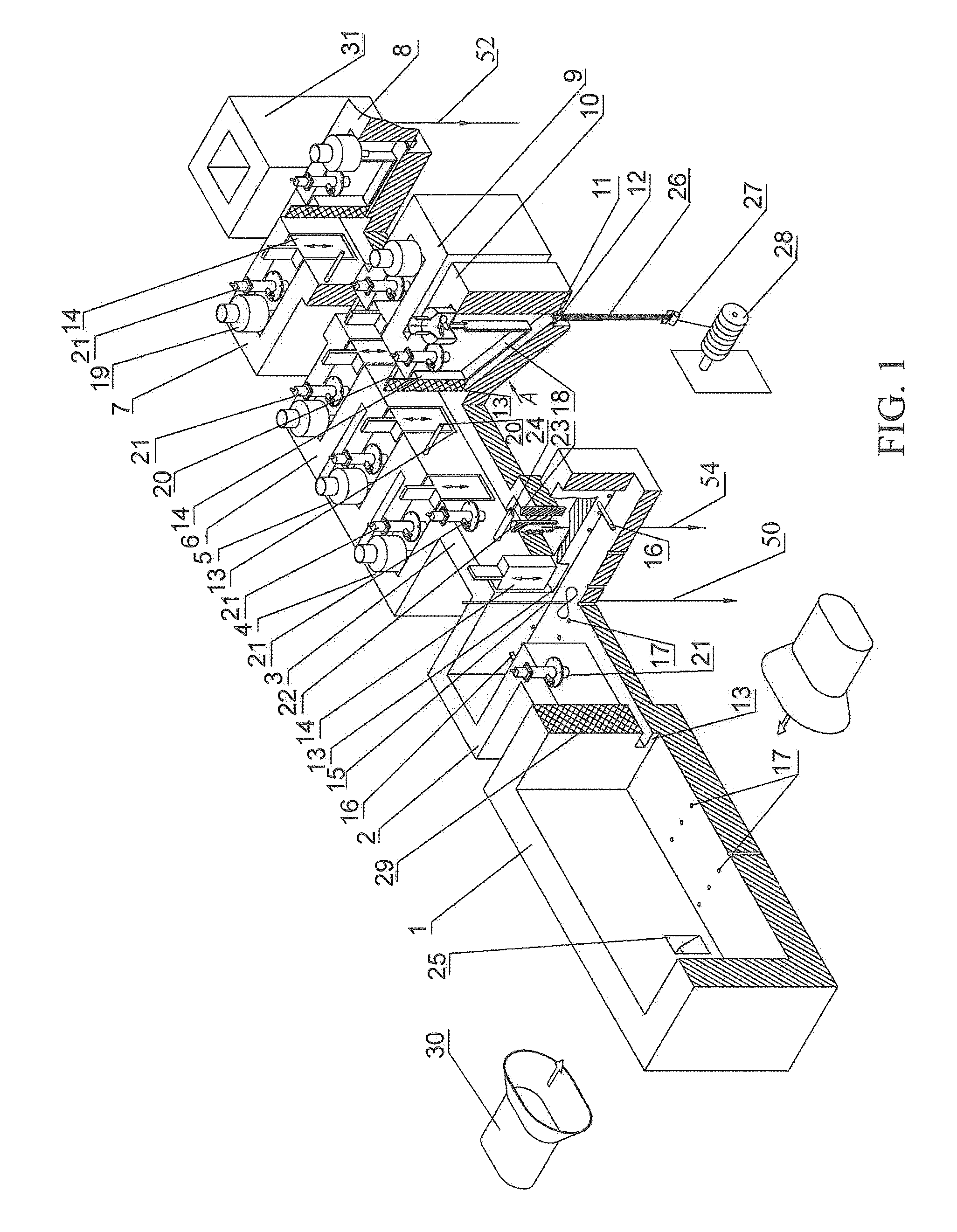

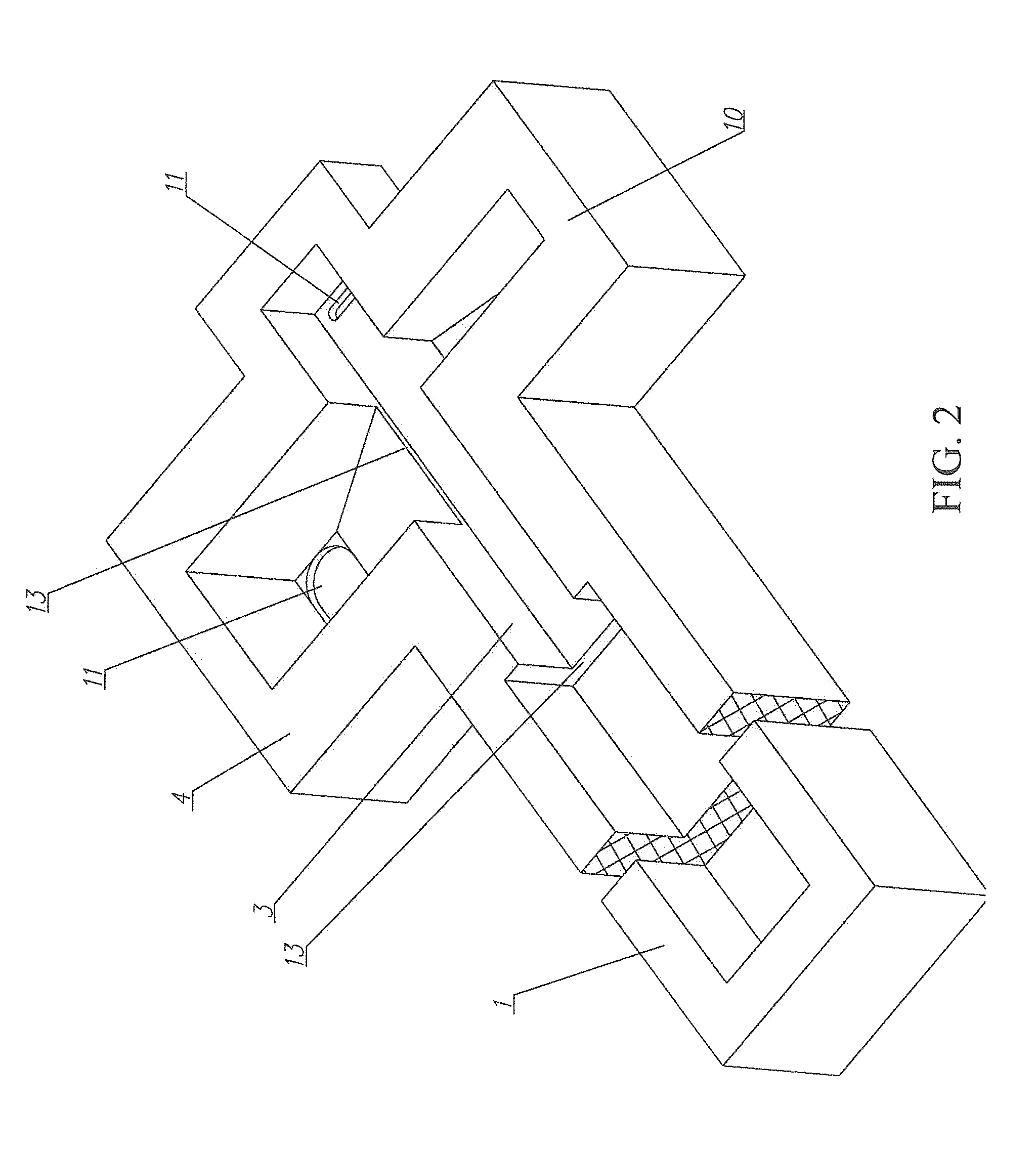

"kibol's module" plant for producing inorganic fibers of rocks

The present invention pertains to plants for producing inorganic fibers from melted rocks, advantageously, with narrow working interval and low diathermy, for example, basalts, diabases, amphibolites, andesites, dacites, rhyolites and other rocks. The plant comprises the furnace for obtaining the melt connected to the feeder, working aperture and a warmed feeder with draw dies located below working aperture where, according to the invention, transition chamber is installed on the feeder exit, such transition chamber is intended for creation of thin layer melt flow, its enclosure contains working aperture, the transition chamber has the heater, the threshold installed at its entrance and adjustable damper located over the threshold, and these components are intended for obtaining the melt flow of needed thickness and quality. The feature of the proposed invention is also the bottom of the transition chamber which has an inclination directed towards the working aperture. The plant has also accumulator tank installed between the exit of the furnace for obtaining the melt and the feeder, which is intended for receiving the melt homogeneous in ten is of composition and temperature. Another feature of the plant is that the plant has the unit for removing iron containing impurities from the melt, such unit being the source of direct or pulsing current with electrodes installed at the feeder entrance, connected to corresponding poles of the current source and intended for creating electric current in the melt. The proposed invention is aimed at creation of such plant which will improve strength, chemical and thermal stability of produced fibers by way of creating conditions near working aperture that will decrease the quantity of external impurities in the flow and allow obtaining of the melt, which is homogenous in terms of composition and temperature, in said zone of the plant. It is attained by means of adjustable damper installed at the entrance of the transition chamber, which does allow upper part of the melt flow (i.e. foam) to pass to the working aperture, and by means of the threshold installed below the adjustable damper, which does not allow lower part of the melt containing heavy unmelted rock particles to pass to the transition chamber. This significantly reduces the possibility of formation of stress concentrators in produced fiber and also the draw dies clogging.

Owner:KIBOL VIKTOR F +1

Universal diathermy heat applicator

ActiveUS9802057B2Eliminate needMinimize radiationElectrotherapyElectrical resistance and conductanceRadio frequency

A resonant radio frequency diathermy heat applicator, including a flexible pad, an inductive coil with moderate defined resistance, fixed tuning capacitors, connecting cable and shielding that is broadly tuned to the signal source in a manner that eliminates the requirement for variable tuning elements.

Owner:VIATHERM THERAPEUTICS LLC

Circumcision instrument

ActiveUS9345512B2Surgical instruments for heatingSurgical instruments using microwavesForeskinEngineering

A circumcision instrument used to perform a circumcision procedure. The circumcision instrument generally includes a housing having a chamber configured to receive a glans penis and an outer surface configured to be enveloped by a prepuce. An annular groove is disposed in the outer surface. A conductive ring is located at the bottom of the annular groove. A clamp has a pair of jaws that are moveable from an open position to a closed position surrounding the prepuce. In the closed position the jaws are disposed at least partially within the annular groove. A conductive inner cutting edge is located on the jaws. The clamp and the housing are connectable to a source of diathermy energy such that diathermy energy can flow between the inner cutting edge and the conductive ring, thereby cutting the prepuce.

Owner:ALTOKHAIS TARIQ IBRAHIM

Artemisia argyi levl diathermal moxibustion tool

PendingCN107684521AGuaranteed stabilityWith fire insulationDevices for heating/cooling reflex pointsCardboardCombustion

The invention discloses a moxa moxibustion heat penetrating moxibustion, which comprises a paper tube frame, a paper tube, a damper cardboard and double-sided adhesive tape; the paper tube frame is a boss structure, and a plurality of moxibustion holes are arranged in the paper tube frame , the moxibustion hole runs through the paper tube frame; the upper end of the moxibustion hole is inserted into the paper tube; the paper tube is filled with moxa, and wire mesh is fixed in the upper and lower ends of the paper tube; A number of air intake holes are evenly distributed on the side wall; double-sided adhesive tape is adhered to the lower end of the paper tube holder. In the present invention, by igniting the moxa in the paper tube, the moxa burns inside to generate heat and smoke, and treats the corresponding acupoints or moxibustion parts, directly acts on the human skin, and applies the corresponding acupoints through double-sided adhesive Or the site where moxibustion is applied; the paper tube is set in the paper tube holder, and multiple paper tubes are set to increase the range of action. The length of the paper tube on the paper tube holder can be adjusted according to needs, thereby controlling the temperature during moxibustion.

Owner:李时珍臻艾蕲春生物医药有限公司

Universal Diathermy Heat Applicator

ActiveUS20140350646A1Eliminate needAvoid radiationElectrotherapyRadiation therapyElectrical resistance and conductanceRadio frequency

A resonant radio frequency diathermy heat applicator, including a flexible pad, an inductive coil with moderate defined resistance, fixed tuning capacitors, connecting cable and shielding that is broadly tuned to the signal source in a manner that eliminates the requirement for variable tuning elements.

Owner:VIATHERM THERAPEUTICS LLC

Surface warming diathermy apparatus and method

A surface warming diathermy apparatus and method includes an applicator with a first chamber and a second chamber where the first chamber contains a dielectric solution. A primary coil is wrapped around the applicator beginning with the first chamber. A secondary coil is wrapped around the applicator also beginning with the first chamber and a RF energy source connected with the primary coil. The apparatus is tuned to a near resonant state by means of a variable high-voltage capacitor connected to each end of the secondary coil.

Owner:OLSEN RICHARD G

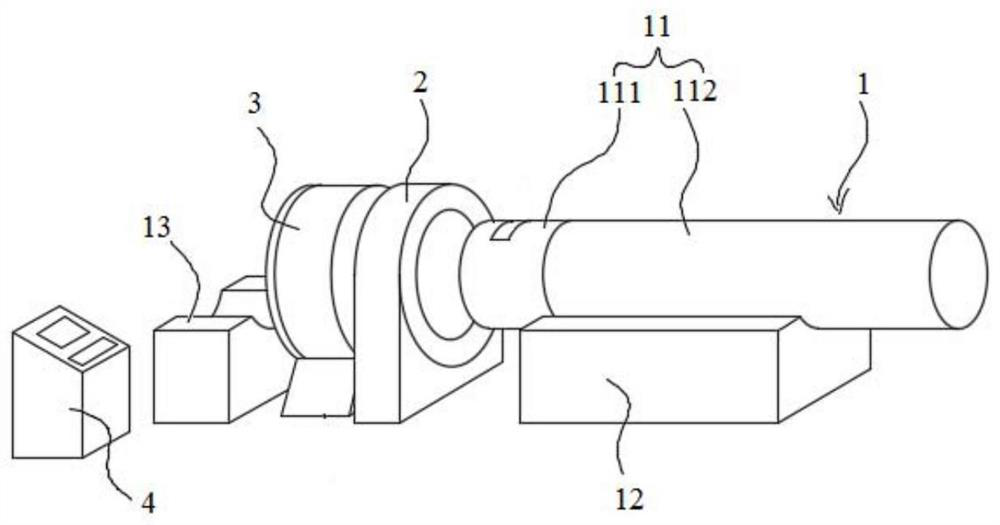

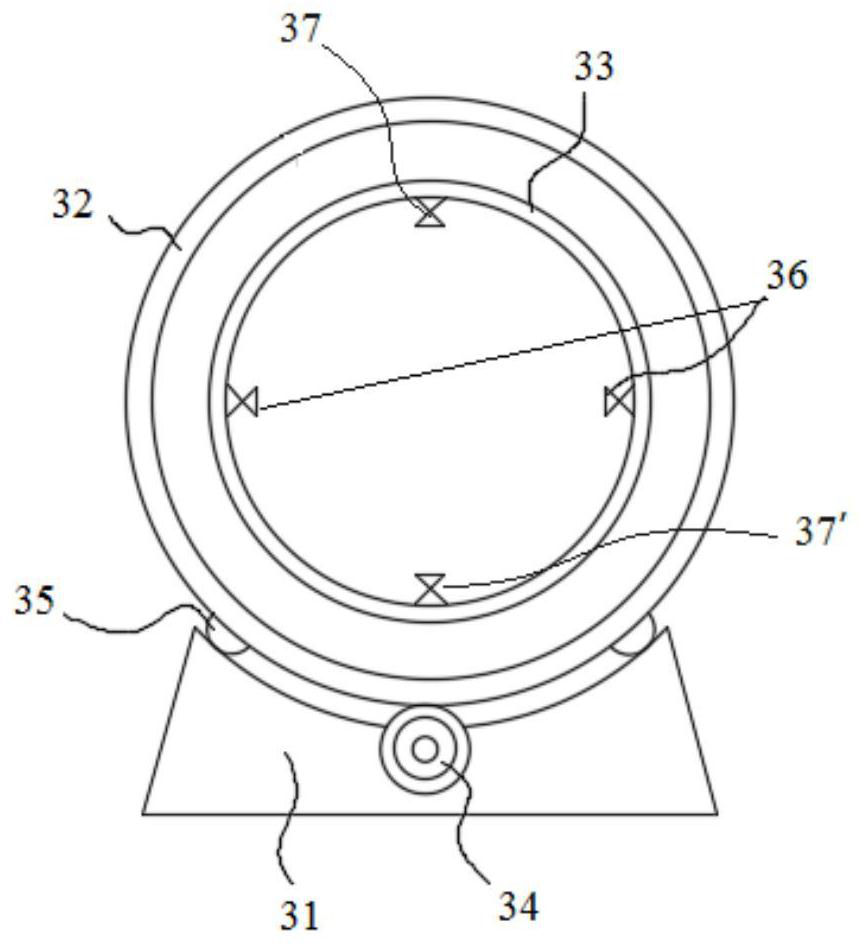

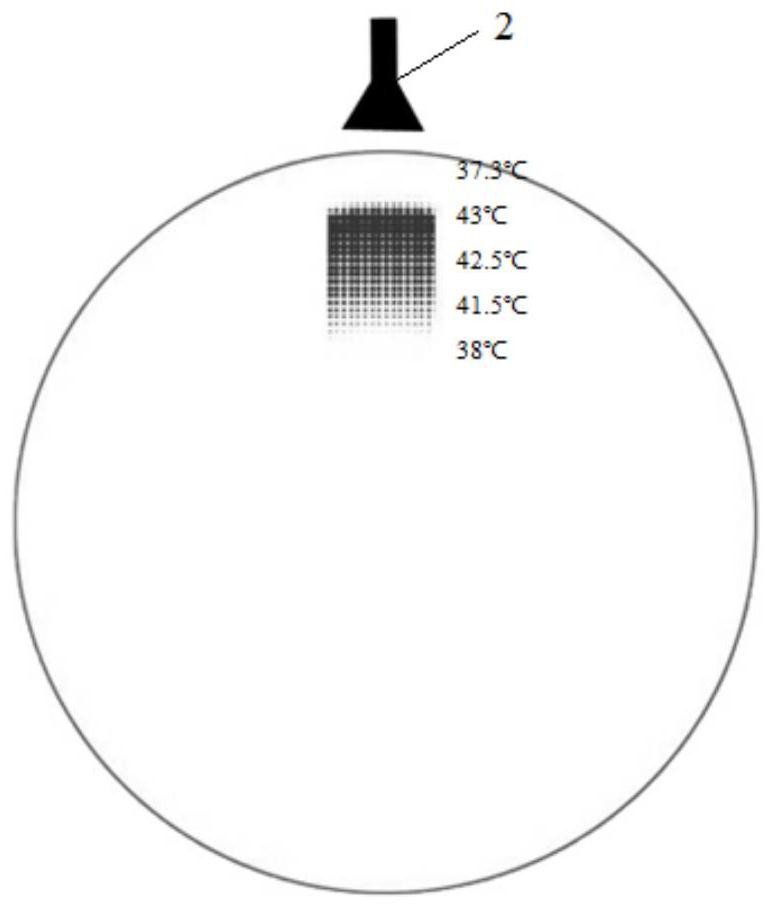

Microwave radio-frequency synergistic rotation irradiation tumor global thermal therapy instrument

The invention discloses a microwave radio-frequency synergistic rotation irradiation tumor global thermal therapy instrument. The device comprises a temperature measuring unit, a global irradiation unit, a treatment heat preservation bin and a control unit, wherein the global irradiation unit comprises a microwave irradiation mechanism, a capacitive radio-frequency irradiation mechanism and a rotating mechanism; a microwave heating mechanism and a capacitive radio-frequency heating mechanism are arranged on one or two global irradiation rings; the control unit cooperatively utilizes the rotaryirradiation advantages of the microwave heating mode and the capacitive radio-frequency heating mode to conduct deep and shallow layered complementary diathermy on the human body, and by means of theprecise temperature measurement and control technology, global precise high-fever blanching is achieved and used for radical treatment of tumors. The thermal therapy instrument is a pure physical precise temperature control thermal therapy device, is safe, convenient and efficient, can radically treat various solid tumors and keep normal tissues and organs intact, has the characteristics of shorttime, small pain, low cost and the like for tumor treatment, and is wide in adaptation disease range.

Owner:尚圣杰

Coupling method for resonant diathermy and other bio-tissue heating applicators

ActiveUS9050166B2Efficiently boosting the common-mode rejection ratio (CMRR)Eliminate couplingMagnetotherapy using coils/electromagnetsSurgical instruments for heatingCapacitanceTissue heating

Owner:VIATHERM THERAPEUTICS LLC

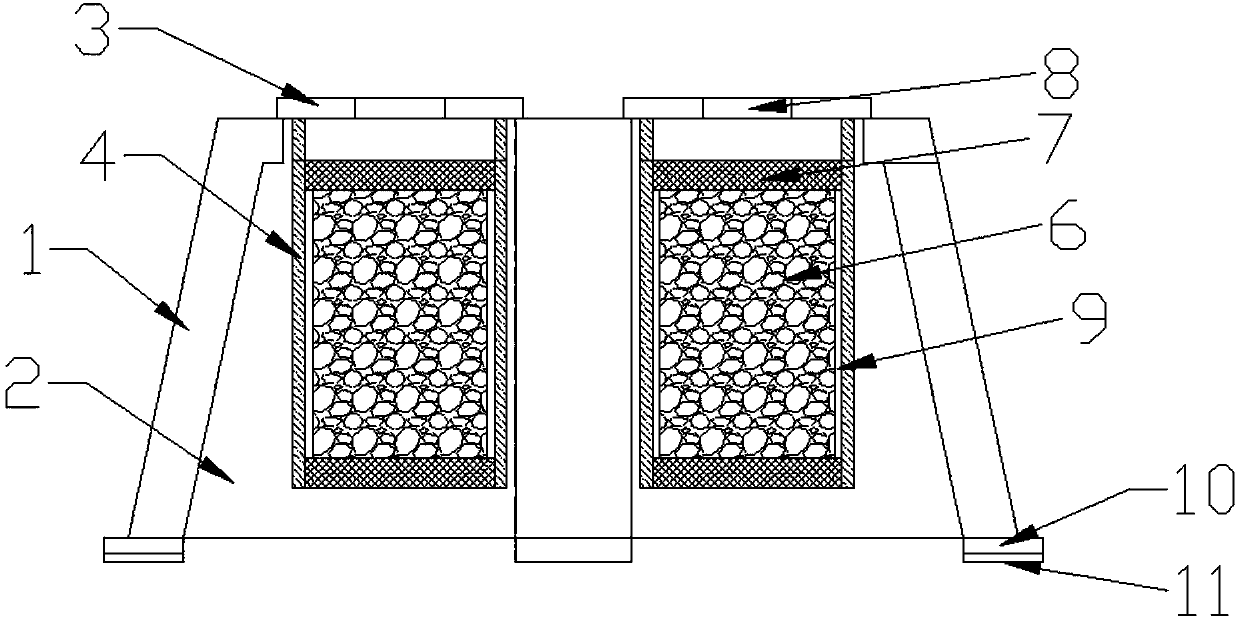

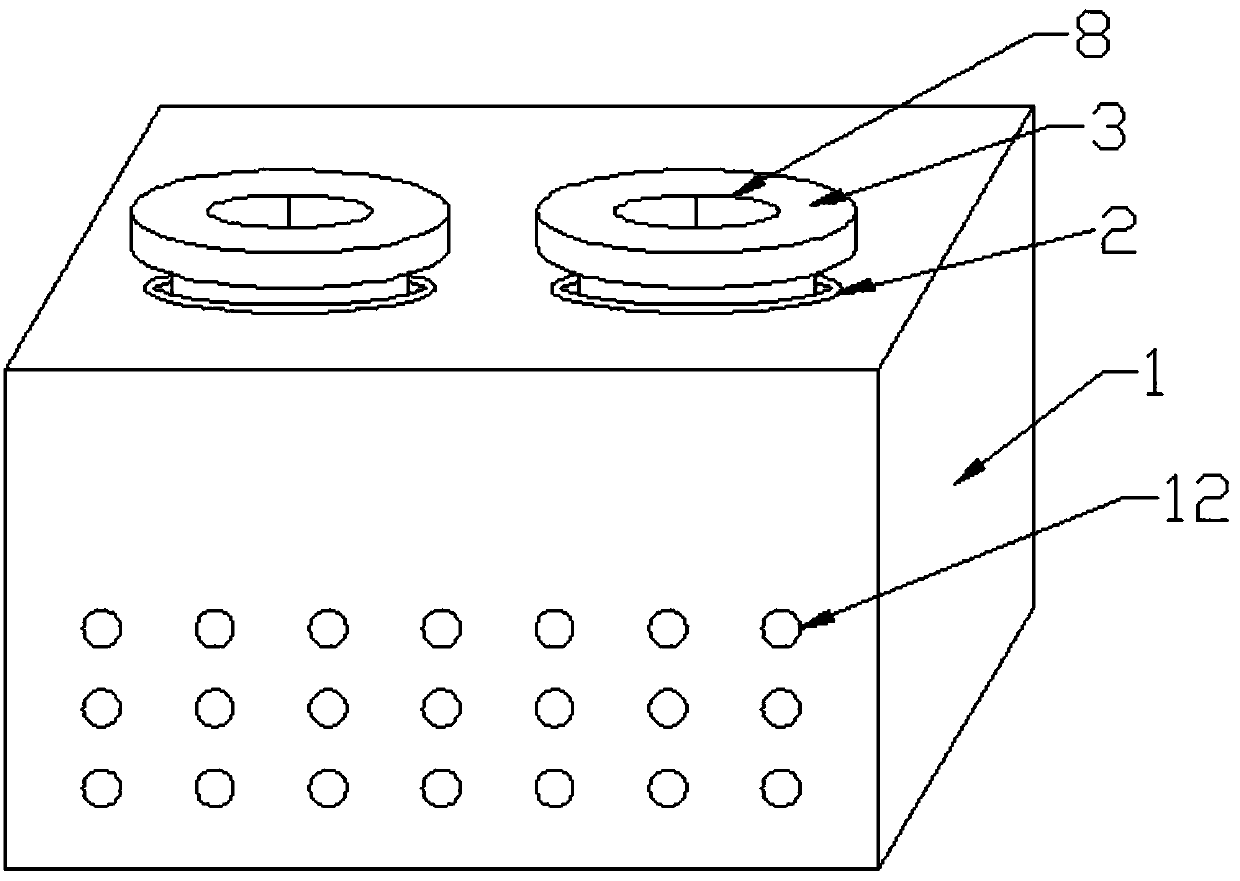

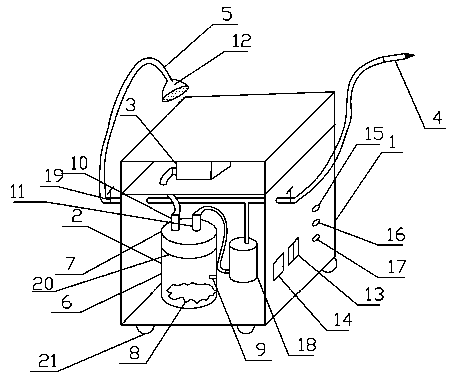

Diathermy apparatus and application method thereof

InactiveCN105496761APromote generationRelieve spasmsMedical devicesBathing devicesPower switchingMedicine

The invention provides a diathermy apparatus for treating cervical or lumbar vertebra diseases and an application method thereof. The diathermy apparatus comprises a box body, a heating kettle, an inflator pump, tapered therapeutic equipment and a hyperthermia therapy cover, wherein the heating kettle comprises a kettle body and a kettle cover; a heating tube is arranged at the bottom part of the inner side of the kettle body; an inductor is arranged at the middle and lower part of the inner side of the kettle body; an air inlet joint and an air outlet joint are arranged on the kettle cover; the air inlet joint is connected with the inflator pump; a valve is arranged on a connecting pipeline; the inflator pump is arranged at the upper part of the box body; the air outlet joint is connected with the tapered therapeutic equipment and the hyperthermia therapy cover through a pipeline; a medicine bag storage chamber is arranged in a semicircular ball body of the hyperthermia therapy cover; a plurality of holes are formed in the cover surface; the plurality of holes are formed in the taper surface of the tapered therapeutic equipment; a switch, a controller, a heating indicator light, a constant-temperature indicator light and a minimum water level indicator light are arranged at the outer side of the box body; the controller is connected with the inductor, the switch, the heating indicator light, the constant-temperature indicator light and the minimum water level indicator light respectively; and the switch comprises a power switch and a heating switch.

Owner:郑中辉

Thin-gauge high-toughness steel plate and manufacturing process thereof

The invention relates to the technical field of metallurgy, in particular to a thin-gauge high-toughness steel plate and a manufacturing process thereof. The thin-gauge high-toughness steel plate is manufactured according to the following manufacturing process: (1) preparing blanks; (2) milling and cleaning the surfaces of the blanks; (3) spraying an isolating agent on to-be-assembled surfaces of the blanks and drying the to-be-assembled surfaces of the blanks; (4) making the blanks aligned and assembled, and carrying out peripheral girth welding on interface gaps of the adjacent blanks to obtain a composite blank; (5) heating the composite blank, discharging and rolling the composite blank after diathermy, controlling the thickness of an intermediate blank according to 30-50mm, and flattening and air-cooling after rolling to obtain a composite steel plate; and (6) shearing the head, tail and two sides of the composite steel plate and separating the steel plate. The alloy adding cost and the heat treatment cost are low, the yield strength ReH of the prepared thin-gauge high-toughness steel plate is larger than or equal to 355 MPa, the tensile strength Rm is larger than or equal to 470 MPa, the elongation is larger than or equal to 22%, and the longitudinal impact toughness KV2 at the temperature of -40 DEG C is larger than or equal to 120 J.

Owner:SD STEEL RIZHAO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com