Automatic mashed garlic smashing device

A technology of a power device and a power transmission device is applied in the field of automatic garlic mashing devices, which can solve the problems of easy waste, flying out of garlic cloves, laborious device, etc., and achieve the effects of avoiding waste, preventing splashing and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0031] The invention includes a frame device, a power device, a power transmission device and a mashed garlic device.

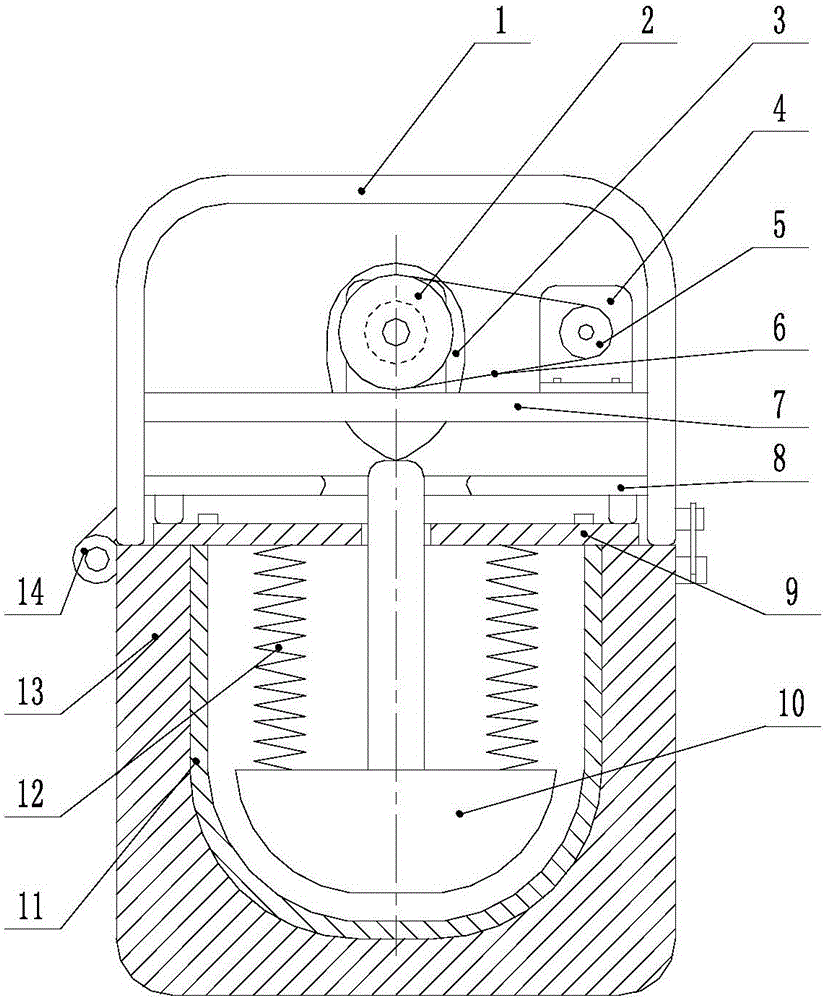

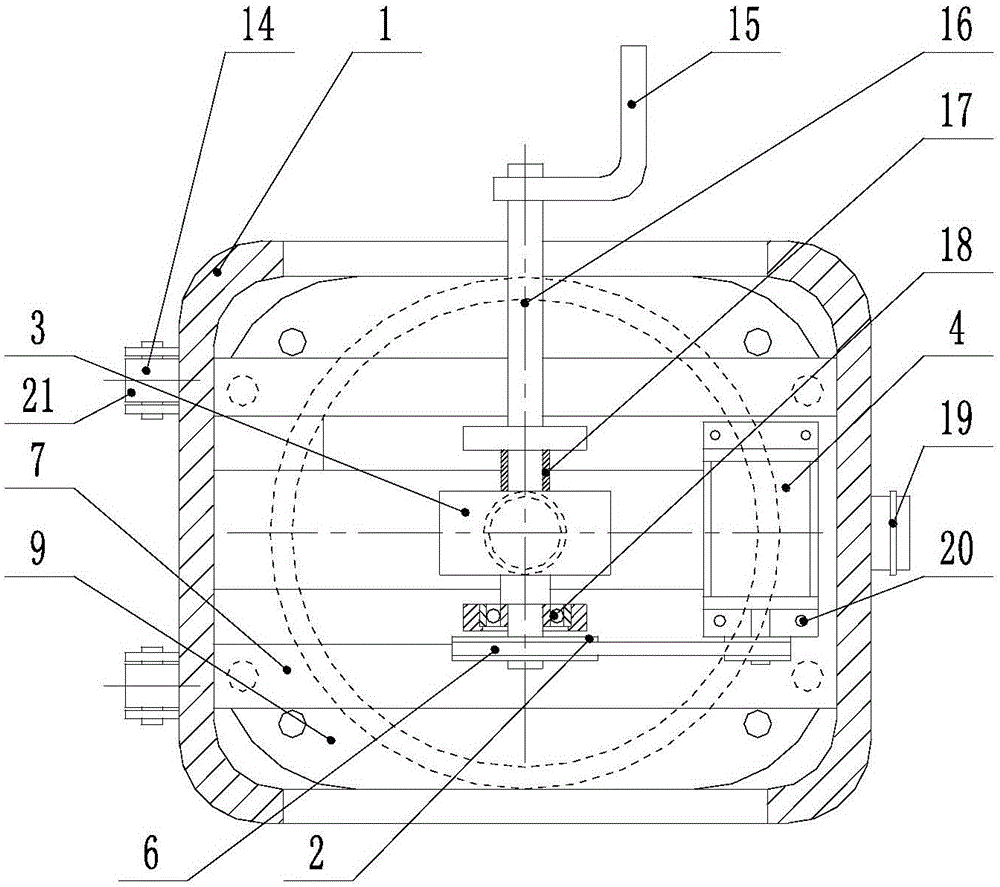

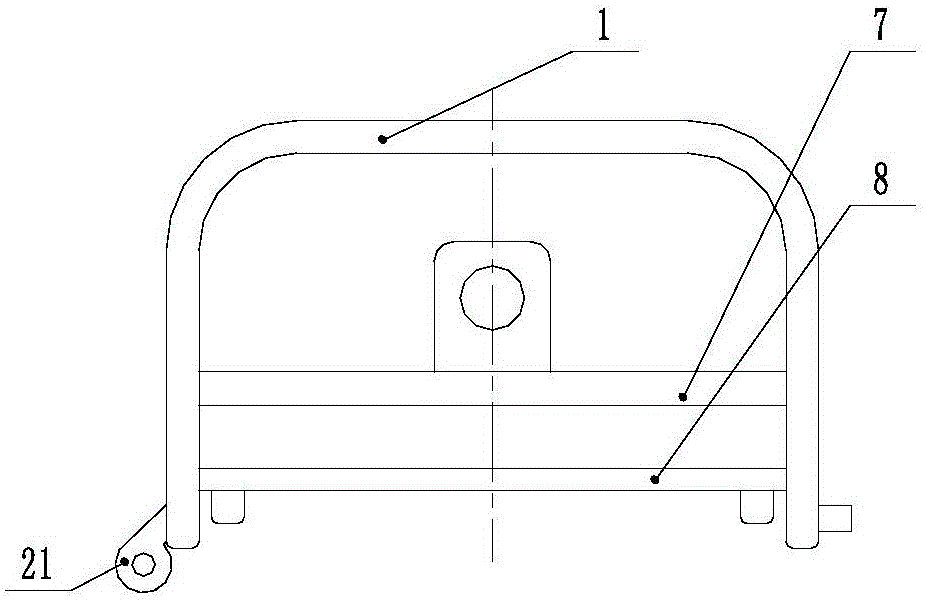

[0032] see figure 1 and figure 2 , wherein the frame device includes a hinged loam cake 1 and a garlic bowl barrel 13; the power unit includes a motor 4; The mashed garlic device comprises a covering plate 9, a mashed garlic hammer 10 and a resetting device.

[0033] Referring to Fig. 3(a) and Fig. 3(b), a camshaft seat 7 is fixedly arranged in the upper cover 1, the camshaft 16 is mounted on the camshaft seat 7 through a bearing 18, and the motor 4 is fixed on the camshaft seat by screws 20 7 on. In order to facilitate the replacement of the cam 3 and the motor 4, the front and rear sides of the loam cake 1 are connected. An upper boss seat 8 is fixedly arranged in the upper cover 1 , and several upper bosses are arranged on the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com