Patents

Literature

32results about How to "Change operating conditions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

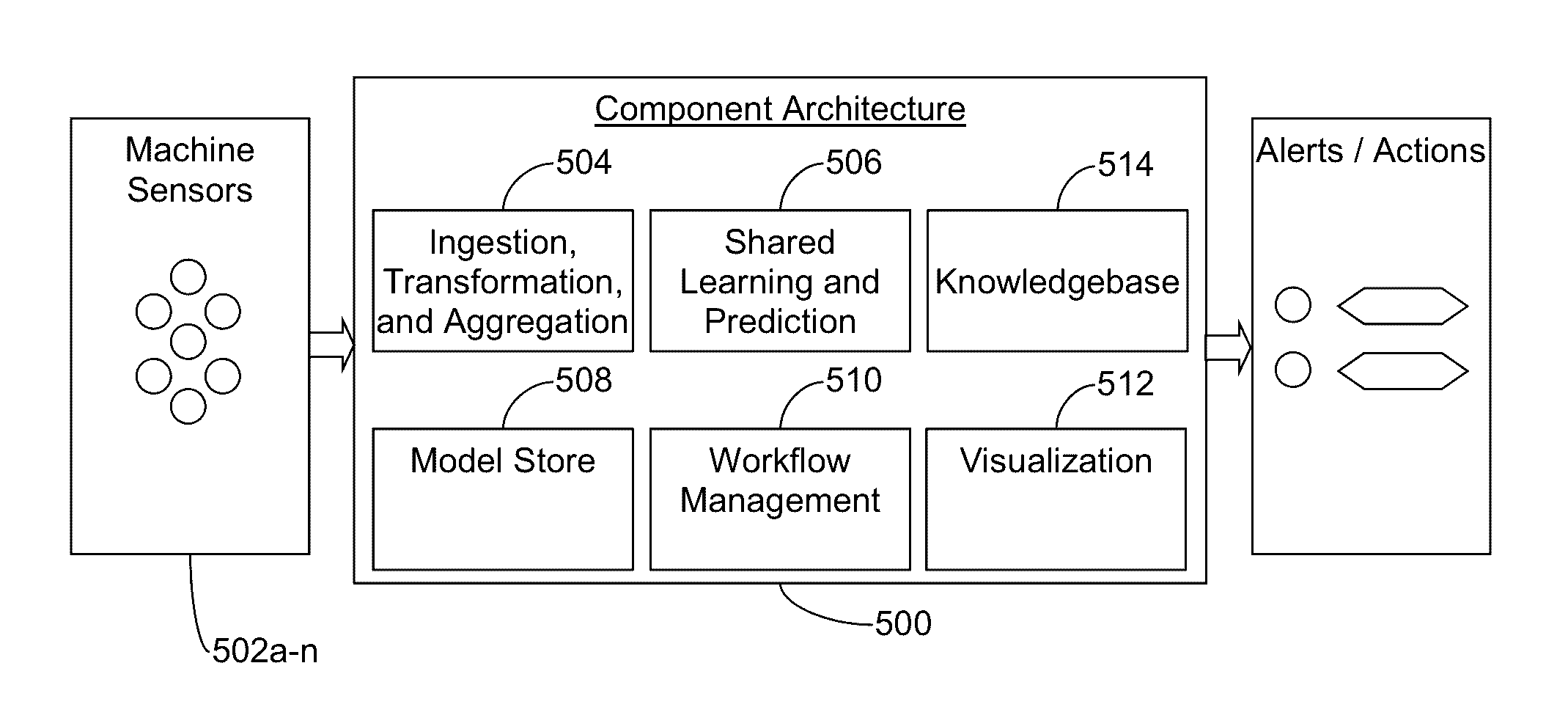

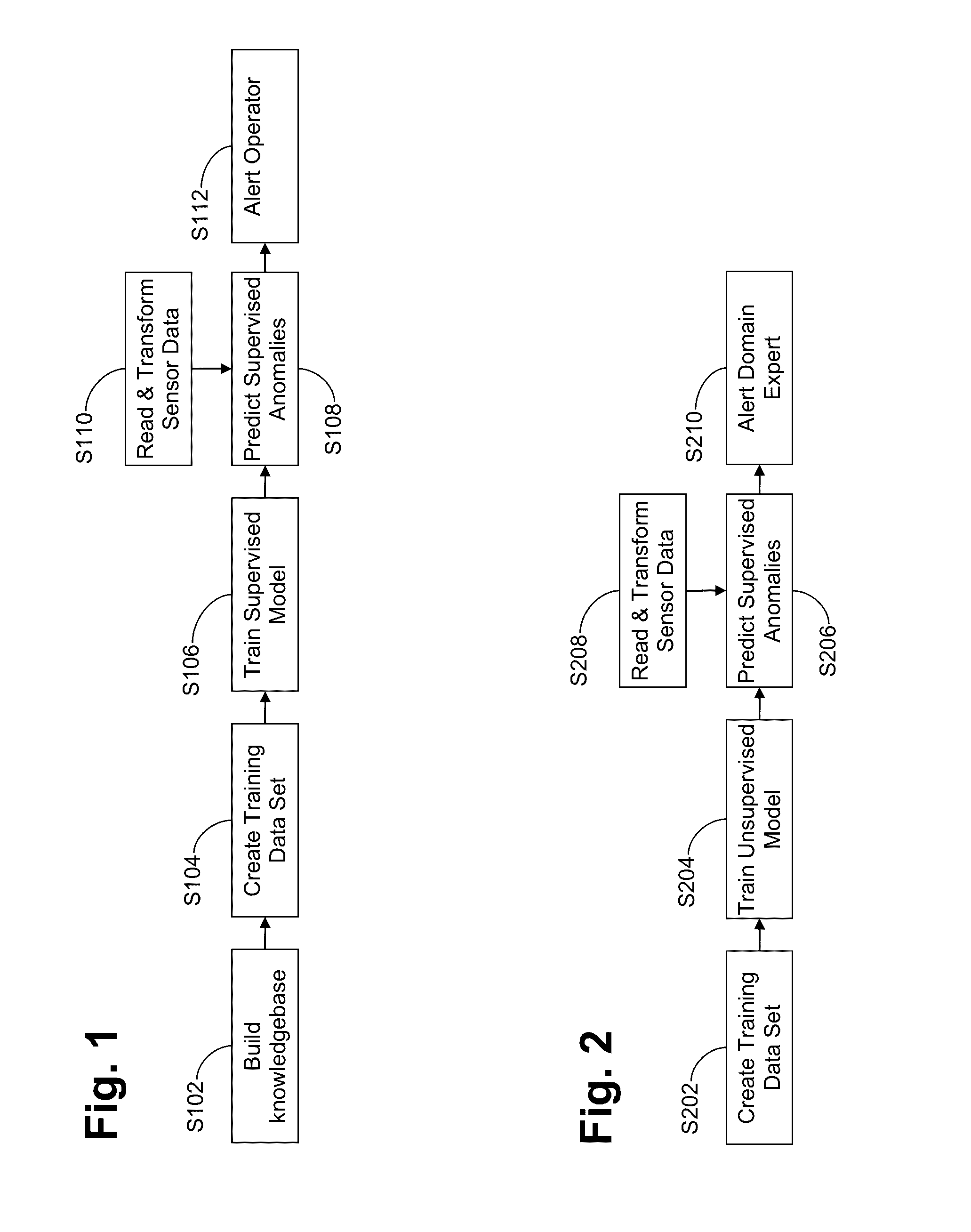

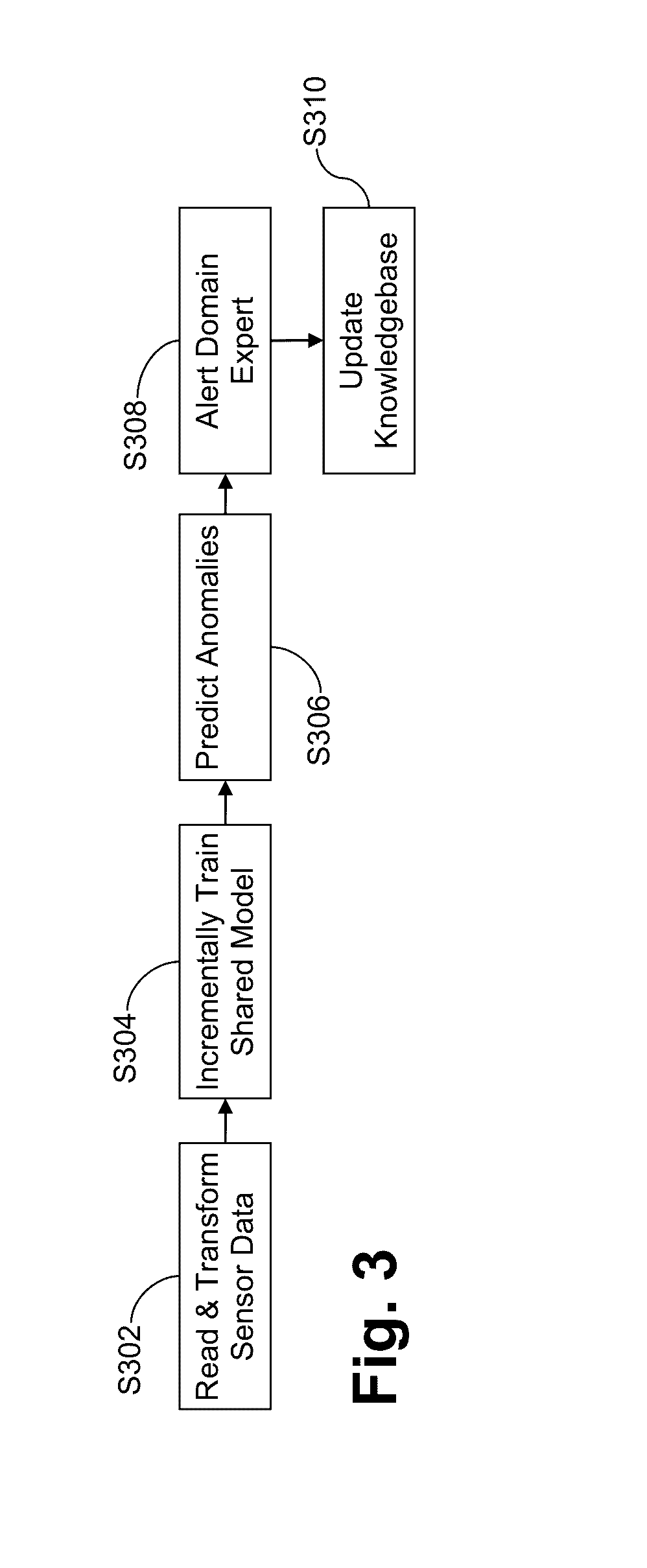

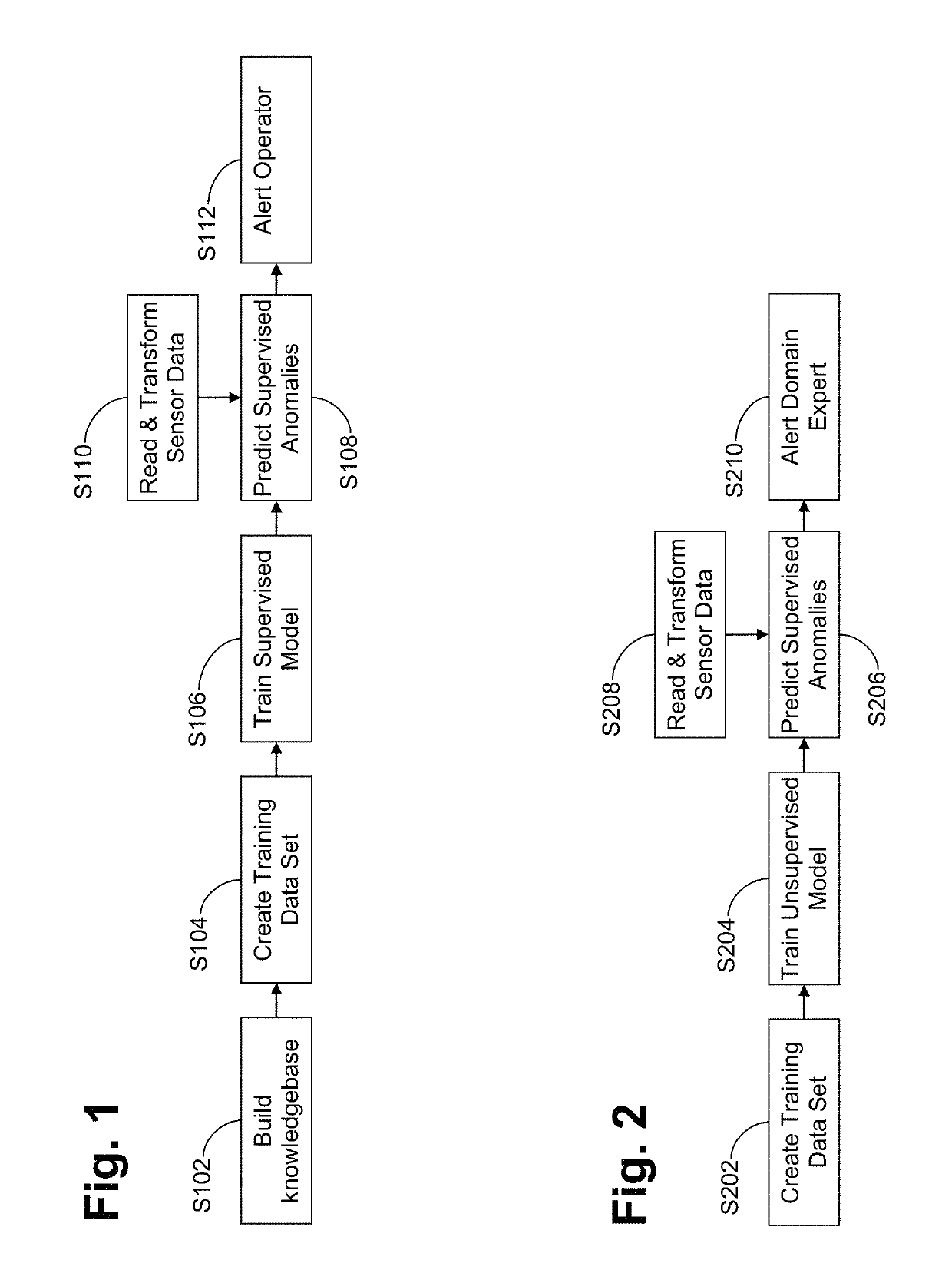

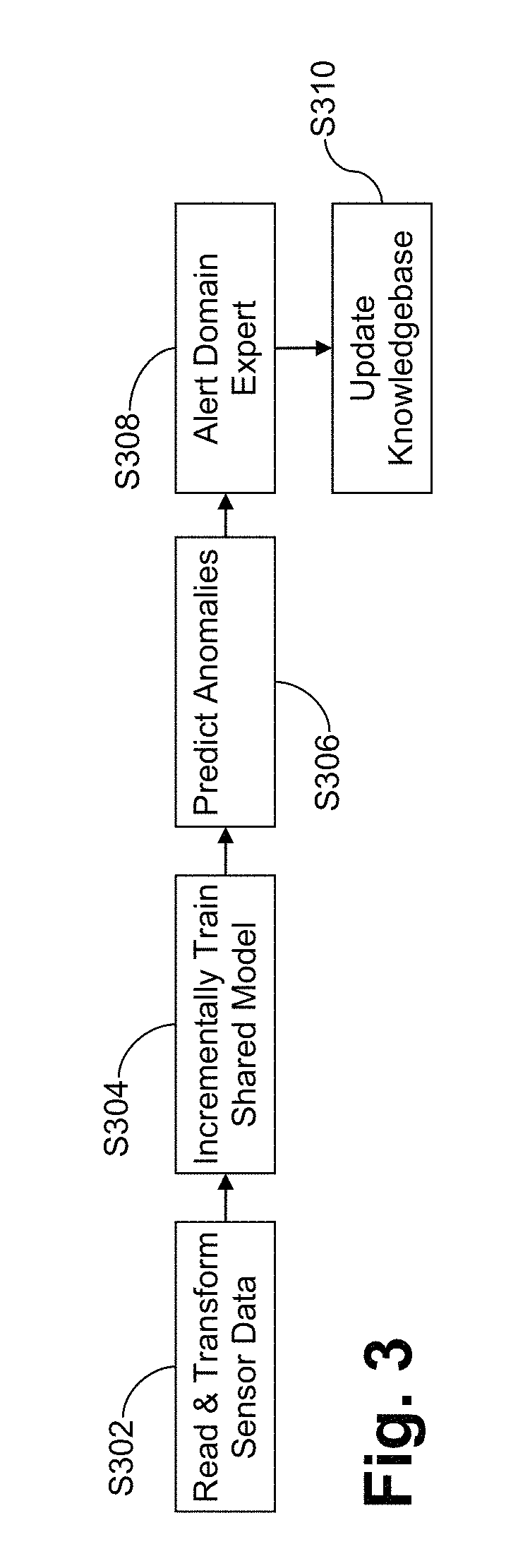

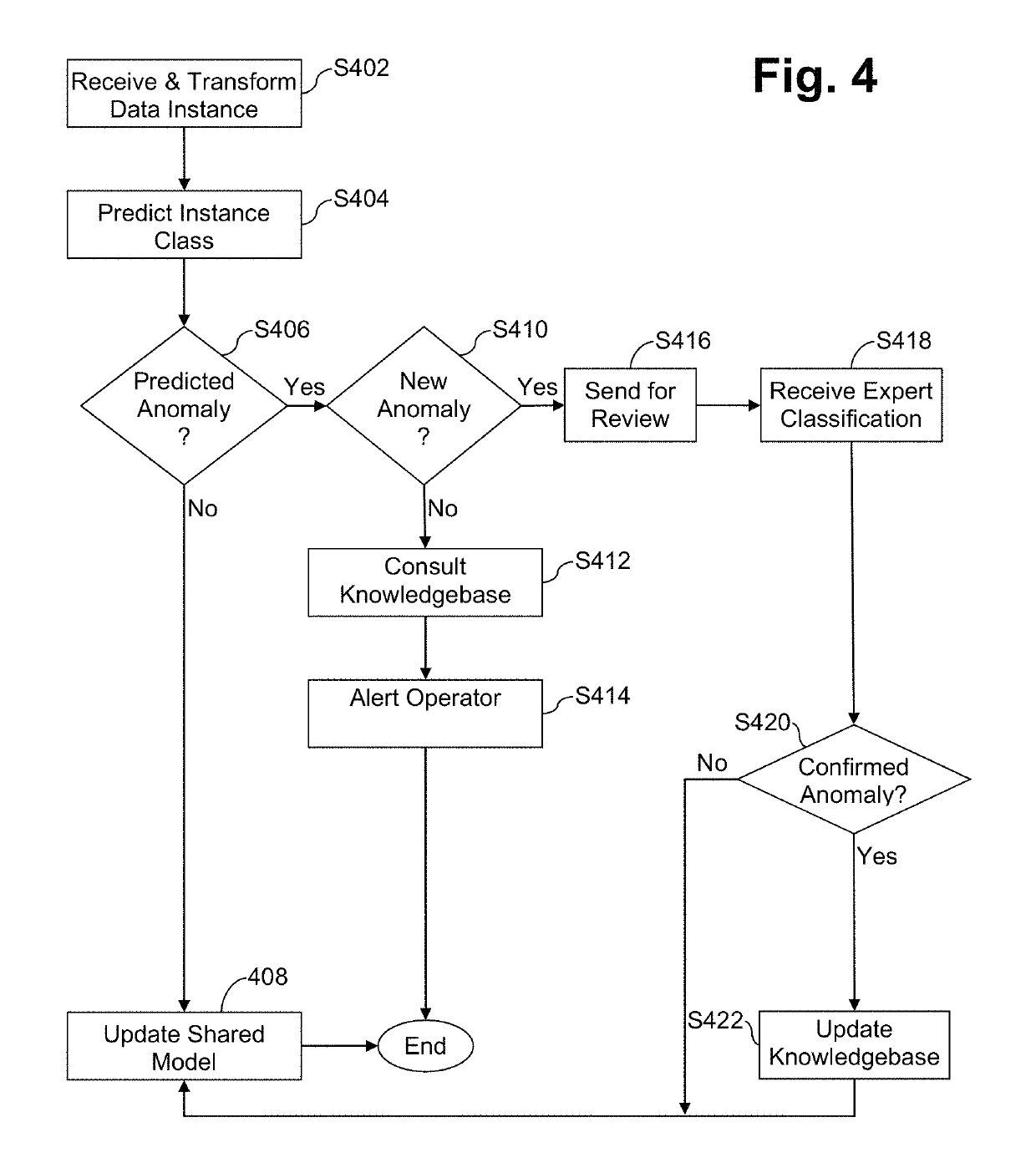

Systems and/or methods for dynamic anomaly detection in machine sensor data

ActiveUS20160342903A1Reduce the possibilityQuickly and in large amountFault responseReliability/availability analysisIndefinite timeCluster algorithm

Certain example embodiments relate to techniques for detecting anomalies in streaming data. More particularly, certain example embodiments use an approach that combines both unsupervised and supervised machine learning techniques to create a shared anomaly detection model in connection with a modified k-means clustering algorithm and advantageously also enables concept drift to be taken into account. The number of clusters k need not be known in advance, and it may vary over time. Models are continually trainable as a result of the dynamic reception of data over an unknown and potentially indefinite time period, and clusters can be built incrementally and in connection with an updatable distance threshold that indicates when a new cluster is to be created. Distance thresholds also are dynamic and adjustable over time.

Owner:SOFTWARE AG USA

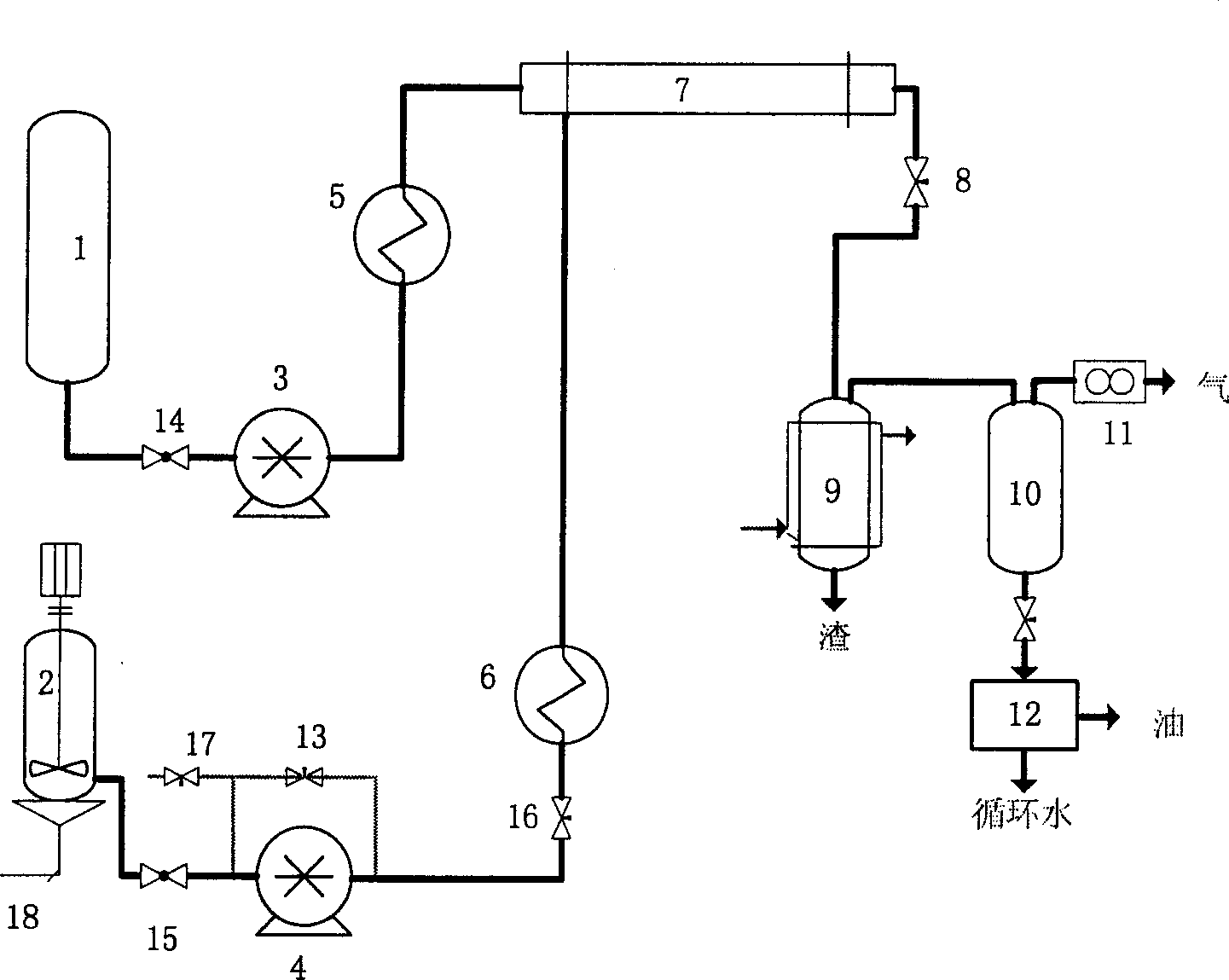

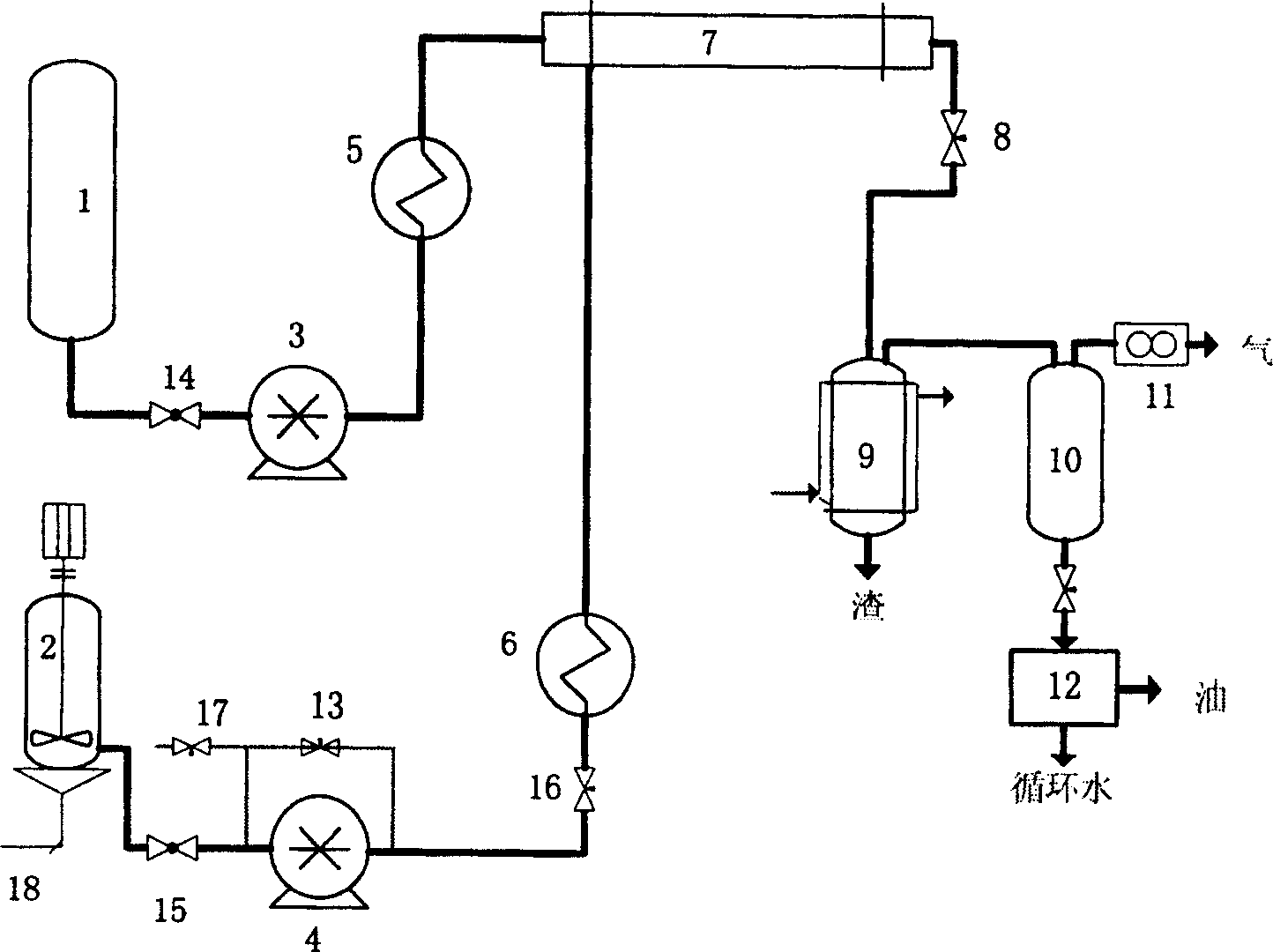

Method for continuous conversion of low-rank coal in subcritical water or supercritical water

ActiveCN1544580ANo emissionsQuick responseLiquid hydrocarbon mixture productionSolid solvent extractionCoal waterLower grade

The invention discloses a process for preparing coal water slurry or the mixture of coal water slurry with alkaline metal and / or alkaline earth oxides or hydroxides by the method of low level coal continuous transformation in subcritical or supercritical water which comprises, conducting continuous high pressure conveying of coal water slurry, charging into reaction system, usting the peculiarity of the hypercritical water to extracting and pyrolising low grade coal, converting it into useful product in gas, liquid and solid forms.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

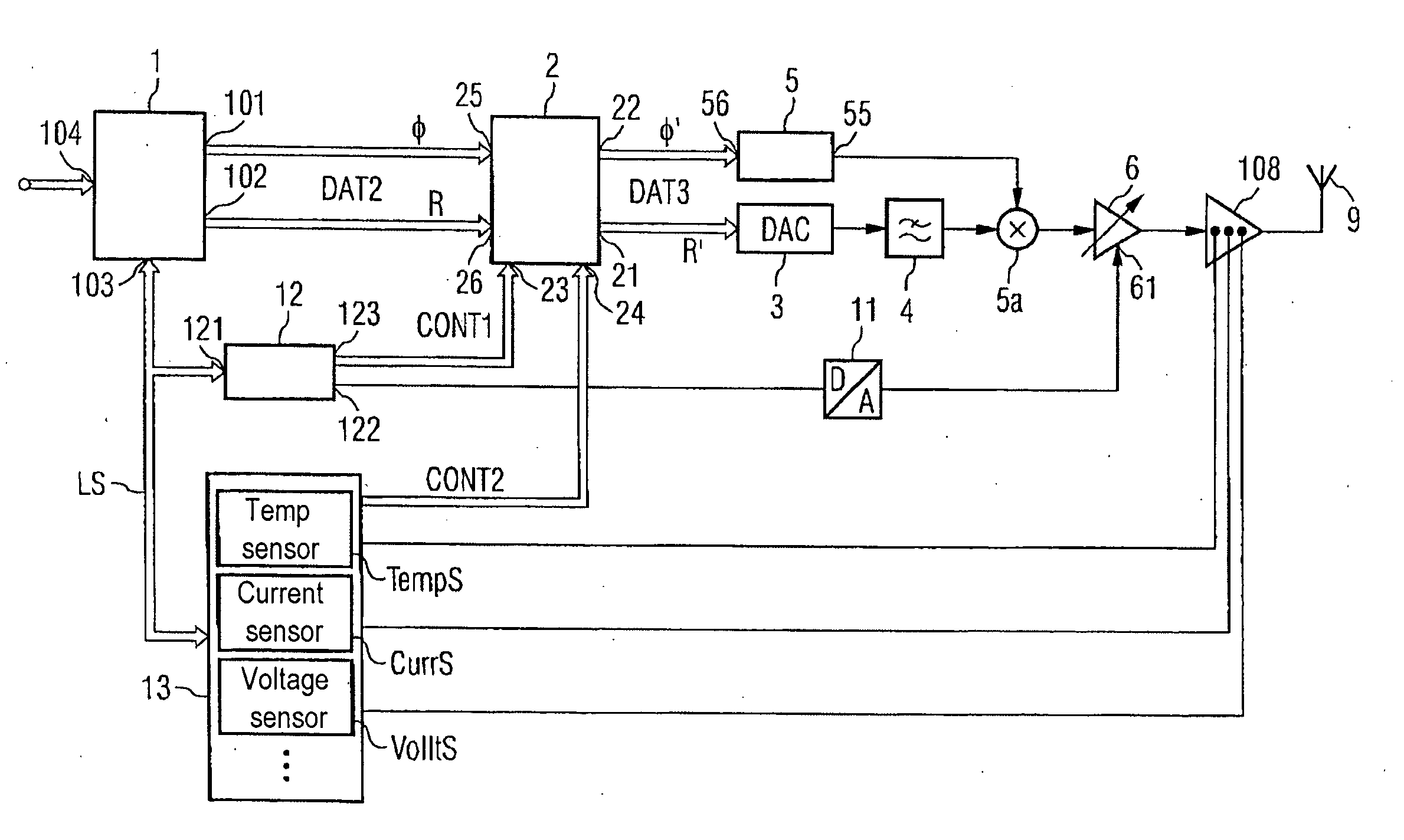

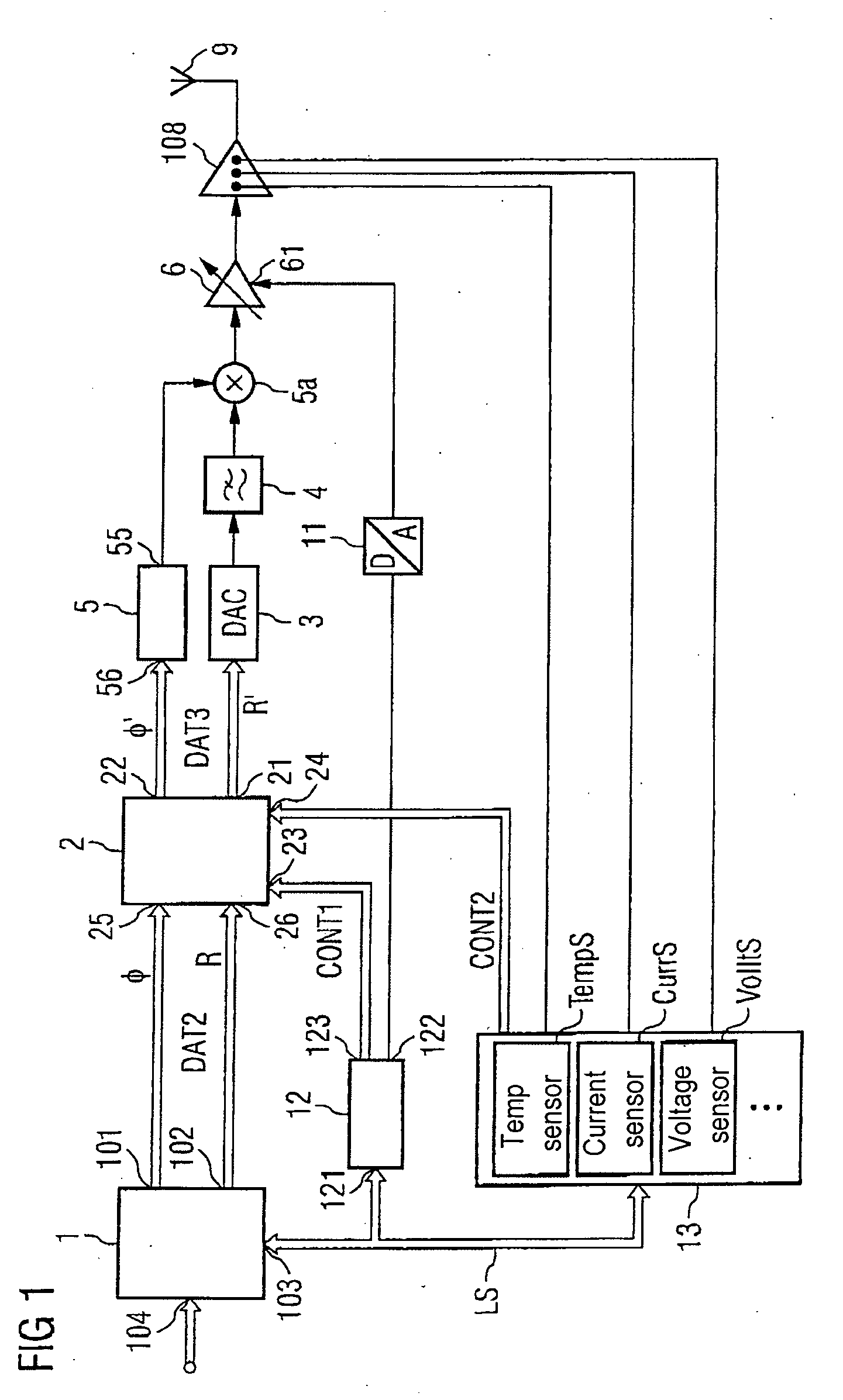

Method for signal processing and a transmitting device with digital predistortion, in particular for mobile radio

InactiveUS20060226903A1Reduce power consumptionChange operating conditionsAmplifier modifications to reduce non-linear distortionAmplifier modifications to reduce noise influenceSignal qualityCarrier signal

A transmitting device with digital predistortion is disclosed. The device produces a power word derived from an amplitude component of a digital modulation signal and a desired output power. The power word is compared with a limit value, and depending on the result, one pair of predistortion coefficients is selected and distortion of a first and second component of the digital modulation signal is thus carried out. The phase and the amplitude of a carrier signal are then modulated with the distorted components. Selective distortion of the modulation signal is carried out by comparison of the power word with a limit value, when the signal quality or the linearity of the modulated carrier signal falls below a predetermined limit value. Otherwise, the predistortion unit can be switched off, and the power consumption can thus be reduced.

Owner:INFINEON TECH AG

Method of loading titanium dioxide photo catalyst on metal surface

InactiveCN1410158AEasy to manufactureSolve the load problemCatalyst activation/preparationPhotocatalytic reactionPowder suspension

A process for carrying TiO2 photocatalyst on metal surface includes such steps as cleaning metal surface, anodizing in acidic medium, hydrolyzing, leaching and coating tetrabutyl titanate and TiO2 film under the weak alkaline condition by the sol-gel-powder suspension method, and igniting at proper temp. Its advantages are strong photocatalysis action for degradating organic pollutants, and good electric conductivity and machinability.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN) +1

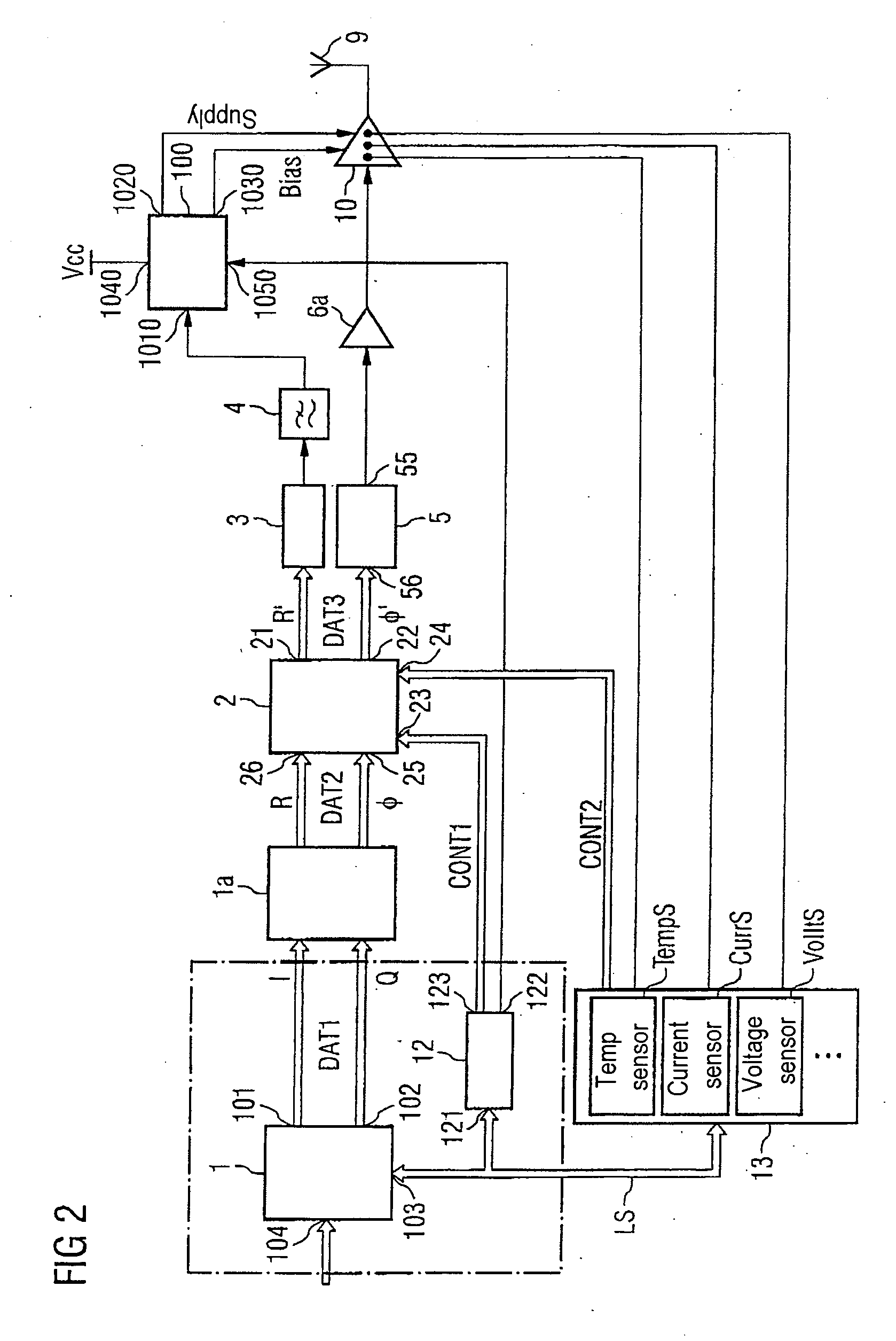

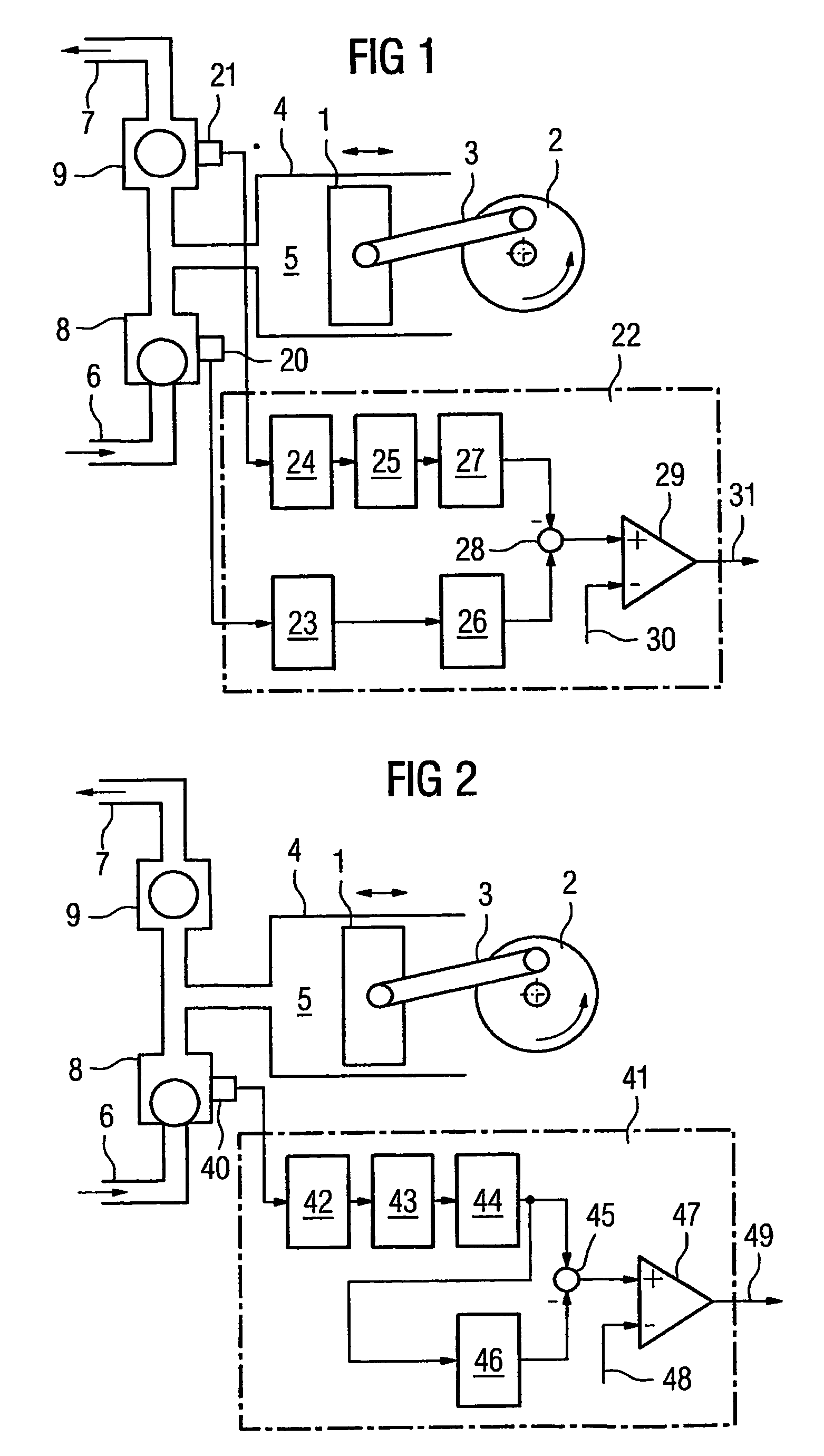

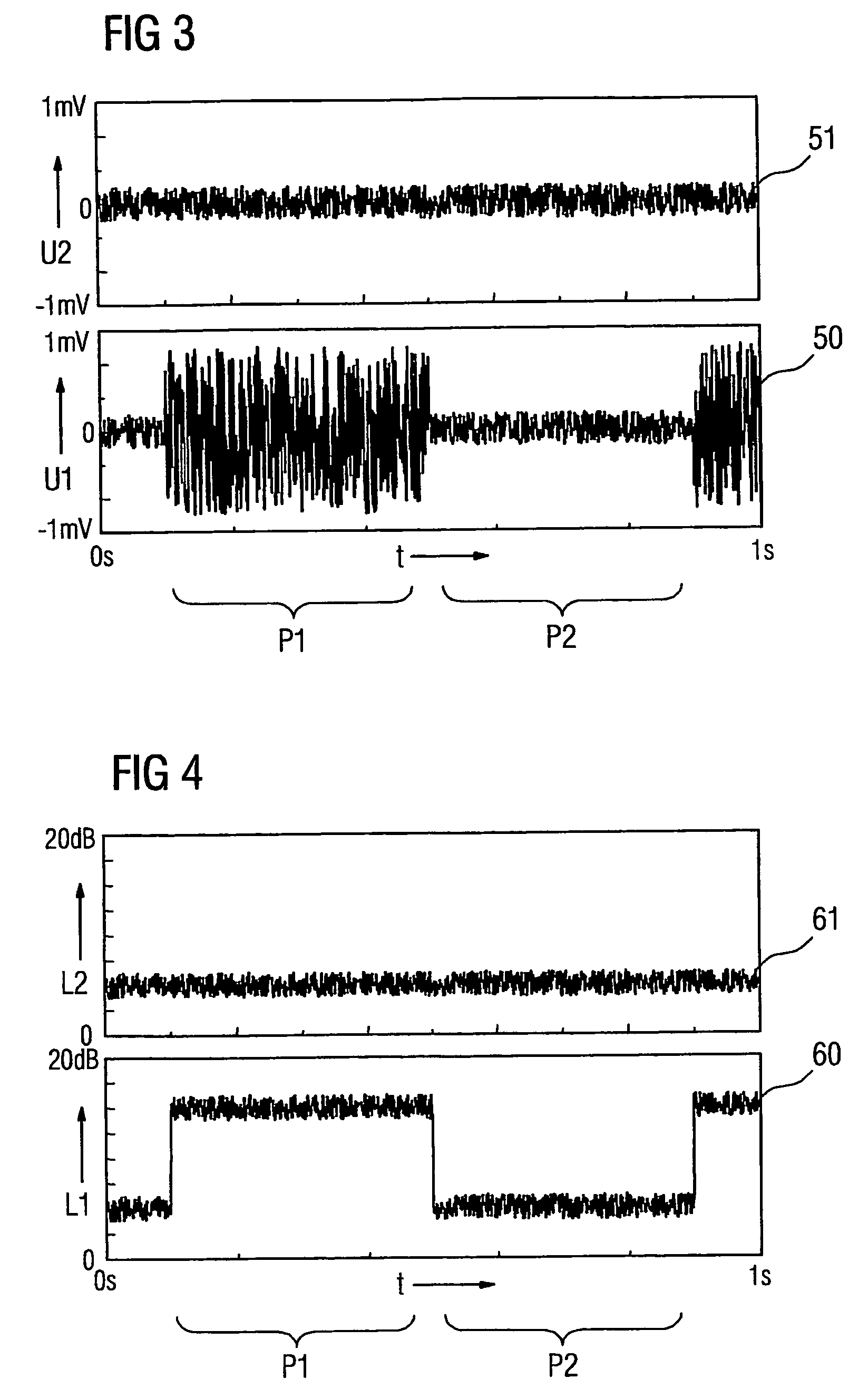

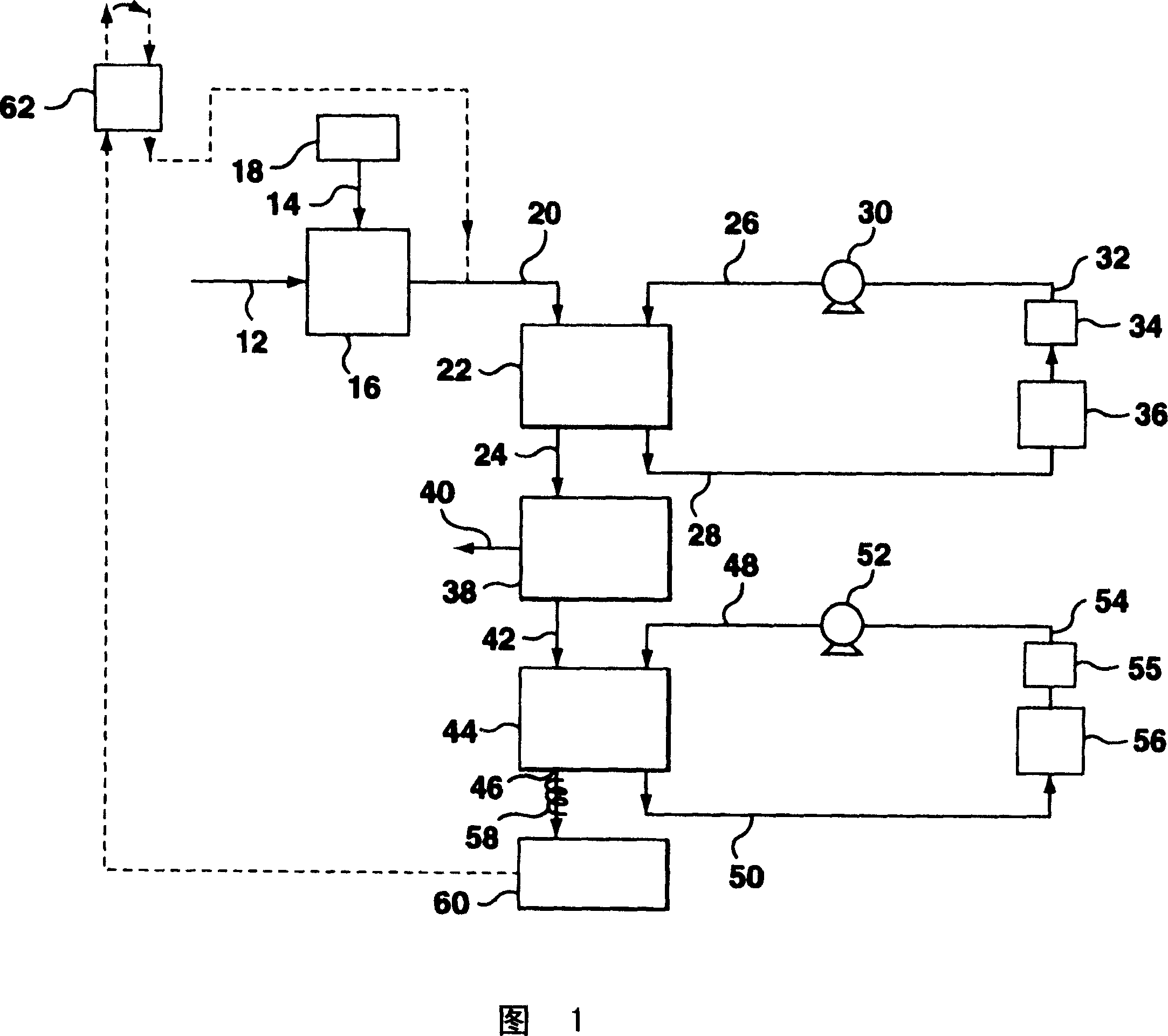

Diagnostic system and method for a valve, especially a check valve of a positive displacement pump

InactiveUS7621179B2Reliable diagnosisReliable detectionVibration measurement in solidsValve arrangementsEngineeringCheck valve

A diagnostic system and method for a valve, especially a check valve of a positive displacement pump, including at least one solid-borne sound sensor is provided. A first value of a parameter of a sound signal recorded in the closed state of the valve and a second value of a parameter of a sound signal recorded in the open state of a valve are determined essentially. A signal indicating a disturbance is issued if the deviation between the first value and the second value exceeds a predefined threshold value, resulting in particularly good insensitivity.

Owner:SIEMENS AG

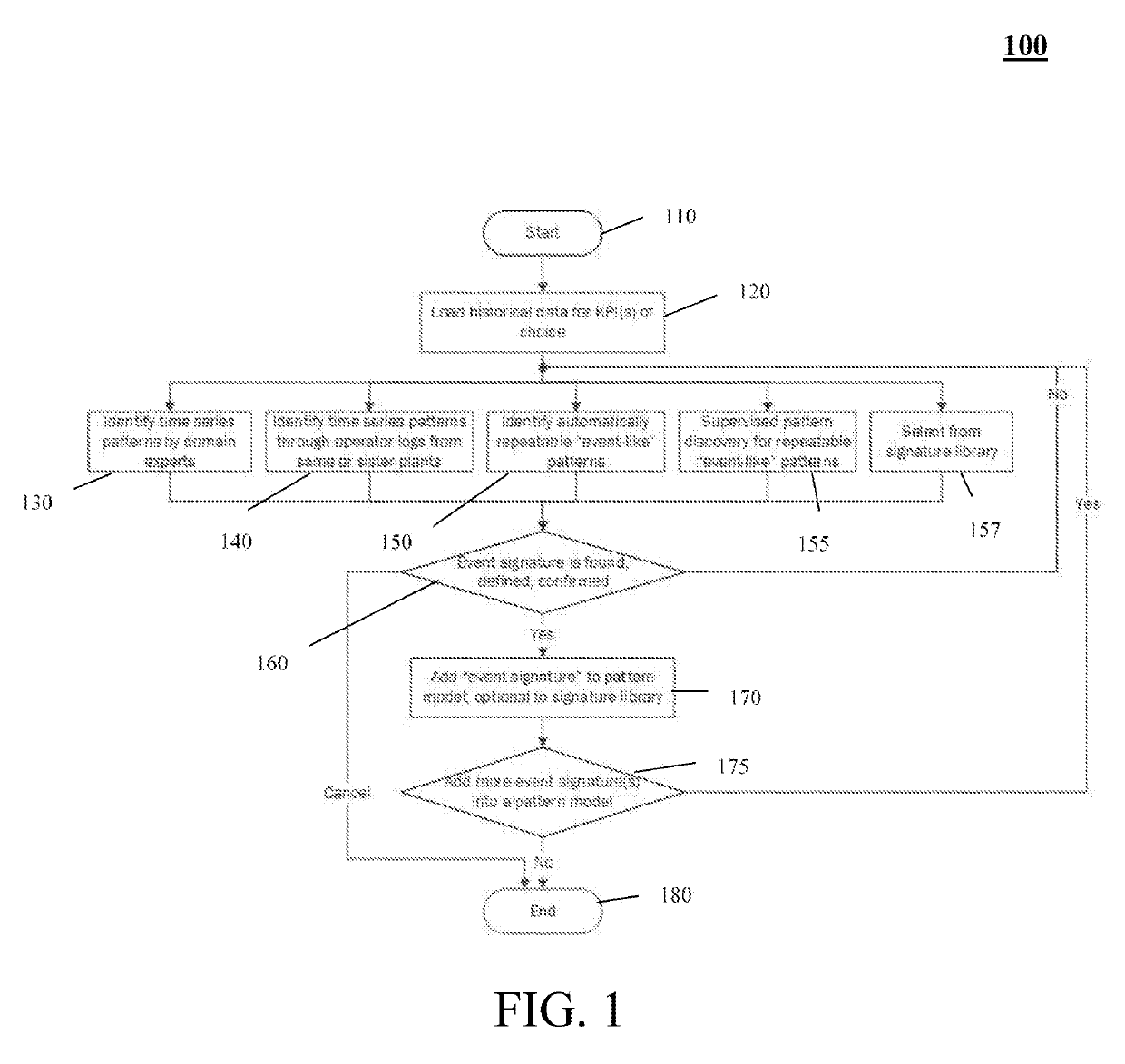

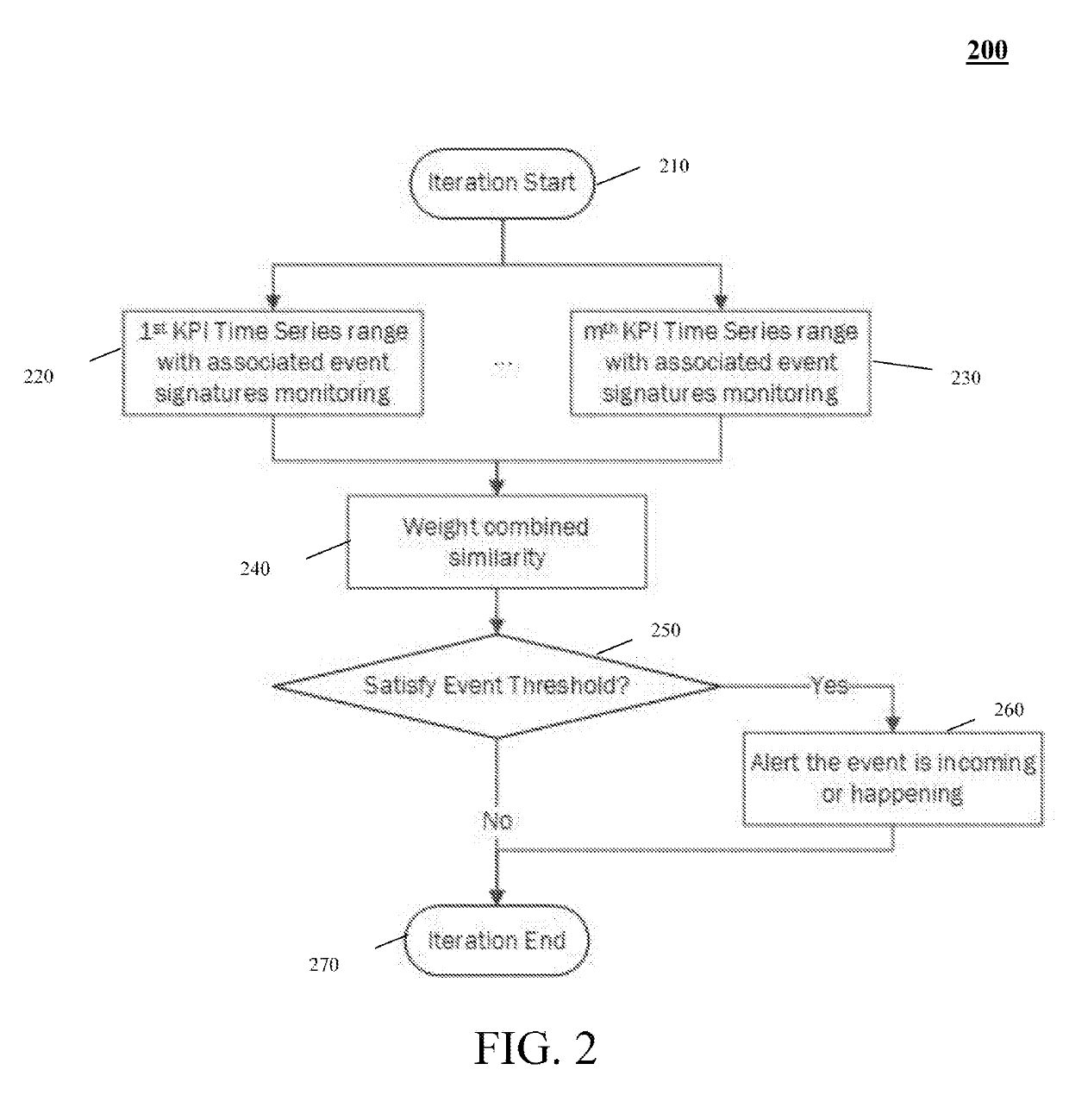

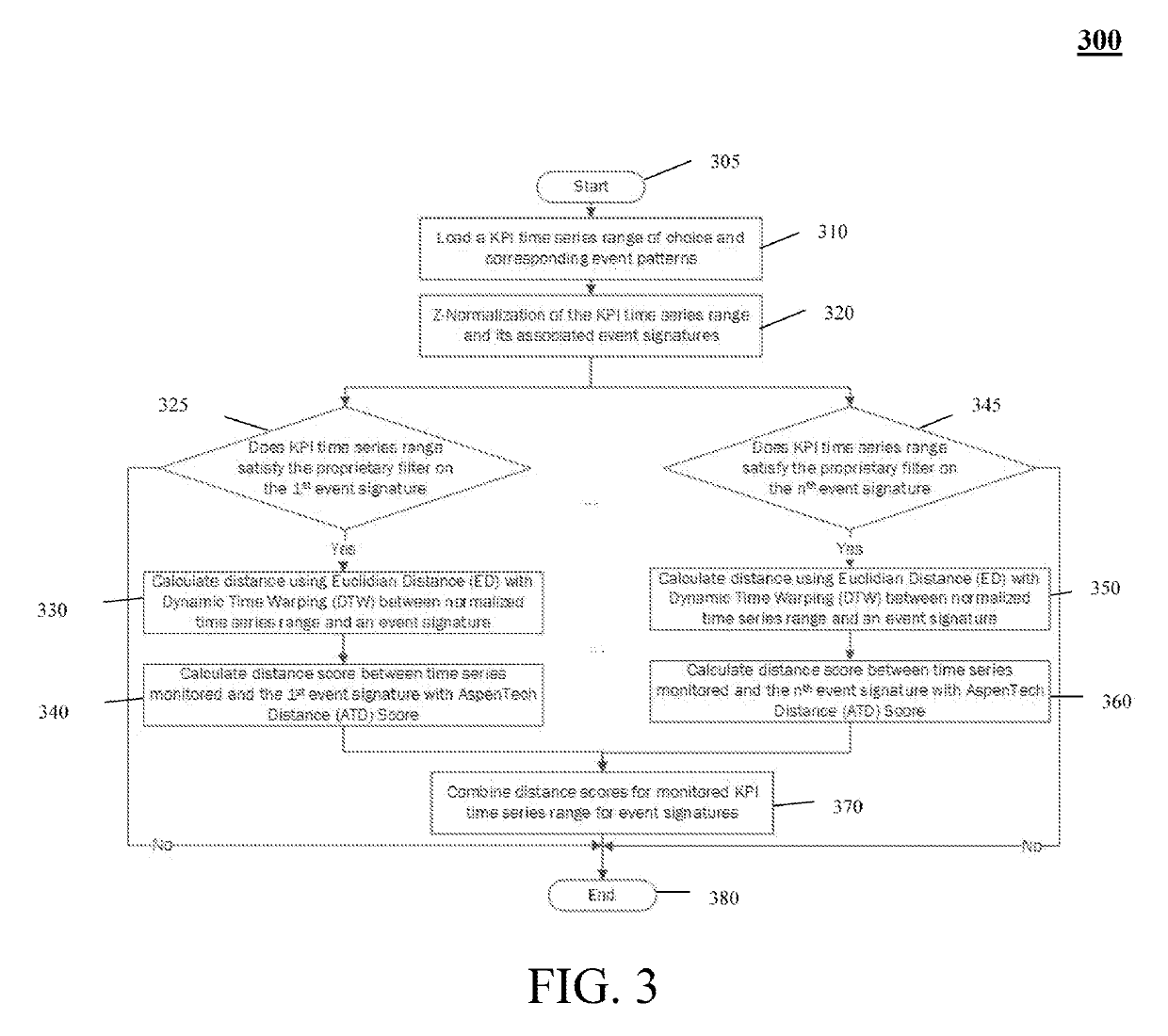

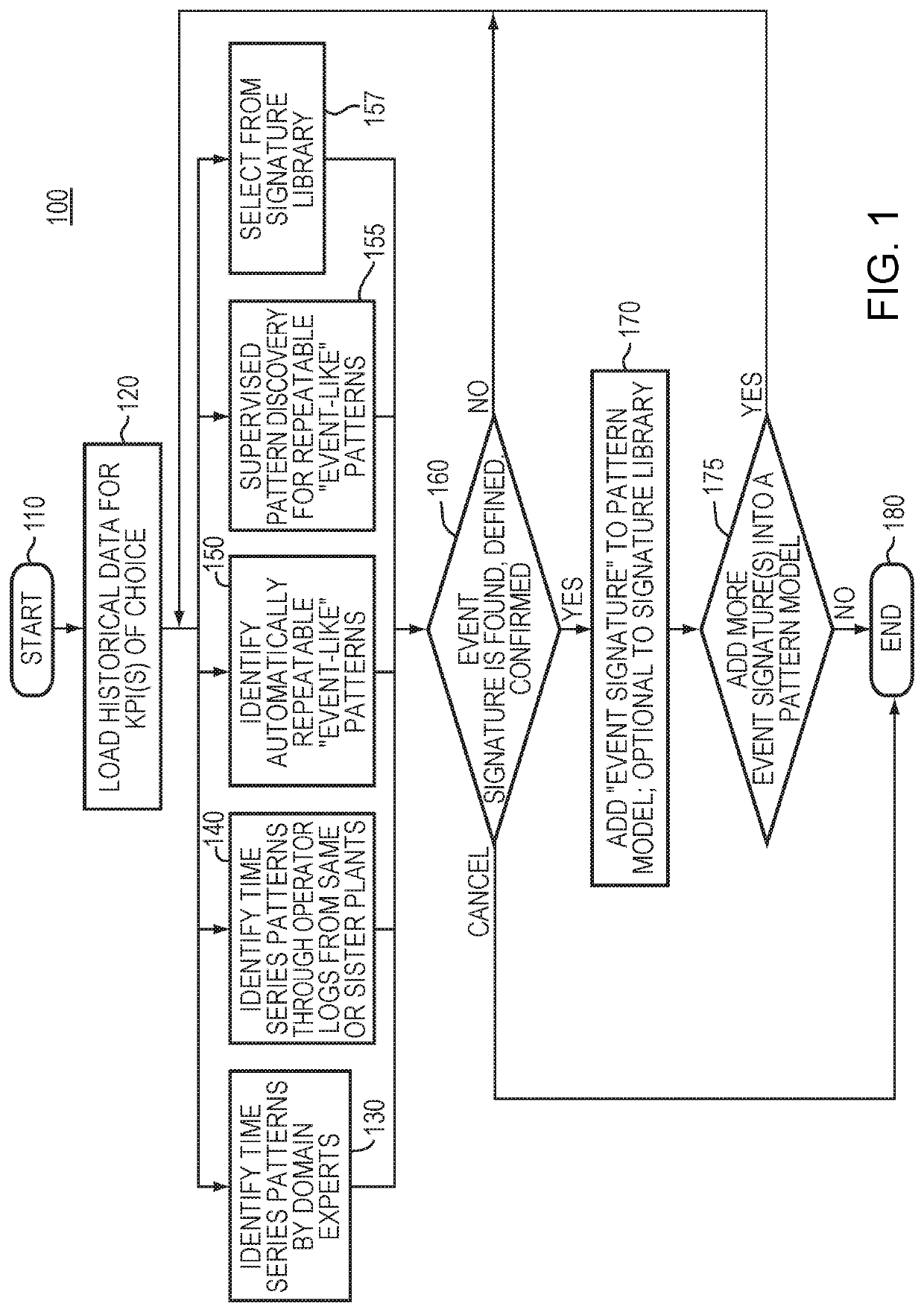

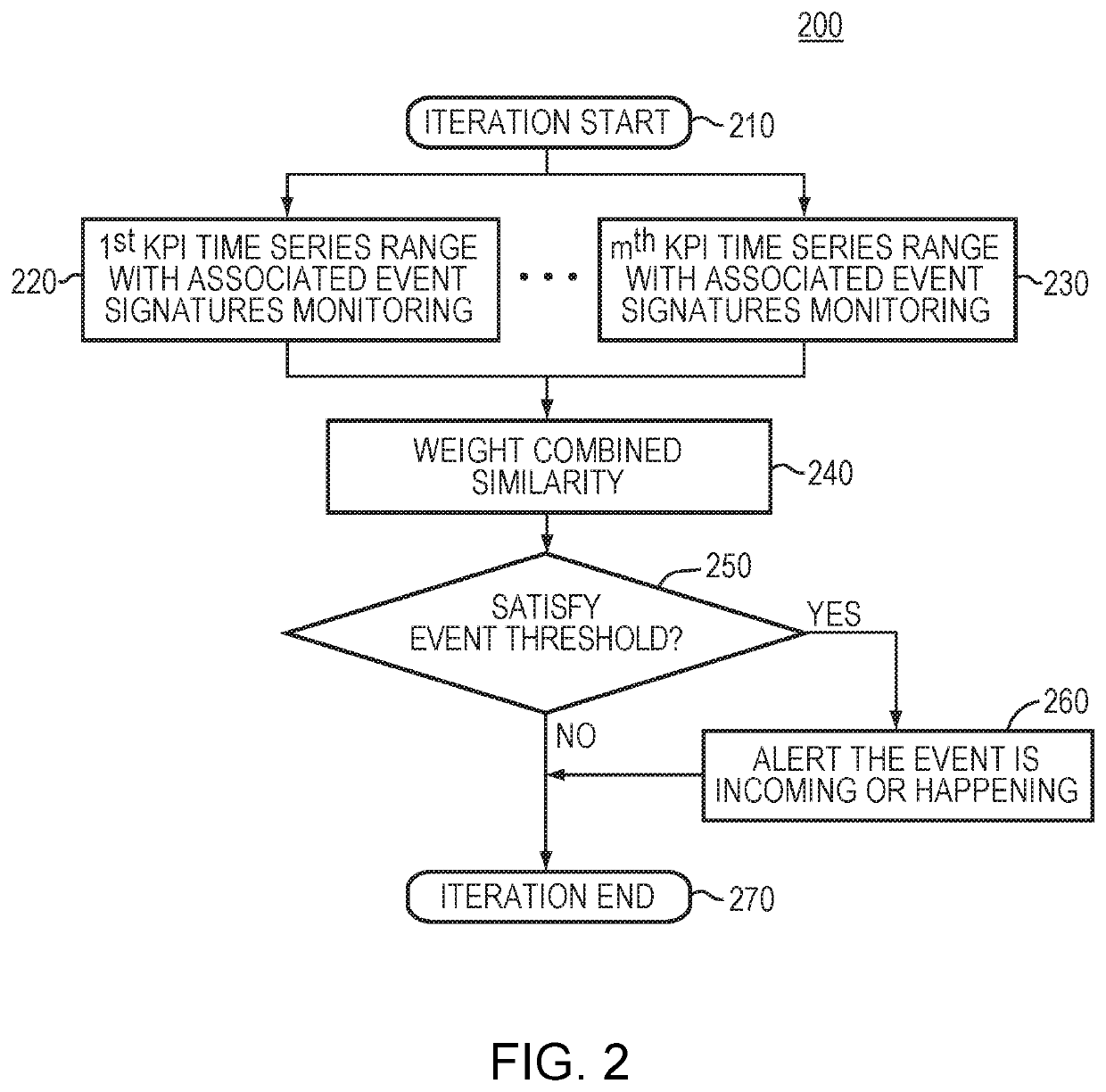

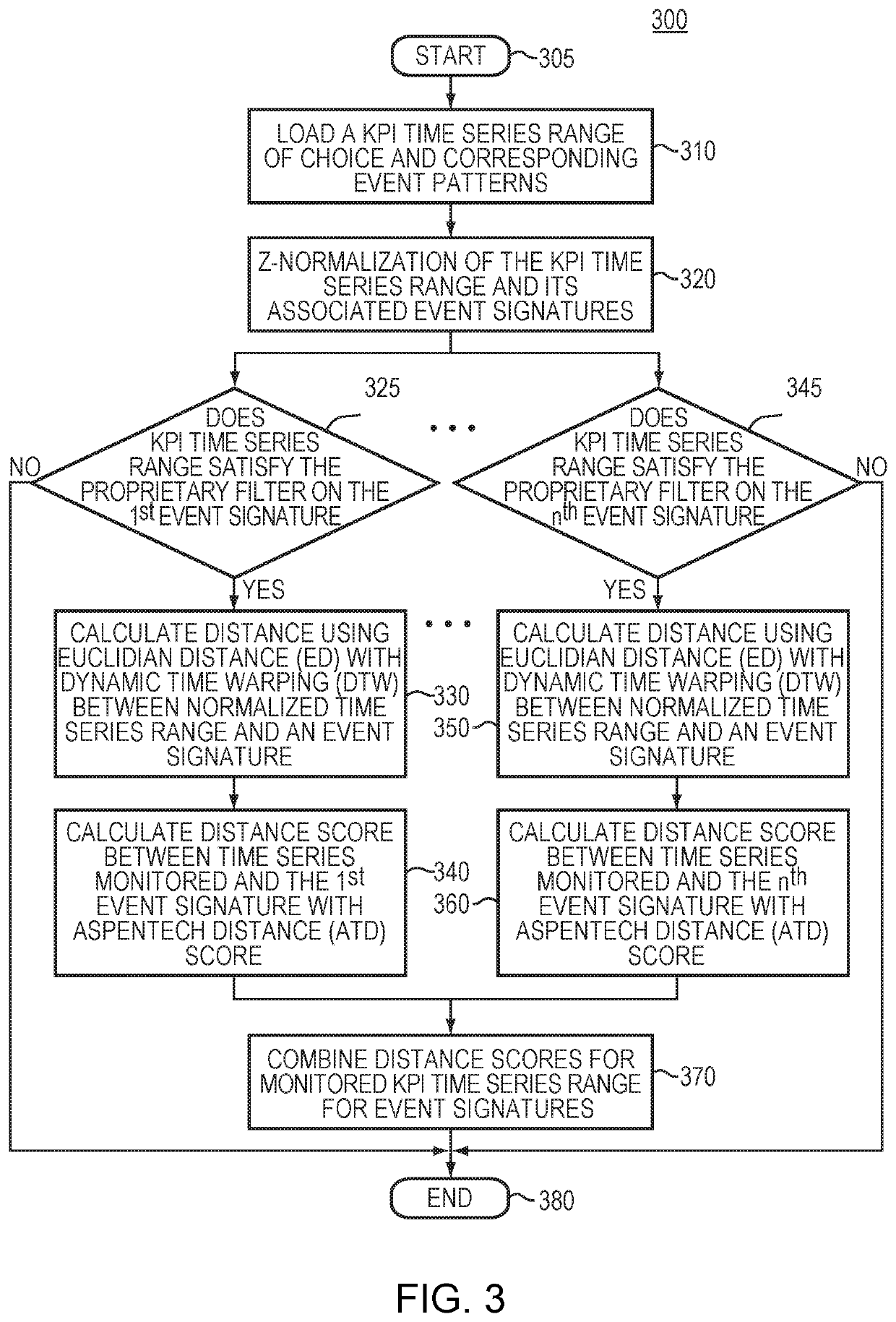

Computer System And Method For Monitoring Key Performance Indicators (KPIs) Online Using Time Series Pattern Model

ActiveUS20190227504A1Process is performedReduce in quantityTesting/monitoring control systemsAdaptive controlModel methodPerformance index

Embodiments are directed to computer methods and systems that build and deploy a pattern model to detect an operating event in an online plant process. To build the pattern model, the methods and systems define a signature of the operating event, such that the defined signature contains a time series pattern for a KPI associated with the operating event. The methods and systems deploy the pattern model to automatically monitor, during online execution of the plant process, trends in movement of the KPI as a time series. The methods and systems determine, in real-time, a distance score between a range of the monitored time series and the time series pattern contained in the defined signature. The methods and systems automatically detect the operating event in the online industrial process based on the determined distance score, and alter parameters of the process (e.g., valves, actuators, etc.) to prevent the operating event.

Owner:ASPENTECH CORP

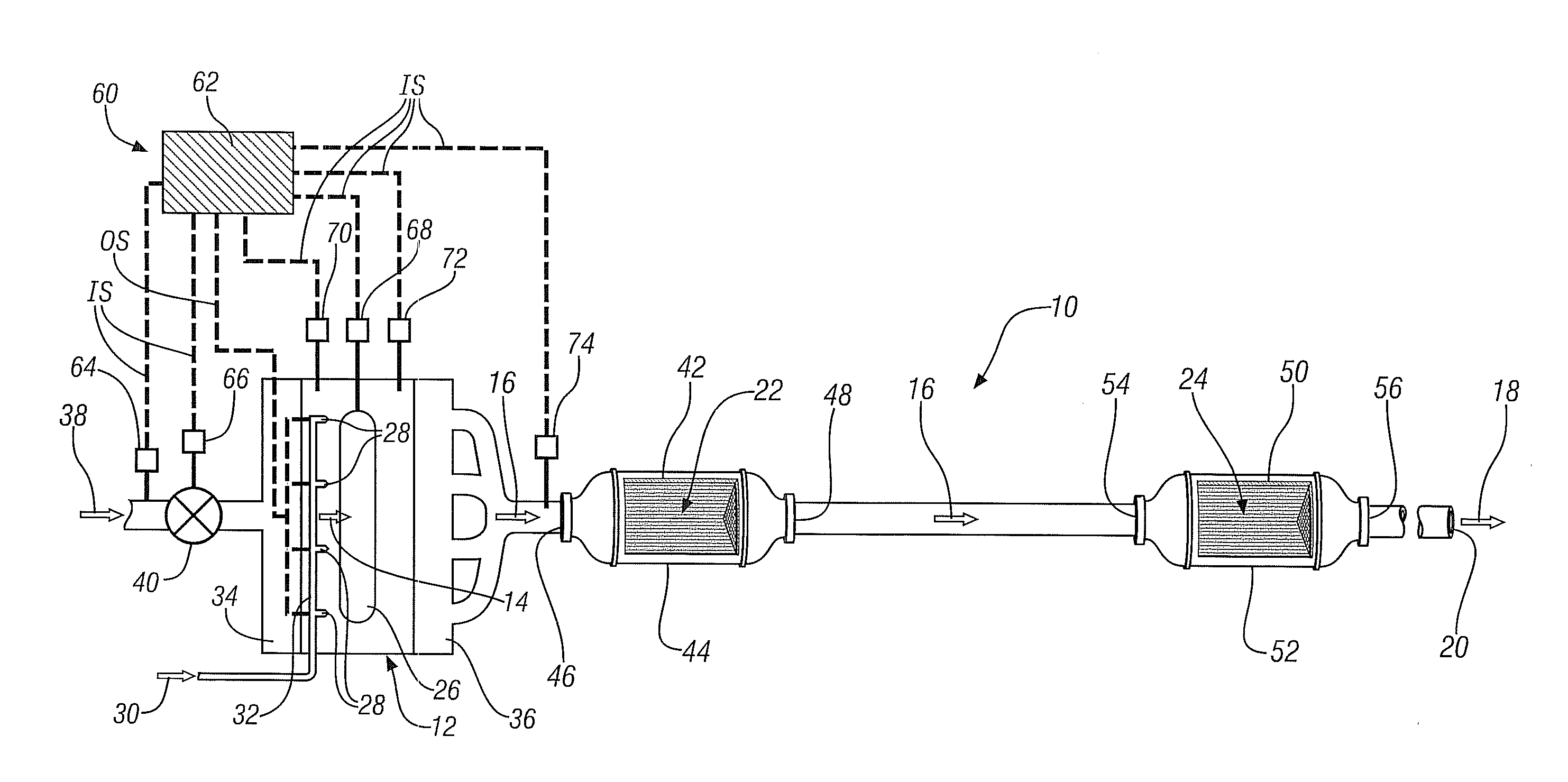

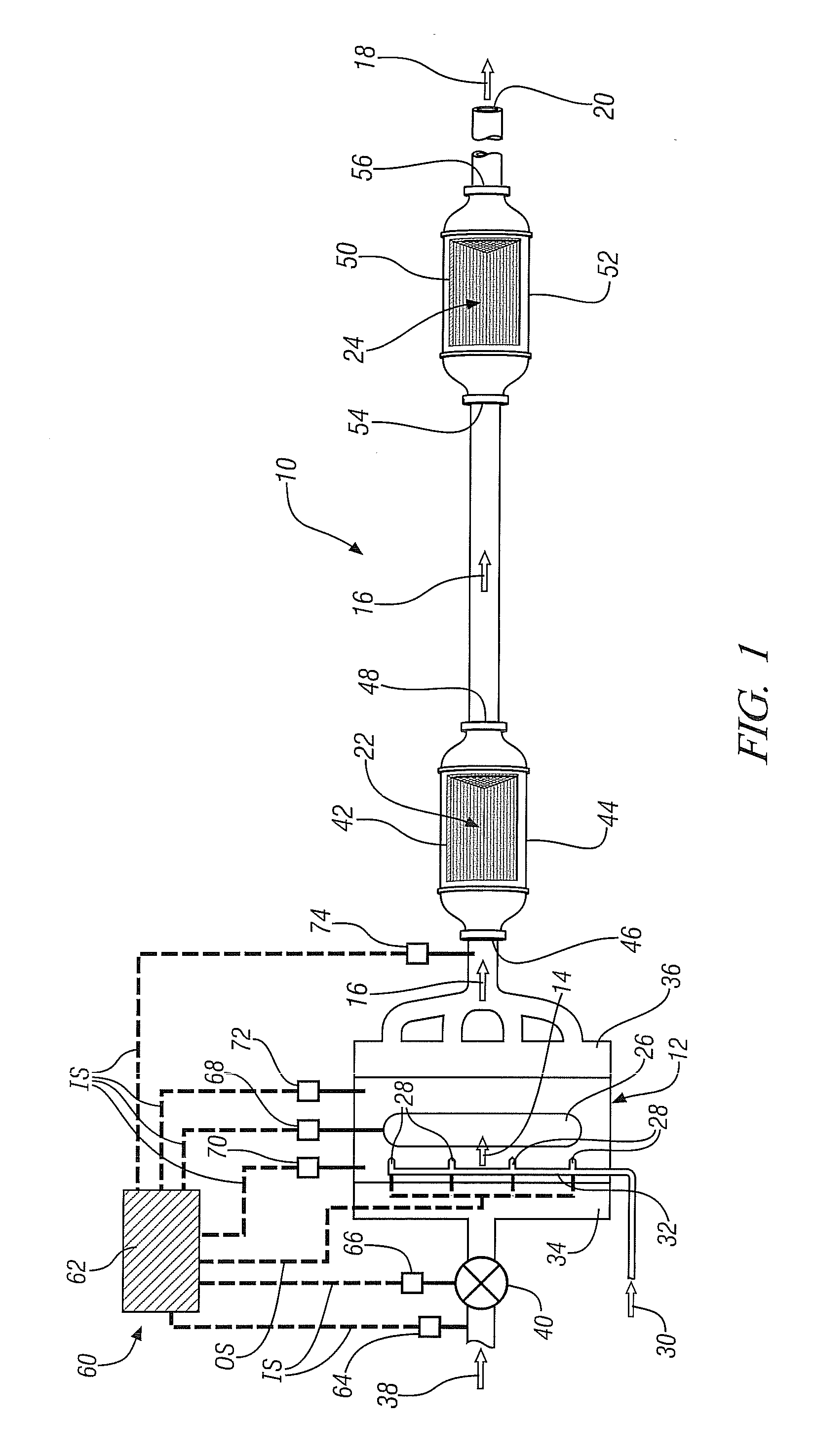

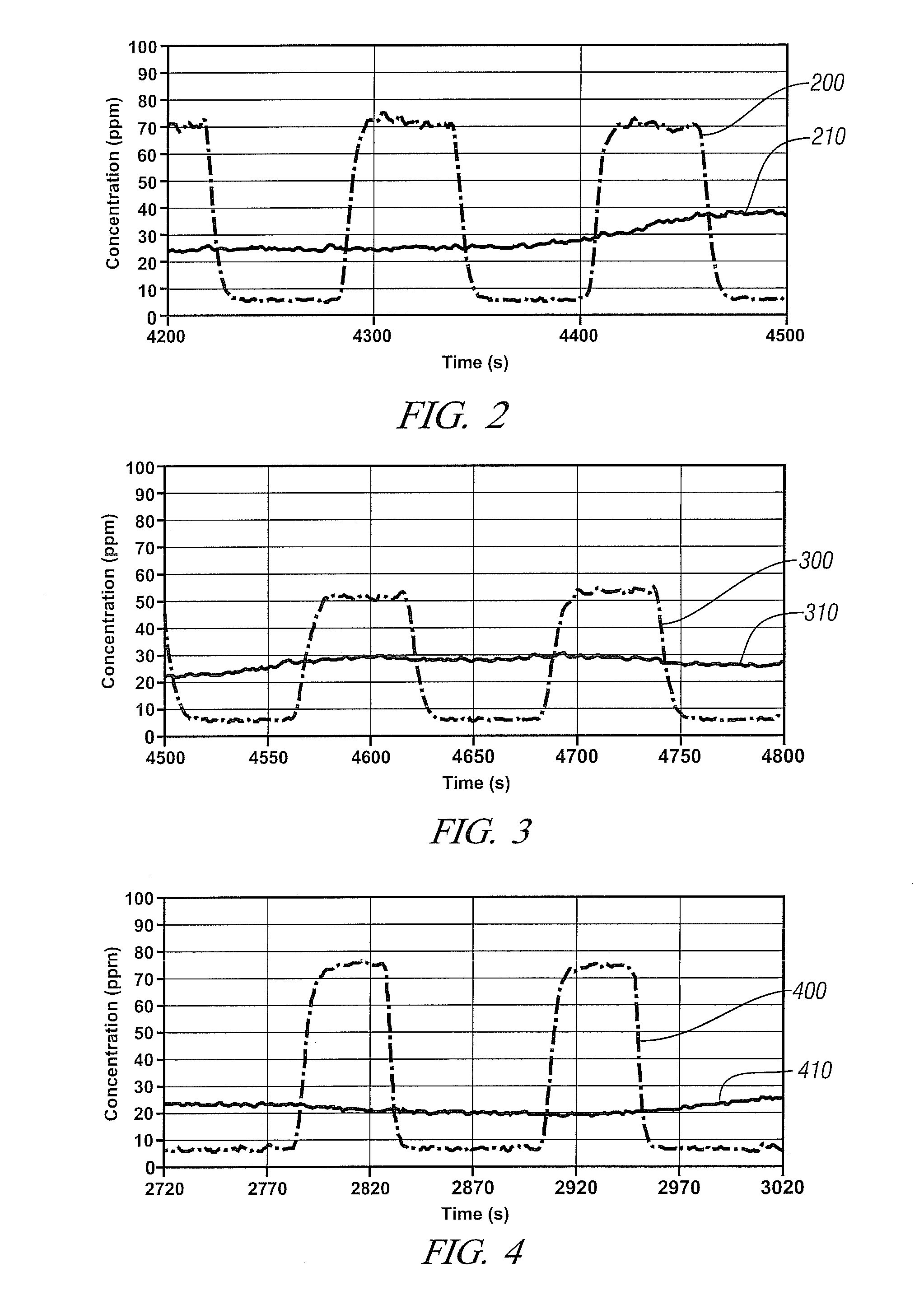

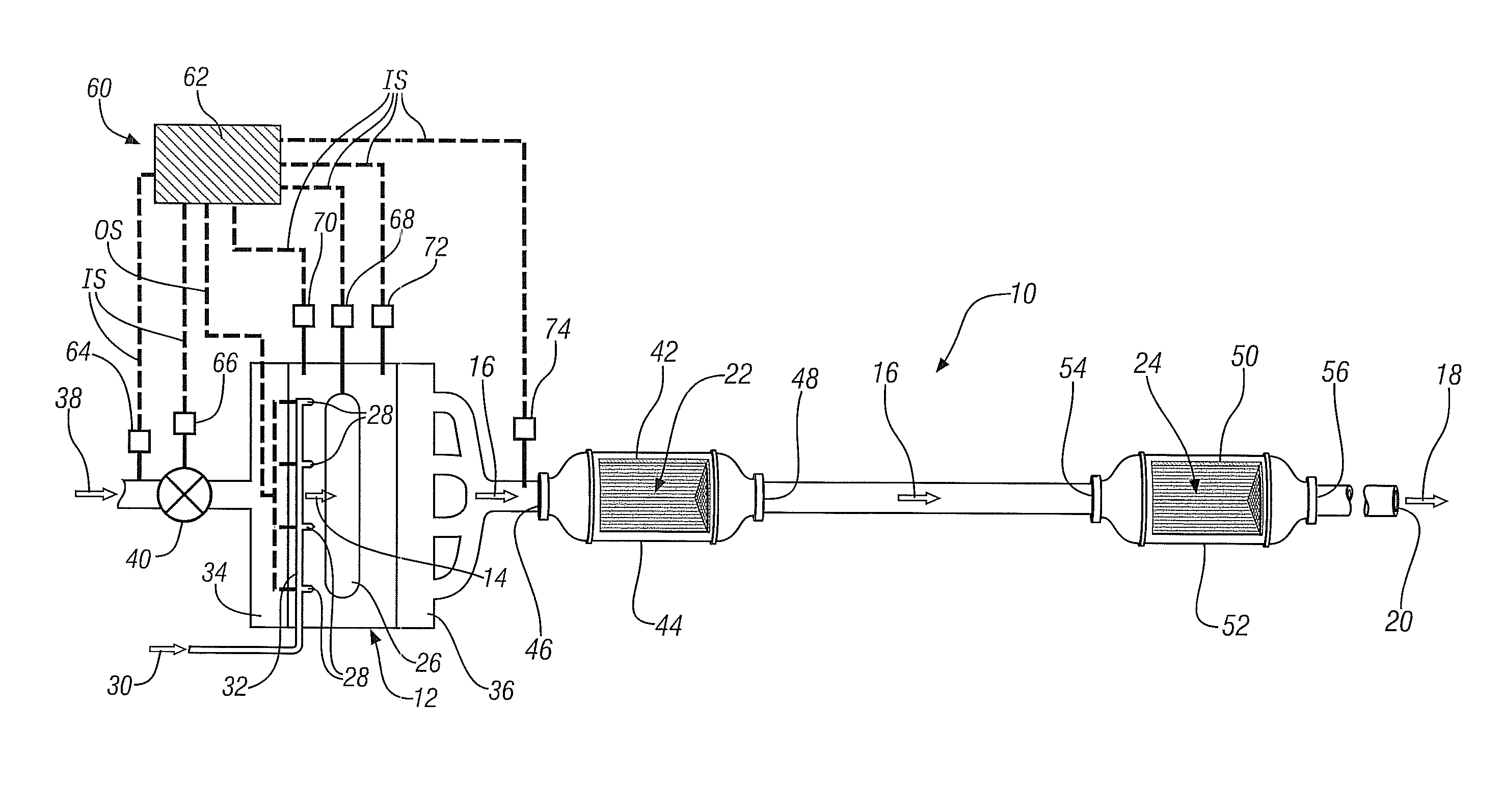

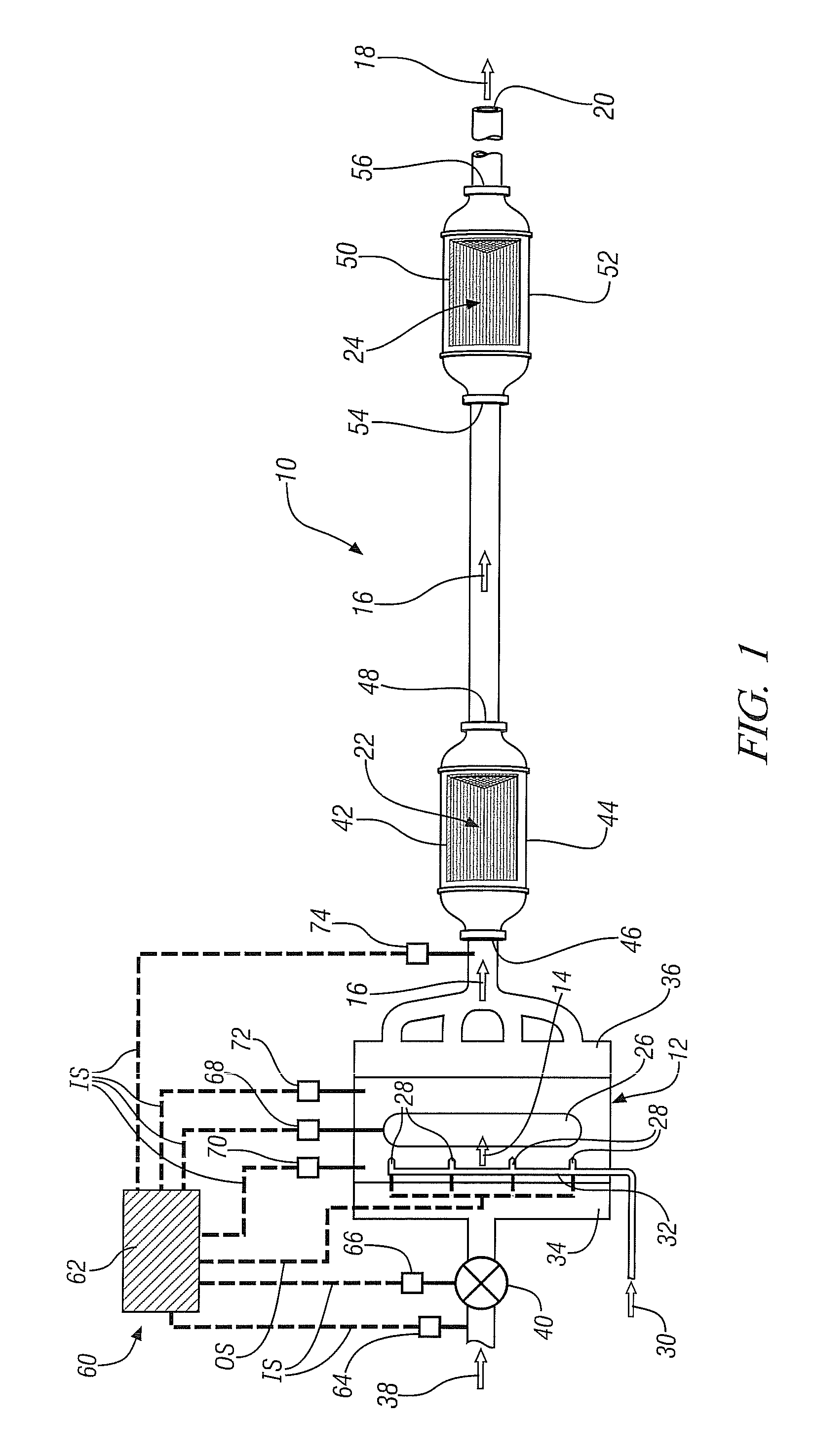

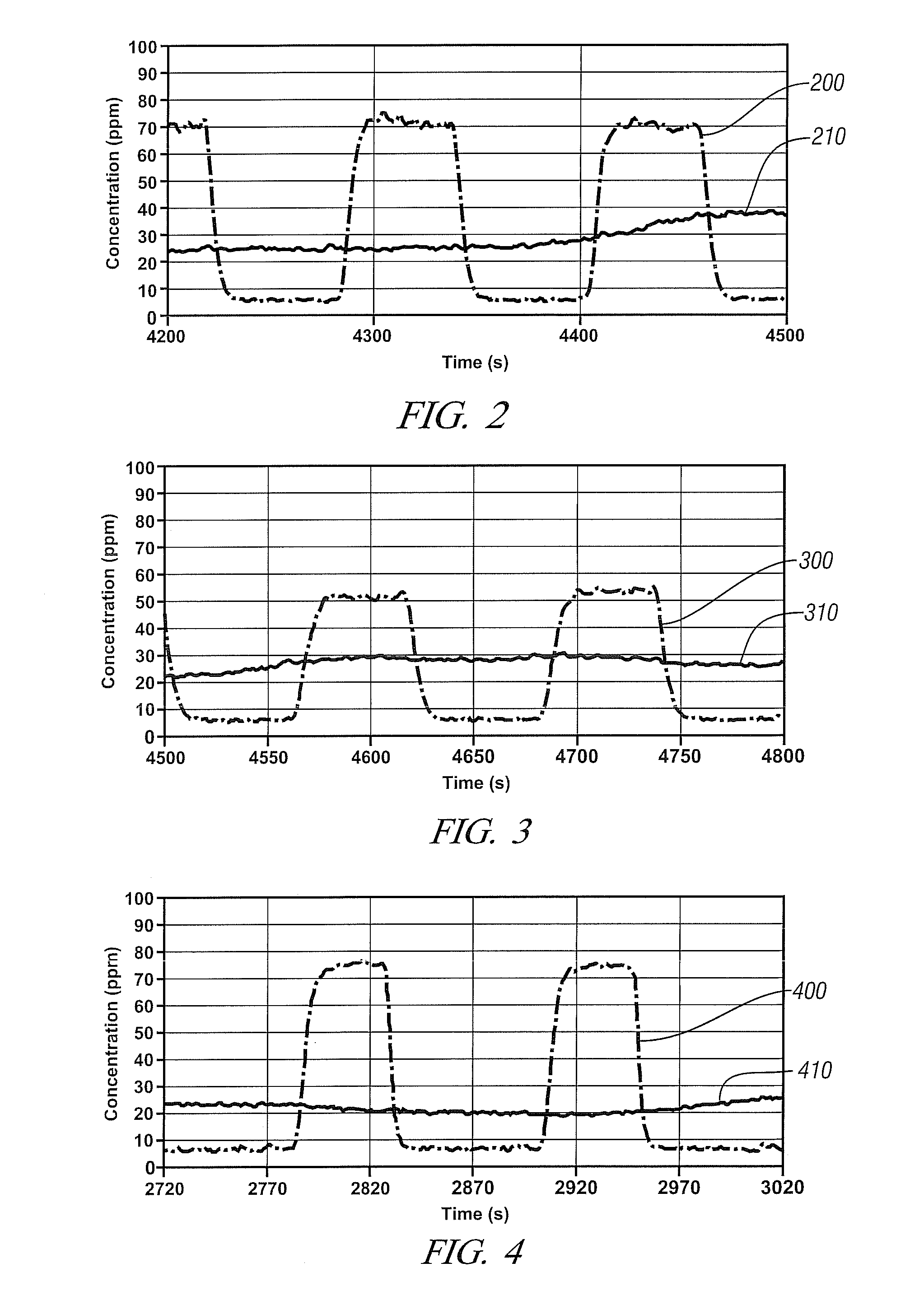

Exhaust aftertreatment systems that include an ammonia-scr catalyst promoted with an oxygen storage material

ActiveUS20120167553A1Reduce the amount requiredReduce NOxInternal combustion piston enginesDispersed particle separationAtmospheric airChemical measurement

A low-oxygen content exhaust flow produced by an engine that is combusting, on average, a stoichiometric mixture of air and fuel generally contains various unwanted gaseous emissions. The exhaust flow is treated by an exhaust aftertreatment system that includes a three-way-catalyst (TWC) and an ammonia-selective catalytic reduction (ammonia-SCR) catalyst positioned downstream from the TWC in a flow direction of the exhaust flow. The ammonia-SCR catalyst includes (1) a base metal ion-substituted zeolite and / or a base metal ion-substituted silicoaluminophosphate and (2) an oxygen storage material selected from the group consisting of a metal oxide or a mixed metal oxide that exhibits oxygen storage and release capacity. The serial arrangement of the TWC and the ammonia-SCR catalyst enhances the conversion of NOX to N2 in the low oxygen-content exhaust flow produced by the engine and helps prevent ammonia slip to the atmosphere.

Owner:GM GLOBAL TECH OPERATIONS LLC

Exhaust aftertreatment systems that include an ammonia-SCR catalyst promoted with an oxygen storage material

ActiveUS8661788B2Reduce the possibilityEffective activityNitrous oxide captureCombination devicesChemical measurementLow oxygen

A low-oxygen content exhaust flow produced by an engine that is combusting, on average, a stoichiometric mixture of air and fuel generally contains various unwanted gaseous emissions. The exhaust flow is treated by an exhaust aftertreatment system that includes a three-way-catalyst (TWC) and an ammonia-selective catalytic reduction (ammonia-SCR) catalyst positioned downstream from the TWC in a flow direction of the exhaust flow. The ammonia-SCR catalyst includes (1) a base metal ion-substituted zeolite and / or a base metal ion-substituted silicoaluminophosphate and (2) an oxygen storage material selected from the group consisting of a metal oxide or a mixed metal oxide that exhibits oxygen storage and release capacity. The serial arrangement of the TWC and the ammonia-SCR catalyst enhances the conversion of NOX to N2 in the low oxygen-content exhaust flow produced by the engine and helps prevent ammonia slip to the atmosphere.

Owner:GM GLOBAL TECH OPERATIONS LLC

Systems and/or methods for dynamic anomaly detection in machine sensor data

ActiveUS10410135B2Reduce the possibilityQuickly and in large amountFault responseReliability/availability analysisIndefinite timeStreaming data

Owner:SOFTWARE AG USA

Method for continuous conversion of low-rank coal in subcritical water or supercritical water

InactiveCN1219852CNo emissionsQuick responseLiquid hydrocarbon mixture productionSolid solvent extractionCoal waterLower grade

The invention discloses a process for preparing coal water slurry or the mixture of coal water slurry with alkaline metal and / or alkaline earth oxides or hydroxides by the method of low level coal continuous transformation in subcritical or supercritical water which comprises, conducting continuous high pressure conveying of coal water slurry, charging into reaction system, usting the peculiarity of the hypercritical water to extracting and pyrolising low grade coal, converting it into useful product in gas, liquid and solid forms.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

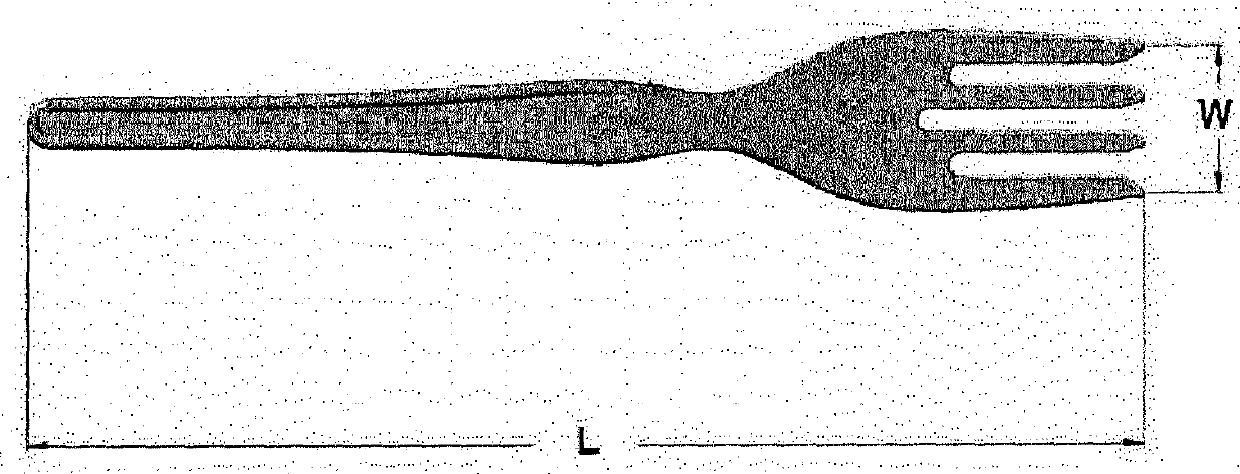

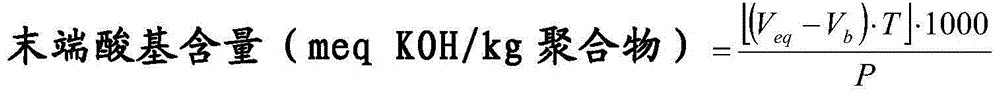

Biodegradable polymer composition for the manufacture of articles having a high heat deflection temperature

This invention relates to a biodegradable polymer composition which is particularly suitable for use in the manufacture of articles having a high heat deflection temperature (HDT) by injection moulding and thermoforming.

Owner:NOVAMONT SPA

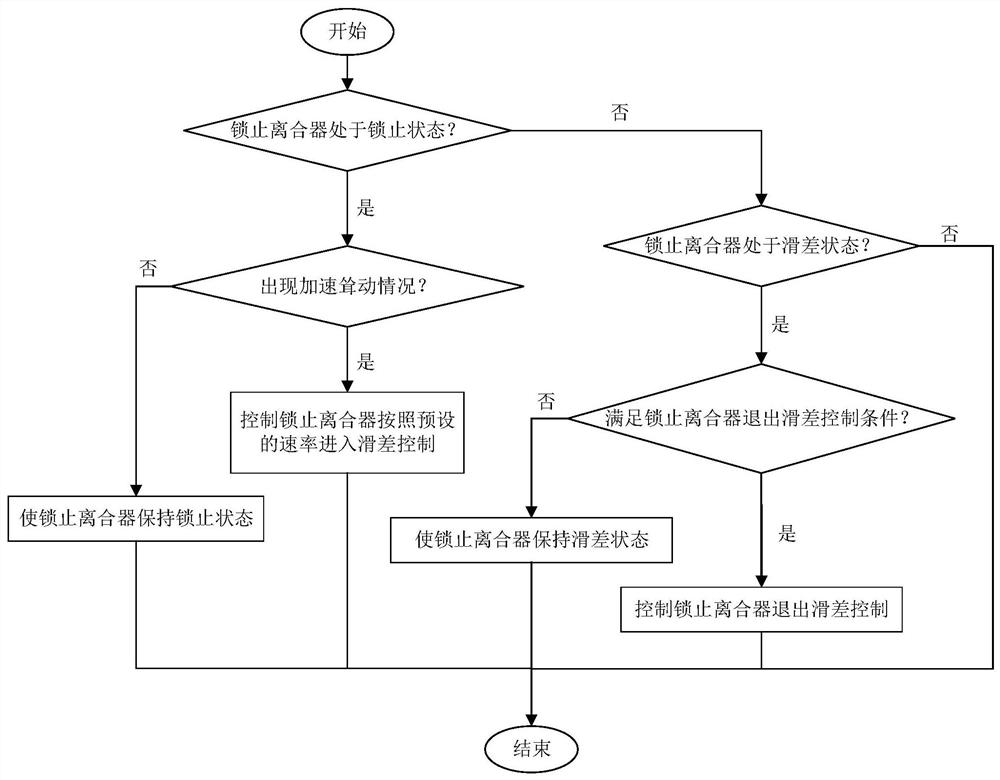

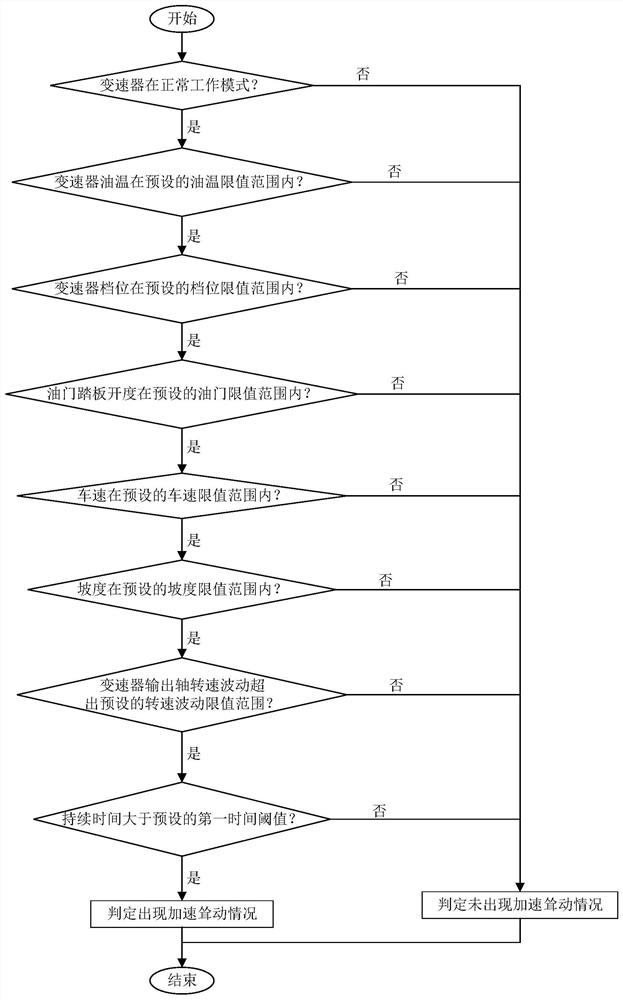

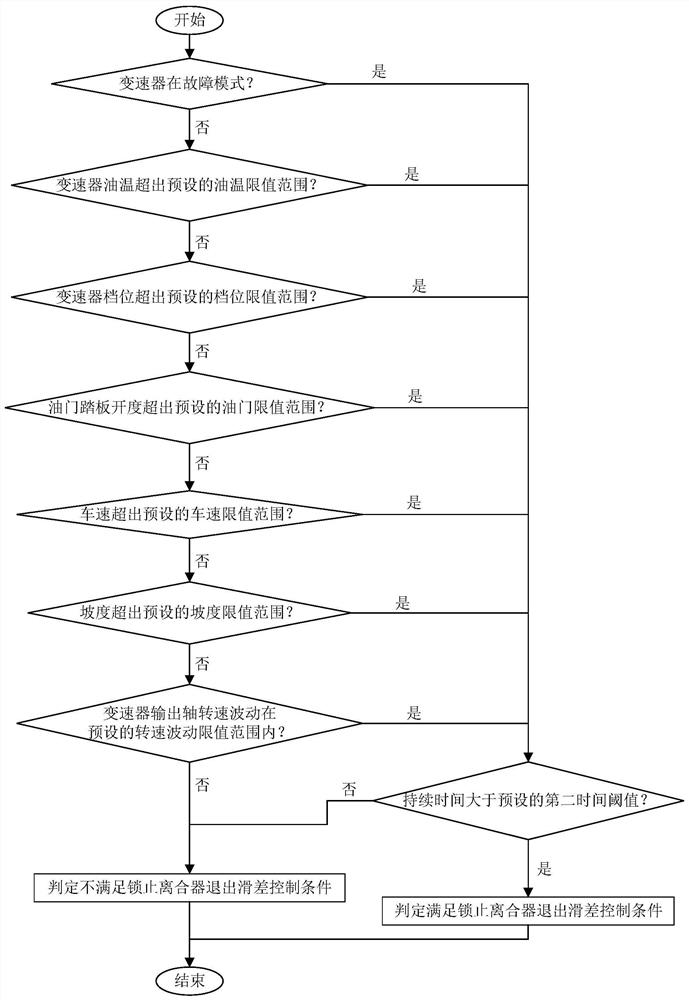

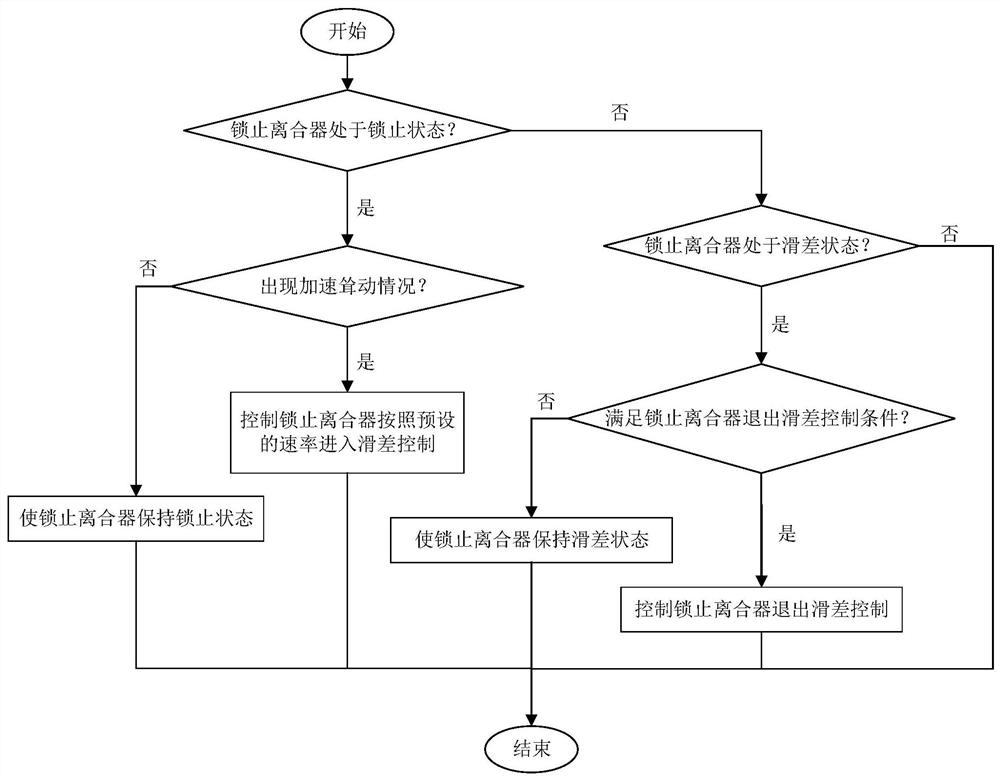

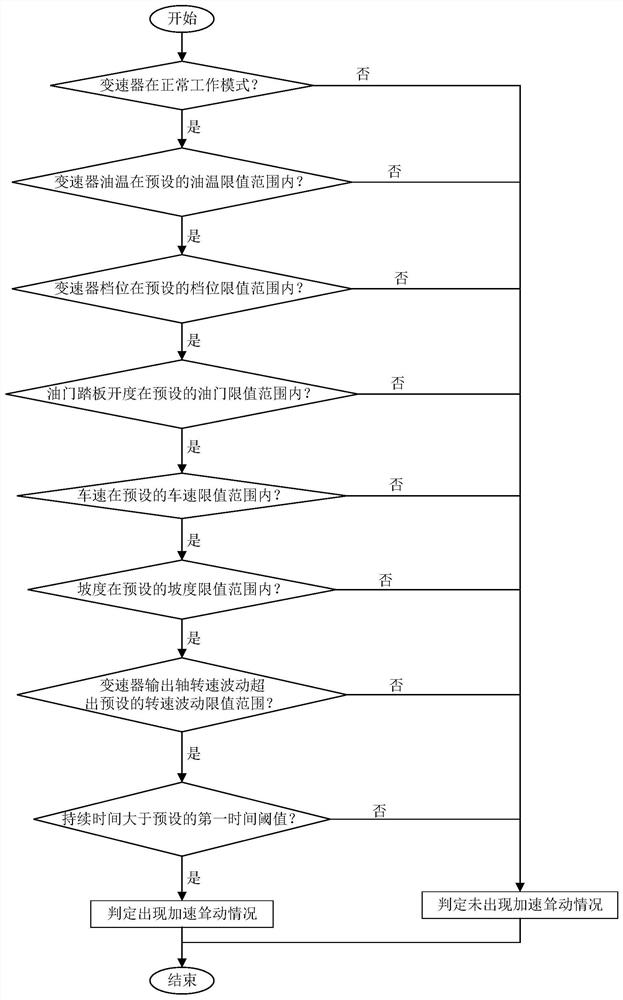

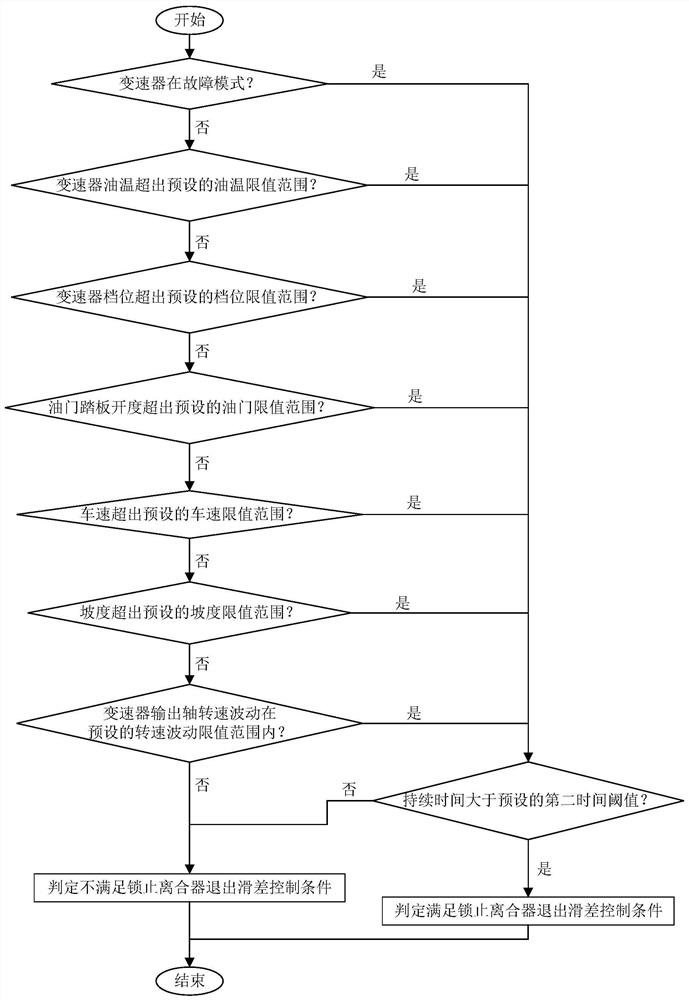

Lock-up clutch control method and system for automatic transmission provided with hydraulic torque converter

ActiveCN112303224AImprove acceleration shockImprove driving comfortRoad transportGearing controlVariatorSlip frequency

The invention discloses a lock-up clutch control method and system for an automatic transmission provided with a hydraulic torque converter. The control method includes the steps that a lock-up clutchis controlled to enter slip frequency control under the condition that the lock-up clutch is in a locked state and the accelerated rising condition occurs; and when the lock-up clutch is in the slipfrequency state, if the condition that the lock-up clutch quits slip frequency control is met, the lock-up clutch is controlled to quit slip frequency control. According to the method and the system,the accelerated rising condition can be improved, so that the dynamic property and comfort of the whole vehicle are balanced.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

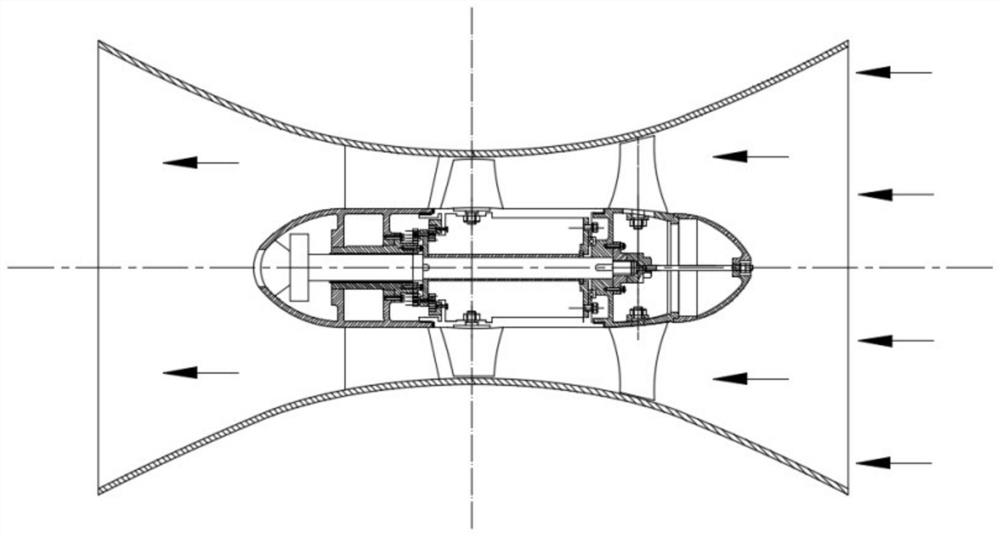

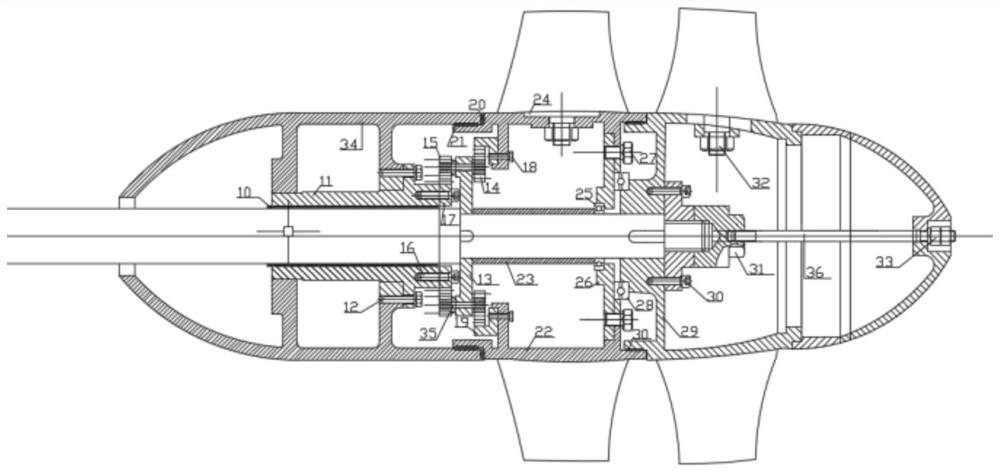

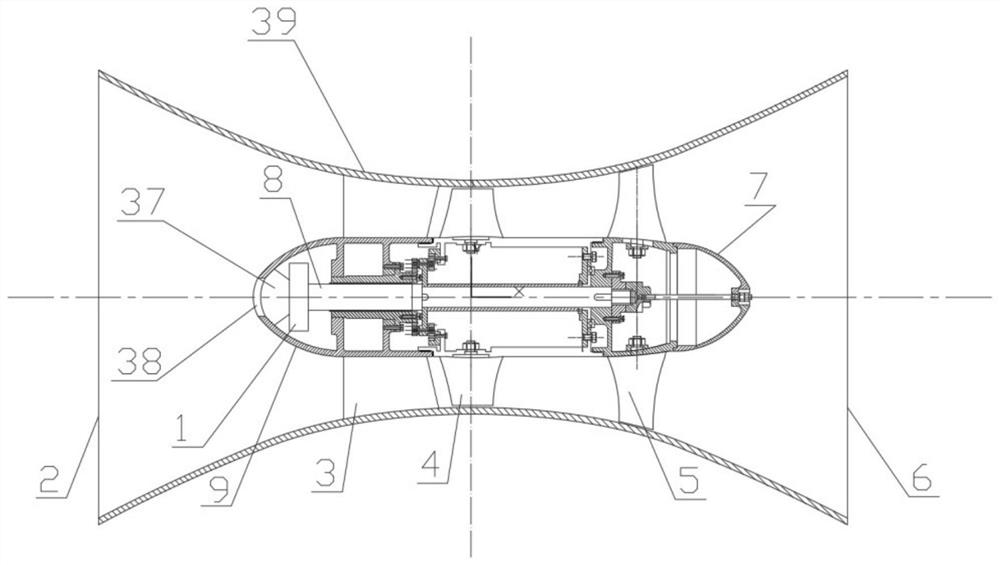

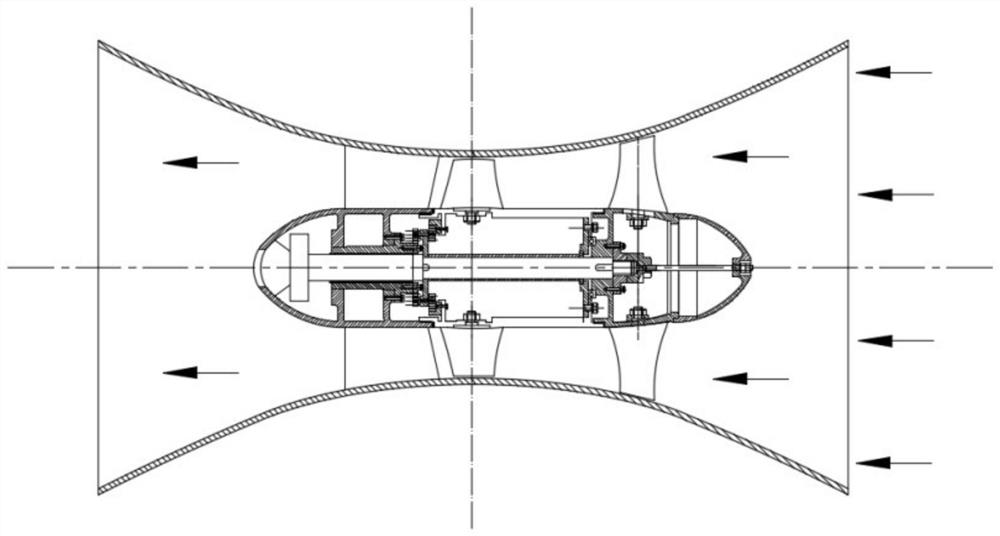

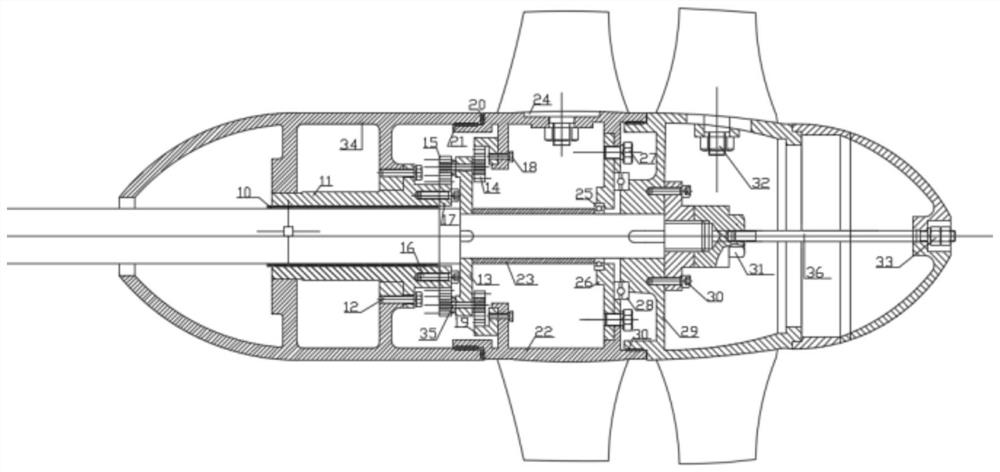

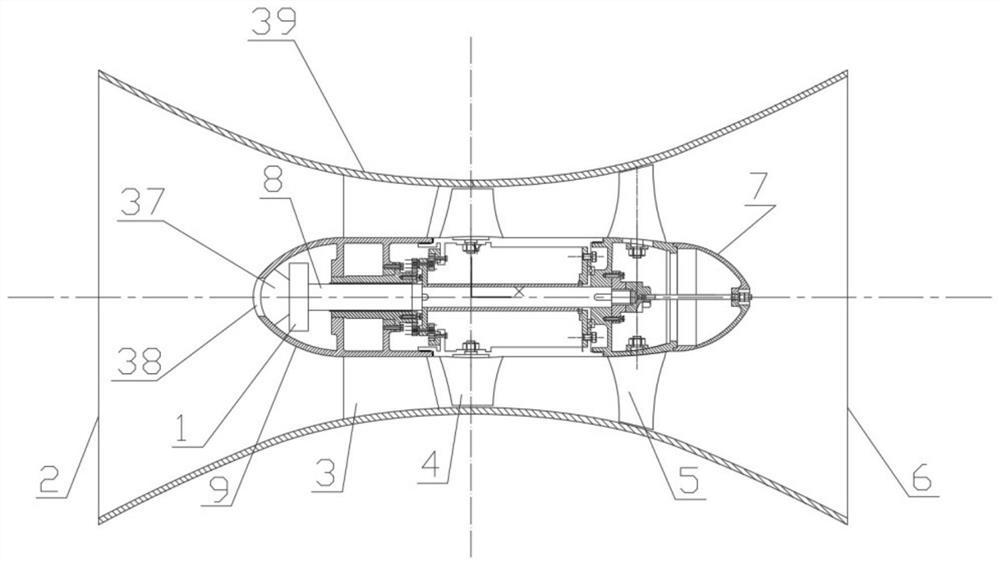

Single-shaft variable speed second-level asynchronous heart pump based on error term iterative curve flow channel, and use method

The invention relates to a single-shaft variable speed second-level asynchronous heart pump based on an error term iterative curve flow channel, and a use method. The single-shaft variable speed second-level asynchronous heart pump comprises a pump shell flow channel with a pump inlet and a pump outlet, wherein the pump shell flow channel is internally provided with a fixed guide vane body, and afirst-level impeller and a second-level impeller are fixed on a transmission shaft through keys. The single-shaft variable speed second-level asynchronous heart pump also comprises that a direct current permanent magnet motor is fixed on the inner side of a hub of the fixed guide vane body through a shock absorption supporting seat, the shell of a frequency sensor and the tail of the hub of the fixed guide vane are inlaid into a whole, the fixed guide vane body is provided with a plurality of guide vanes which are evenly distributed around an x shaft, the fixed guide vane body is fixed on theinner wall of a shell cavity of the pump shell flow channel through the guide vanes, and the molded line of the inner wall of the shell cavity is an error term iterative curve. The single-shaft variable speed second-level asynchronous heart pump has the advantages of a compact structure, a large flow, a high lift and a small injury to blood cells, a possibility of hemolysis due to the heart pump can be lowered, through a frequency sensor, the revolving speed of the pump can be changed in real time to meet a real-time requirement of the blood pressure and the blood flow of the human body.

Owner:HOHAI UNIV

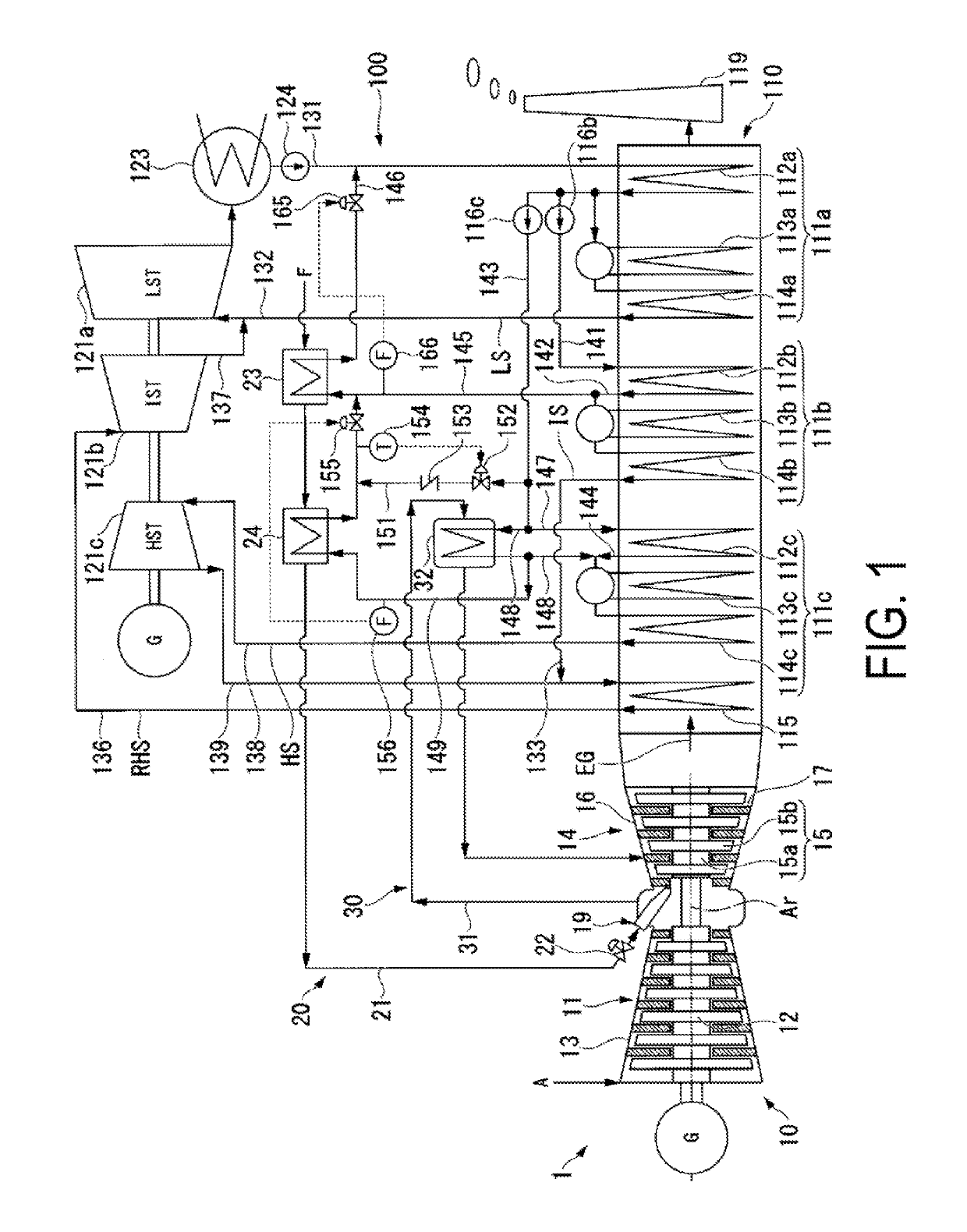

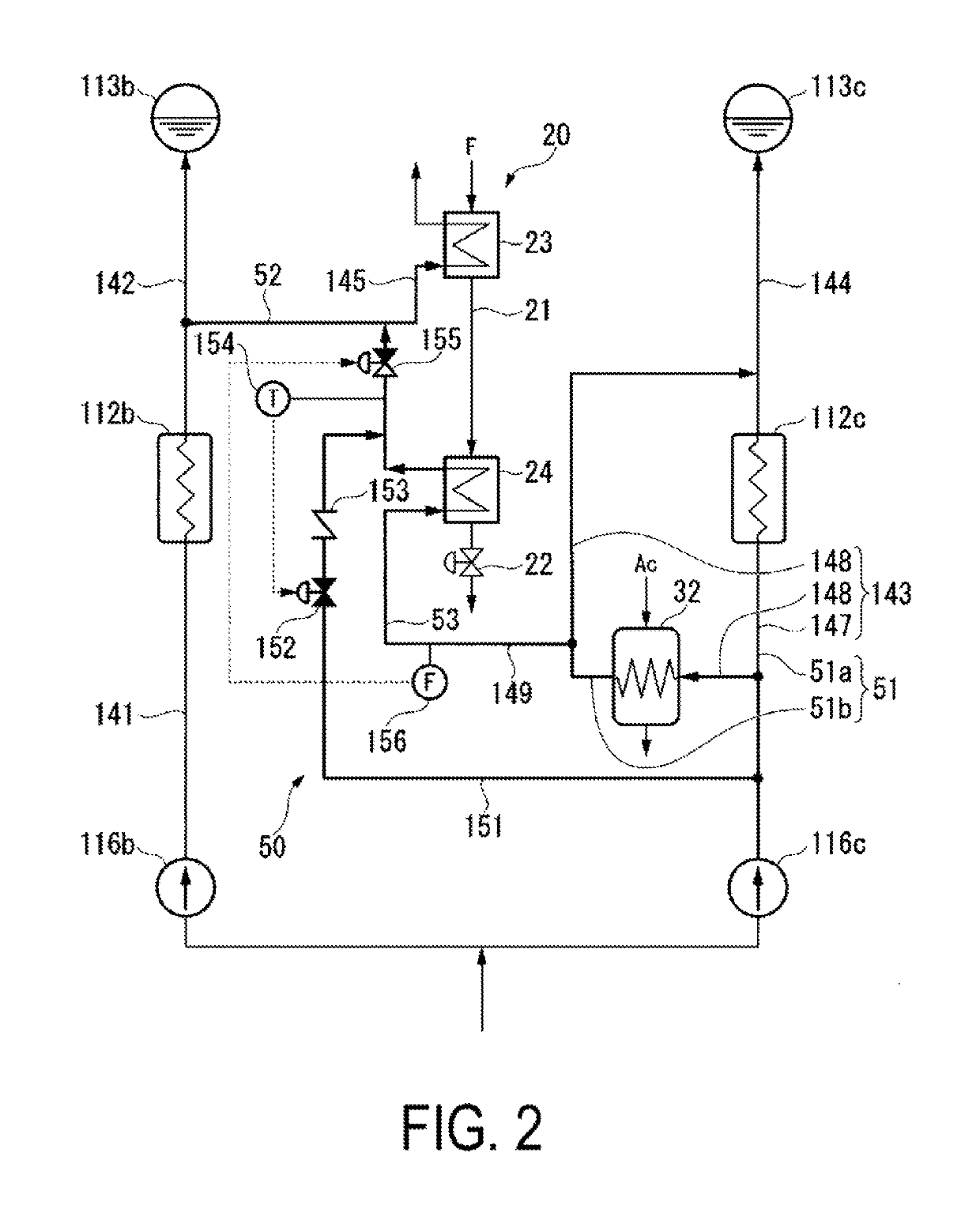

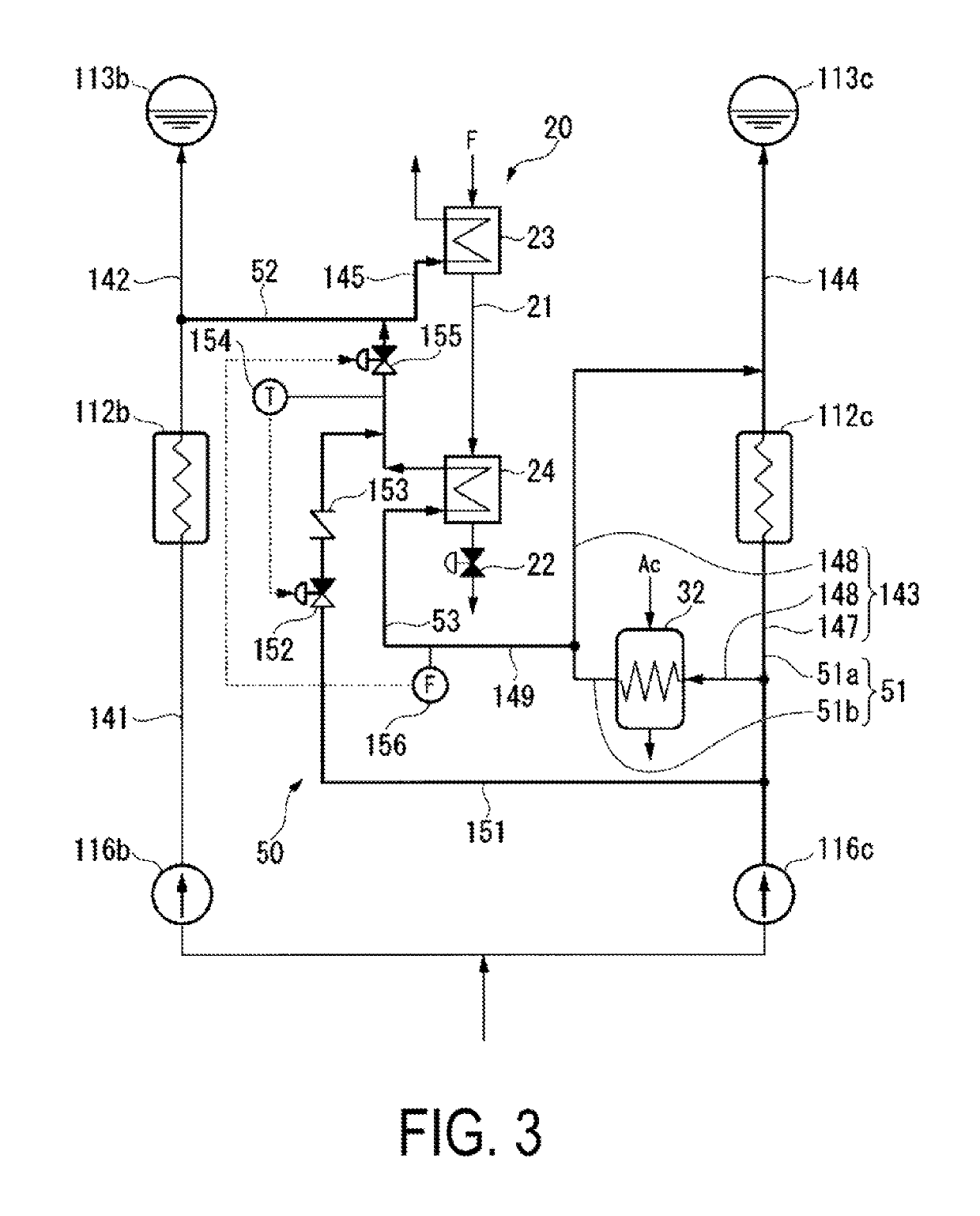

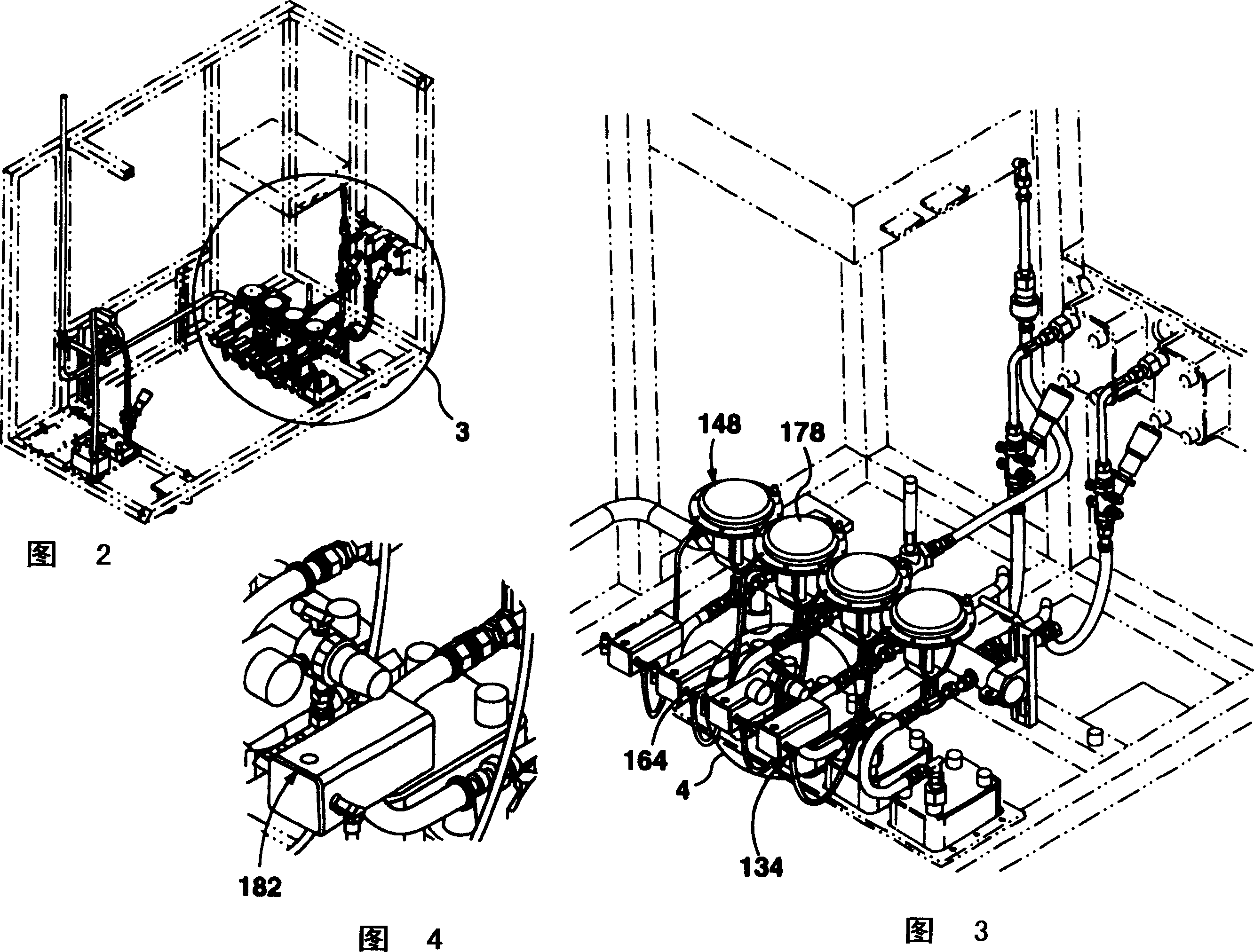

Water feeding method, water feeding system implementing said method, and steam generating facility provided with water feeding system

ActiveUS10352246B2Avoid flashSuppress changesTurbine/propulsion fuel heatingGas turbine plantsWater flowEngineering

A water feeding system provided with: a first feed water line through which first feed water flows; a second feed water line through which second feed water having a lower pressure than the first feed water flows; a first heater that heats the first feed water; a first feed water introducing line that guides first heated feed water, which is the first feed water that has been heated by the first heater, to the second feed water line; a medium heat exchanger that causes the first heated feed water to exchange heat with a medium, thereby cooling the first heated feed water and heating the medium; and a cooling water injecting line that injects cooling water having a lower temperature than the first heated feed water into the first feed water introducing line, at a position located further to the second feed water line side than the medium heat exchanger.

Owner:MITSUBISHI POWER LTD

Method of loading titanium dioxide photo catalyst on metal surface

InactiveCN1142014CEasy to makeSimple methodCatalyst activation/preparationPhotocatalytic reactionPowder suspension

A process for carrying TiO2 photocatalyst on metal surface includes such steps as cleaning metal surface, anodizing in acidic medium, hydrolyzing, leaching and coating tetrabutyl titanate and TiO2 film under the weak alkaline condition by the sol-gel-powder suspension method, and igniting at proper temp. Its advantages are strong photocatalysis action for degradating organic pollutants, and good electric conductivity and machinability.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN) +1

Computer system and method for monitoring key performance indicators (KPIs) online using time series pattern model

ActiveUS10921759B2Reduce in quantityShorten the timeElectric testing/monitoringAdaptive controlEngineeringData mining

Embodiments are directed to computer methods and systems that build and deploy a pattern model to detect an operating event in an online plant process. To build the pattern model, the methods and systems define a signature of the operating event, such that the defined signature contains a time series pattern for a KPI associated with the operating event. The methods and systems deploy the pattern model to automatically monitor, during online execution of the plant process, trends in movement of the KPI as a time series. The methods and systems determine, in real-time, a distance score between a range of the monitored time series and the time series pattern contained in the defined signature. The methods and systems automatically detect the operating event in the online industrial process based on the determined distance score, and alter parameters of the process (e.g., valves, actuators, etc.) to prevent the operating event.

Owner:ASPENTECH CORP

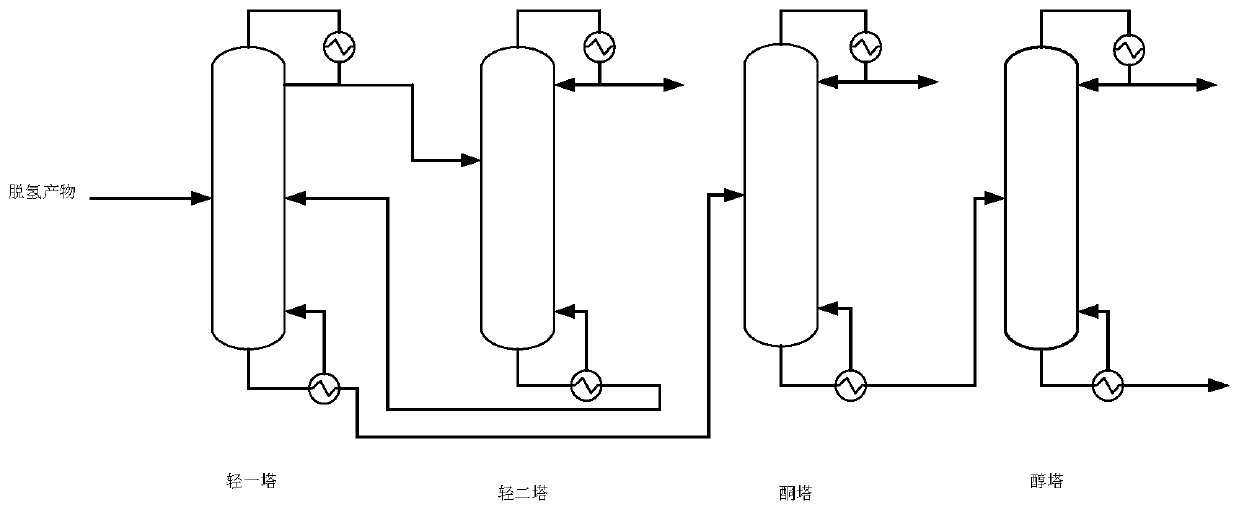

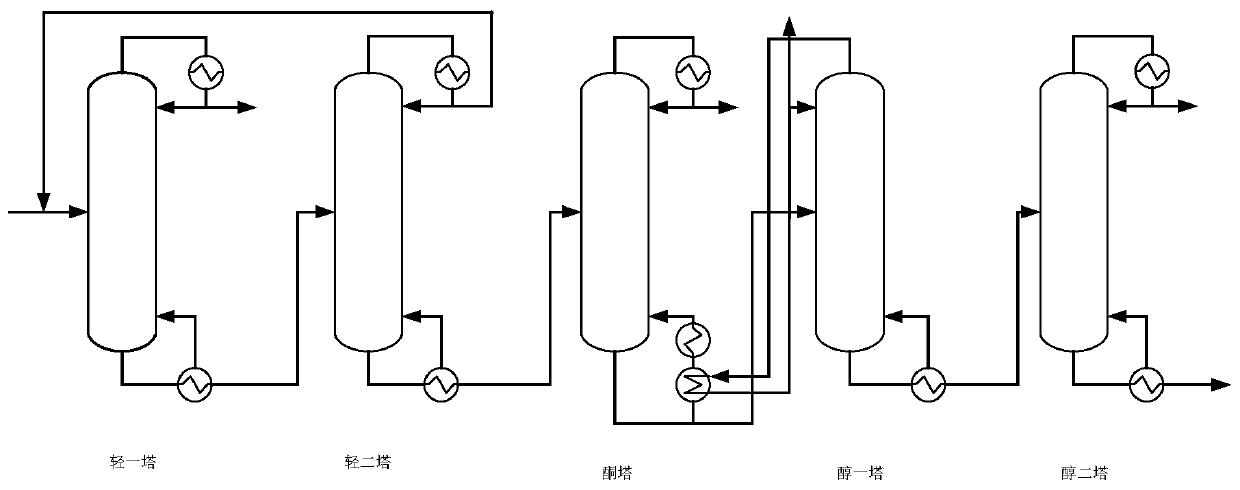

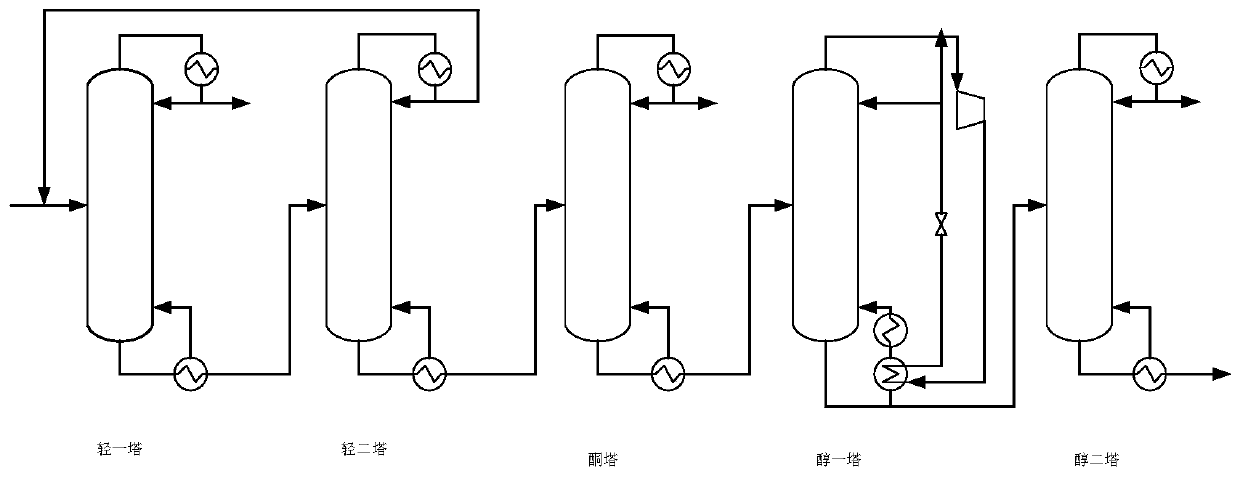

Design method of rectification process for synthesizing cyclohexanone-cyclohexanol by cyclohexene technology

ActiveCN110642672AChange structureChange operating conditionsOrganic compound preparationHydroxy compound preparationCyclohexanoneAlcohol

The invention provides a design method of a rectification process for synthesizing cyclohexanone-cyclohexanol by a cyclohexene technology. The method is concretely characterized in that existing four-tower alcohol ketone rectification is optimized, and double-effect heat pump heat integrated rectification is introduced; the tower bottom material of a first light tower is used as a feeding materialfor a second light tower, the tower top material of the first light tower is extracted, a material discharged from the top of the second light tower is circulated back to the feeding position of thefirst light tower, the tower bottom material of the second light tower is used as a feeding material for a ketone tower, the operation parameters of the light tower system are optimized optimal values, two alcohol towers are adopted to replace an existing cyclohexanol single-tower separation process, and a gas phase at the top of a first alcohol tower is used as a heat source for the bottom of theketone tower. Compared with an existing four-tower process, the method can remarkably reduce the energy consumption and TAC in the cyclohexanone-cyclohexanol rectification process under the conditionthat the same separation requirement is met.

Owner:TIANJIN UNIV

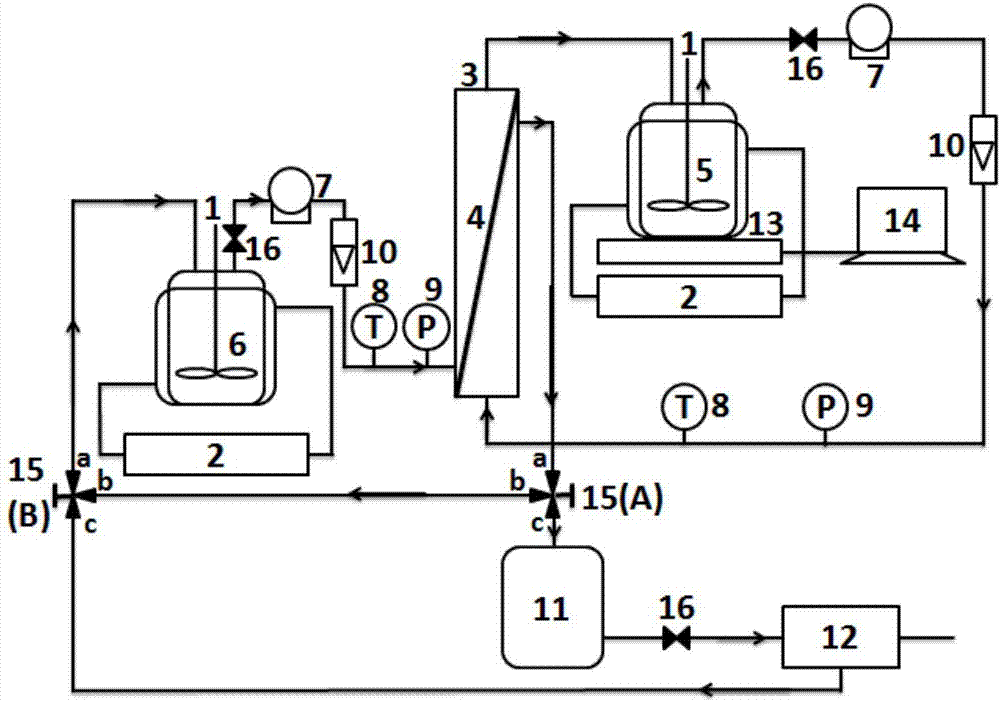

A device and method for dissolution and crystallization with membrane-assisted control

ActiveCN106166400BGood dispersionIncrease contact areaSemi-permeable membranesSolution crystallizationFiltrationDissolution

The invention provides a solventing-out crystallization technique device and method through auxiliary control of films, and belongs to the technical field of crystallization engineering. When a crystallization solution is added to a raw material pot, a solventing-out agent is added to a material-liquid pot, electronic scales, a computer, a stirring device and temperature controlling devices are started, and after a system is stable, squirm pumps of the material-liquid pot are started, so that solventing-out agents can circulate between the material-liquid pot and a film assembly; and after the solventing-out agent is stable in circulation, the squirm pump connected to the raw material pot is started so that the crystallization solution enters the film assembly. The solventing-out agent and the crystallization solution which are in sufficient contact in the film assembly can perform nucleation growth in the film assembly, and then the solventing-out agent and the crystallization solution, after the nucleation growth, can flow into an external storing pot for filtration and post-treatment; and the solventing-out agent and the crystallization solution can also perform nucleation growth outside the film assembly, and after solutes are wholly dissolved, filtration is performed. The electronic scales record the addition quantity of the solventing-out agent in a real-time manner, and the addition quantity of the solventing-out agent is systematically controlled through controlling films and operation conditions, so that ideal crystal products are obtained.

Owner:DALIAN UNIV OF TECH

Process for preparing unsaturated nitrile

InactiveCN1100034CEasy to operateChange operating conditionsPreparation by hydrocarbon ammoxidationMetal/metal-oxides/metal-hydroxide catalystsFluidized bedAmmonia

A process for producing acrylonitrile or methacrylonitrile, wherein a molybdenum compound, which is convertible to molybdenum oxide and not supported on a carrier is added to a fluidized bed reactor as an activator, in such a way that the ratio y of molybdenum atoms in the oxide catalyst represented by the formula:MoyBipFeqAaBbCcDdEeOfwill be maintained in the range of 1.02x to 1.12x (x=1.5p+q+a+c+1.5d+1.5e) during an ammoxydation reaction.

Owner:ASAHI KASEI KK

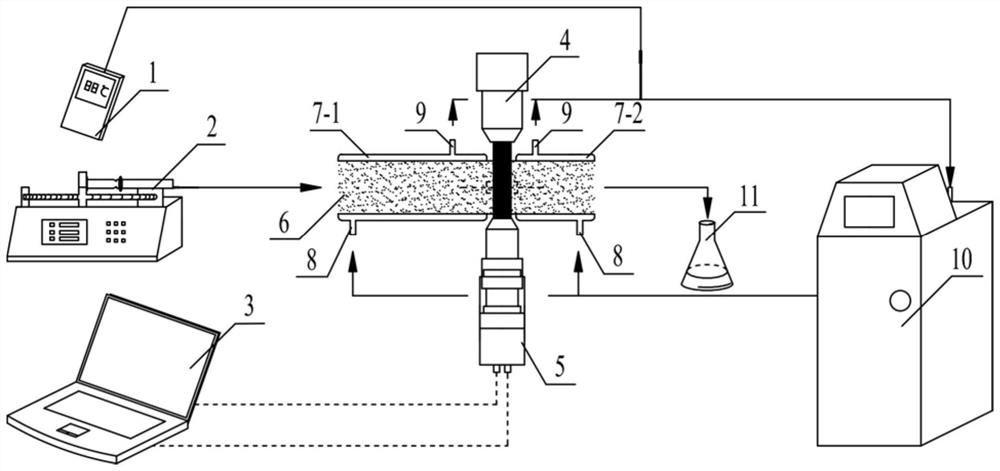

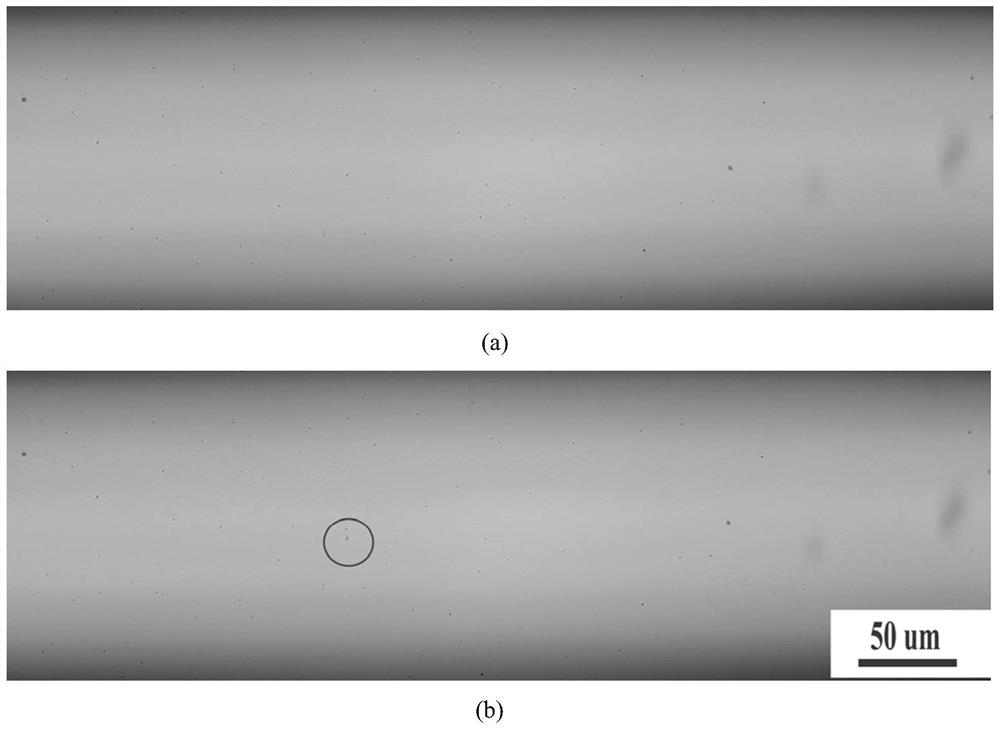

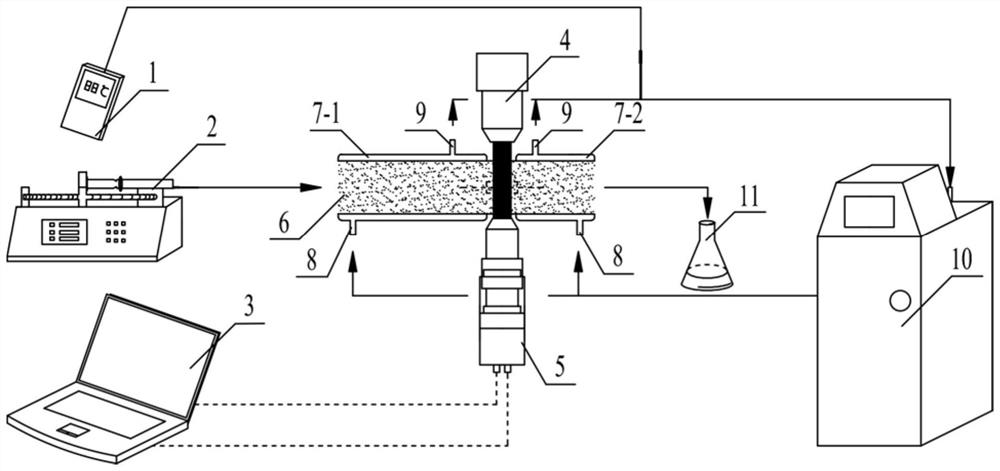

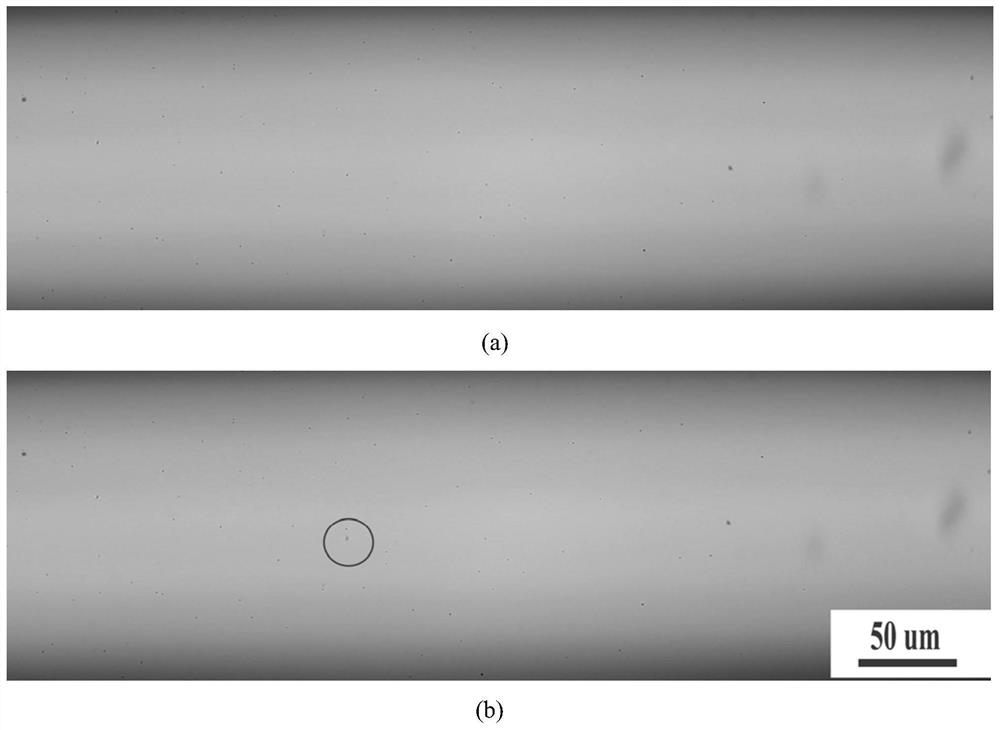

Device and method for measuring width of crystallization metastable region of micro-scale flow system

ActiveCN112162003AAccurate judgmentGuaranteed accuracyMaterial crystallisationInvestigating crystalsTemperature controlWater baths

The present invention discloses a device for measuring the width of the crystallization metastable region of a micro-scale flow system. The device comprises a temperature control system, a microscope,a camera, a computer and an injection pump, and the temperature control system is composed of a constant-temperature circulating water bath device, a first heat preservation jacket, a second heat preservation jacket and a temperature sensor. According to a method for measuring the width of the crystallization metastable region of the micro-scale flow system, by using the above device, a measuredsolution with the temperature being the initial test temperature and reaching the saturation state at the initial test temperature is injected into a micro-channel at the constant flow rate through the injection pump, and by combining the amplification effect of the microscope on the micro-channel, the camera is adopted to shoot the measured liquid in the micro-channel in real time, the crystallization state of the liquid is captured, the crystallization point temperature is obtained, the difference value between the initial test temperature and the crystallization point temperature is calculated, and the difference value is the width of the crystallization metastable region of the micro-scale flow system of the measured solution. The device and the method provided by the invention providethe quantitative data analysis support for the micro-channel-crystallization coupling technology research.

Owner:SICHUAN UNIV +1

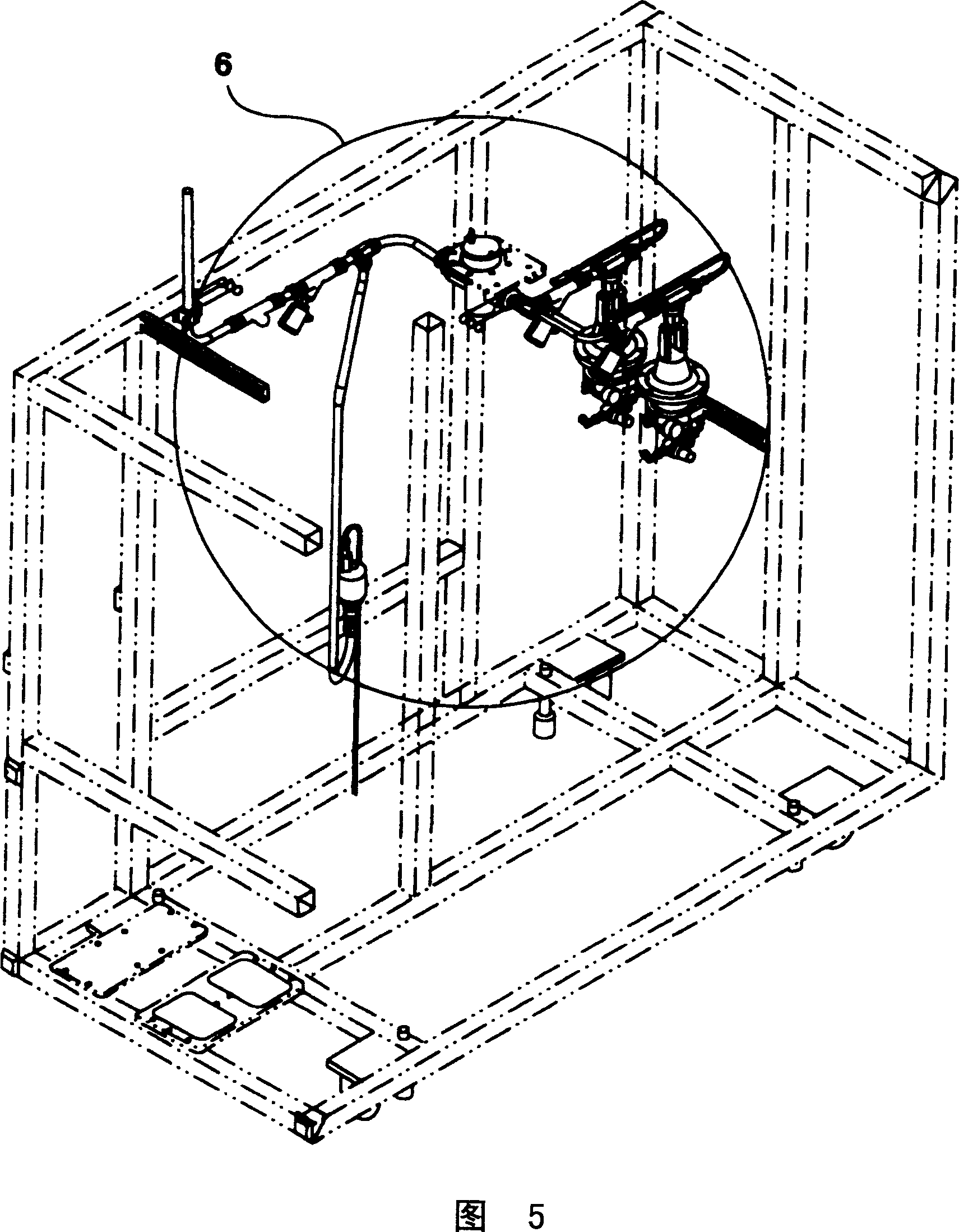

Method and apparatus for humidification and temp. control of incoming fuel cell process gas

InactiveCN1314154CChange operating conditionsRealize dynamic controlFuel cell heat exchangeSolid electrolyte fuel cellsTemperature controlFuel cells

A method of humidifying and controlling the temperature of a process gas comprising the steps of: supersaturating the process gas with steam and heating it to a first predetermined temperature; cooling the process gas until it reaches a second predetermined temperature; removing excess condensed water from the process gas stream; and heating the process gas stream until it reaches a third preset temperature. The invention also discloses a device for implementing the method.

Owner:HYDROGENICS CORP

Producing raw material containing benzyl carbinol glycosides from Cistanche deserticola by using membrane separation technique and preparation method thereof

InactiveCN100503626CHigh retention rateRemove invalid ingredientsSugar derivativesPlant ingredientsSeparation technologyAdditive ingredient

Owner:HETIAN DCM MEDICINE BIOLOGICAL TECH

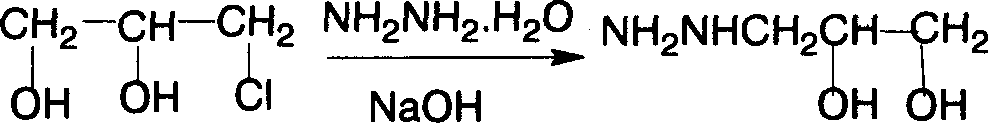

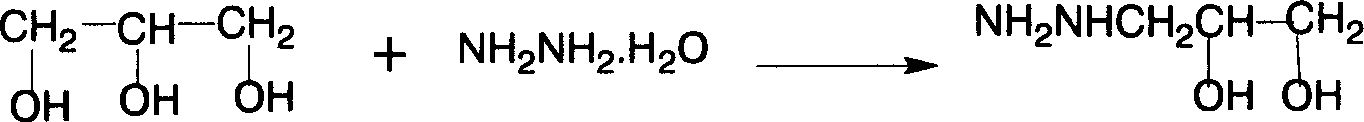

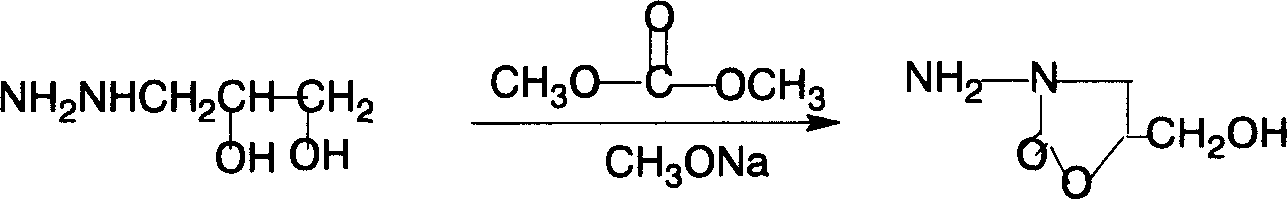

Synthesis method of 5-hydroxy methyl furazolidone

InactiveCN1274688CSimple operating conditionsFew stepsAntibacterial agentsOrganic chemistrySynthesis methodsHydrazine compound

A process for synthesizing 5-hdyroxymethyl-furoxone from 1-chloroglycerine, hydrazine hydrate, sodium hydroxide, methanol sodium, dimethyl ester and 5-nitrofurfural diacetate is disclosed. Its advantages are lower concentration of the aqueous solution of hydrazine hydrate (less than 100%) and no deposit of sodium chloride.

Owner:曹桂东

Method of making hydrogen containing gas using lignite and peat

InactiveCN1205303CNo emissionsQuick responseHydrogen productionLiquid hydrocarbon mixture productionHydrogenPeat

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Single-axis variable-speed two-stage asynchronous heart pump with differential term iterative curve flow channel and its application method

The invention relates to a single-axis variable-speed two-stage asynchronous heart pump with a difference term iterative curve flow path and a method for using it. The single-axis variable-speed two-stage asynchronous heart pump includes a pump casing flow path with a pump inlet and a pump outlet. The pump casing flows There is a fixed guide vane body in the channel, and the first-stage impeller and the second-stage impeller are fixed on the drive shaft through keys; a DC permanent magnet motor is also fixed on the inner side of the hub of the fixed guide vane body through a shock-absorbing support, and the frequency sensor The shell of the fixed guide vane hub is inlaid as a whole, and the fixed guide vane body is provided with a plurality of guide vane blades uniformly distributed around the x-axis, and the fixed guide vane body is fixed on the pump casing through the guide vane blades. On the inner wall of the shell cavity of the channel, the shape line of the inner wall of the shell cavity is a difference iterative curve. The invention has the advantages of compact structure, large flow rate, high head, less damage to blood cells, and reduces the probability of hemolysis caused by the heart pump. The pump speed can be changed in real time through the frequency sensor to meet the real-time demands of human blood pressure and blood flow.

Owner:HOHAI UNIV

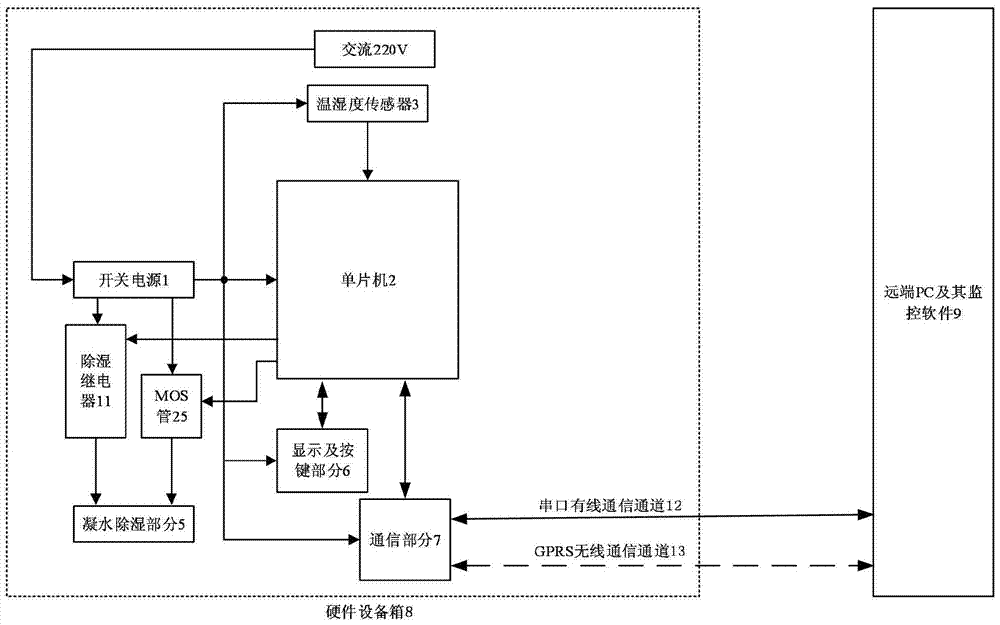

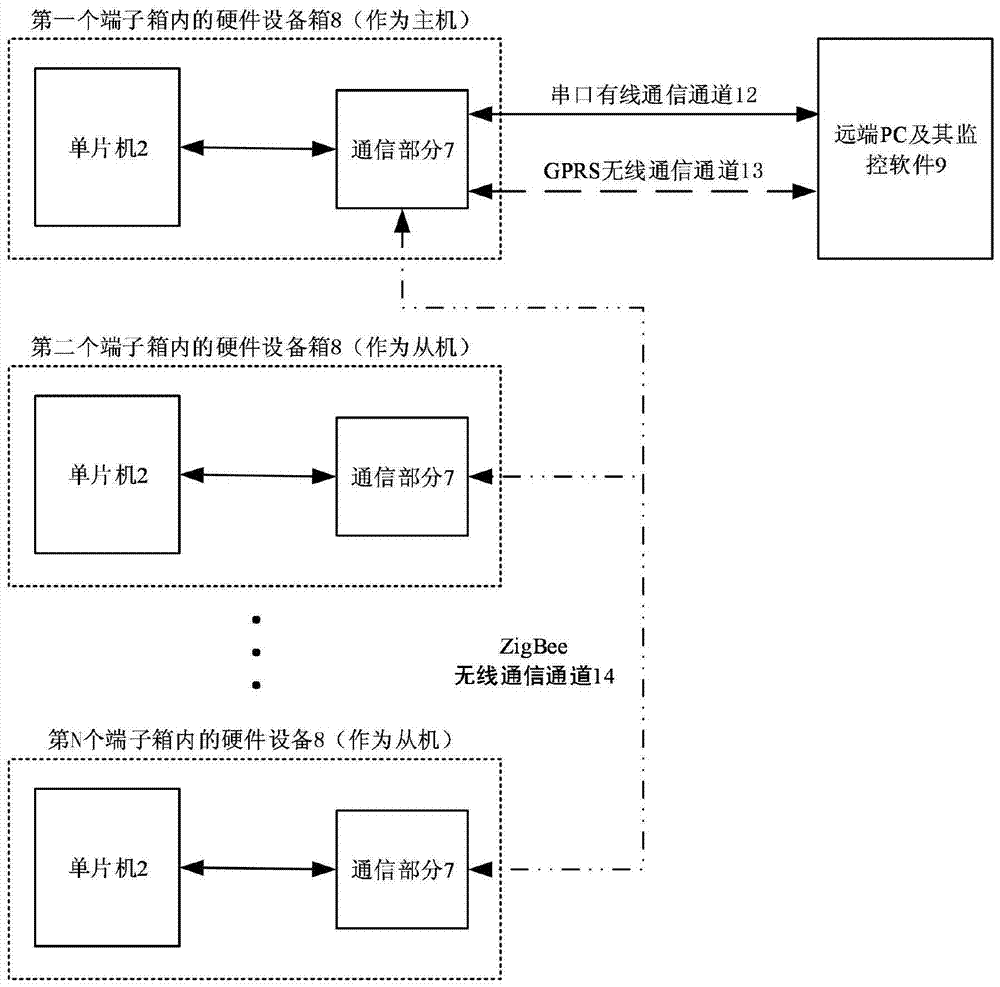

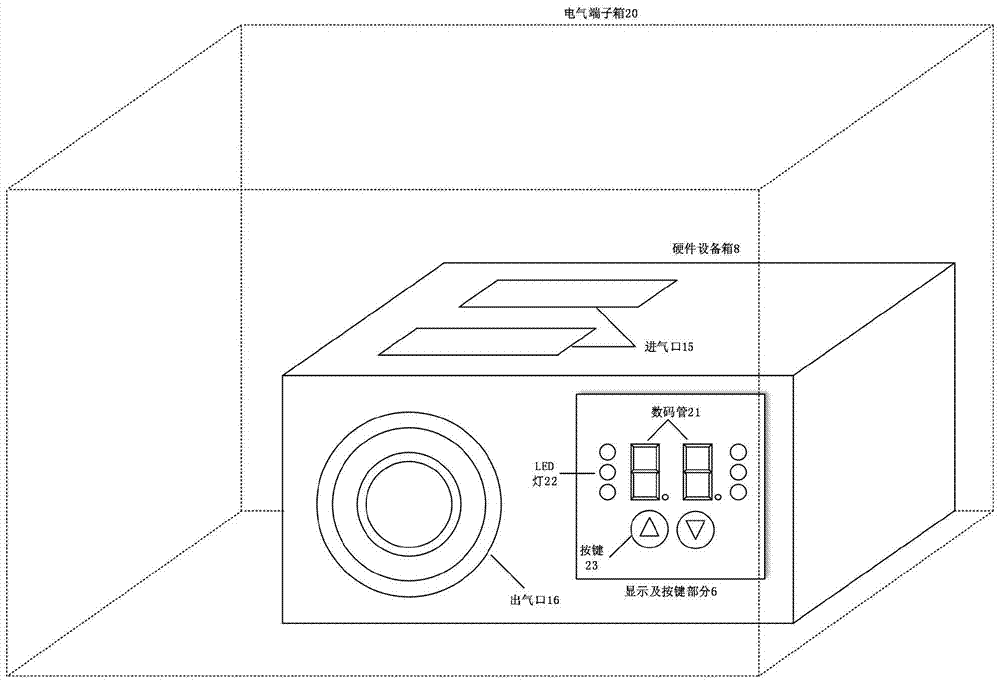

An intelligent dehumidification system for an electrical terminal box

ActiveCN105511515BEasy to circulate condensationEnhanced convectionHumidity controlMicrocontrollerEngineering

The invention discloses an intelligent dehumidifying system of an electrical terminal box. The intelligent dehumidifying system comprises a hardware equipment box which is installed in the electrical terminal box and a far-end upper computer which communicates with the hardware equipment box. The hardware equipment box comprises a box body, and a switching power supply, a single-chip microcomputer, a temperature and humidity sensor, a water condensing and dehumidifying mechanism and a communication module which are arranged in the box body. The working characteristics of semiconductor refrigeration sheets are utilized, an extremely cold surface is formed on condensation sheets for condensation and dehumidification, and a high temperature surface is formed on heat-radiating fins to heat the previously condensed air again so that temperature in the electrical terminal box is enabled not to sharply fluctuate, and air can be cyclically condensed on the condensation sheets; temperature near an air inlet is low and temperature near an air outlet is high due to the installation position of the condensation sheets and the heat-radiating fins, and the position of the air inlet relative to the air outlet is higher so that air convection is facilitated by the design; and air circulation can be formed in a forced way by the effect of fans so that the common condensation problem in the terminal box, a switch cabinet and other electrical cabinets can be fundamentally solved.

Owner:HANGZHOU ICEWAY ELECTRIC SCI & TECH CO LTD

Biodegradable polymer composition for the manufacture of articles having a high heat deflection temperature

Owner:NOVAMONT SPA

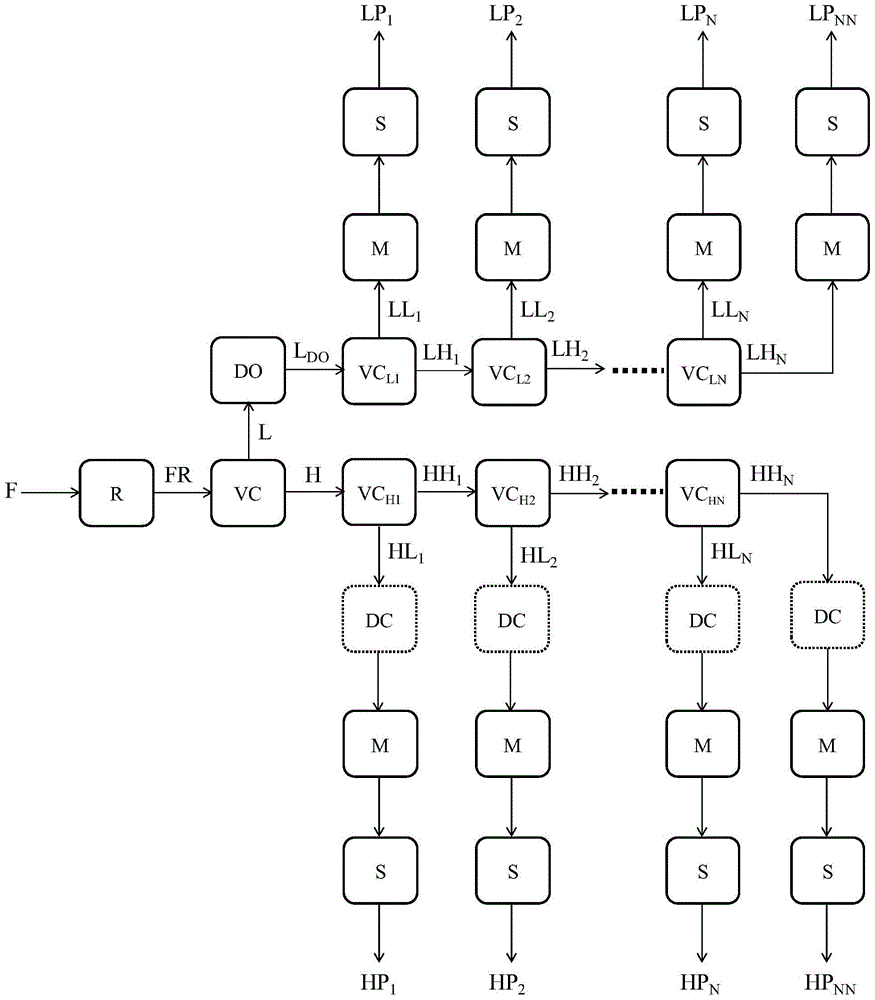

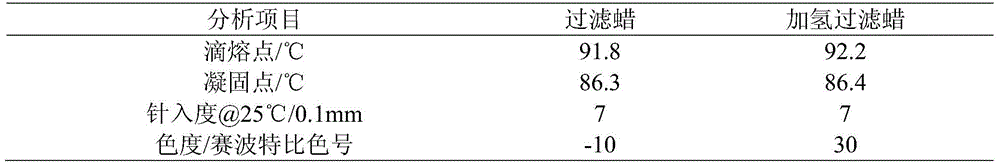

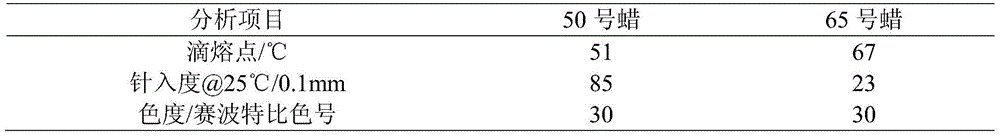

A kind of method for processing Fischer-Tropsch wax production series products

The invention provides a method for processing Fischer-Tropsch wax production series products. The method comprises: carrying out hydrofinishing on a Fischer-Tropsch wax raw material F to prepare a hydrofinished material FR; separating FR to obtain a light component material L and a heavy material H; carrying out oil removing operation on L to obtain an oil-removed light component material LDO; separating LDO to obtain a light component material LL1 and a remaining component material LH1; carrying out improvement of physicochemical properties on LL1 and forming so as to obtain a lightweight product LP1; treating LH1 according to the processes of the steps (4) and (5) to obtain a lightweight product LP2 and a remaining component material LH2; treating LH2 according to the processes of the steps (4), (5) and (6) to finally obtain a series of lightweight products LP3,..., LPN, and LPNN; separating H to obtain a light component material HL1 and a remaining component HH1; carrying out improvement of physicochemical properties on HL1 andforming so as to obtain a heavyweight product HP1; treating HH1 according to the processes of the steps (8) and (9) to obtain a heavyweight product HP2 and a remaining component material HH2; and treating HH2 according to the processes of the steps (8), (9) and (10) to finally obtain a series of heavyweight products HP3,..., HPN, and HPNN.

Owner:SYNFUELS CHINA TECH CO LTD

Lock-up clutch control method and system for automatic transmission with hydraulic torque converter

ActiveCN112303224BChange operating conditionsAccelerate sensational improvementRoad transportGearing controlClutch controlAutomatic transmission

The invention discloses a lock-up clutch control method and system of an automatic transmission with a hydraulic torque converter. The clutch enters the slip control; when the lock-up clutch is in the slip state, if the lock-up clutch exit slip control condition is satisfied, the lock-up clutch is controlled to exit the slip control. The invention can improve the vibration of acceleration and balance the power and comfort of the whole vehicle.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Apparatus and method for measuring the width of crystallization metastable zone in microscale flow system

ActiveCN112162003BAccurate judgmentGuaranteed accuracyMaterial crystallisationInvestigating crystalsWater bathsThermal insulation

The device for measuring the width of the crystallization metastable zone of the micro-scale flow system of the present invention includes a temperature control system, a microscope, a camera, a computer and a syringe pump. The temperature control system consists of a constant temperature circulating water bath, a first heat preservation jacket, a second Composed of insulation jacket and temperature sensor. The method for measuring the width of the crystallization metastable zone of the micro-scale flow system of the present invention uses the above-mentioned measuring device to inject the tested solution whose temperature is the initial test temperature and reaches saturation at the initial test temperature into the microchannel at a constant flow rate through a syringe pump In this method, combined with the magnification effect of the microscope on the microchannel, the camera is used to take real-time pictures of the measured liquid in the microchannel to capture the crystallization state of the fluid, obtain the crystallization point temperature, and calculate the difference between the initial test temperature and the crystallization point temperature , the difference is the width of the crystallization metastable zone of the microscale flow system of the measured solution. The device and method of the present invention provide quantitative data analysis support for research on microchannel-crystal coupling technology.

Owner:SICHUAN UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com