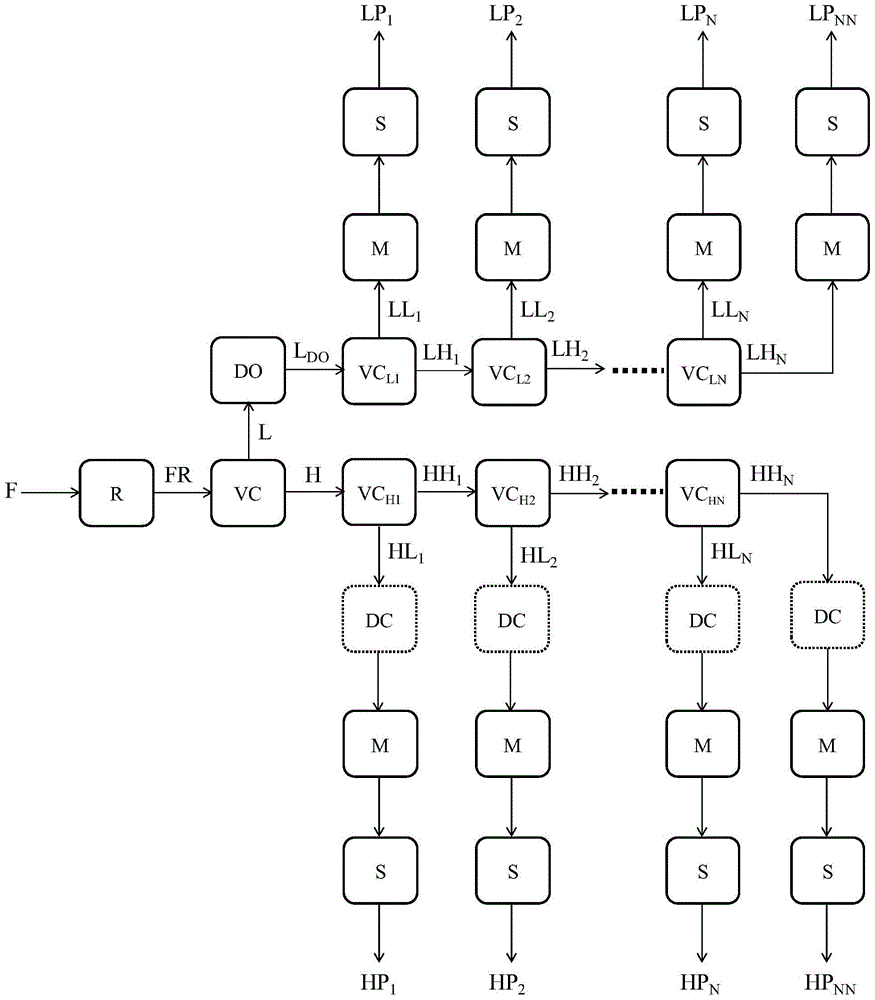

A kind of method for processing Fischer-Tropsch wax production series products

A series of products and processing fee technology, applied in the field of processing fee-Tropsch wax production series products, can solve problems such as carbon deposition and coking, product purpose is not strong, affect product quality, etc., to achieve high operating flexibility and strong product pertinence , the effect of rich product line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

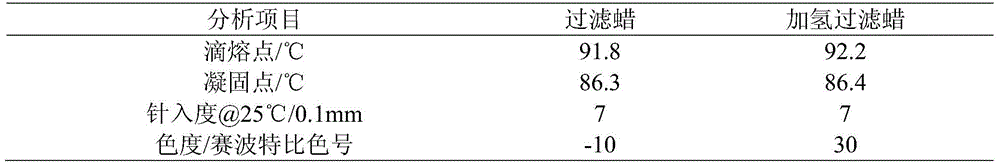

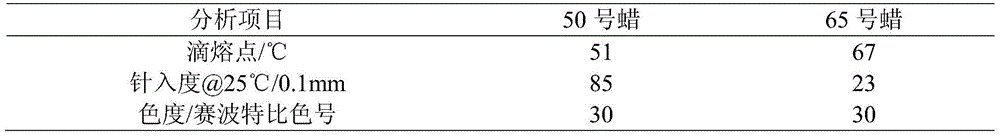

Embodiment 1

[0048] The Fischer-Tropsch synthetic filter wax obtained by a low-temperature Fischer-Tropsch synthesis process is used as raw material, and the hydrogenated filter wax is obtained through hydrogenation refining. The hydrogenation temperature is 310 ° C, and the reaction pressure is 6 MPa. The properties of the material before and after hydrogenation are shown in Table 1. The hydrogenation filtration wax enters the thin-film evaporator, the operating temperature is 250°C, and the operating pressure is 30Pa, and the hydrogenation filtration wax is separated into a Fischer-Tropsch light wax oil component and a Fischer-Tropsch heavy wax group with an end boiling point of about 500°C point. The Fischer-Tropsch light wax oil component enters the deoiling unit, and the deoiled Fischer-Tropsch light wax enters the short-path evaporator with an operating temperature of 125°C and an operating pressure of 0.7Pa to evaporate the diesel fraction and the remaining Fischer-Tropsch light wax ...

Embodiment 2

[0059] Fischer-Tropsch synthesis filter wax obtained by another Fischer-Tropsch synthesis process was used as raw material, and hydrogenated filter wax was obtained through hydrogenation refining. The hydrogenation temperature was 300°C and the reaction pressure was 10MPa. The hydrogenated filtration wax enters the thin-film evaporator, the operating temperature is 260°C, and the operating pressure is 30Pa, and the hydrogenated filtration wax is separated into a Fischer-Tropsch light wax oil component and a heavy Fischer-Tropsch wax component with an end boiling point of about 600°C . The Fischer-Tropsch light wax oil component enters the deoiling unit, and the deoiled Fischer-Tropsch light wax enters the short-path evaporator with an operating temperature of 125°C and an operating pressure of 0.7Pa to evaporate the diesel fraction and the remaining Fischer-Tropsch light wax The high quality wax component enters the next stage evaporator. The Fischer-Tropsch light wax compone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com