Method for fast flaking paraffin by microwave radiation water bath diathermy and device

A microwave radiation and rapid technology, applied in the field of rapid paraffin preparation of biological tissue specimens, can solve the problems of insufficient, too brittle tissue, artificial ice crystals, etc. Membrane and nucleolus clear effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

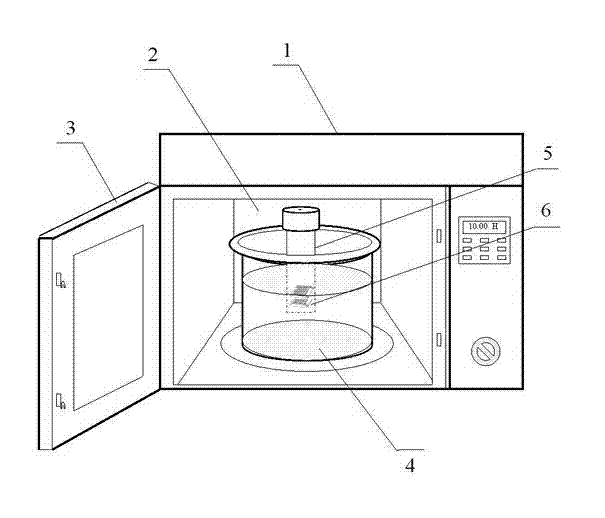

[0021] combine figure 1 , figure 2 with image 3 . figure 1 A schematic diagram of a common commercial microwave oven used as a microwave irradiation tool. Including the microwave oven shell 1, the oven cavity 2, and the oven door 3, place the water container 4 with prepared specimens and reagents in the center of the bottom of the oven cavity 2, and place the tissue sample box 6 and the reagent tube 5 in the reagent tube 5 filled with reagents. Part of the reagent is immersed in the water of the water container 4, adjusted to the central position, the furnace door 3 is closed, the fire gear is set up, and the operation is started.

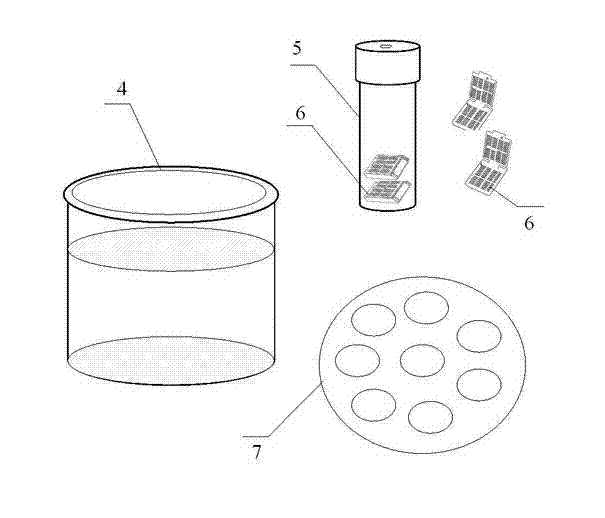

[0022] figure 2 It is a schematic diagram of the composition of the water bath diathermy part of the rapid paraffin slicing device. Put 500 milliliters of water into a water container 4 with a volume of 1000 milliliters; at the same time, pour 30 milliliters of reagents such as fast fixative solution in the reagent tube 5 and add a cover,...

Embodiment 2

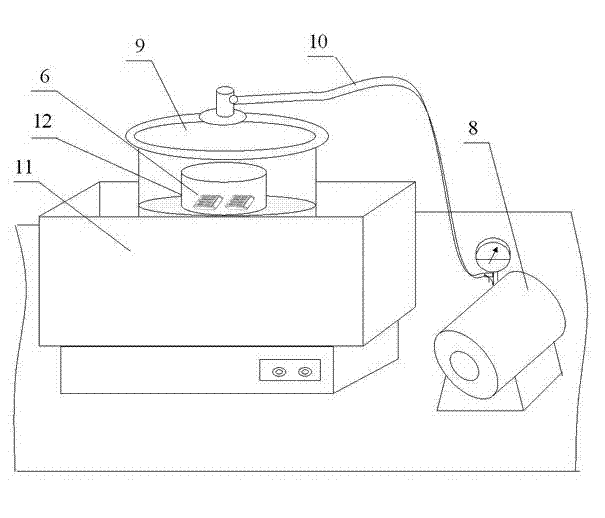

[0025] 1) Materials: Prepare rapid fixative solution (10% formaldehyde solution l5ml, 95% ethanol 80ml and glacial acetic acid 5ml); prepare rapid dehydration transparent agent: (100% isopropanol 500ml, absolute alcohol 400ml, poly Ethylene glycol (molecular weight 300) l00 ml and dimethyl sulfoxide (DMSO) l ml; melting point 58-60 ° C paraffin. Instrument: WP750 Galanz household microwave oven. Pour 100 ml of melted paraffin into a beaker and place it in an electric thermostat Stand by at any time, and the fast paraffin film production device is installed according to the above-mentioned embodiment 1 figure 1 microwave and figure 2 Water bath diathermy components and image 3 Vacuum negative pressure wax impregnated parts.

[0026] 2) Operation steps: (1) Preheating: Add about 500ml of water to a 1000ml beaker, put it in a microwave oven and preheat the water to 60°C for 3-5 minutes on high heat. (2) Fast tissue fixation: put the taken tissue block into a tissue specimen...

Embodiment 3

[0028] 1) Materials: Prepare a rapid decalcification solution: add 16 ml of hydrochloric acid, 10 ml of acetic acid, 20 g of salicylic acid and 174 ml of distilled water in sequence and mix, and the salicylic acid in the solution shows insoluble precipitation. The same equipment as in Example 1 was used.

[0029]2) Operation steps: take the sample to be decalcified with a volume of (1-1.5) cm × (0.7-1) cm × (0.3-0.5) cm and place it in a tissue specimen box. Pour 200 mL of rapid decalcification solution into a 500 mL glass beaker and put the tissue specimen box into it. Take another 1000ml beaker, add 500ml of water, fix the small beaker in the water of the large beaker, then place the two matching beakers in the center of the microwave oven cavity, heat for 5 minutes at high heat level 10, and then use low heat level 1 or 2 Continue to heat for 30 minutes. Use the needle to easily penetrate to judge the decalcification, and repeat the operation if necessary.

[0030] The p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com