Apparatus and method for measuring the width of crystallization metastable zone in microscale flow system

A metastable zone, micro-scale technology, applied in the direction of measuring devices, material crystallization, test crystals, etc., can solve the problem of large micro-channel size, inability to measure the metastable zone of micro-scale flow system, and inability to solve the problem of measuring the width of crystal metastable zone, etc. problems, to achieve the effect of simple process control, easy to change operating conditions, and less raw material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

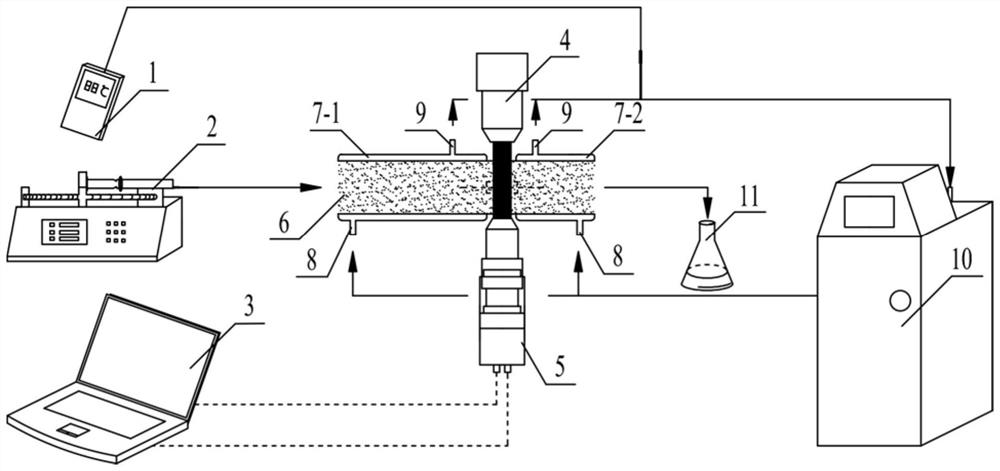

[0031] In this embodiment, the microchannel 6 is a quartz glass tube with an inner diameter of 0.9 mm, an outer diameter of 1.5 mm, and a length of 23 cm. The device for measuring the width of the crystallization metastable zone in the microscale flow system is as follows: figure 1 As shown, it includes a temperature control system, a microscope 4 , a camera 5 , a computer 3 , and a syringe pump 2 . The temperature control system is composed of a constant temperature circulating water bath 10, a first thermal insulation jacket 7-1, a second thermal insulation jacket 7-2 and a temperature sensor 1. The length of the first thermal insulation jacket 7-1 is 17.5cm, and the suit In the section of the liquid inlet end of the microchannel, the second thermal insulation jacket 7-2 is set on the section of the liquid outlet end of the microchannel, and the spacing between the first thermal insulation jacket and the second thermal insulation jacket is 1 cm, and the spacing forms a micr...

Embodiment 2

[0034] In this example, the apparatus described in Example 1 is used to measure the width of the metastable zone when the potassium dihydrogen phosphate aqueous solution reaching saturation at 40° C. flows at a microscale.

[0035] According to the existing potassium dihydrogen phosphate solubility curve, dissolve 33.5g of potassium dihydrogen phosphate crystals (analytical pure) in 100g of deionized water to form an aqueous solution of potassium dihydrogen phosphate that reaches saturation at 40°C, and keep the temperature at 40°C spare.

[0036] The assay steps of the present embodiment are as follows:

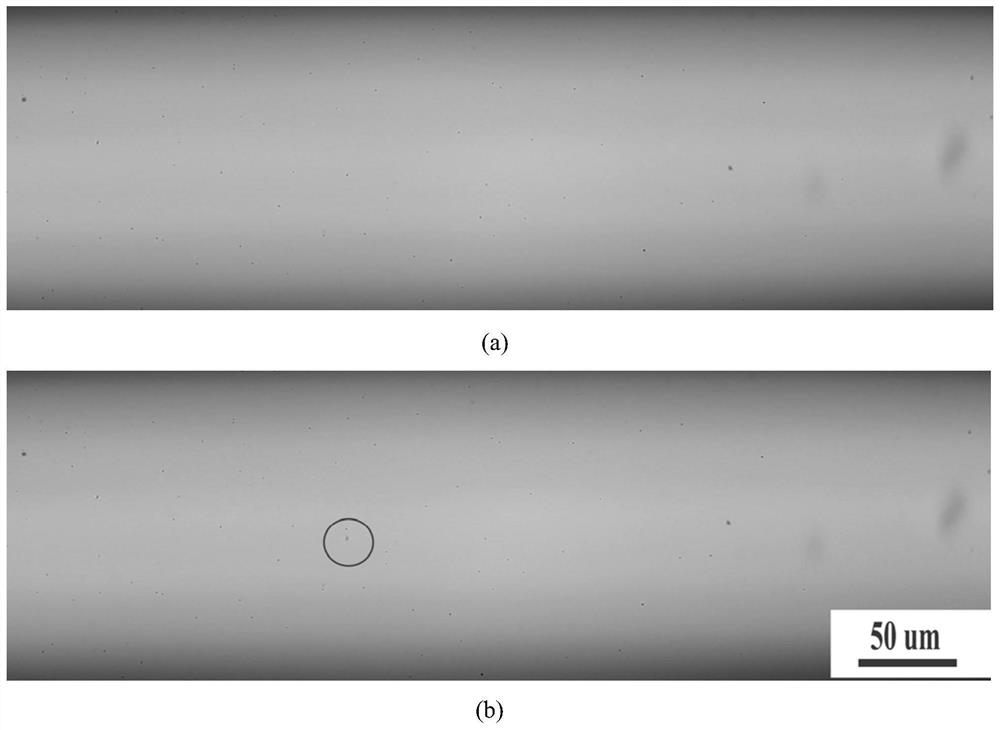

[0037] (1) Fix the microchannel 6 equipped with the first thermal insulation jacket 7-1 and the second thermal insulation jacket 7-2 on the stage of the microscope 4, and make the microscope objective lens aim at the microchannel observation section, open and The camera 5 combined with the eyepiece of the microscope 4 observes the inside of the microchannel, and shoots the ...

Embodiment 3

[0042] In this example, the device described in Example 1 was used to measure the width of the metastable zone of the microscale flow system of the potassium dihydrogen phosphate aqueous solution reaching saturation at 40°C.

[0043] According to the existing potassium dihydrogen phosphate solubility curve, dissolve 33.5g of potassium dihydrogen phosphate crystals (analytical pure) in 100g of deionized water to form an aqueous solution of potassium dihydrogen phosphate that reaches saturation at 40°C, and keep the temperature at 40°C spare.

[0044] The assay steps of the present embodiment are as follows:

[0045] (1) Fix the microchannel 6 equipped with the first thermal insulation jacket 7-1 and the second thermal insulation jacket 7-2 on the stage of the microscope 4, and make the microscope objective lens aim at the microchannel observation section, open and The camera 5 combined with the eyepiece of the microscope 4 observes the inside of the microchannel, and shoots th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com