Patents

Literature

155 results about "Polyethylene matrix" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Crosslinked, heat shrinkable polypropylene compositions

InactiveUS6569915B1Reduced effectivenessReduce the degree of crosslinkingElastomerEthylene Homopolymers

A heat-shrinkable article suitable for use as an insulating or coating material comprises a crosslinked composition of a polypropylene homopolymer or copolymer and an ethylene-propylene elastomer. The article is formed by a process comprising: i) creating a blend of the polypropylene homopolymer or copolymer and the ethylene-propylene elastomer by melt mixing; ii) melt processing the blend produced in i) to produce a melt processed material; iii) crosslinking the melt processed material produced in ii) by exposing it to radiation to produce a crosslinked material; iv) stretching the crosslinked material at a first temperature close to or above its softening or melting point and subsequently cooling it to a second temperature below its softening or melting point, to thereby freeze the crosslinked material in its stretched form. Subsequent heating of the article close to or above its softening point or crystalline melting point results in recovery of the pre-stretched dimensions of the article. Due to its relatively high content of polypropylene, the heat-shrinkable article thus produced has greater toughness and rigidity than polyethylene-based systems, making it suitable for use as insulation for wires and cables a heat-shrinkable corrosion resistant sleeves for high-temperature transmission pipeline joints, and for heat-shrinkable tubing or shapes for electrical insulation and mechanical protection.

Owner:SHAWCOR LTD

Noice insulation dumping noise reducing sheet material with high modulus material for car and preparation process thereof

InactiveCN1793211AImprove sound insulation and noise reductionExcellent vacuum thermoforming performanceSound producing devicesMohs scale of mineral hardnessPolyvinyl alcohol

The invention discloses a vehicle using high molding quantity filling sound insulation damping noise reduction sheet material and the manufacture method. It has good sound insulation and noise reduction function, and has simple technology. The raw material includes polyvinyl alcohol resin, coupler, lubricant and powder material that has Mohí»s hardness above 6 as high molding quantity material.

Owner:HENKEL CORP

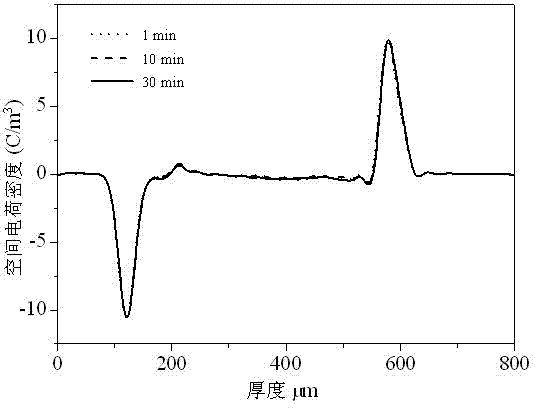

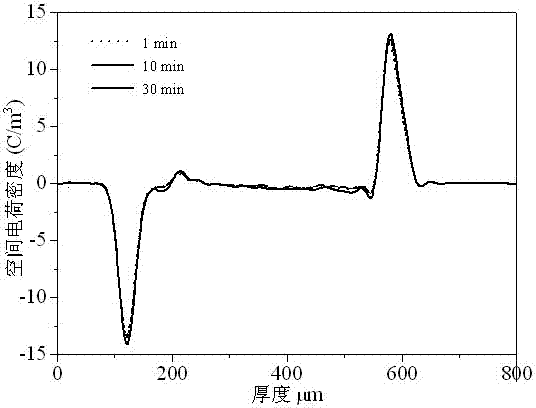

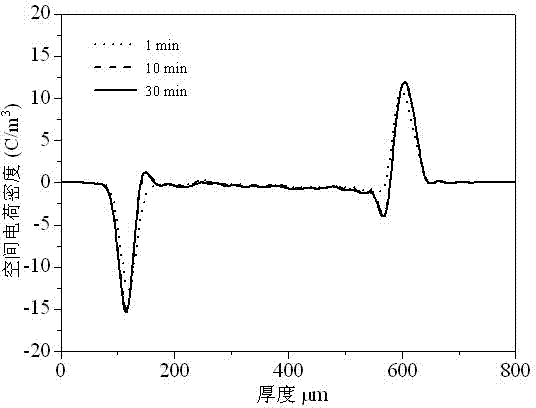

High-voltage direct-current cable material as well as preparation method and applications thereof

ActiveCN103613828AEffective Control RatioGood dispersionPlastic/resin/waxes insulatorsLow-density polyethyleneHigh-voltage direct current

The invention discloses a high-voltage direct-current cable material as well as a preparation method and applications thereof. The high-voltage direct-current cable material is technically characterized by being prepared from low density polyethylene, graft modified polyethylene, core-shell double-component inorganic nanofiller treated by a silane coupling agent, an antioxidant, a cross-linking agent, and an anti-copper agent. The preparation method comprises the following steps: firstly, mixing the low density polyethylene, the graft modified polyethylene, the antioxidant and the anti-copper agent; after melting polyethylene, adding the inorganic nanofiller treated by a silane coupling agent; and then adding the cross-linking agent to obtain a polyethylene nanocomposite. In the polyethylene nanocomposite prepared by the method, the inorganic nanofiller is uniformly dispersed in a polyethylene matrix and is excellent in compatibility with the matrix, and covalent bonds interact with each other, so that the mechanical property and the electrical property of the cable material can be effectively enhanced; the accumulation of charges in the internal space of the cable material can be remarkably inhibited, so that the cable material can serve as an insulating material for high-voltage direct-current cables.

Owner:WUXI MINGZHU CABLE

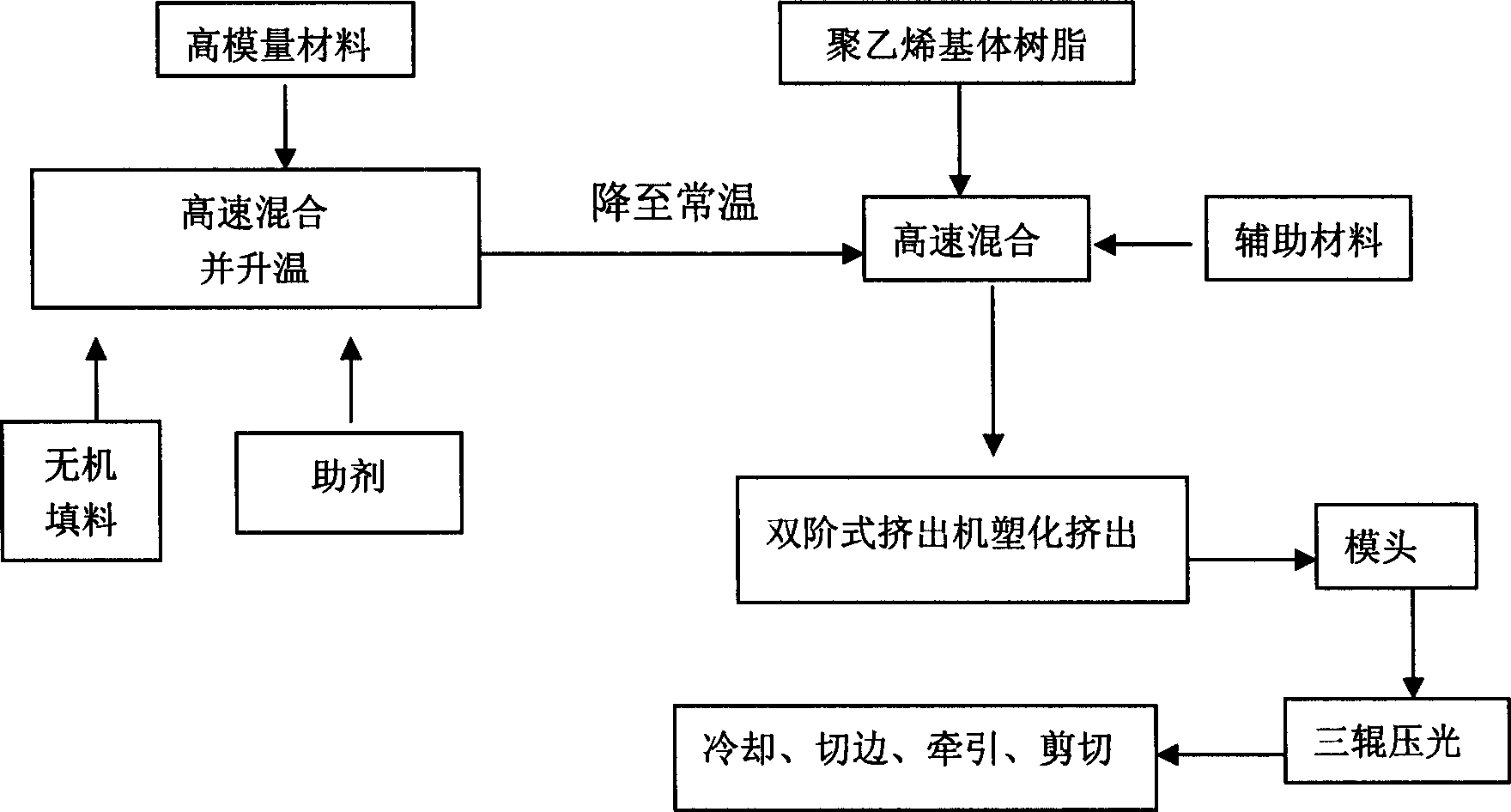

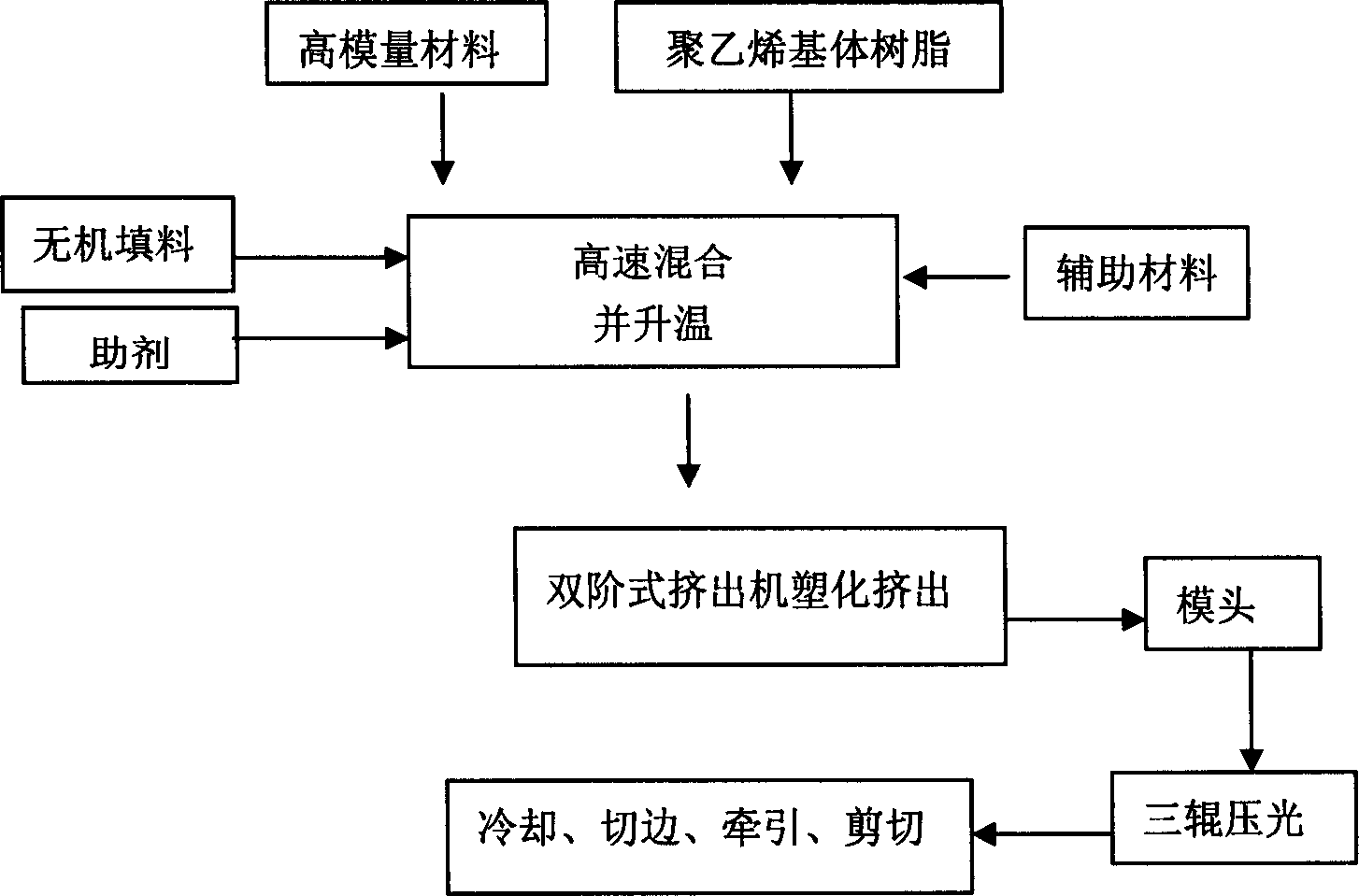

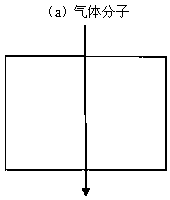

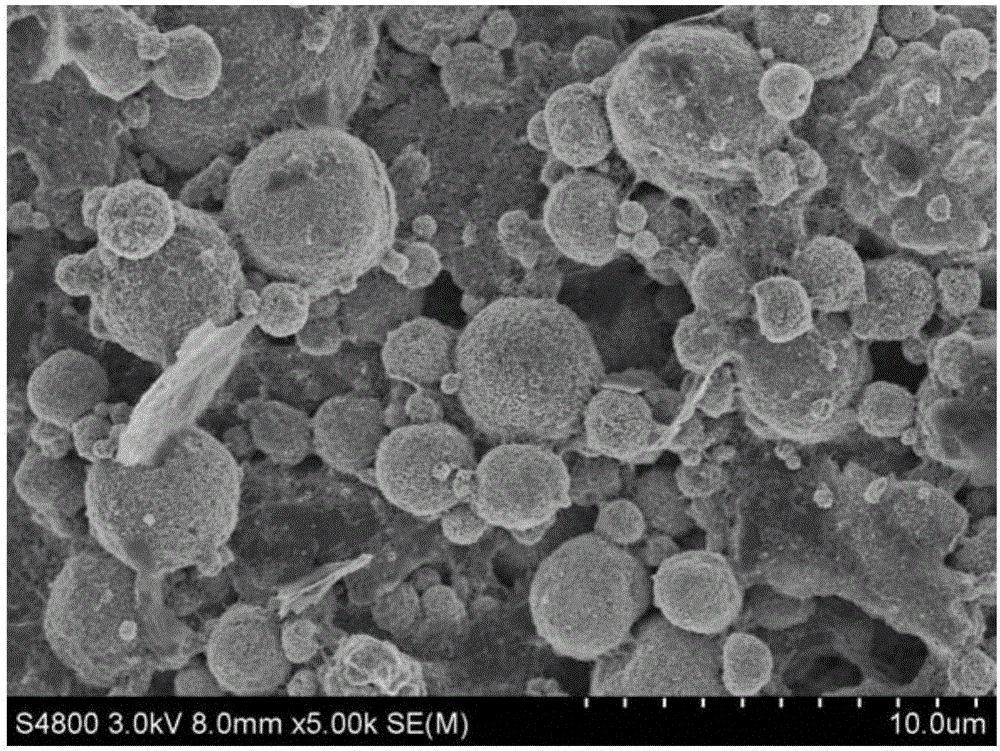

Micro-foaming polyethylene-matrix wood-plastic composite material and preparation method thereof

The invention discloses a micro-foaming polyethylene-matrix wood-plastic composite material and a preparation method thereof. The micro-foaming polyethylene-matrix wood-plastic composite material is prepared by the following steps of stirring a matrix polyethylene resin, modified wollastonite powder and talcum powder, a crosslinking agent, a lubricant, a heat balance type foaming agent, an antioxidant, an anti-ultraviolet agent, pigment and modified plant fiber, heating and uniformly mixing, then cooling and discharging to obtain a premix, wherein the modified plant fiber is one of wood powder, bamboo powder and rice hull powder or a mixture of two or more at any proportion; putting the premix into an extruder, and performing granulation, extrusion foaming and cooling formation. The micro-foaming polyethylene-matrix wood-plastic composite material disclosed by the invention is convenient to produce and manufacture, the raw materials are cheap and environment-friendly, the average diameter of the pores of the micro-foaming polyethylene-matrix wood-plastic composite material is reduced to 10 microns, and the content of the plant fiber is increased to 45%; moreover, the composite material has low density and high bending strength and impact toughness, is widely applicable and can be applied to the fields such as decoration, building, municipal administration, packaging, automotive upholsteries and the like.

Owner:FUJIAN AGRI & FORESTRY UNIV

Method for preparing halogen-free smoke-suppressant and flame-retardant plastic optical fiber sheath

ActiveCN101950044AGuaranteed flame retardant performanceSmall mechanical propertiesCladded optical fibreOptical waveguide light guideTwo stepPlastic optical fiber

The invention discloses a method for preparing a halogen-free smoke-suppressant and flame-retardant plastic optical fiber sheath, which is characterized by comprising the following steps of: (1) modifying magnesium hydroxide; and (2) preparing a flame-retardant plastic optical fiber. The method has the advantages that: by modifying a magnesium hydroxide flame retardant by two steps, the affinity of the magnesium hydroxide flame retardant with a polyethylene matrix is greatly improved, a flame-retardant accelerant and a synergist are added, the reduction of the mechanical properties of the prepared flame-retardant plastic optical fiber sheath is a little under the condition of ensuring the flame retardance, and the mechanical demand of the product can be met.

Owner:江西大圣塑料光纤有限公司

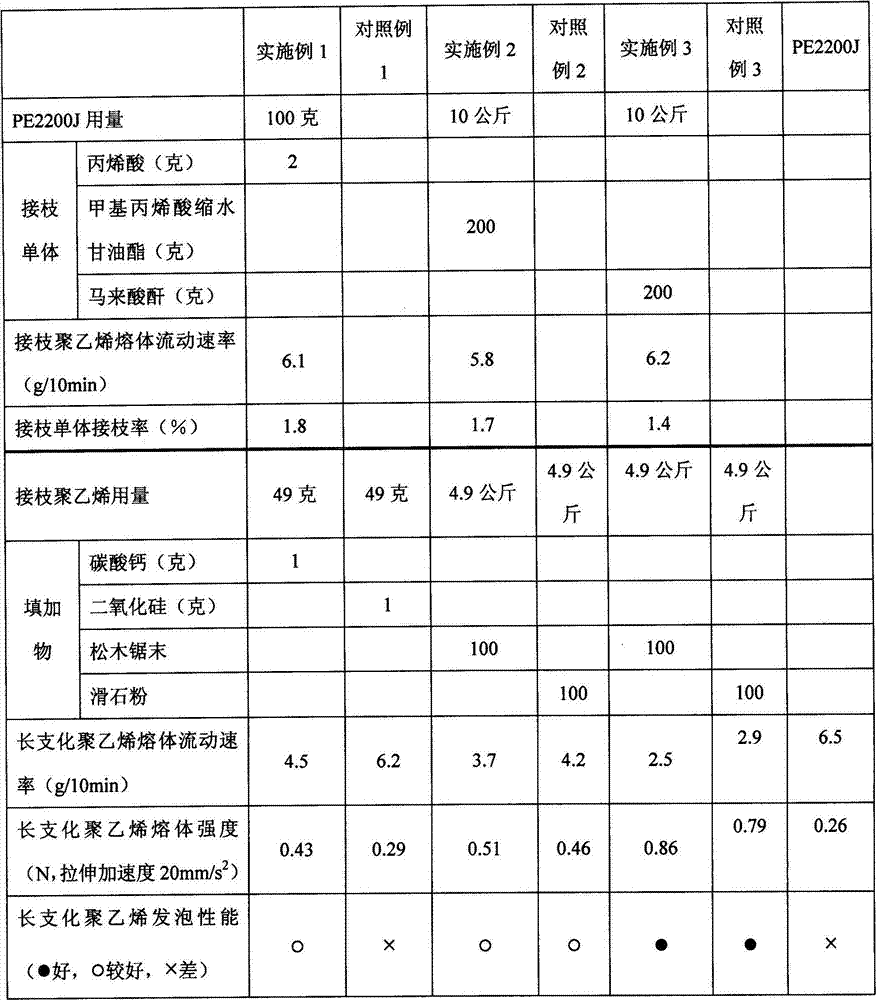

Preparation method of long chain branched polyethylene

The invention discloses a preparation method of long chain branched polyethylene. The preparation method comprises the following steps of: A, under the action of an initiator, performing a graft reaction on a vinyl monomer containing a polyfunctional group, and a polyethylene substrate under the synergistic action of a second olefin monomer to obtain grafted polyethylene of which the side chain is provided with a functional group; B, and performing a branching reaction on the grafted polyethylene obtained in the step A and an additive to obtain long chain branched polyethylene in which the additive is taken as a core and a polyethylene macromolecule is taken as an arm. Due to the adoption of the preparation method disclosed by the invention, long chain branched polyethylene with high melt strength can be produced, the branching degree is relatively controllable, the cost is low, the production efficiency is high, and superior foaming performance is realized. Expanded polyethylene with various functionality such as a wood-plastic composite expanded material added with wood fiber, an enhanced polyethylene expanded material added with glass fiber, a fire-proof polyethylene expanded material added with an expansion flame retardant and the like can be prepared according to different use requirements.

Owner:SHANGHAI FUYUAN PLASTICS SCI CO LTD

Hydrophilic polyethene microporous membrane and preparation method thereof

The invention provides a hydrophilic polyethene microporous membrane and a preparation method thereof, belonging to a polyethene microporous membrane containing blending compatilizer with a polar group, calcium carbonate and thinner and a preparation method thereof. In the preparation method of the microporous membrane, polyethene, blending compatilizer, calcium carbonate and thinner are taken as raw materials; and hydrophilic polyethene microporous membrane is finally prepared by blending processing, membrane pressing by a flat bed presser, quenching by water bath in constant temperature, extracting by extracting agent, acid cleaning, washing and drying. The invention is characterized in that the blended compatilizer with a polar group is selected to react with the calcium carbonate particles, calcium carbonate particles are evenly filled into polyurethane base body through blending processing; and porous structures are formed by the thermal induced phase separation method and the method for removing fillings by acid cleaning. As for the hydrophilic polyethene microporous membrane prepared by the method, the range of the internal average aperture is 0.1-10mu m, the aperture rate is greater than 50% and the contact angle is less than 80 degrees.

Owner:PETROCHINA CO LTD

Environment friendly ant-proof mouse-proof cable sheath material and preparation method thereof

ActiveCN101492554AHigh hardnessImprove wear resistancePlastic/resin/waxes insulatorsHardnessControllability

The invention belongs to the technical field of functional polymer materials and insulating material, in particular to a new environment protection ant and rat defending type cable sheathing material and a preparation method thereof. The invention increases the hardness and wear-resisting property of the polyethylene cable sheathing material by adding non-toxic high-efficient intensifier into polyethylene matrix resin, thus achieving the function of the ant and rat defending. Meanwhile, the sheathing material has good mechanical property. The preparation method for the insulating material described by the invention has good controllability, simple technique, and lower cost and has wide application prospect in electrical wire and cable industries.

Owner:深圳市古力新型材料科技有限公司

Continuous fiber reinforced polyethylene prepreg tape, preparing method therefor and application thereof

The invention belongs to the technical field of material science, and relates to a continuous fiber reinforced polyethylene prepreg tape, a preparing method therefor and an application thereof. The prepreg tape comprises, by weight, 100 parts of polyethylene matrix, 5-8 parts of a flexibilizer, 3-5 parts of a compatilizer, 0.6-1.2 parts of an anti-oxidant and 40-60 parts of glass fibers. The flexibilizer continuous glass fiber reinforced polyethylene prepreg tape is of excellent flexibility, and can form good interface combination with a pipeline base material, so that a problem of poor combination between matrix resin and the prepreg tape employed as a pipeline reinforcing material is solved.

Owner:LIAONING LIAOJIE SCI & TECH

Dealkalized red mud-containing flame-retardant polyvinyl plastic and preparation method thereof

The invention relates to dealkalized red mud-containing flame-retardant polyvinyl plastic and a preparation method thereof, and belongs to the technical fields of dealkalization and comprehensive utilization of red mud and flame-retardant plastic. Polyethylene and an in-situ dealkalizing agent are used as resin bases, and the red mud is used as a flame retardant. The method comprises the following steps of: crushing the red mud; drying; grinding and sieving; adding the red mud into an internal mixer with the polyethylene and the in-situ dealkalizing agent for melting and internal mixing; and machine-shaping with a flat vulcanizing machine to obtain a flame-retardant polyvinyl plastic finished product, wherein the plastic has smooth appearance, the pH value is between 9 and 11, and the limiting oxygen index ranges from 23 to 31 percent. The polyvinyl plastic prepared by the method is suitable for fire disaster safety protection in important public places in the fields of electronic appliances, building materials and traffic; a dealkalization process used for the red mud serving as the flame retardant is simplified by in-situ dealkalization; the in-situ dealkalizing agent can effectively reduce the alkalinity of the red mud, improve the flame-retardant effect and improve the compatibility between the red mud and the polyethylene base; and the polyvinyl plastic is low in cost and causes small damage to environment.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

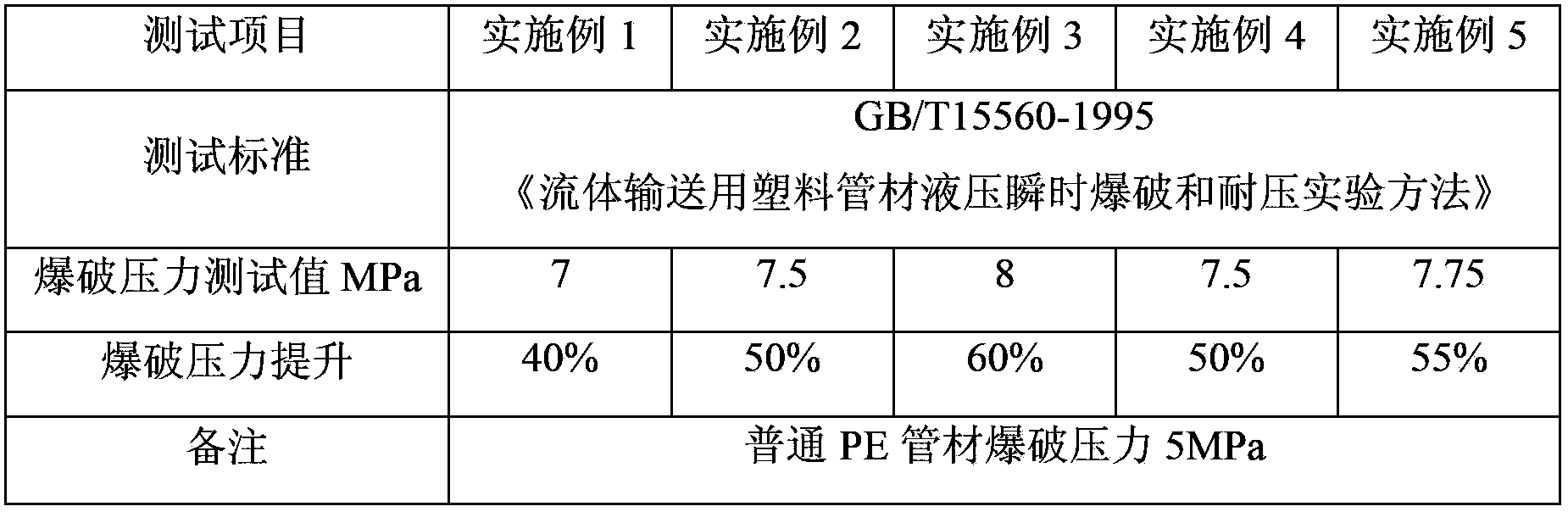

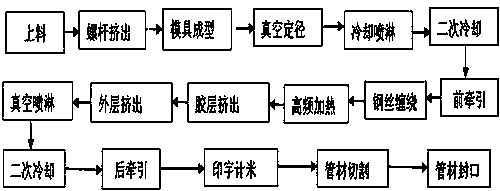

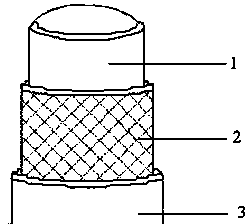

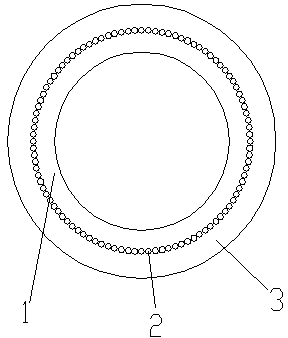

Manufacture process of steel wire mesh framework composite pipe

The invention provides a manufacture process of a steel wire mesh framework composite pipe. A steel wire mesh framework layer is formed by adopting bare steel wires through weaving, the steel wire mesh framework layer and a polyethylene base body material are melted together by using resin in a molten state in a process of producing the composite pipe without causing quality hidden dangers such as spinning, and an inner-layer polyethylene pipe extruding machine and an outer-layer polyethylene pipe extruding machine and a mould are integrated, thus the production efficiency is greatly increased and the production cost is lowered.

Owner:扬州金鑫管业有限公司

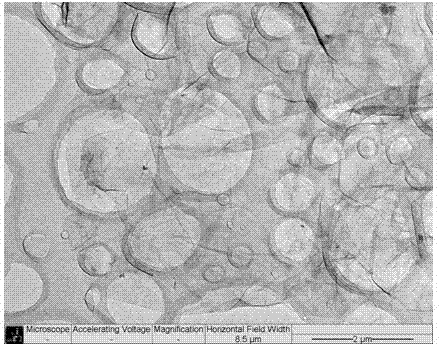

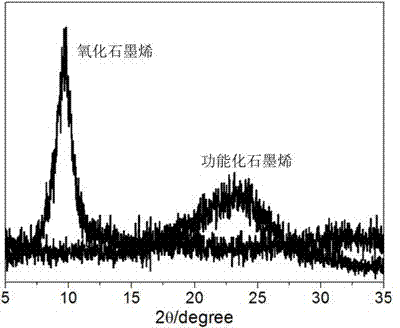

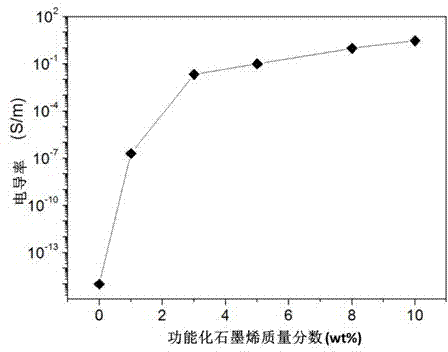

Functional graphene and preparation method as well as application thereof to graphene /non-polar polymer composite material

ActiveCN102898872AGood dispersionEasy to prepareOther chemical processesPigment treatment with organosilicon compoundsElectromagnetic shieldingControllability

The invention discloses functional graphene and a preparation method as well as application thereof to a graphene / non-polar polymer composite material. The preparation method of the functional graphene comprises the following steps of: uniformly bonding oleic acid molecules to the surface of the graphene in a covalent bond mode; mixing the functional graphene obtained in a solution blending mode and polyethylene solution; and then performing settling, drying and die pressing to obtain the conductive functional graphene / polyethylene shielding material, or performing melt blending to directly obtain the functional graphene / polyethylene shielding material. The percentage content of the graphene in the composite material is controllable within a range of 1-10 percent. The preparation method has the advantages of simplicity, easiness in operation, high controllability and capability of realizing large-scale production; the functional graphene can be uniformly dispersed in the polyethylene matrix; and thus, the obtained polyethylene composite material has higher conductivity in case of low graphene mixing amount, and has great application value in the fields such as cable shielding, electromagnetic shielding and anti-static electricity.

Owner:WUXI MINGZHU CABLE

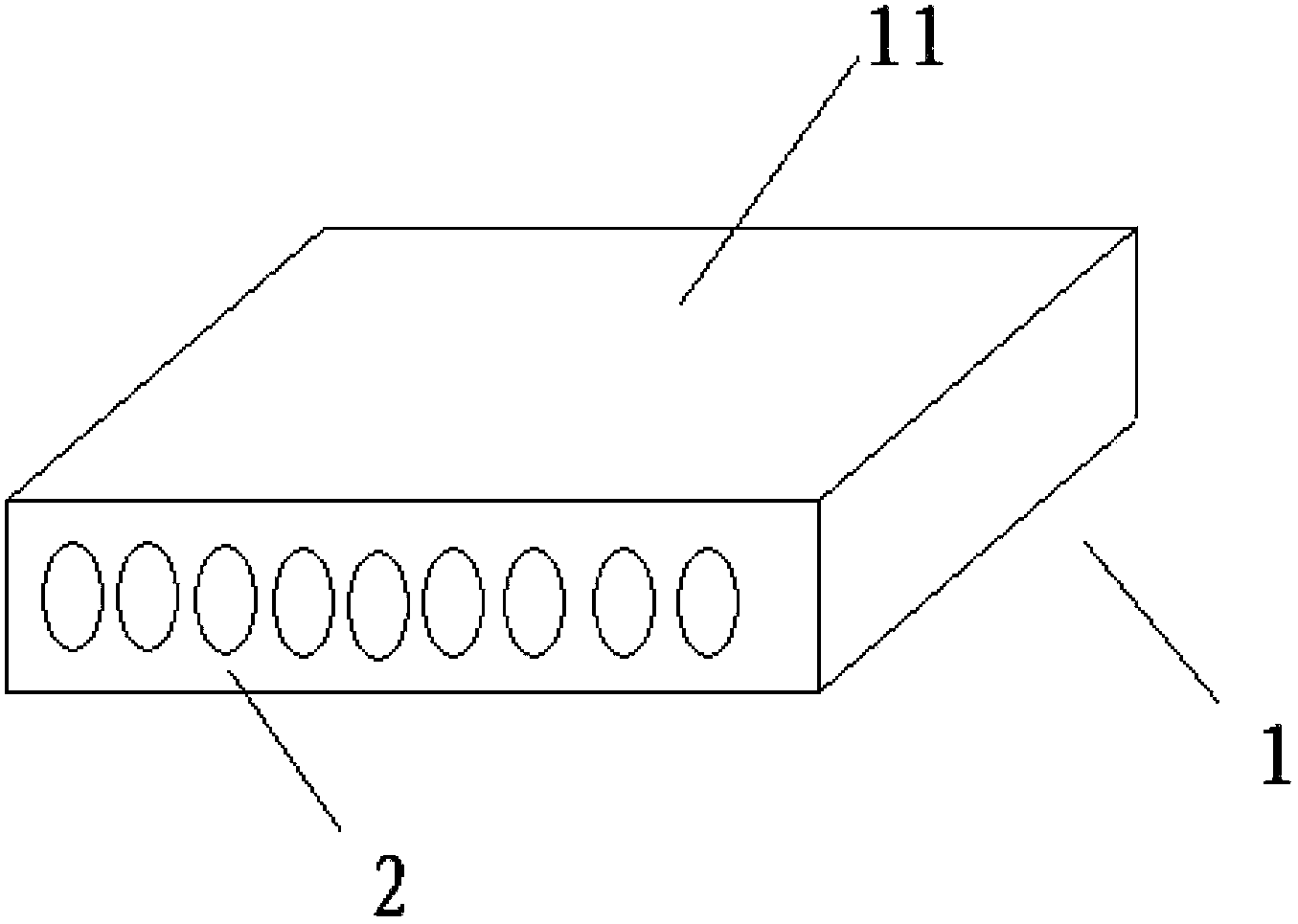

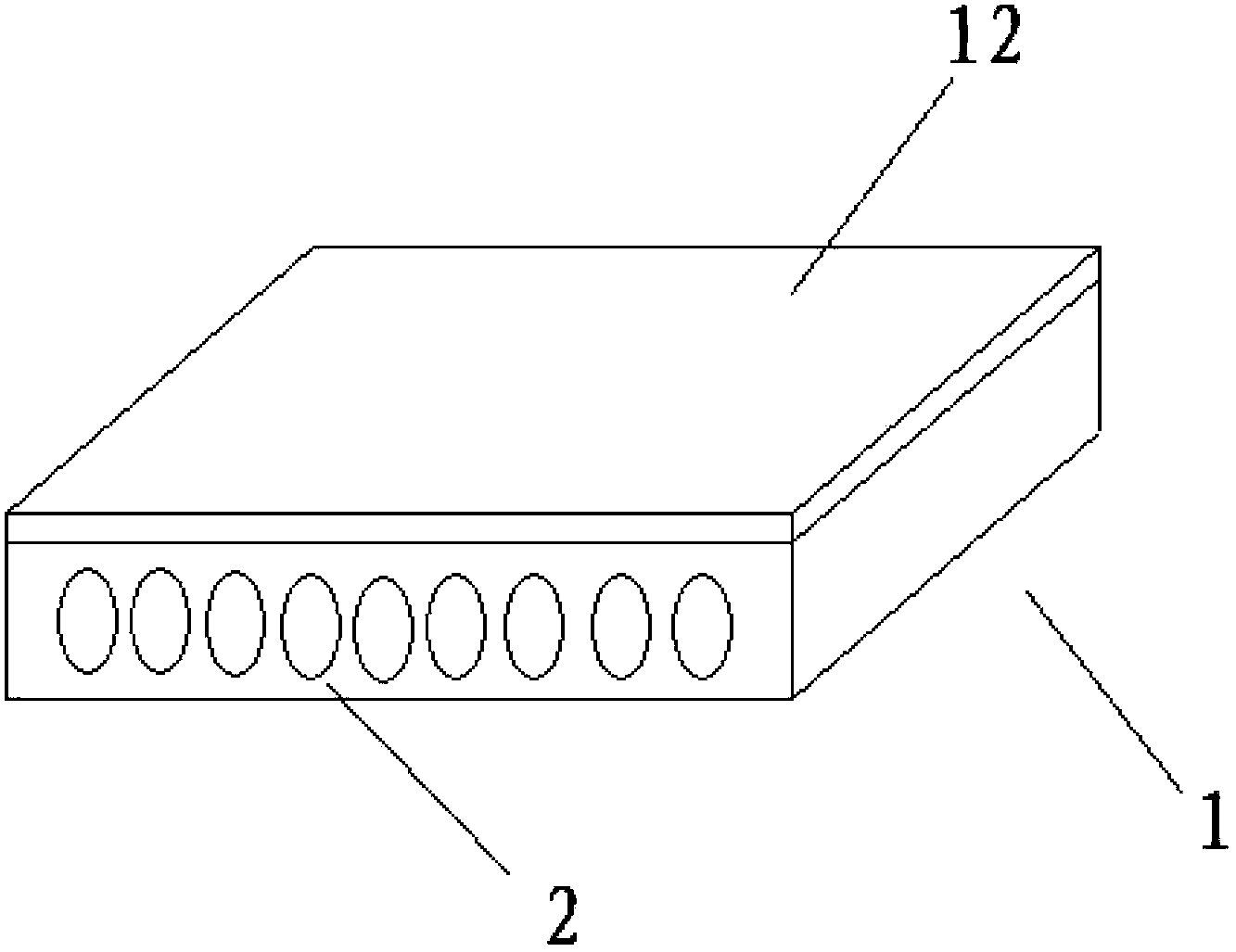

Nano-calcium highly-filled polypropylene anti-aging building formwork and technology thereof

InactiveCN103835494ASynthetic resin layered productsForming/stuttering elementsPolypropylene compositesManufacturing technology

The invention belongs to the field of composite materials, and relates to a nano-calcium highly-filled polypropylene building formwork, in particular to a nano-calcium highly-filled polypropylene anti-aging building formwork and the technology thereof. The nano-calcium highly-filled polypropylene anti-aging building formwork comprises a building formwork body made of nano-calcium highly-filled polypropylene composite materials, and the nano-calcium highly-filled polypropylene composite materials comprise polypropylene plastics, polyethylene substrates, nanoscale calcium carbonate, coupling agents, a flexibilizer and an ultraviolet light absorber. The nano-calcium highly-filled polypropylene anti-aging building formwork with the technology has the advantages of being low in cost, environmentally friendly, recyclable and the like. The manufacturing technology of the nano-calcium highly-filled polypropylene building formwork comprises the steps that materials are mixed at first, melt blending forming is conducted on the mixture at the temperature ranging from 160 DEG C to 180 DEG C, an extruder conducts extruding forming, cooling and cutting, and anti-aging enhanced calcium plastic particles are obtained; the enhanced calcium plastic particles are sent to a formwork profile extruder to be extruded to form formwork profiles, and the extruded formwork profiles are cooled in a vacuum mode, pulled and cut to be the nano-calcium highly-filled polypropylene anti-aging building formwork.

Owner:九鼎环保纸业股份有限公司

Foamed material prepared from nano-calcium-carbonate-filled polypropylene/polyethylene blend and preparation process thereof

The invention provides a foamed material prepared from a nano-calcium-carbonate-filled polypropylene / polyethylene blend and a preparation process thereof. The foamed material comprises the following components in parts by weight: 100-120 parts of polypropylene plastic, 10-15 parts of polyethylene matrix, 1-5 parts of foaming agent, 1-10 parts of nano calcium carbonate and 1-1.5 parts of coupling agent. The preparation process comprises the following steps: firstly uniformly mixing polypropylene, the polyethylene matrix, nano calcium carbonate and the coupling agent in weight proportion; then carrying out melt blending and granulating on the mixture at the temperature of 160-180 DEG C, and carrying out extrusion molding by virtue of an extrusion machine; and finally heating the molded material for 3-10 minutes, adding the foaming agent, mixing, foaming at the temperature of 185-200 DEG C, extruding and foaming by virtue of the extrusion machine at the extrusion machine temperature of 170-200 DEG C and cooling the extruded foam to obtain a product. In the preparation method provided by the invention, the polypropylene / polyethylene blend is filled with nano calcium carbonate and has a better foam shape, foam density and foamed material density than other foamed materials, and simultaneously the obtained product has the advantages of excellent impact strength and physical and mechanical properties.

Owner:CHANGSHU JIANGSHUN PLASTIC PROD

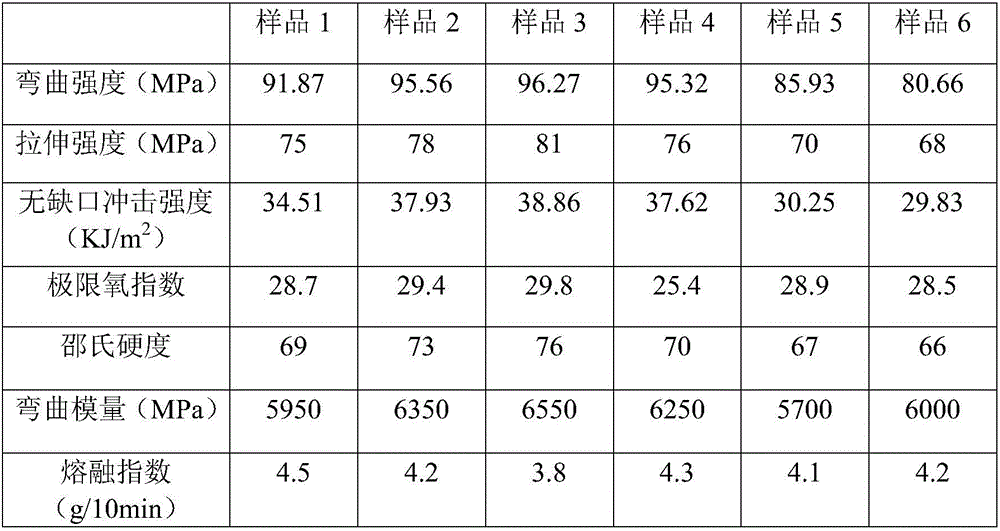

Graphene-modified polyethylene flame-retardant composite material and preparation method thereof

InactiveCN106832504AIncreased void densityHigh degree of expansionCarbon nanotubeInjection molding machine

The invention relates to a graphene-modified polyethylene flame-retardant composite material and a preparation method thereof. The preparation method comprises the following steps of uniformly mixing a polyethylene matrix, modified graphene, a silicon and phosphor compound flame retardant agent, a synergistic enhancer, a filler, a toughener and an additive in a mixing machine, and performing injection molding by an injection molding machine, so as to obtain a final product, namely the graphene-modified polyethylene flame-retardant composite material. The modified graphene is prepared by treating graphene oxide by phosphonitrilic chloride trimer; the synergistic enhancer is prepared by mixing a carbon nanotube and modified titanium dioxide; the filler consists of modified glass fiber and modified nanometer silicon dioxide; under the synergistic action of the modified graphene, the silicon and phosphor compound flame retardant agent, the synergistic enhancer and the filler, the graphene-modified polyethylene flame-retardant composite material is prepared. The preparation method has the advantages that the preparation technology is simple; the additive component has no pollution to environment; the prepared polyethylene composite material can meet the requirement of mechanical strength, and can realize the flame retardant effect; the use range of the polyethylene is widened.

Owner:DONGGUAN POLYTECHNIC

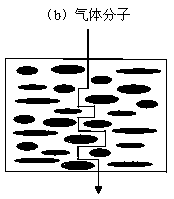

Graphene modified oxygen-resistant polyethylene master batch and preparation method and application thereof

InactiveCN111117041AEvenly dispersedGood oxygen barrierBulk chemical productionPolymer chemistryChemistry

The invention relates to the technical field of functionalization and high performance of plastic pipes, in particular to a graphene modified oxygen-resistant polyethylene master batch and a preparation method and application thereof. The modified plastic master batch is composed of the following components: a polyethylene matrix, graphene, a second oxygen inhibitor, a coating agent, a surface treating agent, a dispersing agent and an antioxidant. According to the three-step production process, the mixing, dispersing and stripping effects of graphene in a polyethylene matrix are improved, thefilling proportion of graphene in the composite material is increased through organic combination of a new material, a new technology and a new method, and formation of a perfect network structure inthe composite material matrix is promoted. The oxygen barrier property of the composite material can be remarkably improved through good construction of a network, so that the application potential ofgraphene in the oxygen barrier pipe is brought into full play, and the pipe filled with the high-barrier graphene nanosheet layer structure is obtained.

Owner:江苏新奥碳纳米材料应用技术研究院有限公司 +1

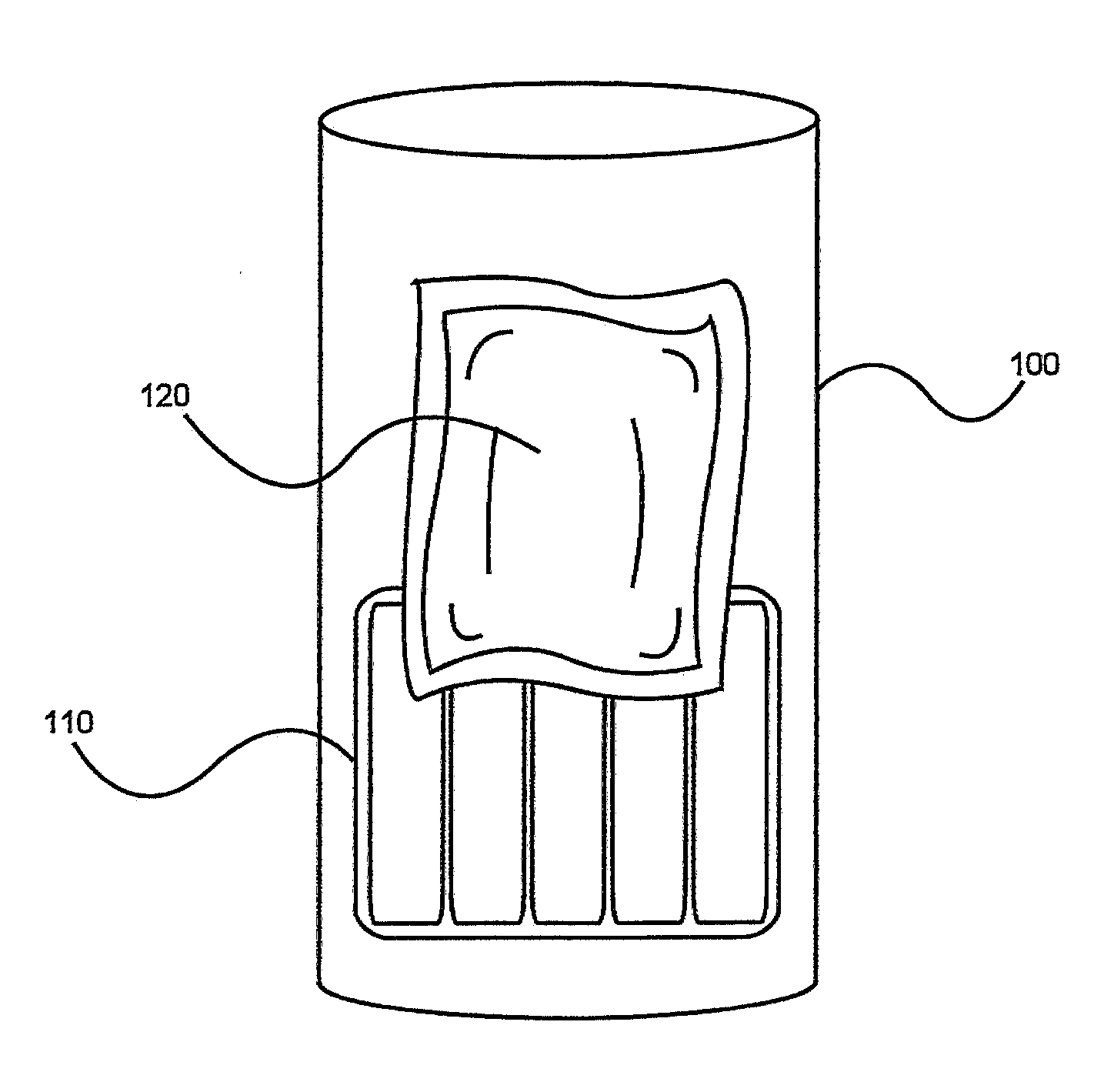

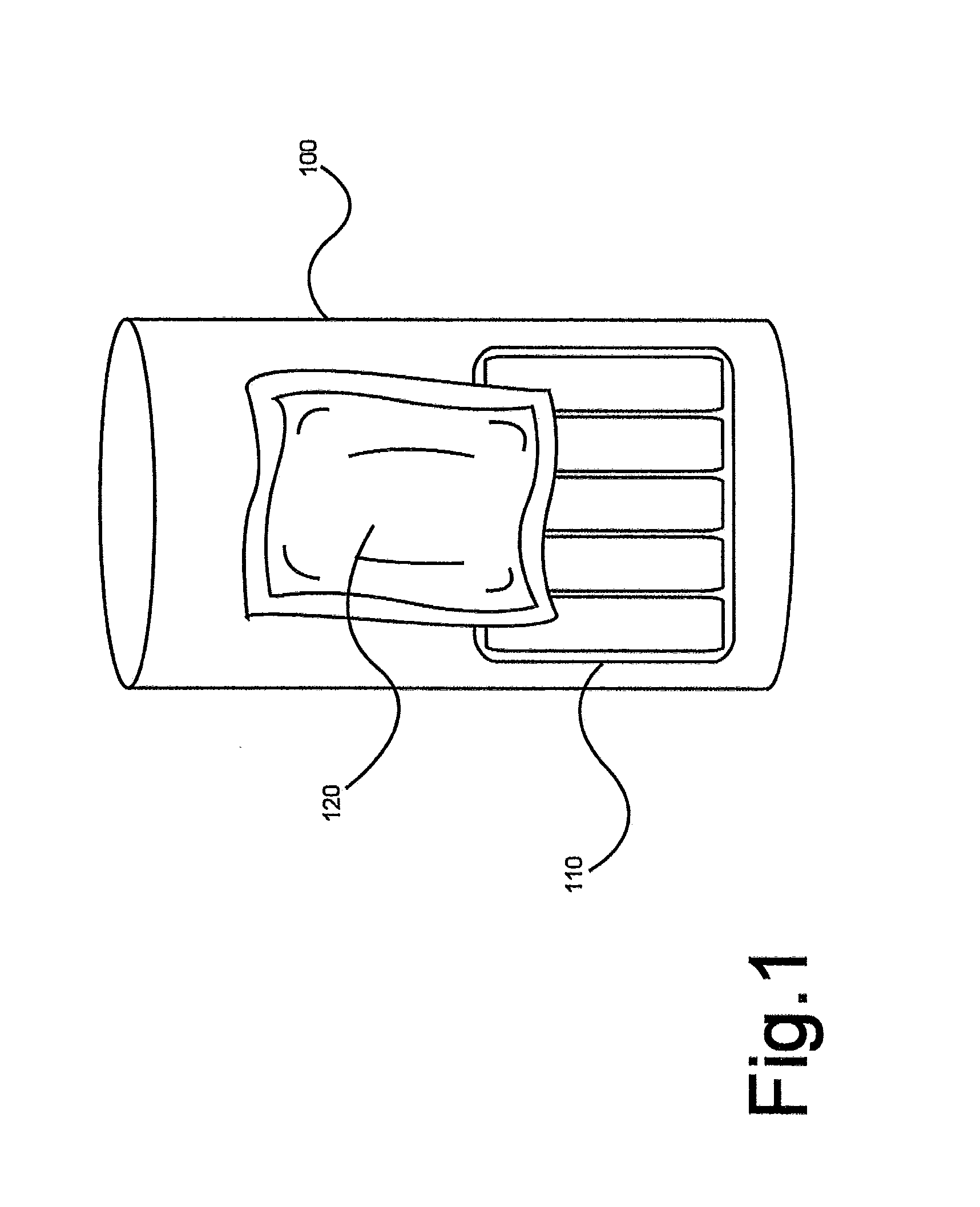

Heater

InactiveUS20120210996A1Improve securityIncrease usageExothermal chemical reaction heat productionOther heat production devicesHydrogenUnit mass

The present invention relates to flameless heating apparatus for food products. In particular, it relates to an improved potentially exothermic mixture / blend for such heaters and to meal packages including foods and heating apparatus. An embodiment of the invention comprises a composite material consisting of a potentially exothermic metallic alloy powder dispersed throughout a porous polyethylene matrix, which releases hydrogen in an exothermic reaction. The present invention seeks to reduce the production of such gas per unit mass, and further seeks to improve the efficiency of the reaction.

Owner:LUXFER MAGTECH INT LTD

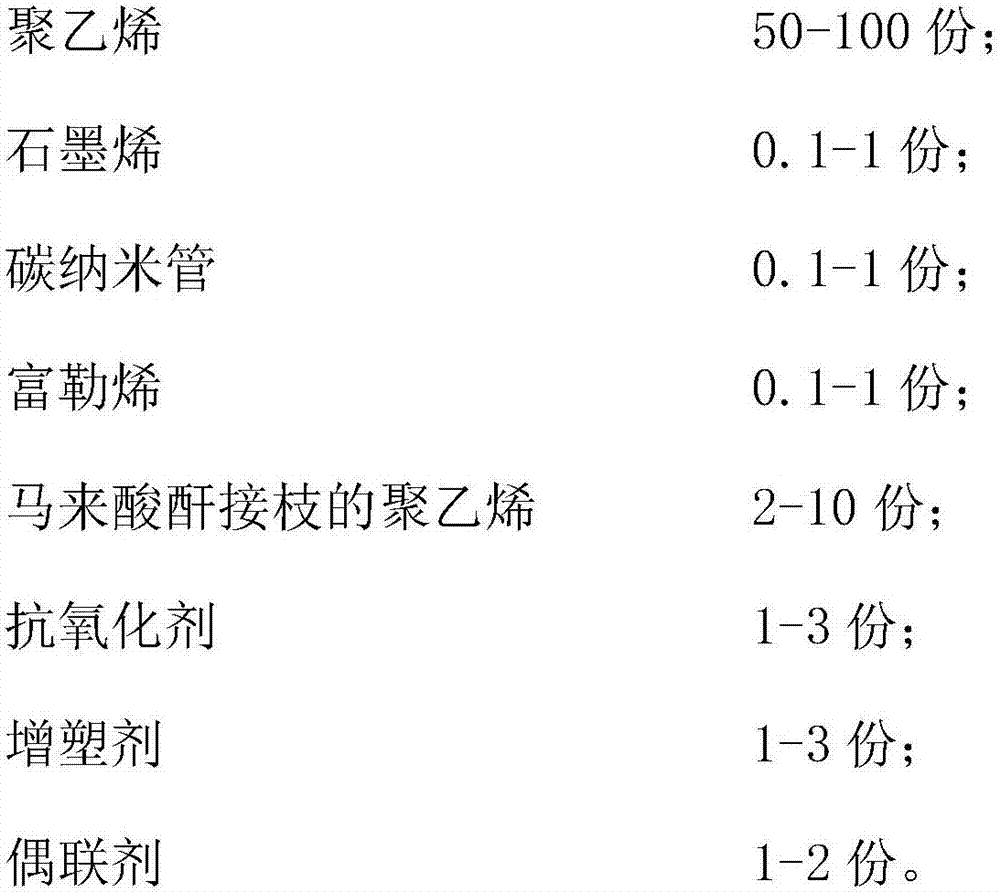

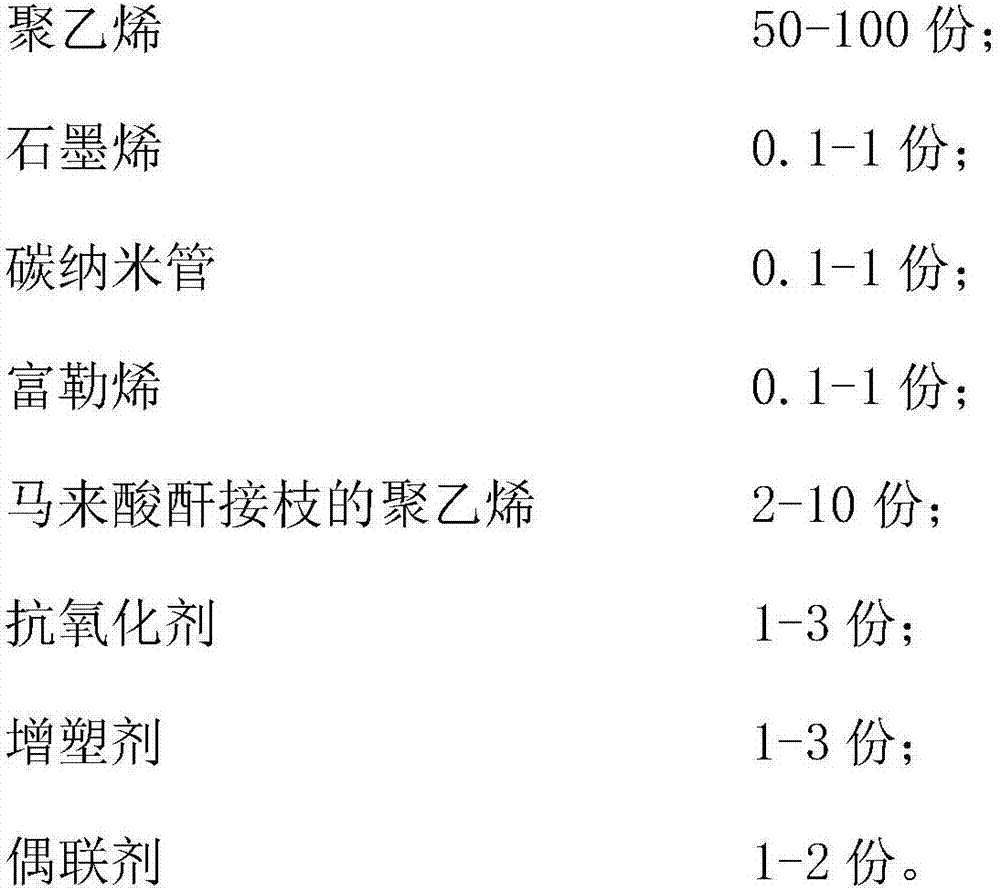

Polyethylene composite material jointly modified by graphene, carbon nanotubes and fullerene and preparation method of polyethylene composite material

The invention relates to the field of preparation of high polymer materials and in particular to a polyethylene composite material jointly modified by graphene, carbon nano tubes and fullerene. The material is prepared from the following components: 50 to 100 parts of polyethylene, 0.1 to 1 part of the graphene, 0.1 to 1 part of the carbon nano tubes, 0.1 to 1 part of the fullerene, 2 to 10 parts of maleic anhydride grafted polyethylene, 1 to 3 parts of antioxidant, 1 to 3 parts of plasticizer and 1 to 2 parts of coupling agent. According to the polyethylene composite material disclosed by the invention, two-dimension graphene, one-dimensional carbon nano tubes and zero-dimensional fullerene are mixed to set up a three-dimensional carbon material antistatic network; a carbon material with smaller proportion is used in a polyethylene matrix to construct a conductive network. The composite material has the advantages that a processing technology is simple, and batch production can be realized; products obtained by one-time injection molding can be applied to the field of antistatic electricity.

Owner:JIANGNAN GRAPHENE RES INST

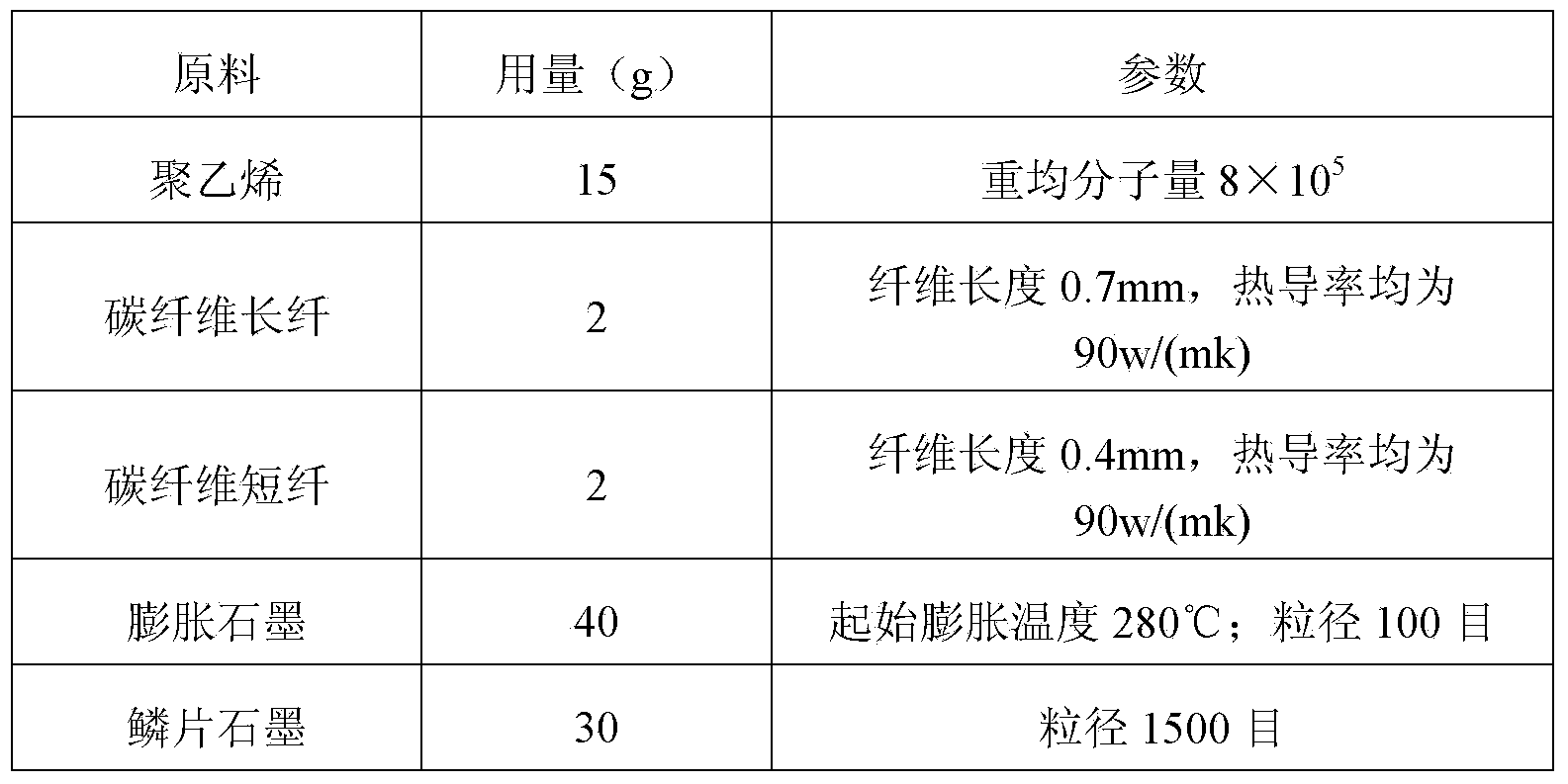

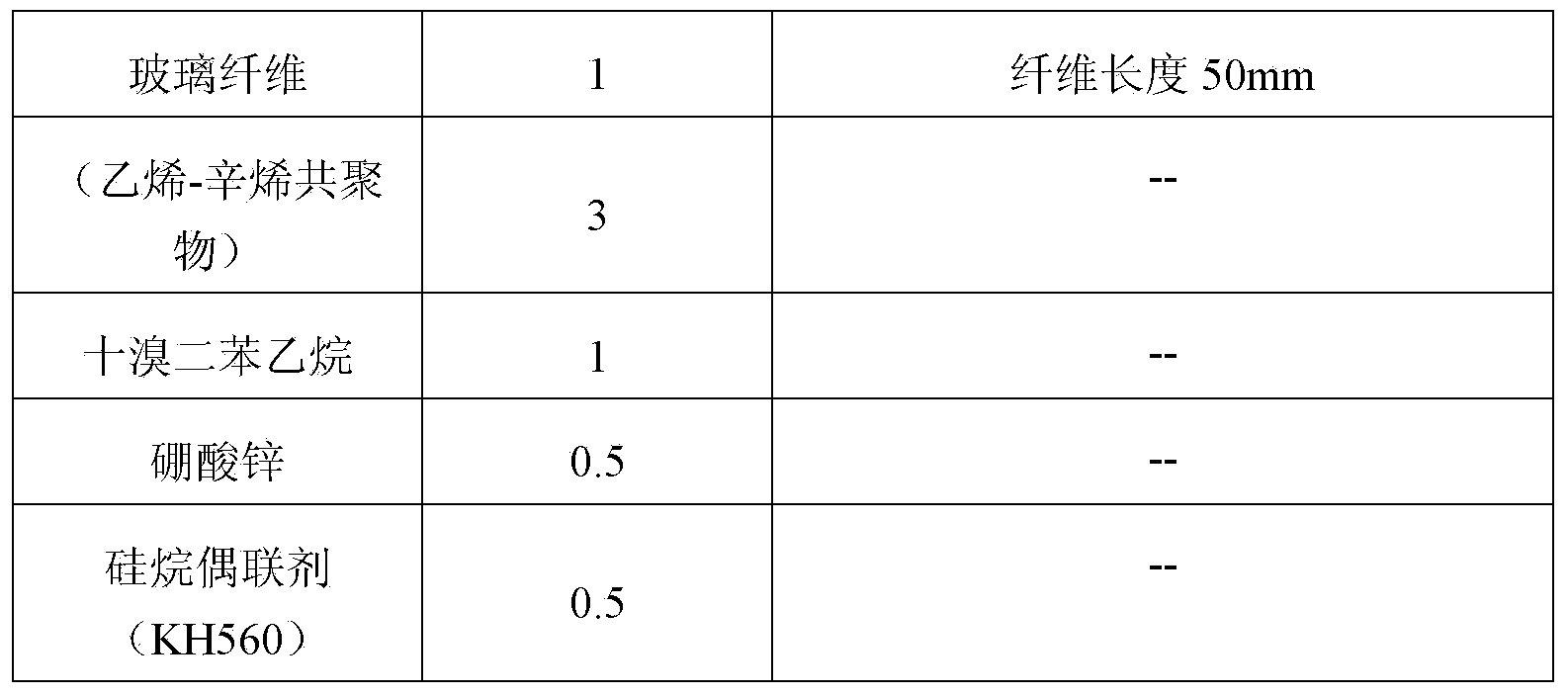

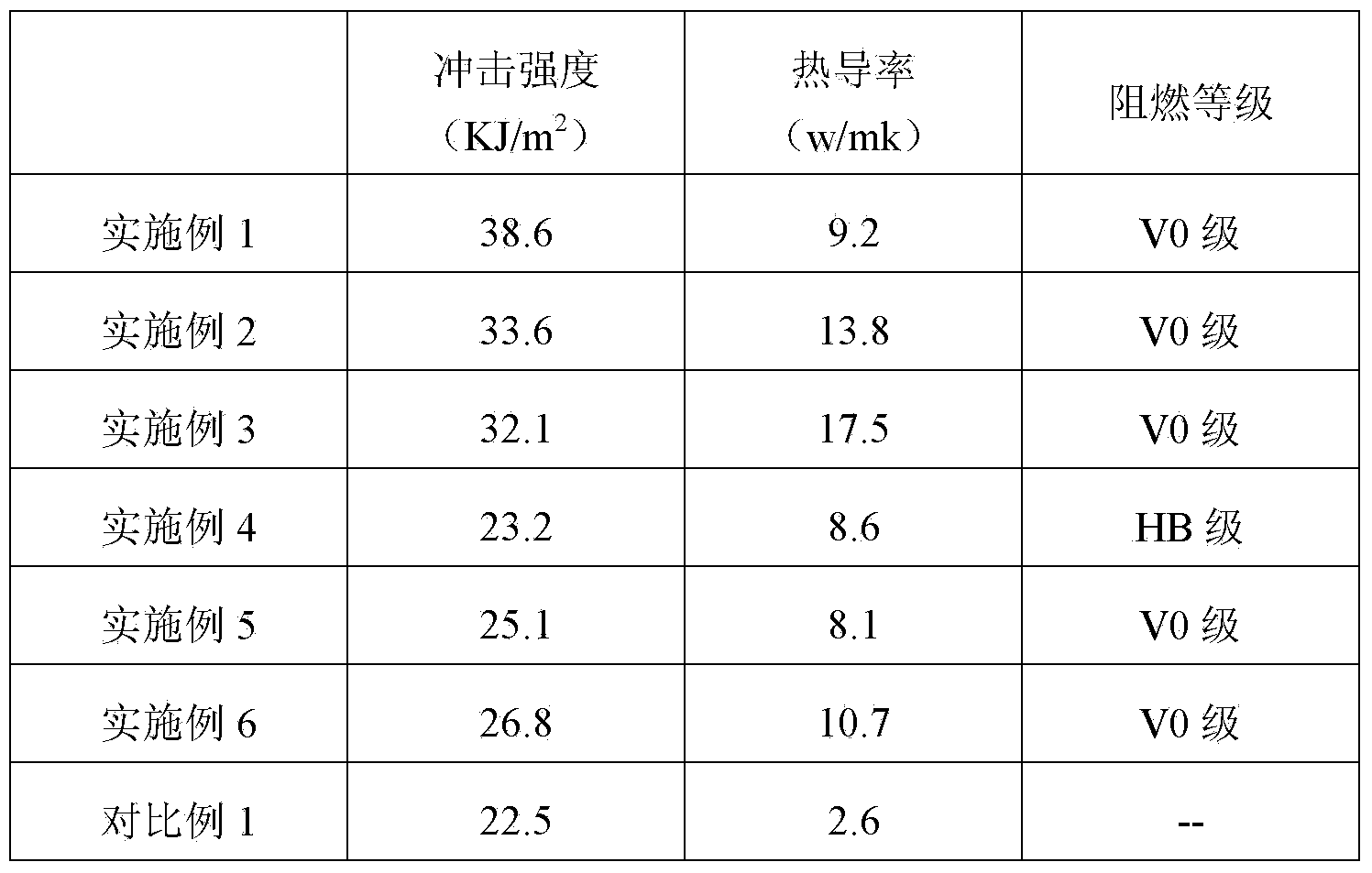

Heat-conductive polyethylene composite material and preparation method thereof

The invention provides a heat-conductive polyethylene composite material and a preparation method thereof. The composite material comprises the following components in parts by weight: 15 to 50 parts of polyethylene, 4 to 35 parts of heat-conductive fibers and 23 to 80 parts of heat-conductive granules. The heat-conductive fibers taken as heat-conductive filling materials are added into the polyethylene substrate, so that the heat-conductive polyethylene composite material is formed. Compared with granular heat-conductive filling materials, according to the composite material provided by the invention, after the fibriform heat-conductive fibers enter the polyethylene substrate, an overlapping state can be easily formed between the heat-conductive fibers and the polyethylene substrate, so that the formed overlapping network can easily pass through the whole polyethylene substrate; and thus, the heat in the substrate can be rapidly dispersed under the heat-conductive action of the overlapping network, thereby being favorable for improving the heat transfer efficiency of the composite material. Meanwhile, after the heat-conductive granules are added, the heat-conductive granules can be used for enwrapping joints among the different heat-conductive fibers, so that strong heat-conductive channels are formed among the heat-conductive fibers.

Owner:BEIJING SINOREFINE AIR CONDITIONING TECH +1

Preparation method of nanoporous high-efficiency heat-insulating polyethylene film

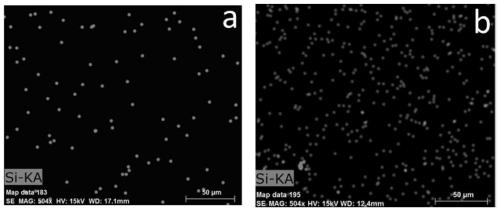

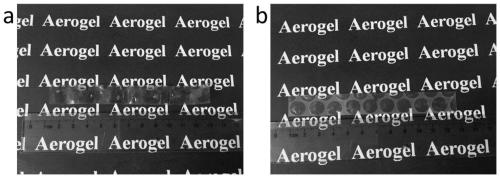

InactiveCN109912874AImprove insulation performanceLow thermal conductivityBulk chemical productionMasterbatchUltimate tensile strength

The invention relates to a preparation method of a nanoporous high-efficiency heat-insulating polyethylene film, by which the nanoporous high-efficiency heat-insulating polyethylene film is prepared from nanometer aerogel powder as an inorganic filler and polyethylene powder as a main raw material. The preparation process comprises the following main steps: performing surface modification on the nanometer aerogel powder, preparing masterbatch, casting the film and the like. Through certain technical characterization, the fact that the nanometer aerogel powder is uniformly dispersed in a polyethylene matrix is proved. Compared with the conventional polyethylene film, the nanoporous high-efficiency heat-insulating polyethylene film provided by the invention has the advantages as follows: theheat conductivity of the nanoporous high-efficiency heat-insulating polyethylene film doped with 3% of the aerogel powder is decreased by 26.1%, and the tensile strength and the elongation at break are not changed too much. Decrease in the heat conductivity indicates increase in heat-preserving and heat-insulating properties of the film, so that the film prepared by the preparation method provided by the invention has a very good application prospect in the field of heat preservation and heat insulation.

Owner:罗瑞尔纳米合成材料(江苏)有限公司

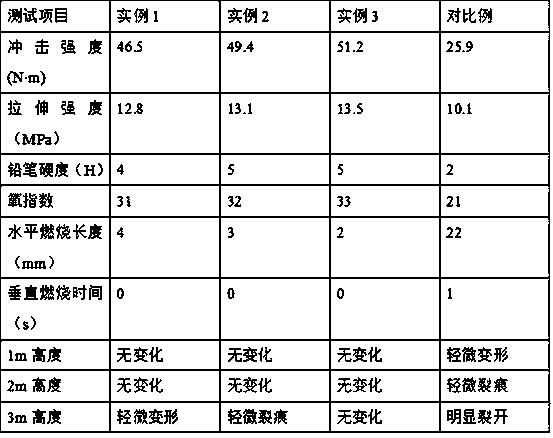

Preparation method for high-strength flame-retardant wood-plastic floor

The invention discloses a preparation method for a high-strength flame-retardant wood-plastic floor, and belongs to the technical field of preparation of floors. According to the method provided by the invention, sepiolite and a phosphoric acid solution are mixed and dispersed to obtain a flame-retardant functional mother liquor, a dimethyl sulfoxide solution of E-51 epoxy resin is added dropwiseinto an alkalizing solution of beta-cyclodextrin for a reaction to obtain nano fibers, polyethylene masterbatch particles are subjected to rubber mixing for melting, a wood and stone fiber sponge is mixed, the obtained material is injected into a hot pressing mold for hot pressing to obtain the high-strength flame-retardant wood-plastic floor, lignin is adsorbed on the fiber surface and in the pores to enhance interfacial bonding force of the lignin and sepiolite fibers, and therefore the compressive strength of the wood-plastic floor is improved; and the nano fiber sponge is prepared by soaking of resin in the flame-retardant functional mother liquor, sepiolite powder in the flame-retardant functional mother liquor is a magnesium-enriched silicate compound, the compound can form a magnesium hydroxide crystal and ammonium phosphate under the action of an ammonia gas and phosphoric acid, the integrity of a polyethylene matrix skeleton is maintained, oxygen supply during combustion is insufficient, combustion is quickly stopped, and therefore the better flame retardant effect on the wood-plastic floor is achieved.

Owner:常州鼎众冷暖设备工程有限公司

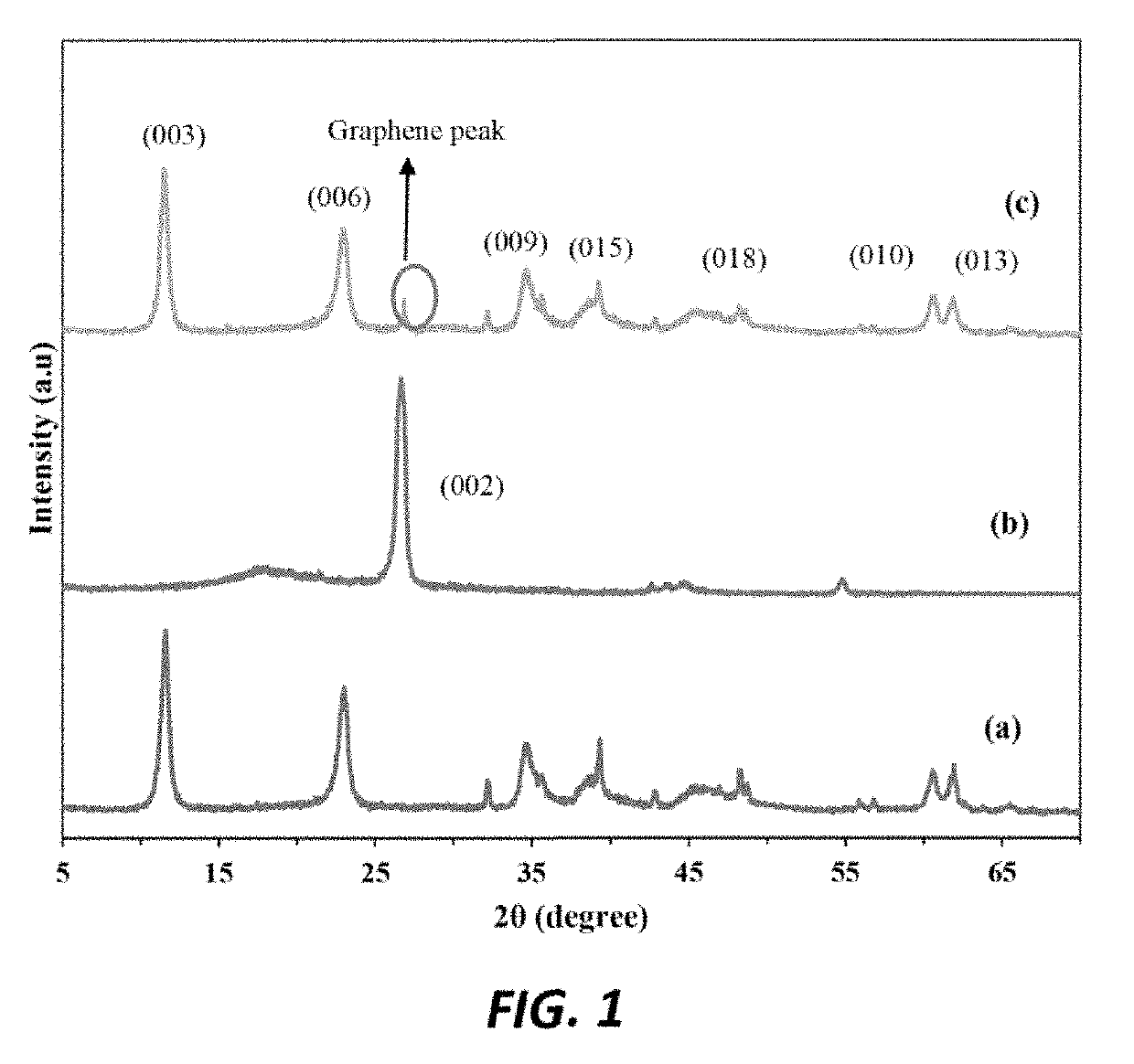

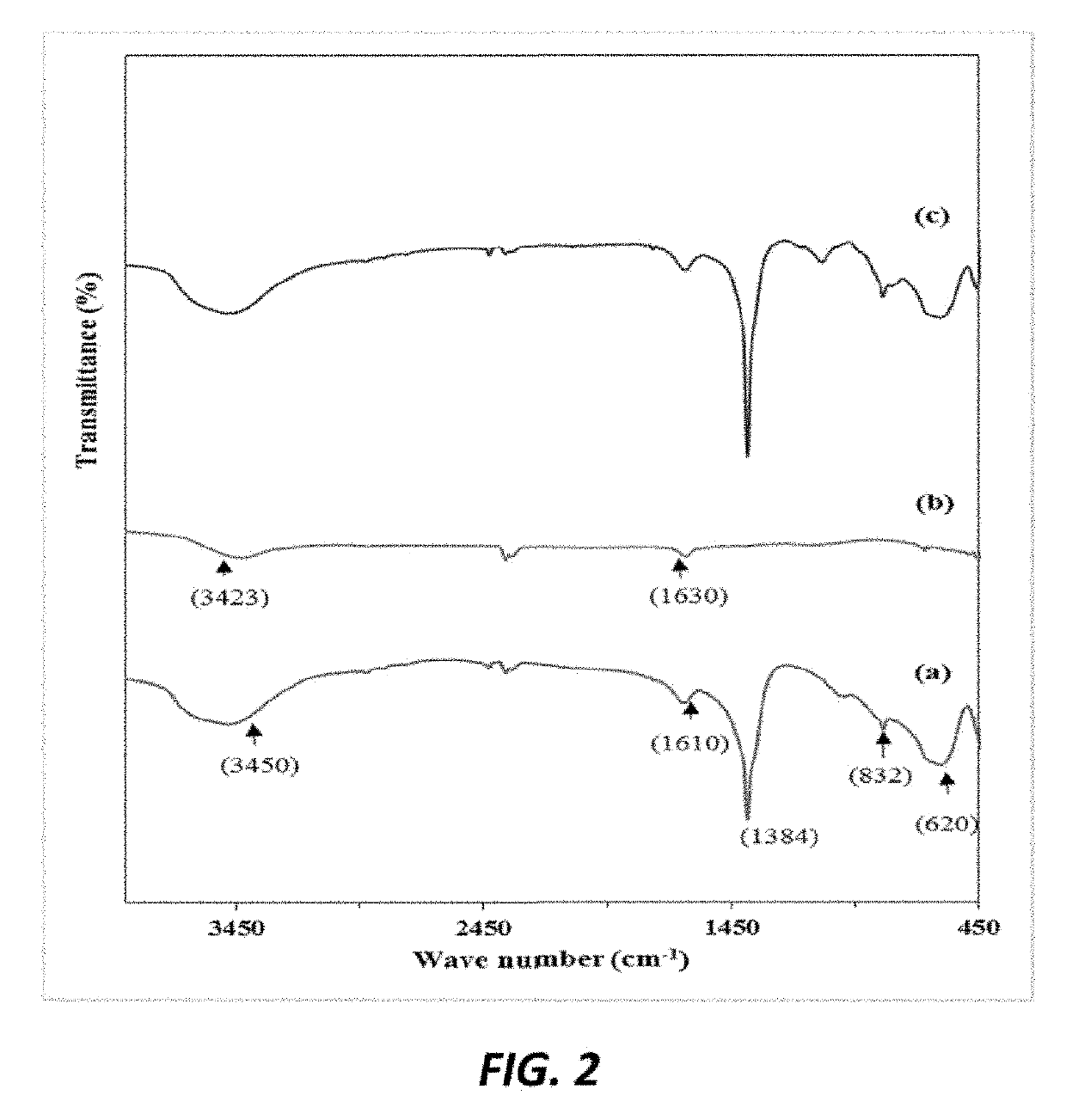

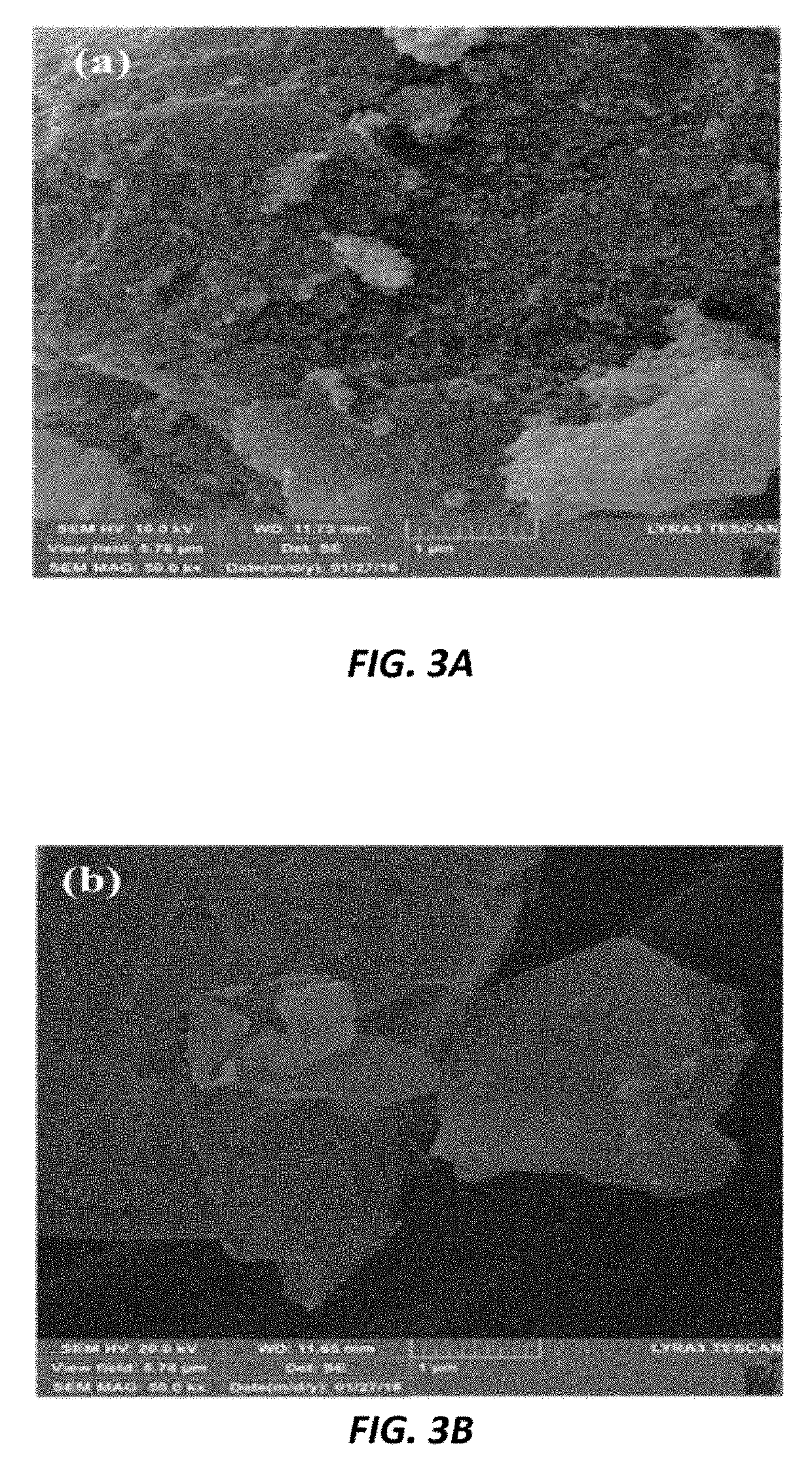

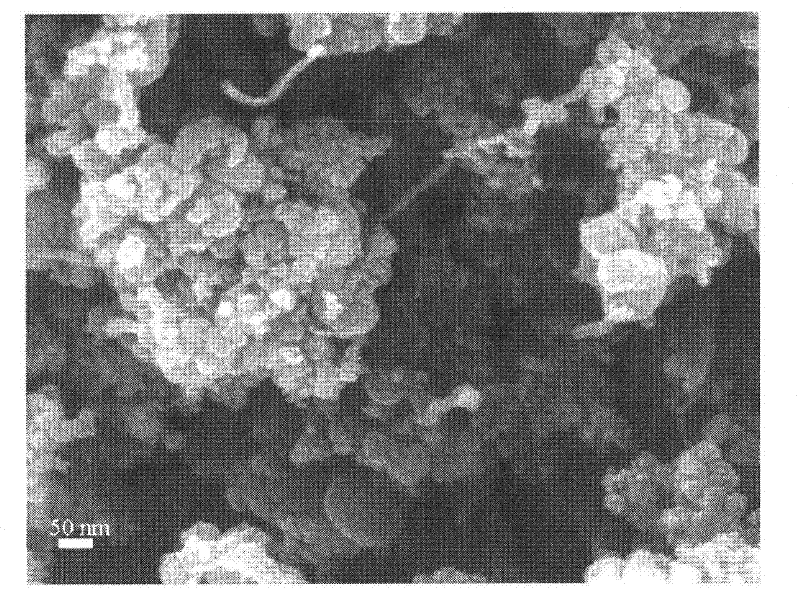

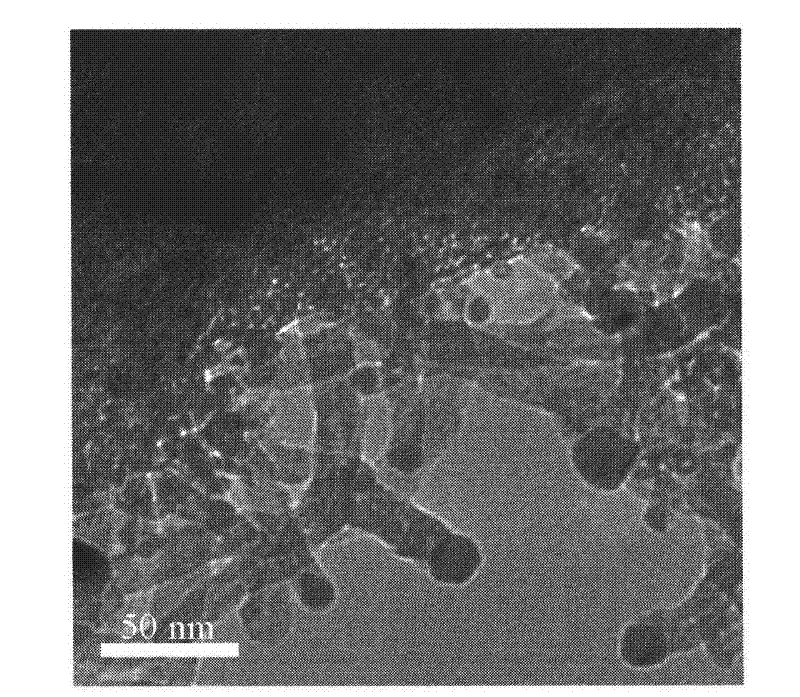

In-situ polymerization method for producing a polyethylene nanocomposite

PendingUS20190284350A1High catalytic activityHigh molecular weightOrganic solventIn situ polymerization

A method for producing a polyethylene nanocomposite by polymerizing ethylene in a polymerization mixture that contains a graphene-layered double hydroxide nanocomposite, a metallocene catalyst, an alkylaluminoxane co-catalyst, and an organic solvent to form a polyethylene nanocomposite in which the graphene-layered double hydroxide nanocomposite is dispersed in a matrix of polyethylene and wherein the graphene-layered double hydroxide nanocomposite contains 1 to 7 wt. % graphene relative to a total weight of the graphene-layered double hydroxide nanocomposite.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

Preparation method of carbon nanotube, nickel and aluminum composite powder reinforced polyethylene-based composite material

InactiveCN102296281AControl ratioSolve the problem of fragmentationChemical vapor deposition coatingAluminum compositesPolyethylene matrix

The invention relates to the field of polyethylene composite materials, in particular to a preparation technology for a carbon nanotube / nickel / aluminum in-situ enhanced polyethylene based composite material, and aims to provide a method for keeping controllable contents and uniform dispersion and distribution of the carbon nanotubes and metal composite powder in a polymer based composite materialand keeping good interface infiltration of carbon tubes and a base and high binding strength. The method comprises the following steps of: synthesizing CNTs (Carbon Nanotubes)-Ni-Al composite powder with uniformly dispersed CNTs, excellently kept structure and controllable content by using a chemical vapor deposition method; and doping the in-situ composite powder into a polyethylene base by using a melt blending method so as to prepare the CNTs / Ni / Al / polyethylene based composite material with high strength and modulus and excellent conductivity and heat-conducting property. By adopting the composite powder, the proportion of the carbon nanotubes, nickel and aluminum can be controlled excellently; meanwhile, the problem of dispersion of the metal and the carbon nanotubes in the composite material can be solved well; the carbon nanotubes do not agglomerate in the composite powder and are widely dispersed to achieve a nano-size effect; and the carbon nanotubes have high binding strengthwith the base, so that the polyethylene based composite material can be effectively enhanced by the carbon nanotubes and the aluminum, and the comprehensive performances such as strength, conductivity, heat conduction and the like of the composite material are greatly improved.

Owner:SANITARY EQUIP INST ACAD OF MILITARY MEDICAL SCI PLA

Adhesive resin for steel-mesh reinforcing polyethylene hot water pipe and preparation method of adhesive resin

ActiveCN106349976AImprove heat resistanceGood adhesionNon-macromolecular adhesive additivesMacromolecular adhesive additivesHeat deflection temperatureElastomer

The invention discloses adhesive resin for steel-mesh reinforcing polyethylene hot water pipe. The adhesive resin comprises, by weight, 5-50% of polyethylene grafts, 20-80% of polyethylene matrix resin, 5-60% of heat-proofness enhancing particles and 1-30% of elastomer toughening particles, and the total percentage of the components is 100%. The invention further discloses a preparation method of the adhesive resin. The adhesive resin prepared is good in heat resistance, steel-mesh adhesive effect is good, vicat softening point reaches more than 120DEG C, heat distortion temperature reaches above 95DEG C, and peel strength at the temperature of 85DEG C reaches more than 100N / cm.

Owner:GUANGZHOU LUSHAN NEW MATERIALS

Creep resistance continuous glass fiber reinforced polyethylene prepreg tape and preparation method thereof

The invention belongs to the technical field of material science, and discloses a creep resistance continuous glass fiber reinforced polyethylene prepreg tape and a preparation method thereof. The polyethylene prepreg tape is prepared from the following components, by weight: 100 parts of a polyethylene matrix, 10-30 parts of a creep resistance modifier, 3-5 parts of a compatibilizer, 0.6-1.2 parts of an antioxidant, and 40-60 parts of glass fibers. The preparation method comprises: sequentially adding 100 parts of a polyethylene matrix, 10-30 parts of a creep resistance modifier, 3-5 parts of a compatibilizer, and 0.6-1.2 parts of an antioxidant to a high speed mixer, uniformly mixing, and sealing, wherein a mixing speed is 400-600 r / min, and a mixing time is 60-160 s; and extruding the obtained mixture, carrying out laminating on 40-60 parts of preheated glass fibers, and carrying out cooling and shaping on the laminated continuous glass fiber tape material to obtain the creep resistance continuous glass fiber reinforced polyethylene prepreg tape. The polyethylene prepreg tape has characteristics of excellent mechanical property and ultra-strong creep resistance.

Owner:LIAONING LIAOJIE SCI & TECH

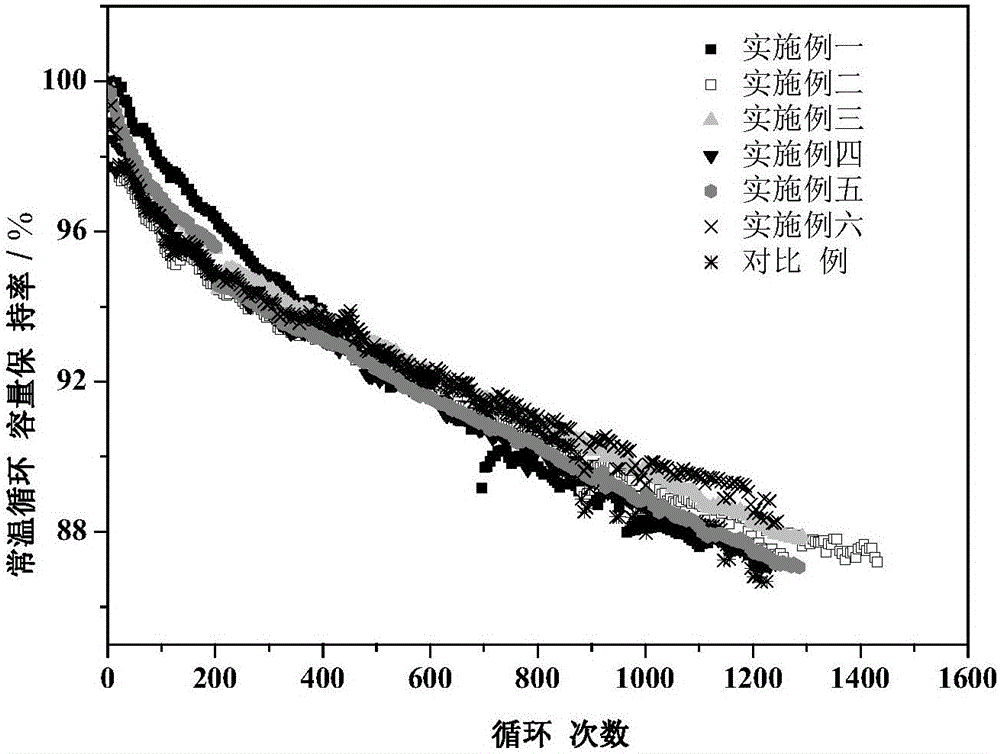

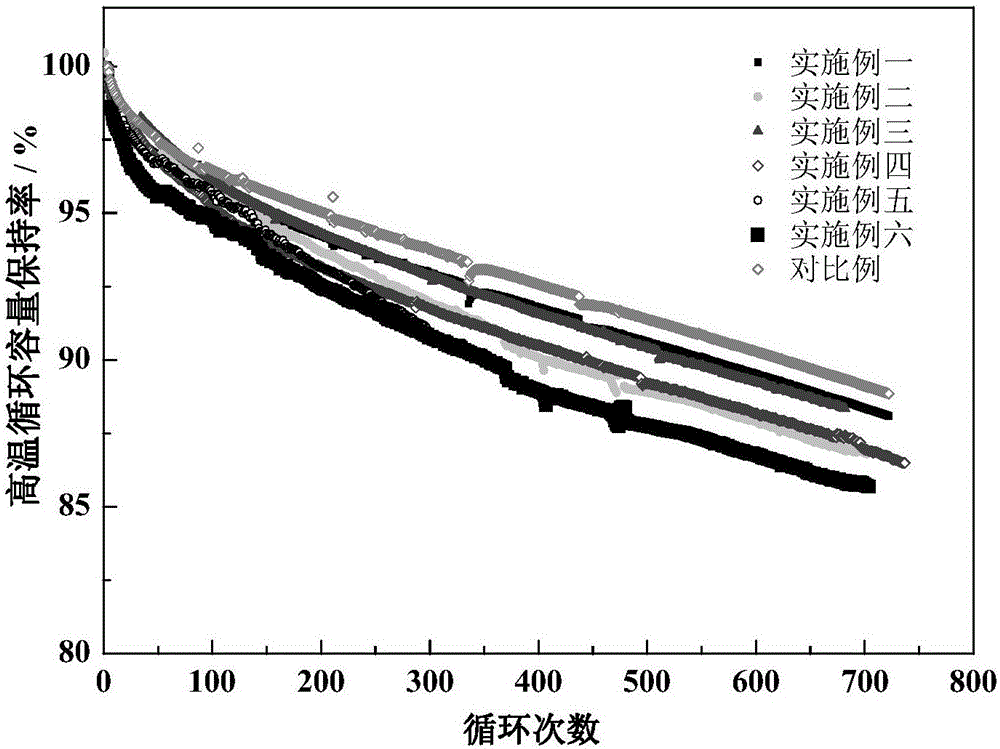

Composite system power battery with high safety and long service life and preparation method of composite system power battery

InactiveCN106328935APromote circulationImprove thermal stabilityCell electrodesSecondary cells servicing/maintenanceAdditive ingredientCeramic coating

The invention relates to the field of research, development and preparation of lithium batteries, in particular to a composite system power battery with high safety and long service life and a preparation method of the composite system power battery. The preparation method of the power battery comprises steps as follows: 70%-90% of LiNi0.6Co0.2Mn0.2O2 and 10%-30% of LiMn0.8Fe0.2PO4 are mixed, sufficient mixing and pulp preparation are performed in cooperation of high-conductivity carbon nanotubes, then, pulp is subjected to coating, rolling and slitting, and a positive plate is prepared; as for a negative electrode, synthetic graphite is mixed with acetylene black, sufficient mixing and pulp preparation are performed, pulp is subjected to coating, rolling and slitting, and a negative plate is prepared; cells are prepared according to the desired size from diaphragms by the aid of a wet-method polyethylene substrate, an aluminum oxide ceramic coating and a binder PVDF, then, liquidation ingredients are injected, the battery is prepared, and used electrolyte adopts a high-molar-concentration mixed solvent system of multiple compound additives. The retention rate of the prepared battery reaches 88% after 1,200 cycles of cycling at the normal temperature and reaches 87% after 680 cycles of cycling at the high temperature of 45 DEG C, and the battery has excellent heat stability, energy density, normal-temperature and high-temperature cycling performance and excellent safety and can be widely used for electric automobiles and related products.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

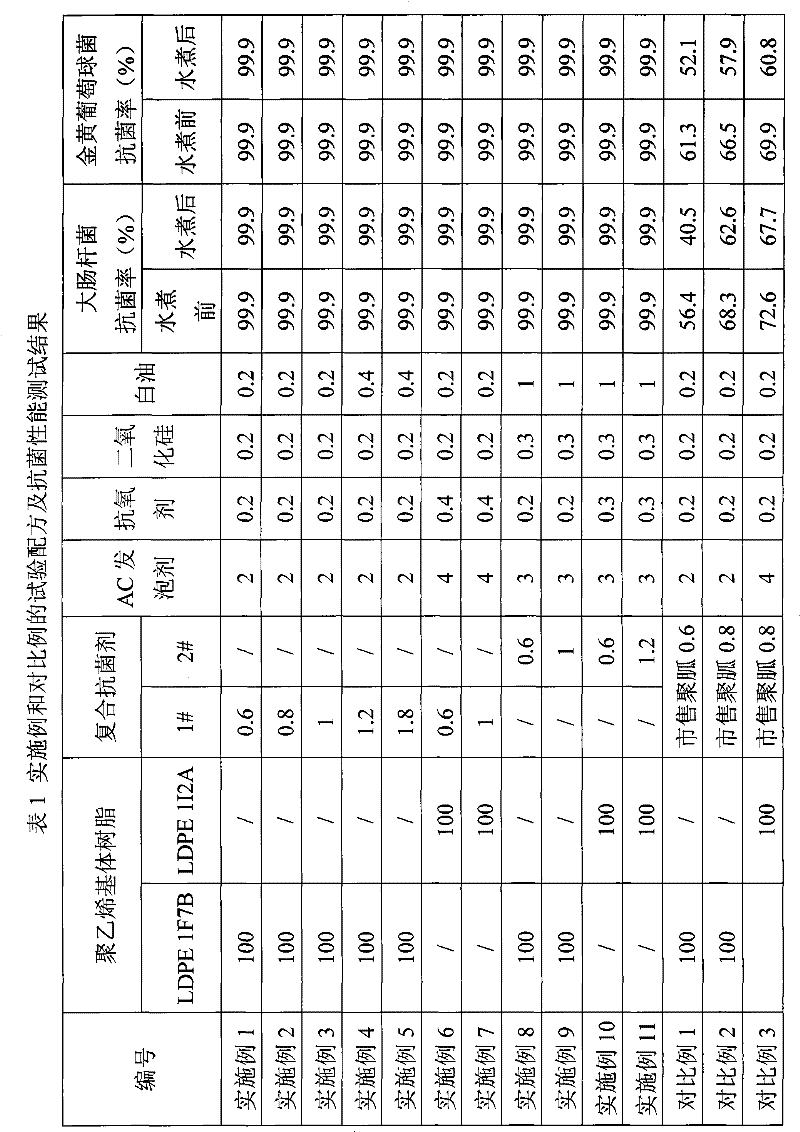

A kind of antibacterial polyethylene foam plastics and preparation method thereof

ActiveCN102286164ASimple manufacturing methodMild reaction conditionsLow-density polyethyleneLinear low-density polyethylene

The invention relates to an antibacterial polyethylene foamed plastic and a preparation method thereof. The composition provided by the invention comprises blended polyethylene base resin, a composite antibacterial agent and a chemical foaming agent, wherein in terms of 100 parts by weight of polyethylene, the amount of the composite antibacterial agent is 0.2-2 parts by weight; the polyethylene base resin is selected from polyethylene with high melt strength or linear low-density polyethylene with a long chain branch structure; and the composite antibacterial agent is a polyguanidine / polysilicate composite antibacterial agent, which is prepared by mixing an aqueous solution of a water-soluble polyguanidine inorganic acid salt or organic acid salt with an aqueous solution of a water-soluble silicate and adding an aqueous solution of a water-soluble metal salt, the molar ratio of the water-soluble polyguanidine inorganic acid salt or organic acid salt to the water-soluble silicate is (10:1)-(1:50) and the molar ratio of the water-soluble silicate to the water-soluble metal salt is (5:1)-(1:3). The polyethylene foamed plastic material composition provided by the invention has the advantages of high sterilization efficiency, high water washing resistance, stable performance and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

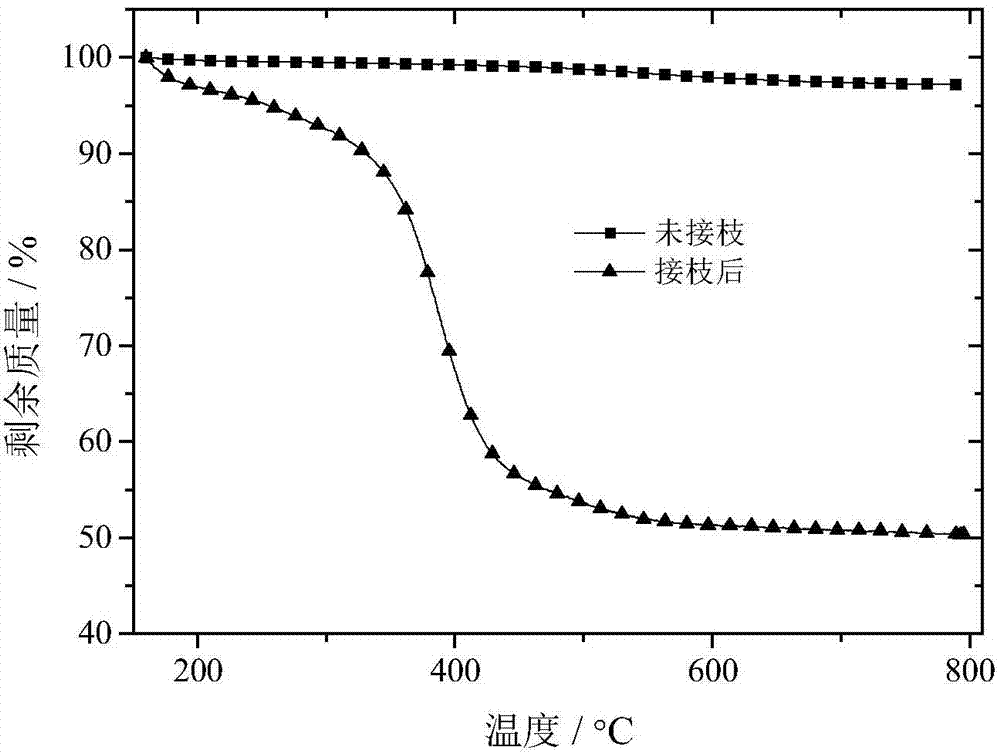

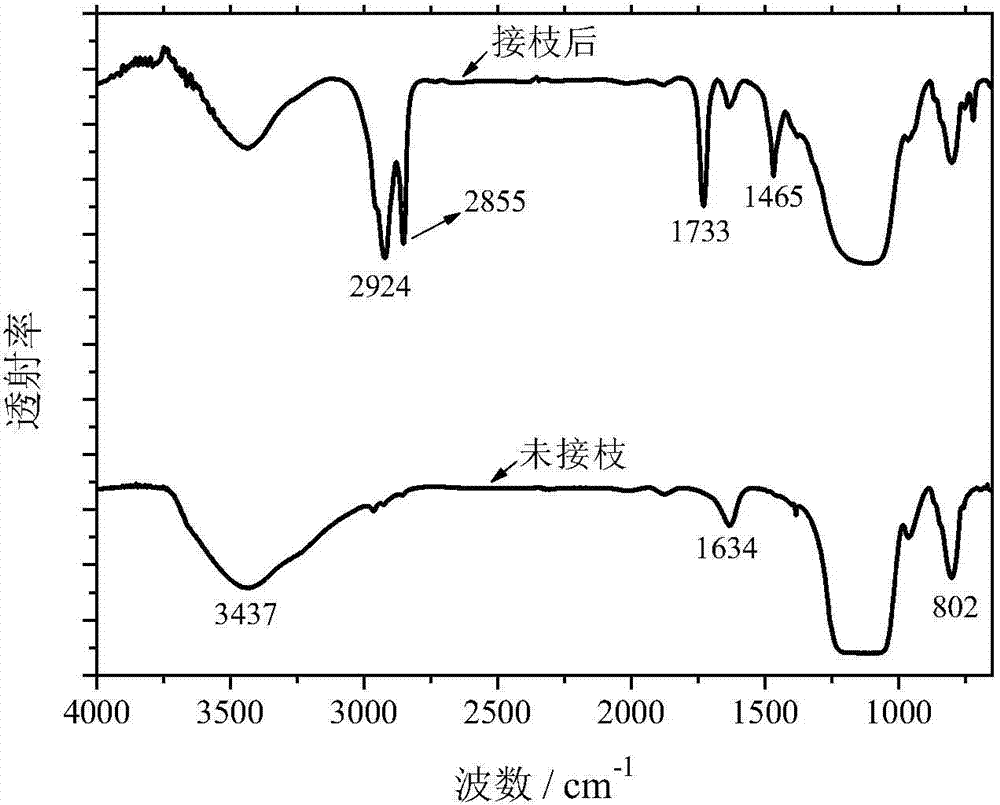

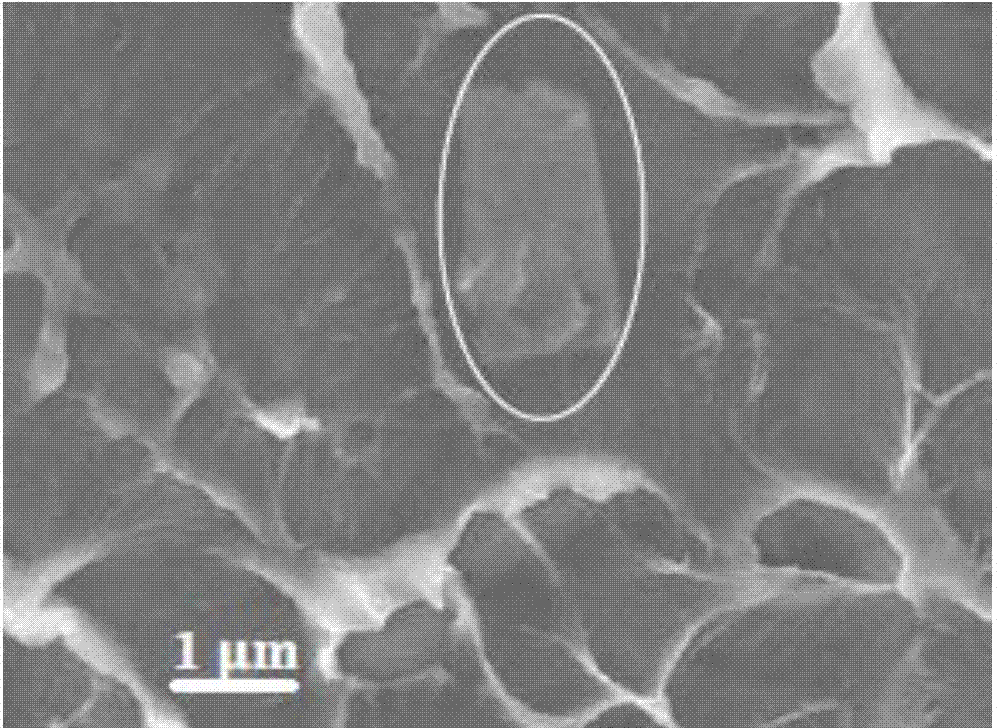

Preparation method of nano-silica with surface grafted with polystearylmethacrylate

ActiveCN104497641AGood dispersionImprove mechanical propertiesPigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsLow-density polyethyleneDispersity

The invention relates to a preparation method of nano-silica with the surface grafted with polystearylmethacrylate, belonging to the field of surface grafting and modification of nano-particles. The preparation method comprises the following steps of firstly grafting amino silane to the surface of nano-silica in a high polar solvent by virtue of a reversible addition-fragmentation chain transfer polymerization method; then grafting a chain transfer agent to the surfaces of nano-particles through amino silane by virtue of the combination between thiol ester functional groups and amino functional groups on the chain transfer agent; finally providing free radicals by an initiator, and polymerizing monomers of polystearylmethacrylate to the tail end of the chain transfer agent. According to the polystearylmethacrylate-grafted nano-silica nano-particles prepared by virtue of the preparation method, the dispersity of nano-silica in low density polyethylene and a crosslinked polyethylene matrix is improved. According to the preparation method, a firm foundation is laid for the further improvement of mechanical and electrical properties of polyvinyl nano-composite materials.

Owner:TSINGHUA UNIV +1

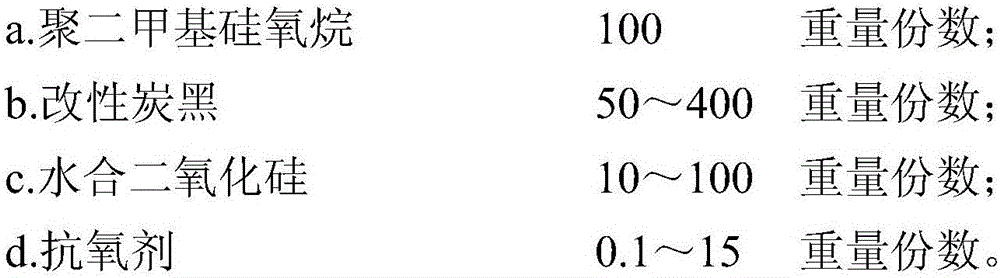

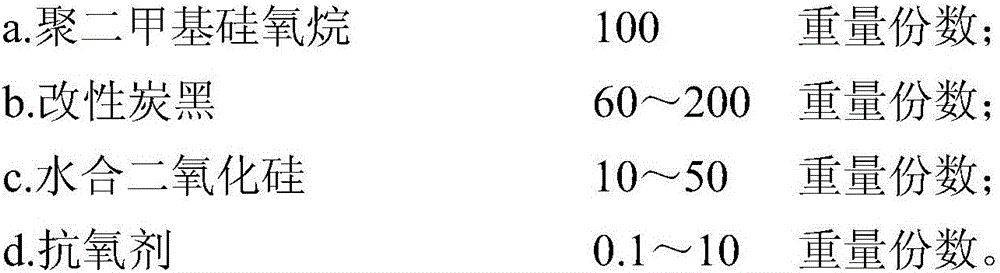

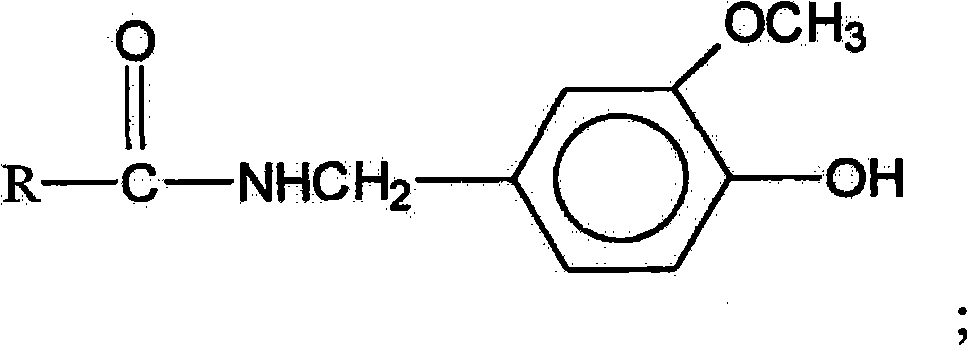

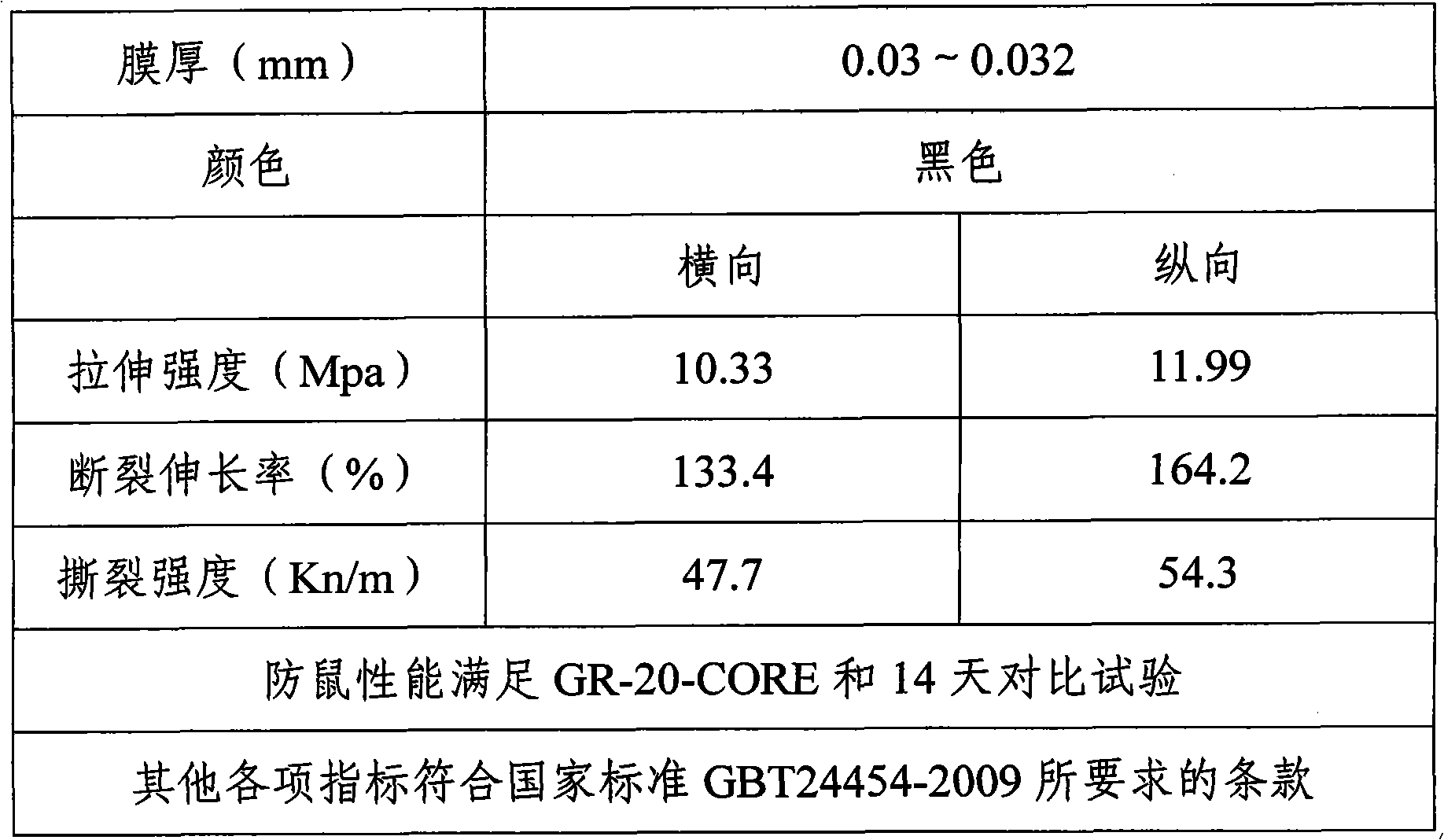

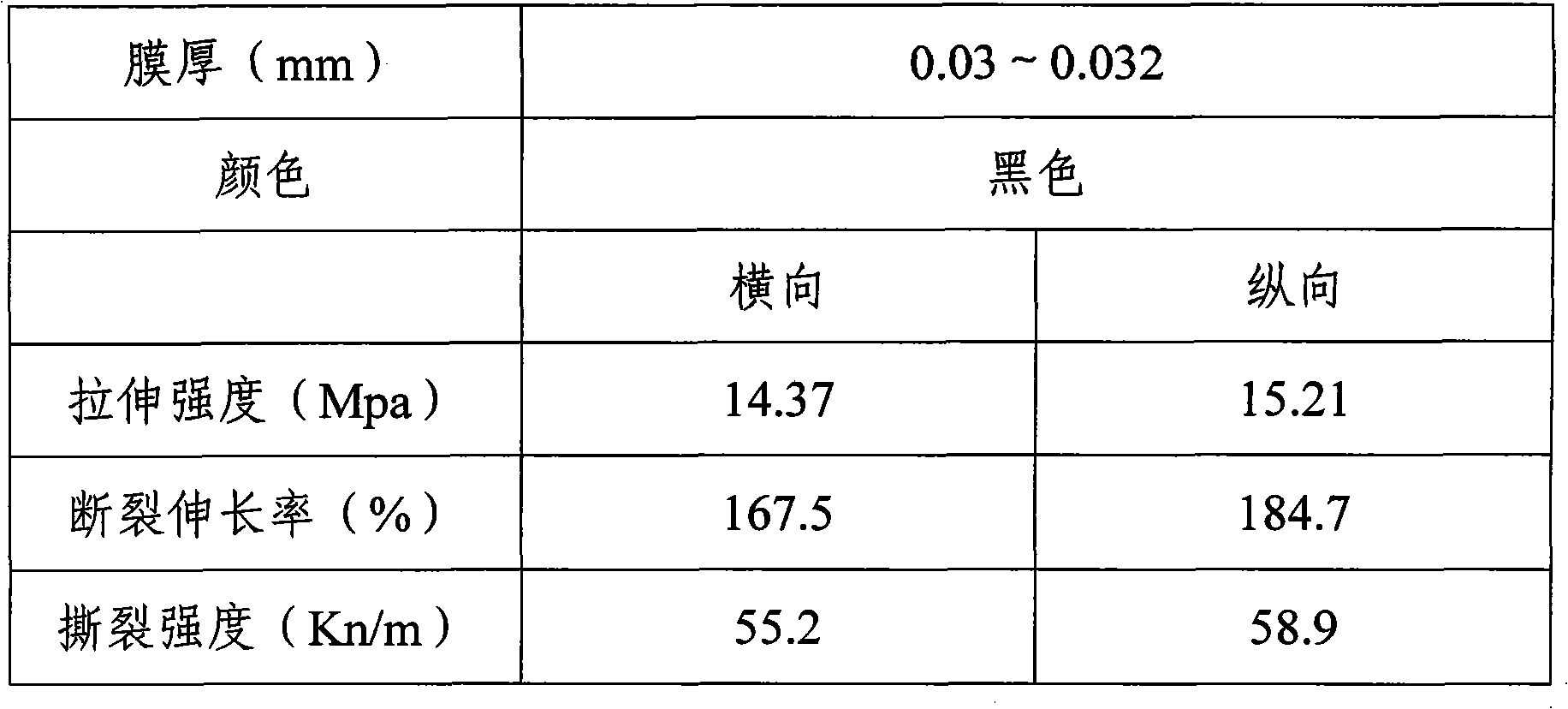

Polydimethylsiloxane carbon black master batch and preparation method thereof

The invention relates to a polydimethylsiloxane carbon black master batch and a preparation method thereof, and solves the technical problems of high performance reduction, reduction of product glossiness, accumulation of materials in a mouth mold in the extrusion of the product and affection on continuous production due to adoption of a polyethylene matrix resin and a low-molecule dispersing agent in the prior art. The polydimethylsiloxane carbon black master batch provided by the invention comprises the following mixed components: a, 100 parts by weight of polydimethylsiloxane; b, 50-400 parts by weight of modified carbon black; c, 10-100 parts by weight of hydrated silica; and d, 0.1-15 parts by weight of antioxygen. The invention also provides the preparation method of the polydimethylsiloxane carbon black master batch. The polydimethylsiloxane carbon black master batch and the preparation method of the polydimethylsiloxane carbon black master batch can be applied in the field of preparation of the carbon black master batch.

Owner:BEIJING BEIHUA GAOKE NEW TECH

Degradable rodent-proof bio-based garbage bag and preparation method thereof

The invention relates to a rat-proof biobased garbage bag and a preparation method thereof. The rat-proof biobased garbage bag comprises the following components in parts by mass: 20-70 percent of polyethylene, 15-60 percent of starch, 5-10 percent of plasticizer, 5-10 percent of rat-proof repellent and 0.5-2 percent of color master batch. The preparation method of the degradable rat-proof biobased garbage bag comprises the following steps of: preparing a required biobased material from the polyethylene, the starch, the the plasticizer and the rat-proof repellent according to a specific production process; and matching the biobased material with the color master batch and carrying out secondary processing to obtain the degradable rat-proof biobased garbage bag. In the invention, the polyethylene is filled with the thermoplastic starch, so that the thermoplastic starch is uniformly dispersed in a polyethylene matrix; then a polyethylene modified material is disintegrated into fragments along with the biodegradation of the starch, so that the polyethylene modified material has a certain biodegradability; and due to the utilization of the plasticizer, the starch has thermoplasticity, so that the machinability of the starch and the compatibility of polyethylene matrix resin are improved.

Owner:WUHAN HUALI ENVIRONMENTAL PROTECTION IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com