Curable silicone-based composition comprising polycyclic hydrocarbon skeleton containing component

A technology of composition and polycyclic hydrocarbons, applied in coatings, plastic/resin/wax insulators, organic insulators, etc., can solve problems such as poor gas barrier properties, discoloration of silver electrodes, impossible slicing, etc., to prevent discoloration of electrodes , good gas barrier effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051]

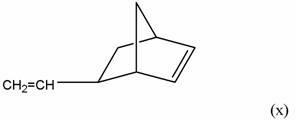

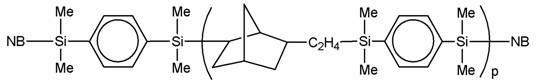

[0052] The component (A) of the composition of the present invention can be produced as an addition reaction product containing no SiH group by making 1 mole of the above-mentioned group containing two SiH groups per molecule in the presence of a hydrosilylation reaction catalyst. (A) and an excess equivalent of more than 1 mole but not more than 10 moles, preferably more than 1 mole but not more than 5 moles of the above-mentioned component containing two addition-reactive carbon-carbon double bonds per molecule ( b) Obtained by addition reaction.

[0053] The above-mentioned hydrosilylation reaction catalyst can adopt any conventionally used materials. Suitable examples include platinum-based catalysts such as carbon powder-supported metallic platinum, platinum black, platinum (IV) chloride, chloroplatinic acid, reaction products of chloroplatinic acid and monohydric alcohols, complexes of chloroplatinic acid and olefins, and Platinum diacetoacetate; and other platinum...

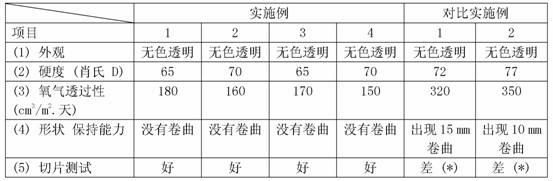

Embodiment 1

[0127] (A) The reaction product obtained in Synthesis Example 1: 40 parts by mass,

[0128] (B) Me 3 SiO(MeHSiO) 3 (Ph 2 SiO) 2 SiMe 3 : 52 parts by mass,

[0129] (C) 1-(2-Trimethoxysilylethyl)-3-(3-glycidoxypropyl)-1,3,5,7-tetramethylcyclotetrasiloxane: 8 Mass parts,

[0130] The molar ratio of SiH / carbon-carbon double bond in the above is 1.03,

[0131] (D) Platinum-vinylsiloxane complex: 20 ppm, in terms of platinum metal atoms relative to the total mass of the composition, and

[0132] 1-ethynyl cyclohexanol: 0.03 parts by mass, the above-mentioned substances are uniformly mixed together to form a composition.

Embodiment 2

[0134] (A) The reaction product obtained in Synthesis Example 1: 56 parts by mass,

[0135] (B) Me 3 SiO(MeHSiO) 4 (Ph 2 SiO) 2 SiMe 3 : 36 parts by mass,

[0136] (C) 1-(2-Trimethoxysilylethyl)-3-(3-glycidoxypropyl)-1,3,5,7-tetramethylcyclotetrasiloxane: 8 Mass parts,

[0137] The molar ratio of SiH / carbon-carbon double bond in the above is 1.04,

[0138] (D) Platinum-vinylsiloxane complex: 20 ppm, in terms of platinum metal atoms relative to the total mass of the composition, and

[0139] 1-ethynyl cyclohexanol: 0.03 parts by mass, the above-mentioned substances are uniformly mixed together to form a composition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com