Adhesive resin for steel-mesh reinforcing polyethylene hot water pipe and preparation method of adhesive resin

A technology for bonding resin and polyethylene, applied in the direction of graft polymer adhesives, adhesives, adhesive types, etc. Thermal denaturation temperature of adhesive resin, high temperature peeling strength, hydrostatic strength of composite pipe and other performance improvements, the influence of hot water transportation, and the heat resistance of adhesive resin are not mentioned, so as to achieve excellent high temperature adhesive strength, excellent heat resistance, adhesion Excellent connection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

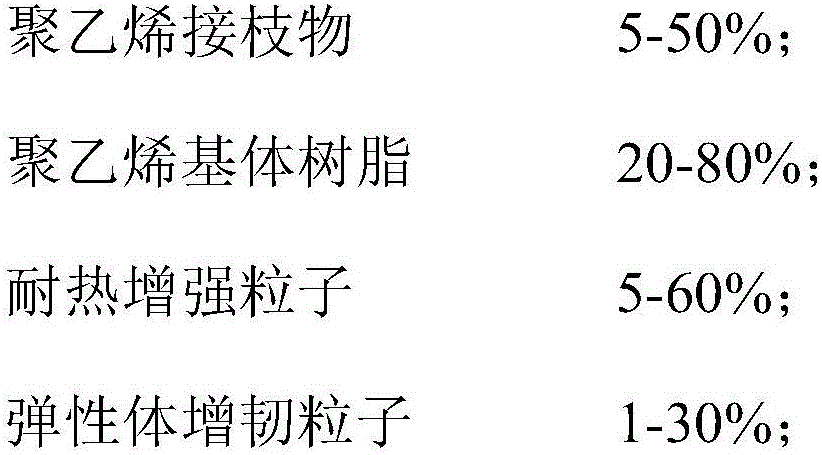

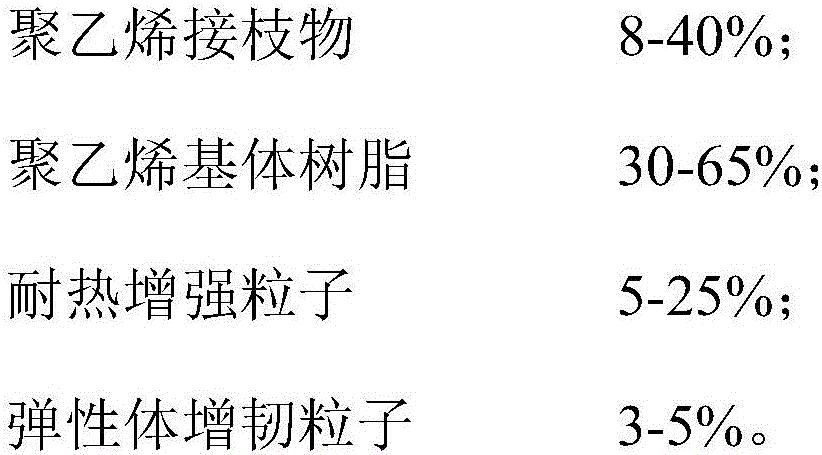

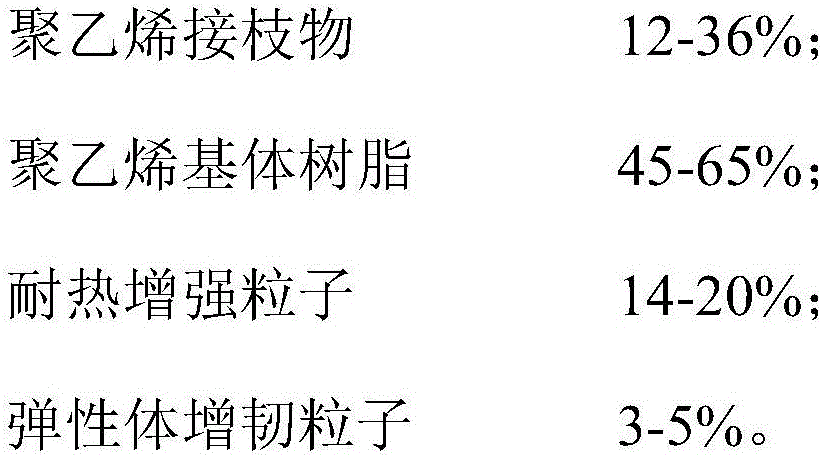

[0034] The adhesive resin formulation (100%) is as follows: 12% polyethylene graft; 65% polyethylene matrix resin; 20% heat-resistant reinforcing particles; 3% elastomer toughening particles.

[0035] Among them, the polyethylene graft is HDPE-g-GMA, the polyethylene matrix resin is made of DOW DGDA-2399 and YEM-4705T with a weight ratio of 3:2, the heat-resistant reinforcement particles are SiC whiskers, and the elastomer reinforcement is The tough particle is EBA 3107AC.

Embodiment 2

[0037] The adhesive resin formula (100%) is as follows: polyethylene graft 36%; polyethylene matrix resin 45%; heat-resistant reinforcing particles 14%; elastomer toughening particles 5%.

[0038] Among them, the polyethylene graft is HDPE-g-BA, the polyethylene matrix resin is DOW DGDA-2399, the heat-resistant enhancing particles are SiC whiskers, and the elastomer toughening particles are EPDM 8600.

Embodiment 3

[0040] The adhesive resin formulation (100%) is as follows: 12% polyethylene graft; 65% polyethylene matrix resin; 20% heat-resistant reinforcing particles; 3% elastomer toughening particles.

[0041] Among them, the polyethylene graft is HDPE-g-GMA, the polyethylene matrix resin is DGDA-2399, the heat-resistant reinforcing particles are continuous polyester fibers, and the elastomer toughening particles are EPDM 8600.

[0042] The above-mentioned Examples 1-3 were prepared into adhesive resin pellets according to the requirements of the present invention, the properties of which are shown in the following table and the properties of the prepared steel mesh reinforced polyethylene hot water pipe are shown in the following table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com