Patents

Literature

109 results about "Polycyclic Hydrocarbons" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrocarbons consisting of two or more ring structures.

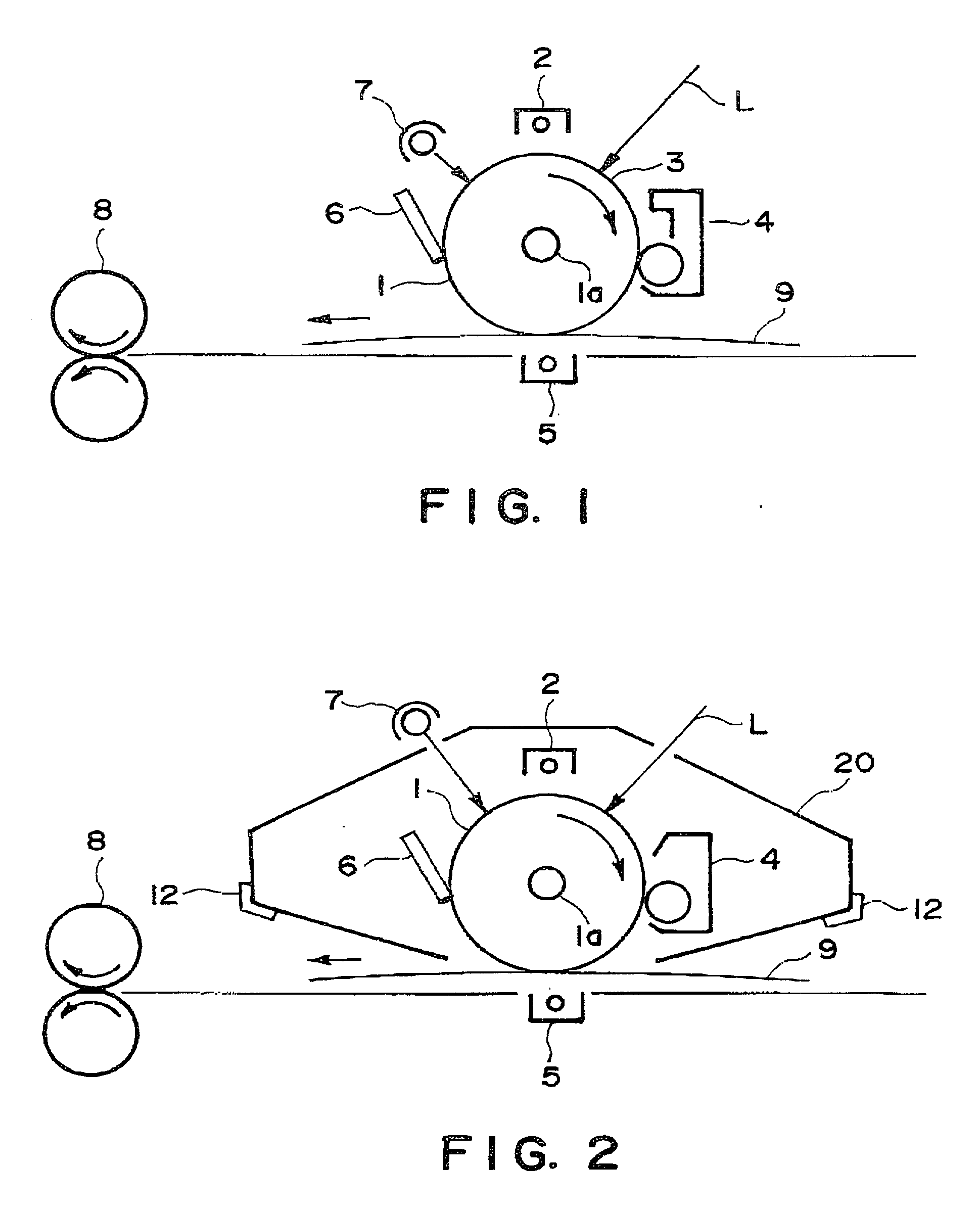

Cyclocondensed polycyclic hydrocarbon compound and light-emitting device using the same

InactiveUS20010008711A1Reduce the driving voltageImprove efficiencyOrganic chemistryDischarge tube luminescnet screensSimple Organic CompoundsOrganic compound

An organic light-emitting device comprising a light-emitting layer or a plurality of organic compound thin layers including a light-emitting layer formed between a pair of electrodes, wherein at least one layer comprises at least one kind of compound represented by the following formula (1): wherein R11, R12 and R13 each represents a group having a cyclocondensed polycyclic hydrocarbon structure in which three or more rings are cyclocondensed; and a novel cyclocondensed polycyclic hydrocarbon compound.

Owner:UDC IRELAND +1

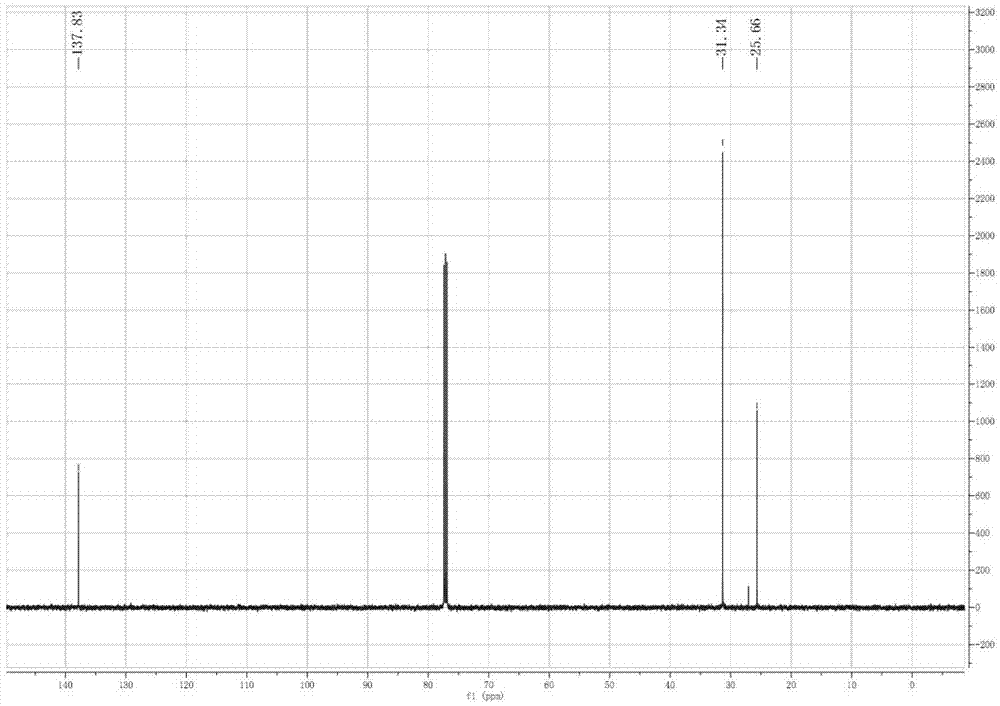

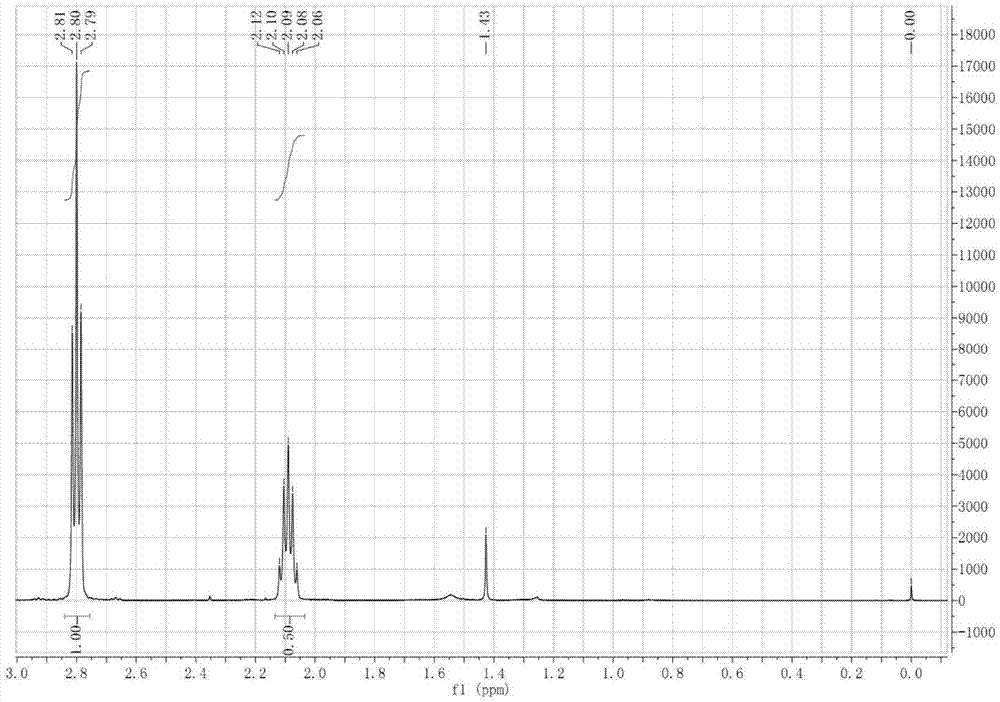

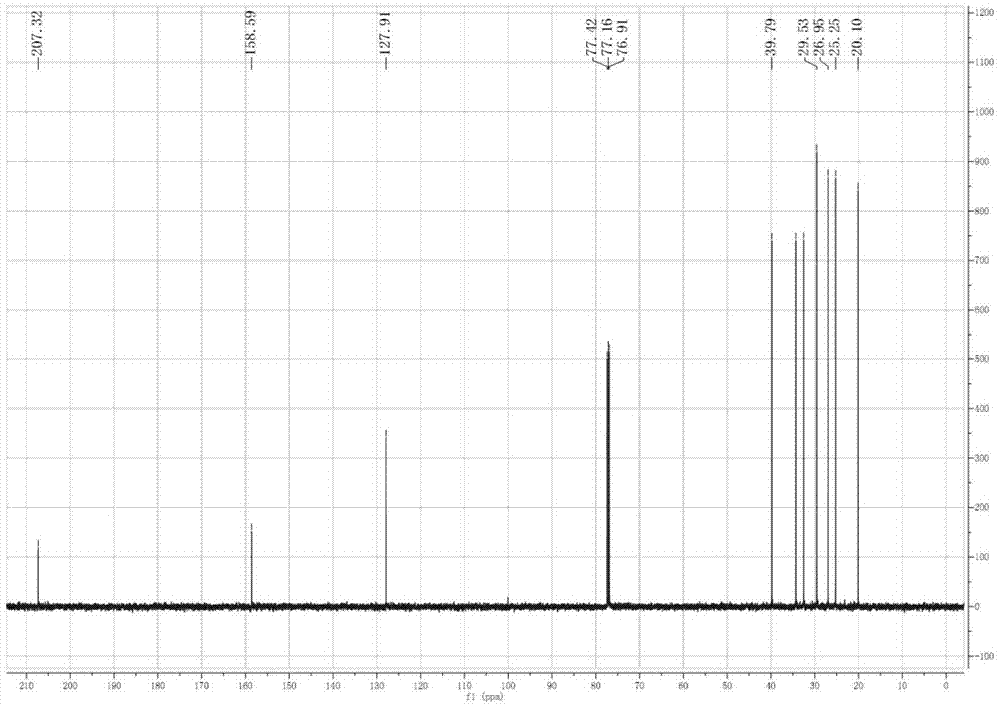

Method for synthesizing high-density aviation fuel by using cyclopentanone as raw material

ActiveCN104232140AImprove combustion effectIncreased carrying energyLiquid hydrocarbon mixture productionBio-feedstockCarbon numberSolvent free

The invention relates to a synthetic route of a hydrocarbon fuel with high density and high volumetric calorific value by using a lignocelluloses-based platform chemical compound as a raw material and completely independent of fossil energy. A liquid fuel obtained by the method can be used in various aircrafts or used as an additive to raise combustion performance of aviation fuel. The method is divided into two parts: 1) under the promotion action of an acid / base catalyst, cyclopentanone (furfural selective hydrogenation product) is subjected to an aldol self-condensation reaction to synthesize unsaturated organic compounds with C10 and C15 polycyclic structures; and 2) a metal loaded A / X catalyst is used to carry out a one-step hydrodeoxygenation and hydrogenation reaction on products generated from the step 1 under low-temperature solvent-free conditions, so as to obtain polycyclic hydrocarbon fuel with carbon number being 10 and 15. The liquid fuel has high density (C10: 0.92g / cm<3>; C15: 1.12g / cm<3>), can be used to effectively raise carrying energy of an aircraft and reduce fuel consumption rate, and meets requirements of high navigational speed, large load and long range.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

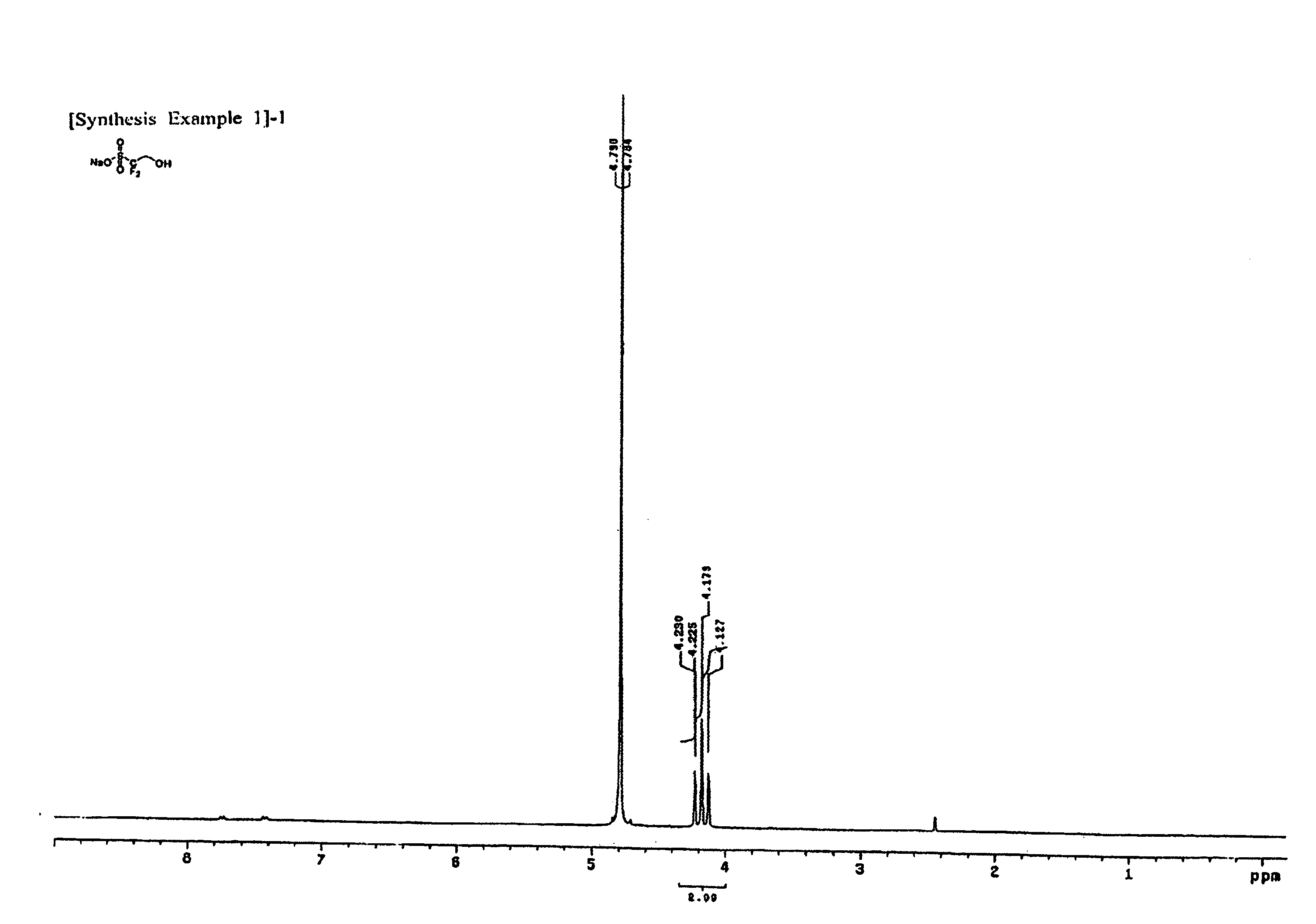

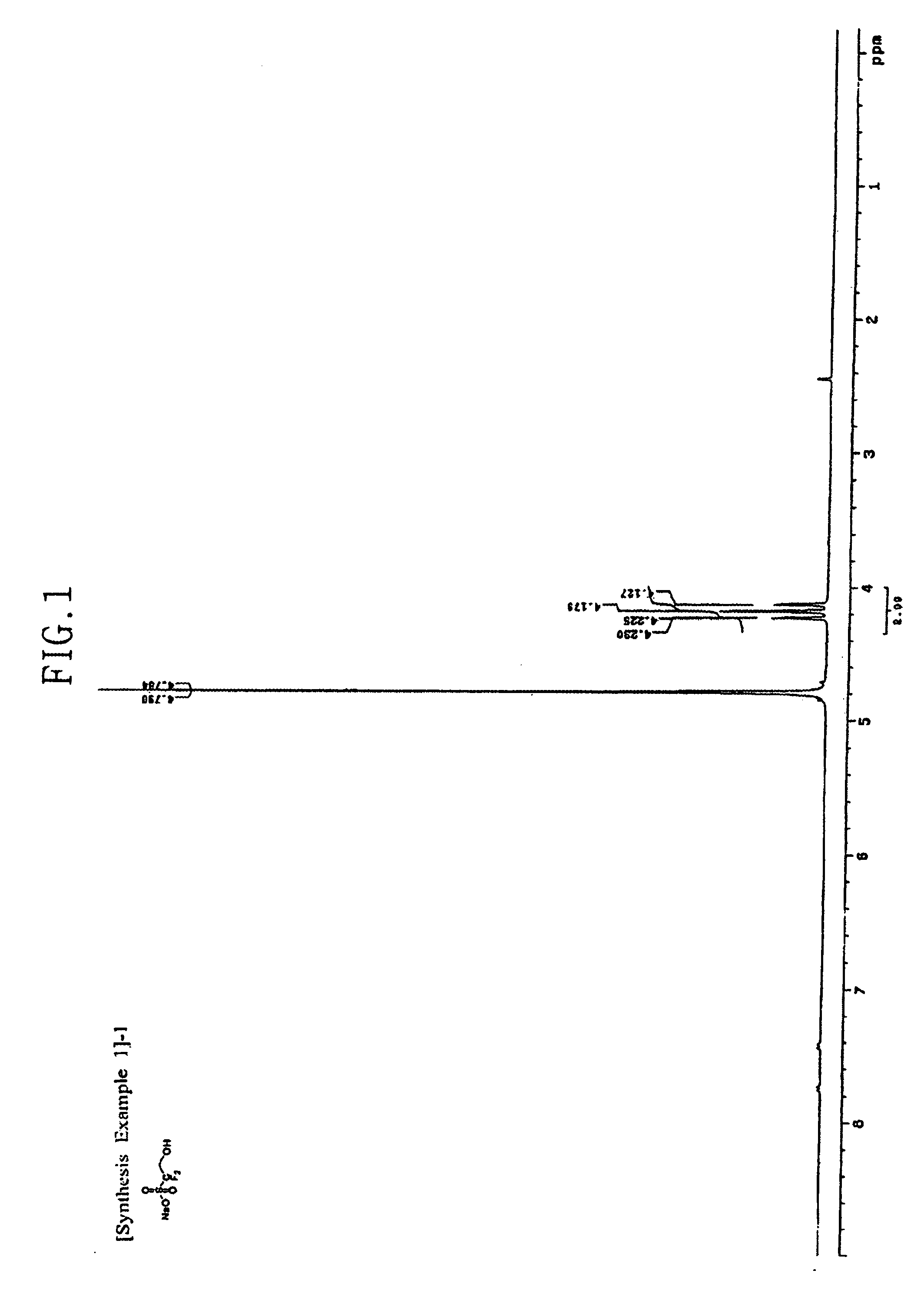

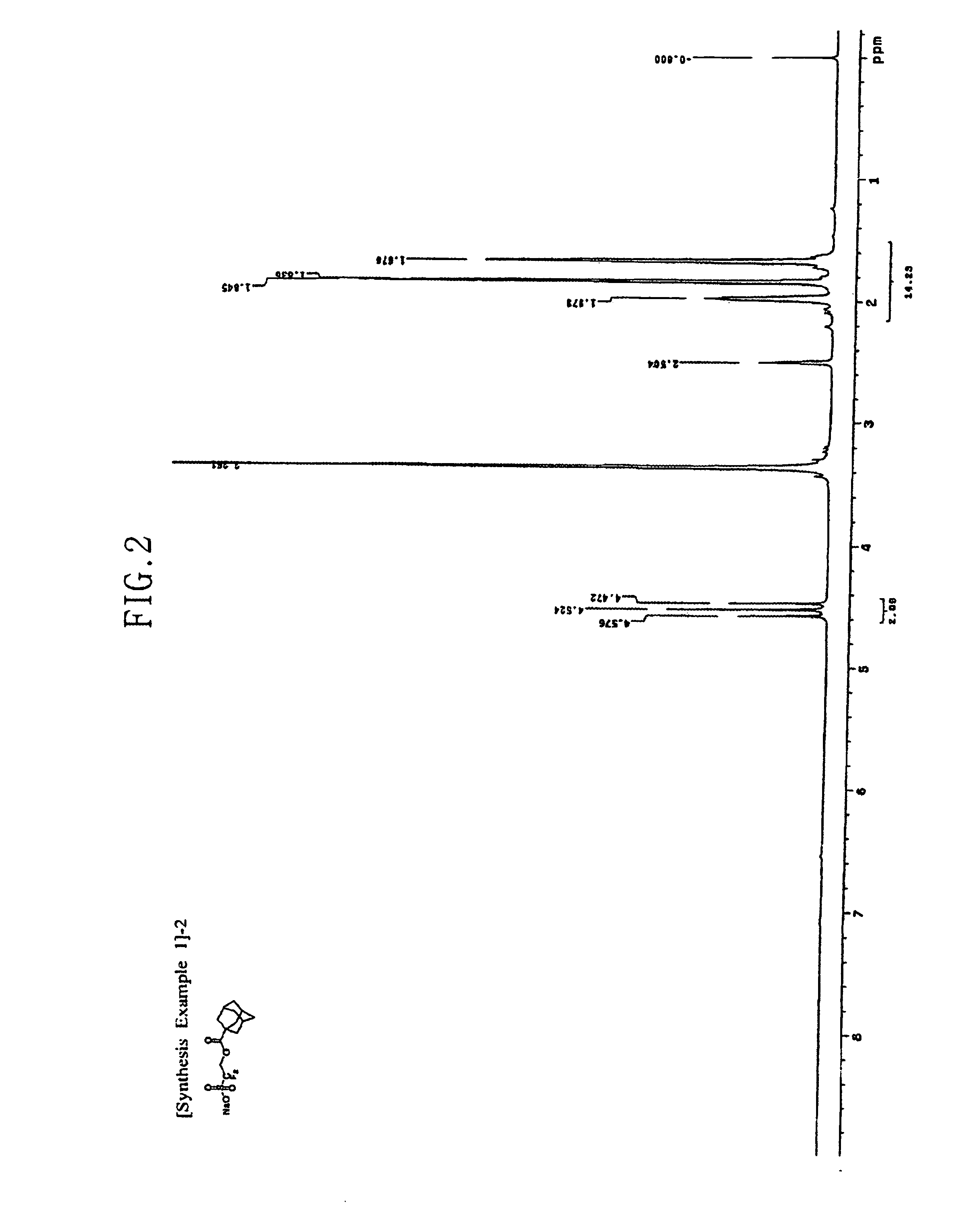

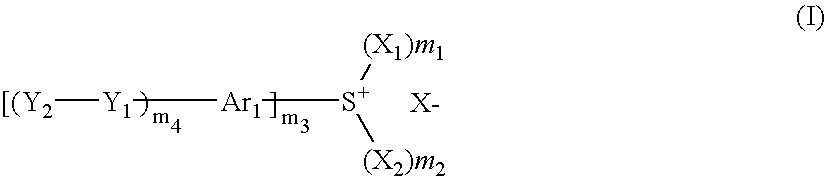

Acid generating agent for chemically amplified resist compositions

ActiveUS20090234155A1Excellent line width roughnessHigh resolutionOrganic chemistryOrganic compound preparationPolymer scienceAlkoxy group

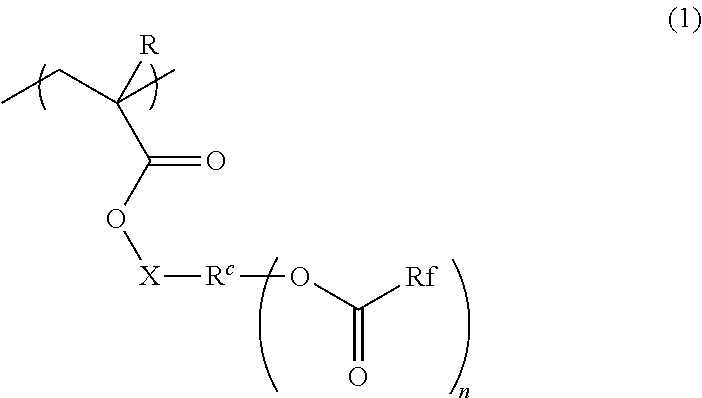

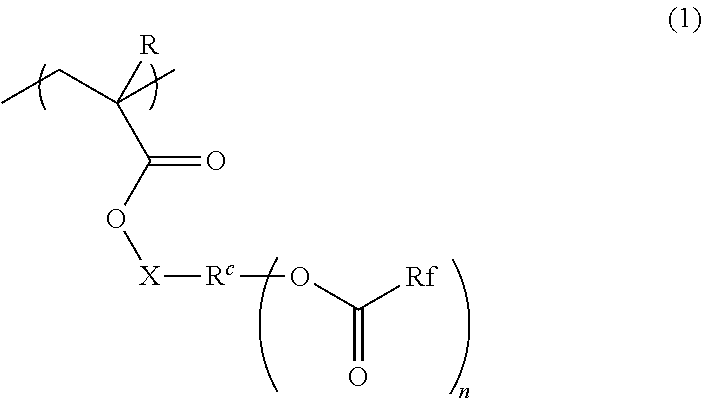

An acid generating agent used for chemically amplified resist compositions is provided, which agent is represented by the following formula (1):wherein X represents a monocyclic or polycyclic hydrocarbon group having 3 to 30 carbon atoms, and having at least one hydrogen atom on the ring substituted by an alkyl or alkoxy group which and may be unsubstituted or substituted with a group selected from an ether group, an ester group, a carbonyl group, an acetal group, an epoxy group, a nitrile group and an aldehyde group, or by a perfluoroalkyl group, a hydroxyalkyl group, or a cyano group; R6 is an alkyl group, an alkoxy group, or a heteroatom selected from the group consisting of N, S and F; m is an integer from 0 to 2; and A+ is an organic counterion.

Owner:SK MATERIALS PERFORMANCE CO LTD

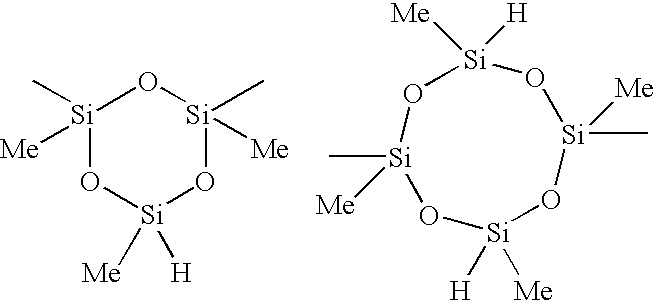

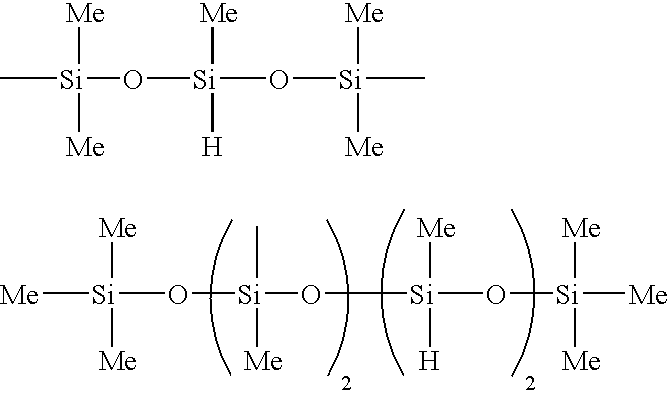

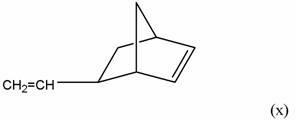

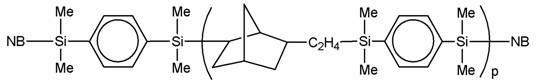

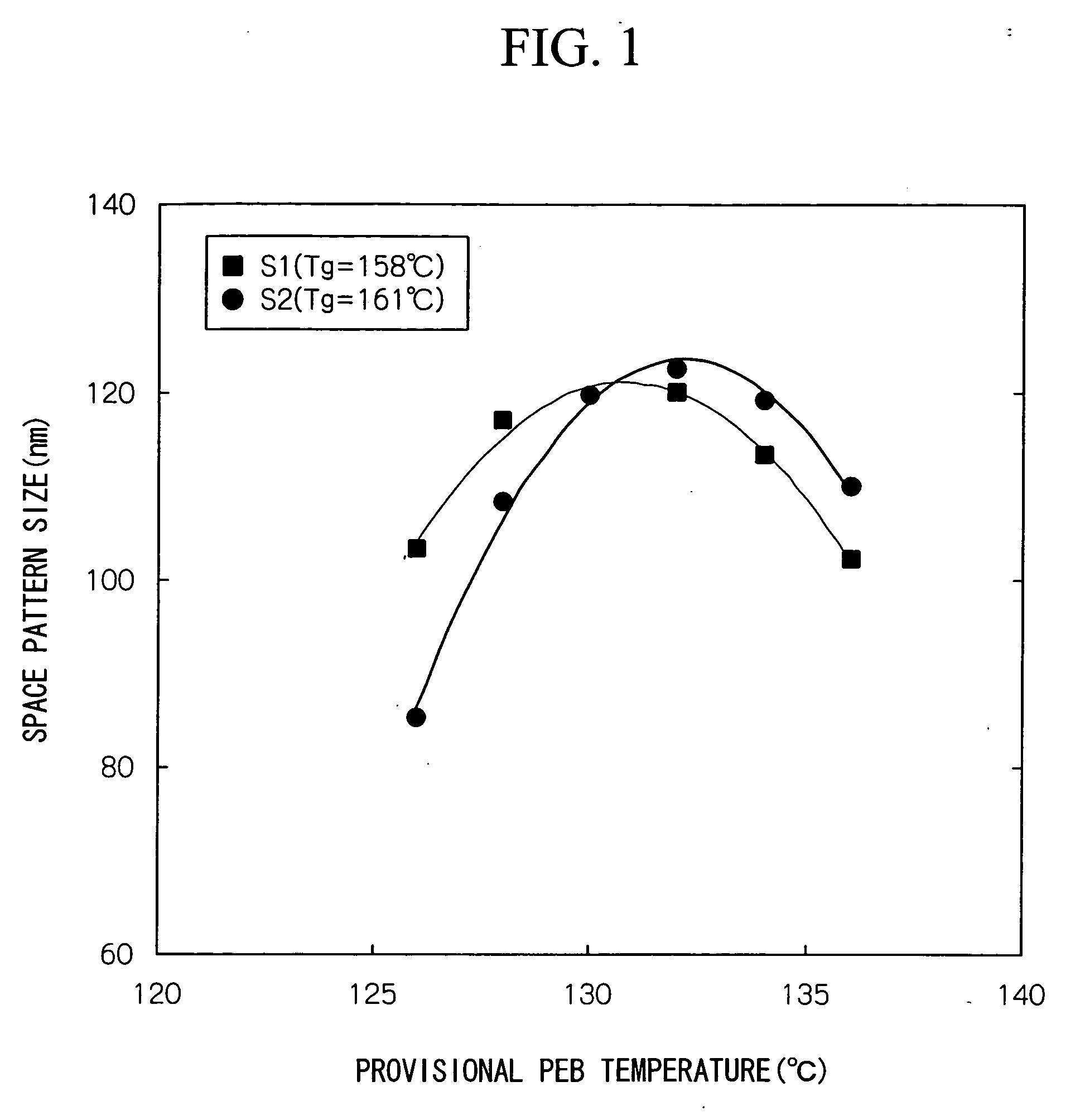

Curable silicone resin composition

Provided is a curable silicone resin composition including (A) a siloxane / polycyclic hydrocarbon-based compound containing at least 2 silicon-bonded hydrogen atoms, which is an addition reaction product of (a) a siloxane-based compound with at least 3 silicon-bonded hydrogen atoms, and (b) a polycyclic hydrocarbon with at least 2 addition reactive carbon-carbon double bonds, (B) a siloxane-based compound containing at least 2 silicon-bonded alkenyl groups, and (C) a hydrosilylation reaction catalyst. This composition is useful as a material for optical devices or parts, insulation material for electronic devices or parts, or coating material.

Owner:SHIN ETSU CHEM IND CO LTD

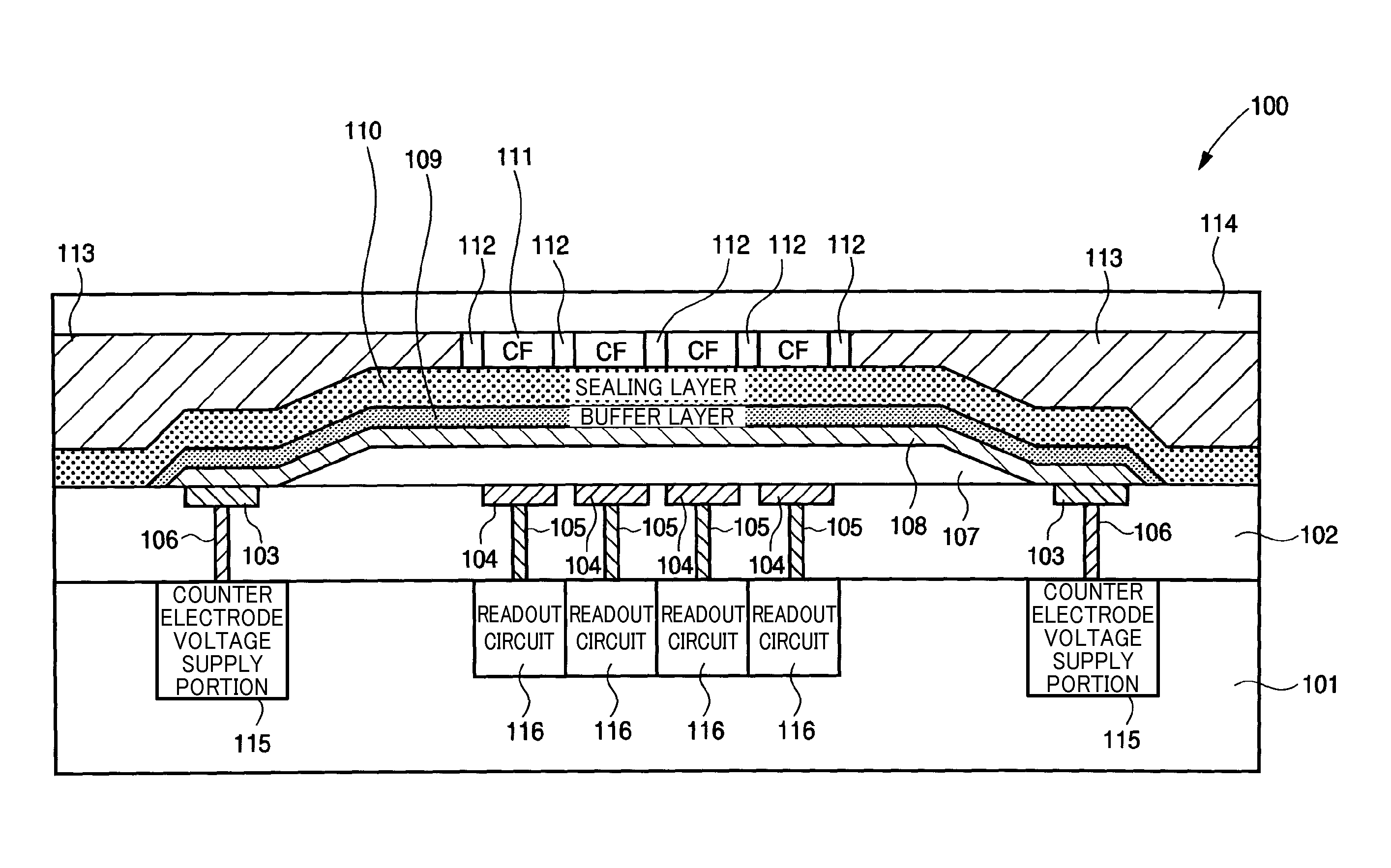

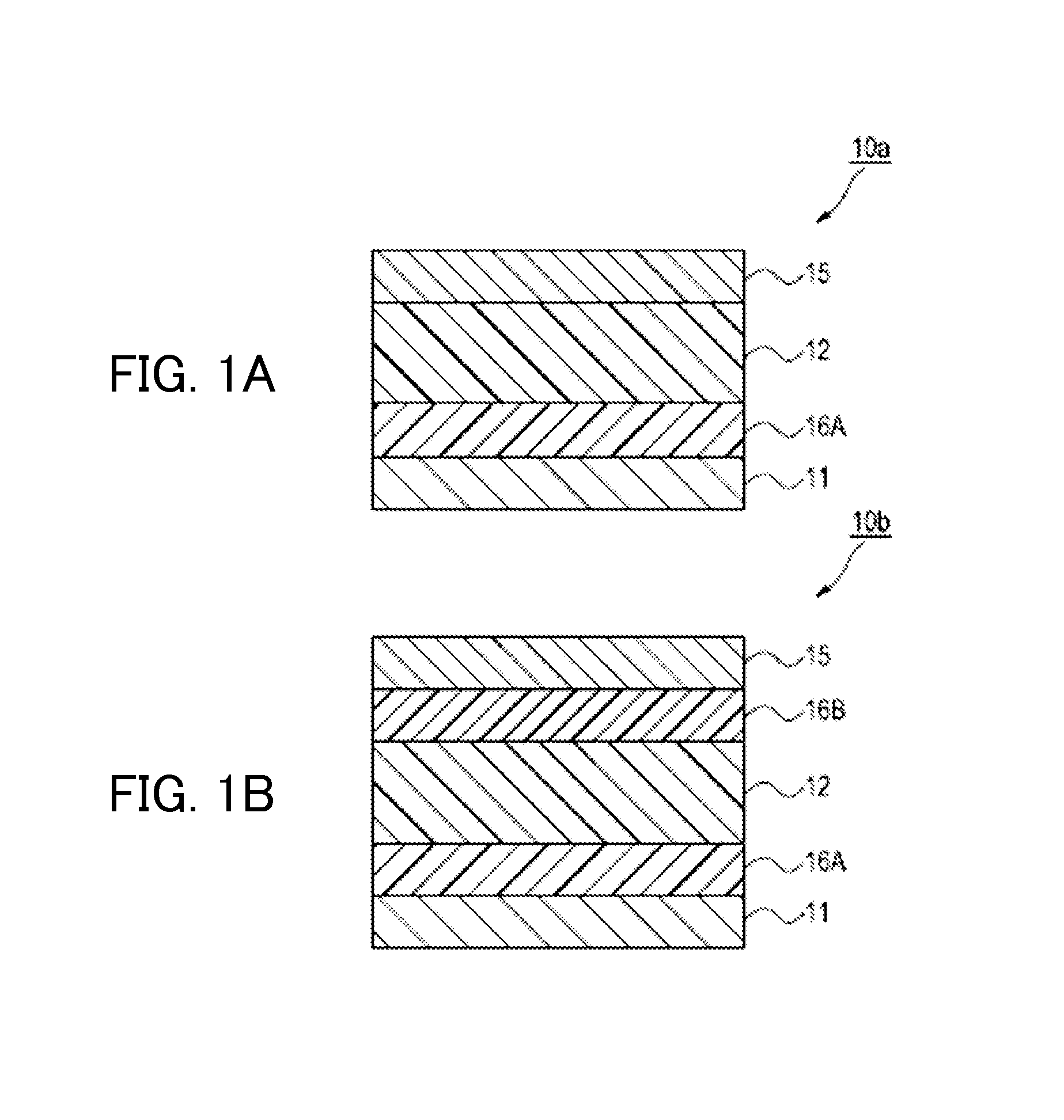

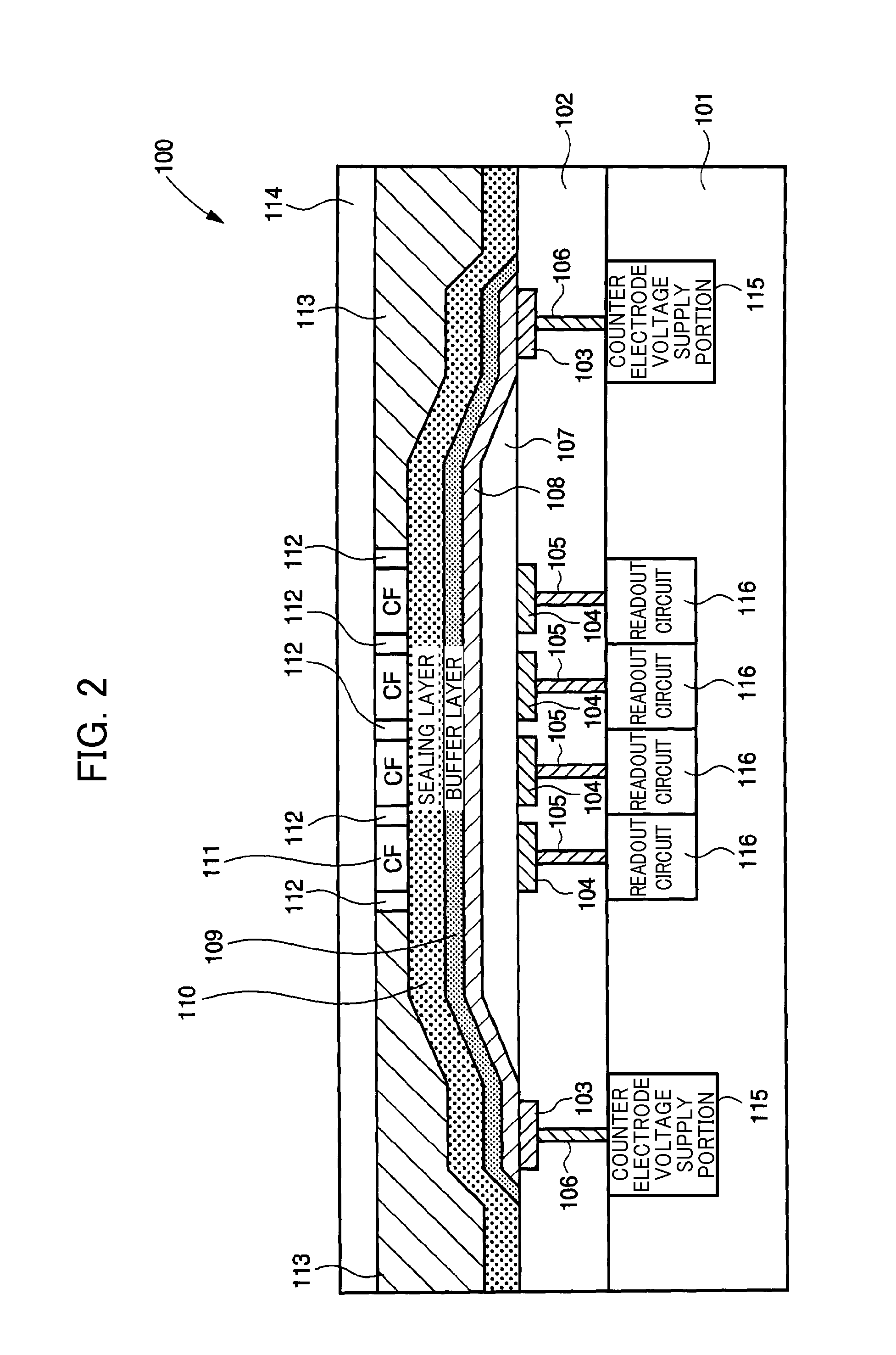

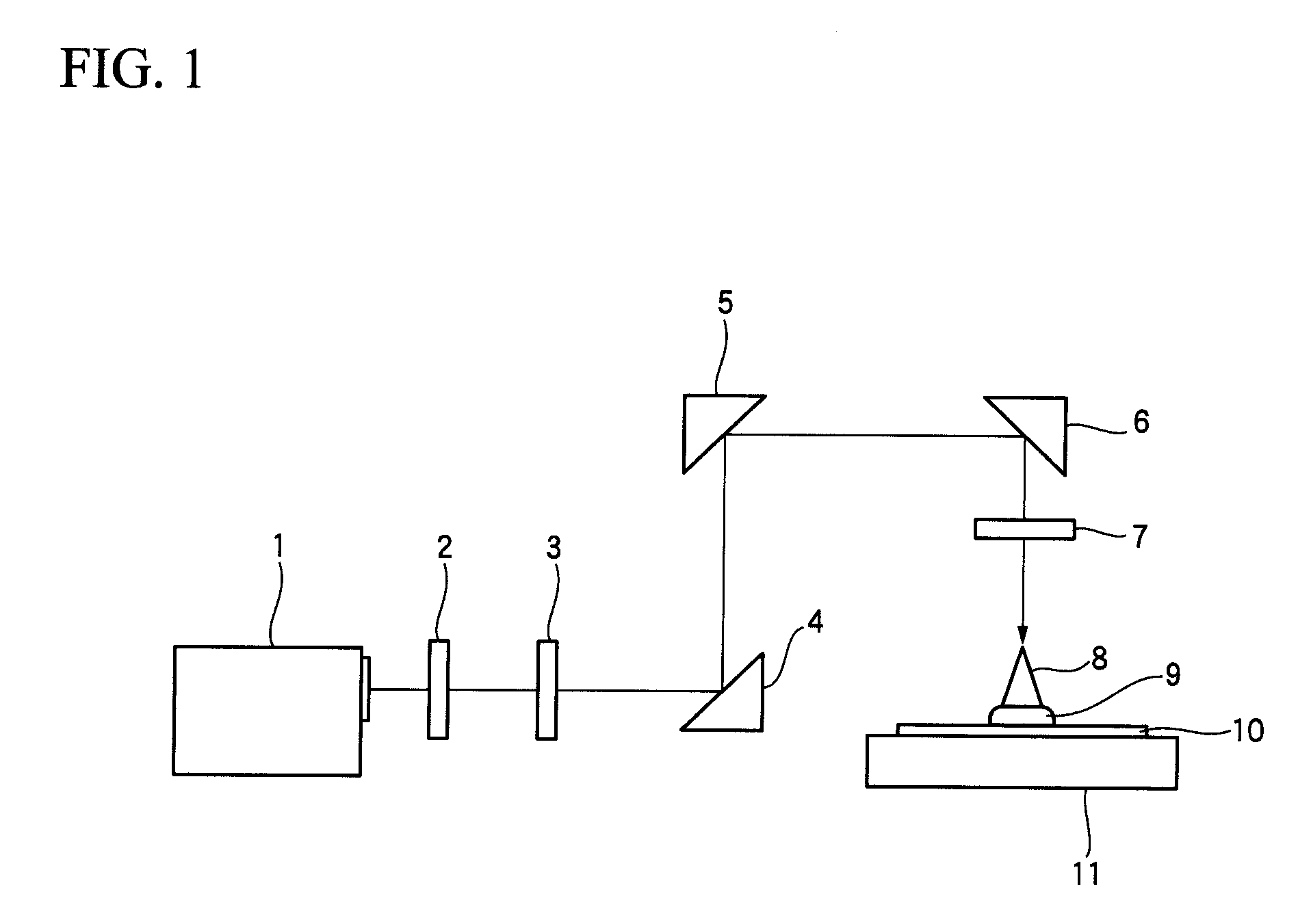

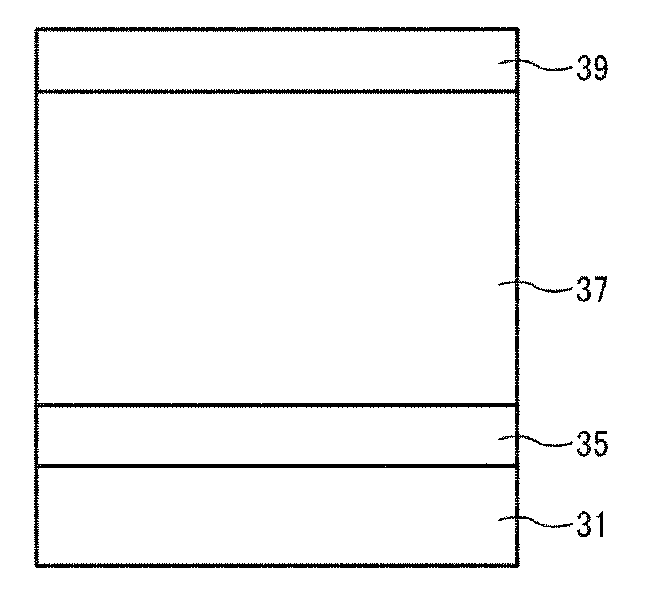

Photoelectric conversion element and method of using the same, image sensor, and optical sensor

ActiveUS20140158859A1High Photoelectric Conversion EfficiencyLower average currentNanoinformaticsSolid-state devicesGlass transition pointBlocking layer

A photoelectric conversion element includes a transparent conductive film, a conductive film, and a photoelectric conversion layer and an electron-blocking layer disposed between the transparent conductive film and the conductive film. The photoelectric conversion layer includes a condensed polycyclic hydrocarbon which contains at least 5 benzene rings, of which a total number of rings is 7 or more and which contains no carbonyl group. The electron-blocking layer includes a compound A having a residue after removal of at least one group of Ra1 to Ra9 from a compound represented by general formula (A) and having a glass transition point (Tg) of 200° C. or more. The photoelectric conversion element exhibits high photoelectric conversion efficiency and low dark current characteristics even after heating treatment, and can be manufactured with high productivity.

Owner:FUJIFILM CORP

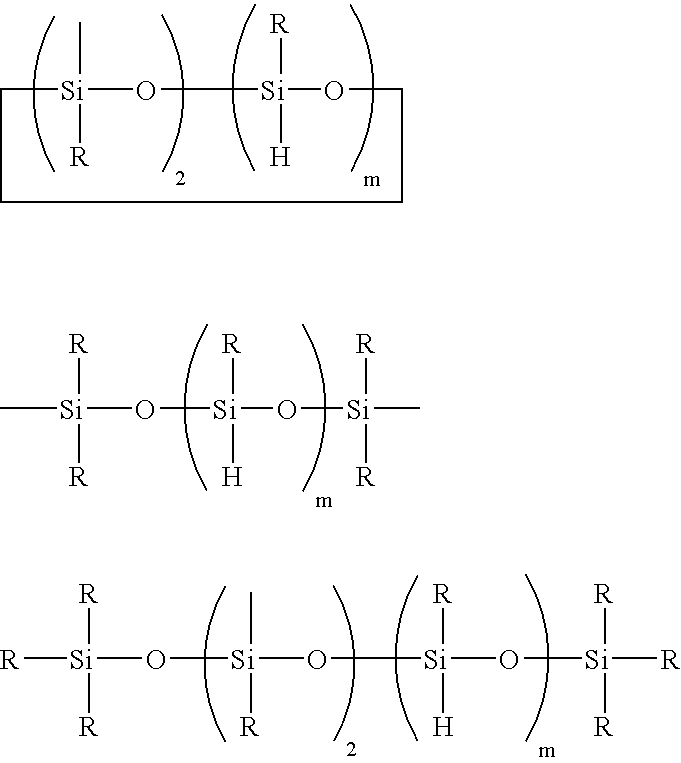

Curable composition

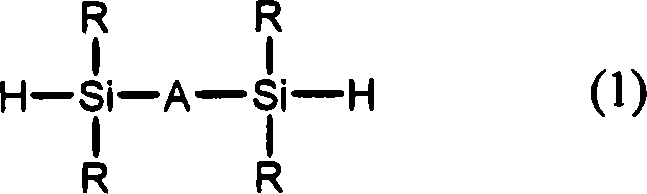

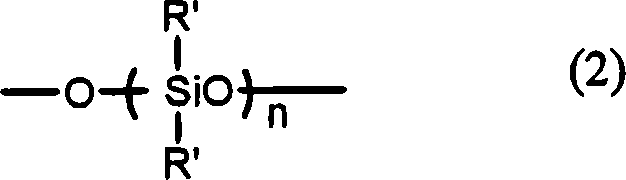

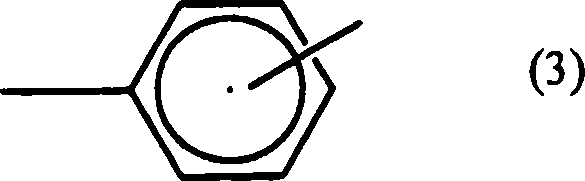

Provided is a curable composition including (A) an addition reaction product of (a) a compound with 2 silicon atom-bonded hydrogen atoms within each molecule, having a general formula (1): wherein, A is a bivalent group represented by a formula (2): (wherein, R′ represents an unsubstituted or substituted monovalent hydrocarbon group of 1 to 12 carbon atoms, or an alkoxy group of 1 to 6 carbon atoms, and n represents an integer from 0 to 100), or a group having a structural formula (3): and each R represents an unsubstituted or substituted monovalent hydrocarbon group of 1 to 12 carbon atoms, or an alkoxy group of 1 to 6 carbon atoms, and (b) a polycyclic hydrocarbon with 2 addition reactive carbon-carbon double bonds within each molecule, said addition reaction product containing at least two addition reactive carbon-carbon double bonds in each molecule, (B) a compound with at least 3 silicon atom-bonded hydrogen atoms within each molecule, and (C) a hydrosilylation reaction catalyst. This composition is useful as a material for optical devices or parts, insulation material for electronic devices or parts, or coating material.

Owner:SHIN ETSU CHEM IND CO LTD

Preparation method of high-density liquid hydrocarbon fuel

InactiveCN106867565AThe synthetic route is simpleEfficient synthetic routeLiquid hydrocarbon mixture productionBio-feedstockCarbon numberAlkane

The invention relates to a preparation method of high-density liquid hydrocarbon fuel. The method totally comprises two parts: (1) on a first catalyst bed layer of a fixed bed continuous reactor, cyclopentanone (furfural water phase selective hydrogenation products) takes a self aldol condensation (and hydrogenation) reaction under the catalysis effect of acid / alkali catalysts or metal doping solid alkali to obtain oxygen-containing organic compounds with the carbon number being 15 and 10; (2) on a second catalyst bed layer of the fixed bed continuous reactor, the products generated on the first catalyst bed layer take a further hydrodeoxygenation reaction under the conditions of low temperature and no solvent under the catalysis effect of load metal A / X type bifunctional catalysts to obtain polycyclic hydrocarbon fuel with the carbon number being 15 and 10. The high-density liquid fuel (C15 tri-cycloalkane: 0.917 g / cm<3>; C10 bi-cycloalkane: 0.866g / cm<3>) has the advantages that the energy carried by an aircraft can be effectively improved; the engine oil consumption rate is reduced; the requirements of high flight speed, great load and long emitting range can be met.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

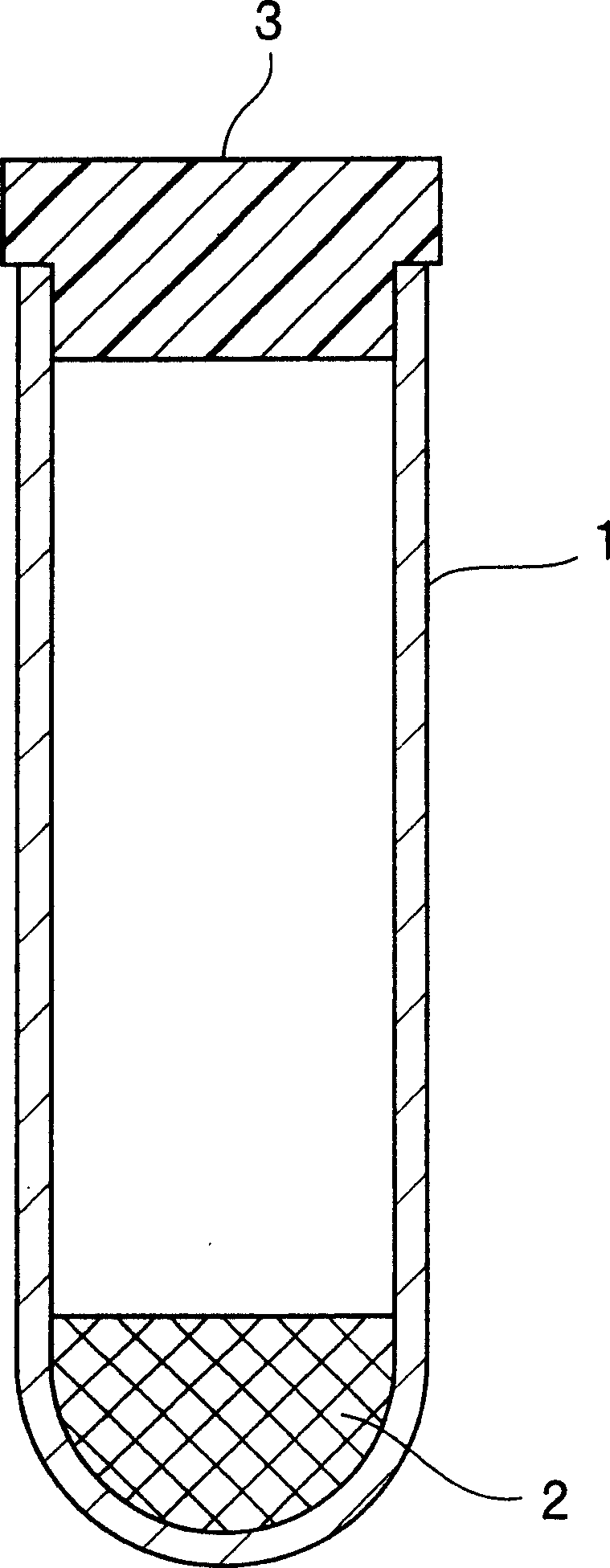

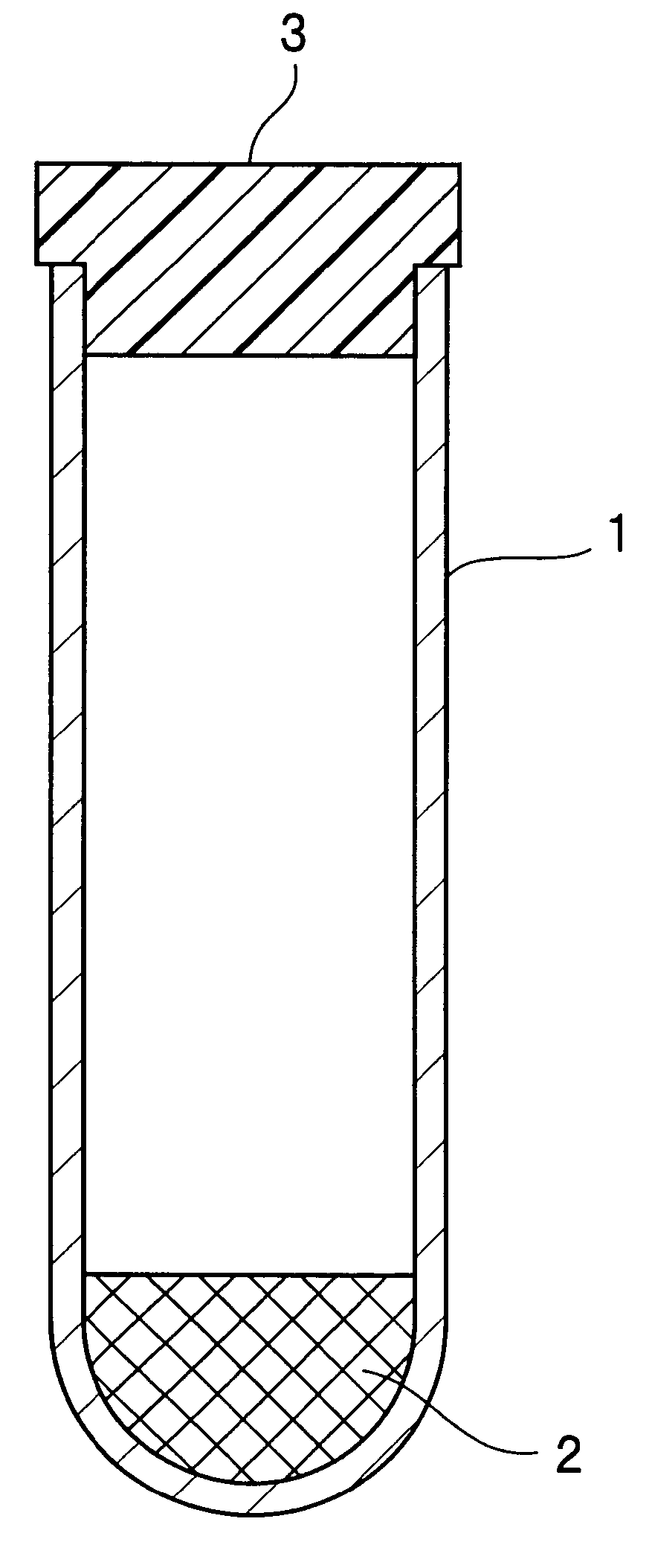

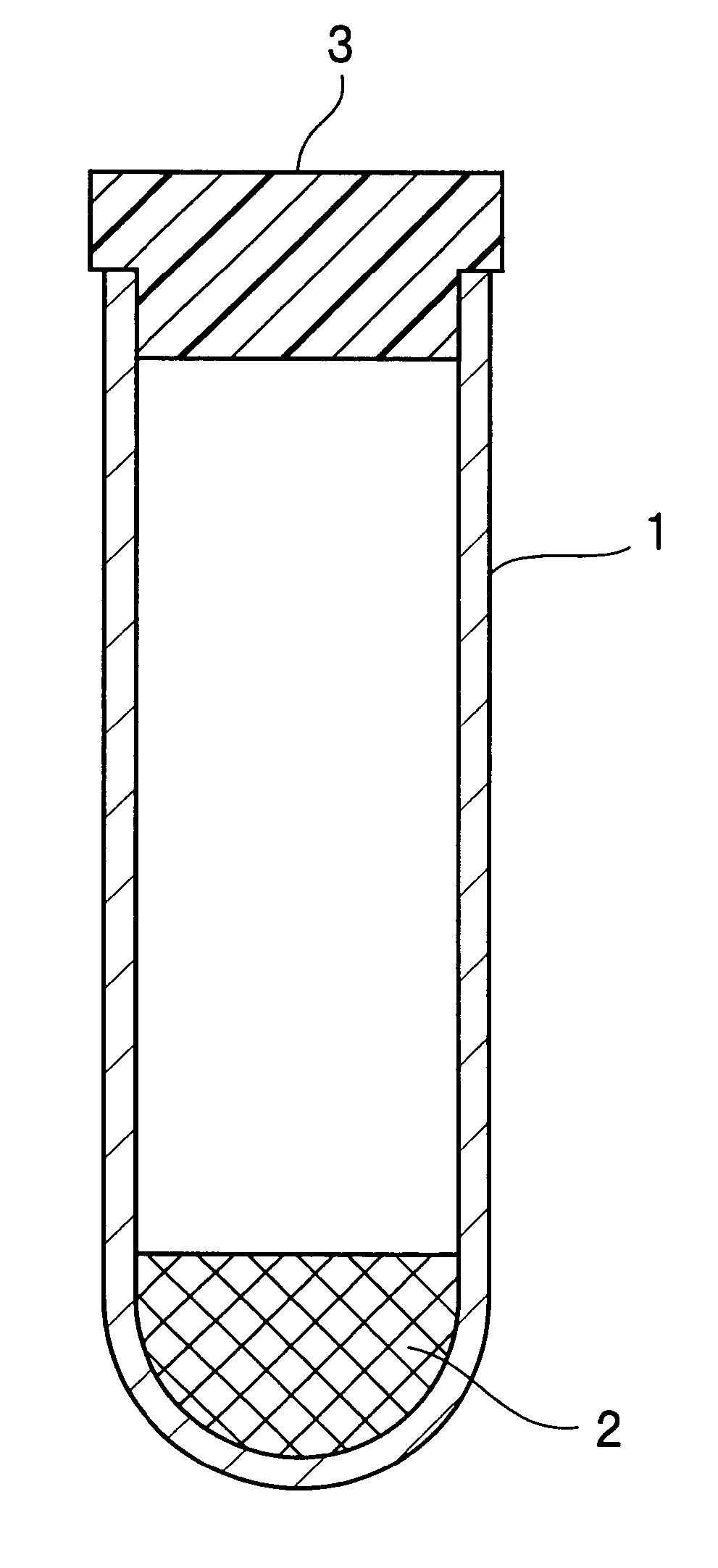

Composition for blood serum or plasma separation and vessel for blood examination containing the same

A composition for blood serum or plasma separation which has improved compatibility between a cyclopentadiene oligomer and a phthalic ester and generates no oily ingredient suspending in the blood serum or plasma after centrifugal separation regardless of the conditions for the centrifugal separation; and a vessel for blood examination which contains the composition. The composition for blood serum or plasma separation comprises: a polycyclic hydrocarbon compound having an unsaturated and / or saturated cyclic structure in the molecule and having a solidifying point or pour point of 0 DEG C or lower; a cyclopentadiene oligomer; and a phthalic ester.

Owner:SEKISUI CHEM CO LTD

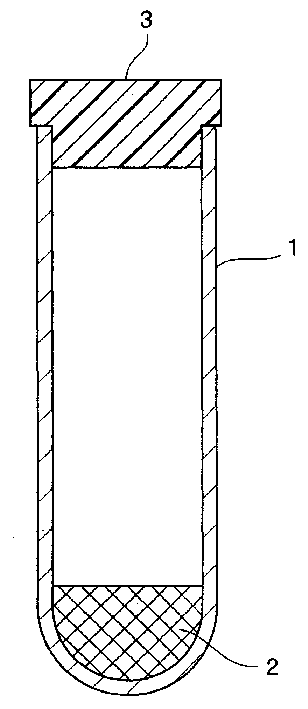

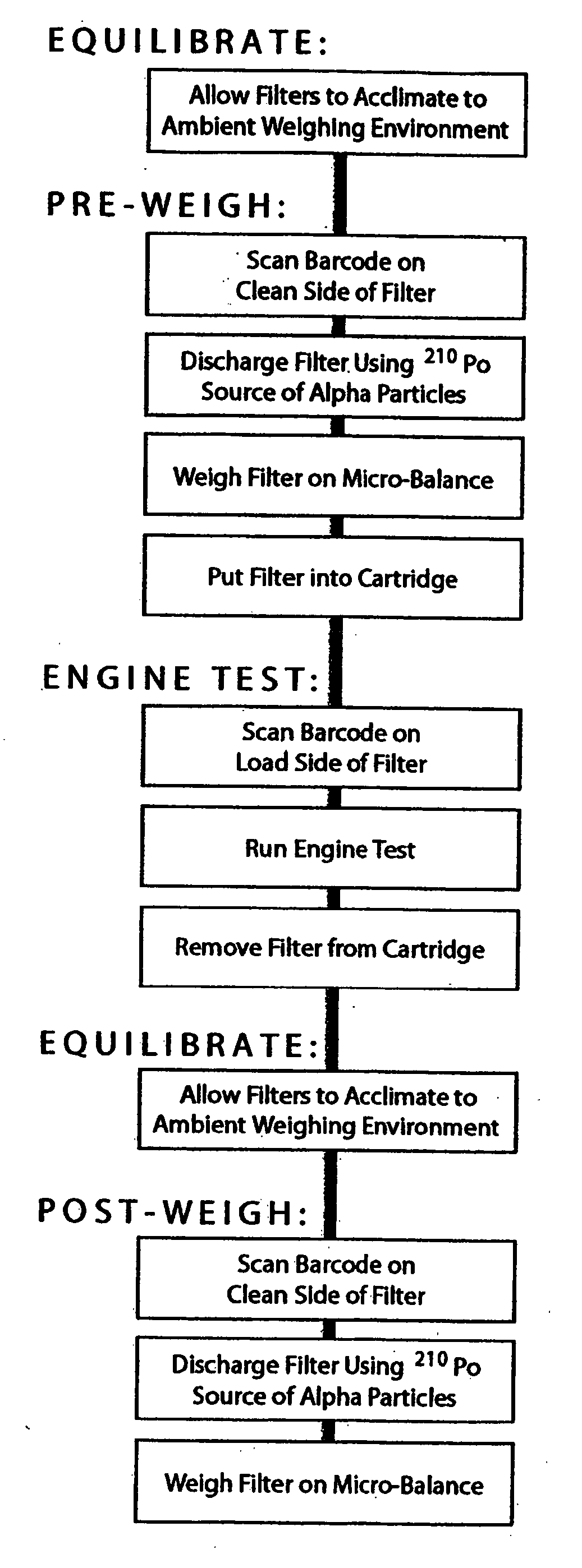

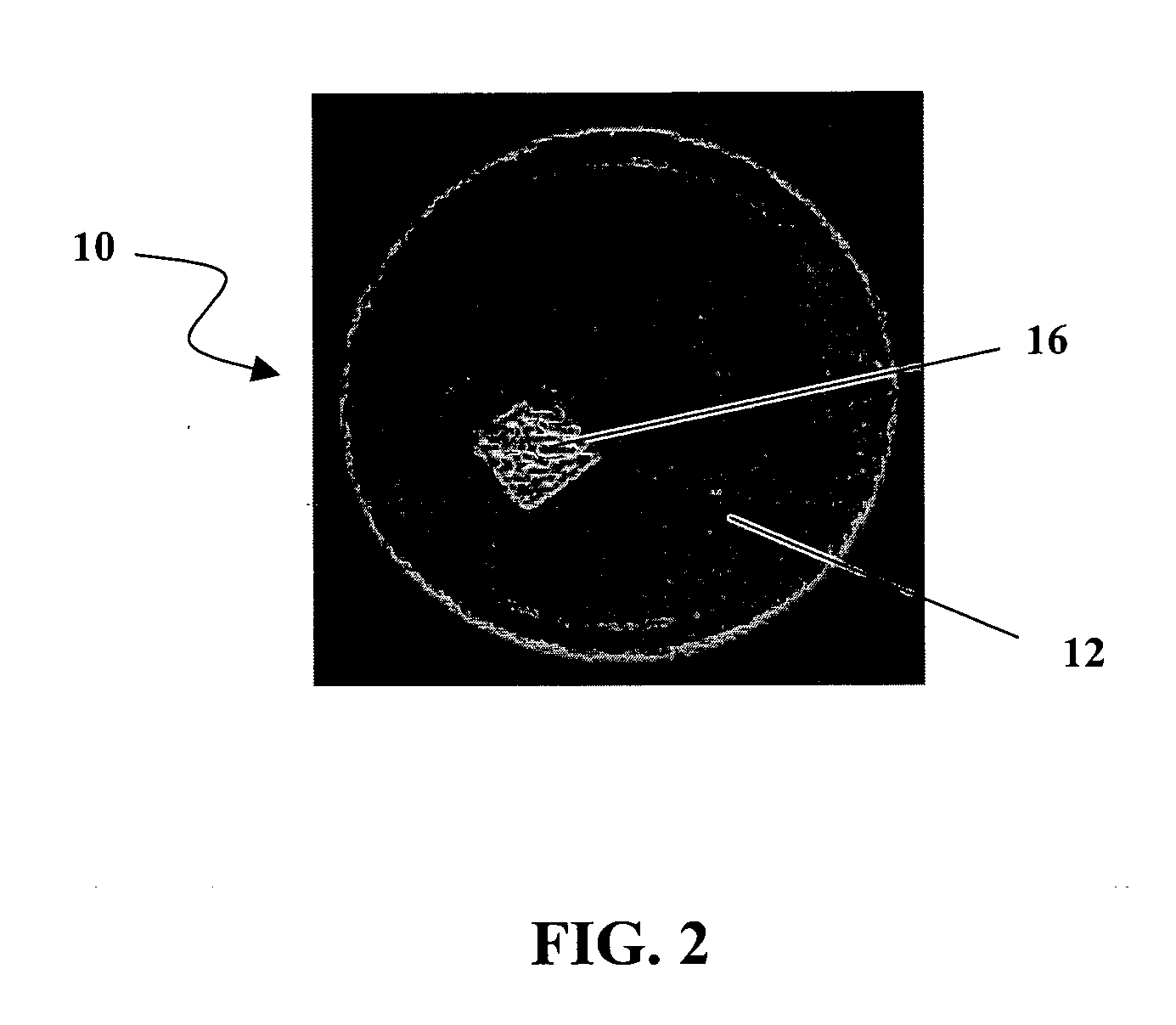

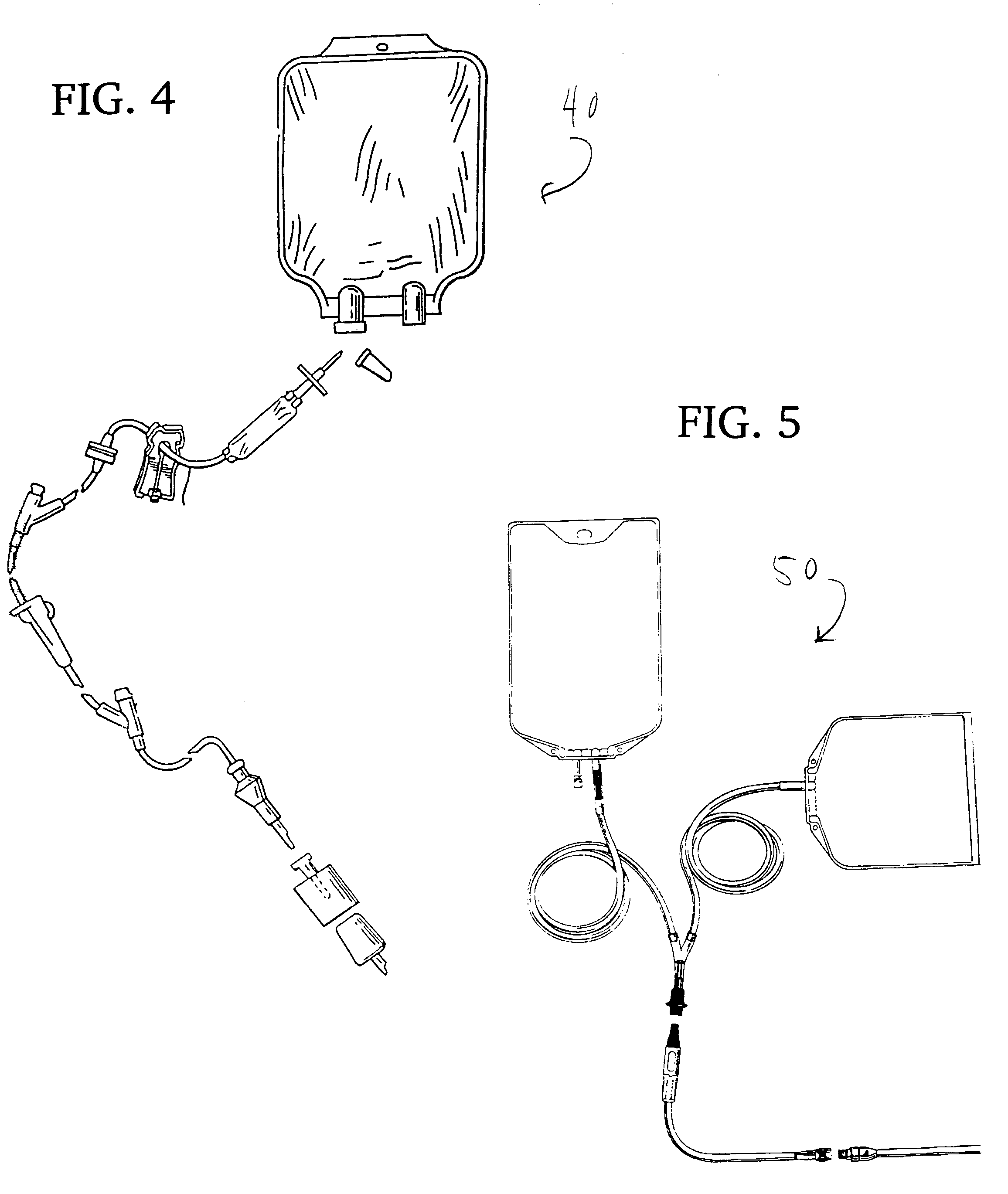

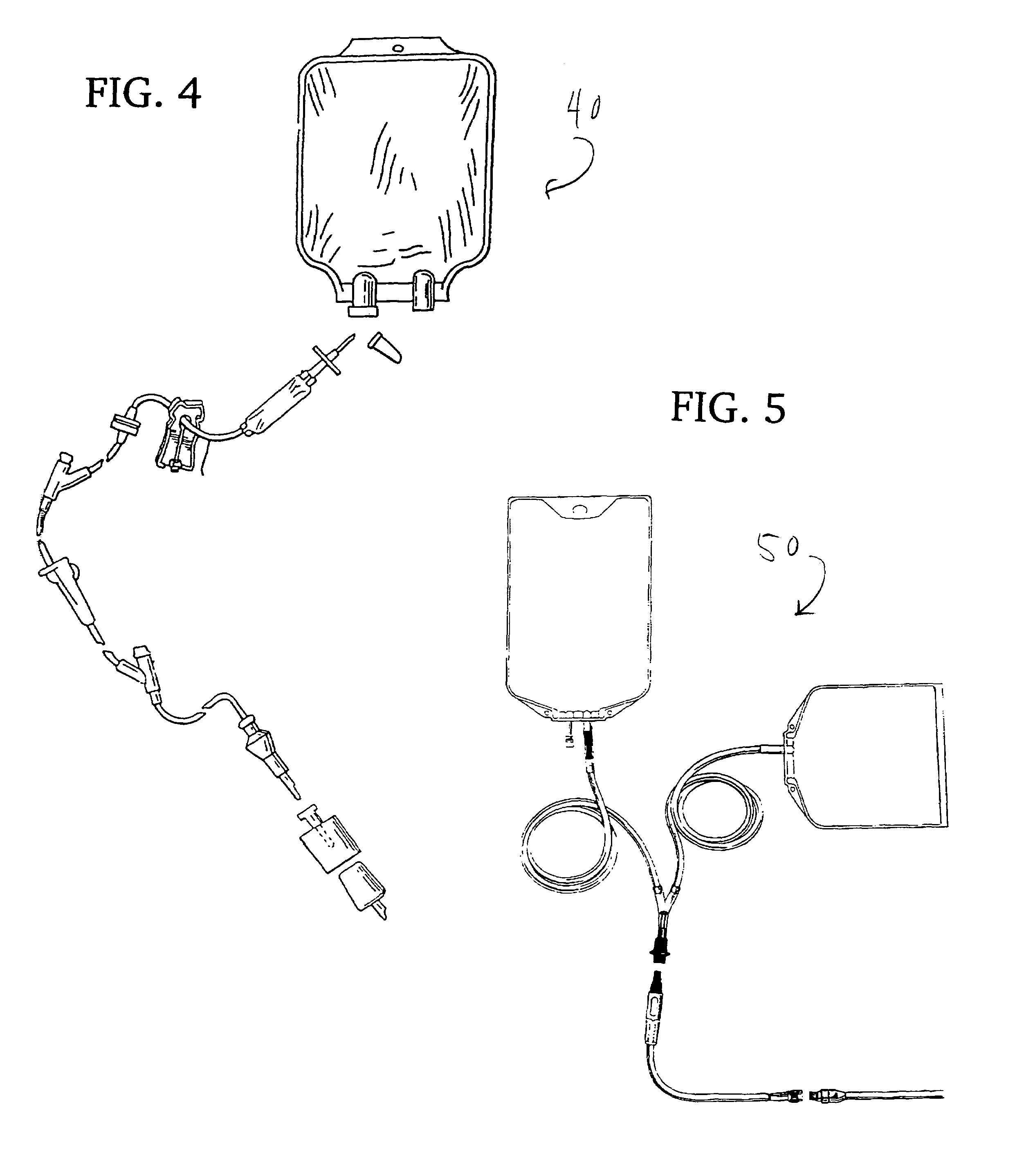

Particulate filter and method of use

InactiveUS20050247105A1Improve efficiencyImprove permeabilityMembranesSemi-permeable membranesParticulatesMetal foil

A particulate filter particularly suited for analytical gravimetric weighing applications is disclosed. The particulate filter includes a polytetrafluoroethylene (PTFE) media supported by a ring and yields stable microgram and submicrogram weighing results. The support ring may be PTFE, metal foil, or another non-hygroscopic polymer such that the mass of the filter does not vary with changes in atmospheric moisture. The filter simplifies the discharge of electrostatic charge buildup such that when a conductive filter media is combined with a conductive ring device, the discharge may be accomplished by placing the filter on a grounded weighing pan or other surface. The particulate filter can simplify filter identification by including identification symbols imprinted on each side of the filter media. Due to the chemically inert qualities of its components, the particulate filter is particularly suited for extraction techniques used during the detection of polycyclic hydrocarbons as is conducted in emissions and ambient air testing.

Owner:DIKKEN DAVID A +4

Composition for blood serum or plasma separation and vessel for blood examination containing the same

InactiveUS7090970B2Improve compatibilityPrevent floatingOrganic chemistryOther chemical processesOligomerAdditive ingredient

A composition for blood serum or plasma separation which has improved compatibility between a cyclopentadiene oligomer and a phthalic ester and generates no oily ingredient suspending in the blood serum or plasma after centrifugal separation regardless of the conditions for the centrifugal separation; and a vessel for blood examination which contains the composition. The composition for blood serum or plasma separation comprises: a polycyclic hydrocarbon compound having an unsaturated and / or saturated cyclic structure in the molecule and having a solidifying point or pour point of 0° C. or lower; a cyclopentadiene oligomer; and a phthalic ester.

Owner:SEKISUI CHEM CO LTD

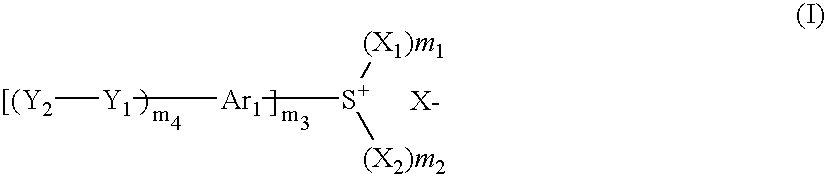

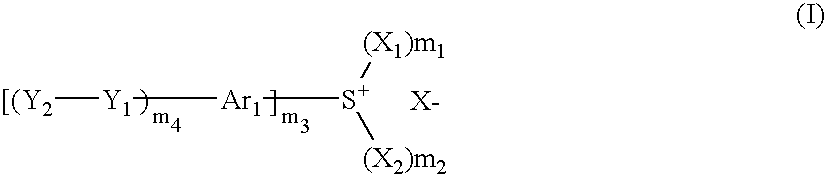

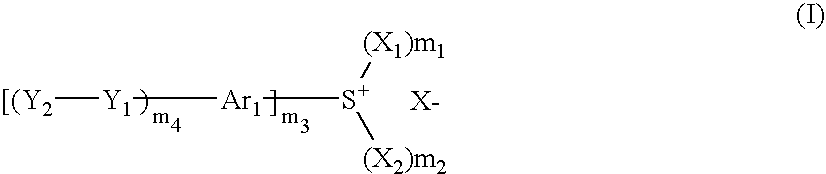

Photosensitive composition, compound for use in the photosensitive composition and pattern forming method using the photosensitive composition

ActiveUS7799505B2Pattern collapse is improvedEnhance the imageOrganic chemistryOrganic compound preparationPhotochemistryPolycyclic Hydrocarbons

The invention is related to an arylsulfonium salt compound having a polycyclic hydrocarbon structure in a cation moiety.

Owner:FUJIFILM CORP

Particulate filter and method of use

InactiveUS20100218595A1Easy dischargeAccurate measurementMembranesSemi-permeable membranesParticulatesMetal foil

Owner:MEASUREMENT TECH LAB CORP

Autoclavable, non-adherent, heat sealable polymer blends for fabricating monolayer and multiple layered films

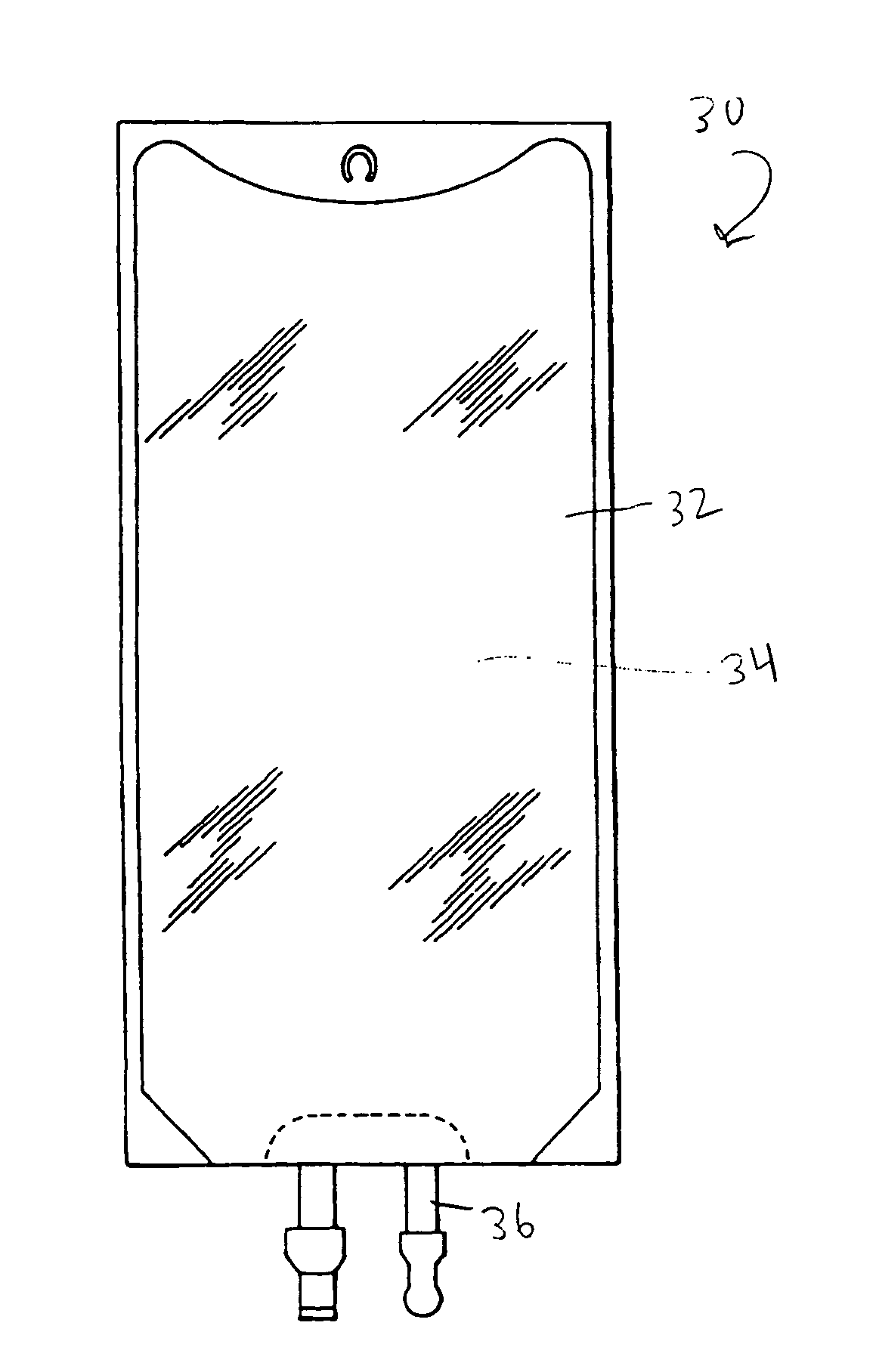

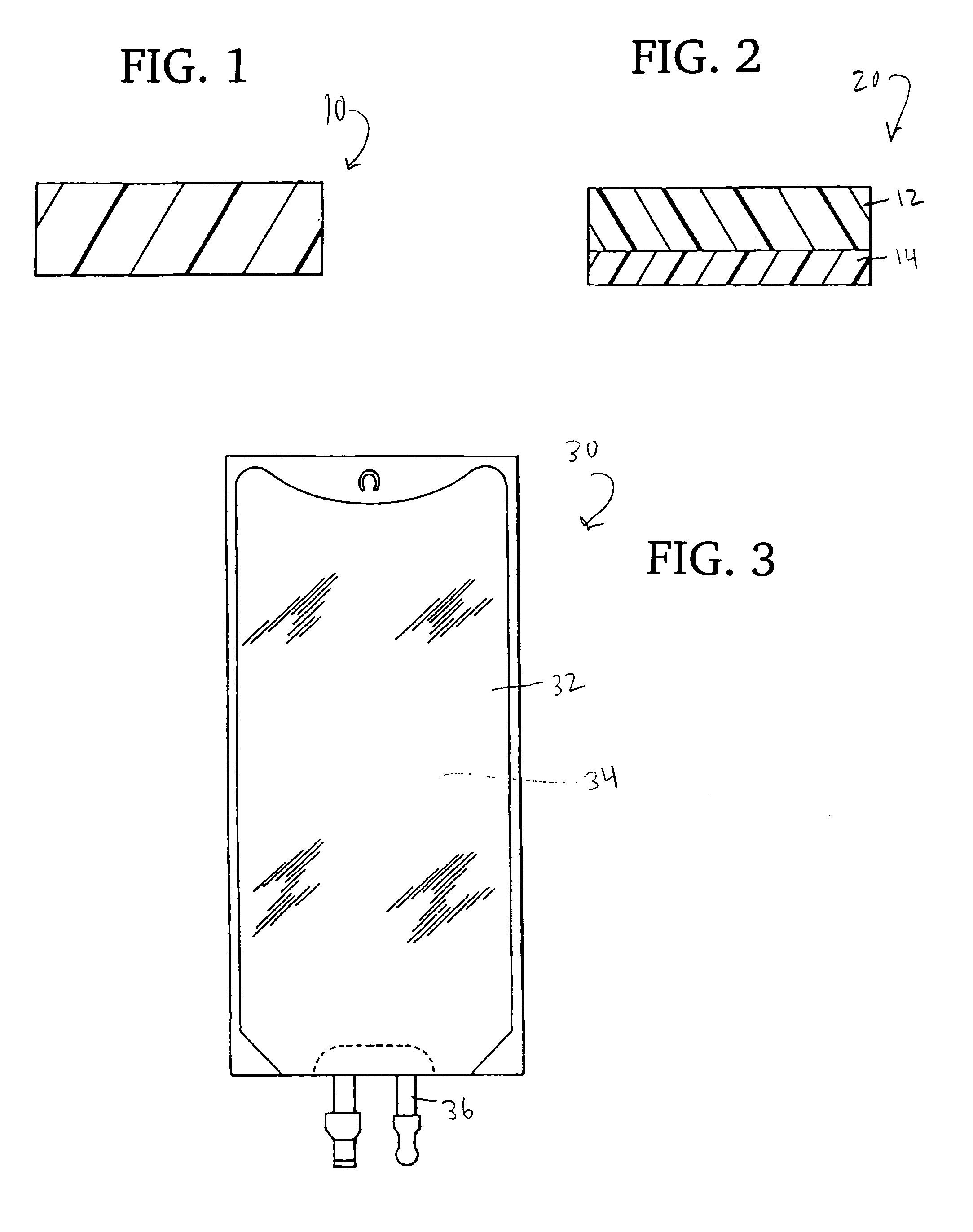

The present invention provides a polymer blend for fabricating monolayer films or a layer within a multilayer film. The blend has a first component and a second component. The first component is selected from the group of: (1) an ethylene and α-olefin copolymer having a density of less than about 0.915 g / cc, (2) lower alkyl acrylates, (3) lower alkyl substituted alkyl acrylates and (4) ionomers. The first component should be present in an amount from about 99% to about 55% by weight of the blend. The second component in an amount by weight of the blend from 45% to about 1% and consists of one or more polymers of the group: (1) propylene containing polymers, (2) polybutene polymers, (3) polymethylpentene polymers, (4) cyclic olefin containing polymers and (5) bridged polycyclic hydrocarbon containing polymers. When the blend is fabricated into a film it has a modulus of elasticity when measured in accordance with ASTM D882 of less than about 60,000 psi, an internal haze when measured in accordance with ASTM D1003 of less than about 25%, an internal adhesion ranking of greater than about two, a sample creep at 120° C. under 27 psi loading of less than or equal to 150% for a film having a thickness from about 5 mils to about 15 mils, and the film being capable or being heat sealed into a container having seals wherein the seals remain intact when the container is autoclaved at 121° C. for one hour.

Owner:BAXTER INT INC

Photosensitive composition, compound for use in the photosensitive composition and pattern forming method using the photosensitive composition

ActiveUS20080138742A1Enhance the imagePattern collapse is improvedOrganic chemistryOrganic compound preparationPhotochemistryPolycyclic Hydrocarbons

The invention is related to an arylsulfonium salt compound having a polycyclic hydrocarbon structure in a cation moiety.

Owner:FUJIFILM CORP

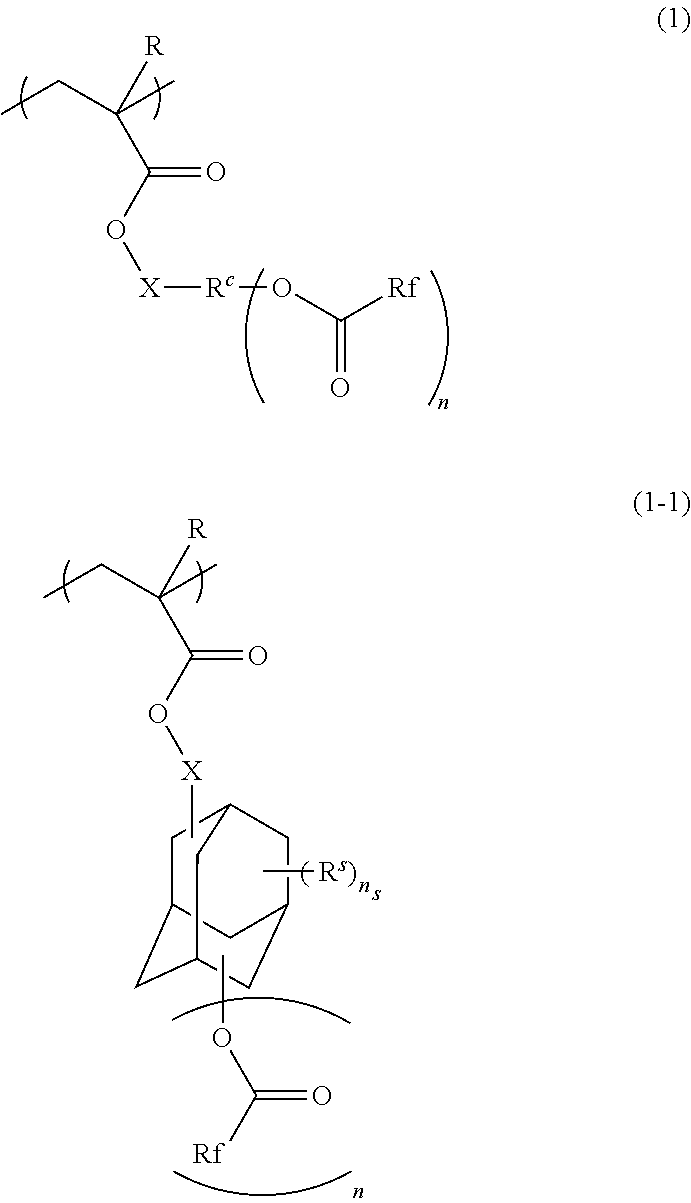

Radiation-sensitive resin composition, method for forming resist pattern, polymer and compound

A radiation-sensitive resin composition includes a first polymer having a structural unit represented by a following formula (1), and a radiation-sensitive acid generator. RC in the formula (1) preferably represents an aliphatic polycyclic hydrocarbon group having a valency of (n+1) and having 4 to 30 carbon atoms. The structural unit represented by the formula (1) is preferably a structural unit represented by a n following formula (1-1).

Owner:JSR CORPORATIOON

Containers and peelable seal containers of new non-PVC material

The present invention provides a flowable materials container. The container has a first sidewall and a second sidewall sealed together along a peripheral seam to define a fluid chamber. At least one sidewall is a film having at least one layer of blend of a first component selected from the group of: (1) ethylene and α-olefin copolymers having a density of less than about 0.915 g / cc, (2) ethylene copolymerized with lower alkyl acrylates, (3) ethylene copolymerized with lower alkyl substituted alkyl acrylates and (4) ionomers, the first component being present in an amount from about 99% to about 55% by weight of the blend, a second component in an amount by weight of the blend from about 45% to about 1% and consists of one or more polymers of the group: (1) propylene containing polymers, (2) polybutene polymers, (3) polymethylpentene polymers, (4) cyclic olefin containing polymers and (5) bridged polycyclic hydrocarbon containing polymers; and the film has a modulus of elasticity when measured in accordance with ASTM D882 of less than about 60,000 psi, an internal haze when measured in accordance with ASTM D1003 of less than about 25%, an internal adhesion ranking of greater than about 2, a sample creep at 120° C. under 27 psi loading of less than or equal to 150% for a film having a thickness of from about 5 mils to about 15 mils, and the film can be heat sealed into a container having seals wherein the seals remain intact when the container is autoclaved at 121° C. for one hour.

Owner:BAXTER INT INC

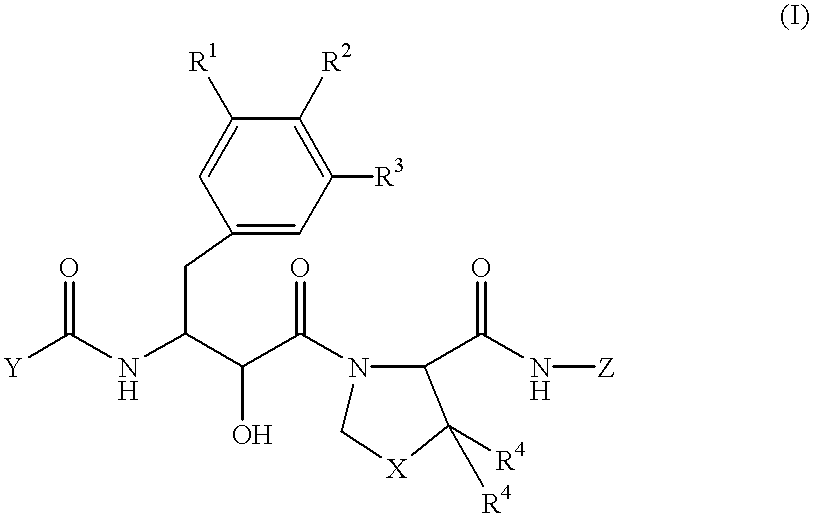

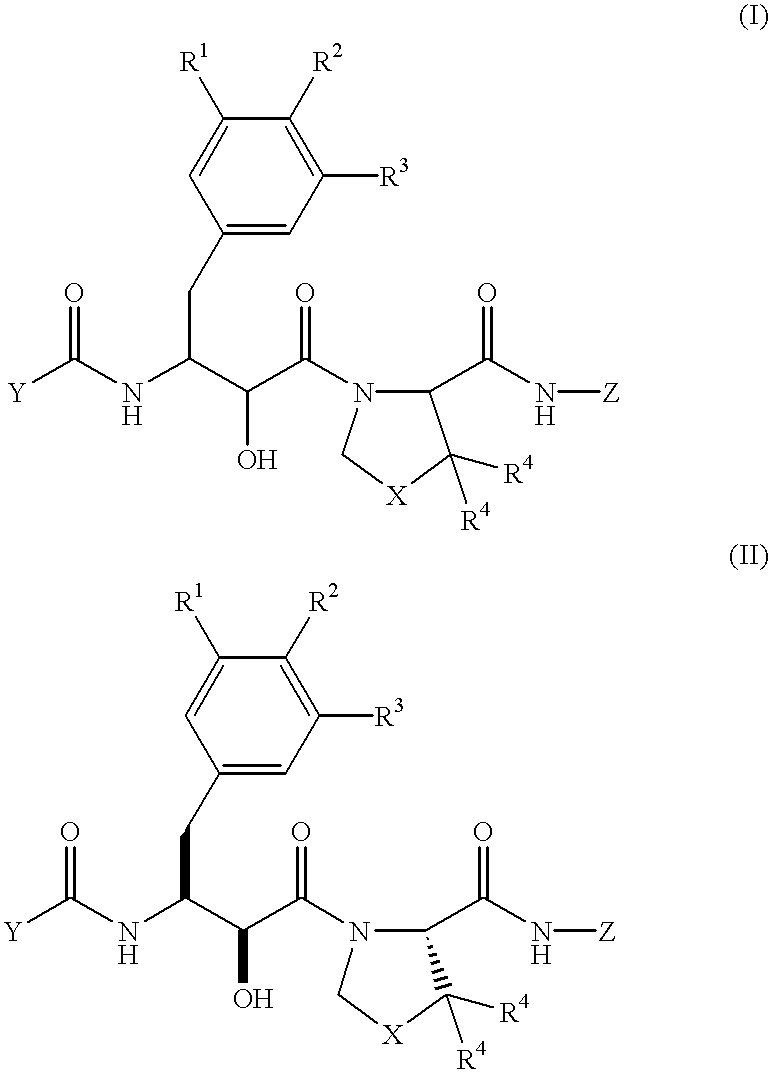

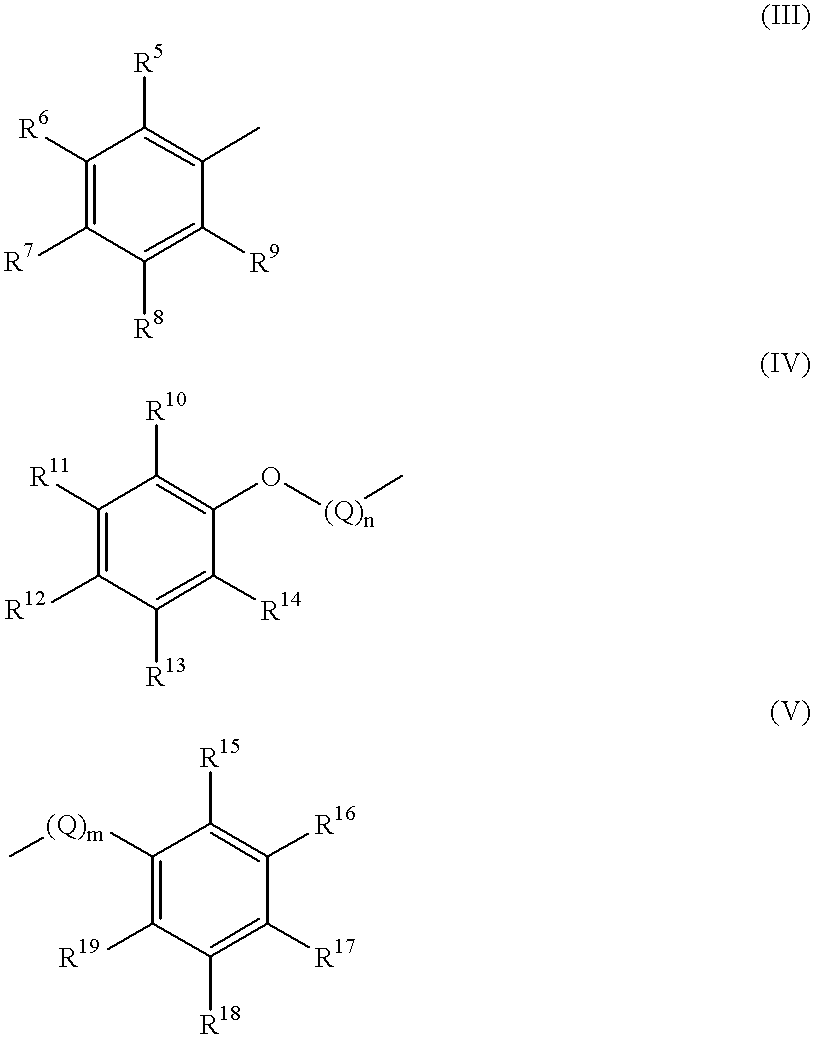

Novel dipeptide compounds and their use as medicines

A novel dipeptide compound inhibiting the enzymatic activity of HIV protease, an anti-AIDS medicine comprising this dipeptide compound as an effective component. The dipeptide compound is the compound represented by the formula (I) or a pharmaceutically acceptable salt thereof wherein R1, R2, and R3 independently represent a linear or branched, saturated or unsaturated lower alkyl group, alkoxyl group, alkyl amino group, or dialkyl amino group having 1-4 carbon atoms (with a carbon atom being either replaced by an oxygen atom or not), a halogeno group, or a hydrogen atom, provided that all of the R1, R2, and R2 are not a hydrogen atom at the same time, R2 and R3 may form a ring together, R4 represents a linear or branched lower alkyl group having 1-4 carbon atoms or a hydrogen atom; X is a methylene group or a sulfur atom; Y represents a five or six member monocyclic or polycyclic hydrocarbon group, a heterocyclic group having a structure in which one or more carbon atom in the monocyclic or polycyclic hydrocarbon group is replaced by a hetero atom, an aryloxy group having 12 or less carbon atoms, in which the aromatic ring may be substituted with an alkyl group, alkoxy group, halogeno group, amino group or hydroxyl group; and Z represents an aliphatic hydrocarbon group having 1-6 carbon atoms or an aromatic hydrocarbon group having 12 or less carbon atoms in which the aromatic ring may be substituted with an alkyl group, alkoxy group, or halogeno group, or one or more carbon atom in the aromatic hydrocarbon group may be replaced by a hetero atom.

Owner:SUMITOMO DAINIPPON PHARMA CO LTD

Silicone-based curable composition containing polycyclic hydrocarbon group

The present invention relates to a curable composition having relatively high hardness, excellent heat resistance and chipping resistance, which can be used as a sealing material for optical elements and the like. The curable composition of the present invention is a polycyclic hydrocarbon group-containing silicone-based curable composition, which contains: (A) an addition reaction product of compounds (a) and (b), wherein (a) is a compound containing two (b) a polycyclic hydrocarbon containing two addition-reactive carbon-carbon double bonds per molecule, wherein the addition reaction product contains at least two addition-reactive carbon-carbon double bonds per molecule reactive carbon-carbon double bonds, (B) compounds containing three or more hydrogen atoms bonded to silicon atoms per molecule, (C) hydrosilylation reaction catalysts, and (D) compounds containing Stabilizer for hindered amine structure and phenol structure.

Owner:SHIN ETSU CHEM IND CO LTD

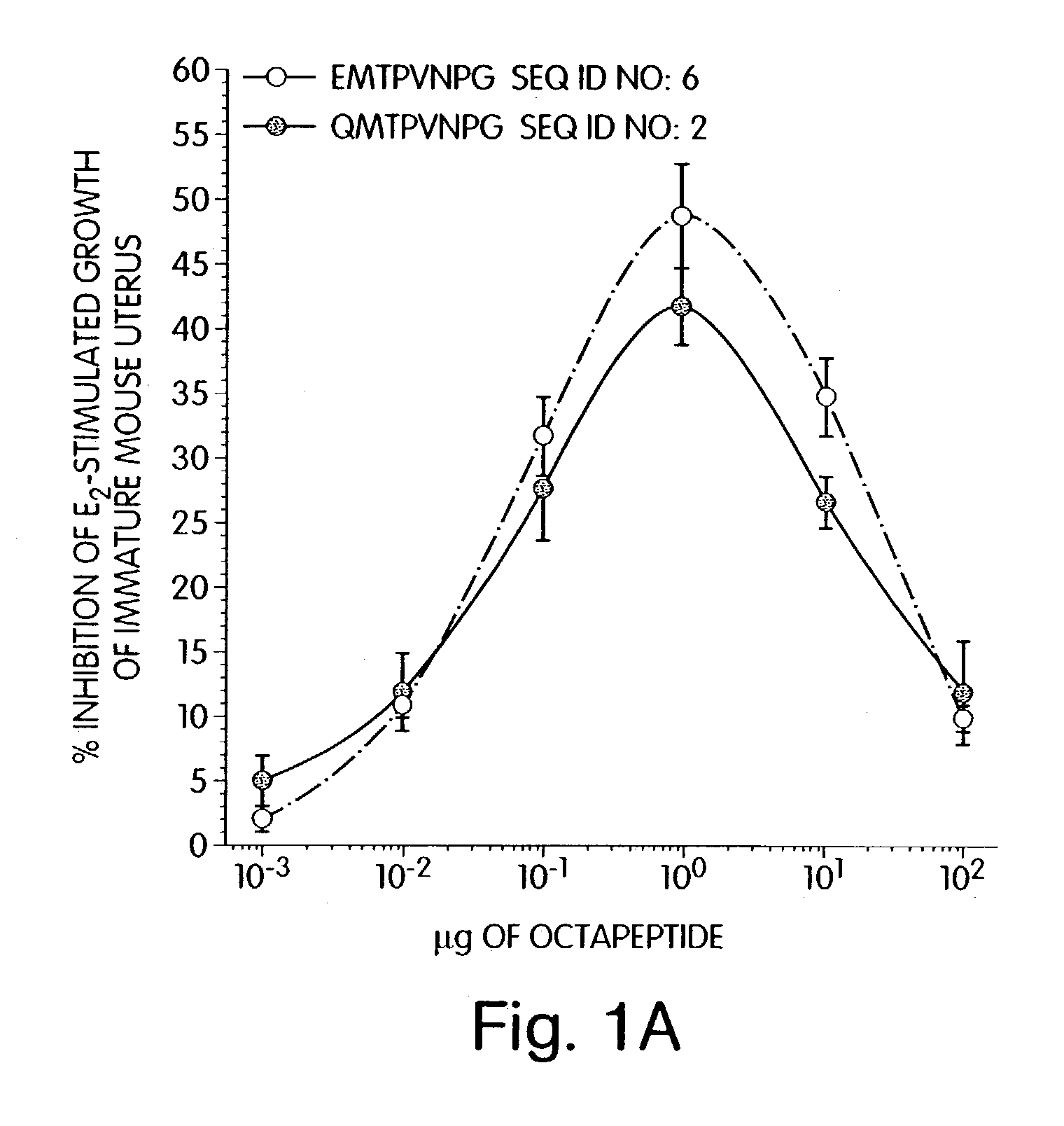

Alpha-fetoprotein peptides and uses thereof

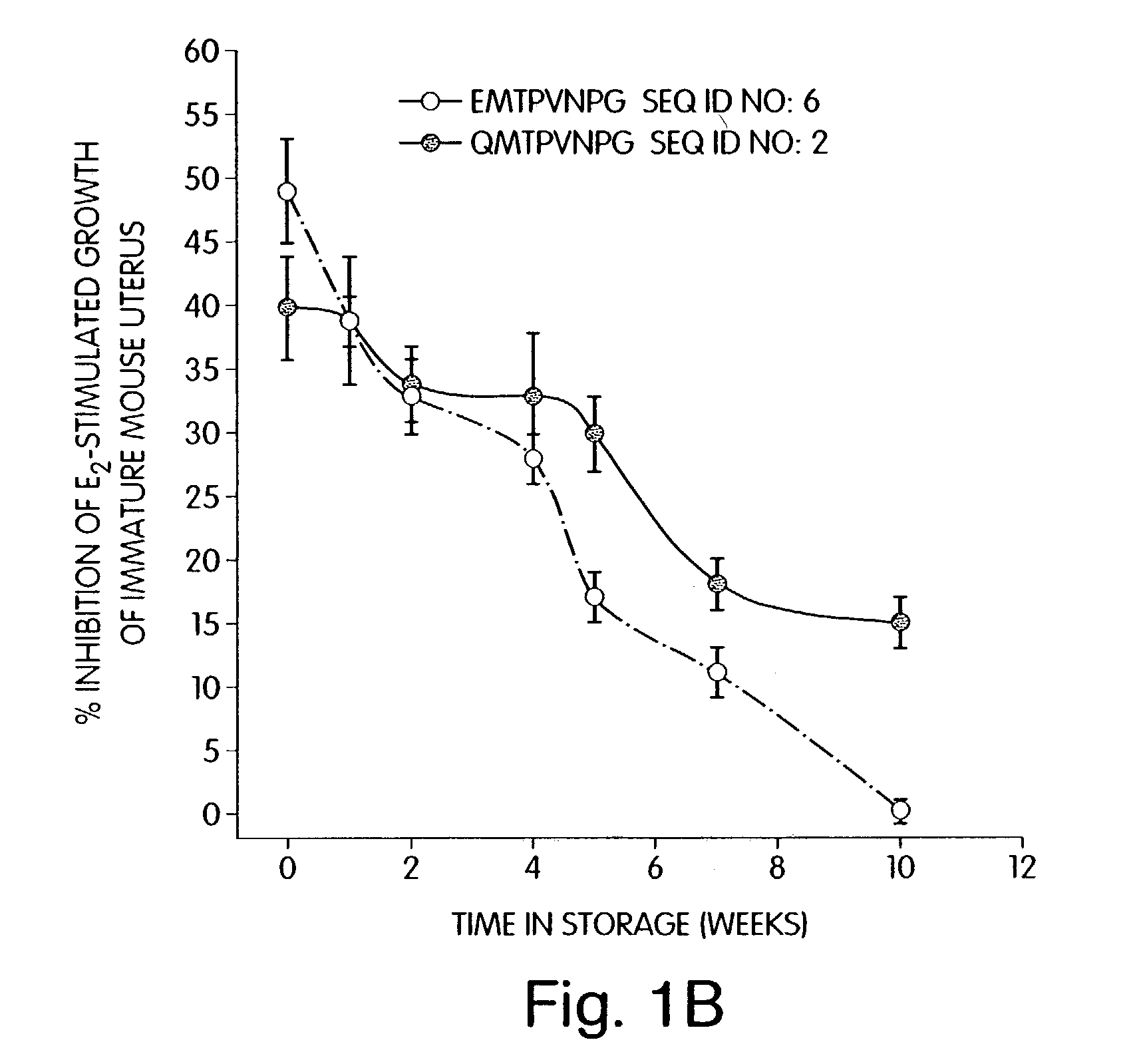

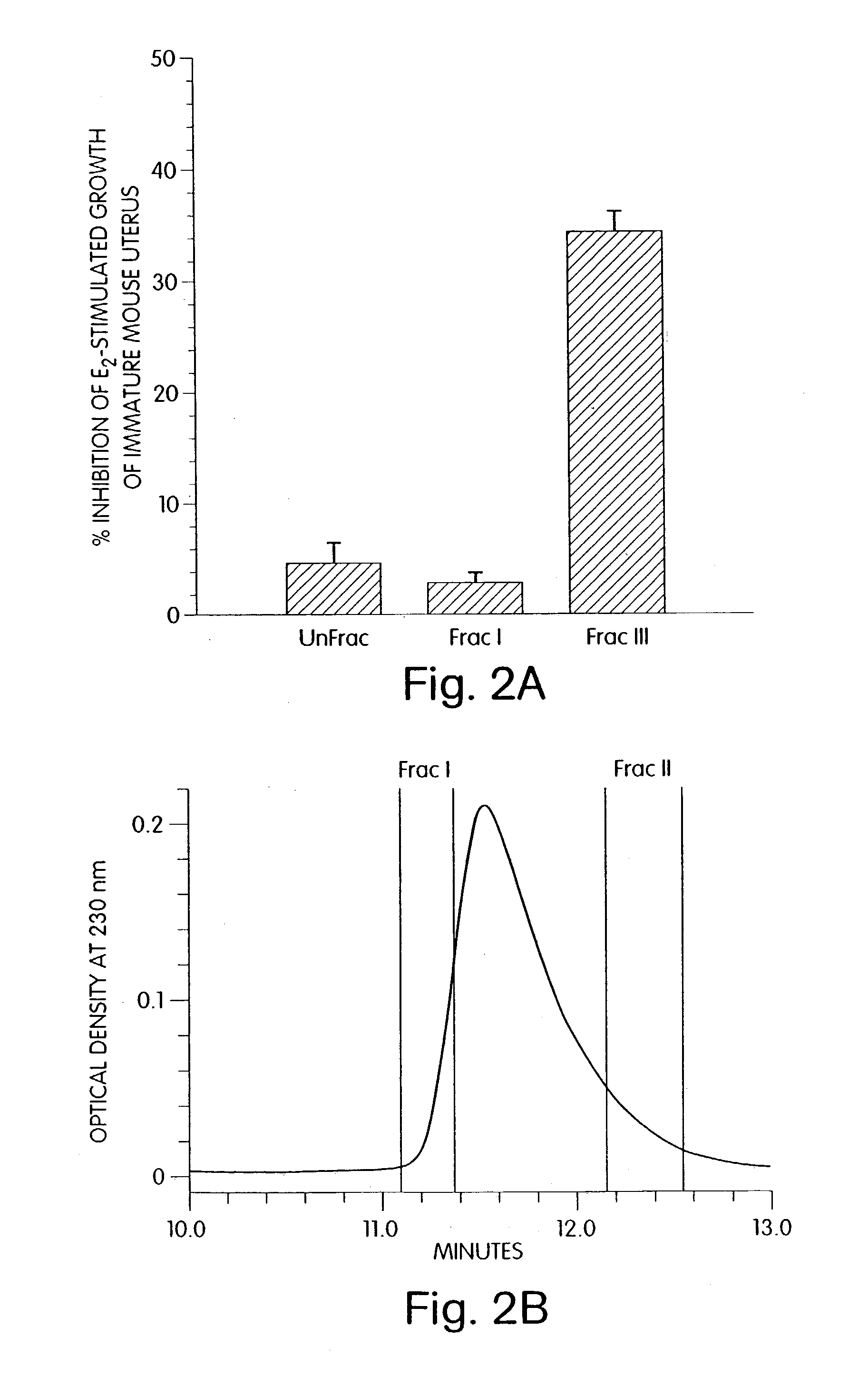

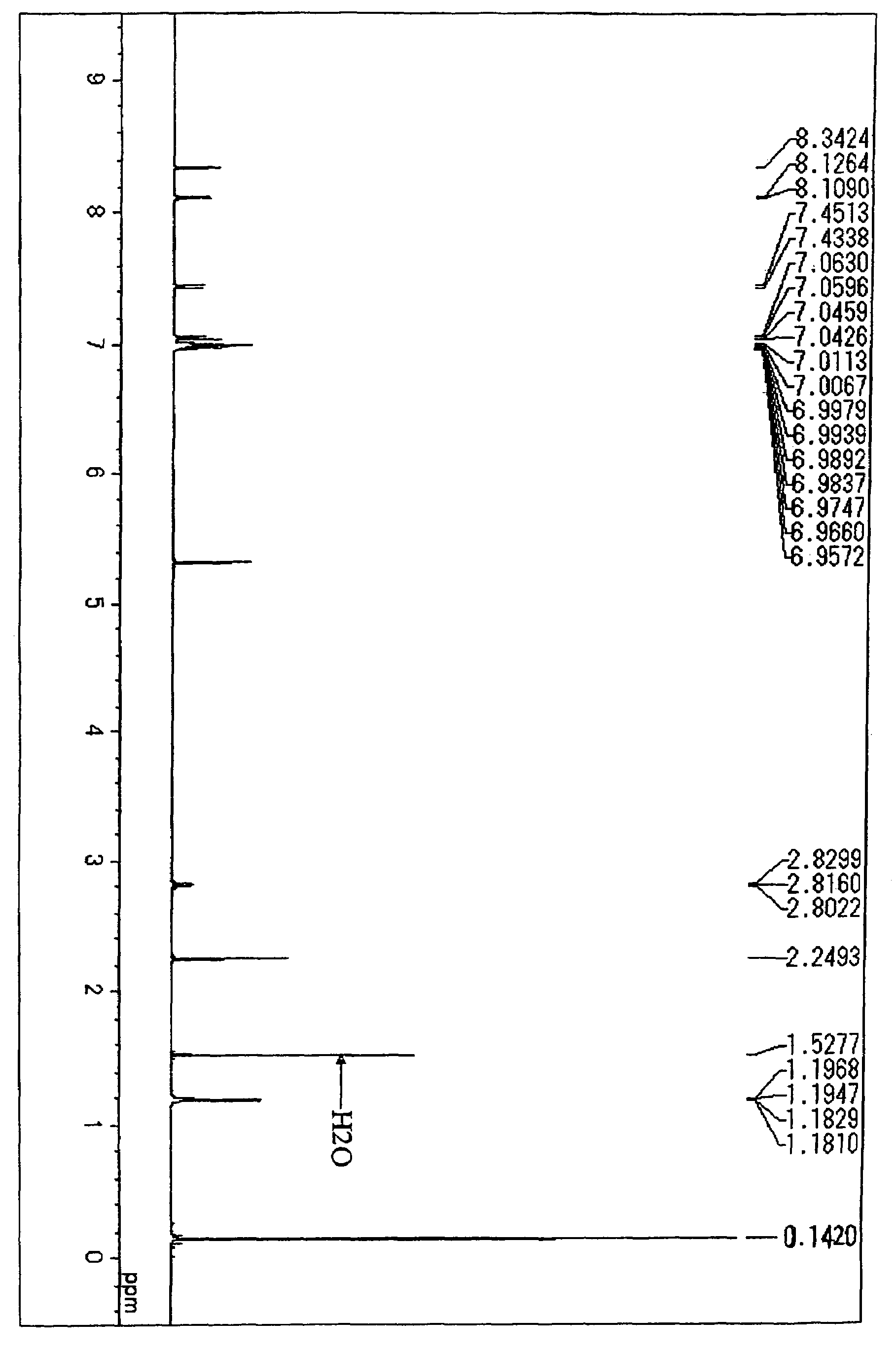

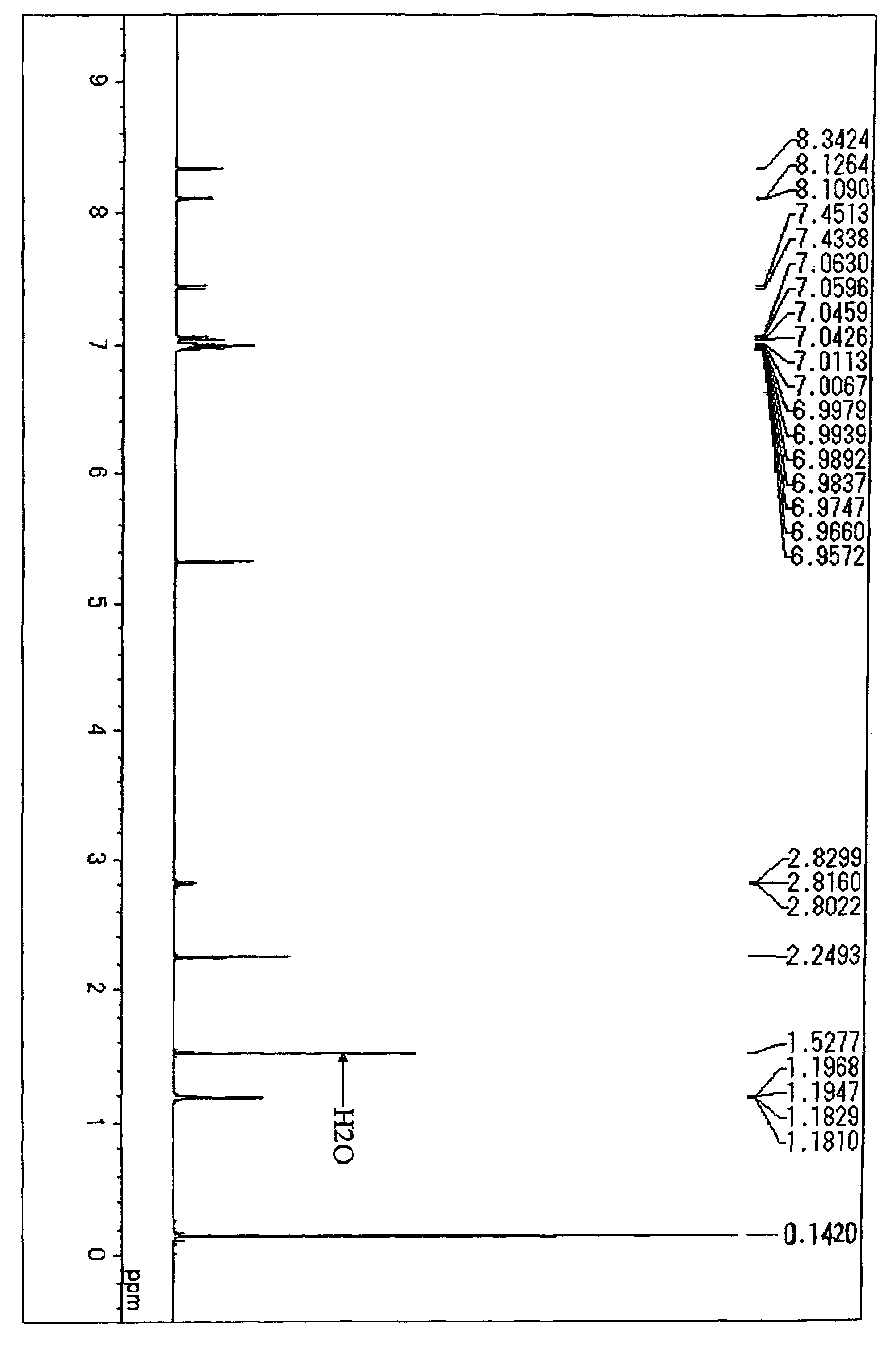

ActiveUS7122522B2Antibody mimetics/scaffoldsGeneral/multifunctional contrast agentsCancer preventionTamoxifen therapy

Therapeutic compounds which are cell proliferation modulators, preferably inhibitors. These modulators contain amino acid structures that are arranged as a hydrophilic analog of an alpha-fetoprotein. The modulator may be a peptide itself, e.g., an octapeptide like that of SEQ ID NO: 5; a peptidomimetic; or may be in the form of a pharmaceutically acceptable scaffold, such as a polycyclic hydrocarbon to which is attached the necessary amino acid structures for biological and / or chemical activity. The modulators of the invention are distinguished in one aspect over previous compounds in that they are orally active, and therefore do not have to be injected into the patient. The compositions and methods are useful for reducing estrogen-stimulated growth of cells, and treating or preventing cancer, such as breast cancer. The treatment or prevention methods can include the use of tamoxifen therapy in combination with the peptide therapy.

Owner:ALBANY MEDICAL COLLEGE

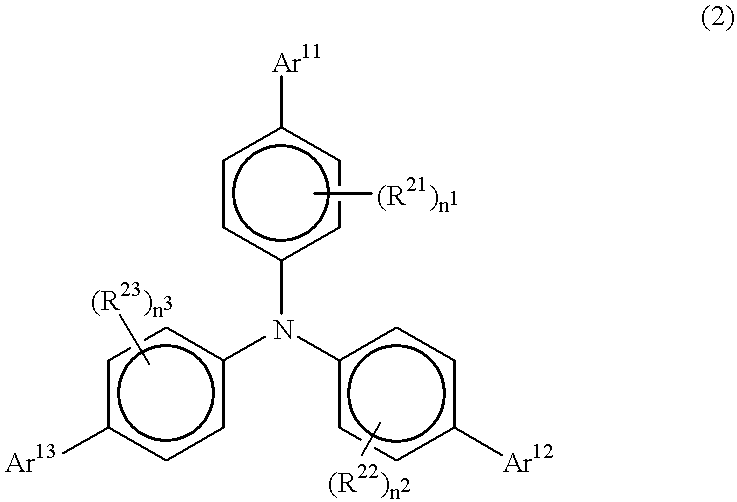

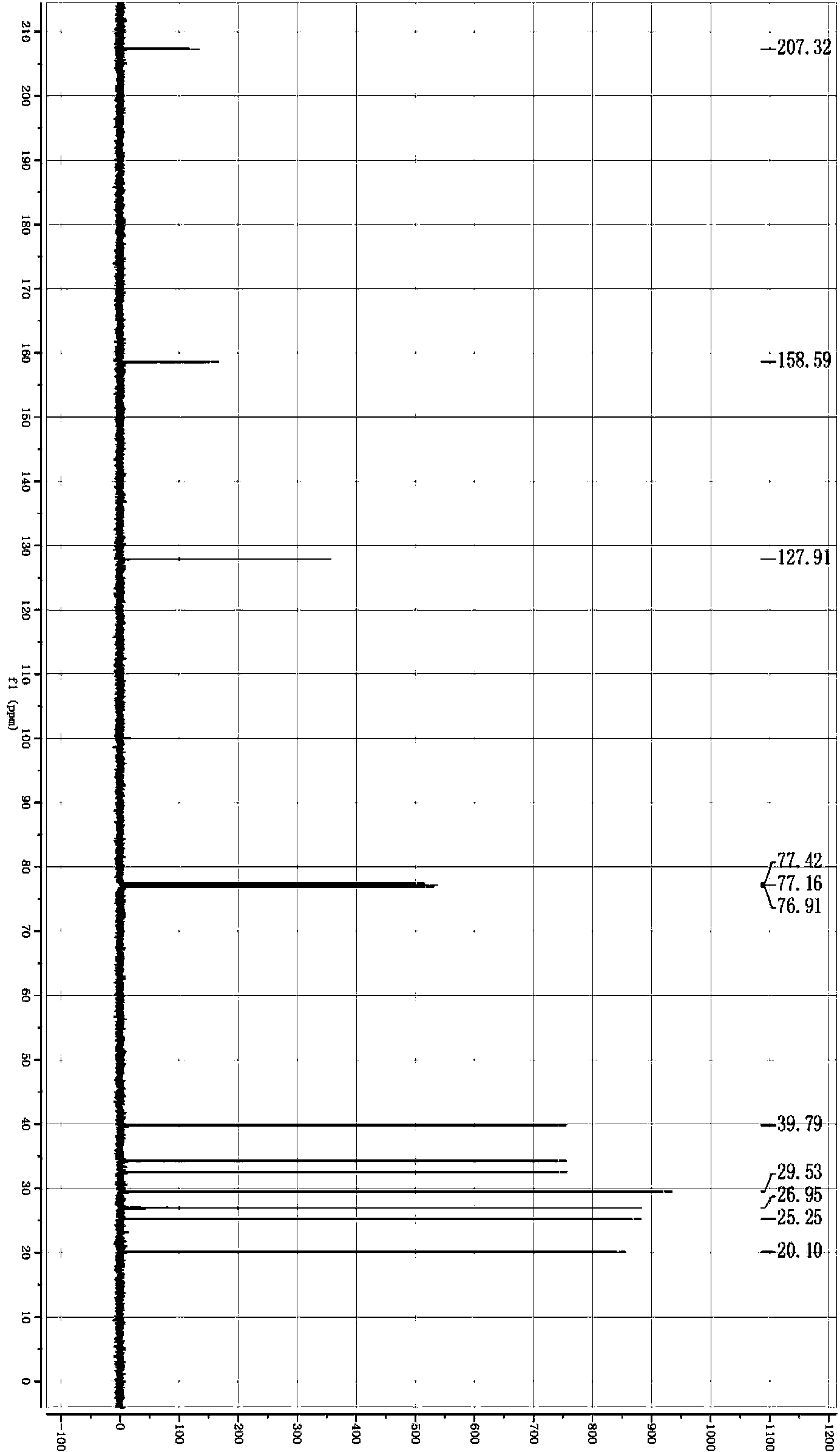

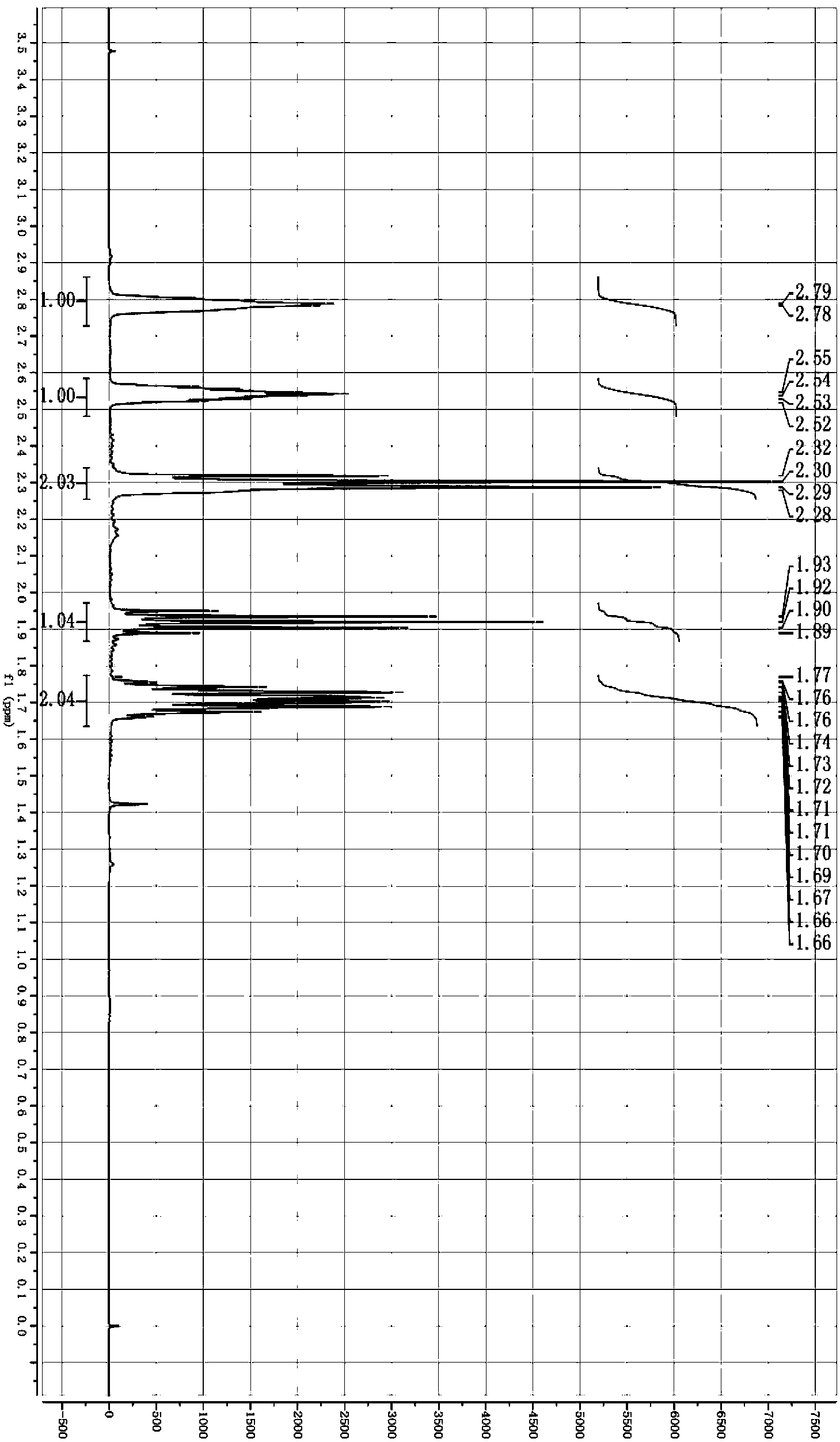

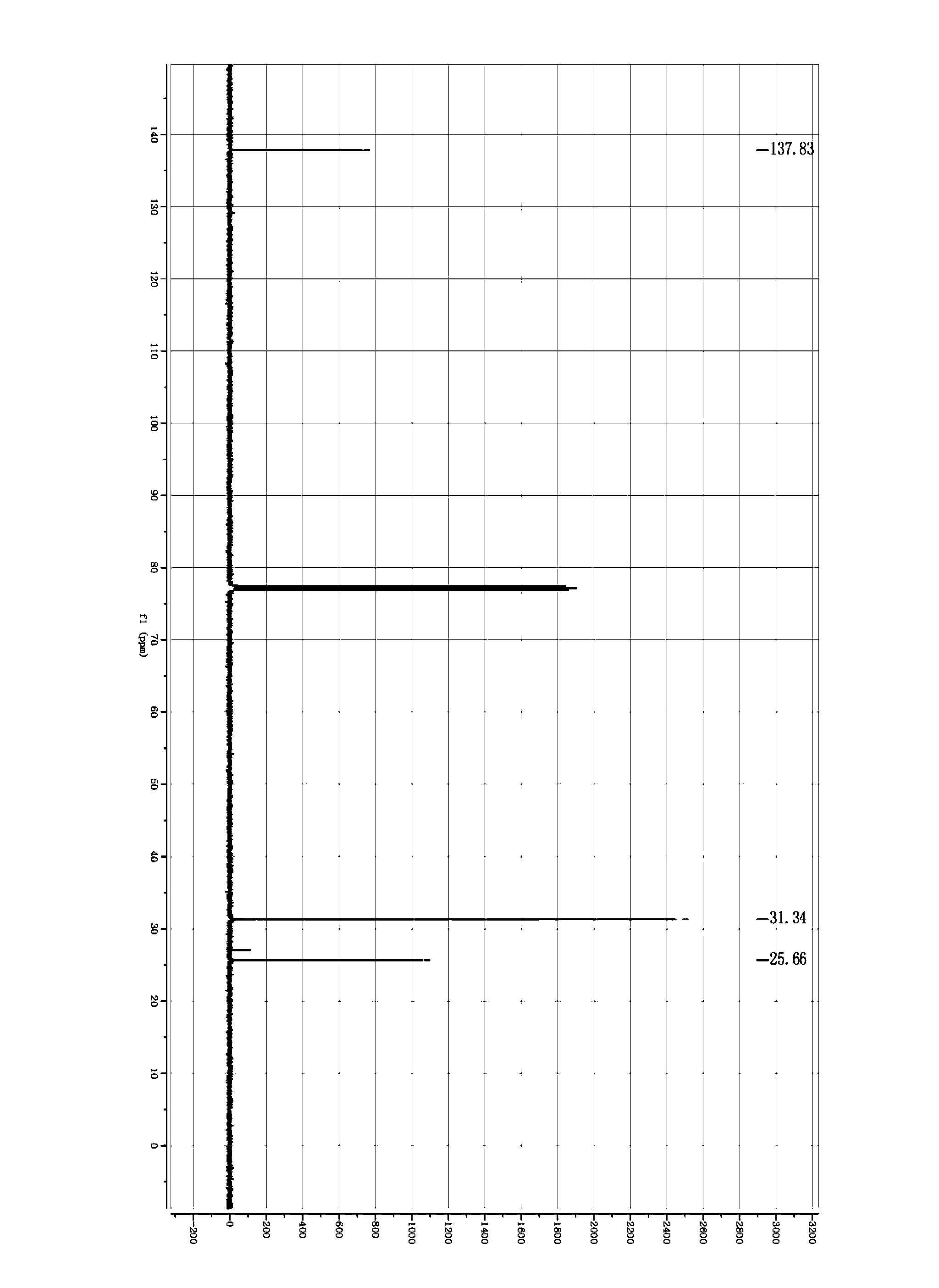

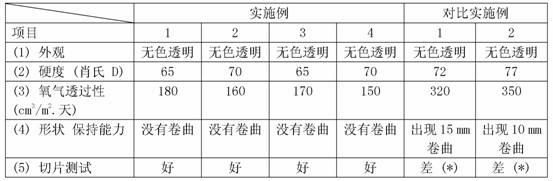

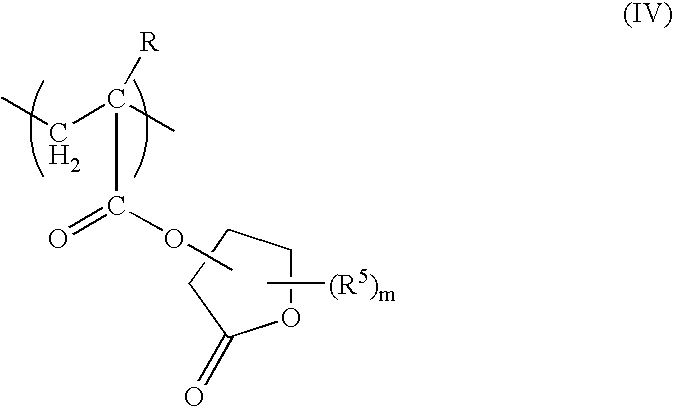

Aromatic amine derivative and organic electroluminescence device employing the same

InactiveUS7705183B2Long lastingImprove efficiencySilicon organic compoundsElectroluminescent light sourcesSilyleneOrganic electroluminescence

An aromatic amine derivative with a special structure bonding to a fused polycyclic hydrocarbon group having silyl group. An organic electroluminescence device which comprises one or more organic thin film layers comprising at least a light emitting layer sandwiched between a cathode and an anode, wherein at least one of the organic thin film layer comprises the above aromatic amine derivative singly or as its mixture component. An organic electroluminescence device having a long lifetime and an enhanced efficiency of light emission together with the aromatic amine derivatives realizing the device are provided.

Owner:IDEMITSU KOSAN CO LTD

Polymer compound and polymer light emitting device

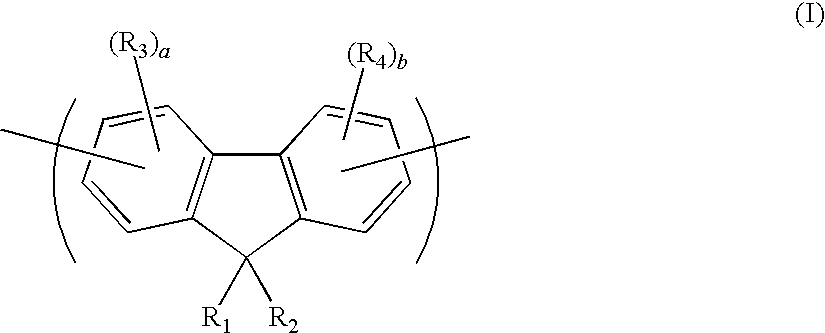

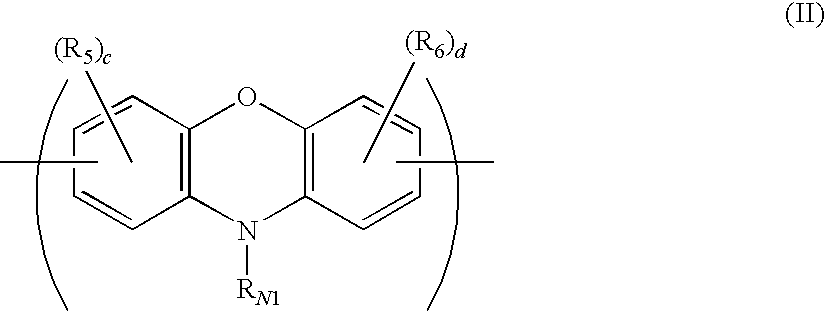

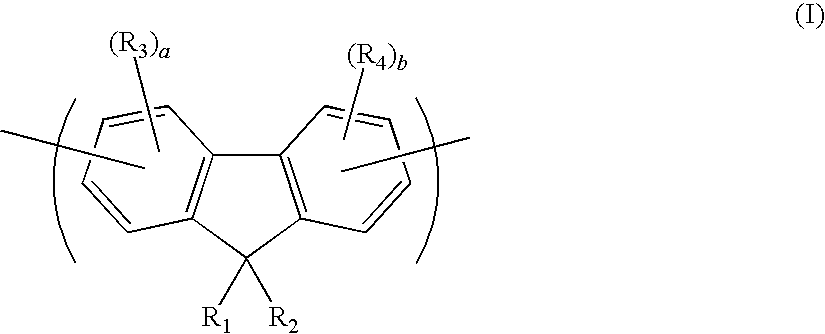

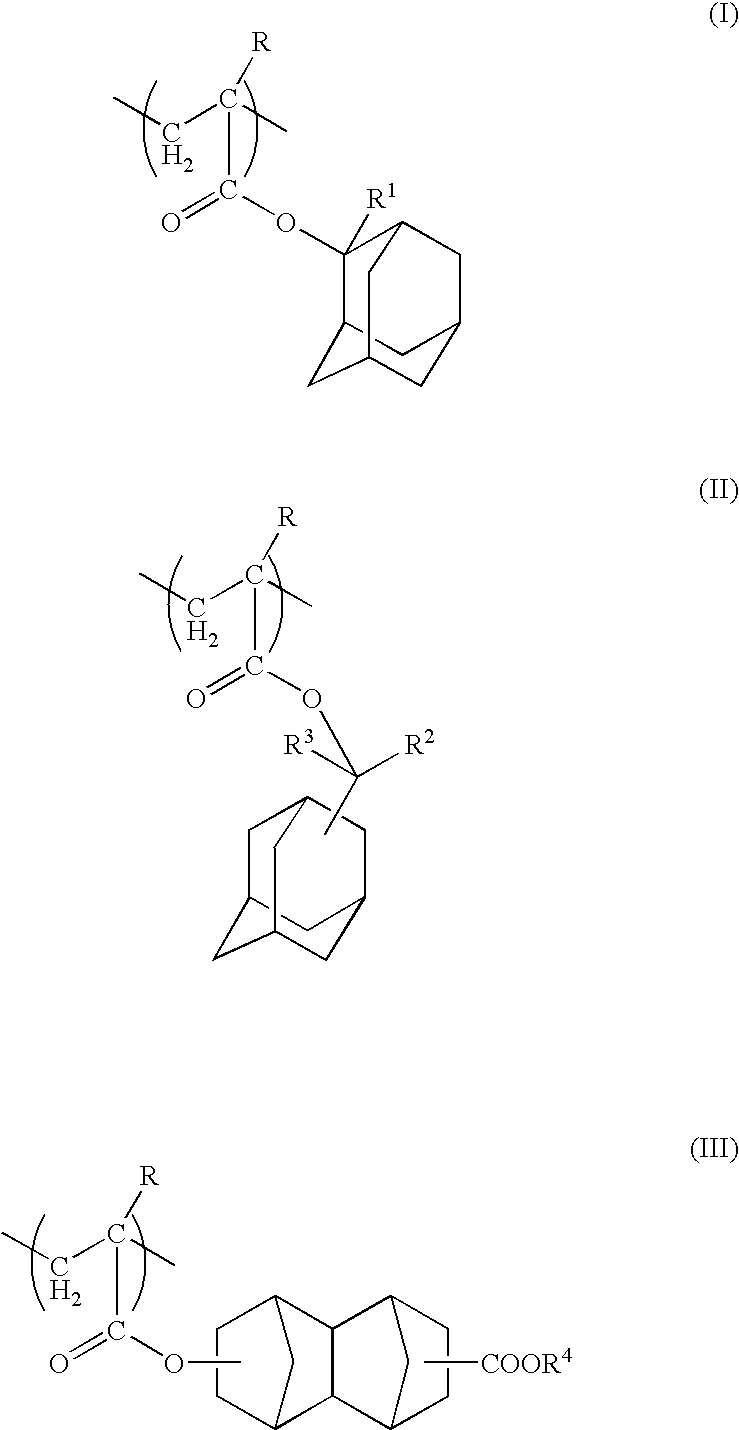

InactiveUS20090302748A1Long luminance half-life periodDischarge tube luminescnet screensElectroluminescent light sourcesHydrogen atomAlkoxy group

A polymer compound comprising repeating units of the following formulae (I), (II) and (III):(wherein, R1 and R2 represent a hydrogen atom, alkyl group, alkoxy group or the like, R3 and R4 represent an alkyl group, alkoxy group or the like, and a and b represent 0 to 3, and the like.)(wherein, RN1 represents an alkyl group, R5 and R6 represent an alkyl group, alkoxy group or the like, and c and d represent 0 to 3.)AR (III)(wherein, Ar represents a divalent condensed polycyclic hydrocarbon group or the like).

Owner:SUMITOMO CHEM CO LTD

Curable silicone-based composition comprising polycyclic hydrocarbon skeleton containing component

InactiveCN102433004AHigh transparencyExcellent gas barrier propertiesPlastic/resin/waxes insulatorsCoatingsDouble bondHydrosilylation

A curable silicone-based composition is provided to have gas barrier ability, to prevent the bending of a substrate even in case of sealing the substrate mounted of a plurality of LED chips, and to offer transparent hardened material with high hardness enough for dicing. A curable silicone-based composition comprises: an addition reactant having two addition reactive carbon-carbon double bonds per one molecule; linear siloxane containing phenyl group and three or more SiH bonds per one molecule; a siloxane compound having SiH bond, and an alkoxysilyl group and / or an epoxy group; a hydrosilylation catalyst. The addition reactant is an addition reactant of the reaction of a compound which has two SiH bond in chemical formula per one molecule, and a polycyclic hydrocarbon having two addition reactive carbon-carbon double bonds. In chemical formula 1, R is a substituted or non-substituted monovalent hydrocarbon radical or the alkoxy radical.

Owner:SHIN ETSU CHEM IND CO LTD

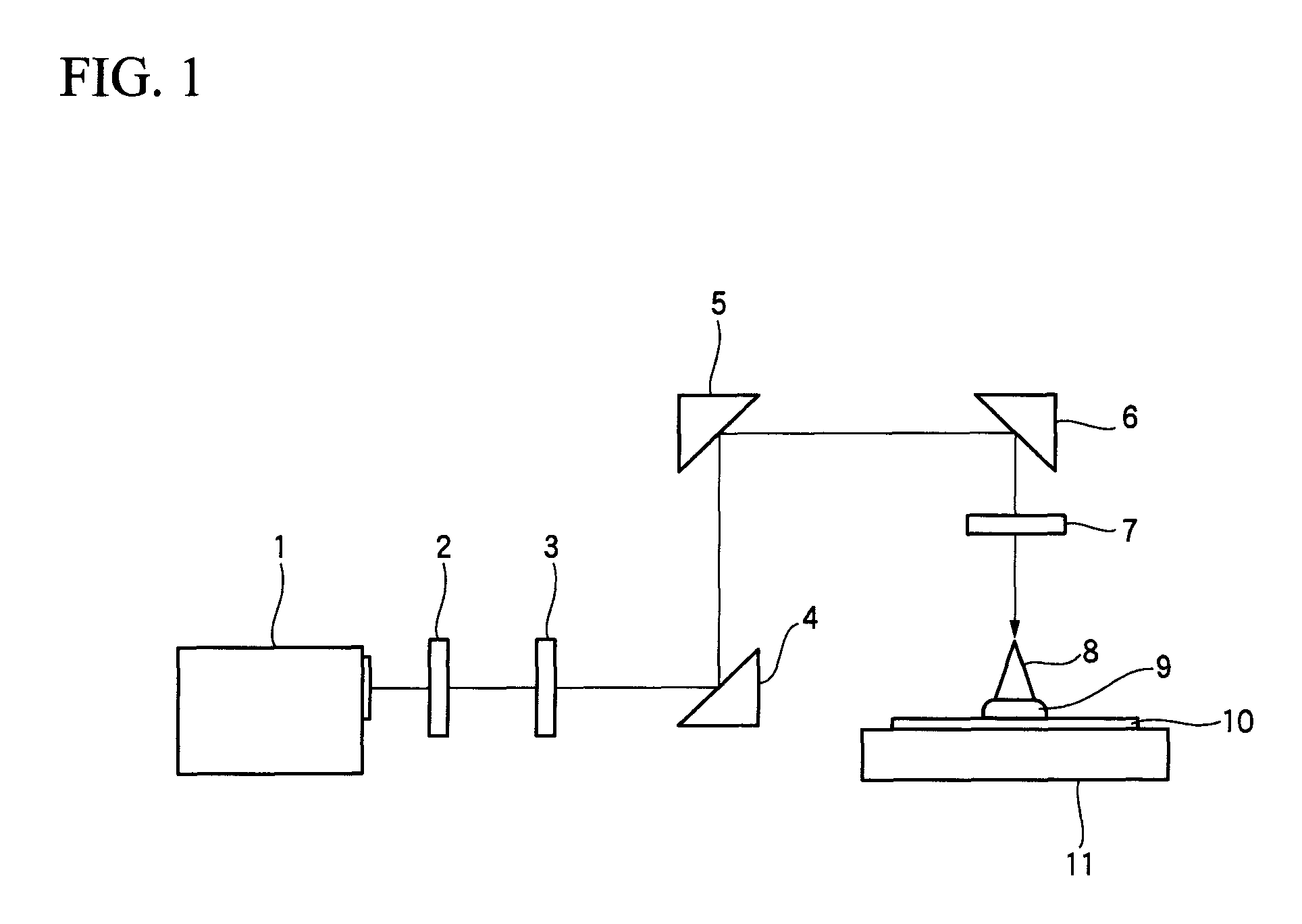

Ultraviolet degradation method for soil polluted by polycyclic hydrocarbon

InactiveCN101168164AHigh speedImprove efficiencyContaminated soil reclamationPhotochemical degradationFiltration

The invention relates to degradation of soil polluted by polycyclic aromatic hydrocarbon, specifically an ultraviolet light degradation method of soil polluted by polycyclic aromatic hydrocarbon, namely treating soil polluted by polycyclic aromatic hydrocarbon with ultraviolet light illumination. The method is specifically that spreading out polluted soil in a ware, and placing the two in an ultraviolet light illumination box for illumination degradation. The illumination conditions in the illumination box are ultraviolet light illumination wavelength 210-365nm, distance of sample to light source 5-20cm, light intensity 500-10000mu w / cm 2, temperature 25-35 DEG C, humidity in draft control box 30-50%, and illumination time 2-50 days, which is easy to operate. The invention is simple in treatment of removing polluted soil, low in cost, high in speed and efficiency. What is needed is only to conduct simple treatment of air dehydration to polluted soil and filtration, then to place a device with paved polluted soil under an ultraviolet light source for illuminating. The invention belongs to chemical degradation, and causes no secondary pollution, which is an environment-friendly method of treating polluted soil.

Owner:SHENYANG INST OF APPLIED ECOLOGY - CHINESE ACAD OF SCI

Curable composition

Provided is a curable composition including (A) an addition reaction product of (a) a compound with 2 silicon atom-bonded hydrogen atoms within each molecule, having a general formula (1):wherein, A is a bivalent group represented by a formula (2):(wherein, R′ represents an unsubstituted or substituted monovalent hydrocarbon group of 1 to 12 carbon atoms, or an alkoxy group of 1 to 6 carbon atoms, and n represents an integer from 0 to 100), or a group having a structural formula (3):and each R represents an unsubstituted or substituted monovalent hydrocarbon group of 1 to 12 carbon atoms, or an alkoxy group of 1 to 6 carbon atoms, and (b) a polycyclic hydrocarbon with 2 addition reactive carbon-carbon double bonds within each molecule, said addition reaction product containing at least two addition reactive carbon-carbon double bonds in each molecule, (B) a compound with at least 3 silicon atom-bonded hydrogen atoms within each molecule, and (C) a hydrosilylation reaction catalyst. This composition is useful as a material for optical devices or parts, insulation material for electronic devices or parts, or coating material.

Owner:SHIN ETSU CHEM CO LTD

Cyclocondensed polycyclic hydrocarbon compound and light-emitting device using the same

InactiveUS6696178B2Reduce the driving voltageImprove efficiencyOrganic chemistryDischarge tube luminescnet screensOrganic light emitting deviceThin layer

An organic light-emitting device comprising a light-emitting layer or a plurality of organic compound thin layers including a light-emitting layer formed between a pair of electrodes, wherein at least one layer comprises at least one kind of compound represented by the following formula (1):wherein R<11>, R<12 >and R<13 >each represents a group having a cyclocondensed polycyclic hydrocarbon structure in which three or more rings are cyclocondensed; and a novel cyclocondensed polycyclic hydrocarbon compound.

Owner:UDC IRELAND +1

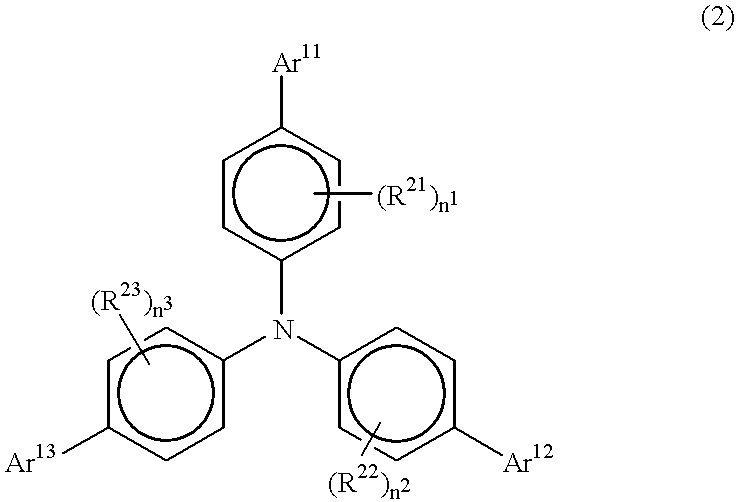

Positive resist composition and method for forming resist pattern

InactiveUS20070105038A1High resolutionHigh level of sensitivity and resolutionPhotosensitive materialsRadiation applicationsCooking & bakingVitrification

A positive resist composition that includes a base resin component (A) and an acid generator component (B), wherein the component (A) is a copolymer that includes structural units (a-1), which are derived from an (α-lower alkyl) acrylate ester that contains an acid dissociable, dissolution inhibiting group, and also contains an aliphatic cyclic group, structural units (a-2), which are derived from an (α-lower alkyl) acrylate ester that contains a γ-butyrolactone residue, and structural units (a-3), which are derived from an (α-lower alkyl) acrylate ester that contains a hydroxyl group-containing aliphatic polycyclic hydrocarbon group, and the glass transition temperature (Tg) of the copolymer is within a range from 100 to 170° C.; together with a method for forming a resist pattern using a lithography process that includes the steps of applying a chemically amplified positive resist composition to a substrate to provide a resist film, conducting selective exposure of the resist film, performing post exposure baking (PEB), and then conducting alkali developing, wherein the PEB temperature in the lithography process is set to a temperature within ±2° C. of the PEB temperature at which the line and space pattern formed by this lithography process reaches a maximum.

Owner:TOKYO OHKA KOGYO CO LTD

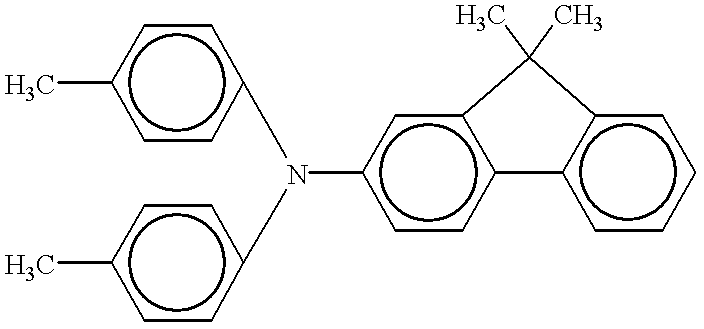

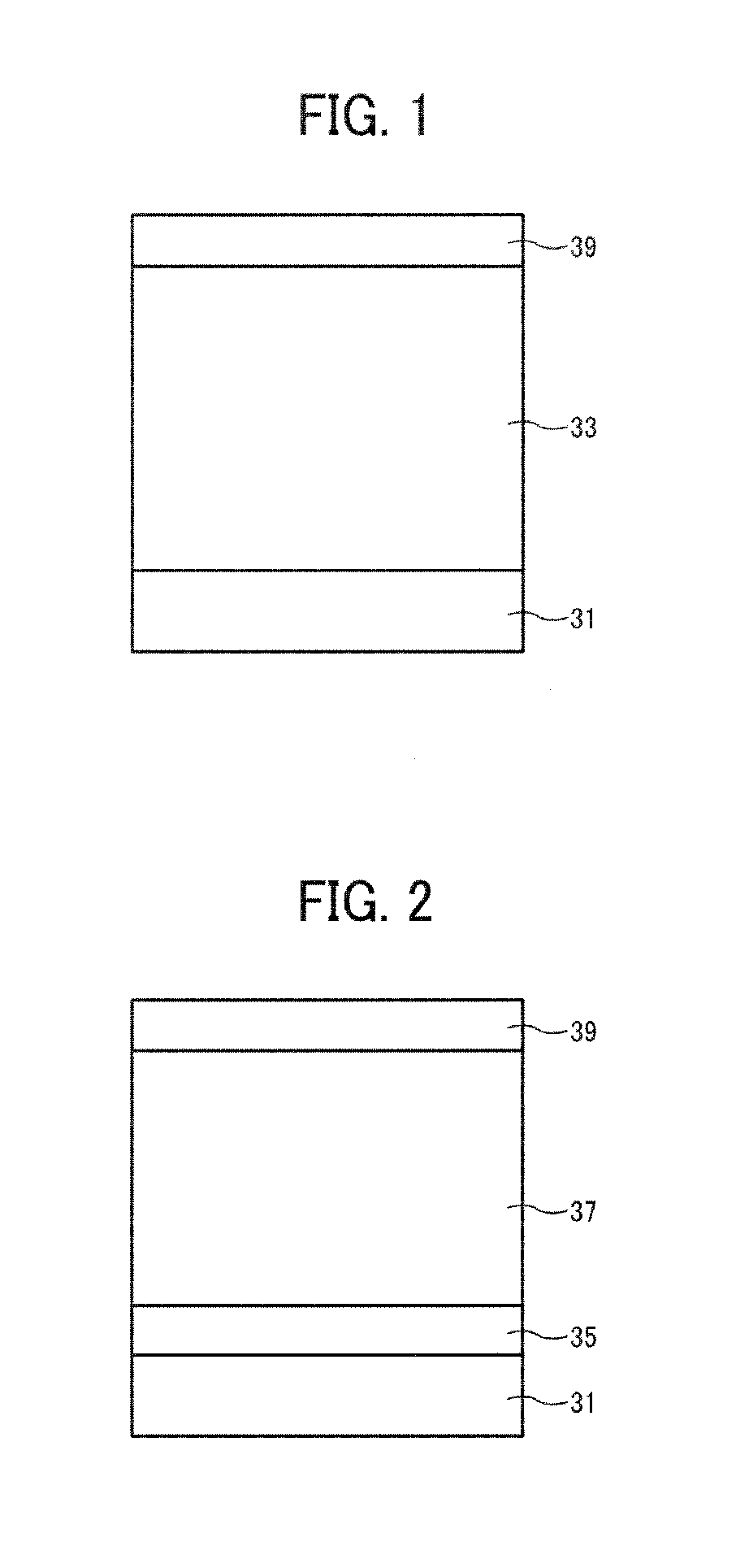

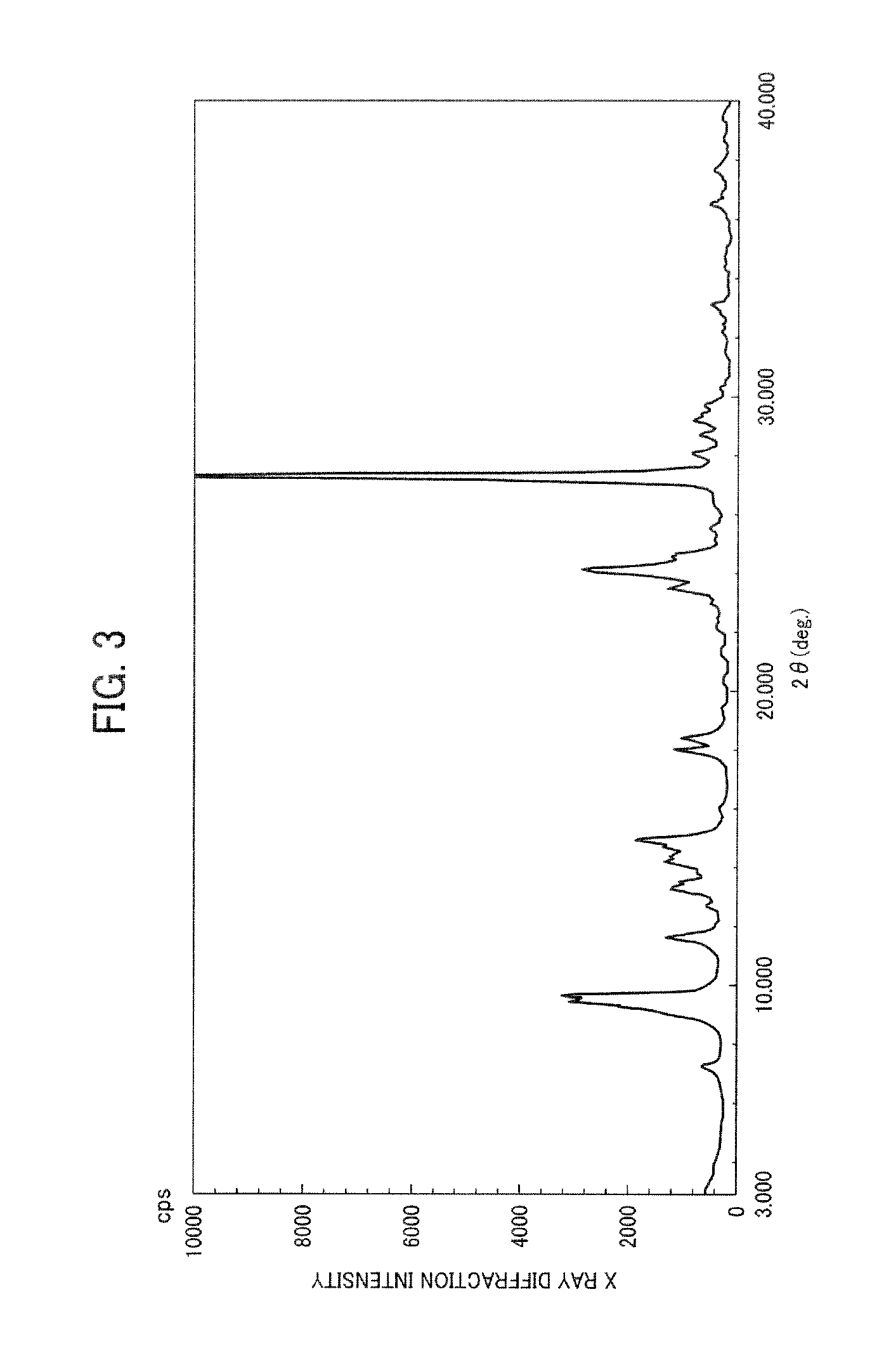

Phthalocyanine crystal, production process therefor, and electrophotographic photosensitive member, process cartridge and apparatus using the crystal

An electrophotographic photosensitive member exhibiting a high sensitivity and a potential stability on repetitive use and capable of suppressing image defects, such as black spots in a reversal development scheme, is provided. The photosensitive member includes a support, and a phthalocyanine layer formed on the support and a novel phthalocyanine crystal, which comprises a phthalocyanine compound and a substituted or unsubstituted condensed polycyclic hydrocarbon compound.

Owner:CANON KK

Image bearing member and image forming method, image forming apparatus, and process cartridge using the same

InactiveUS20120163860A1Electrographic process apparatusElectrographic processes using charge patternCross-linkPhenyl group

An image bearing member having an electroconductive substrate, a photosensitive layer overlying the electroconductive layer, and a cross-linked surface layer overlying the photosensitive layer, which contains a cross-linked polymer and a first compound consisting essentially of a nitrogen atom and a phenyl group, biphenyl group, and condensed polycyclic hydrocarbon group, or a second compound consisting essentially of a nitrogen atom and hydrogen atoms, halogen atoms, alkyl groups, alkoxy groups, or aryl groups, substituted or non-substituted alkyl groups, substituted or non-substituted alkoxy groups, substituted or non-substituted aralkyl groups, substituted or non-substituted aryl group, substituted or non-substituted alkylene groups, cyano groups, nitro groups, or —OCO═CH2R16, in which R16 represents a hydrogen atom, a substituted or non-substituted alkyl group, a substituted or non-substituted alkoxy group, or a substituted or non-substituted aryl group.

Owner:RICOH KK

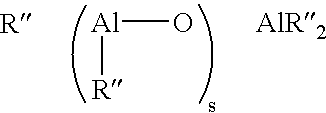

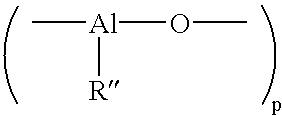

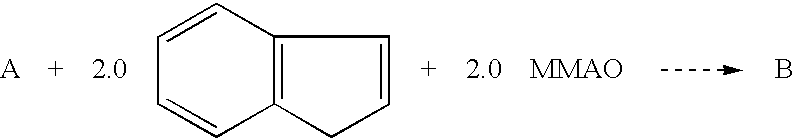

Self-supported hybrd catalysts for the production of polyolefins

InactiveUS20020128401A1Broad molecular weight distributionWide molecular weight distributionPolyolefinMagnesium

A solid self-supported cycloalkadienyl catalyst component is disclosed that includes: (i) a mixed metal alkoxide complex which is the reaction product of a magnesium alkoxide or aryloxide and at least one group IVB metal-containing alkoxide or aryloxide; and (ii) Cp, where Cp is a cyclic or polycyclic hydrocarbon having from 3-30 carbon atoms. A self-supported hybrid catalyst also is disclosed which contains the above components (i) and (ii), as well as (iii) a Ziegler-Natta catalyst species. A method of making the self-supported cycloalkadienyl catalyst and the self-supported hybrid catalyst and a method of polymerizing olefins using the catalysts also are disclosed. The catalysts are capable of producing polyolefins in high yield having a broad molecular weight distribution, or a bimodal distribution.

Owner:UNION CARBIDE CHEM & PLASTICS TECH CORP

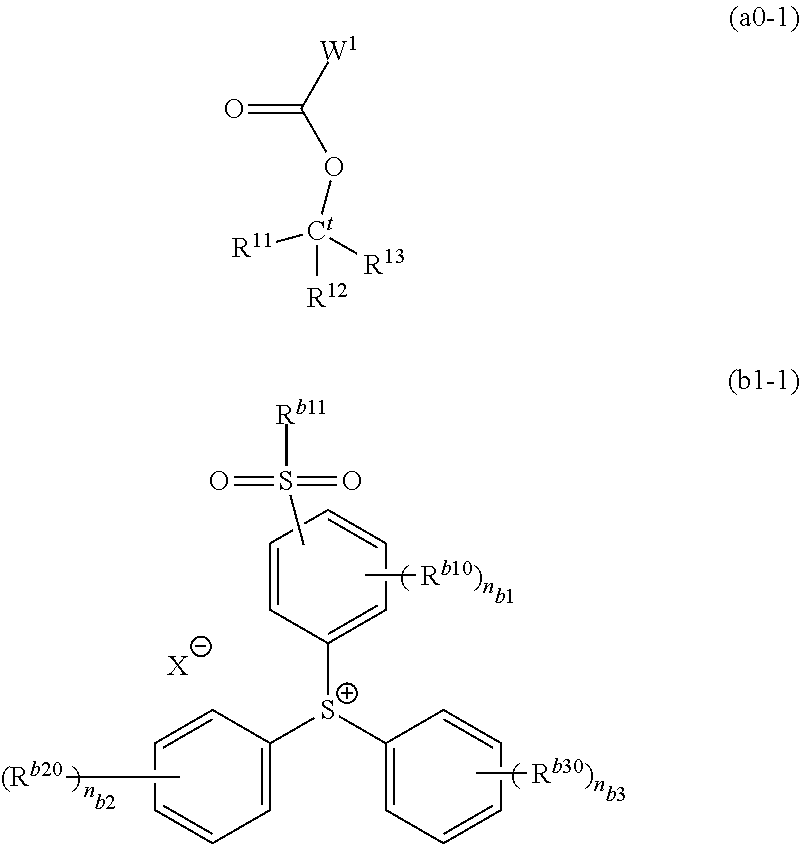

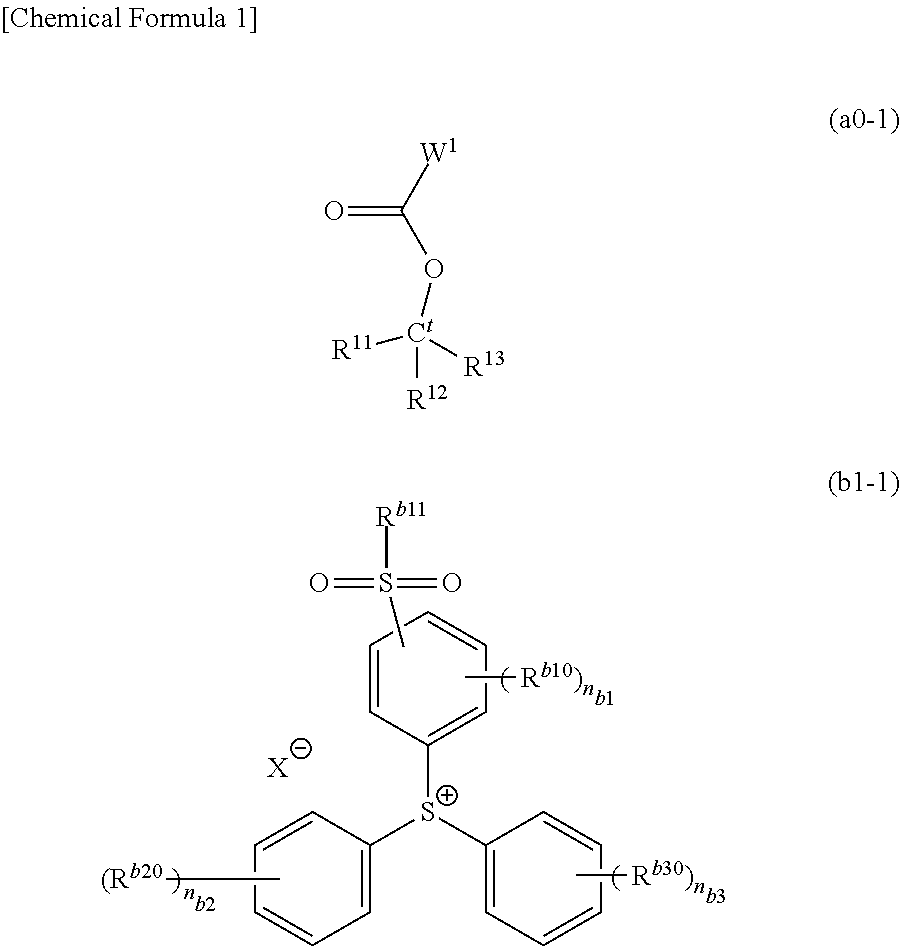

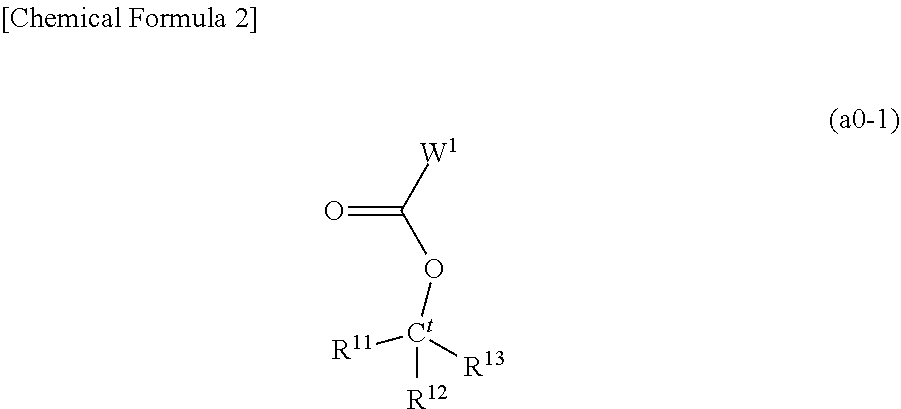

Resist composition and method of forming resist pattern

ActiveUS20200142303A1Good lithography performanceGood body shapePhotosensitive material processingCoatingsPolymer scienceAryl radical

A resist composition including a polymeric compound having a structural unit in which a compound represented by formula (a0-1) has a polymerizable group within the W1 portion converted into a main chain, and a compound represented by formula (b1-1) in which W1 represents a polymerizable group-containing group; Ct represents a tertiary carbon atom, and the α-position of Ct is a carbon atom which constitutes a carbon-carbon unsaturated bond; R11 represents an aromatic hydrocarbon group or a chain hydrocarbon group; R12 and R13 are mutually bonded to form a 5-membered aliphatic monocyclic group, or a condensed polycyclic hydrocarbon group containing a 5-membered aliphatic monocyclic ring; Rb11 represents a cyclic group; Rb10, Rb20 and Rb30 each independently represents a substituent; nb1 represents an integer of 0 to 4; nb2 represents an integer of 0 to 5; nb3 represents an integer of 0 to 5; and X− represents a counteranion.

Owner:TOKYO OHKA KOGYO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com