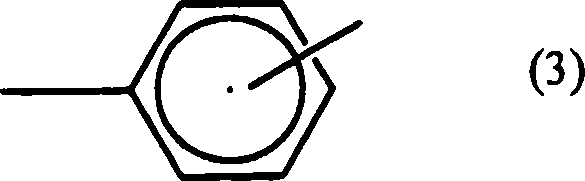

Silicone-based curable composition containing polycyclic hydrocarbon group

A technology of polycyclic hydrocarbon base and composition, which is applied in the field of silicone-based curable composition, can solve problems such as poor operability, poor crack resistance, and easy contamination, and achieve high hardness, good crack resistance, The effect of excellent heat fading resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0068]

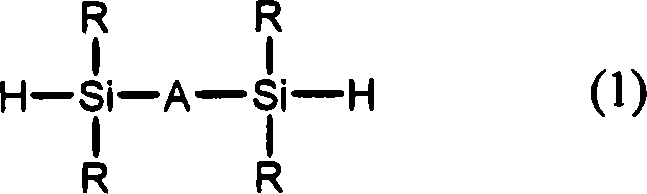

[0069] Component (A) of the composition of the present invention can be produced as an addition reaction product not containing SiH groups by making 1 mole of the above-mentioned component containing two SiH groups per molecule in the presence of a hydrosilylation reaction catalyst (a) with an excess equivalent of more than 1 mole but not more than 10 moles, preferably more than 1 mole but not more than 5 moles of component (b) containing two addition-reactive carbon-carbon double bonds per molecule Response gets.

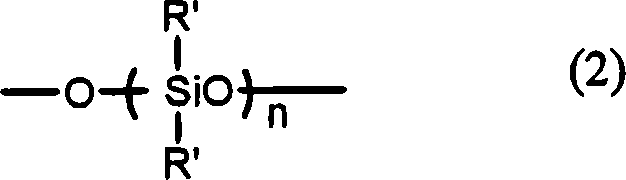

[0070] Component (A) obtained by this method contains not only addition-reactive carbon-carbon double bonds derived from component (b), but also addition-reactive carbon-carbon double bonds derived from component (a) Double bonds (specifically, addition-reactive carbon-carbon double bonds derived from the R group in general formula (1) and / or the R' group in general formula (2)). As a result, component (A) contains at least two addition-reactive carbon-...

Embodiment 1

[0193] (A1) 5 parts by mass of the reaction product obtained in Synthesis Example 1, (A2) 60 parts by mass of the reaction product obtained in Synthesis Example 2.

[0194] (B1) 5 parts by mass of (MeHSiO) 4 , (B2) 30 parts by mass of the reaction product obtained in Synthesis Example 3.

[0195] (molar ratio [total SiH groups in components (B1) and (B2)] / [total carbon-carbon double bonds in components (A1) and (A2)]=1.03, hereinafter, the SiH groups The molar ratio of the carbon-carbon double bond is abbreviated as "SiH / C=C (molar ratio)",

[0196] (C) a sufficient amount of platinum-vinylsiloxane complex relative to the total mass of components (A1), (A2), (B1) and (B2) to provide 20 ppm of platinum metal atoms,

[0197] (D) 0.05 parts by mass of a stabilizer containing a hindered amine structure and a phenol structure (TINUVIN144, produced by Ciba Specialty Chemicals Inc.), and 0.03 parts by mass of 1-ethynylcyclohexanol

[0198] The above materials are mixed uniformly t...

Embodiment 2

[0200] (A2) the reaction product that obtains by synthetic embodiment 2 of 81 mass parts,

[0201] (B1) 19 parts by mass of (MeHSiO) 4

[0202] (SiH / C=C (molar ratio)=0.98),

[0203] (C) a sufficient amount of platinum-vinylsiloxane complex relative to the total mass of components (A2) and (B1) to provide 20 ppm of platinum metal atoms,

[0204] (D) 0.05 parts by mass of a stabilizer containing a hindered amine structure and a phenol structure (TINUVIN144, produced by Ciba Specialty Chemicals Inc.), and 0.03 parts by mass of 1-ethynylcyclohexanol

[0205] The above materials are mixed uniformly to form a composition. The composition was poured into a mold formed of a glass plate to give a thickness of 2 mm, and then heated at 150° C. for 2 hours to obtain a cured product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com