Heat-conductive polyethylene composite material and preparation method thereof

A composite material and polyethylene technology, which is applied in the field of thermally conductive polyethylene composite materials and their preparation, can solve problems such as low thermal conductivity, achieve high mechanical properties, improve impact resistance, and improve heat dissipation effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

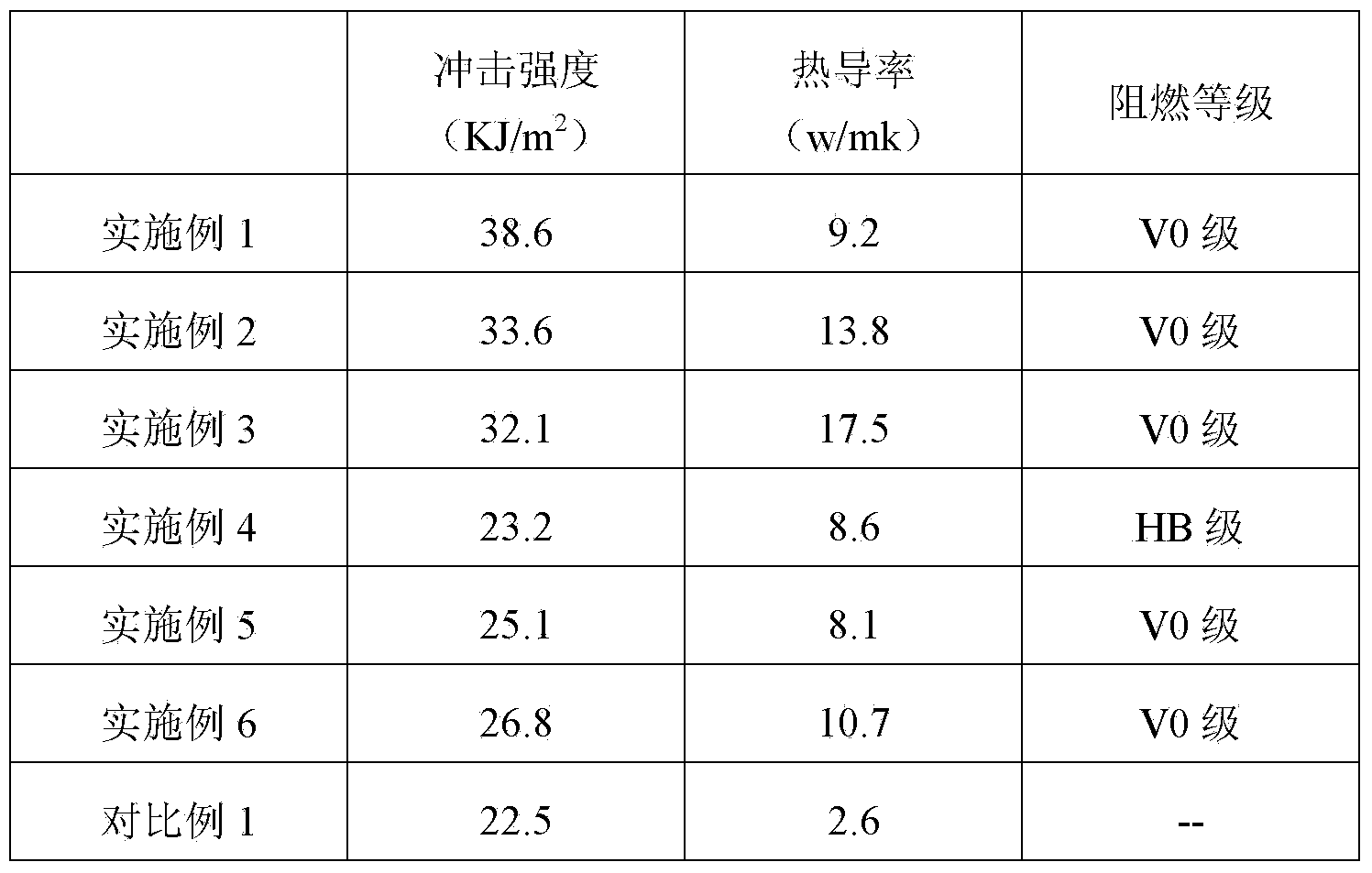

Examples

preparation example Construction

[0035] In addition, the present invention also provides a method for preparing a heat-conducting polyethylene composite material, which includes the following steps: S1. In parts by weight, 15-50 parts of polyethylene, 4-35 parts of heat-conducting fiber and 23-80 parts Parts of heat-conducting particles are mixed in a mixer to obtain a mixture; S2, extruding, pulling and granulating the mixture to obtain the heat-conducting polyethylene composite material. The application of fibrous thermally conductive fillers can form an overlapping network between different thermally conductive fibers, thereby forming a thermally conductive network. This enables the heat in the matrix to be transported out instantly through the heat conduction network, which is conducive to improving the heat conduction performance of the polyethylene composite material. At the same time, when the composite material is subjected to external force, such an overlapping network can use its own deformation to ...

Embodiment 1

[0042] In this embodiment, a heat-conducting polyethylene composite material is prepared.

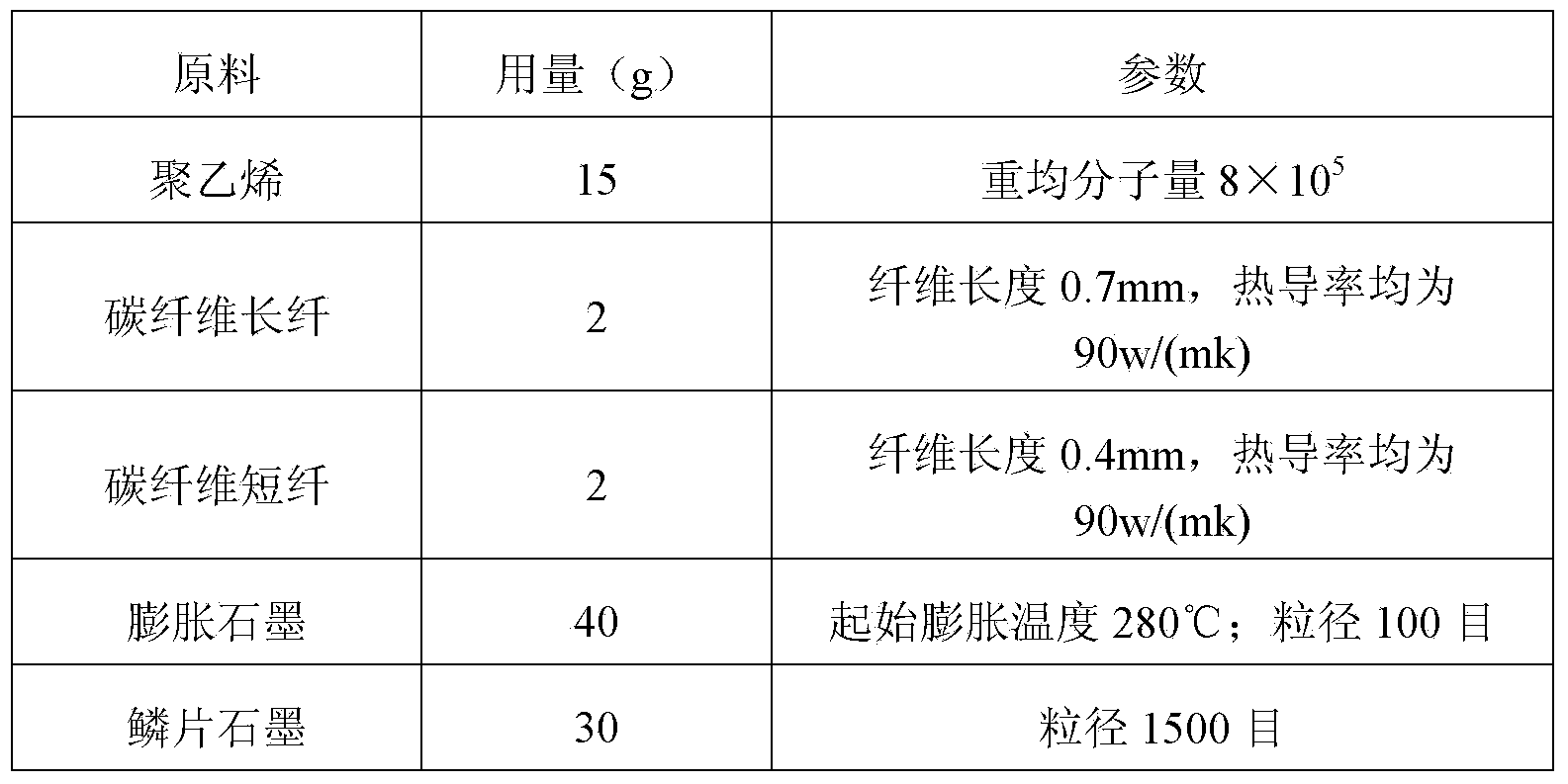

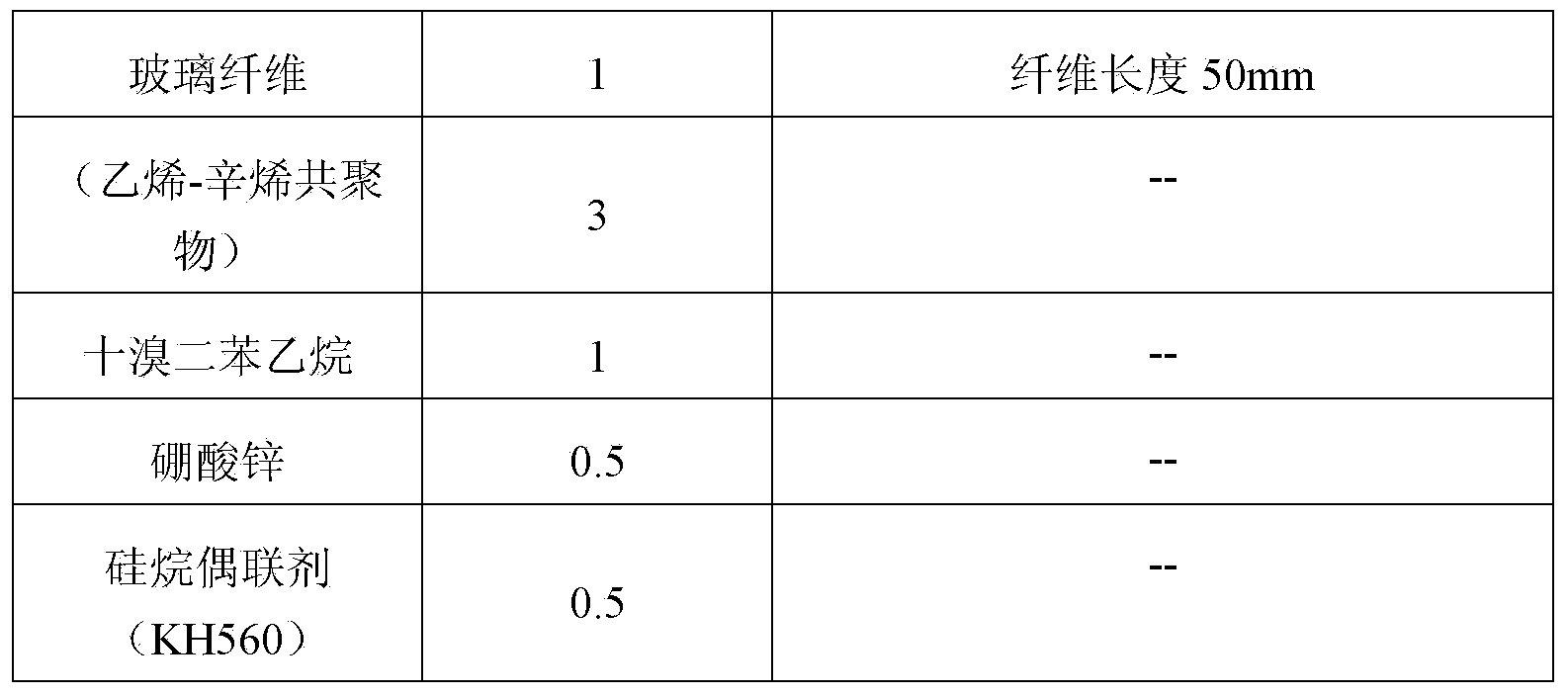

[0043] Preparation raw materials:

[0044] raw material

Dosage (g)

parameters

polyethylene

40

Weight average molecular weight 4×10 5

5

The fiber length is 1mm, and the thermal conductivity is 90w / (mk)

carbon fiber staple

3

The fiber length is 0.15mm, and the thermal conductivity is 90w / (mk)

expanded graphite

30

The initial expansion temperature is 260°C; the particle size is 200 mesh

3

Particle size 2000 mesh

5

Fiber length 50mm

Toughener (EPDM rubber)

10

--

[0045] Decabromodiphenyl ether

2.5

--

0.5

--

1

--

[0046] Preparation Process:

[0047] The polyethylene and the toughening agent particles are sub...

Embodiment 2

[0053] In this embodiment, a heat-conducting polyethylene composite material is prepared.

[0054] Preparation raw materials:

[0055] raw material

Dosage (g)

parameters

polyethylene

30

Weight average molecular weight 8×10 5

carbon fiber long fiber

8

The fiber length is 3mm, and the thermal conductivity is 90w / (mk)

carbon fiber staple

5

The fiber length is 0.2mm, and the thermal conductivity is 90w / (mk)

expanded graphite

35

The initial expansion temperature is 260.℃; the particle size is 100.mesh

6

Particle size 2000 mesh

5

Fiber length 50mm

Toughener (ethylene-octene copolymer)

7

--

2.5

--

0.5

--

1

--

[0056] Preparation Process:

[0057] The polyethylene and the toughening agent particles are subjected ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Onset expansion temperature | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com