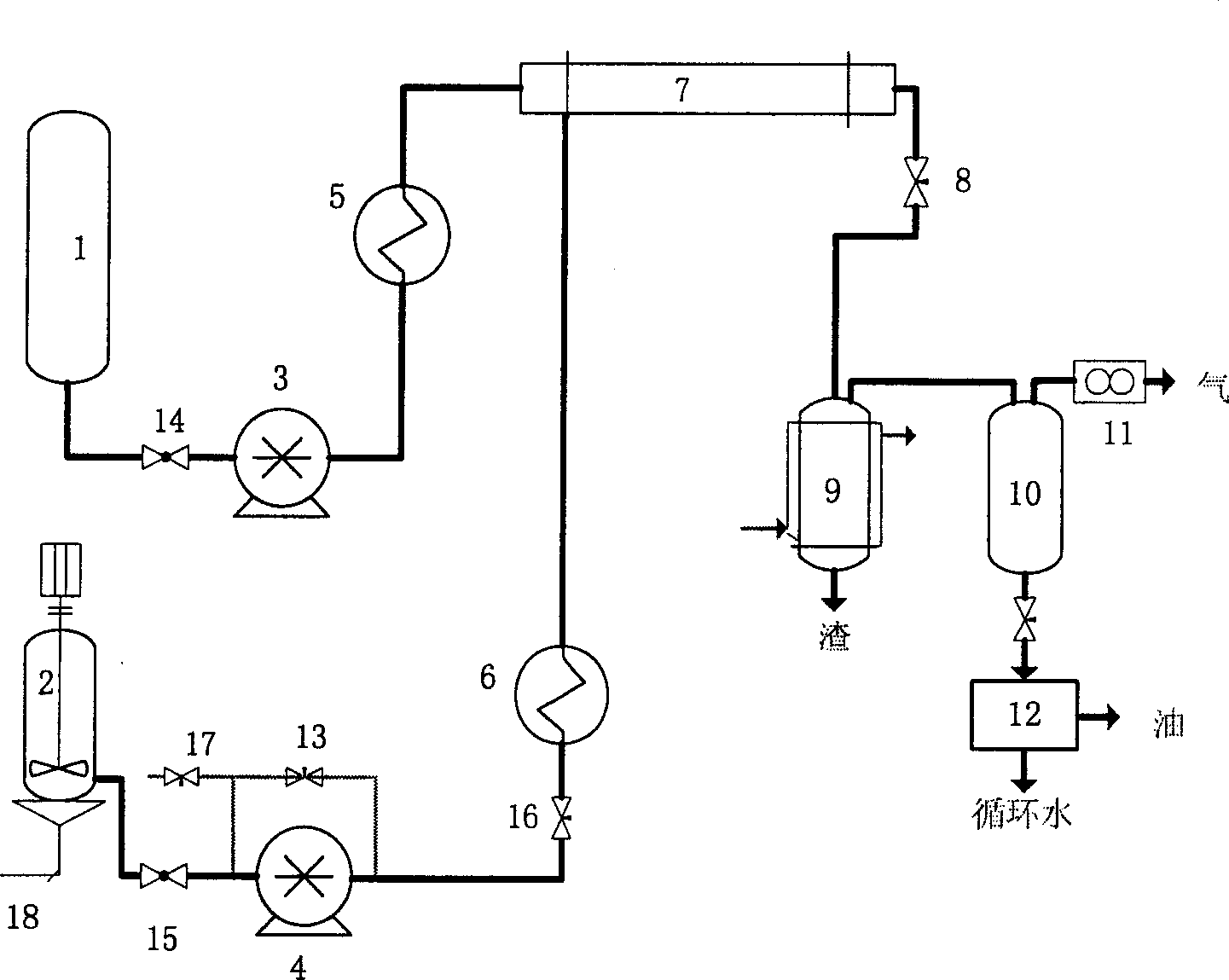

Method for continuous conversion of low-rank coal in subcritical water or supercritical water

A technology for supercritical water and low-rank coal, which is used in the preparation of liquid hydrocarbon mixtures, petroleum industry, solid solvent extraction, etc., to achieve the effects of simple process, short residence time and fast reaction speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The Xiaolongtan lignite with a water content of 14.8% is pulverized to 74 microns and mixed with water to form a 24.8wt% coal-water slurry and placed in the storage tank 2 . When the experiment started, the inlet valve 15 of the boiling coal slurry pump 4, the power switch of the boiling coal slurry pump 4, started the coal water slurry pump 4, and adjusted the flow rate to 4.5 kg / hour, and the coal water slurry was boosted to 24.5MPa; open the inlet valve 14 of the water pump 3, close the system outlet valve 8, start the water pump 3, adjust the flow rate of the water pump to 6.0 kg / hour, the water is boosted to 24.5MPa by the water pump 3, and preheated to 520 by the water preheater 5 ℃. The weight ratio of water to coal is about 9:1. After the temperature and pressure of each point in the system are stabilized, when the outlet pressure of the coal-water slurry pump is balanced with the system pressure of 24.5MPa, the outlet valve 16 of the boiling coal-water slurry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com