Anticorrosive anchor rod capable of preventing slurry from leaking

An anchor and leak-proof technology, which is applied to sheet pile walls, protective devices, buildings, etc., can solve the problem of affecting the durability and pull-out resistance of the anchor section, the main reinforcement sinking into the soil, and the failure to solve the problem of grout leakage and leakage of the free section of the anchor. Corrosion resistance and other issues, to achieve the effect of reliable anchoring technical solutions, saving engineering costs, and reducing technical risks of uncontrollable grouting volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to describe the present invention more specifically, the technical solution of the present invention and its anchoring installation process will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

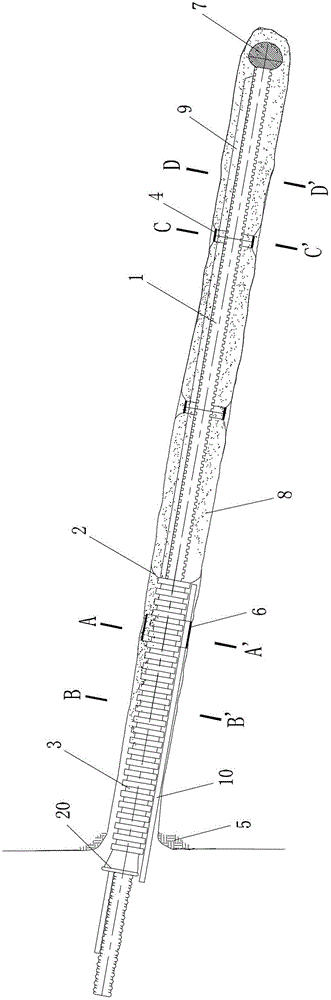

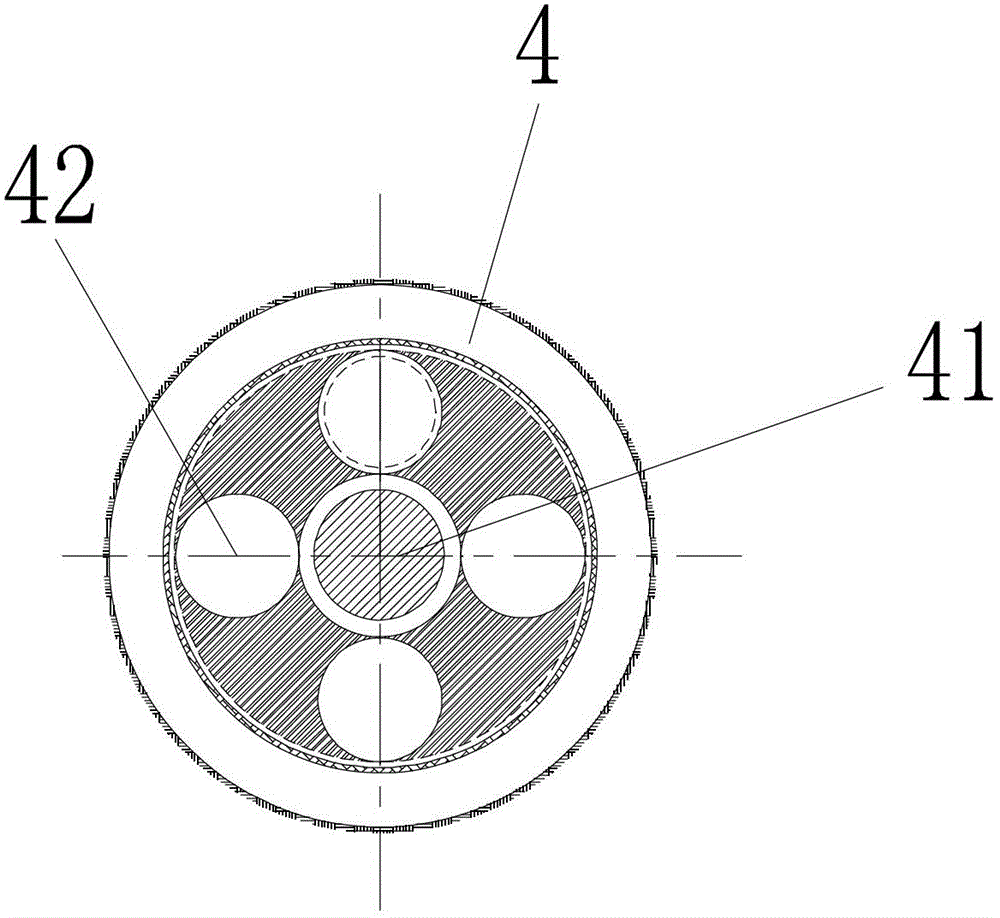

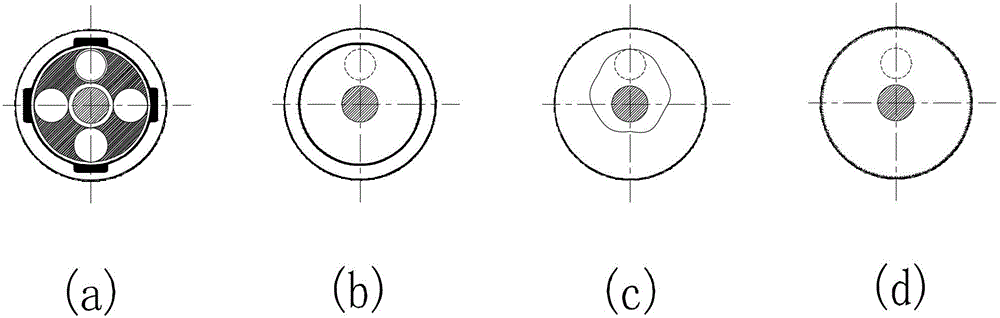

[0028] Such as Figure 1~3 As shown, a leak-proof slurry and anti-corrosion anchor rod includes a steel bar body 1; The inner area section is wrapped with a cylindrical bagging 2; the other end of the steel rod body 1 is provided with a spherical guide cap 7; One side of the bag; the bag opening 20 is tied tightly with the steel bar body 1 by a tie.

[0029] The steel rod body 1 is inserted into the borehole 5 and has a cylindrical bagging 2 and the corrugated sleeve 3 double-wrapped area section is the free section Z of the anchor rod; the steel bar body 1 is inserted into the borehole 5 and is only wrapped with a cylindrical bagging 2 is the anchoring section M of the bolt.

[0030] Tubular bagging 2 is made of f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com