Patents

Literature

378results about How to "Control ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

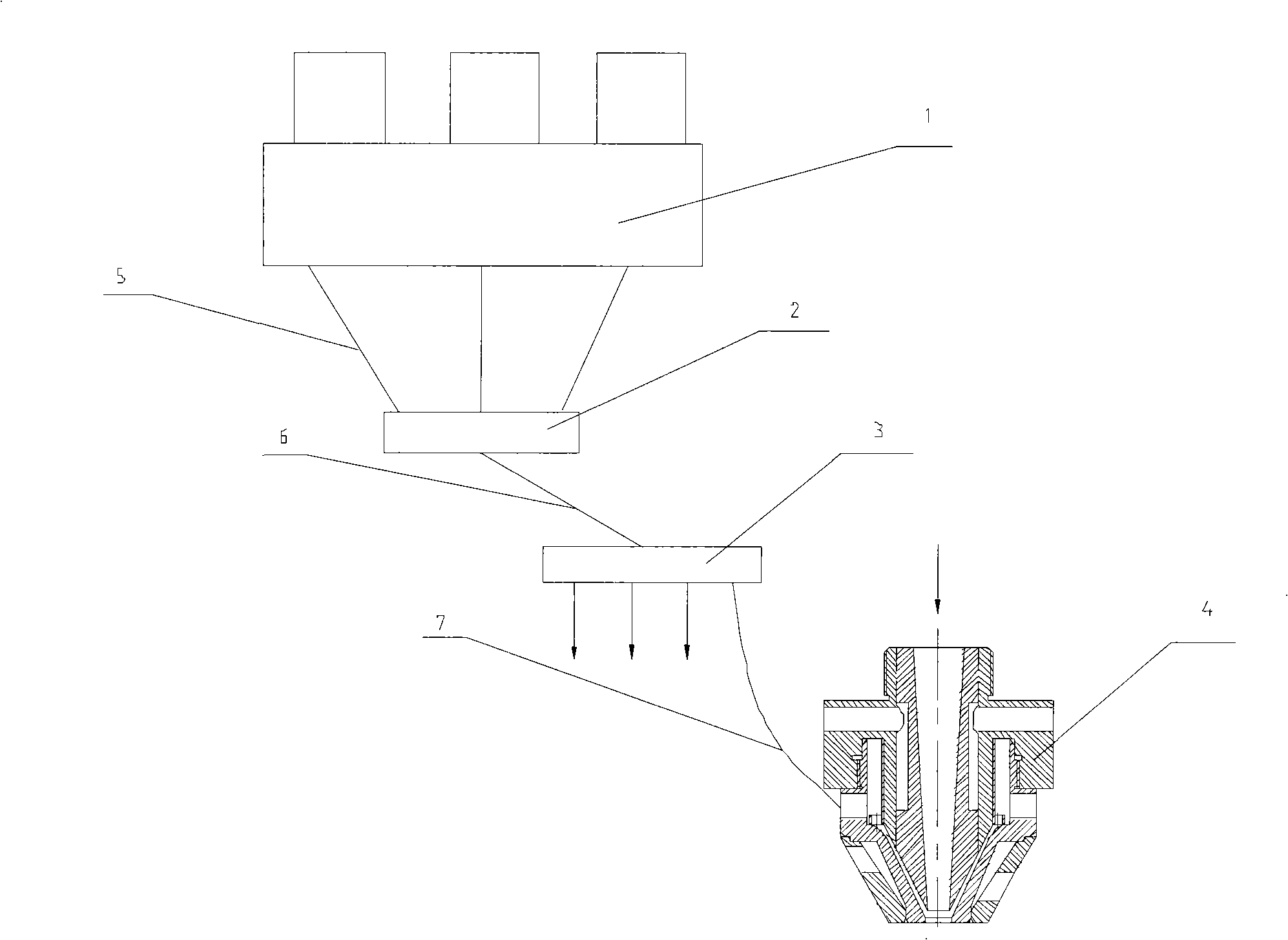

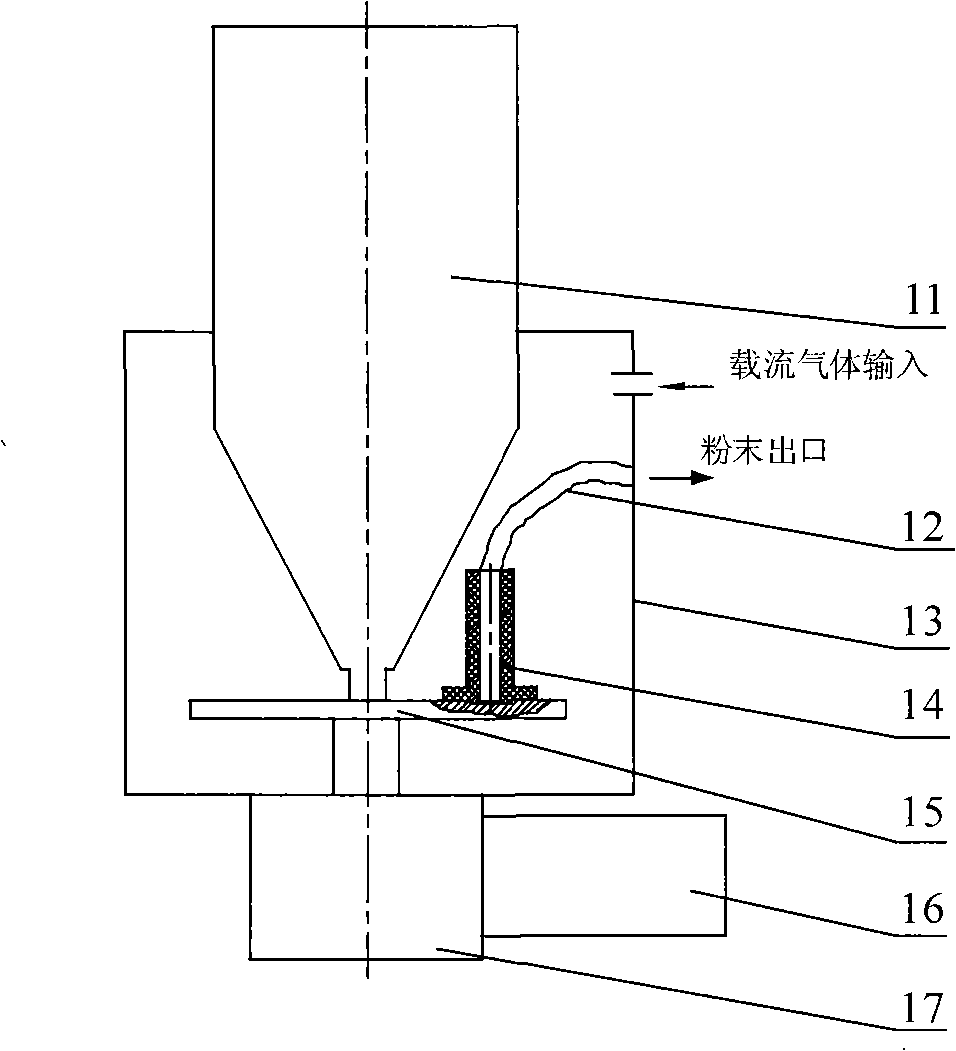

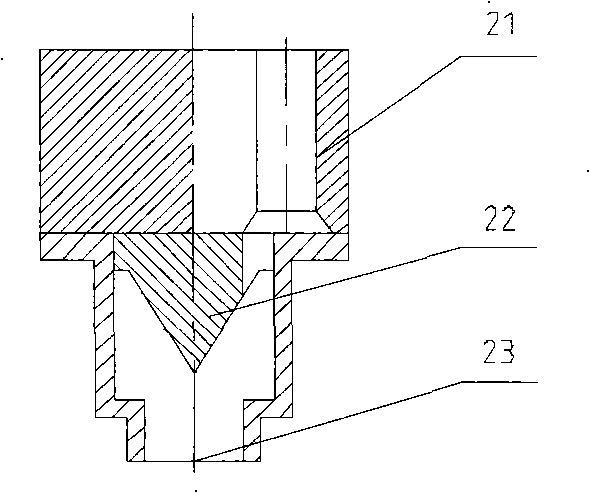

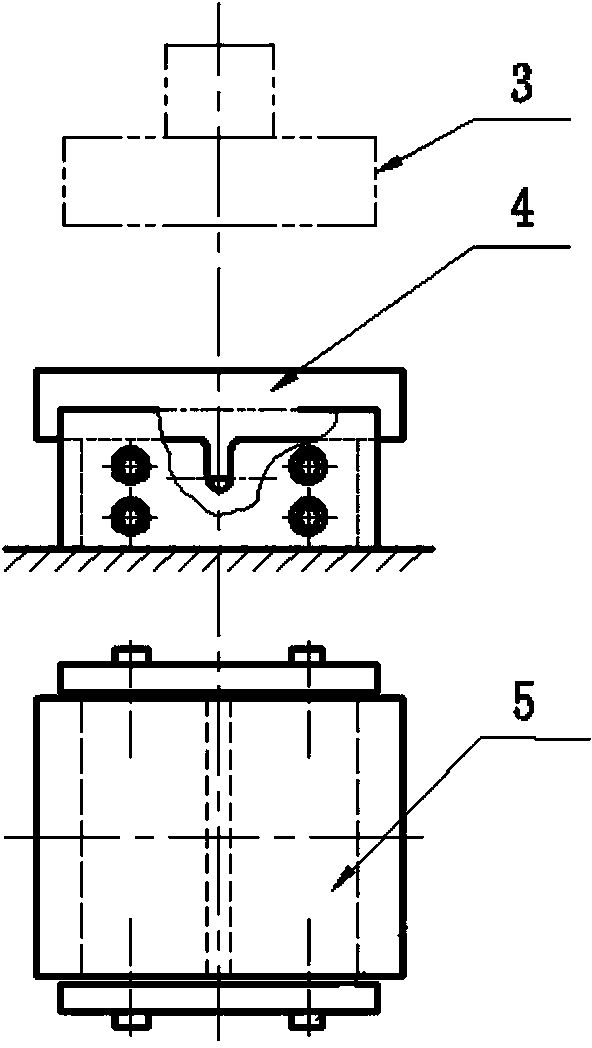

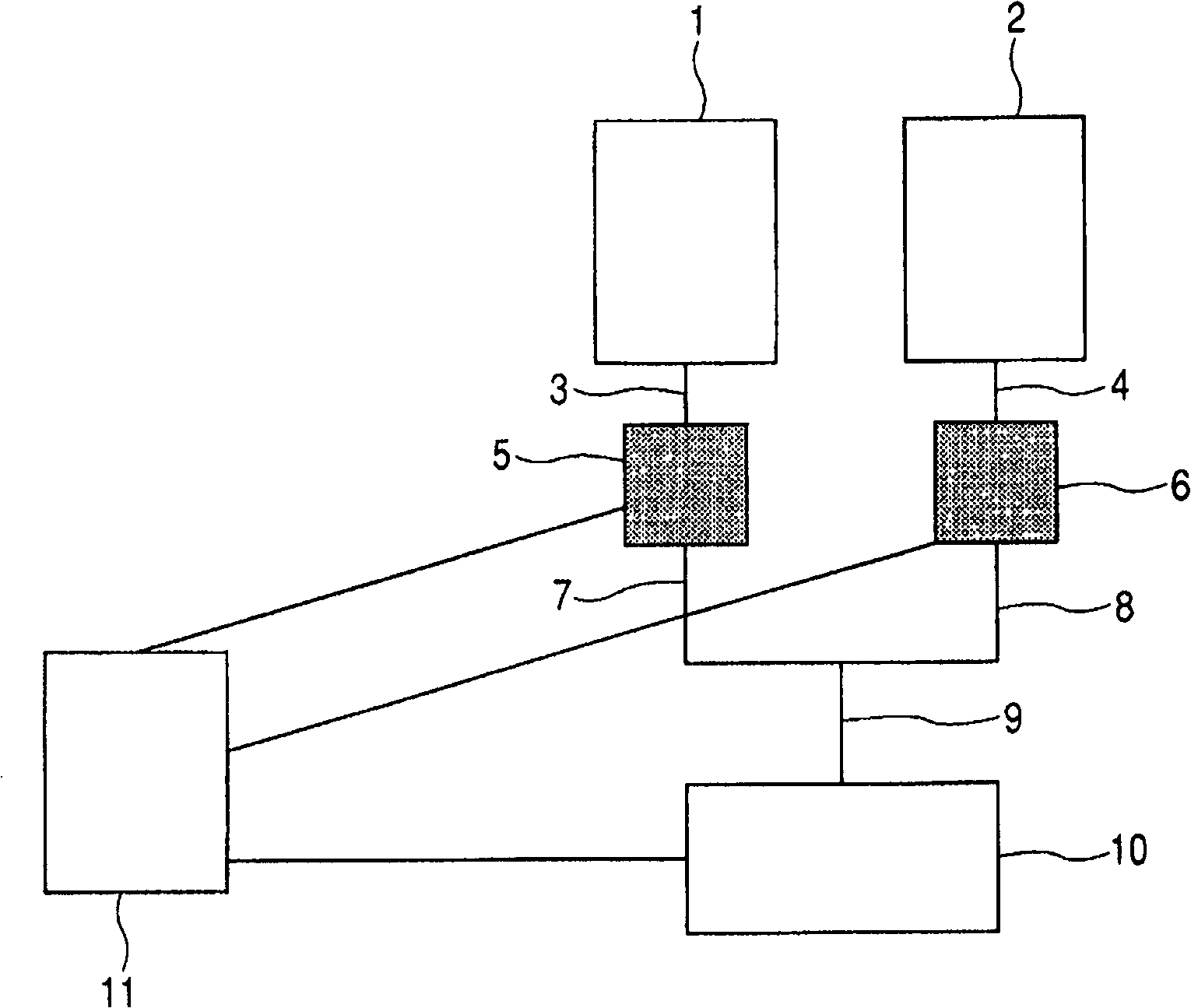

Coaxial powder feeding system for quickly molding and producing functional gradient material with laser

InactiveCN101342640AWell mixedImprove uniformityIncreasing energy efficiencyLaser beam welding apparatusNozzleRapid prototyping

The invention relates to a coaxial powder feeding system of laser rapid prototyping preparation function gradient material, comprising a powder inlet device, and the powder is absorbed and conveyed by carrier gas. The powder inlet device is communicated with a powder mixer through a first conveying pipe. The powder mixer is used for mixing the powder which has been conveyed. The mixed powder enters into a powder separate device through a second conveying pie. The powder separate device is used for separating the mixed powder into multi-path. The powder separate device is communicated with the powder inlet of a nozzle through a third conveying pipe. The nozzle makes the multi-path powder flock together in a molten pool formed by laser. The function gradient material is prepared under the cladding action of laser and powder. The mix of the powder is uniform. The coaxial powder feeding system has good power feeding property, which can realize the optimum processing, and at the same time, can be suitable for different processing distances. The powder utilization rate is high. The manufacturing accuracy is good. At the same time, the powder conveying distance can be adjusted with a certain scope, and so the coaxial powder feeding system can not be limited to the manufacturing space.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

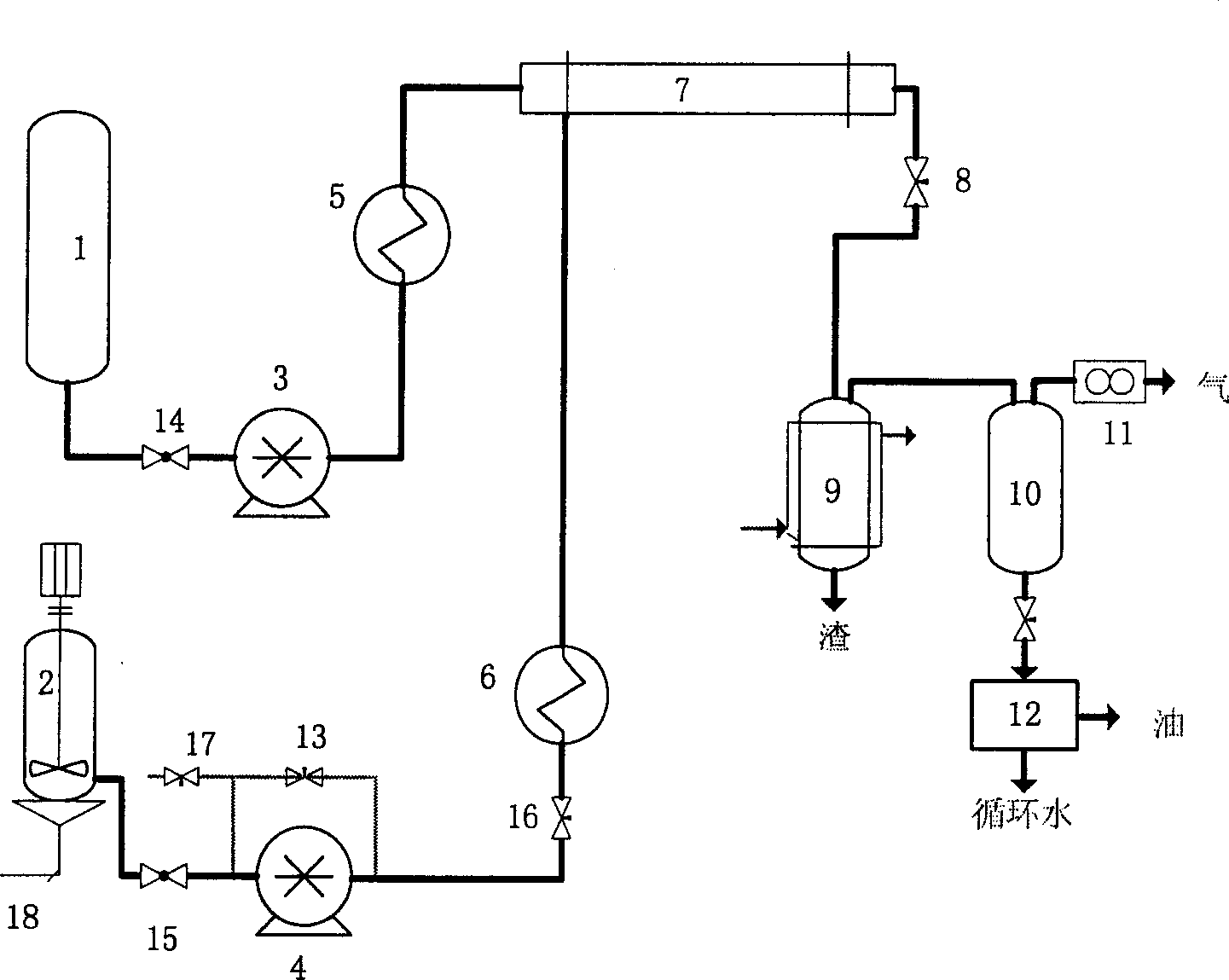

Method for continuous conversion of low-rank coal in subcritical water or supercritical water

ActiveCN1544580ANo emissionsQuick responseLiquid hydrocarbon mixture productionSolid solvent extractionCoal waterLower grade

The invention discloses a process for preparing coal water slurry or the mixture of coal water slurry with alkaline metal and / or alkaline earth oxides or hydroxides by the method of low level coal continuous transformation in subcritical or supercritical water which comprises, conducting continuous high pressure conveying of coal water slurry, charging into reaction system, usting the peculiarity of the hypercritical water to extracting and pyrolising low grade coal, converting it into useful product in gas, liquid and solid forms.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

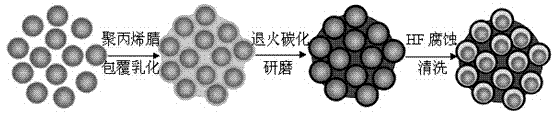

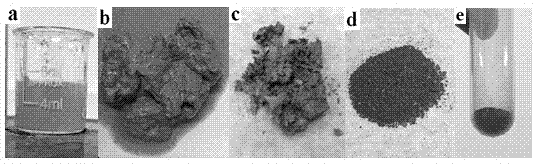

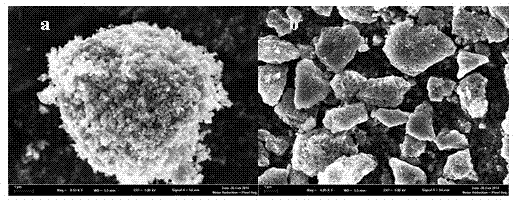

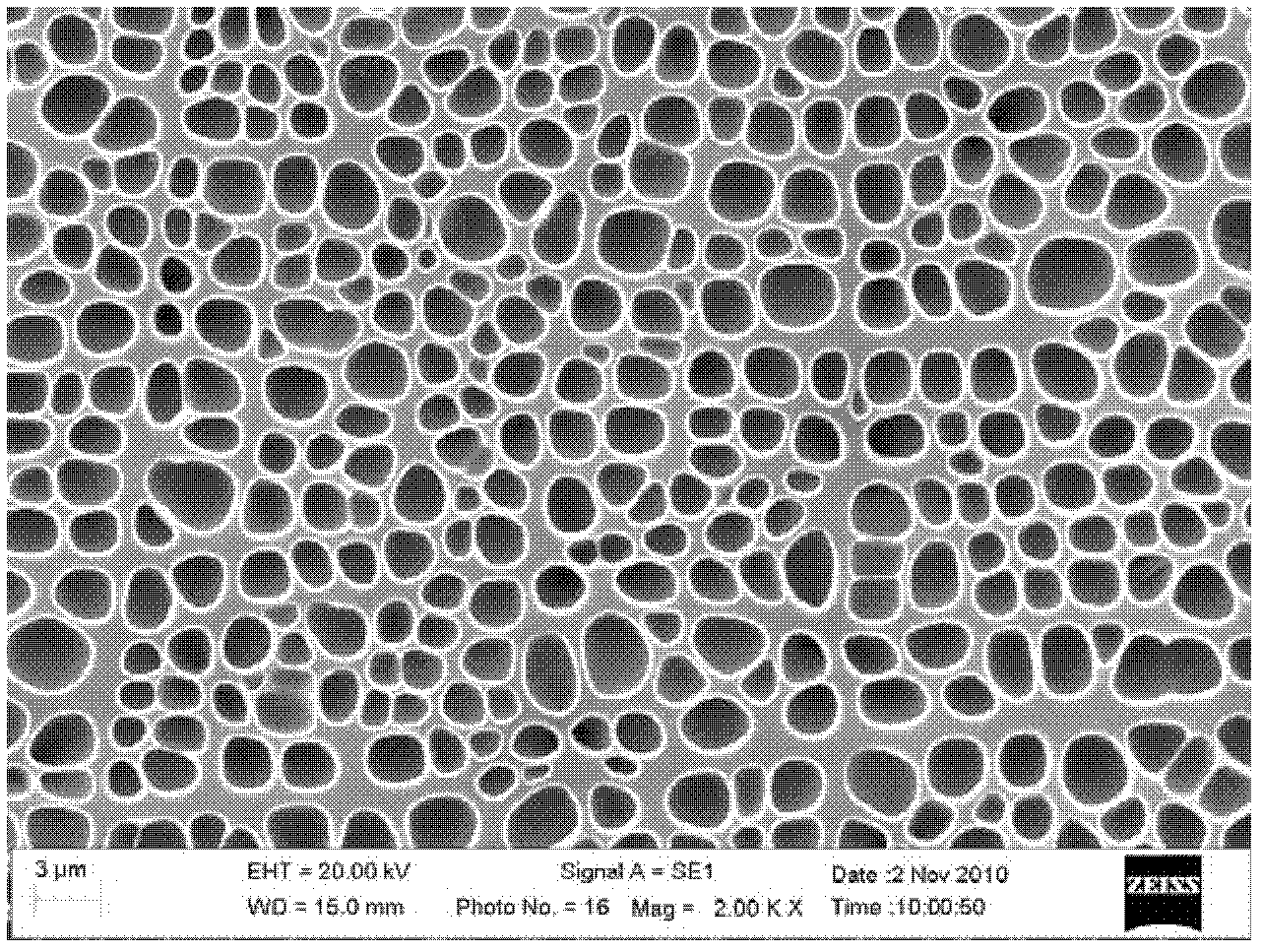

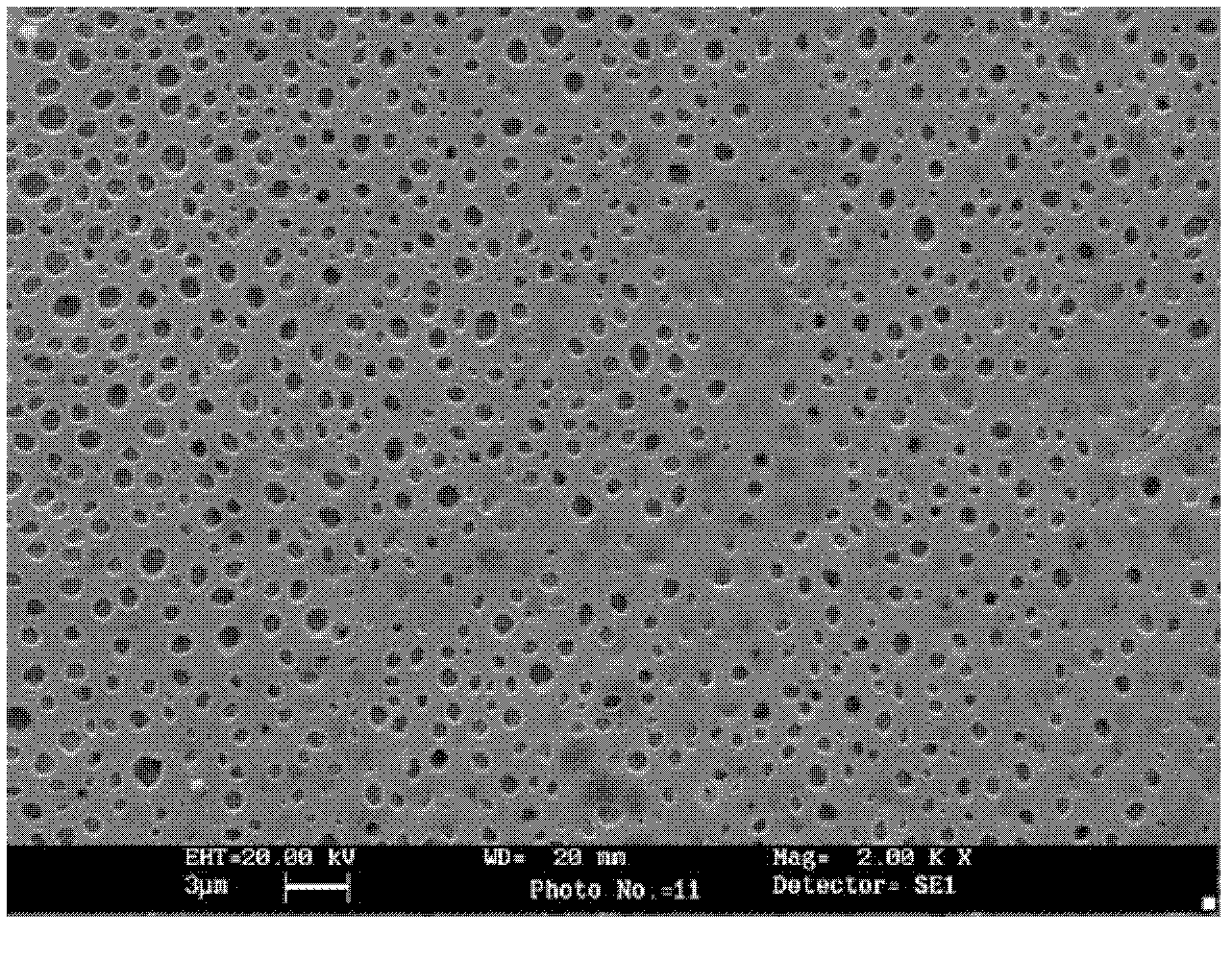

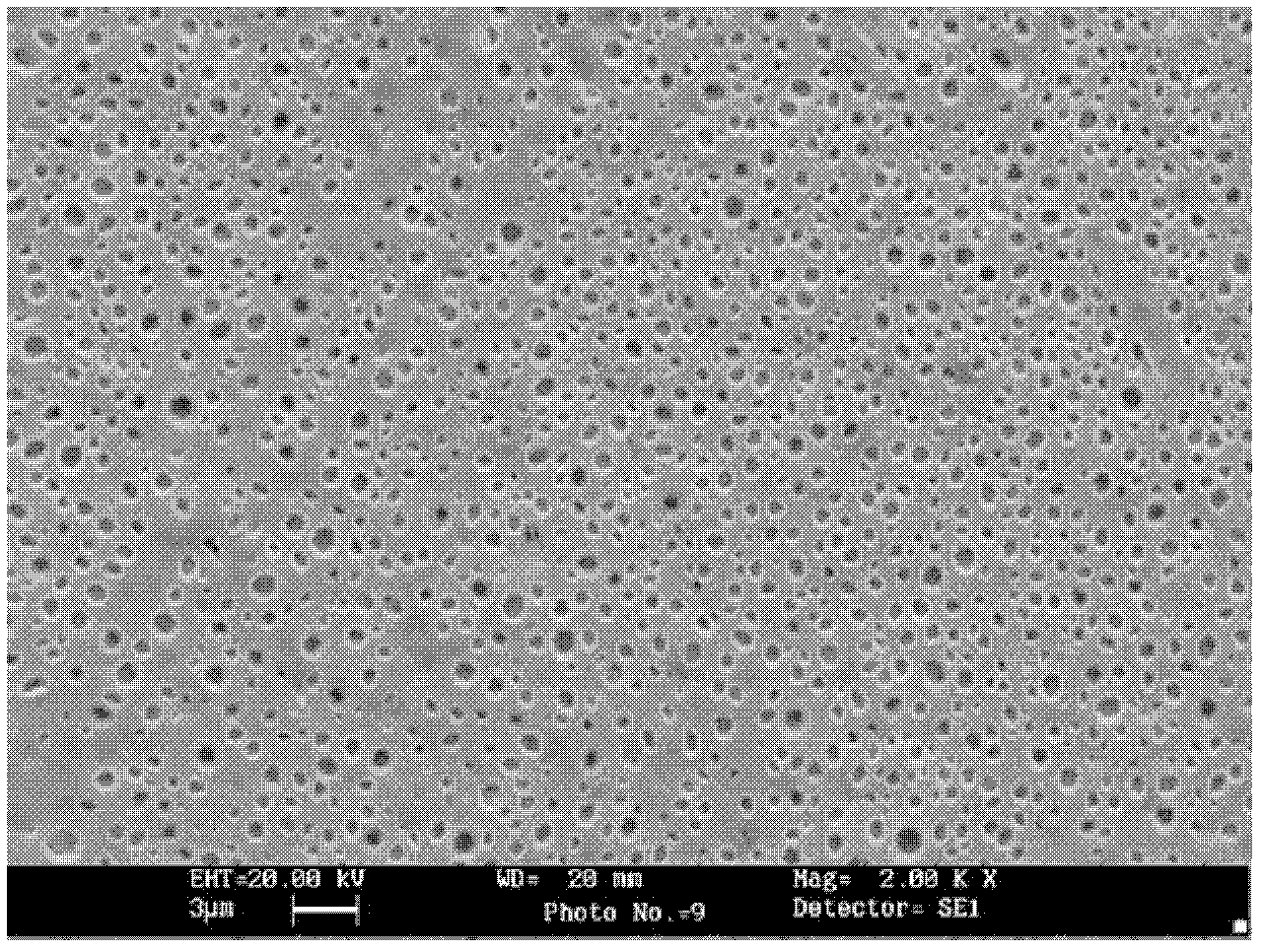

Pomegranate-like structured composite material preparation method

InactiveCN104300125AEasy to prepareThe preparation method is safeMaterial nanotechnologyCell electrodesMaterials preparationSilica particle

The invention discloses a pomegranate-like structured composite material preparation method which comprises the following steps: S1, taking a polyacrylonitrile solution, adding silica nanoparticles, and fully dispersing; S2, adding deionized water after stirring for emulsification to obtain a mud like precursor; S3, heating the mud like precursor obtained in the S2, and annealing to obtain a solid composite; and S4, grinding the solid composite obtained in the S3 into micron particles, adding a hydrogen fluoride solution for corrosion for a certain period of time, washing hydrogen fluoride, and drying to obtain a pomegranate-like structured composite material. According to the method, polyacrylonitrile is used for coating the silica particle surface, the polyacrylonitrile is emulsified when meeting water, so that the coated silicon particles are agglomerated, the coated silicon particles are carbonized and ground for formation of the pomegranate shaped structured silicon carbon composite material, HF is used for direct corrosion of the silicon nanoparticles in the material for preparation of the hollow pomegranate-like structured composite material, and detailed structure characterization and electrochemical performance testing of the material show that the material is good in performances.

Owner:SUN YAT SEN UNIV

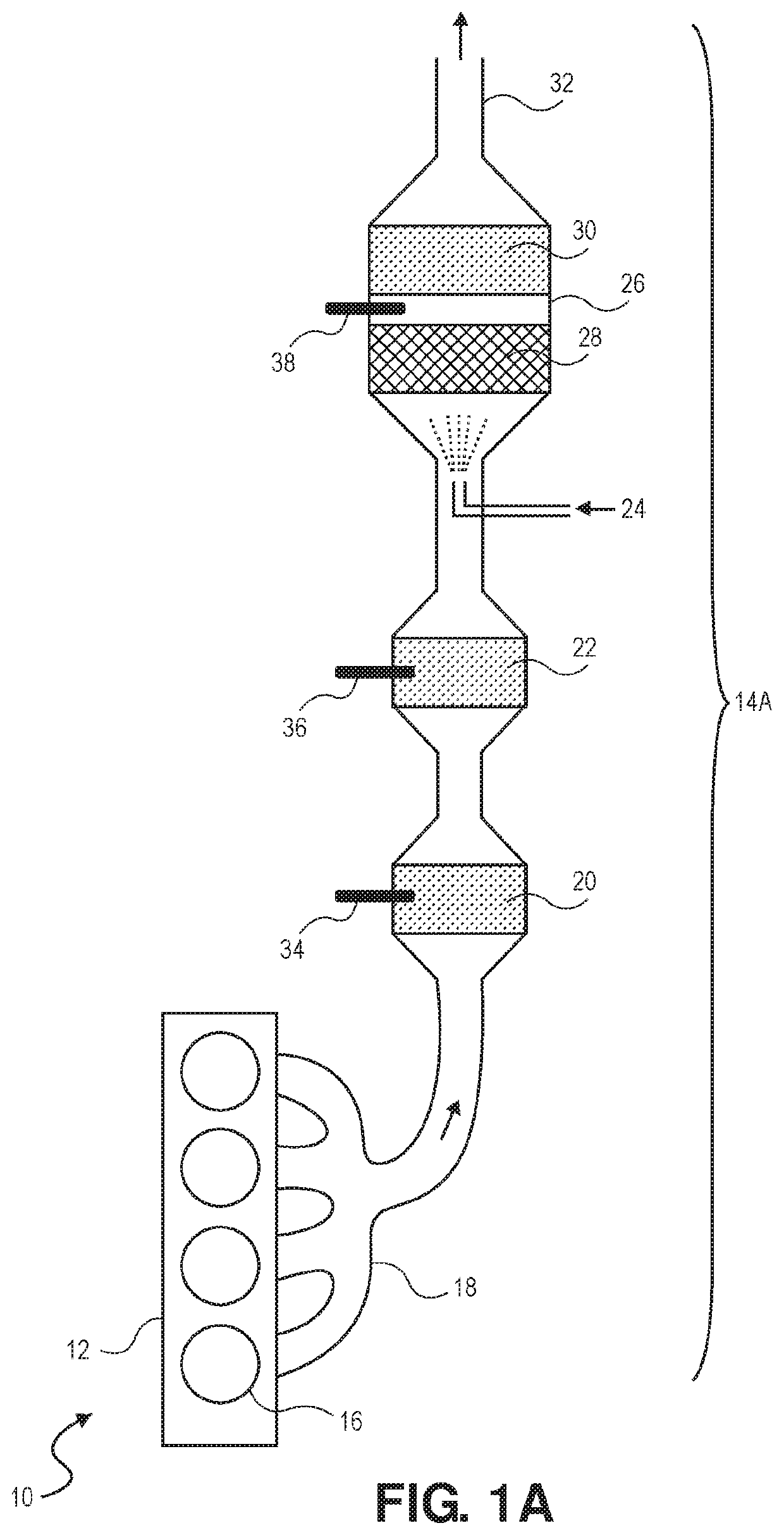

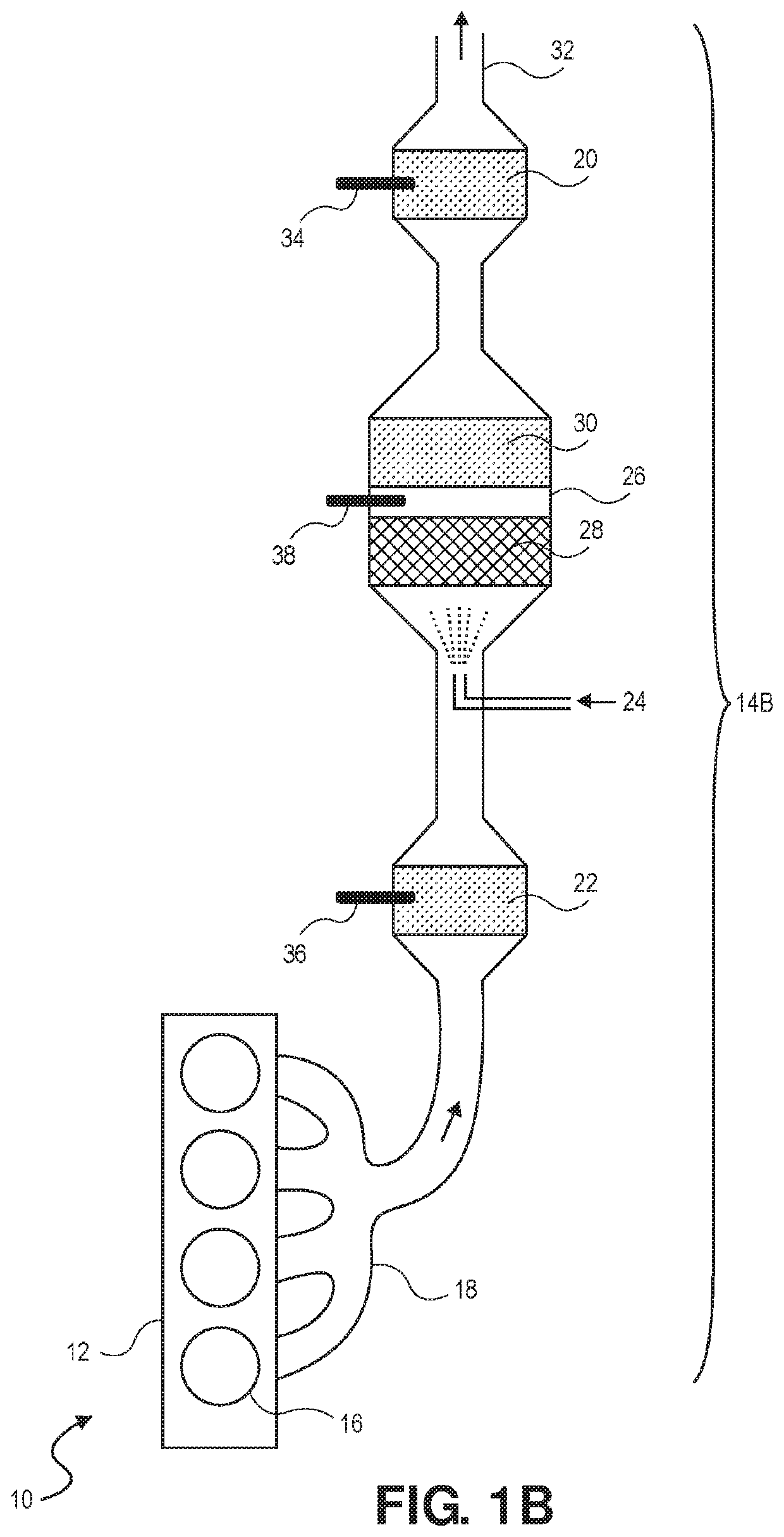

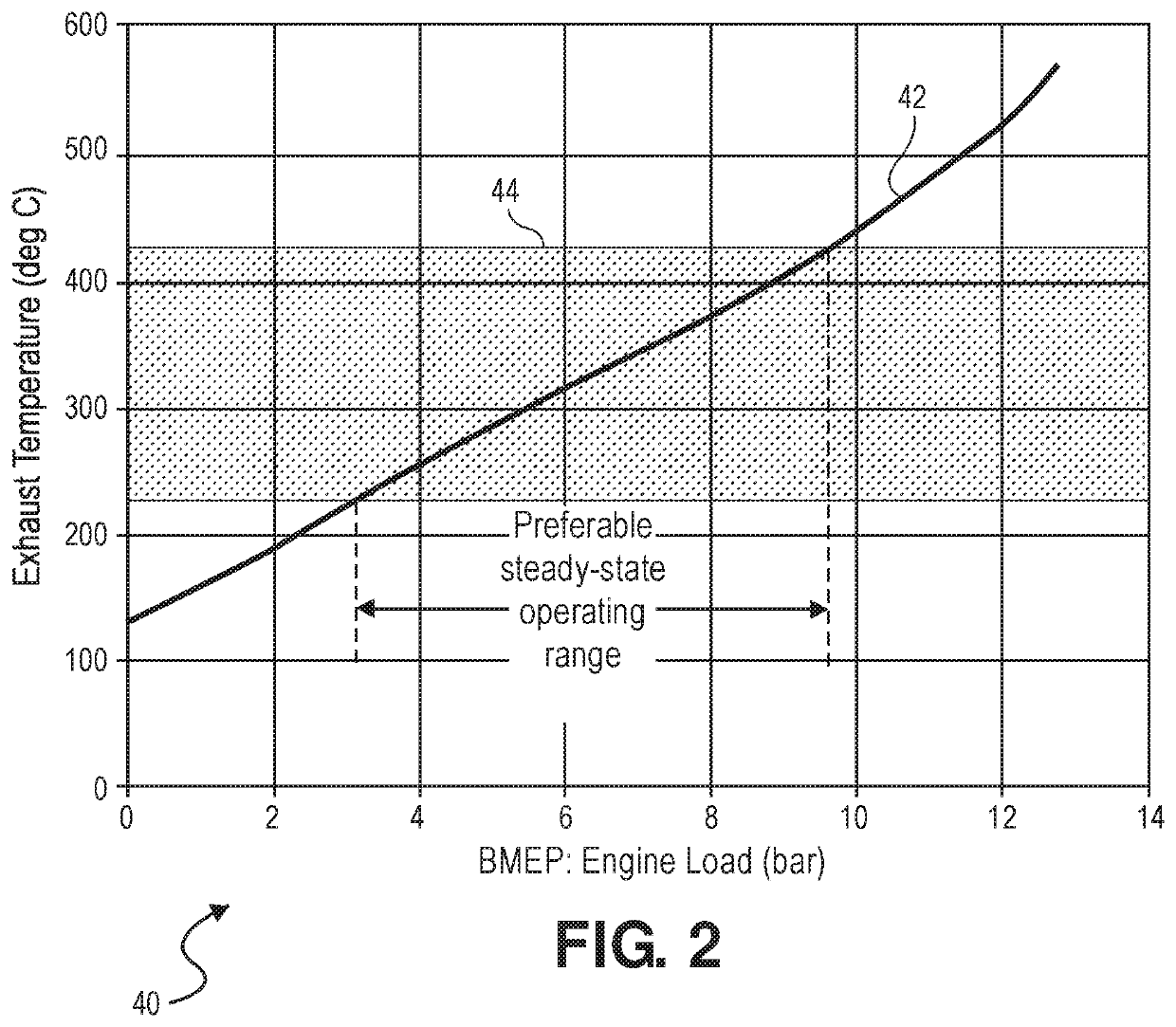

Separately determining firing density and pumping density during firing density transitions for a lean-burn internal combustion engine

ActiveUS20200025050A1Control of ratioAvoid adversely affecting emissionElectrical controlInternal combustion piston enginesEngineeringLean combustion

A skip fire engine controller and method of control is described wherein during transitions from a first firing density to a second firing density, a firing density and a pumping density are separately set so as to balance the conflicting demands of (a) torque control, (b) Noise, Vibration and Harshness (NVH), (c) air flow through the engine and (d) air-fuel ratio.

Owner:TULA TECH INC

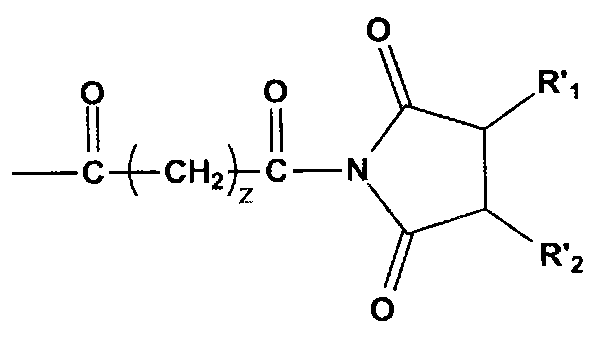

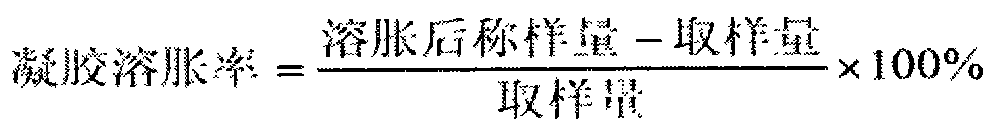

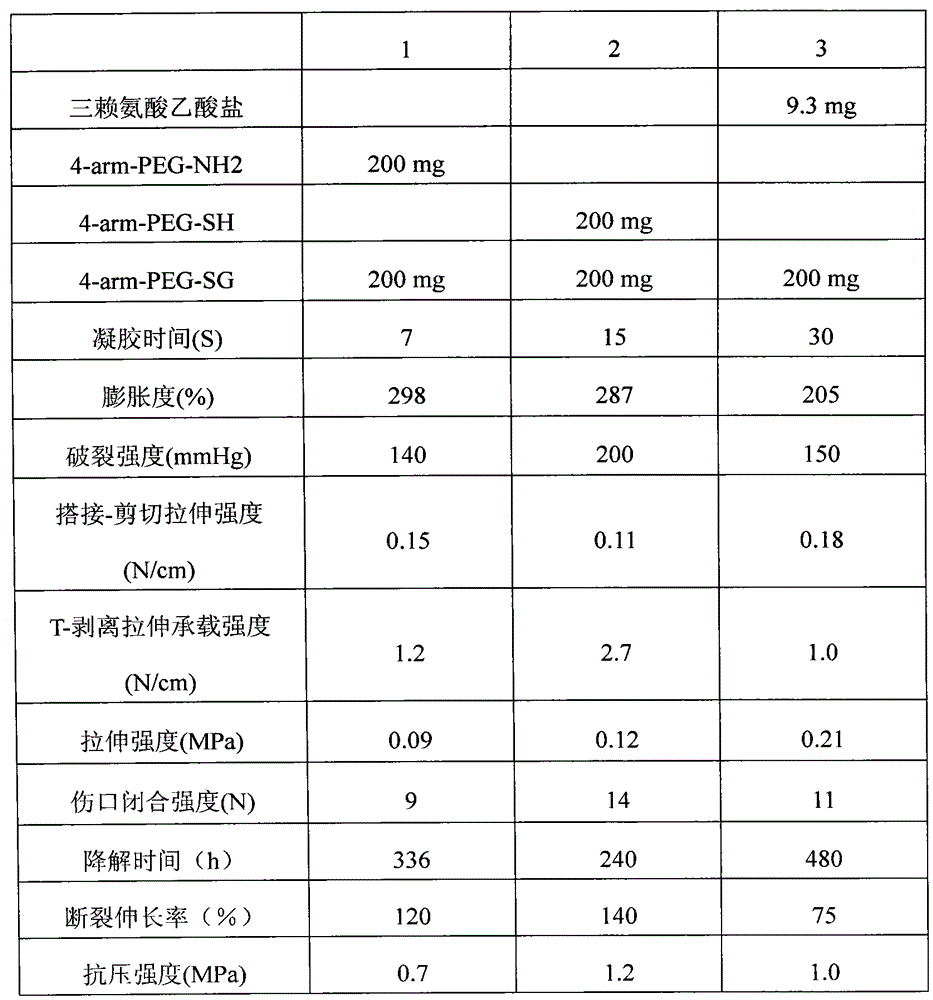

Gel hemostatic material composition and preparation method thereof

The invention relates to a gel hemostatic material and a preparation method thereof. The gel hemostatic material achieves the effect of blocking hemostasis in such a way that a nucleophilic polymer and an amino acid oligomer are in cross-linking reaction with an electrophile polymer to generate a three-dimensional polymer in situ. A gel hemostatic material composition and a preparation method thereof have the advantages that the raw material ratio is controlled accurately, the reasonable gel forming time can be achieved, the gel forming time is less than 10 seconds, the expected strength is relatively high, and the testing result shows that the elongation at break of the biologic gel hemostatic material is 300-600 percent, and the compression strength of the biologic gel hemostatic material is larger than 3 Mpa; the requirement of surgical operation can be met well.

Owner:沈伟

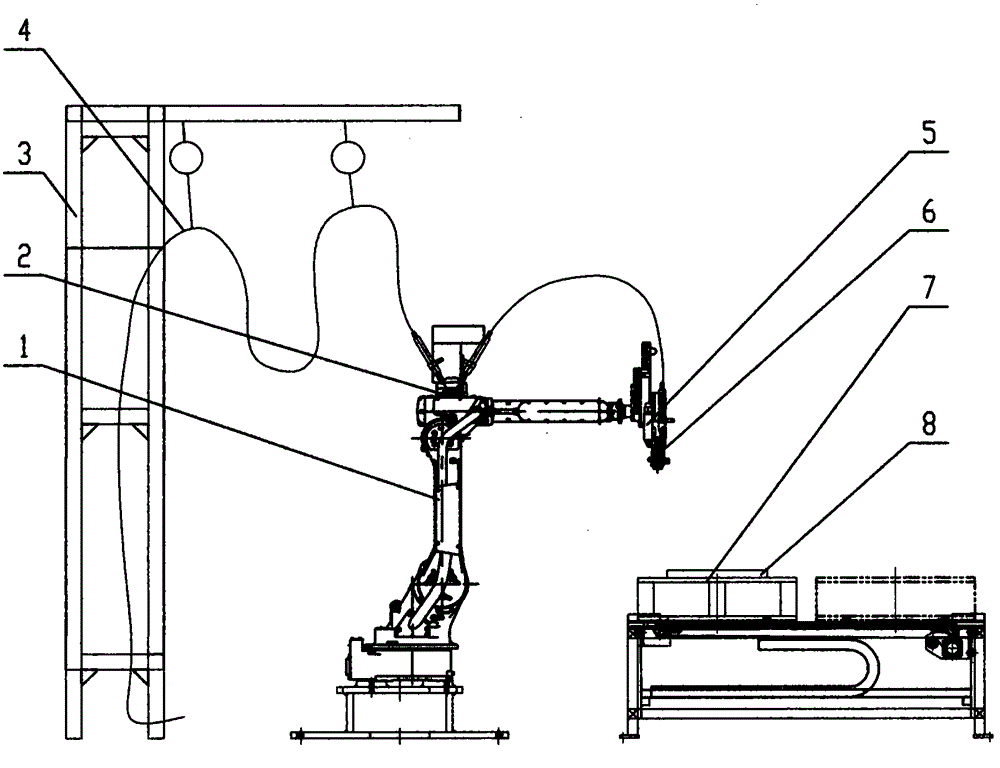

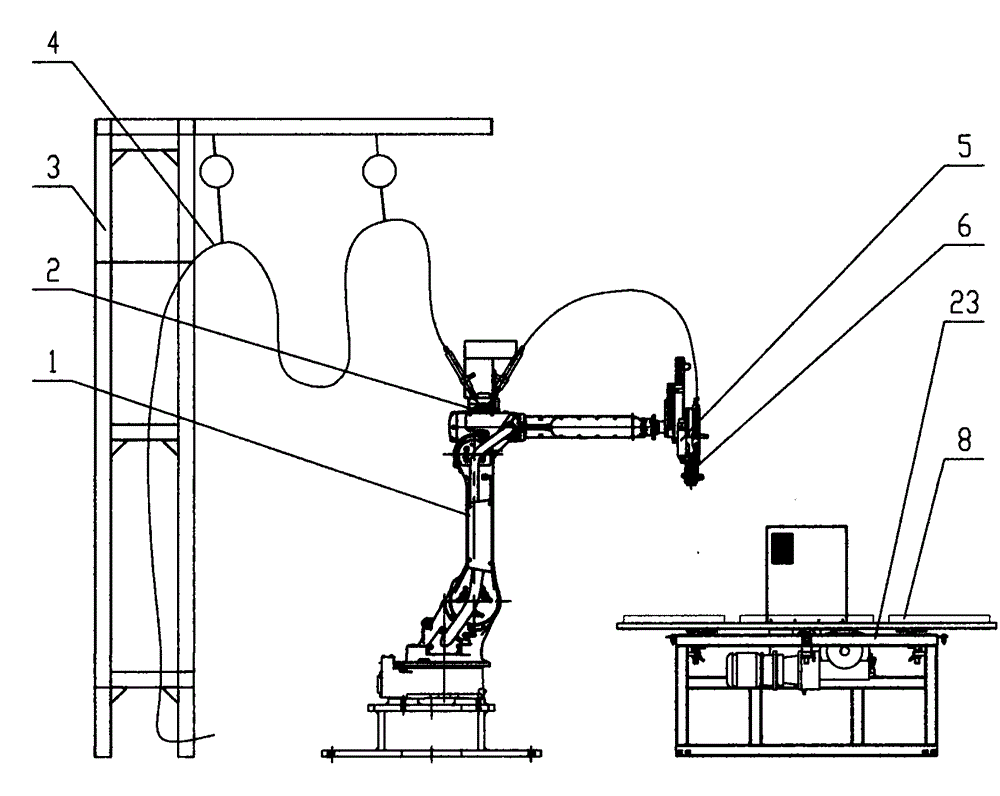

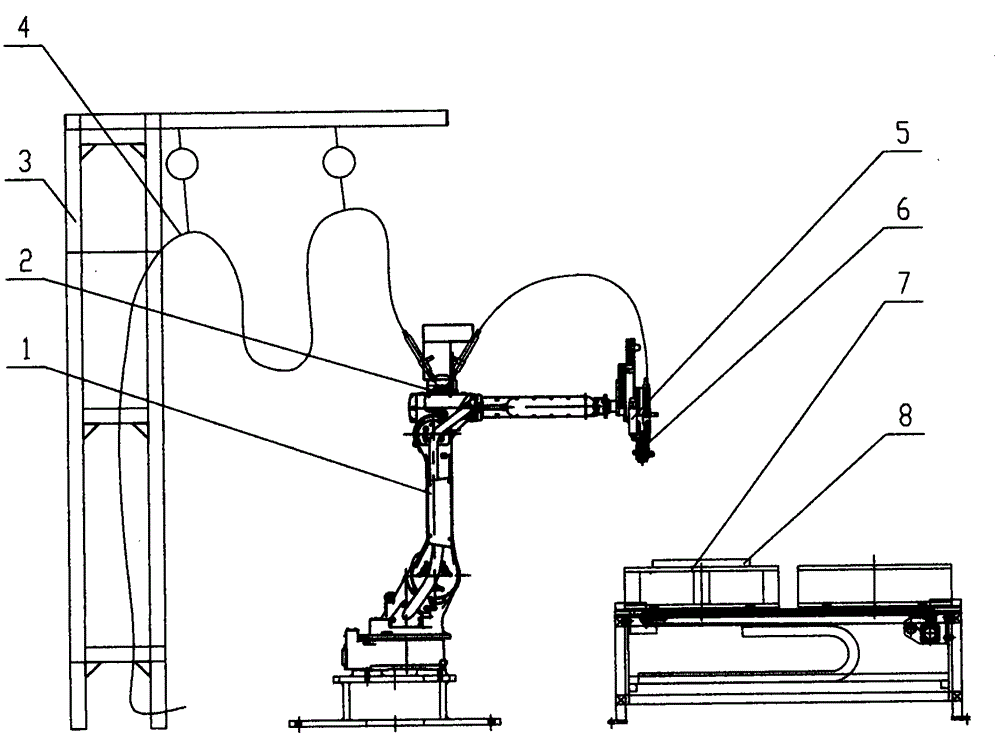

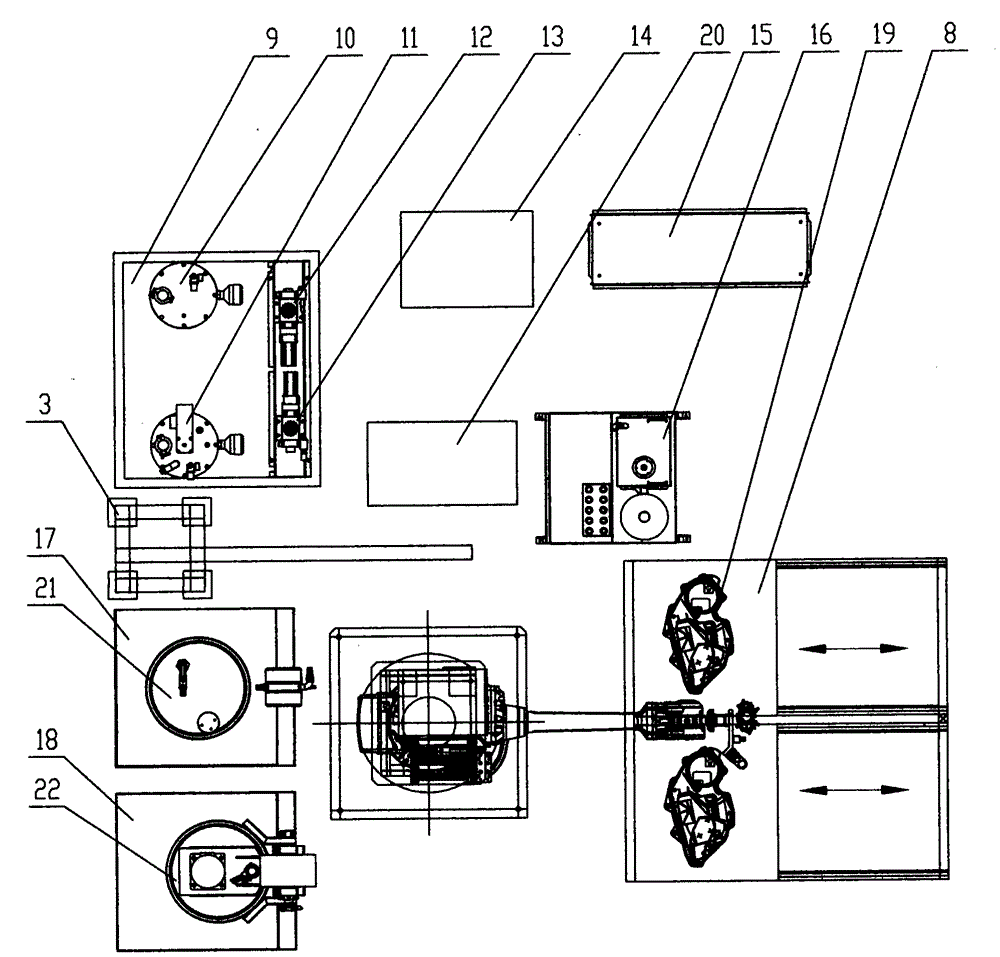

Full-automatic robot gluing equipment and process technology

The invention relates to the technical field of gluing, in particular to full-automatic robot gluing equipment and a process technology which are used for two-component polyurethane gluing. The full-automatic robot gluing equipment is characterized in that the equipment comprises a three-axis robot or a four-axis robot or a five-axis robot or a six-axis robot, a glue supply device, a two-component gluing head, a two-station automatic gluing workbench or a multi-station automatic rotary gluing workbench, plasma treatment equipment, a waste cleaning solution recovery device and an intelligent control system. The three-axis robot or the four-axis robot is of a gantry type or cantilever type structure. The two-component gluing head and a plasma treatment head are fixed to the three-axis robot or the four-axis robot and can be linked in the X axis, the Y axis and the Z axis. The five-axis robot or the six-axis robot is an articulated robot, and five-axis linkage or six-axis linkage of the two-component gluing head and the plasma treatment head can be achieved. According to the novel polyurethane gluing equipment and the process technology, the proportion is precise, glue tape performance is stable, and the sealing effect is good.

Owner:DALIAN HUAGONG INNOVATION TECH

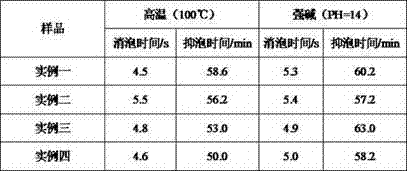

Preparation method of high-efficiency polyether organic silicon defoaming agent applied under severe environment

The invention relates to a preparation method of a high-efficiency polyether organic silicon defoaming agent applied under the severe environment. The preparation method has the characteristics that acrylate monomers or single-capped end polyurethane acrylate macromolecular monomers containing double bonds and allyl polyether are adopted as a compound modifying agent to modify silicone oil with low hydrogen content, the whole process is table, no solvent is needed, polyether organic silicon mother liquor can be prepared, and the high-efficiency polyether organic silicon defoaming agent is prepared by compounding the polyether organic silicon mother liquor with dimethyl silicone oil, hydroxyl silicone oil, white carbon black, a non-ionic emulsifying agent and deionized water and the like. The defoaming agent emulsion can be applied in defoaming of the industries such as paper making, coating, textile, food, pharmacy and petrochemistry under the severe environments with high temperature and strong alkaline.

Owner:南京德俊新材料科技有限公司

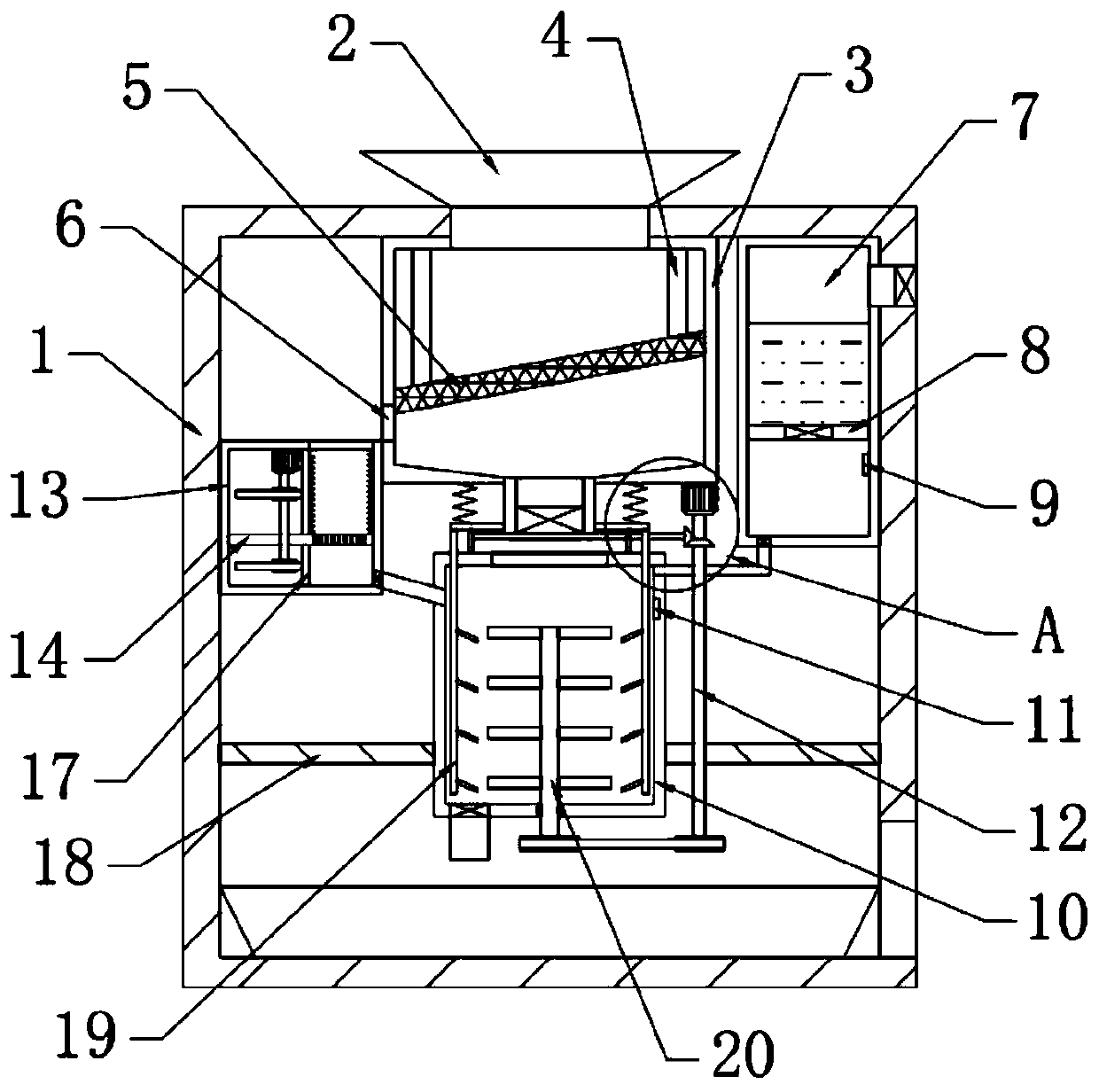

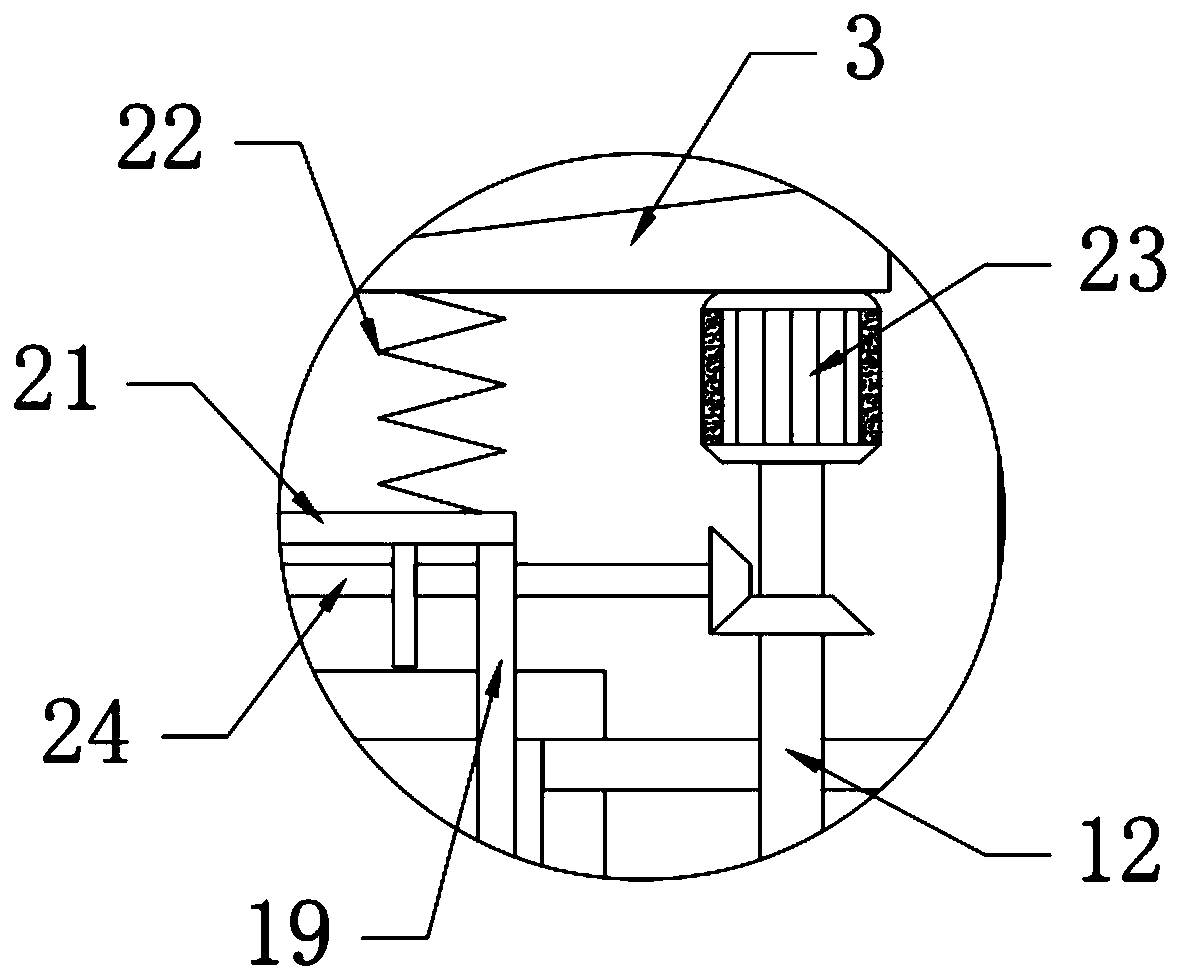

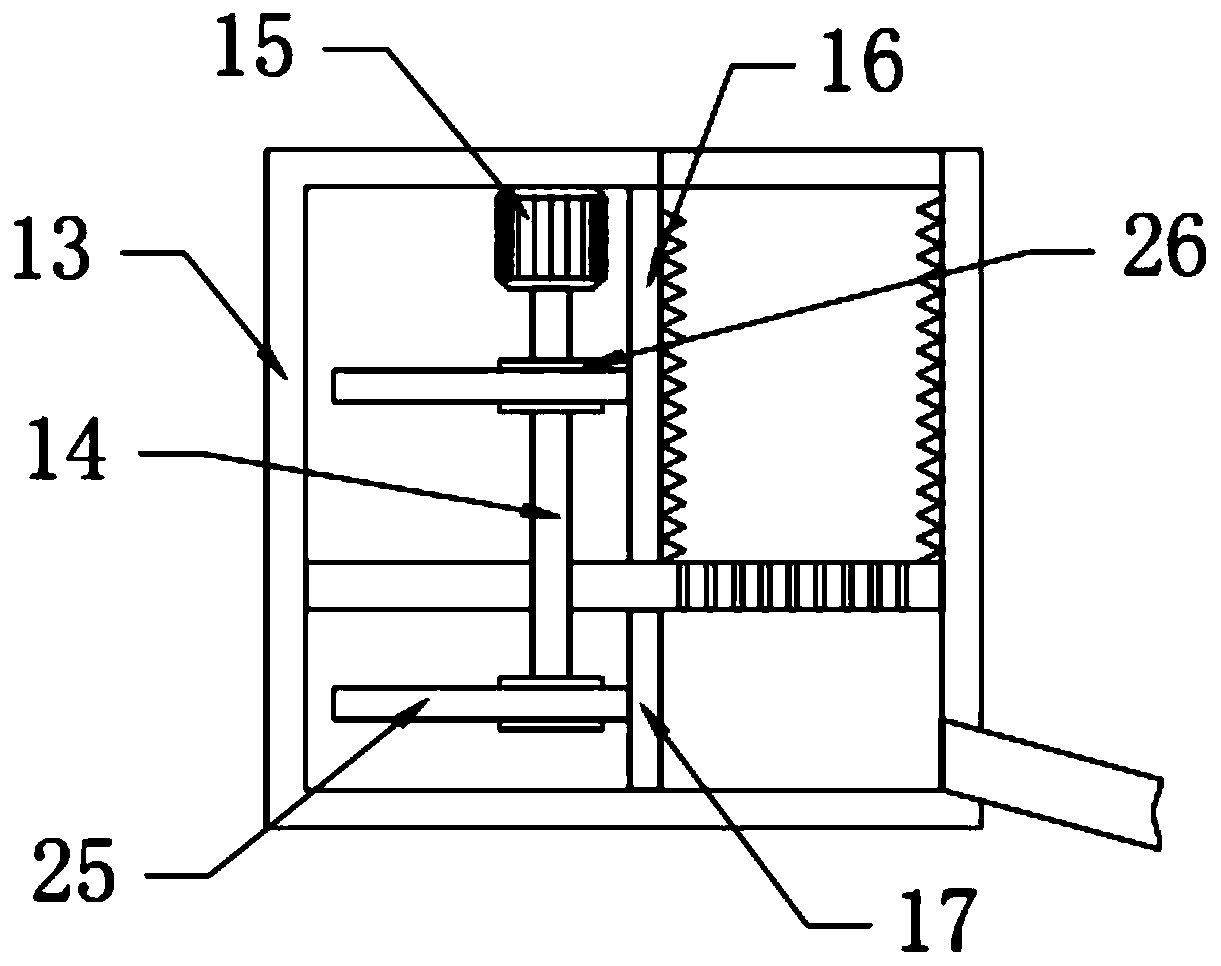

Concrete processing equipment

The invention relates to the technical field of construction, in particular to concrete processing equipment. The concrete processing equipment comprises a housing; the top of the housing is providedwith a feed hopper; the lower side of the feed hopper is provided with a screening box; the left side of the screening box is provided with a gravel processing mechanism; the lower side of the screening box is provided with a fixed plate which is fixedly connected with the housing; the fixed plate is fixedly connected with a stirring bucket; a water tank is arranged at the right side of the screening box; and a storage box is arranged at the lower side of the stirring bucket. According to the concrete processing equipment, the screening box is used for screening impurities such as gravel existing in a raw material so that the raw material falling into the stirring bucket is finer sand, the quality of the prepared concrete is beneficially improved; by arranging the gravel processing mechanism, the screened stone pieces can be crushed so that the stone pieces can be reutilized; by arranging a partition plate, a liquid level sensor and an infrared sensor, the amount of water and raw material added into the stirring bucket can be accurately controlled; and thus the ratio of the raw material to water is effectively controlled.

Owner:郭倩

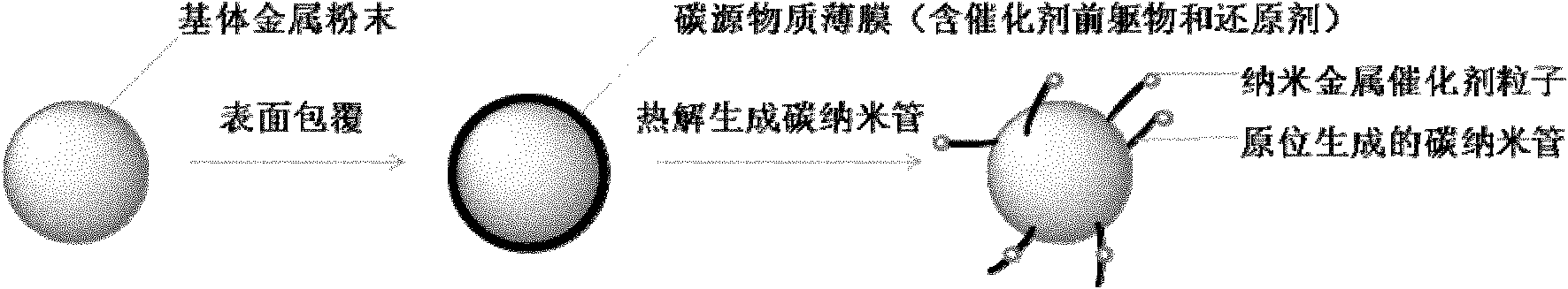

Carbon nano tube reinforced metal matrix composite material and in-situ preparation method thereof

The invention discloses a carbon nano tube reinforced metal matrix composite material and an in-situ preparation method thereof in the technical field of composite materials. The in-situ preparation method comprises the following steps of: firstly, coating a carbon source substance and a catalyst precursor on the surface of metal powder; secondly, generating carbon nano tubes in situ on the surface of the metal powder on the basis of a catalytic pyrolytic reaction to obtain composite powder of the carbon nano tubes and a metal; and finally, performing densification by adopting a powder metallurgy technique to obtain the carbon nano tube reinforced metal matrix composite material. In the preparation method, tiny and dispersed catalyst particles are generated in situ by bringing the steric effect of the carbon source substances such as an organic substance or a polymer and the like, and then uniformly dispersed carbon nano tubes are generated in situ on the surface of the metal powder through the catalytic pyrolytic reaction of the organic substance or the polymer.

Owner:SHANGHAI JIAO TONG UNIV

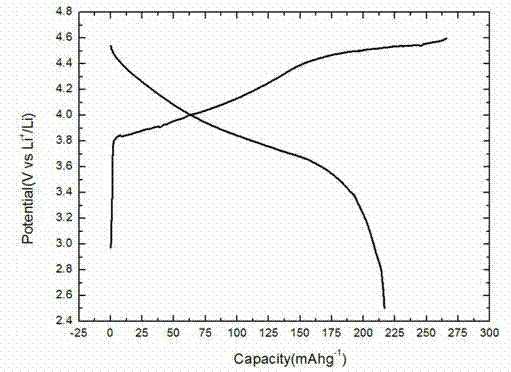

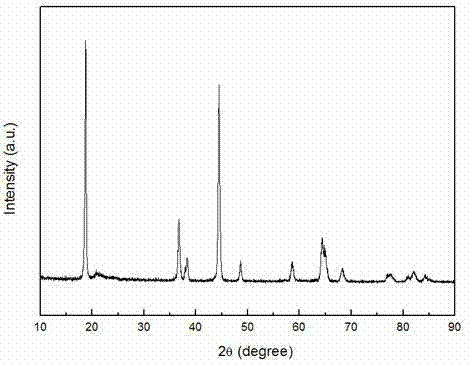

Oxalate coprecipitation preparation method for high-capacity lithium-rich cathode material

InactiveCN102730761AImprove structural stabilityImprove charge and discharge specific capacityCell electrodesManganese oxides/hydroxidesOXALIC ACID DIHYDRATEPhysical chemistry

The invention relates to an oxalate coprecipitation preparation method for a high-capacity lithium-rich cathode material. The preparation method is characterized by comprising the following concrete steps: dissolving soluble Ni salt, or Co salt and Mn salt, or Ni salt, Co salt and Mn salt in a proper amount of deionized water according to a stoichiometric ratio to prepare a metal salt solution with certain concentration, dissolving oxalate or oxalic acid in deionized water to prepare an oxalate solution with certain concentration, mixing the metal salt solution with an oxalate or oxalic acid solution in a way of straight adding, reverse adding or combined adding, adjusting the pH value of a mixed solution to be in a range of from 6.5 to 8.5, allowing a coprecipitation solution to be formed, and carrying out filtration with filter paper, rinsing with deionized water and drying on the coprecipitation solution so as to obtain precipitation precursor; and subjecting excess Li salt and the precipitation precursor in a certain stoichiometric ratio to ball milling and mixing and carrying out high temperature sintering so as to obtain an xLi2MnO3.(1 - x)LiMO2 (wherein M is Co, Ni1 / 2Mn1 / 2 or Ni1 / 3Co1 / 3Mn1 / 3) material at last. The method costs little and does not need a high temperature in preparation of a lithium-rich material and allows the shape and the size of the prepared material to be easily controllable.

Owner:CHINA FIRST AUTOMOBILE

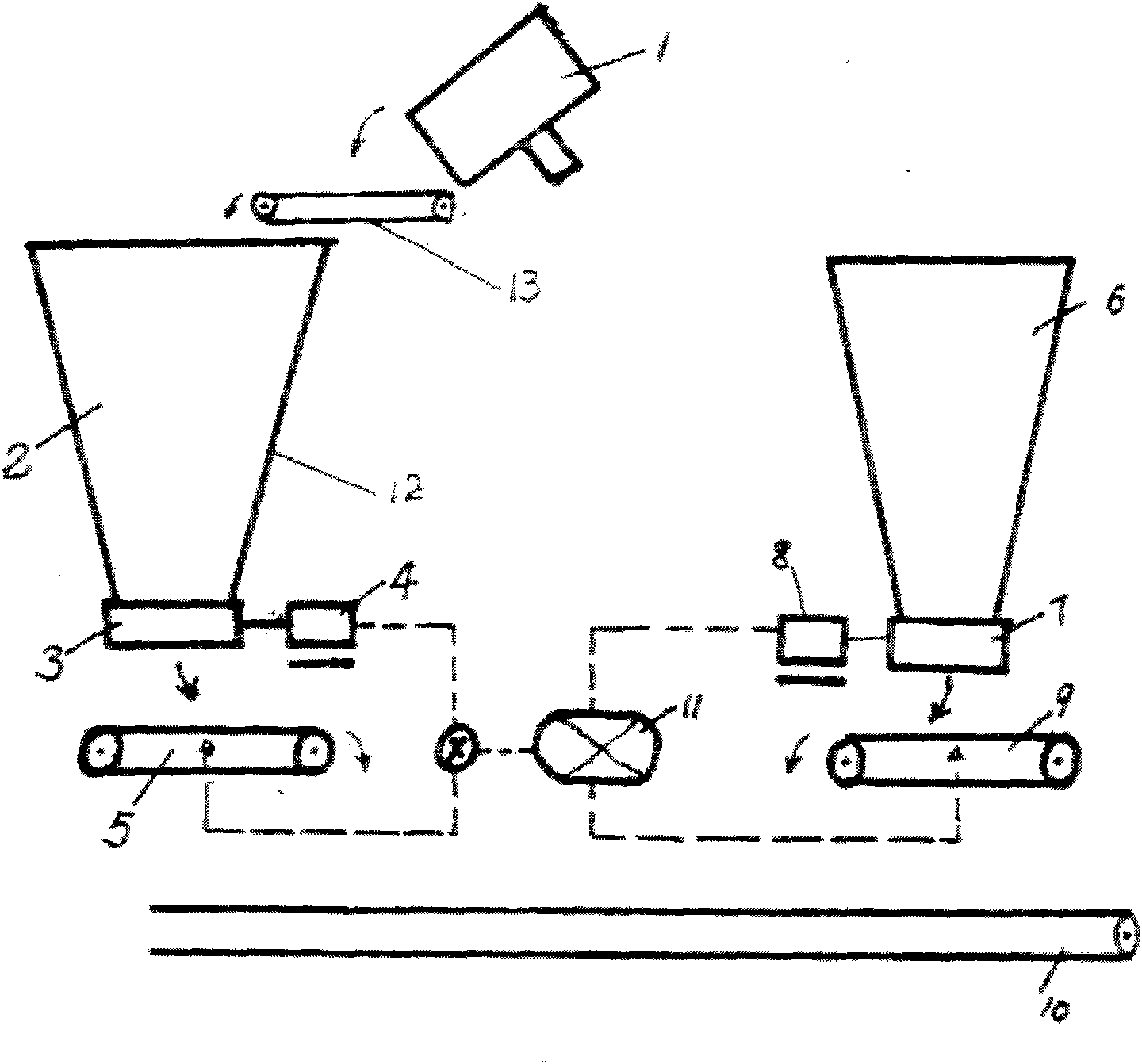

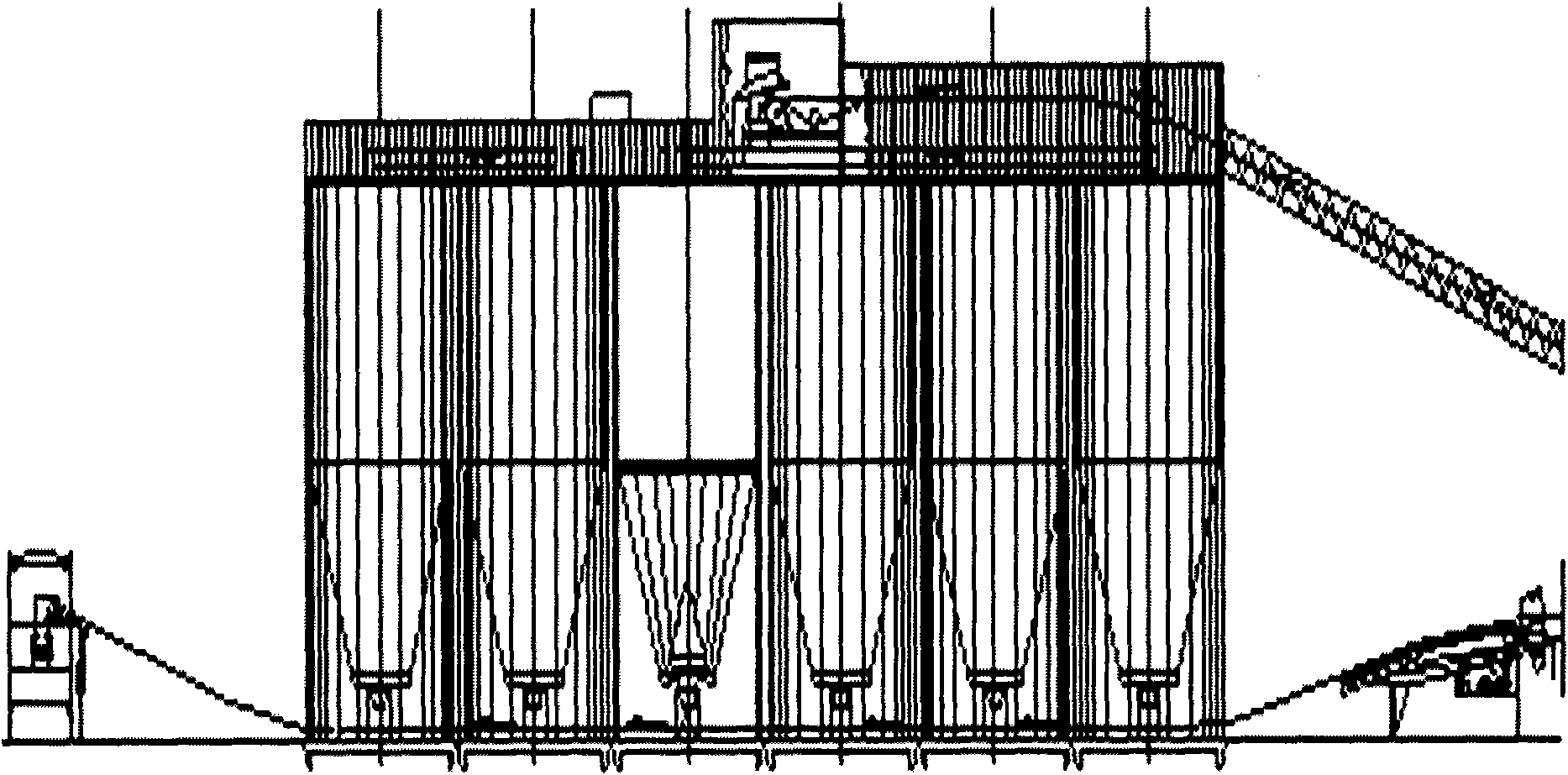

Coal distributing system and coal feeder used in same

ActiveCN102008920ACompact structureControl ratioMixer accessoriesLoading/unloadingCurve shapeDistributor

The invention relates to a coal distributing system which comprises a plurality of raw coal barrel bins, coal feeders, a barrel bin lower belt scale, a coal distribution conveying belt and a coal distributing control device, wherein the raw coal barrel bins are used for respectively storing different kinds of raw coal; and the coal feeders are arranged at the lower parts of all raw coal barrel bins along the axis directions of the raw coal barrel bins; each coal feeder is provided with a shell, a circular coal outlet, a coal distributor and a scraper; the shell is in an inverted cone platform shape, the upper part of the shell is opened, and the lower part is provided with a flat plate-shaped base plate; the circular coal outlet is arranged at the central part of the base plate; the coal distributor is conic and is arranged at the upper side of the coal feeder and arranged on a rod-shaped bracket which is fixedly installed on the shell so that the raw coal falling from the raw coal barrel bins uniformly slide to be near to the coal outlet along the conic surface; the scraper is in a curve shape extending along the flat-plate-shaped base plate and is arranged on a rotatable fixed bracket extending out from the coal outlet; and when the scraper rotates, the scraper is used for scraping the raw coal in the coal feeders into the coal outlet. According to the structure, the coal distributing system can realize precise coal distribution and has compact structure.

Owner:鹏发国际股份有限公司

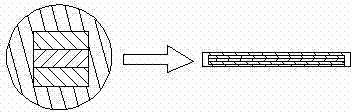

Magnesium-aluminum multilayer composite plate and machining method thereof

ActiveCN103879086AControl ratioReduce processing costsLaminationLamination apparatusSolution treatmentComposite plate

The invention discloses a magnesium-aluminum multilayer composite plate and a machining method thereof. The composite plate consists of a wrapping base material with a cavity and a core material which is wrapped in the cavity of the base material, and the wrapping base material and the core material are integrated through an extruding process to form the composite plate. The cavity adopts a structure with two communicated ends or one communicated end. The machining method comprises the following steps of (1) arranging the cavity with two communicated ends or one communicated end in the magnesium alloy or aluminum alloy base material to form the wrapping base material, filling the core material into the cavity, wherein the core material is a magnesium alloy plate / bar, an aluminum alloy plate / bar or a composite core plate formed by stacking the magnesium alloy plate and the aluminum alloy plate in a separating manner from top to bottom; carrying out solution treatment at the temperature of 400 to 500 DEG C; and (2) finally extruding the wrapping base material which is provided with the core material to a plate with the needed size. The magnesium-aluminum multilayer composite plate is convenient to machine, and low in machining cost and the plate shape can be easily controlled.

Owner:CHONGQING UNIV

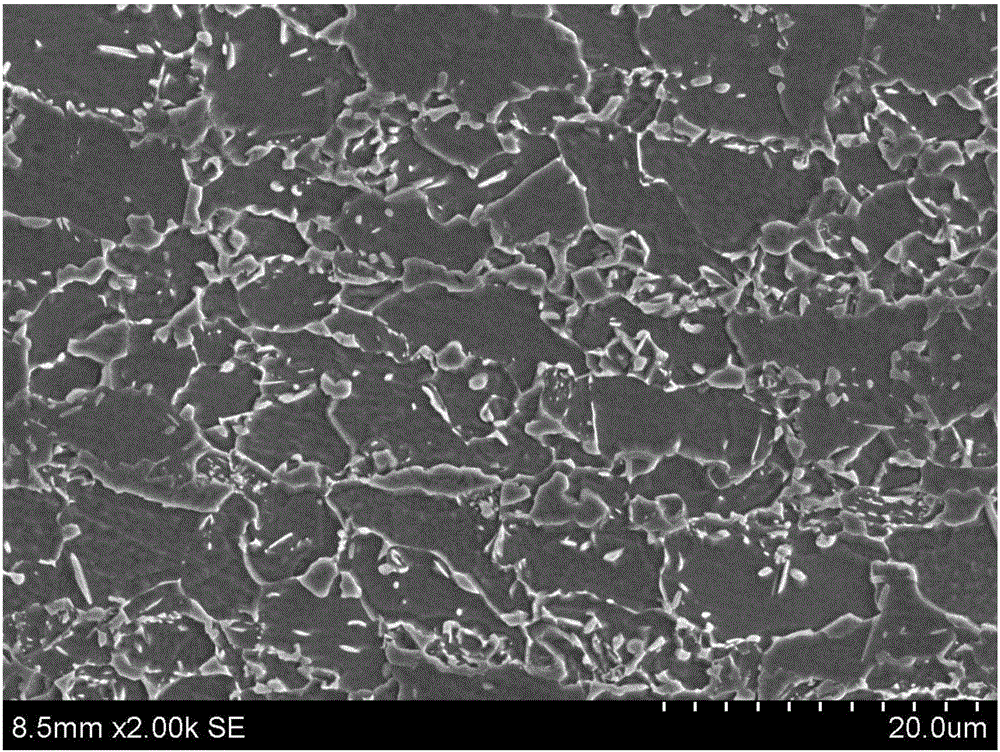

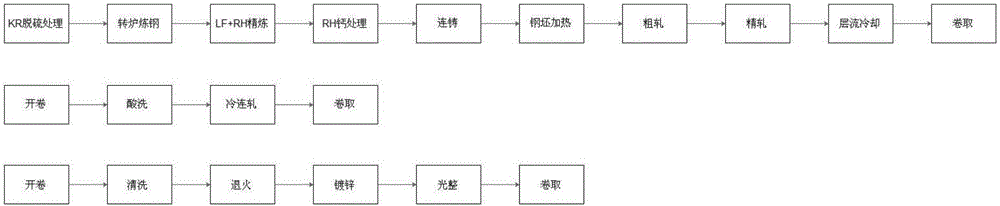

Zinc-plated double-phase steel and production method thereof

The invention belongs to the technical field of cold rolled steel and discloses zinc-plated double-phase steel and a production method of the zinc-plated double-phase steel. The zinc-plated double-phase steel comprises, by weight percentage, 0.085%-0.115% of C, 0.15%-0.24% of Si, 1.45%-1.55% of Mn, not larger than 0.015% of P, not larger than 0.005% of S, 0.025%-0.065% of Alt, 0.14%-0.24% of Cr, 0.24%-0.29% of Mo, not larger than 0.006% of N and the balance Fe and other inevitable impurities. The production method includes the steps of KR desulfuration, converter steelmaking, LF+RH refining treatment, RH calcium treatment, continuous steel casing, billet heating, rough rolling, finish rolling, laminar cooling and winding; unwinding, acid pickling, cold continuous rolling and winding; and unwinding, cleaning, annealing, zinc plating, finishing and winding. Through composition design and process control, the zinc-plated double-phase steel is suitable for annealing production lines having the rapid cooling segment or not.

Owner:SHOUGANG CORPORATION

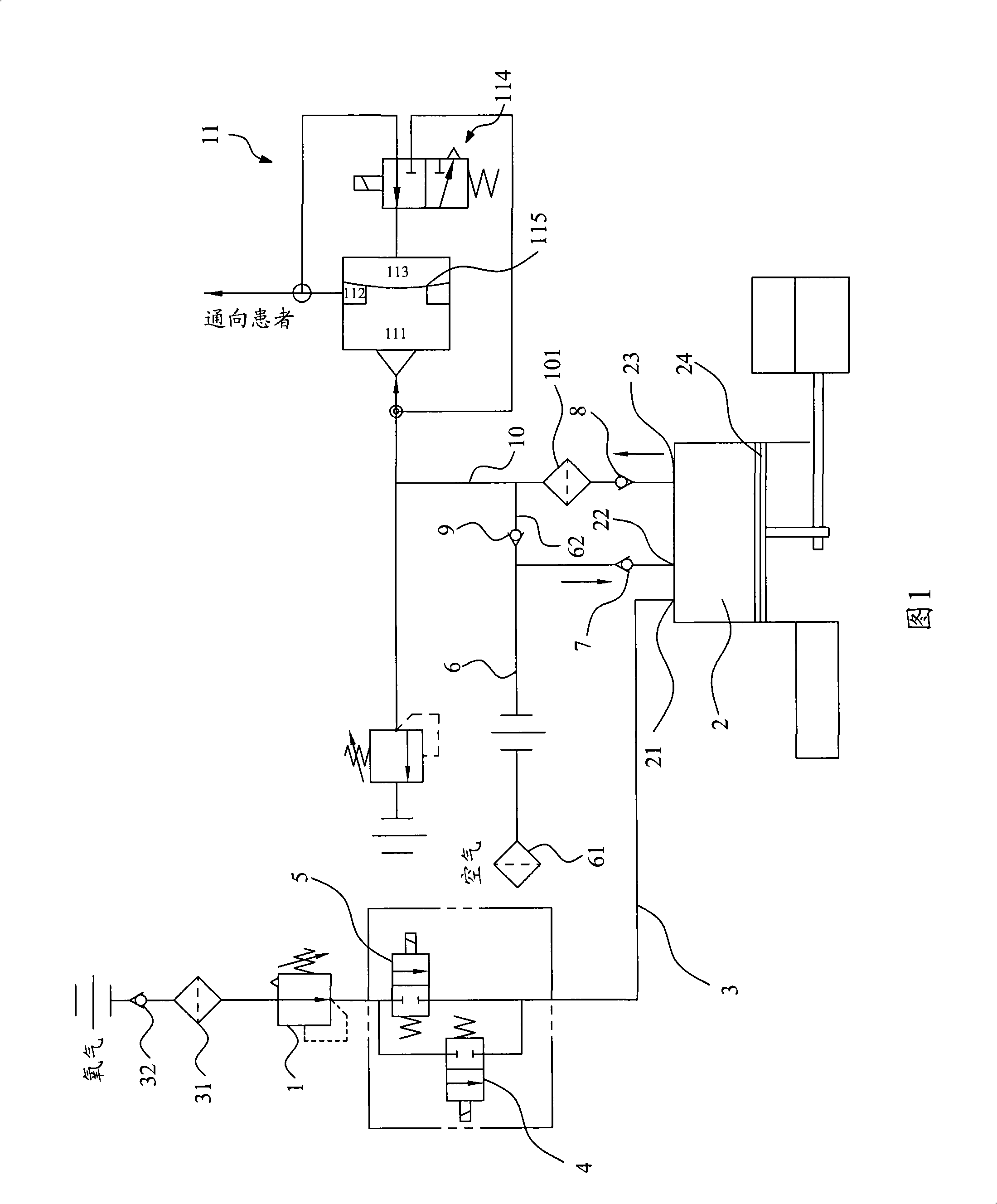

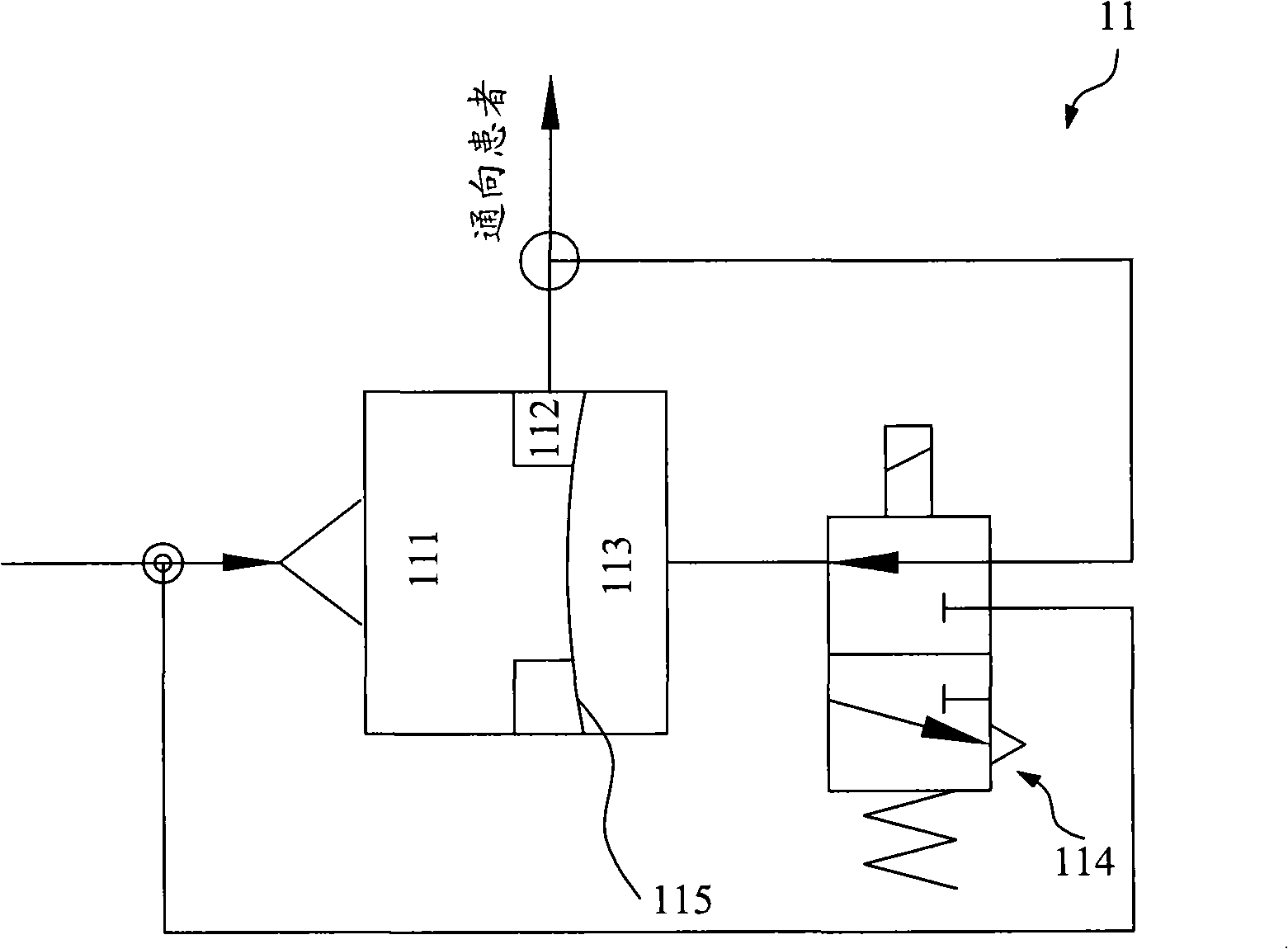

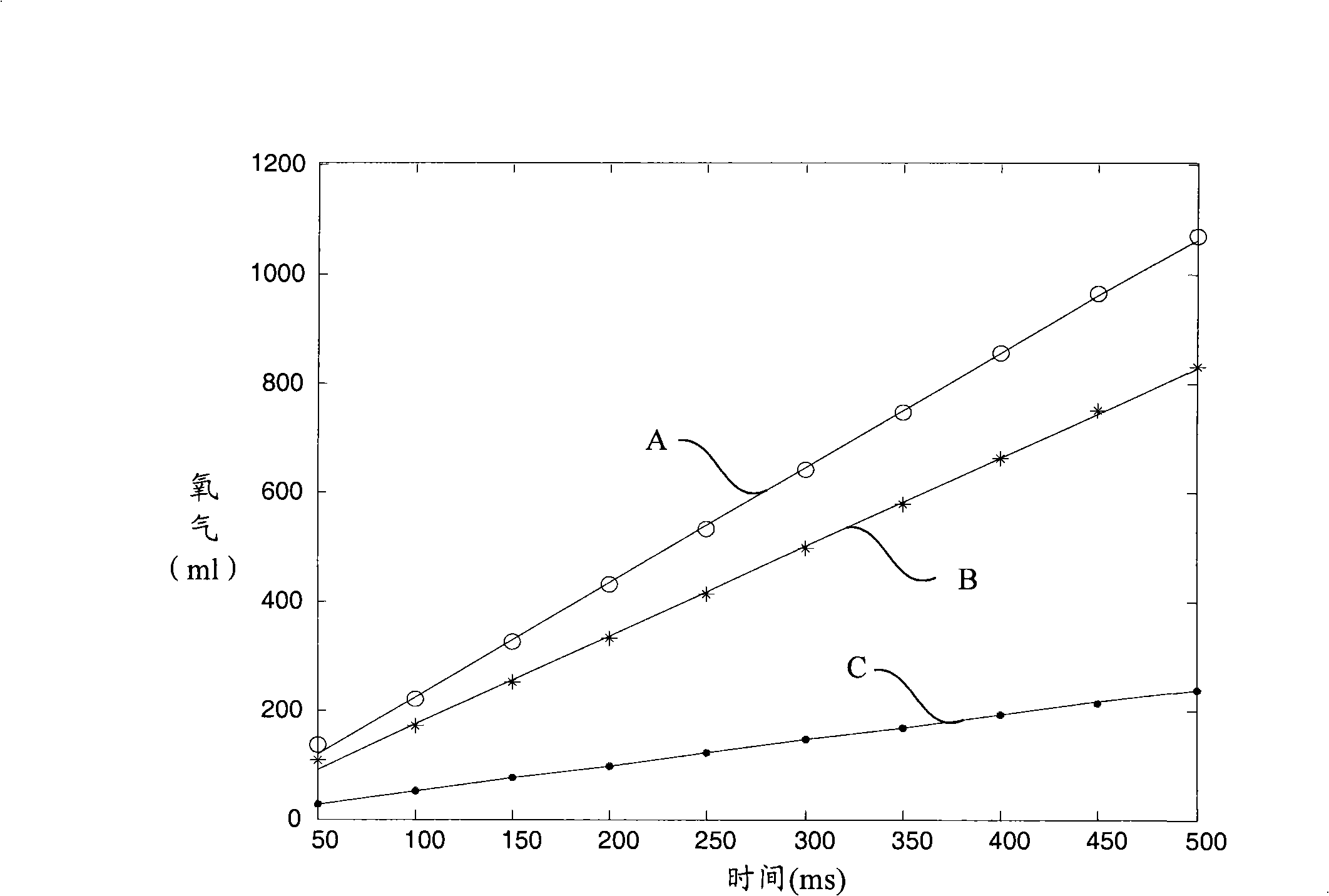

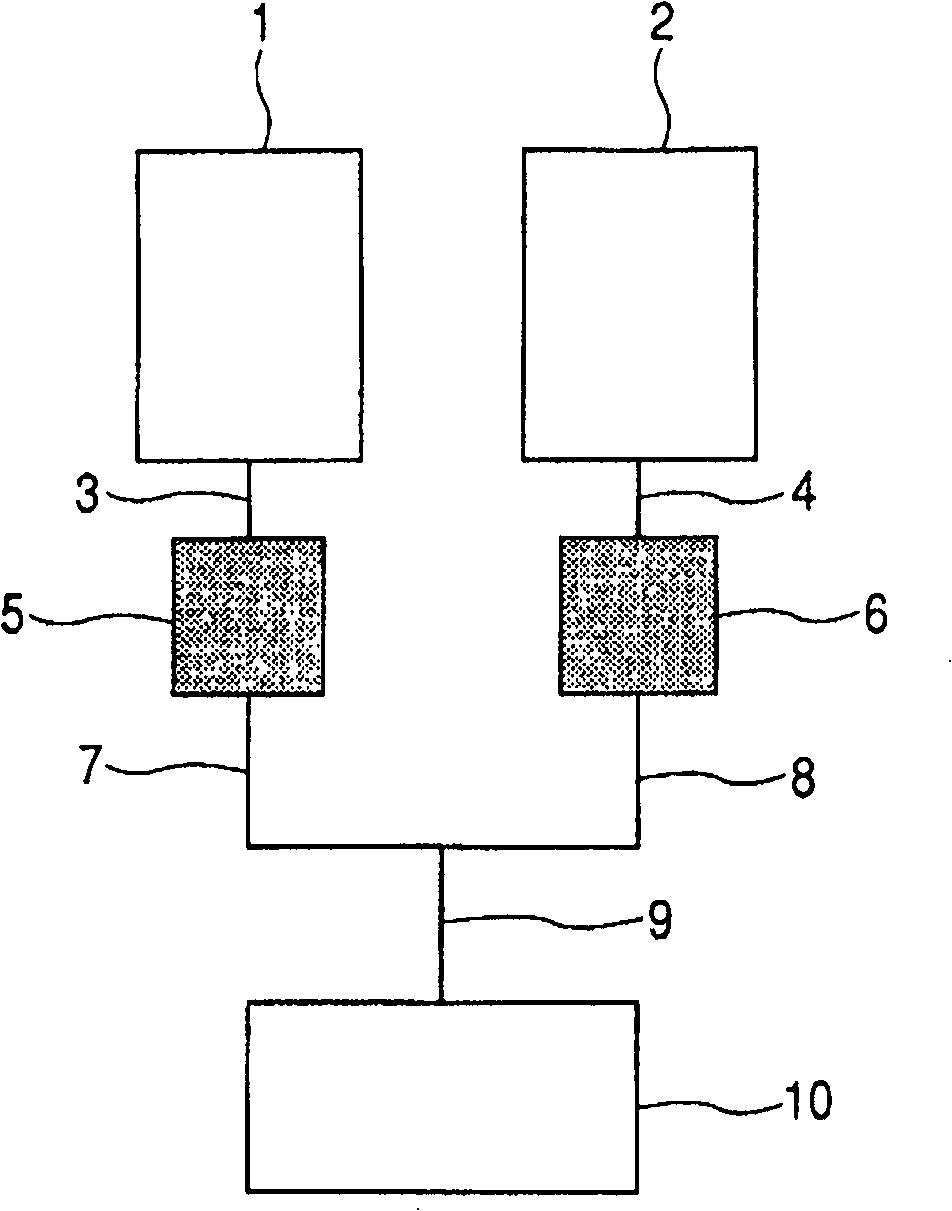

Oxygen concentration adjusting device and method thereof

ActiveCN101310786ASimple control algorithmSimplify complexityRespiratorsPneumatic cylinderProduct gas

The invention relates to an oxygen concentration regulating device, in particular to the oxygen concentration regulating device in an electric pulmotor, the oxygen concentration regulating device comprises: a pressure stabilizing valve; a pneumatic cylinder; an oxygen feed pipeline; the pressure stabilizing valve and the pneumatic cylinder are connected with each other by utilizing the oxygen feed pipeline; an air feed pipeline is connected with the pneumatic cylinder; one end of an air-oxygen mixed gas discharge pipeline is connected with the pneumatic cylinder, and the other end is introduced to a patient; wherein, at least two electromagnetic valves which are connected in parallel are arranged between the pressure stabilizing valve and the pneumatic cylinder, and the electromagnetic valves are used for regulating the oxygen feed amount. In addition, the invention further relates to an oxygen concentration regulating method.

Owner:BEIJING AEONMED

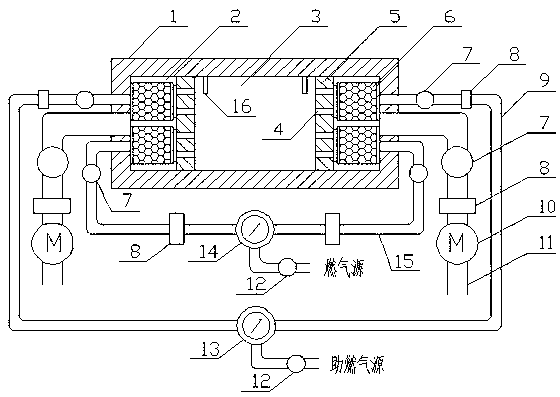

High thermal efficiency regenerative heating furnace

The invention discloses a high thermal efficiency regenerative heating furnace which is used for solving the problem that an existing regenerative heating furnace is low in thermal efficiency. The high thermal efficiency regenerative heating furnace comprises a furnace body, a partition wall divides an inner cavity of the furnace body into a combustion chamber and regenerative chambers arranged at two sides of the combustion chamber, the partition wall is provided with at least one combustion channel used for communicating the regenerative chambers with the combustion chamber. A heat accumulator is arranged inside each regenerative chamber, and is connected with a fuel combustion assisting pipeline and a fuel pipeline, and the fuel combustion assisting pipeline and the fuel pipeline are respectively connected with a combustion assisting gas source and a fuel source. The heat accumulator is further connected with a check valve capable of enabling fuel combustion assisting gas to enter the furnace body. The fuel pipeline is provided with a check valve capable of enabling the fuel to enter the furnace body. The high thermal efficiency regenerative heating furnace is capable of preventing burning smoke from entering the fuel combustion assisting pipeline and the fuel pipeline, and therefore ratio of the fuel and the fuel assisting gas is effectively controlled, and combustion efficiency is improved.

Owner:PANZHIHUA DUOSHI MACHINERY MFG

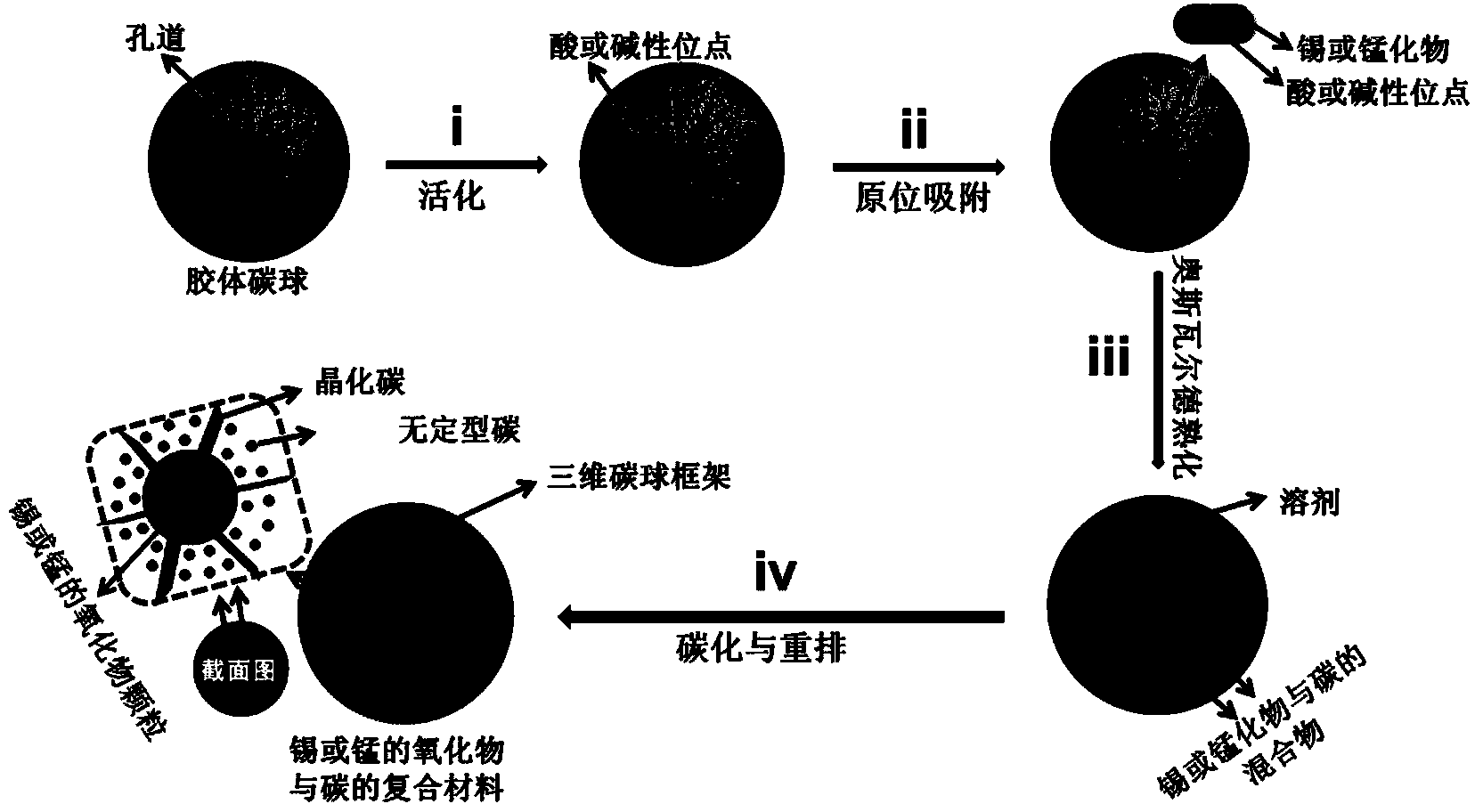

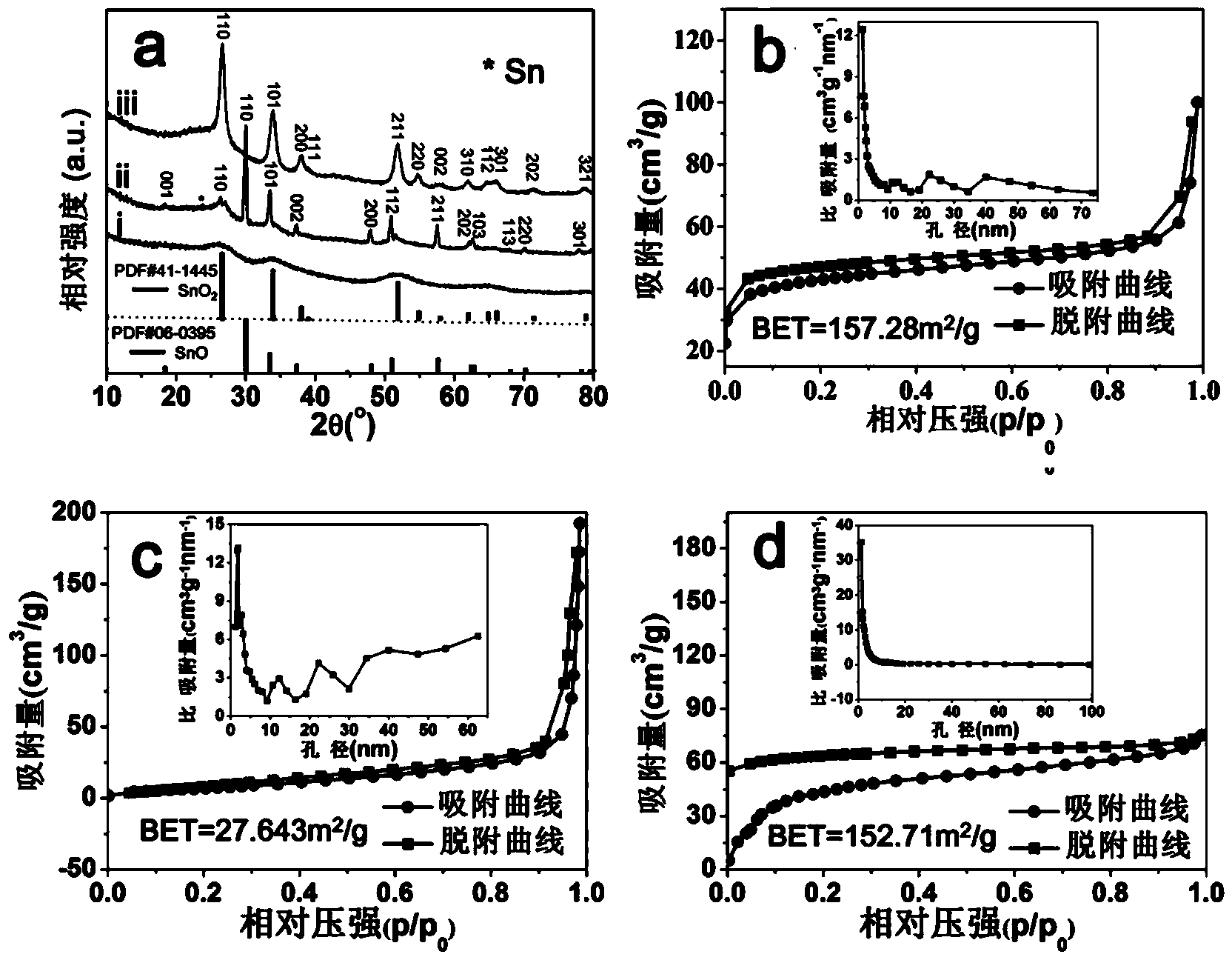

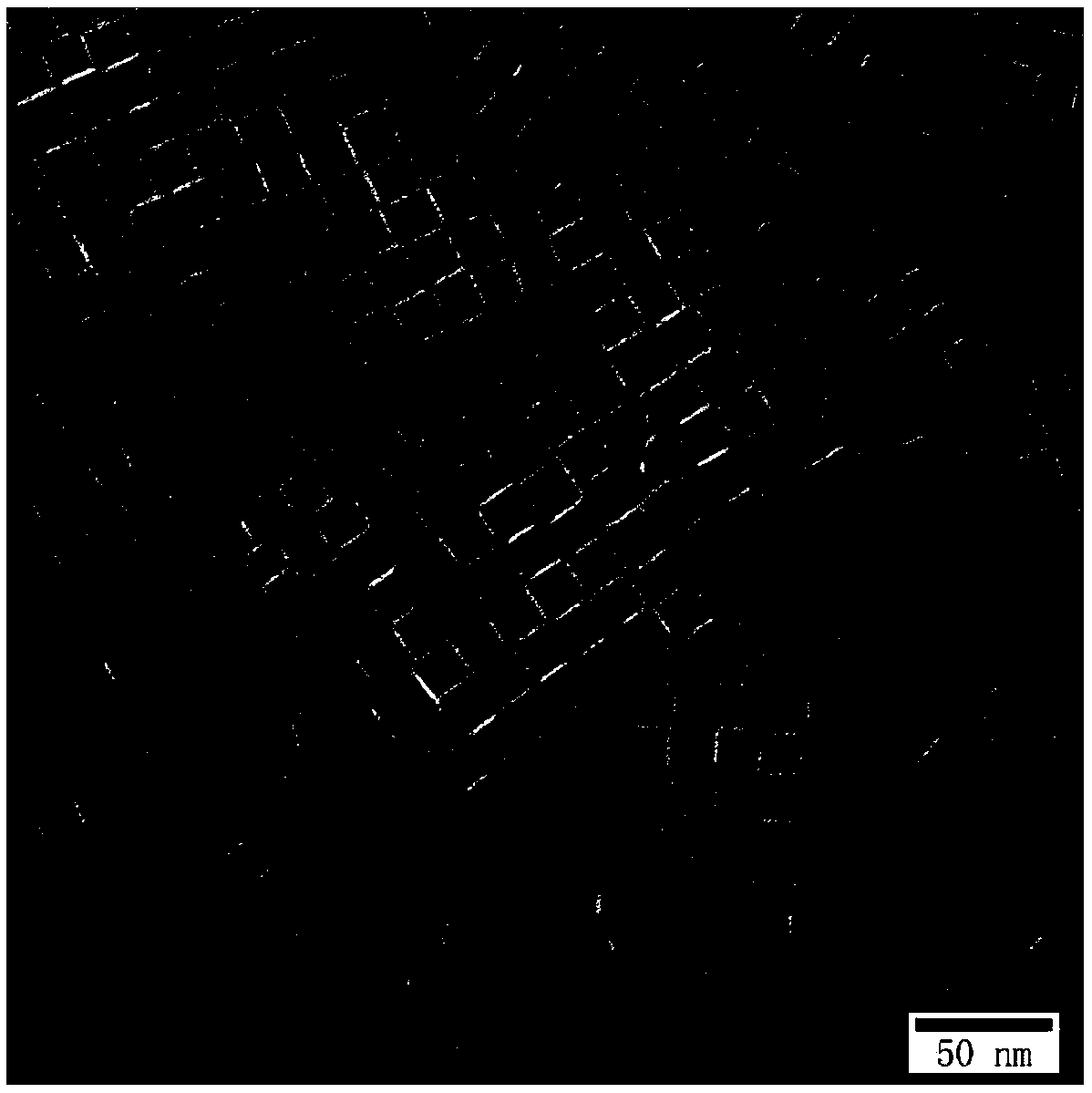

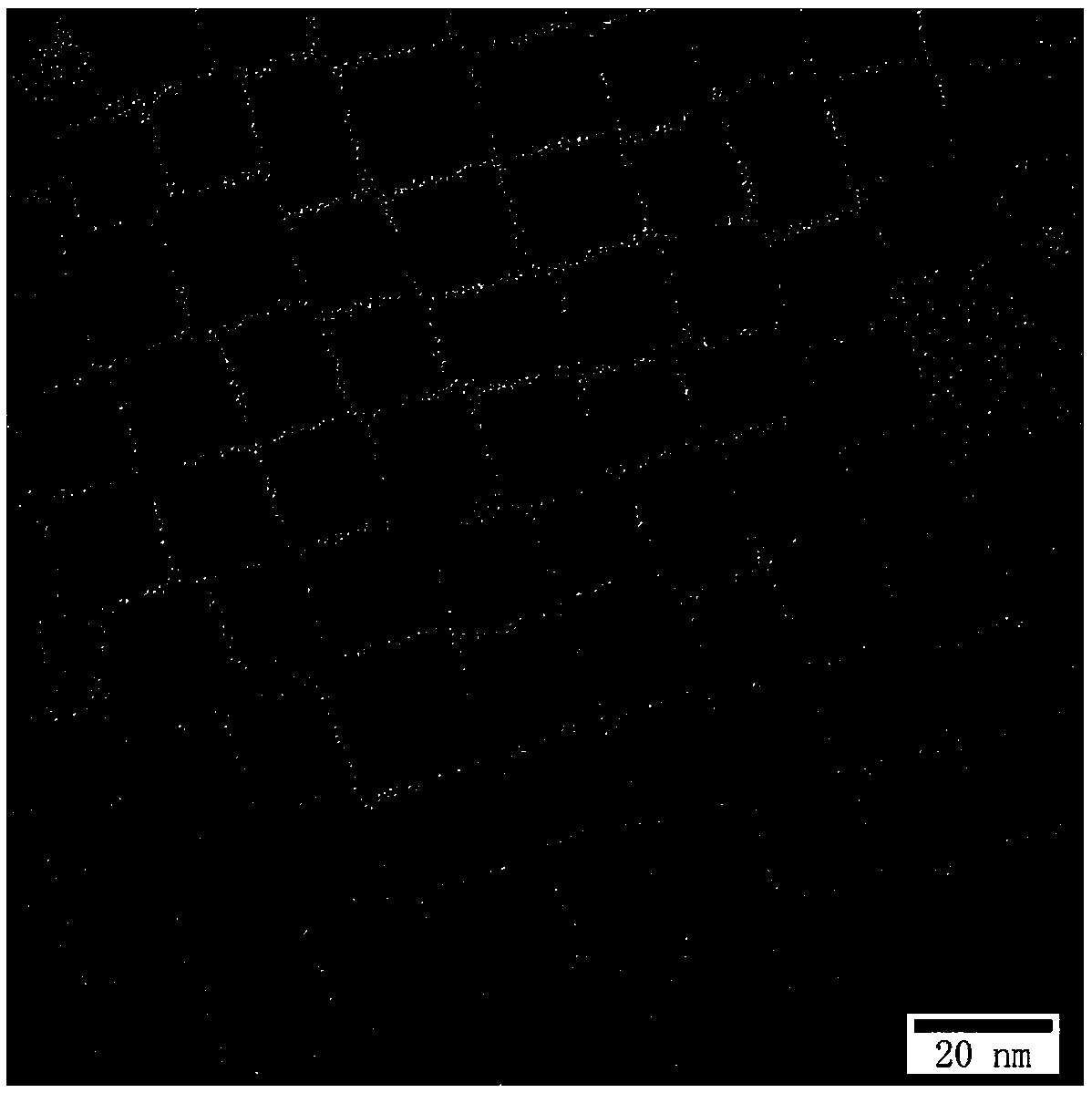

SnO2, MnO or Mn3O4-based composite material based on three-dimensional carbon sphere framework structure and preparation method of material

InactiveCN104183823AHigh modulus of elasticityImprove conductivityCell electrodesSecondary cellsLithiumMicrosphere

The invention relates to a SnO2, MnO or Mn3O4-based composite material based on a three-dimensional carbon sphere framework structure and a preparation method of the material. The SnO2, MnO or Mn3O4-based composite material consists of microspheres formed by SnO2, MnO or Mn3O4 metal oxides packaged by crystallized carbon and amorphous carbon which are distributed in a crossing manner, wherein the diameter of the composite material is 100nm-800nm, and the particle diameters of metal oxides are 2nm-50nm. The composite material prepared by virtue of the preparation method has excellent electrochemical performance, particularly, the three-dimensional carbon sphere framework structure has a large space to allow volume expansion of stannic oxide or manganese oxide in lithium embedding and removing processes, besides, crystallized carbon which packages stannic oxide or manganese oxide particles and is distributed in the crossing manner can be bent during the volume expansion, and amorphous carbon around crystallized carbon is further compressed, so that the composite material has high toughness, the structural stability is guaranteed, and the cycling stability of the composite material is good.

Owner:HUAZHONG NORMAL UNIV

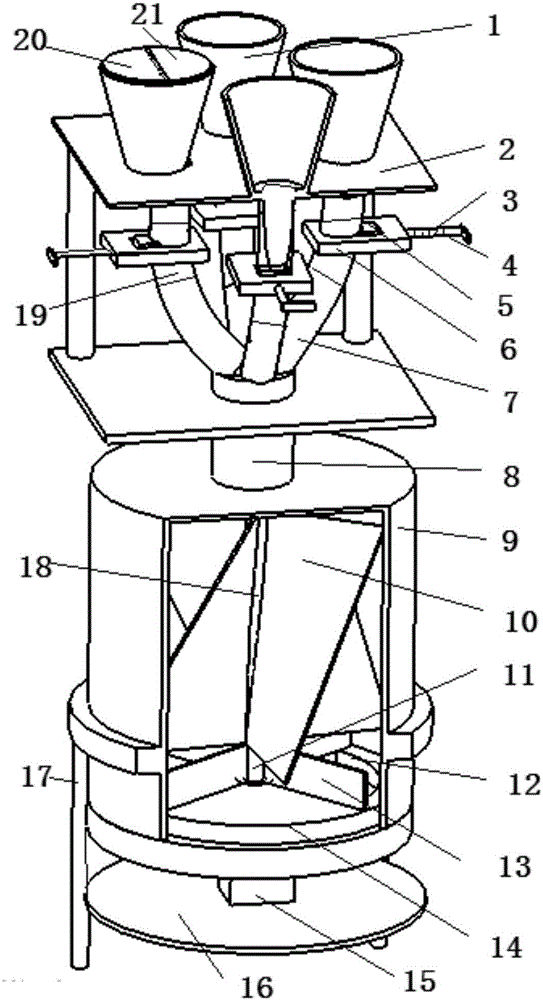

Quantitative powder mixing machine

InactiveCN106512821ARealize automatic proportioning and mixingReduce concentrationRotary stirring mixersTransportation and packagingEngineeringMechanical engineering

The invention provides a quantitative powder mixing machine, comprising a support and a feed hopper, wherein a first pipeline communicated with the feed hopper joins a second pipeline; the other end of the second pipeline is placed above and communicated with a mixing barrel; the inner surface of the bottom of the mixing barrel is rotatably connected with a discharging plate; the discharging plate is provided with discharging holes; the bottom of the mixing barrel is also provided with a discharging hole corresponding to the discharging plate; a stirring device is arranged in the mixing barrel; the first pipeline is provided with a section of an elastic pipe; and an adjusting device is arranged on the elastic pipe and comprises a clamp and an adjusting rod passing through and slidably connected with the clamp. The quantitative powder mixing machine realizes automatic proportioning and mixing of a plurality of materials and quantitative discharging through adjustment of the feed amounts of a plurality of feed inlets, reduces operation steps, lowers dust concentration during mixing, improves production efficiency and decreases cost.

Owner:TIANJIN RONG LEE BIOTECH DEV CO LTD

Method for preparing luminescent band gap tunable double-light emitting manganese doping perovskite nano-crystal

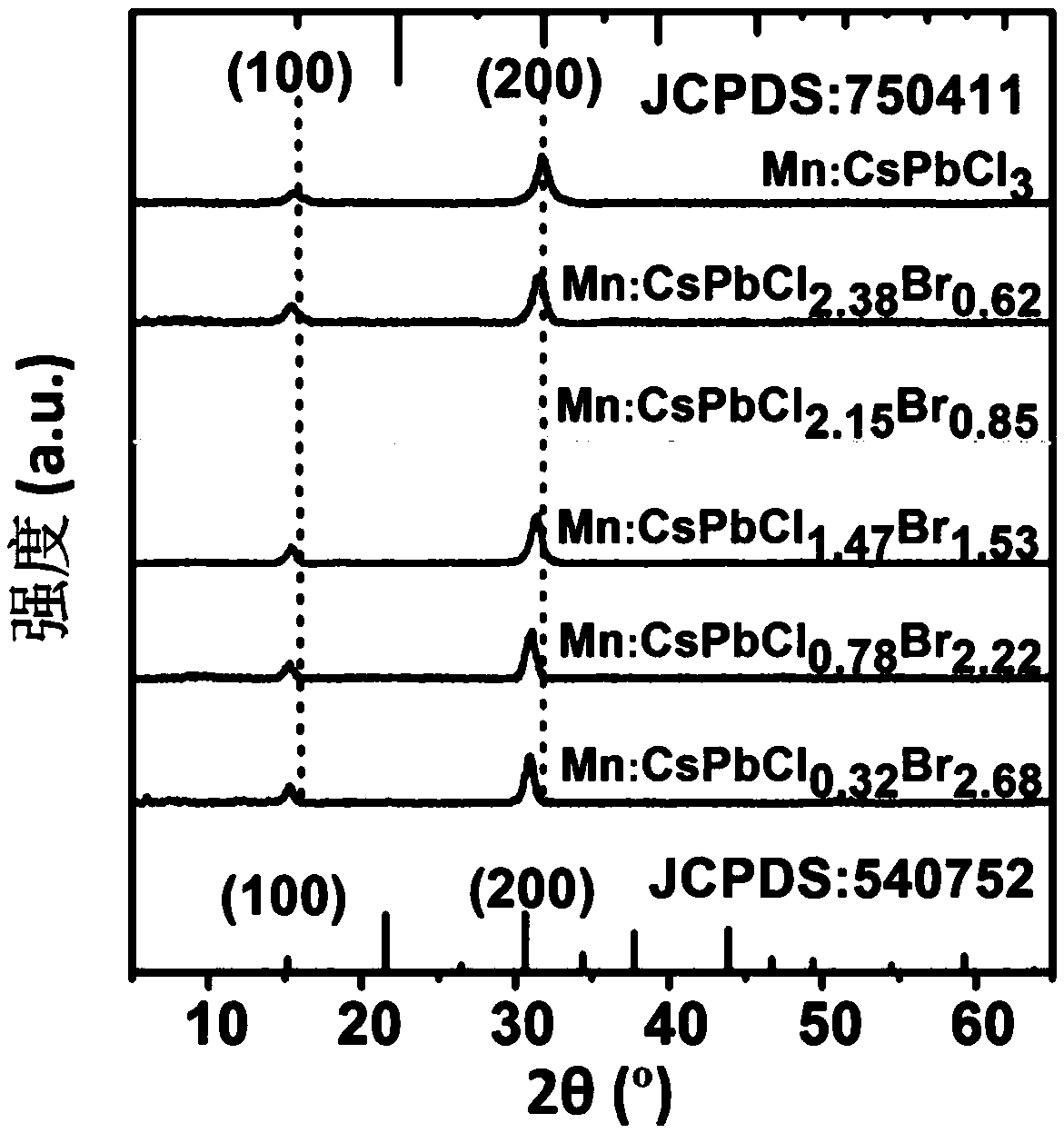

InactiveCN108865126ALuminous color continuous tuningHigh photoluminescence efficiencyNanoopticsLuminescent compositionsTrioctylphosphineIon exchange

The invention provides a method for preparing luminescent band gap tunable double-light emitting manganese-doping perovskite nano-crystal, and belongs to the technical field of material preparation. The method comprises: firstly mixing cesium carbonate, oleic acid, and octadecene, obtaining a cesium oleate precursor solution; mixing lead bromide, oleylamine, oleic acid and octadecene, obtaining alead bromide precursor solution; mixing lead chloride, manganese chloride, and octadecene, obtaining a first mixed solution; adding oleylamine, oleic acid, and tri-n-octylphosphine to the first mixedsolution, obtaining a second mixed solution; adding the cesium oleate precursor solution to the second mixed solution, to obtain Mn:CsPbCl3 nano-crystal solution; injecting the lead bromide precursorsolution to the Mn:CsPbCl3 nano-crystal solution, and stirring, preparing Mn:CsPbCl3-xBrx nano-crystals, wherein X is greater than 0 but less than 3. By adopting the method provided by the invention,the luminescent band gap of the manganese-doping perovskite nanocrystals and continuous tuning of the corresponding illuminating color are realized through anion exchange.

Owner:JILIN NORMAL UNIV

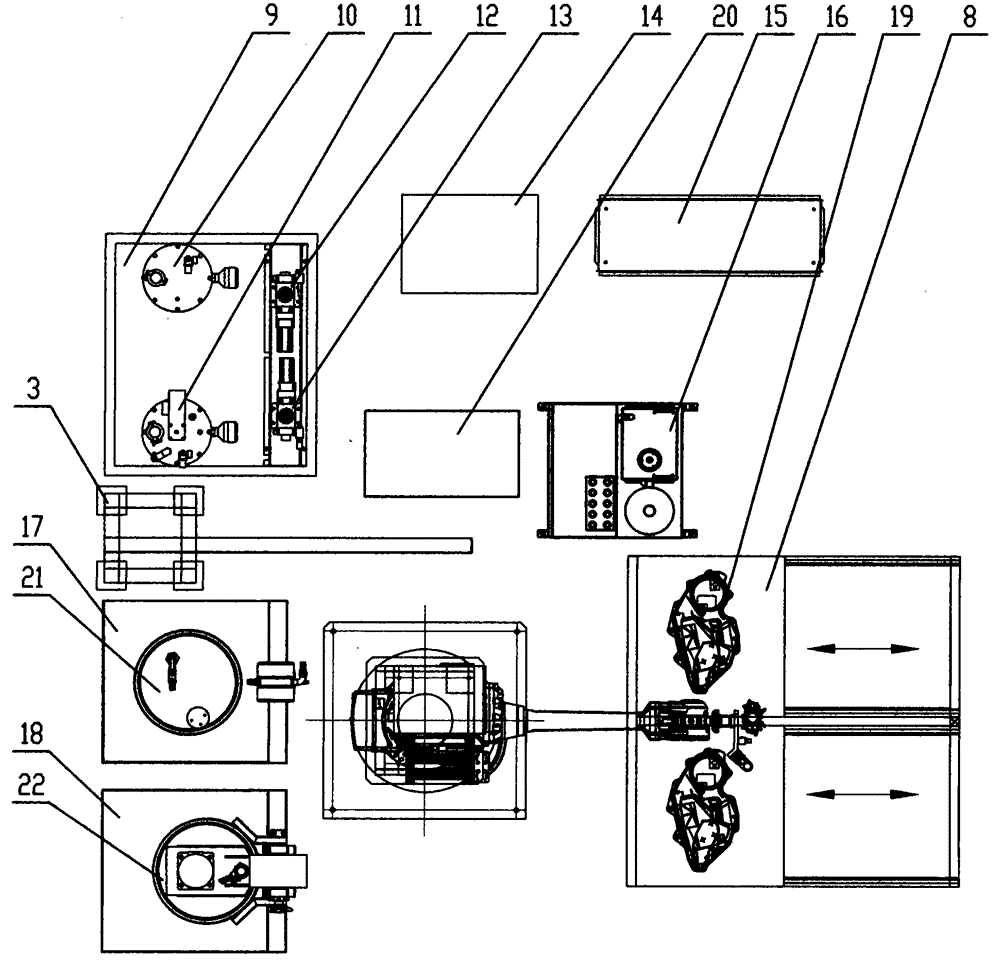

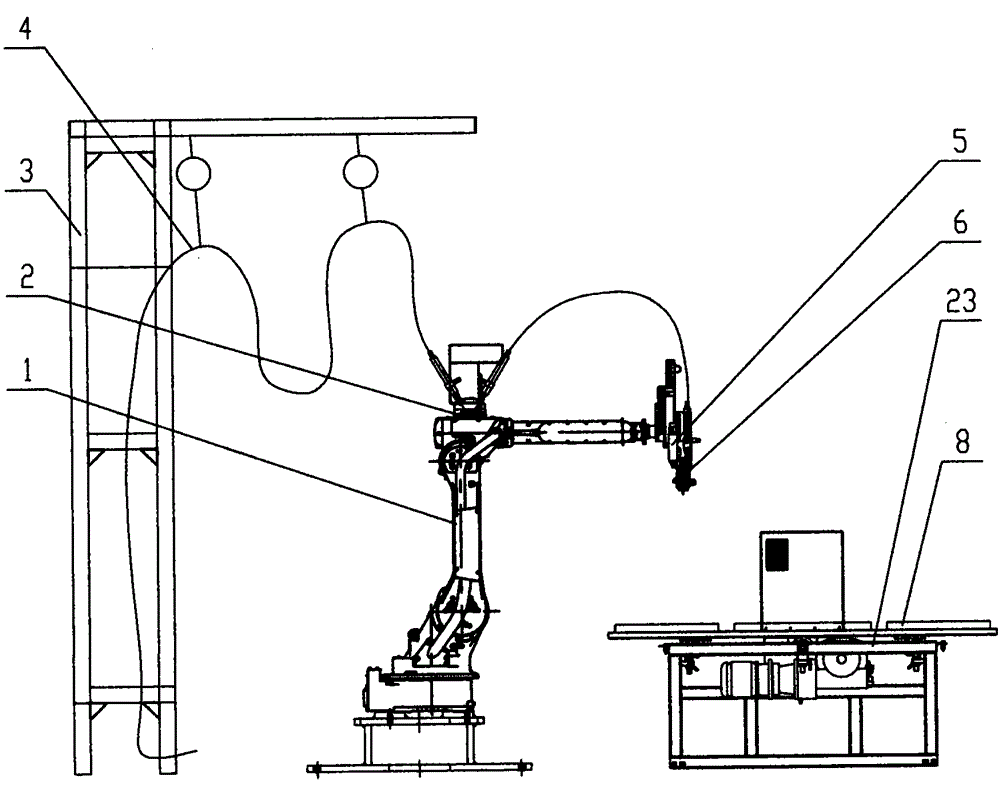

Five-axis robot gumming equipment and technology

ActiveCN104971862ASimple processFast processingProgramme-controlled manipulatorSpraying apparatusMetering pumpArthrobotrys

The invention relates to the technical field of gumming, in particular to five-axis robot gumming equipment and a technology which are used for two-component polyurethane gumming. The five-axis robot gumming equipment is characterized by comprising a five-axis robot, a gum supply device, a two-component gumming head, a double-station automatic gumming workbench or multi-station automatic and rotary gumming workbench, plasma processing equipment, a waste washing liquid recycling device and an intelligent control system. The five-axis robot is a five-joint robot. A workpiece is put on the double-station automatic gumming workbench or multi-station automatic and rotary gumming workbench. The workpiece is fixed or can rotate or swing or move along one axis. The two-component gumming head and aplasma processing head can achieve five-axis linkage. The gum supply device comprises a gum A barrel, a gum B barrel, a gum A metering pump, a gum B metering pump, a gum pipe, a gum supply pipeline, a pipeline support, a gum A material barrel and a gum B material barrel. The polyurethane gumming equipment and the technology are novel, accurate in matching ratio, stable in adhesive tape performance and good in sealing effect.

Owner:DALIAN HUAGONG INNOVATION TECH

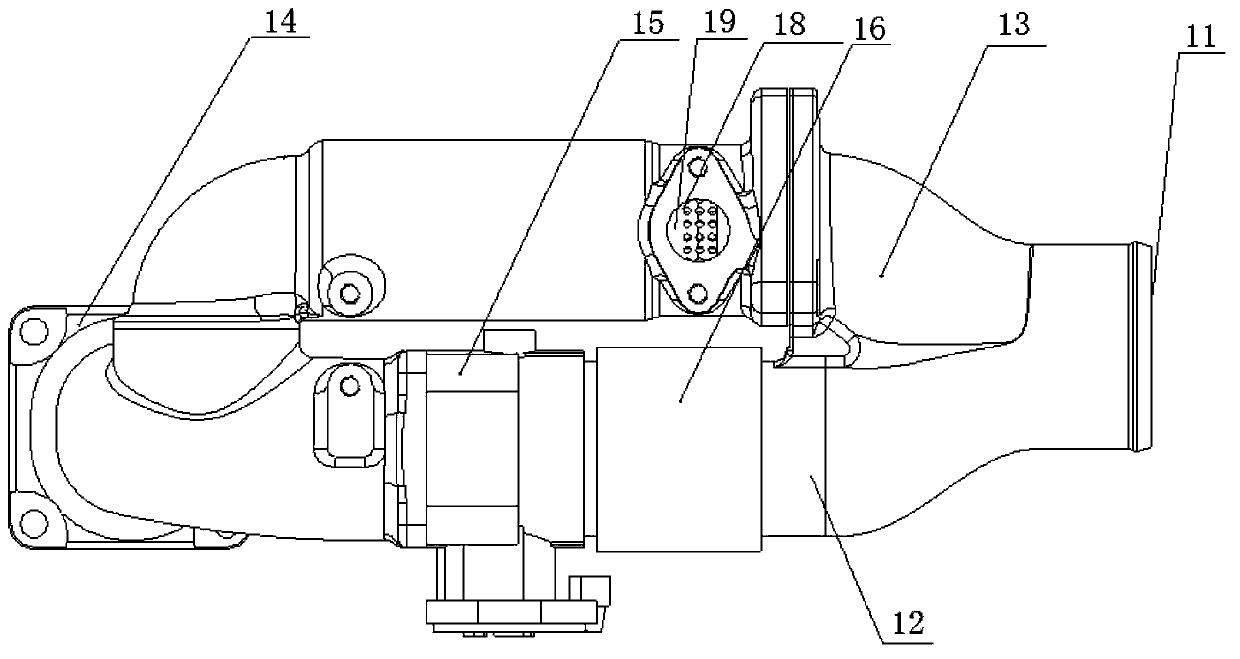

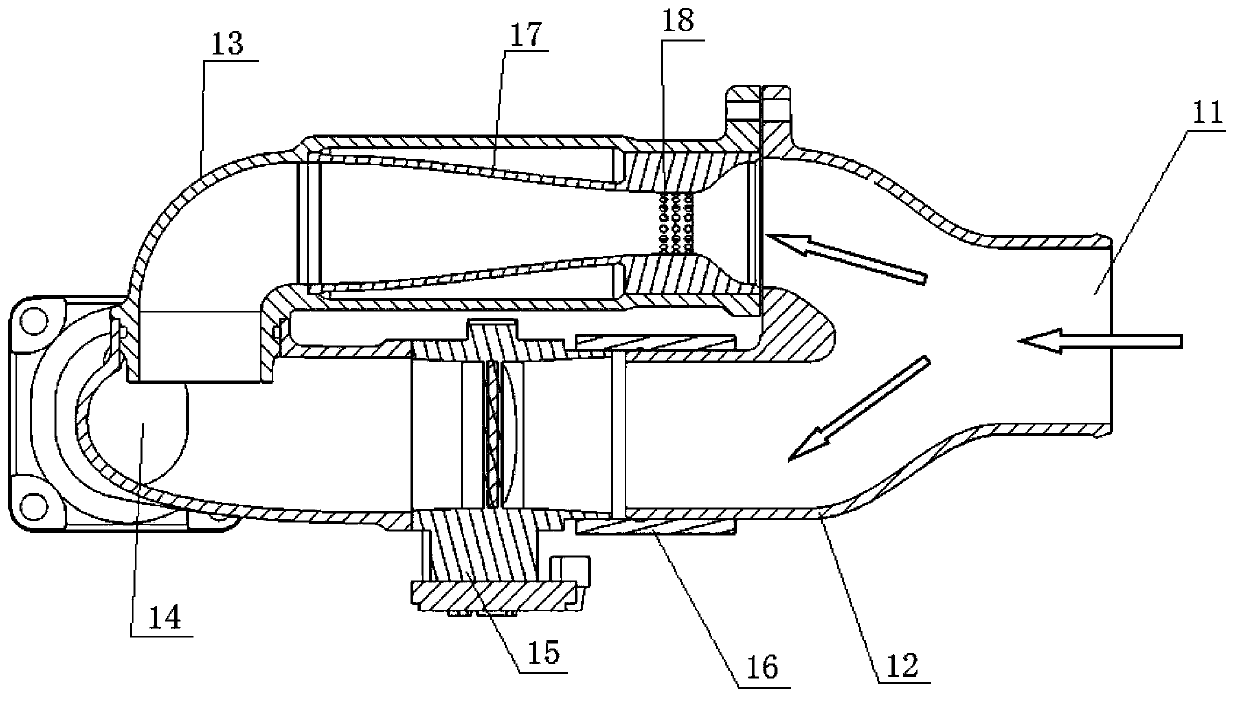

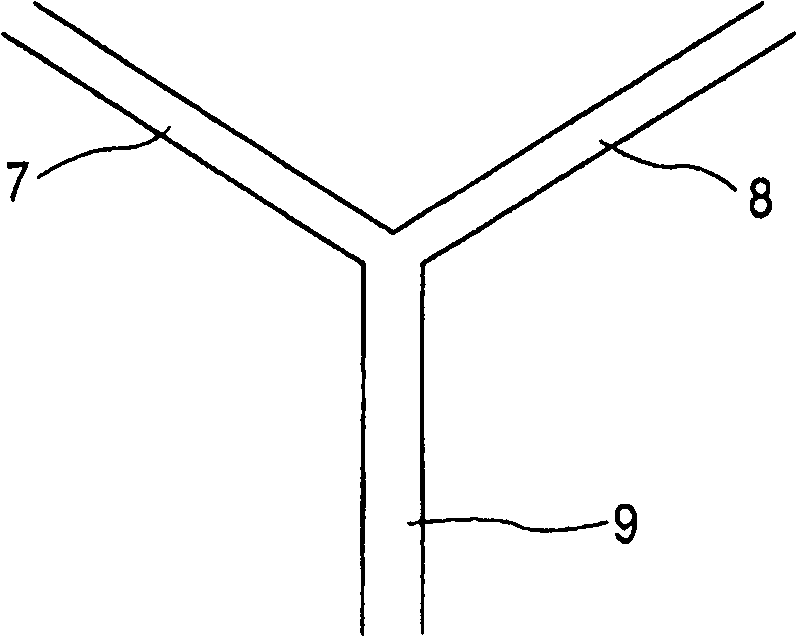

Air inlet connecting pipe of EGR engine

InactiveCN103397959AImprove mixing uniformityIncrease consumption rateNon-fuel substance addition to fuelInternal combustion piston enginesElectronic throttleEngineering

The invention discloses an air inlet connecting pipe of an EGR engine. The air inlet connecting pipe comprises a fresh air inlet single pipe and an exhaust gas mixing tube. The two ends of the fresh air inlet single pipe are provided with a sharing air inlet and a sharing air outlet respectively. The sharing air inlet is connected with a device used for providing fresh air, the sharing air outlet is connected with an air inlet pipe, and an electronic throttle valve which is in control connection with an engine ECU is connected between the sharing air inlet and the sharing air outlet in series. The exhaust gas mixing tube uses the sharing air inlet together with the fresh air inlet single pipe, and an air outlet of the exhaust gas mixing tube is connected into the fresh air inlet single pipe on the upstream portion of the sharing air outlet. A Venturi tube is additionally arranged in the exhaust gas mixing tube, an exhaust gas channel hole which is led to the inside of the Venturi tube is formed in the throat portion of the equal diameter of the Venturi tube, and an exhaust gas air inlet is formed in the side wall of the exhaust gas mixing tube corresponding to the exhaust gas channel hole. According to the air inlet connecting pipe of the EGR engine, a double-channel air inlet mode is adopted, the mixing uniformity of exhaust gas and the fresh air is improved, and nitric oxide in the exhaust gas can be effectively lowered.

Owner:GUANGXI YUCHAI MASCH CO LTD

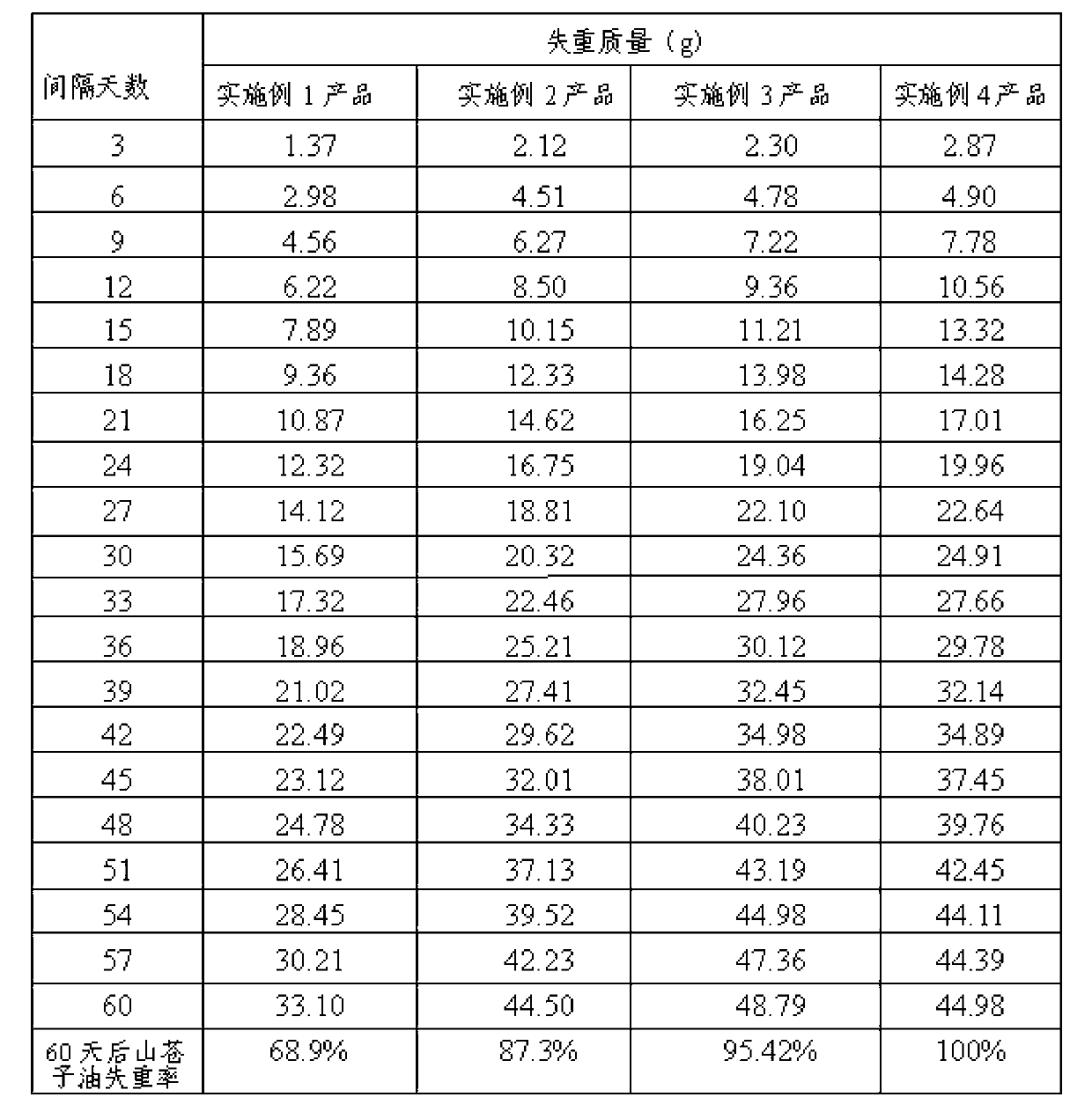

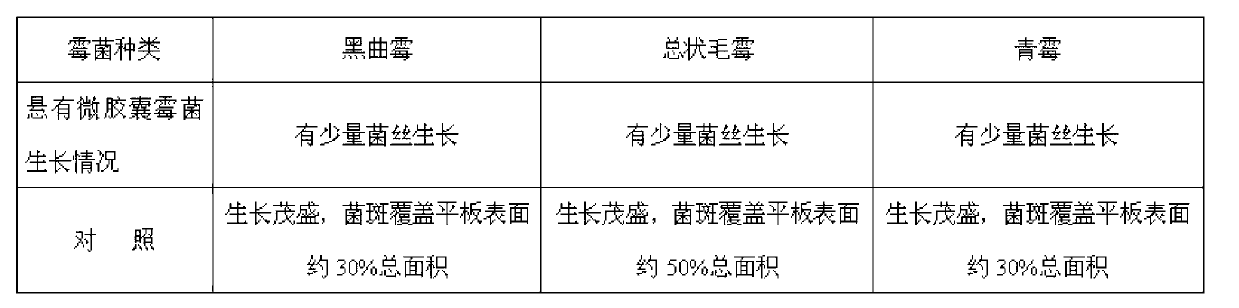

Litsea cubeba oil mildew and moth proof slow release microcapsule and preparation method

The invention provides a litsea cubeba oil mildew and moth proof slow release microcapsule and a preparation method. The Litsea cubeba oil mildew and moth proof slow release microcapsule comprises a wall material and the wall material-coated litsea cubeba oil, the wall material is prepared by employing ethyl cellulose, high-substitution hydroxypropyl cellulose, Arabic gum and maltodextrin. The preparation method comprises the following steps: dissolving ethyl cellulose by N-methyl-2-pyrrolidone to obtain ethyl cellulose viscous fluid; taking high-substitution hydroxypropyl cellulose, Arabic gum and maltodextrin and mixing by water to completely dissolve, adding the prepared ethyl cellulose viscous fluid, then adding the litsea cubeba oil under stirring, dispersing with high speed, homogenizing, spraying and drying to obtain the products. According to the invention, the screened wall material enables penetration and diffusion on the litsea cubeba oil, and enables optimization of the microcapsule preparation technology; the screened wall material can be prepared to the solid state microcapsule mildew and moth proof product with characteristics of green health, high efficiency and notoxicity, convenient usage and slow release property.

Owner:HUBEI UNIV +1

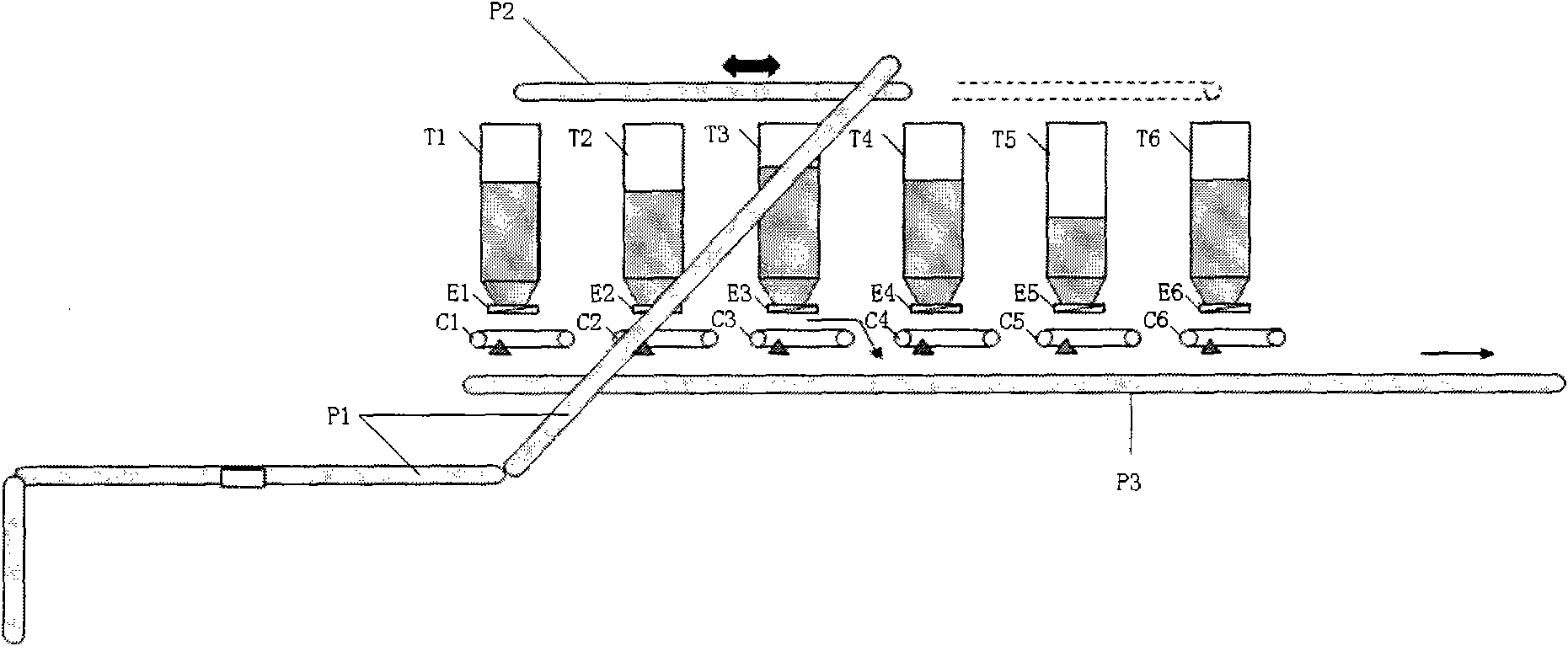

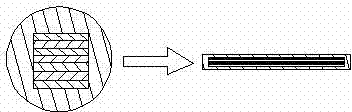

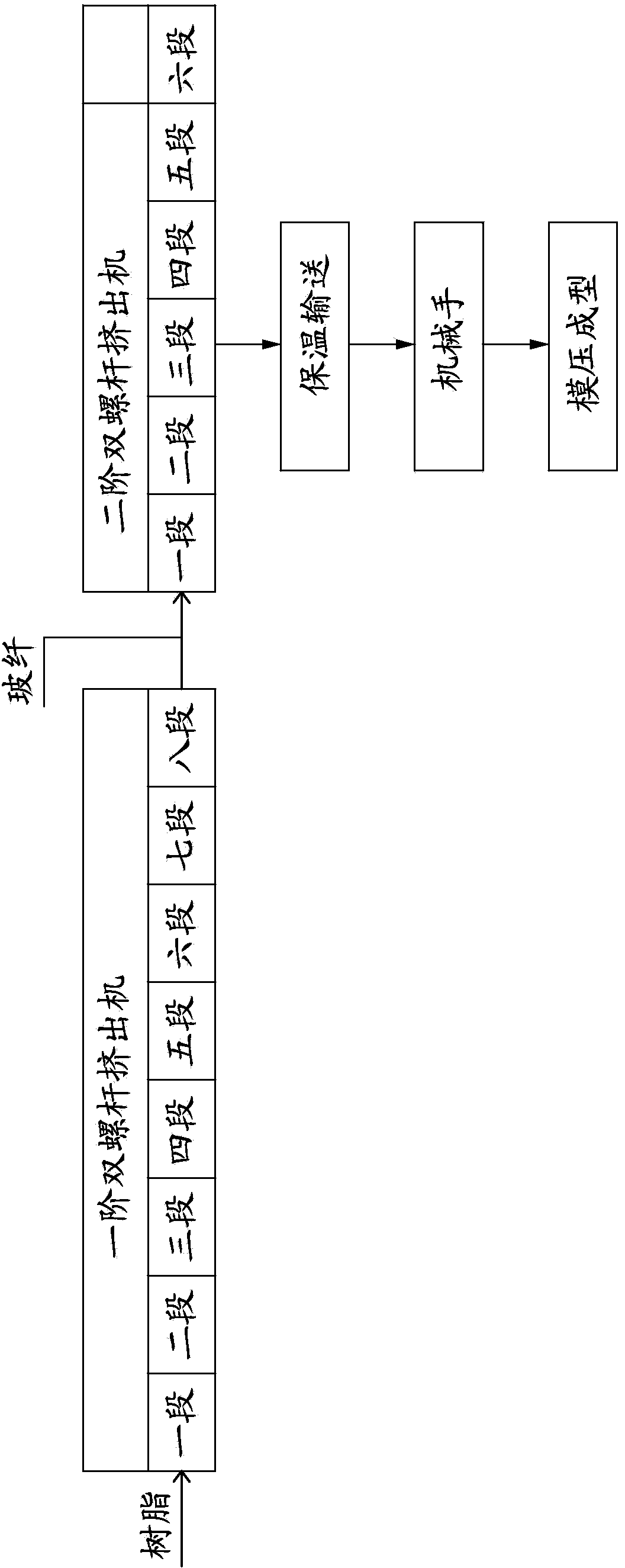

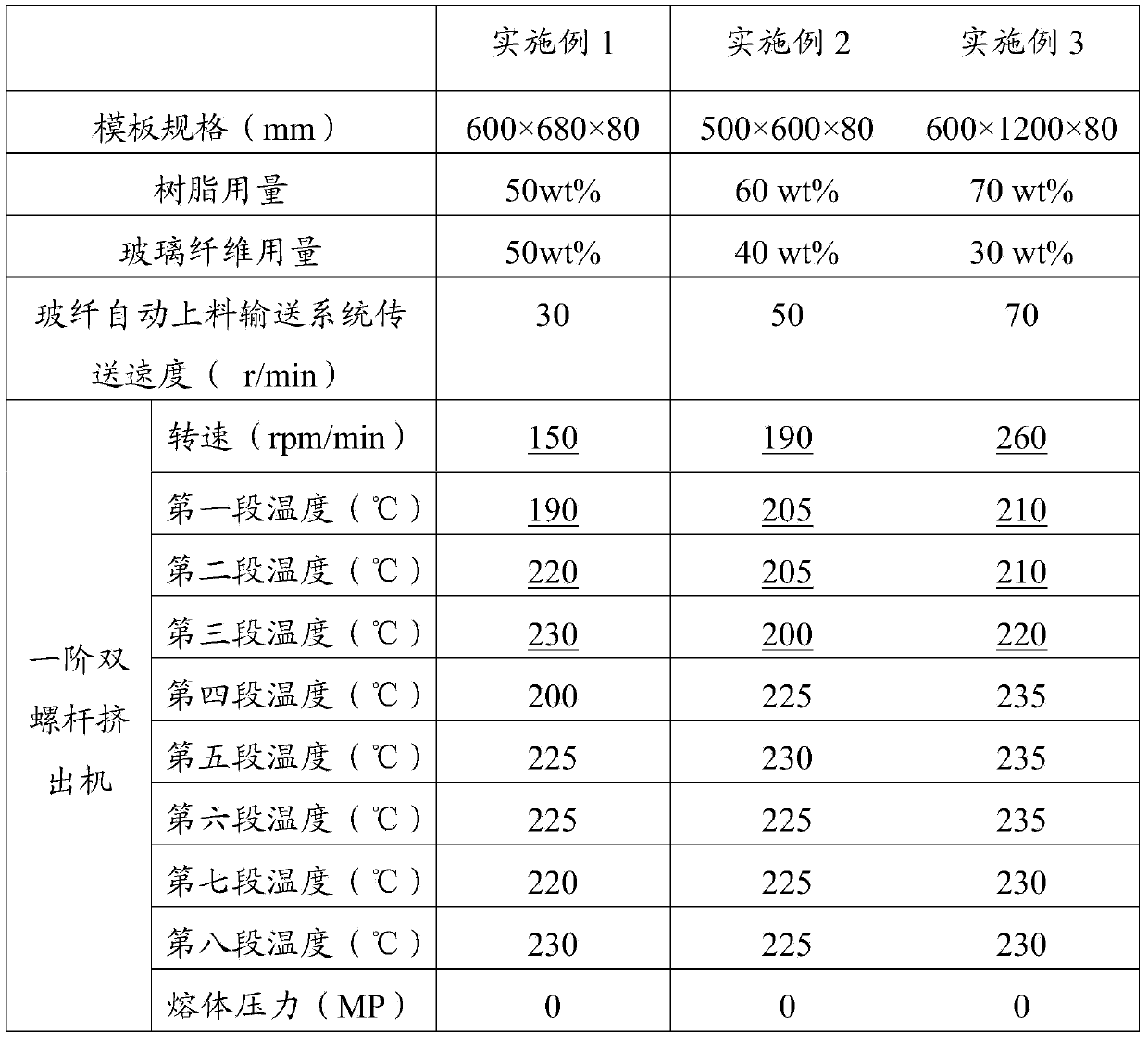

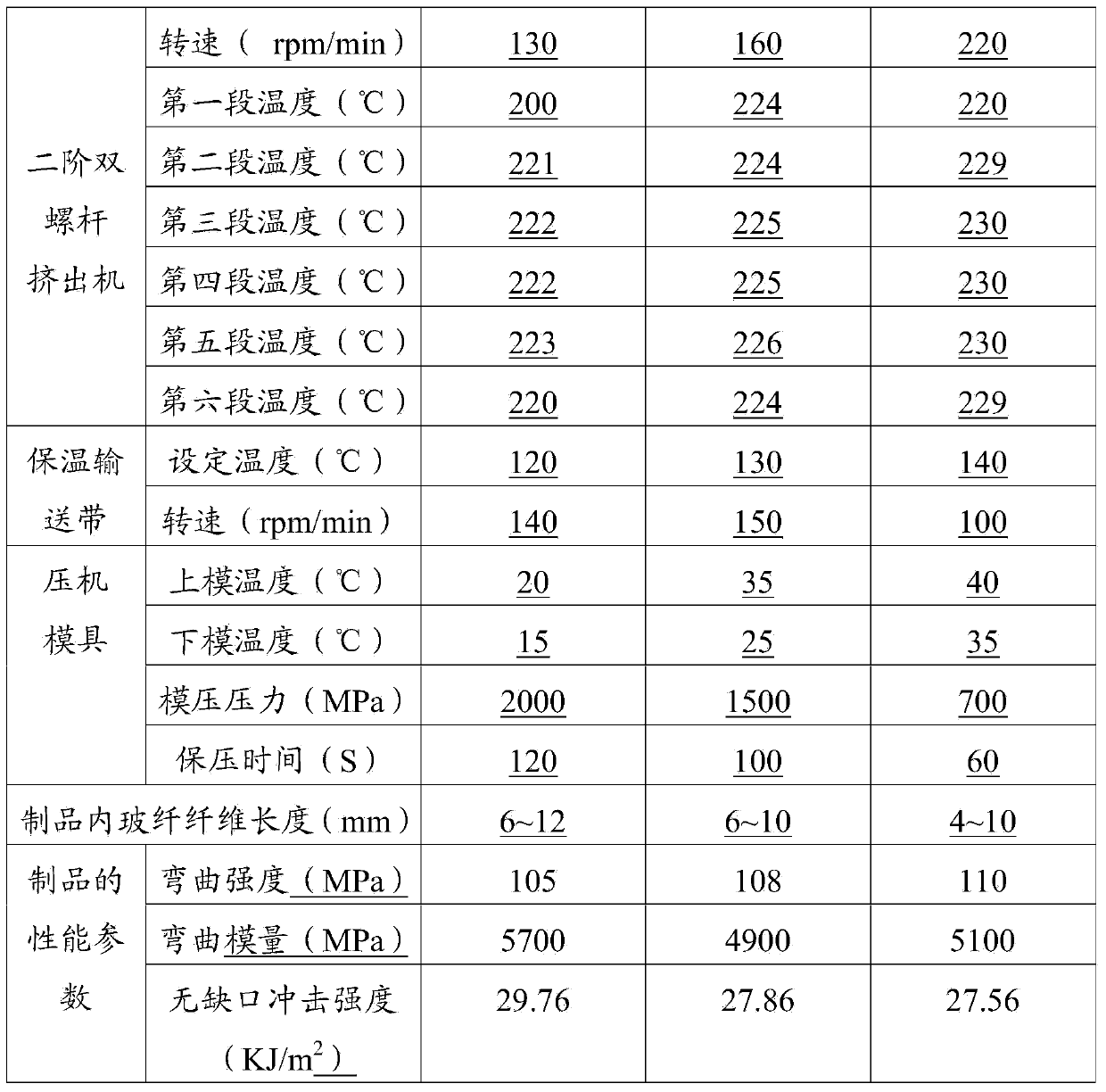

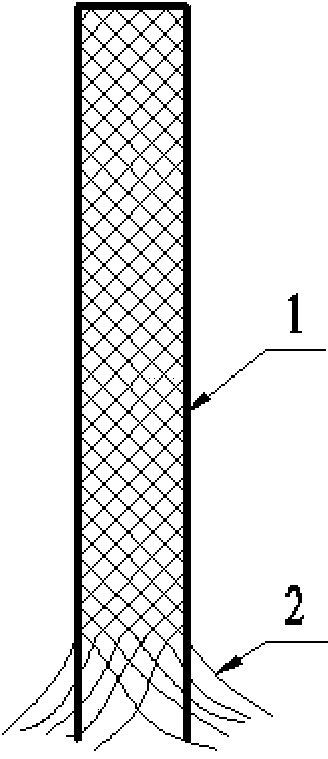

LFT-D (Long Fiber Reinforced Thermoplastic Direct) forming process of composite building template

The invention provides an LFT-D (Long Fiber Reinforced Thermoplastic Direct) forming process of a composite building template. The forming process comprises the following steps of (10) performing quantitative measurement on resin from a vacuum feeding system to a vector type weighing system according to the weight of the template; then feeding the resin to a first-stage twin-screw extruder to be heated and fused; feeding into a second-stage twin-screw extruder in a feed opening of the second-stage twin-screw extruder together with glass fibers, so as to be mixed and plasticized, wherein the glass fibers are cut according to the set length of 24 to 25mm by a glass fiber measuring and cutting device and then are added into the fused resin; performing the secondary length change under the shearing action of the fused resin; and (20) uniformly plasticizing by the second-stage twin-screw extruder, cutting raw materials by a second-stage screw die cutter according to the weight of the template, then insulating and conveying to a material taking and displacement position and putting the raw materials into a press mold by a manipulator for pressing and forming. By using the forming process, the glass fibers in a product are long, and the performance of a product is effectively improved.

Owner:福建易安特新型建材有限公司

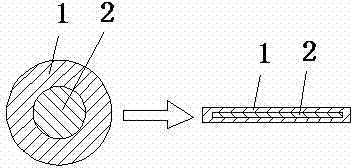

Molding method of continuous fiber reinforced thermoplastic resin-based composite material

The invention provides a molding method of a continuous fiber reinforced thermoplastic resin-based composite material. The molding method comprises the following steps: weaving resin monofilaments and continuous fiber yarn tows to form composite yarns in advance, wherein a resin matrix wraps the surface of the continuous fiber yarn tows in the composite yarns; and next, heating and mold-pressing, wherein the resin matrix and continuous fibers are well immersed and combined during the heating and pressing process, the ratio of the continuous fibers in the composite material can be accurately controlled, and cavity types with different shapes can be designed for a mold so as to form solid bars with specific cross-section profiles. The molding method is applicable to molding of composite material products with relatively complex shapes, the products can be molded once, and thus the production efficiency is high; the continuous fibers are uniformly distributed in the composite material, so that the problem of apparent fiber layering is avoided and the intensity of the composite material products is greatly increased.

Owner:AEROSPACE PRECISION PROD INC LTD

Preparation method of epoxy resin-based polymer dispersion liquid crystal film material

ActiveCN102321233AImprove electro-optic performanceHigh peel strengthLiquid crystal compositionsEpoxy resin adhesivesEpoxyPolymer science

The invention belongs to the field of application of liquid crystal materials, and particularly relates to a preparation method of an epoxy resin-based polymer dispersion liquid crystal film material. The preparation method comprises the following steps of: uniformly mixing liquid crystals, a thermal polymerization monomer, a curing agent and glass microspheres and clamping the mixture between two tin indium oxide-plated conductive films; uniformly pressing with a rolling shaft to form a film layer of which the thickness is 20-30 microns, wherein the liquid crystals account for 40 percent by mass of the total mass of the mixture, the curing agent accounts for 20-30 by mass of the total mass of the thermal polymerization monomer, and the glass microspheres account for 0.1-0.5 percent by mass of the total mass of the mixture; and thermally curing at the temperature 70-80 DEG C for 6-8 hours to obtain the polymer dispersion liquid crystal film. According to the preparation method, the crosslinking density of a polymer is increased, the meshes of the polymer are reduced, the open state transmission is lowered, the contrast is increased, and the electro-optic performance of the polymerdispersion liquid crystal film is improved. Moreover, the content of the liquid crystals is reduced, and the preparation cost is reduced greatly.

Owner:扬州晶彩光电科技有限公司

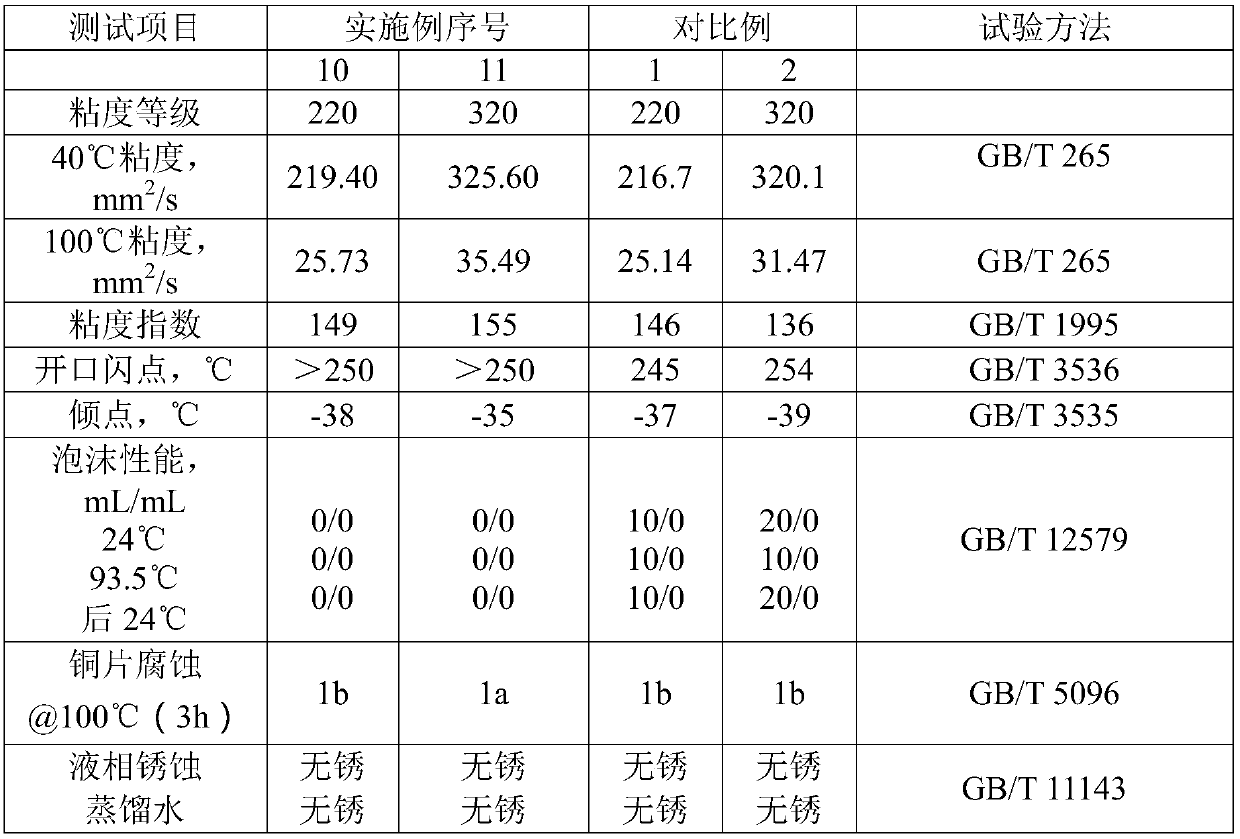

Fully synthetic anti-micropitting wind power gear oil composition and preparation method thereof

ActiveCN109536248ASmall thermal evaporation lossImprove solubilityBase-materialsMass ratioAntioxidant

A fully synthetic anti-micropitting wind power gear oil composition and a preparation method thereof are disclosed, belonging to the technical field of lubricating oil. The composition includes, by mass, 1-5% of an extreme pressure agent, 0.5-3% of anti-wear agent, 0.5-3% of an antioxidant, 0.1-2% of a rust inhibitor, 0.1-1% of a metal deactivator, 0.1-0.5% of an anti-emulsifier and 0.01-0.1% of an antifoaming agent, with the balance being base oil. The base oil is a mixture of poly(alpha-olefin) base oil and ester type base oil in a mass ratio of 7-10:1. The composition is used for gear casesof wind power equipment, evaporation loss of fully synthetic oil is low, and the composition can be used for long time in severe working conditions and climatic conditions, and has advantages of goodresistance to micropitting, high temperature detergency, good wear resistance, good low-temperature fluidity, good oxidation stability, and the like. The poly(alpha-olefin) and ester are adopted as base oil, thus ensuring a high viscosity index and good shear stability of the gear oil and prolonging the service lifetime of the gear oil.

Owner:新疆金雪驰科技股份有限公司 +3

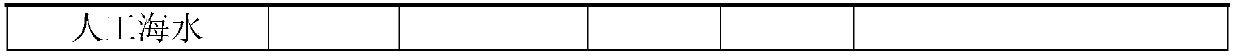

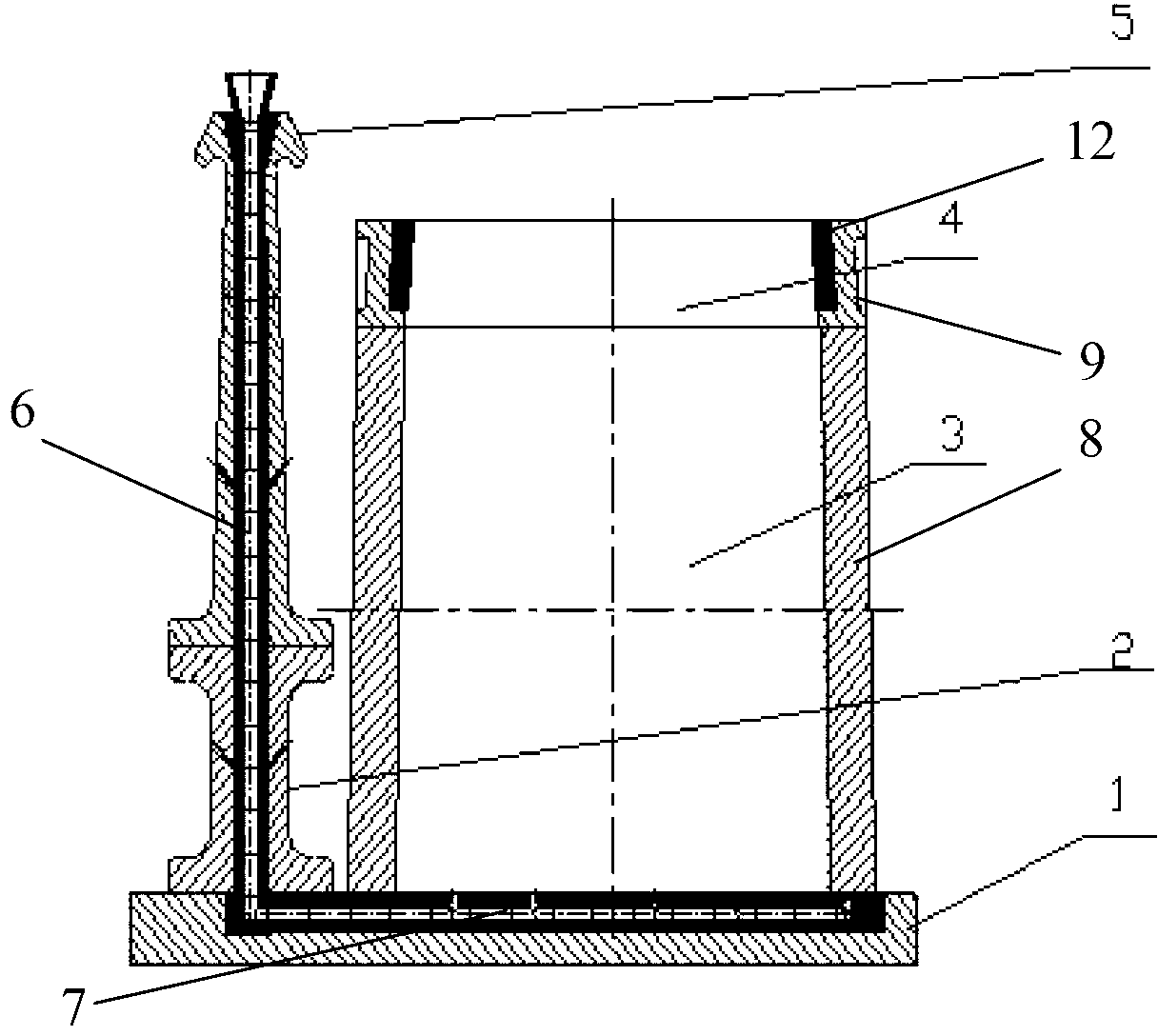

Preparation method and mold for microdefect high-utilization rate high-quality static ingot

The invention relates to the field of static ingot preparation, in particular to a preparation method and a mold for a microdefect high-utilization rate high-quality static ingot. The invention is applied to preparing carbon steel, alloy steel and nonferrous metals under vacuum and non-vacuum conditions and has an effect of inhibiting defects, such as shrinkage cavity and porosity, segregation and deposit cone in ingots of various materials. Through adopting a big end down mold design, microzone triggered nucleation is performed by adopting a vibration device to refine grains; a dead head is heated by adopting plasma submerged arc heating; the ingot is demolded by adopting the high-temperature demolding process; thermal insulation is performed on a demolded ingot by adopting a thermal insulation material, and therefore, the thermal stress of the center of the ingot is reduced, and the shrinkage cavity and porosity defect in the ingot is eliminated by adopting an ingot self-feeding mechanism. According to the preparation method and the mold for the microdefect high-utilization rate high-quality static ingot, the problem of the shrinkage cavity and porosity defect in the ingot is effectively solved, the dimension of the dead head is reduced, and the utilization rate and the production efficiency of the ingot are greatly improved.

Owner:中科西王特钢有限公司

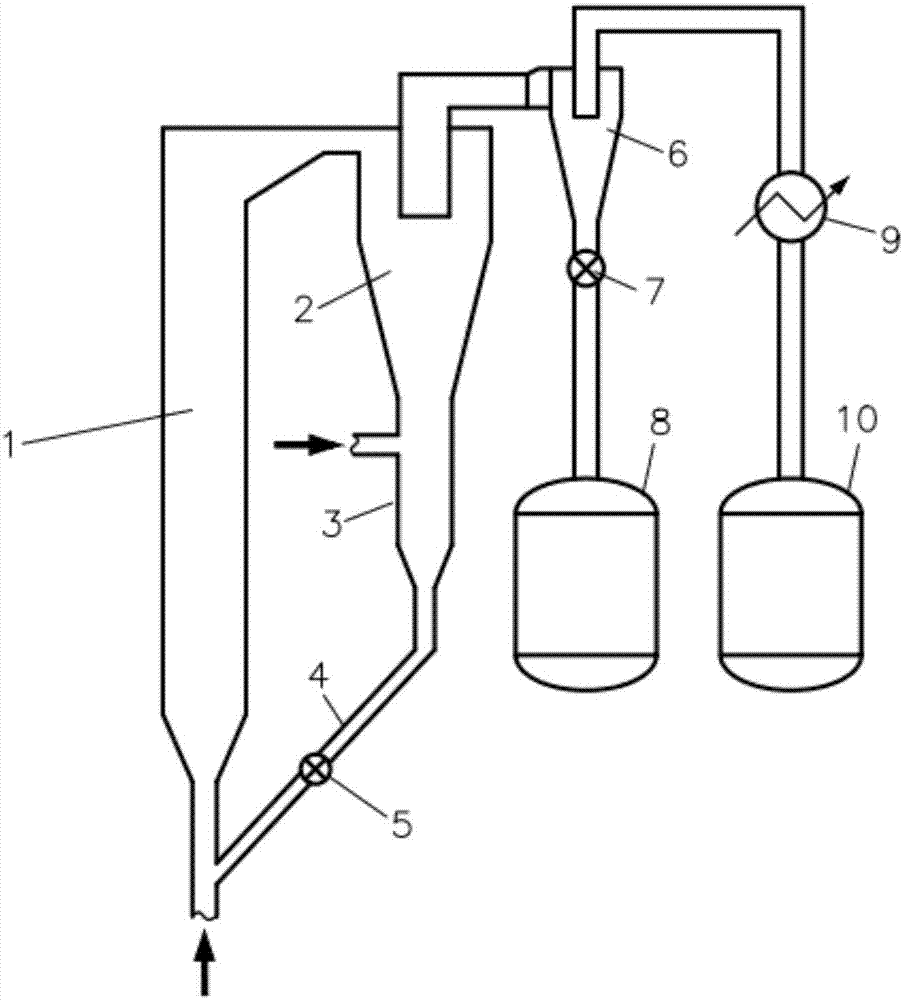

Circulating fluidized bed system and method for production of hydrogen fluoride from fluorite powder

ActiveCN107311109AFlow fastAvoid abnormal phenomena such as agglomeration and sticking to the wallHydrogen fluorideChemical/physical processesGas solidHydrogen fluoride

The invention discloses a circulating fluidized bed system and method for production of hydrogen fluoride from fluorite powder. The system comprises a reactor, a circulating part, a solid separation part and a gas condensation part, wherein the reactor is the place where a reaction takes place; the circulating part separates unreacted solids, allows the unreacted solids to settle and then returns the unreacted solids to the reactor for the reaction again; the solid separation part separates a gas-solid two-phase product and collects totally reacted solids as a solid product; and the gas condensation part liquefies and collects a gas product left after separation in the solid separation part. According to the invention, abnormal phenomena such as agglomeration and adhesion onto walls are avoided; mass transfer and heat transfer efficiency is improved; the circulation rate of a circulating fluidized bed is controlled by controlling the amount of gas and controlling the opening of a valve on an inclined tube, and the ratio of the separated solid product is controlled so as to control the reaction degree of the solids; liquid condensation is controlled via the temperature and amount of a condensate; and when the gas product contains other impurities, multi-stage condensers can be installed so as to control product quality.

Owner:ZHEJIANG UNIV

Liquid discharge device and discharge method

Owner:CANON KK

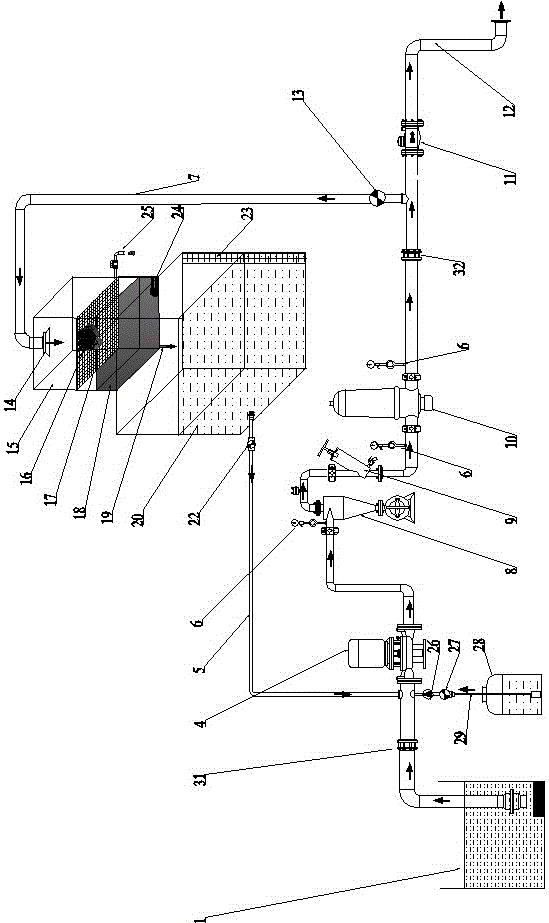

Water, fertilizer and pesticide integrated system based on drip irrigation head and control method of system

ActiveCN106416573ASolve the problem of uneven fertilization and pesticide applicationPracticalMeasurement devicesPressurised distribution of liquid fertiliserDrip irrigationDissolution

The invention discloses a water, fertilizer and pesticide integrated system based on a drip irrigation head and a control method of the system. The water, fertilizer and pesticide integrated system based on the drip irrigation head comprises a drip irrigation head system, a solid dissolution injection system and a liquid injection system, wherein the drip irrigation head system comprises a main irrigation pipeline provided with a first connecting part and a second connecting part sequentially in the water outlet direction, the solid dissolution injection system comprises a spraying, washing and dissolving tank with an opening at the upper part, a spray head is correspondingly arranged above the opening of the spraying, washing and dissolving tank and connected with the main irrigation pipeline at the second connecting part through a water spraying and supplying pipeline, and a spraying tank filtering net is paved in the spraying, washing and dissolving tank; a dissolving solution collecting tank is arranged below the spraying, washing and dissolving tank and connected with the main irrigation pipeline in the first connecting part through a dissolution liquid injection pipeline. Fertilizer application, pesticide application and drip irrigation are really integrated, so that the drip irrigation head becomes a part of the water, fertilizer and pesticide integrated system.

Owner:XUCHANG COMPANY OF HENAN TOBACCO +1

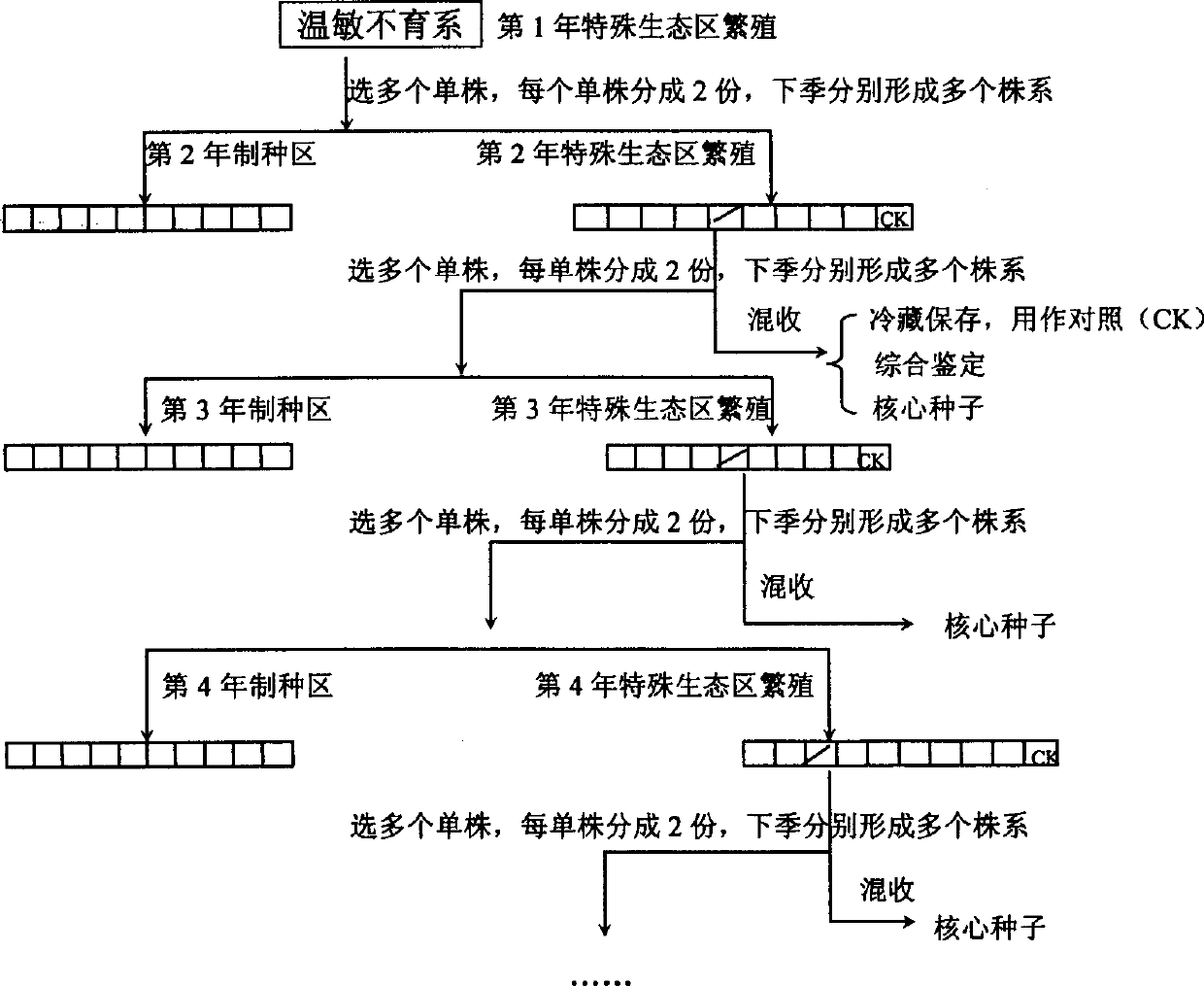

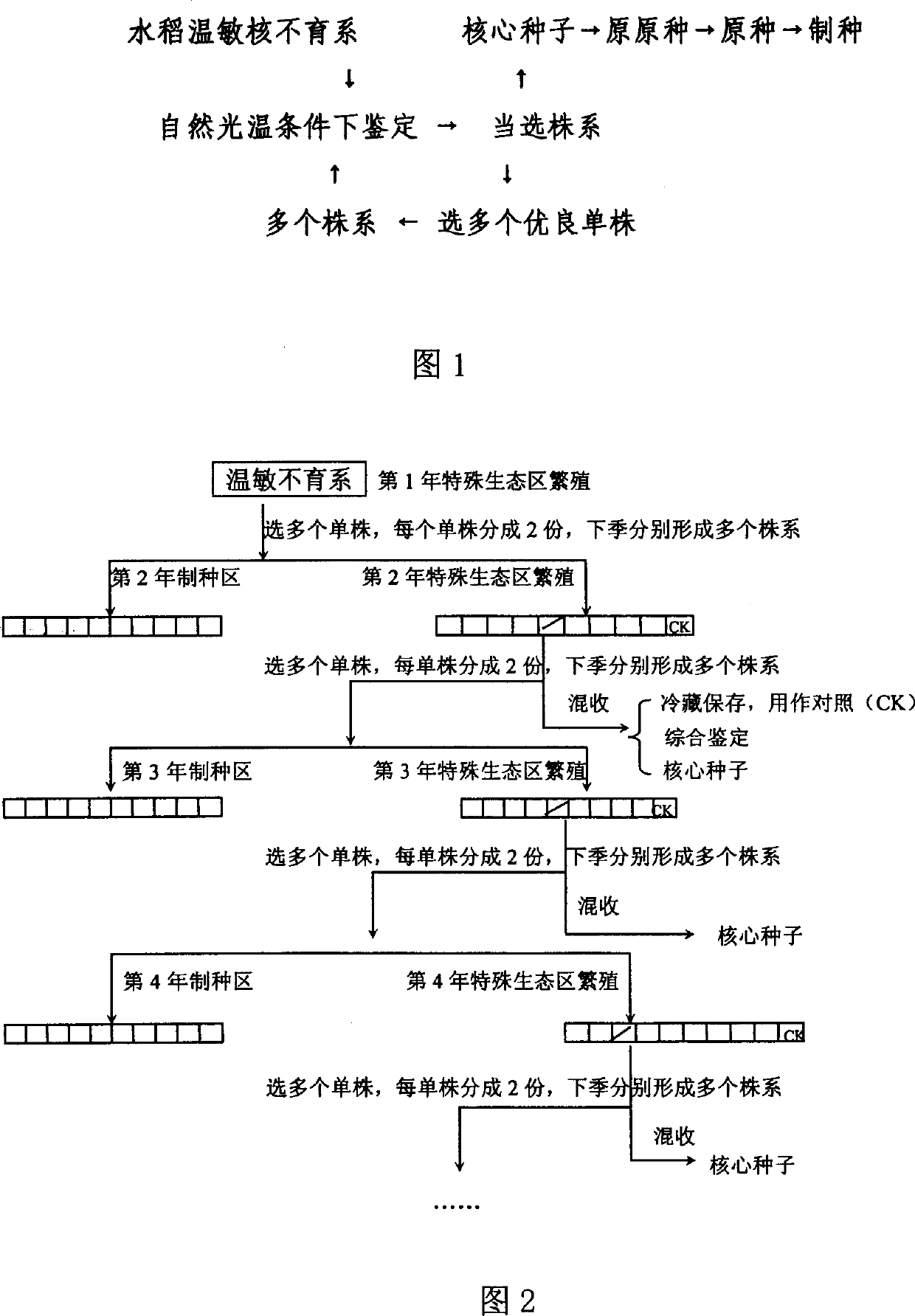

Method for breeding stock of rice temp-sensing sterile line and purifying origin temp

InactiveCN1784951AControl ratioStable starting temperatureHorticulture methodsPlant genotype modificationBiologyReproduction

A protospecies reproduction and origin temp purifying method for temp-sensitive sterile line of paddy rice is disclosed, which features that its selective breeding, protopecies reproduction and origin temp purifying can be conducted in the natural light temp condition. Its advantages are low cost and high safety.

Owner:隆平优粮(天津)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com