Design method of rectification process for synthesizing cyclohexanone-cyclohexanol by cyclohexene technology

A process design and cyclohexanol technology, applied in the field of cyclohexanone-cyclohexanol rectification process, can solve problems such as low energy utilization rate, and achieve the effects of improving energy utilization rate, reducing energy consumption, and improving energy-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

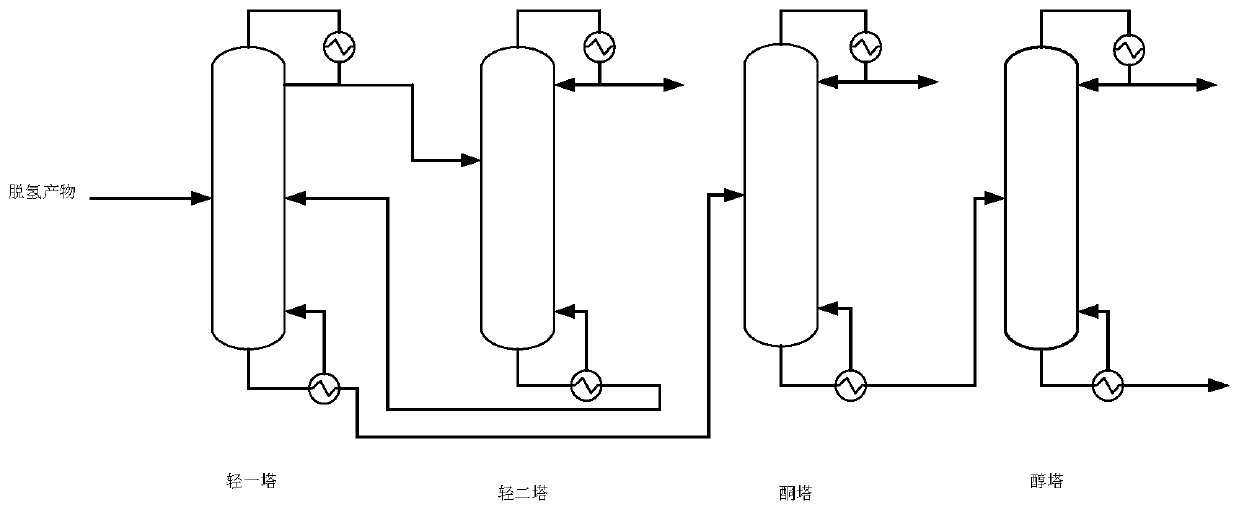

Embodiment 1

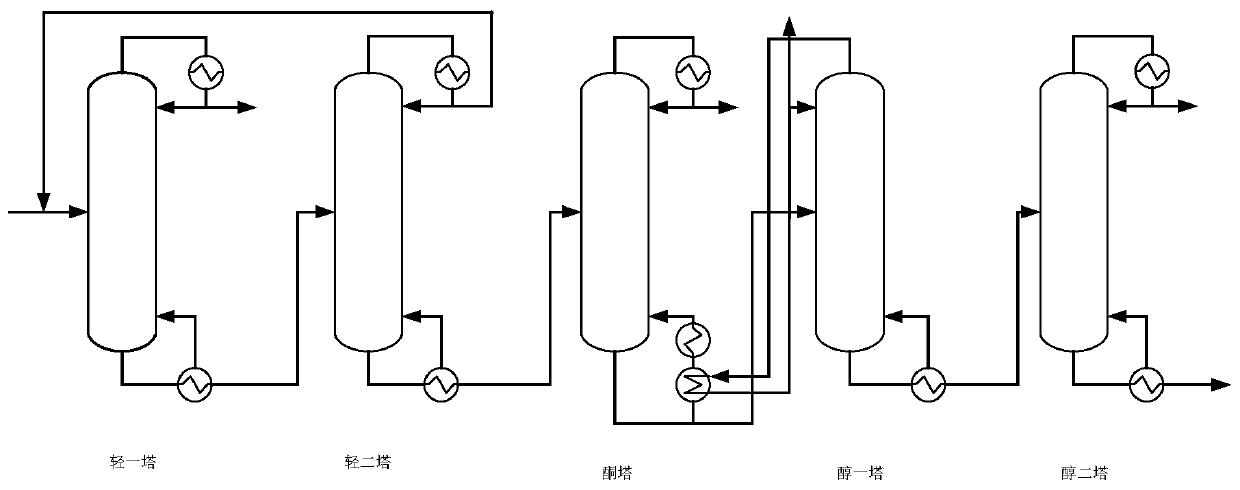

[0018] Embodiment 1: 5 tower cyclohexanone-cyclohexanol double-effect rectification, such as figure 2 shown. The product of the dehydrogenation reaction of cyclohexanol enters the light first tower to extract light components from the top of the tower, and the output from the bottom of the tower is used as the feed of the light second tower, and the top discharge of the light second tower contains a certain amount of light components as feed Circulate back to the light first tower, the bottom of the light second tower is a mixture of cyclohexanone, cyclohexanol and heavy components entering the ketone tower, cyclohexanone is withdrawn from the top of the tower, and the bottom of the ketone tower is a mixture of cyclohexanol and heavy components entering the alcohol In the first tower, part of the cyclohexanol is extracted from the top of the alcohol first tower and recycled to the dehydrogenation reactor, and the output from the bottom of the tower enters the second alcohol t...

Embodiment 2

[0019] Embodiment 2: 5 towers cyclohexanone-cyclohexanol heat pump rectification, as image 3 shown. Introduce heat pump rectification in alcohol one tower to replace the double-effect rectification in embodiment 1, alcohol one tower overhead steam is compressed to 50kPa by compressor and then supplies heat to self reboiler, all the other information is the same as in embodiment 1. Compared with the original 4-tower process, the operating cost and annual total cost of the 5-tower heat pump process are reduced by 45.4% and 23.6% respectively.

Embodiment 3

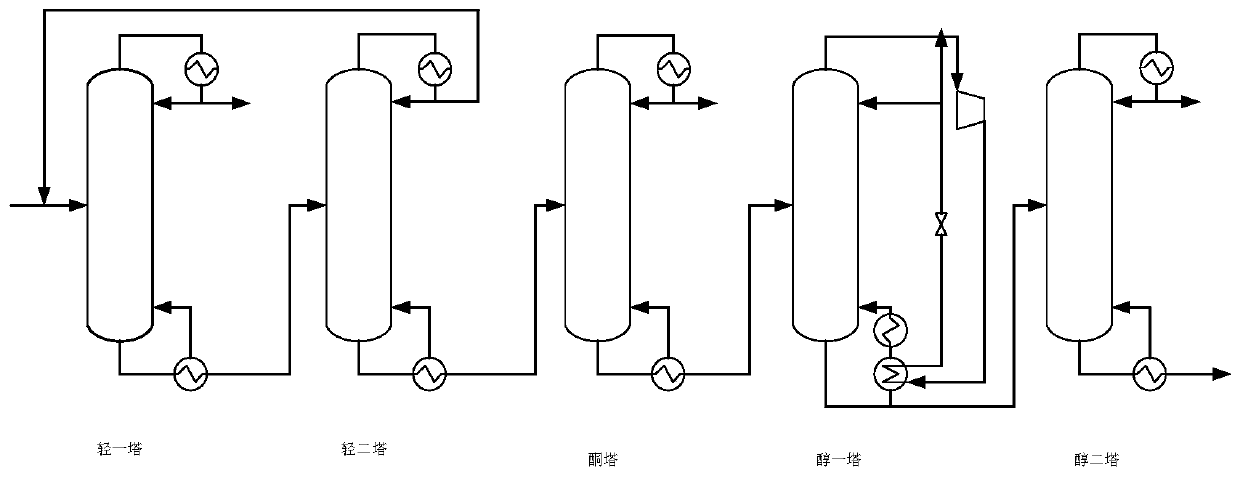

[0020] Embodiment 3: 5 tower cyclohexanone-cyclohexanol double-effect heat pump rectification, such as Figure 4 shown. On the basis of embodiment 1, the reflux rate of the light one tower is reduced to make the light one tower heat load the lowest, and a heat pump is introduced in the light two tower to compress the vapor at the top of the tower to 120kPa to supply heat to its own reboiler, and the rest of the information is consistent with the implementation Same as in Example 1. Compared with the original 4-tower process, the operating cost and annual total cost of the 5-tower double-effect heat pump process are reduced by 56.3% and 29.2% respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com