Composite system power battery with high safety and long service life and preparation method of composite system power battery

A composite material and power battery technology, applied in batteries, battery electrodes, secondary batteries, etc., can solve the problems of poor high temperature cycle performance, safety and security, and achieve high electrical conductivity, improved safety performance, and improved cycle performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

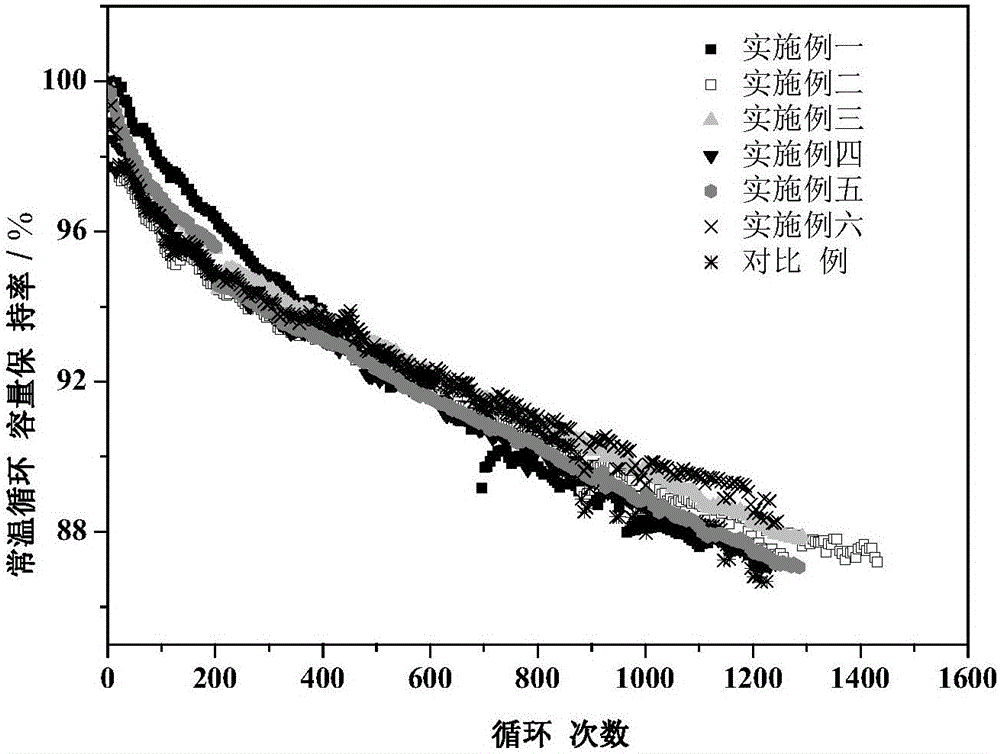

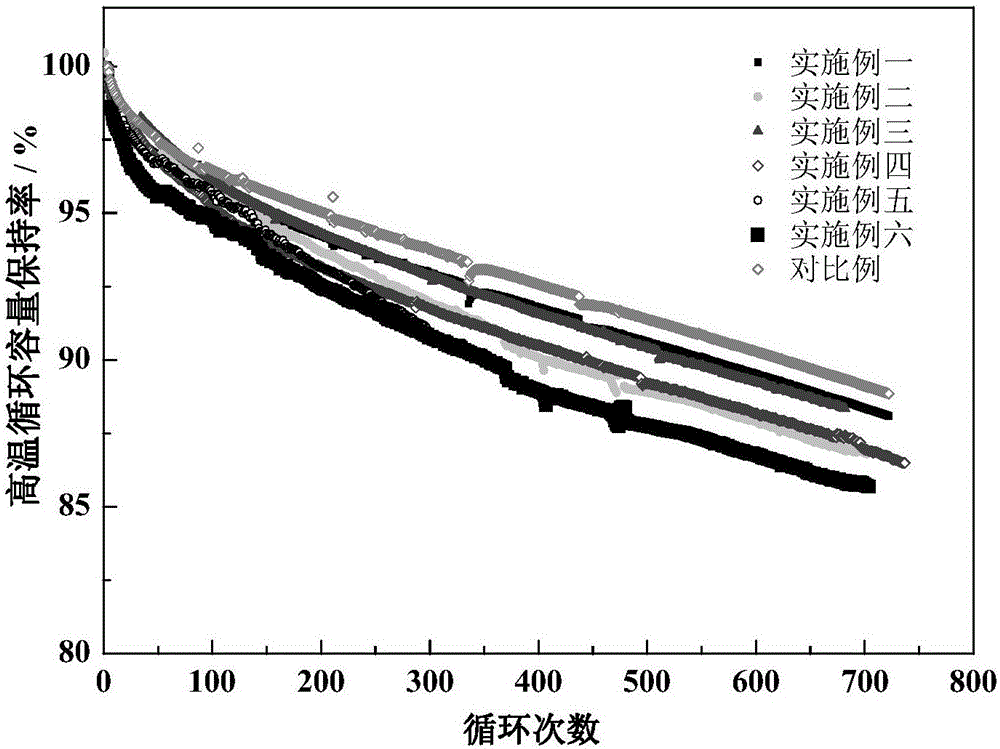

Embodiment 1

[0030] In this example, the coating diaphragm is used as the base material of 14 μm PE, 4 μm Al 2 o 3 Coating (i.e. 14+4).

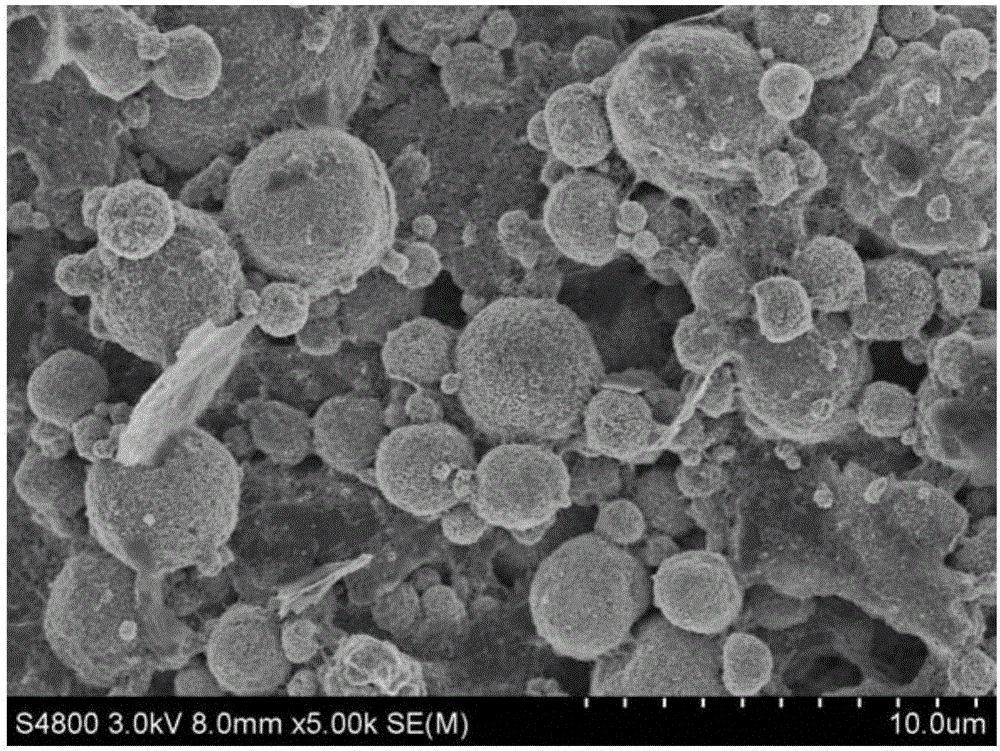

[0031] 1) Using NMP as a solvent, after completely dissolving PVDF, adding carbon nanotubes to disperse at high speed, and then mixing in composite positive electrode active material (LiNi 0.6 co 0.2 mn 0.2 o 2 :LiMn 0.8 Fe 0.2 PO 4 =8:2), after fully mixing the slurry, use a coating machine to evenly coat it on the aluminum foil, after drying, rolling, and slitting, it is made into a positive electrode sheet, PVP 1-2%, PVDF 1-3.5%, nano Carbon tube 1~3.5%, slurry viscosity: 6000~9000mPa.S, positive electrode coating surface density 370kg / m 2 , the edge of the slurry is coated with 2mm Al 2 o 3 ceramic colloid. The negative electrode uses deionized water as a solvent. After completely dispersing CMC, it is mixed with acetylene black and negative electrode active material artificial graphite, and finally mixed with SBR to make pulp, and then co...

Embodiment 2

[0034] In this example, the coated diaphragm is used as the base material of 12 μm PE, 4 μm Al 2 o 3 And 2μm PVDF coating (ie 12+4+2).

[0035]1) Using NMP as a solvent, after completely dissolving PVDF, adding carbon nanotubes to disperse at high speed, and then mixing in composite positive electrode active material (LiNi 0.6 co 0.2 mn 0.2 o 2 :LiMn 0.8 Fe 0.2 PO 4 =8:2), after fully mixing the slurry, use a coating machine to evenly coat it on the aluminum foil, after drying, rolling, and slitting, it is made into a positive electrode sheet, PVP 1-2%, PVDF 1-3.5%, nano Carbon tube 1~3.5%, slurry viscosity: 6000~9000mPa.S, positive electrode coating surface density 370kg / m 2 , the edge of the slurry is coated with 2mm Al 2 o 3 ceramic colloid. The negative electrode uses deionized water as a solvent. After completely dispersing CMC, it is mixed with acetylene black and negative electrode active material artificial graphite, and finally mixed with SBR to make pulp, ...

Embodiment 3

[0038] In this example, the coated diaphragm is used as the base material of 12 μm PE, 4 μm Al 2 o 3 And 1μm PVDF coating on both sides (ie 12+4+1+1).

[0039] 1) Using NMP as a solvent, after completely dissolving PVDF, adding carbon nanotubes to disperse at high speed, and then mixing in composite positive electrode active material (LiNi 0.6 co 0.2 mn 0.2 o 2 :LiMn 0.8 Fe 0.2 PO 4 =8:2), after fully mixing the slurry, use a coating machine to evenly coat it on the aluminum foil, after drying, rolling, and slitting, it is made into a positive electrode sheet, PVP 1-2%, PVDF 1-3.5%, nano Carbon tube 1~3.5%, slurry viscosity: 6000~9000mPa.S, positive electrode coating surface density 370kg / m 2 , the edge of the slurry is coated with 2mm Al 2 o 3 ceramic colloid. The negative electrode uses deionized water as a solvent. After completely dispersing CMC, it is mixed with acetylene black and negative electrode active material artificial graphite, and finally mixed with S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com